WEG Electric CFW701 Quick Reference

Motors | Automation | Energy | Transmission & Distribution | Coatings

Frequency Inverter

Convertidor de Frecuencia

Inversor de Frequência

CFW701

Quick Parameter Reference, Faults and Alarms

Referencia Rápida de los Parámetros, Fallas y Alarmas

Referência Rápida dos Parâmetros, Falhas e Alarmes

Quick Parameter Reference,

English

Faults and Alarms

Series: CFW701

Language: English

Document: 10001538840 / 02

Software Version: 2.0X

Date: 05/2014

Quick Parameter Reference, Faults and Alarms

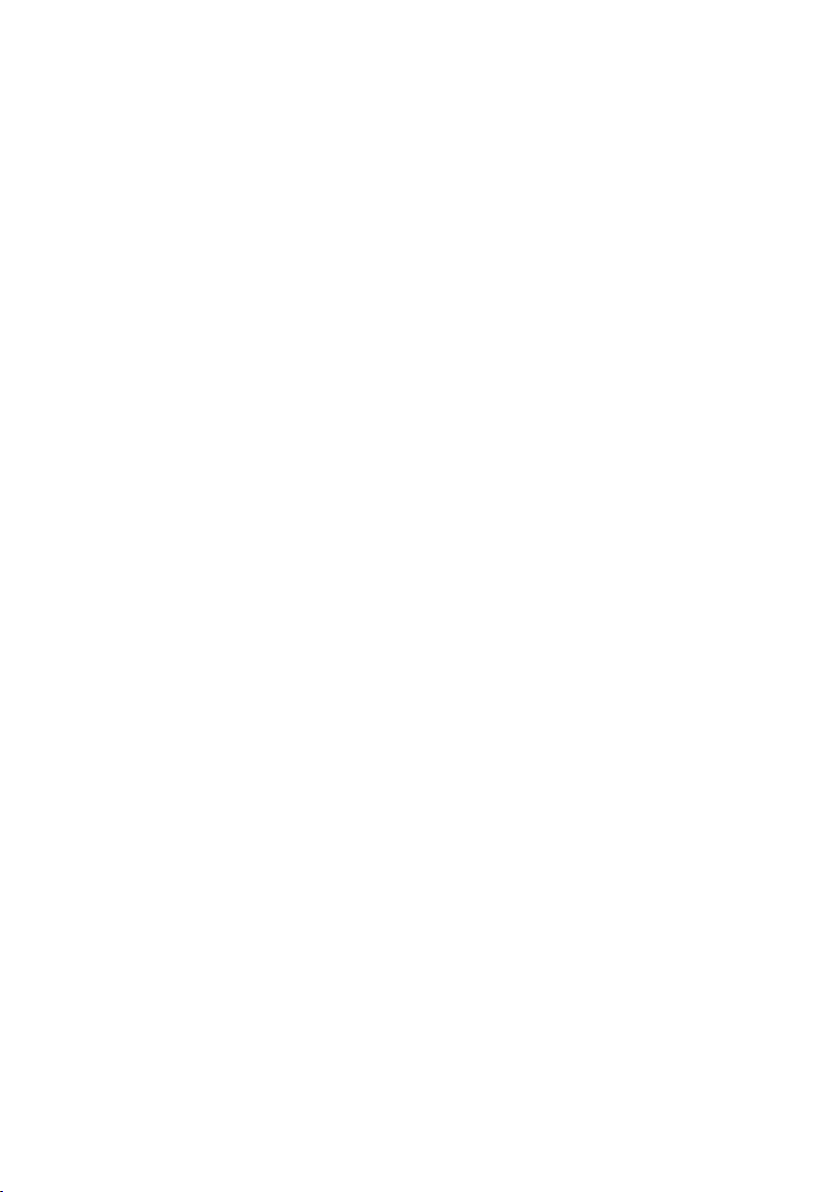

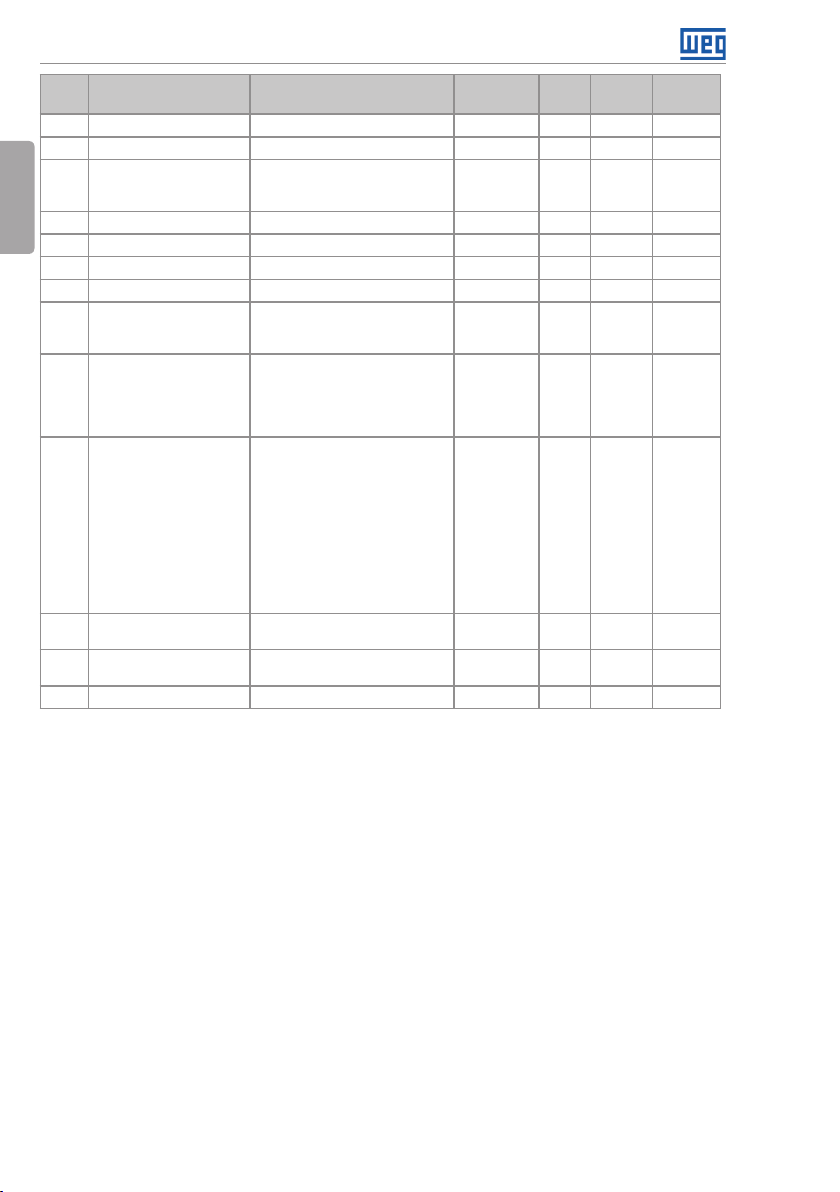

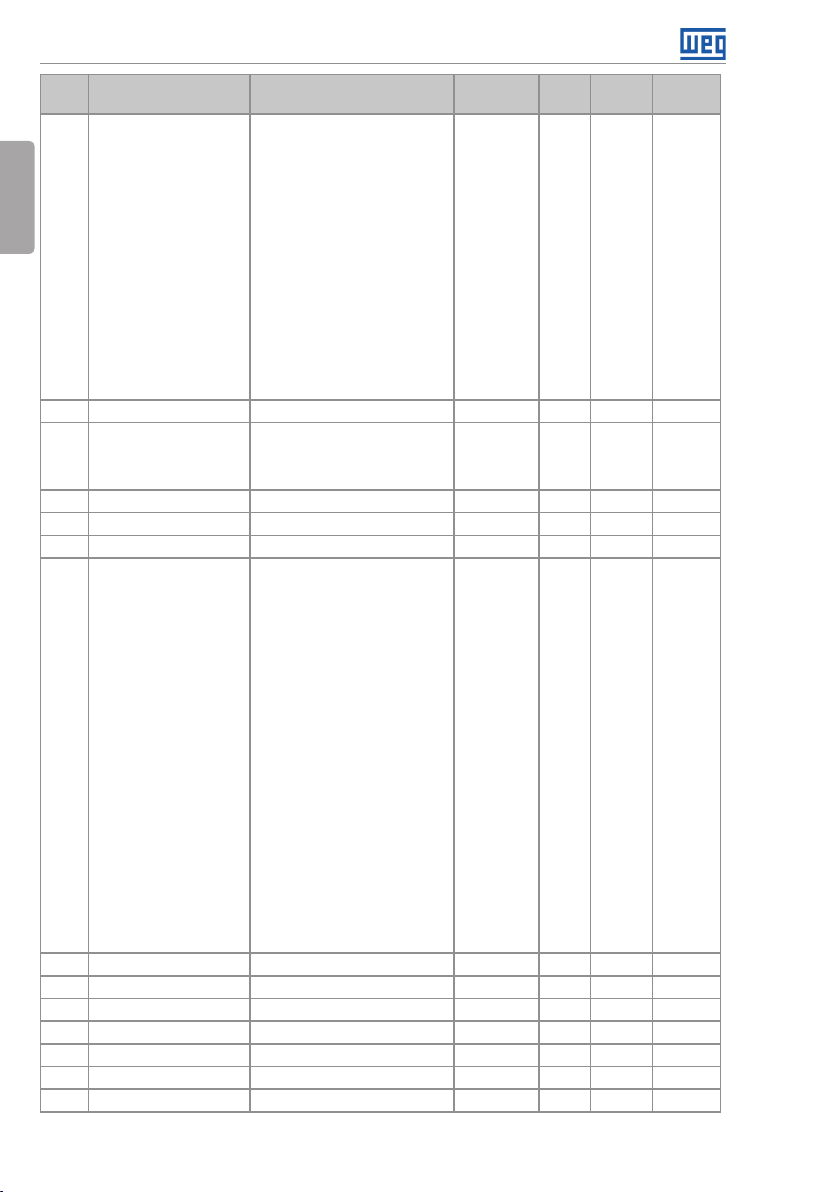

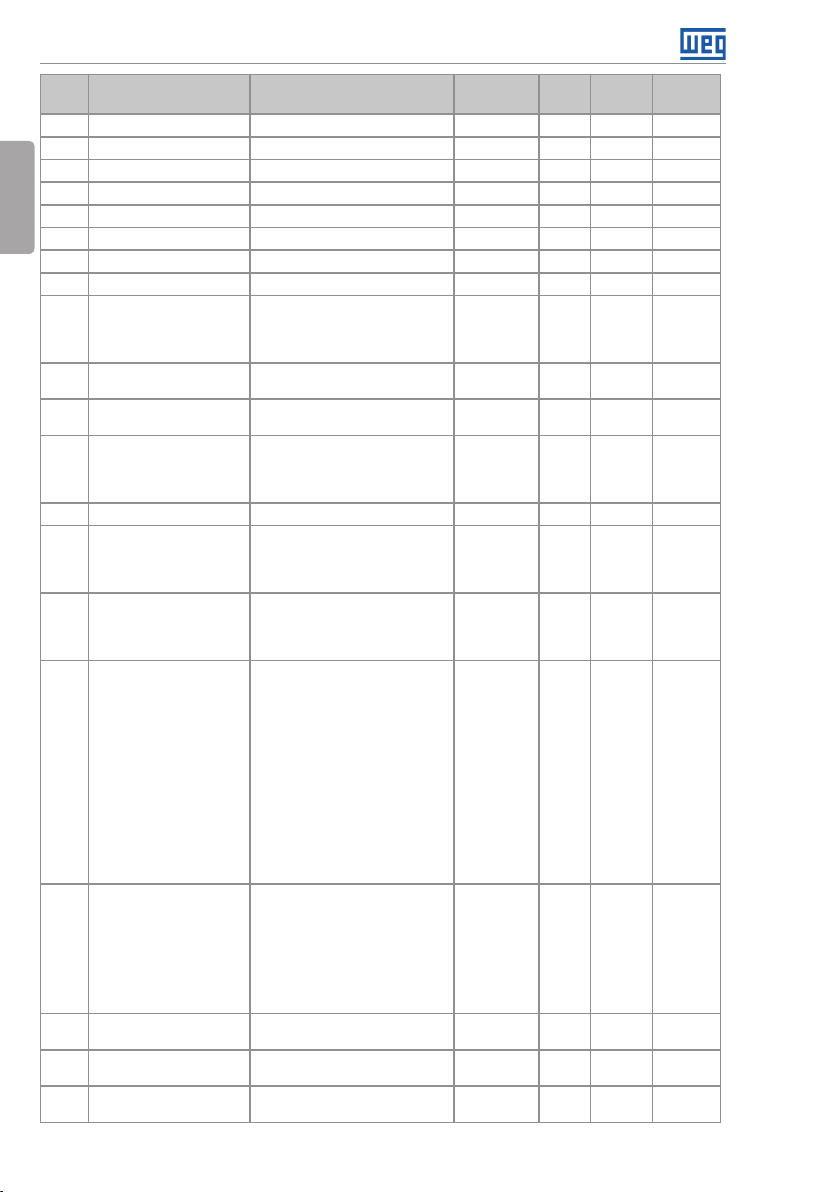

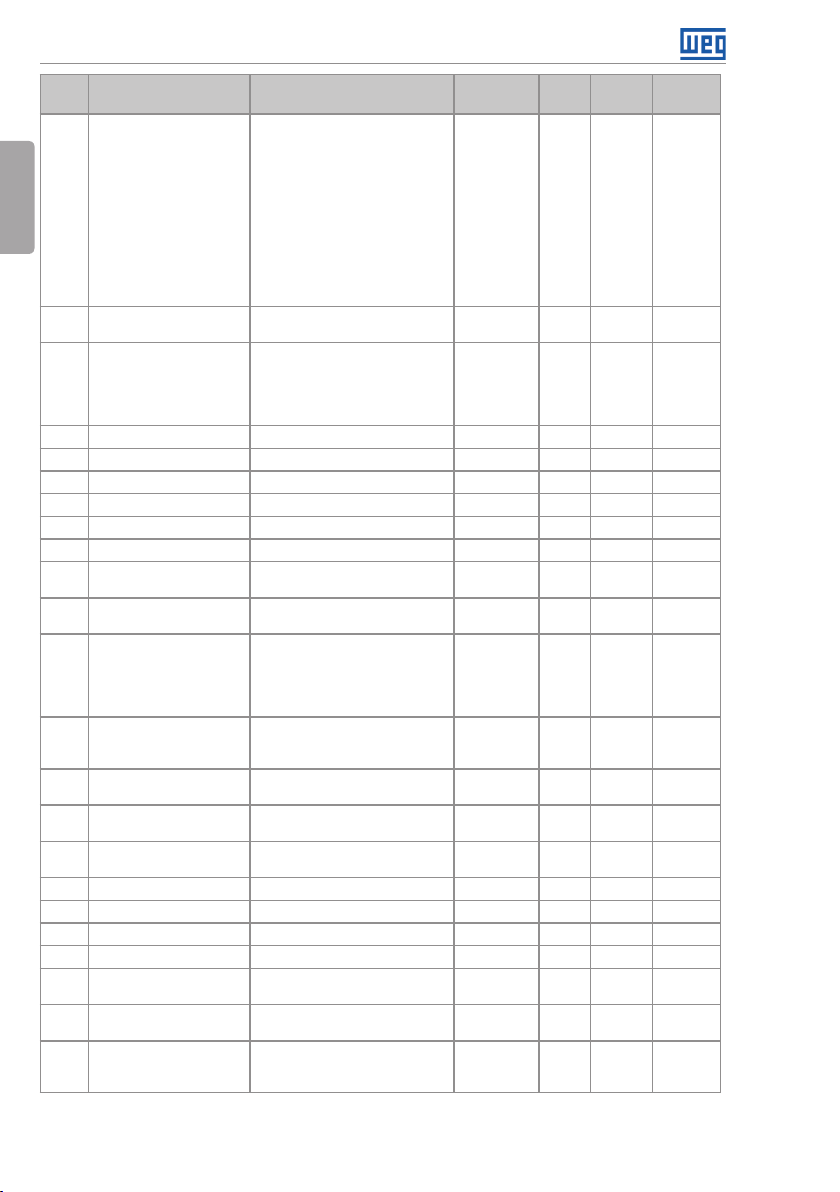

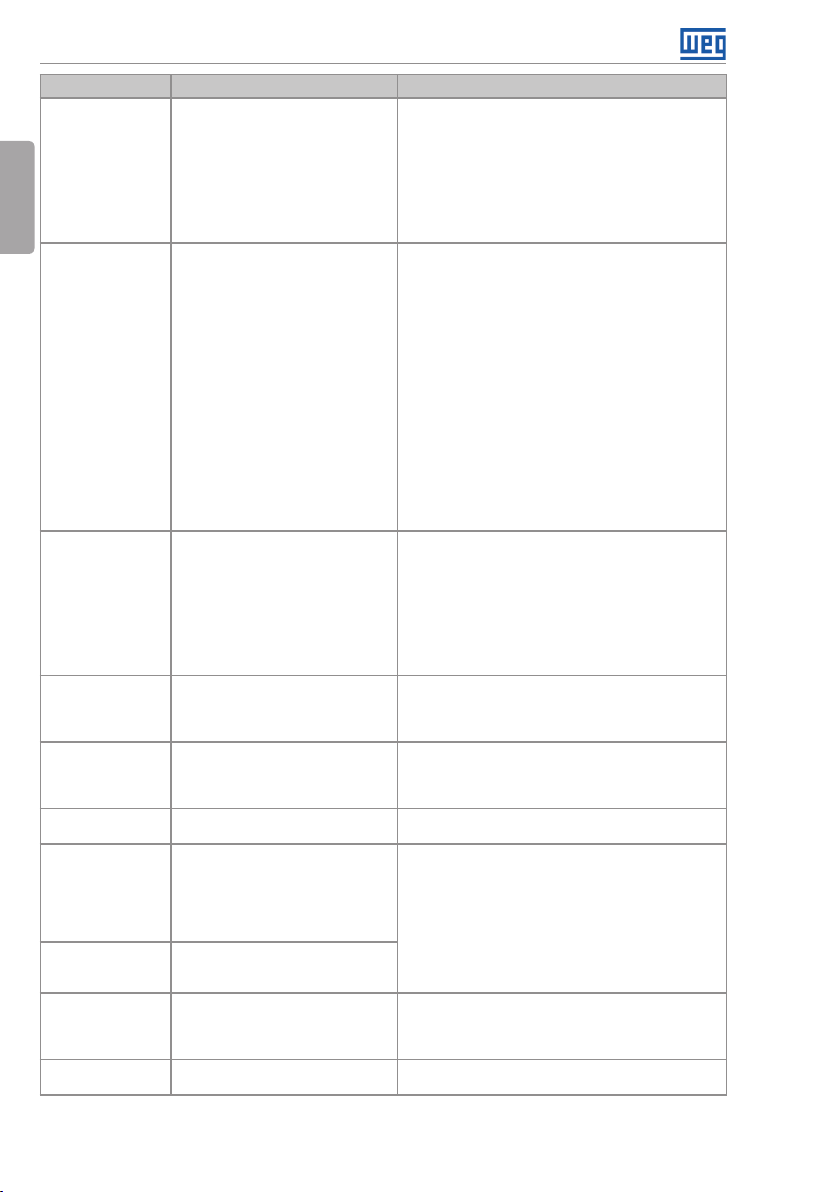

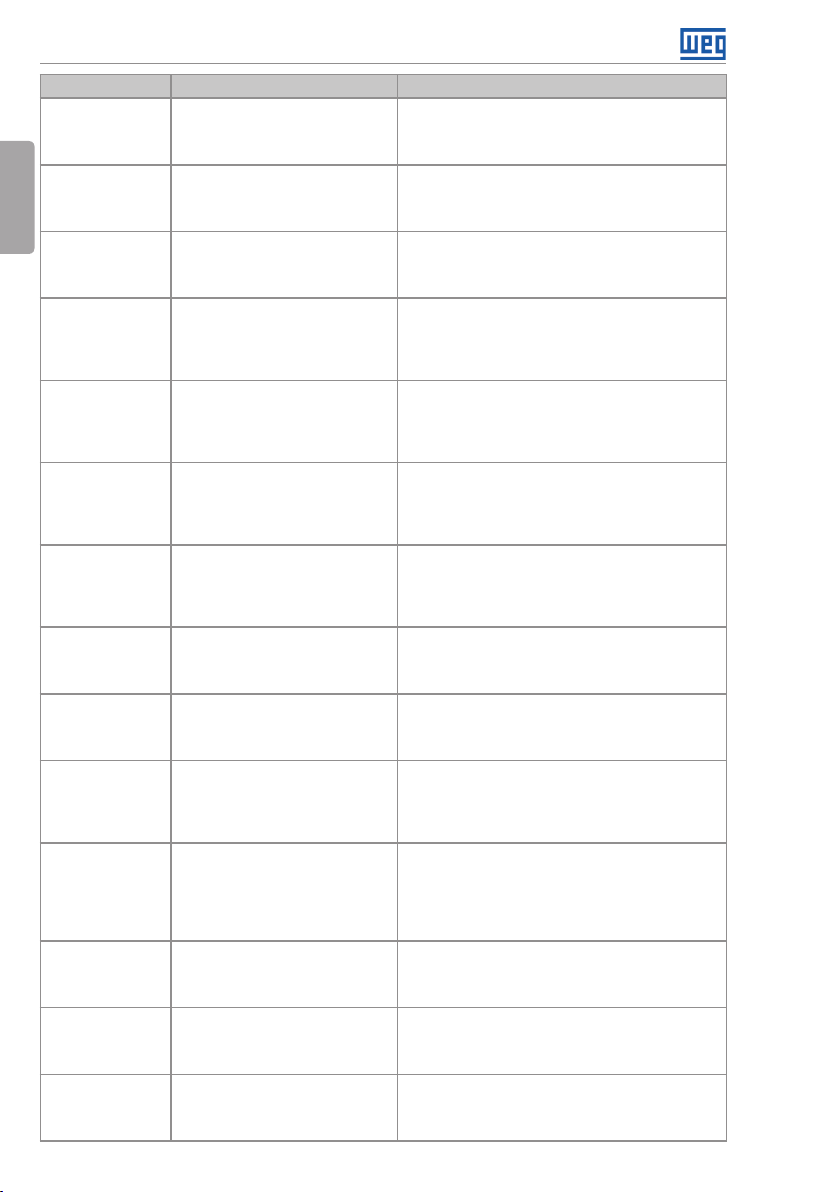

QUICK PARAMETER REFERENCE, FAULTS AND ALARMS

Param. Function

P0000 Access to Parameters 0 to 9999 0

P0001 Speed Reference 0 to 18000 rpm ro READ

P0002 Motor Speed 0 to 18000 rpm ro READ

P0003 Motor Current 0.0 to 4500.0 A ro READ

P0004 DC Link Voltage (Ud) 0 to 2000 V ro READ

P0005 Motor Frequency 0.0 to 1020.0 Hz ro READ

P0006 VFD Status 0 = Ready

P0007 Motor Voltage 0 to 2000 V ro READ

P0009 Motor Torque -1000.0 to 1000.0 % ro READ

P0010 Output Power 0.0 to 6553.5 kW ro READ

P0011 Output Cos φ 0.00 to 1.00 ro READ, I/O

P0 012 DI8 to DI1 Status Bit 0 = DI1

P0 013 DO5 to DO1 Status Bit 0 = DO1

P0 014 AO1 Value 0.00 to 100.00 % ro READ, I/O

P0 015 AO2 Value 0.00 to 100.00 % ro READ, I/O

P0018 AI1 Valu e -100.00 to 100.00 % ro READ, I/O

P0019 AI2 Value -100.00 to 100.00 % ro READ, I/O

P0020 AI3 Value -100.00 to 100.00 % ro READ, I/O

P0022 Frequency Input 3.0 to 6500.0 Hz ro READ, I/O

P0023 Software Version 0.00 to 655.35 ro READ

P0028 Accessories Config. 0000h to FFFFh ro READ

P0029 Power Hardware Config Bit 0 to 5 = Rated Current

P0030 IGBTs Temperature -20.0 to 150.0 °C ro READ

P0034 Internal Air Temp. -20.0 to 150.0 °C ro READ

Adjustable

Range

1 = Run

2 = Undervoltage

3 = Fault

4 = Self-Tuning

5 = Configuration

6 = DC-Braking

7 = STO

8 = Fire Mode

9 = Bypass

Bit 1 = DI2

Bit 2 = DI3

Bit 3 = DI4

Bit 4 = DI5

Bit 5 = DI6

Bit 6 = DI7

Bit 7 = DI8

Bit 1 = DO2

Bit 2 = DO3

Bit 3 = DO4

Bit 4 = DO5

Bit 6 and 7 = Rated Voltage

Bit 8 = RFI Filter

Bit 9 = Safety Relay

Bit 10 = (0)24 V/(1)DC Link

Bit 11 = Always 0

Bit 12 = Dyn. Brak. IGBT

Bit 13 = Special

Bit 14 and 15 = Reserved

Factory

Setting

User

Setting

Propr. Groups

ro READ

ro READ, I/O

ro READ, I/O

ro READ

English

CFW701| 3

Quick Parameter Reference, Faults and Alarms

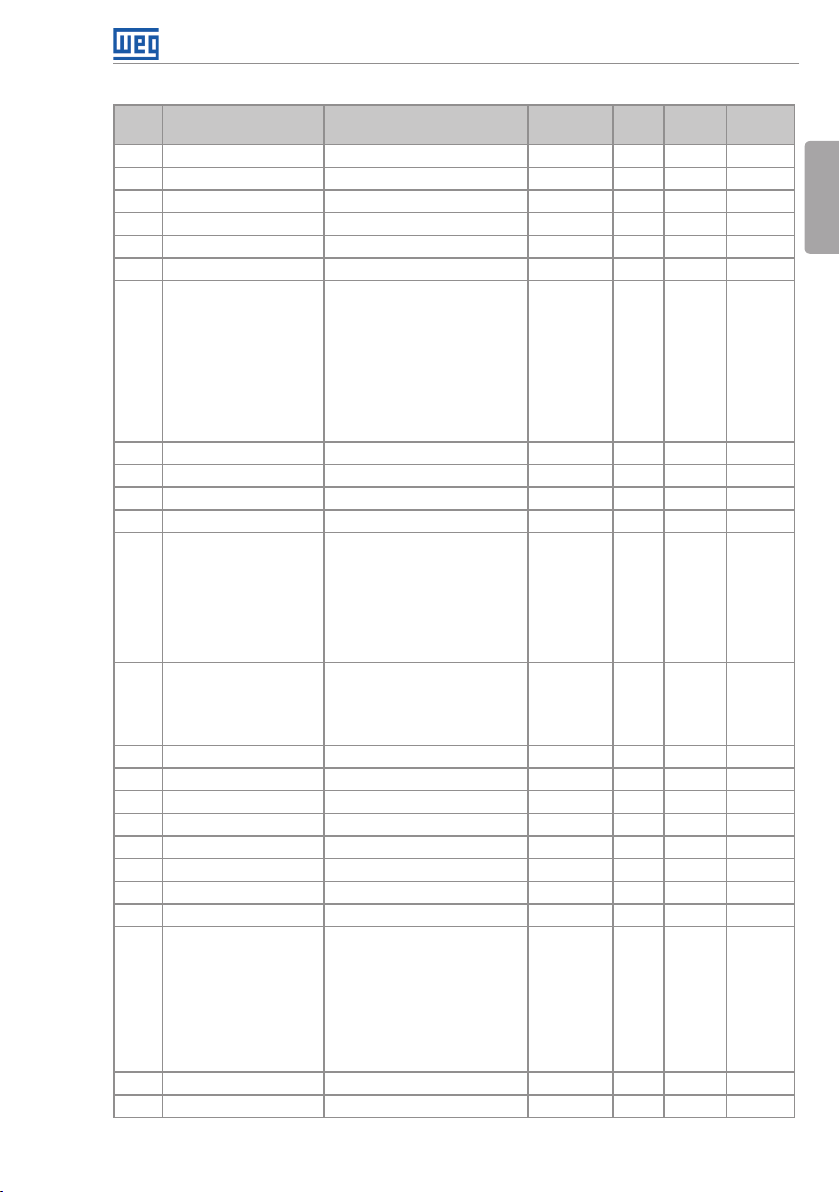

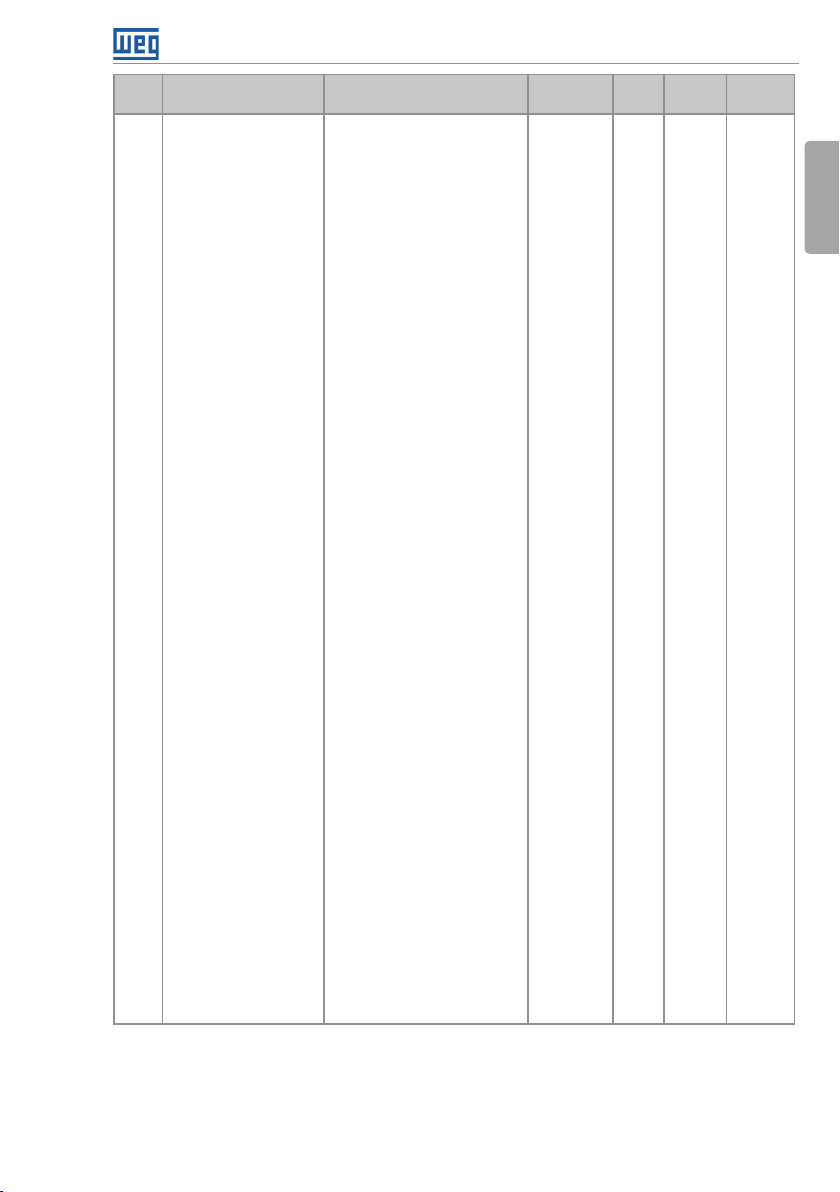

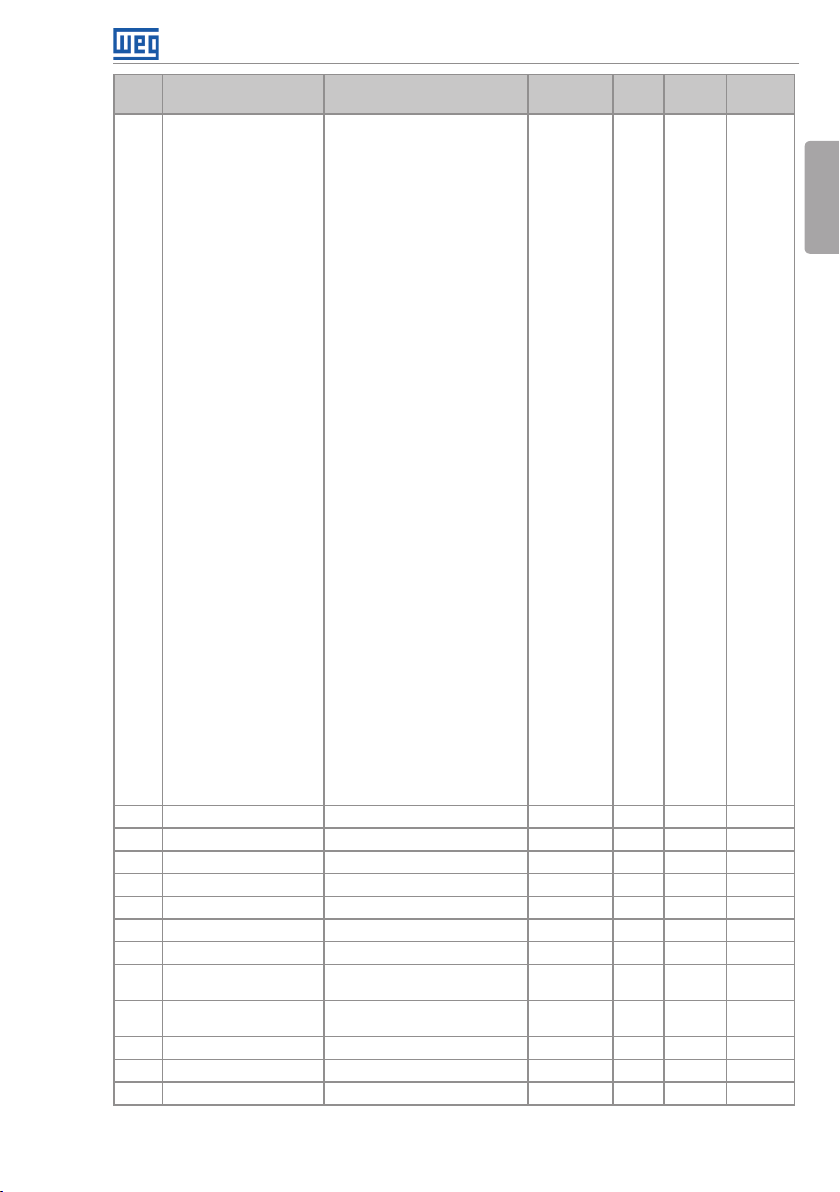

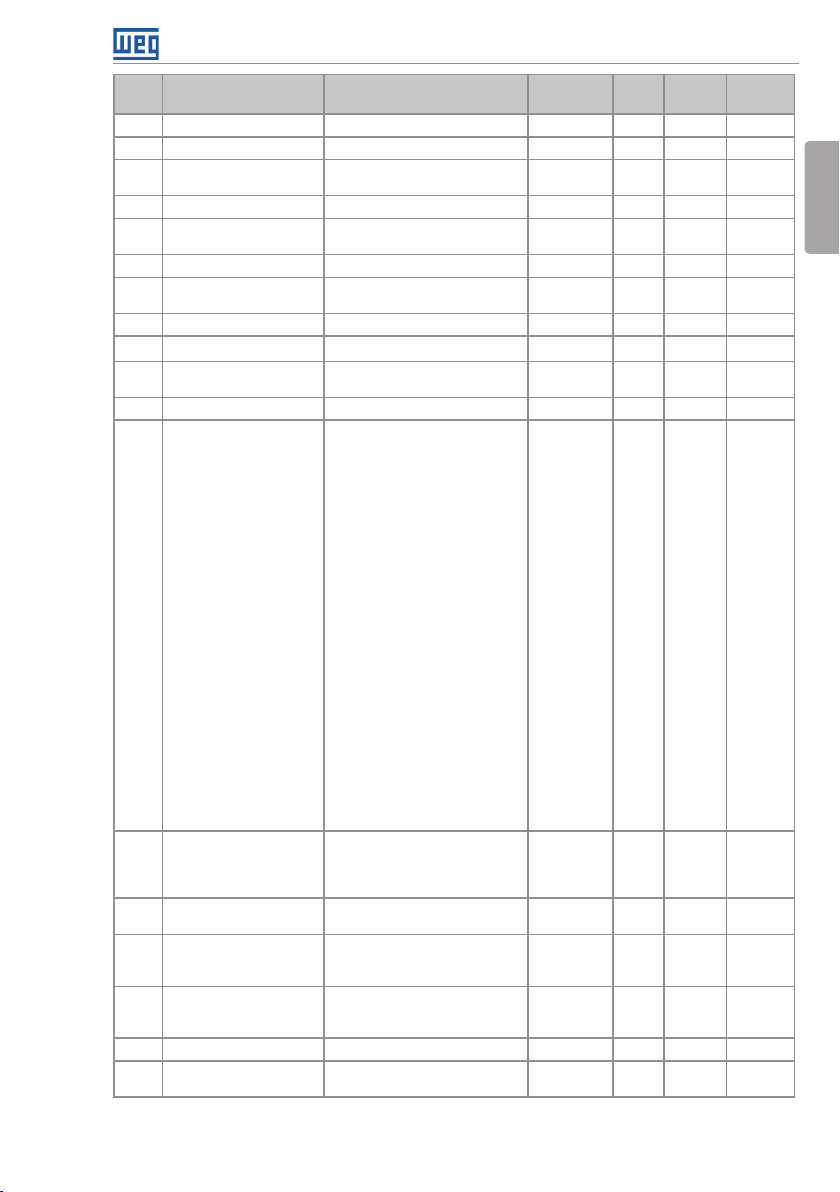

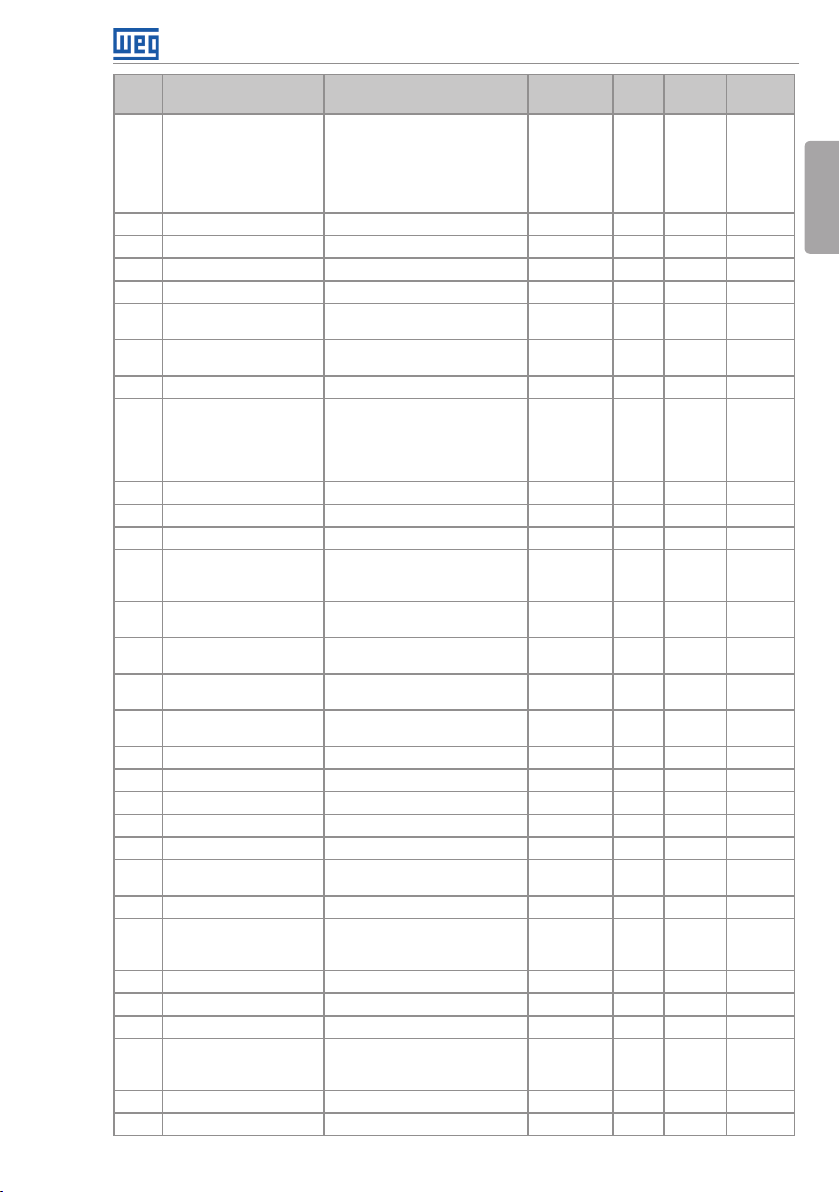

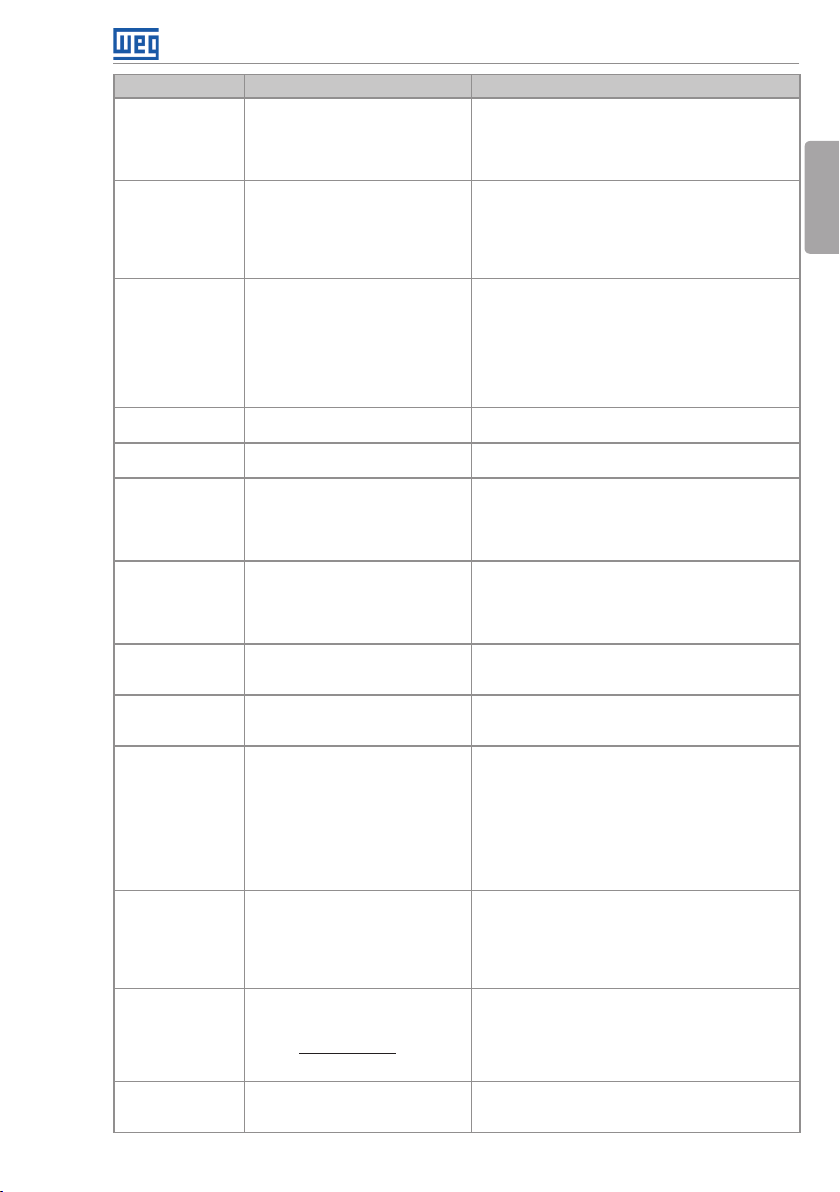

Param. Function

P0036 Fan Heatsink Speed 0 to 15000 rpm ro READ

P0037 Motor Overload Status 0 to 100 % ro READ

English

P0042 Powered Time 0 to 65535 h ro READ

P0043 Enabled Time 0.0 to 6553.5 h ro READ

P0044 kWh Output Energy 0 to 65535 kWh ro READ

P0045 Enabled Fan Time 0 to 65535 h ro READ

P0048 Present Alarm 0 to 999 ro READ

P0049 Present Fault 0 to 999 ro READ

P0050 Last Fault 0 to 999 ro READ

P0054 Second Fault 0 to 999 ro READ

P0058 Third Fault 0 to 999 ro READ

P0062 Fourth Fault 0 to 999 ro READ

P0066 Fifth Fault 0 to 999 ro READ

P0090 Current At Last Fault 0.0 to 4500.0 A ro READ

P0091 DC Link At Last Fault 0 to 2000 V ro READ

P0092 Speed At Last Fault 0 to 18000 rpm ro READ

P0093 Reference Last Fault 0 to 18000 rpm ro READ

P0094 Frequency Last Fault 0.0 to 1020.0 Hz ro READ

P0095 Motor Volt. Last Fault 0 to 2000 V ro READ

P0096 DIx Status Last Fault Bit 0 = DI1

P0097 DOx Status Last Fault Bit 0 = DO1

P010 0 Acceleration Time 0.0 to 999.0 s 20.0 s BASIC

P0101 Deceleration Time 0.0 to 999.0 s 20.0 s BASIC

P0102 Acceleration Time 2 0.0 to 999.0 s 20.0 s

P0103 Deceleration Time 2 0.0 to 999.0 s 20.0 s

P0104 Ra mp Ty pe 0 = Linear

P0105 1st/2nd Ramp Select. 0 = 1st Ramp

P0120 Speed Ref. Backup 0 = Inactive

P0121 Keypad Reference 0 to 18000 rpm 90 rpm

P0122 JOG/JOG + Reference 0 to 18000 rpm 150 (125)

P0123 JOG - Reference 0 to 18000 rpm 150 (125)

P013 2 Max. Overspeed Level 0 to 100 % 10 % cfg

Adjustable

Bit 1 = DI2

Bit 2 = DI3

Bit 3 = DI4

Bit 4 = DI5

Bit 5 = DI6

Bit 6 = DI7

Bit 7 = DI8

Bit 1 = DO2

Bit 2 = DO3

Bit 3 = DO4

Bit 4 = DO5

1 = S Ramp

1 = 2nd Ramp

2 = DIx

3 = Serial

4 = SoftPLC

1 = Active

Range

Factory

Setting

rpm

rpm

User

Setting

0

2 cfg

1

Propr. Groups

ro READ

ro READ

Vector

4 | CFW701

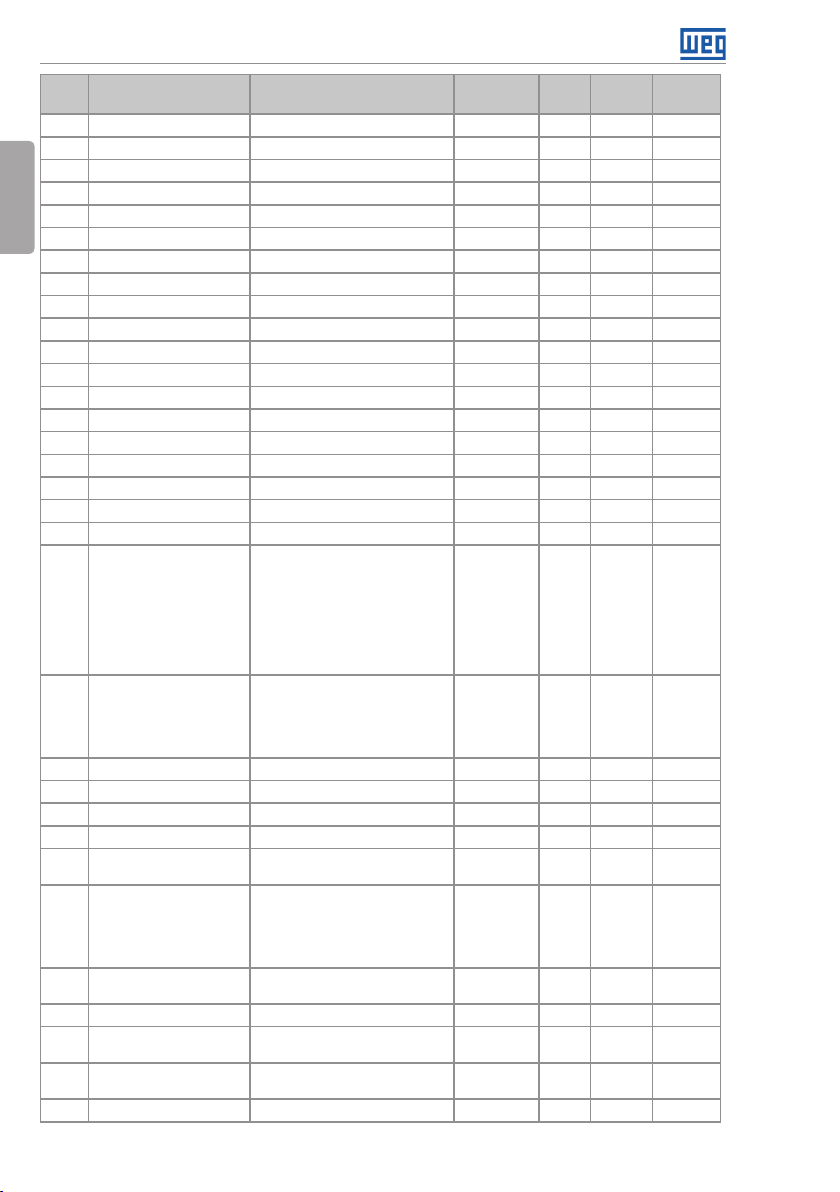

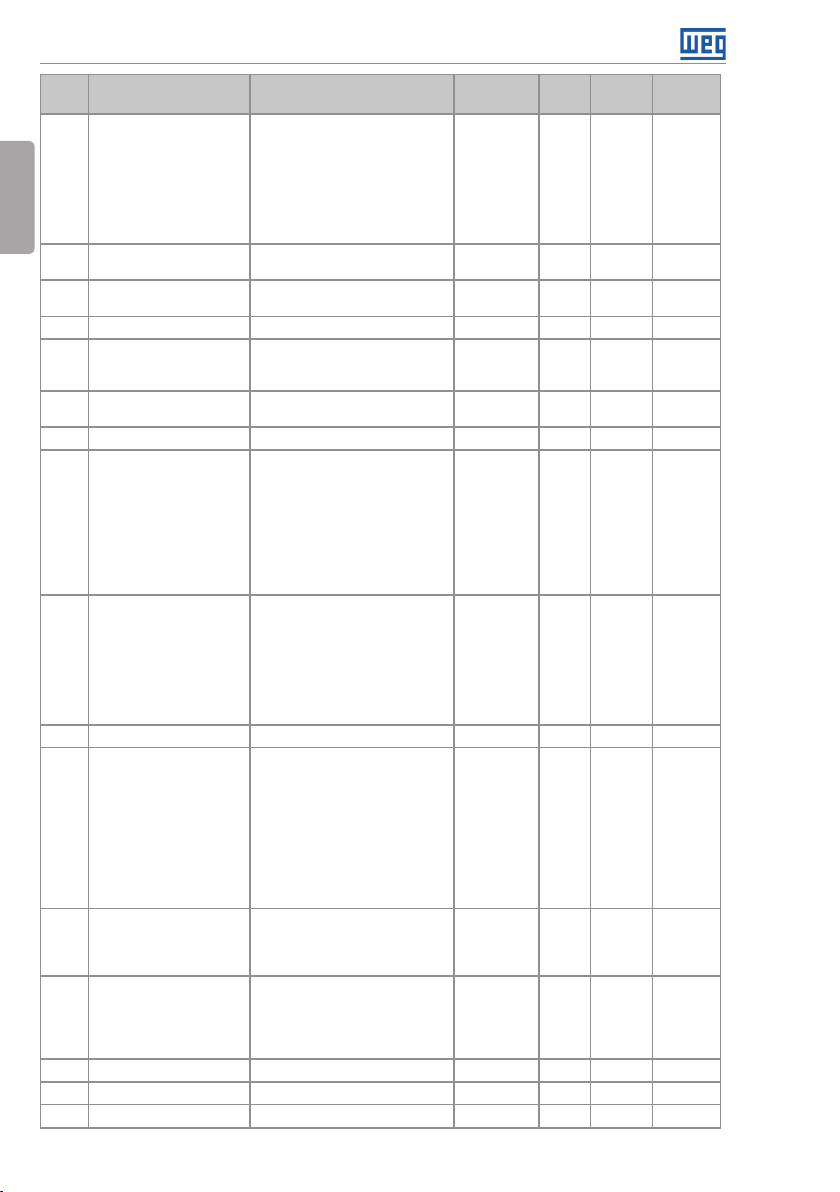

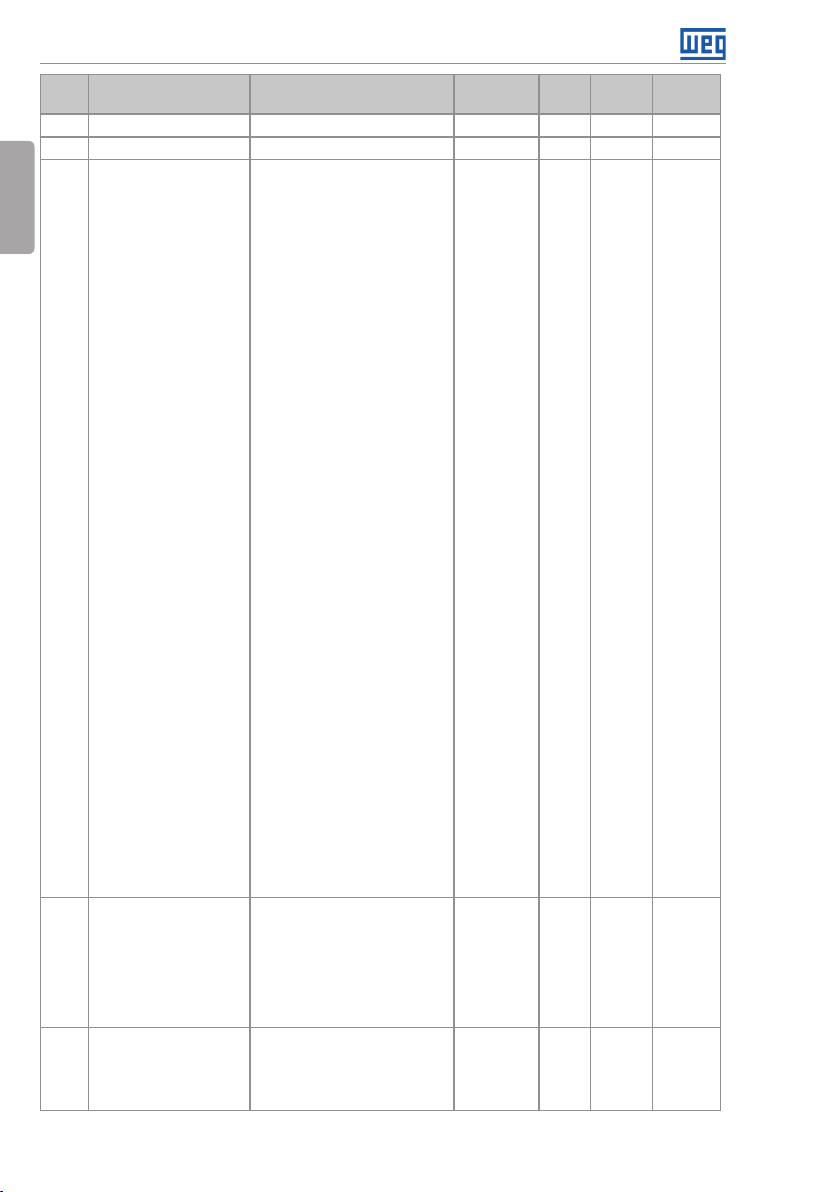

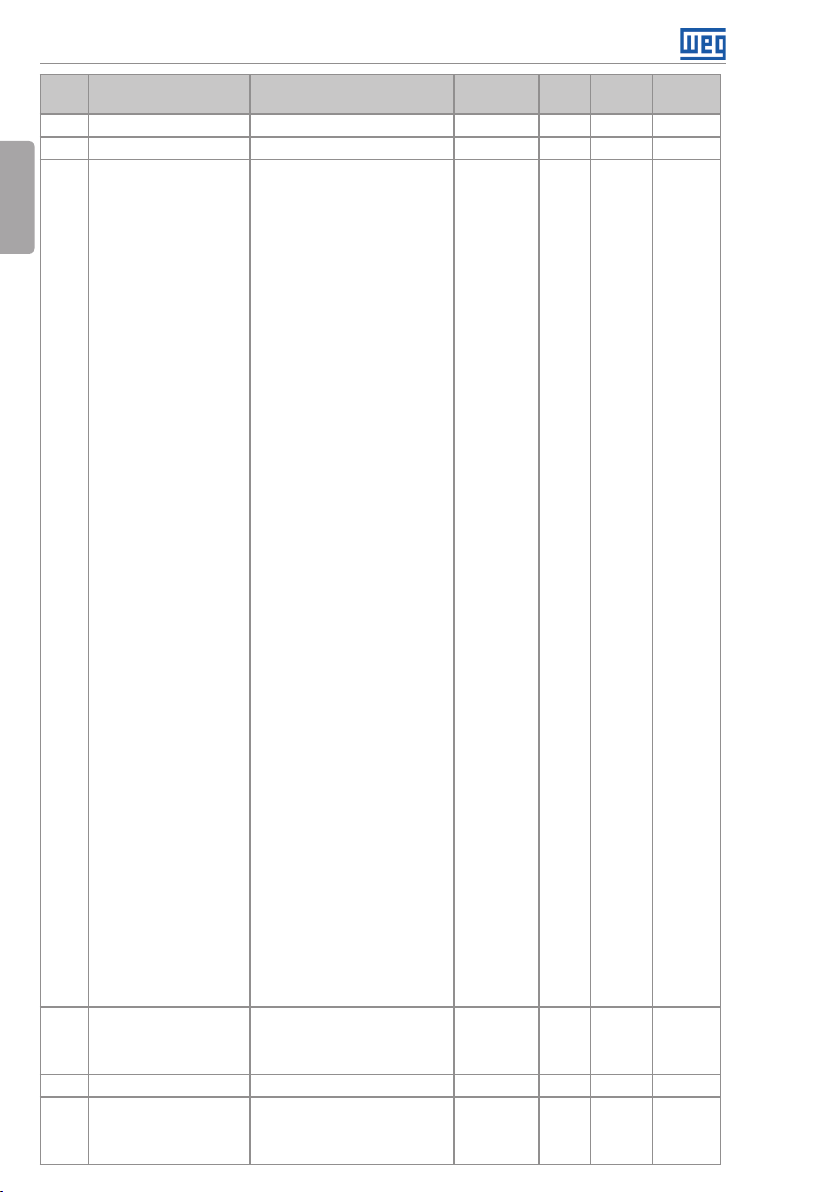

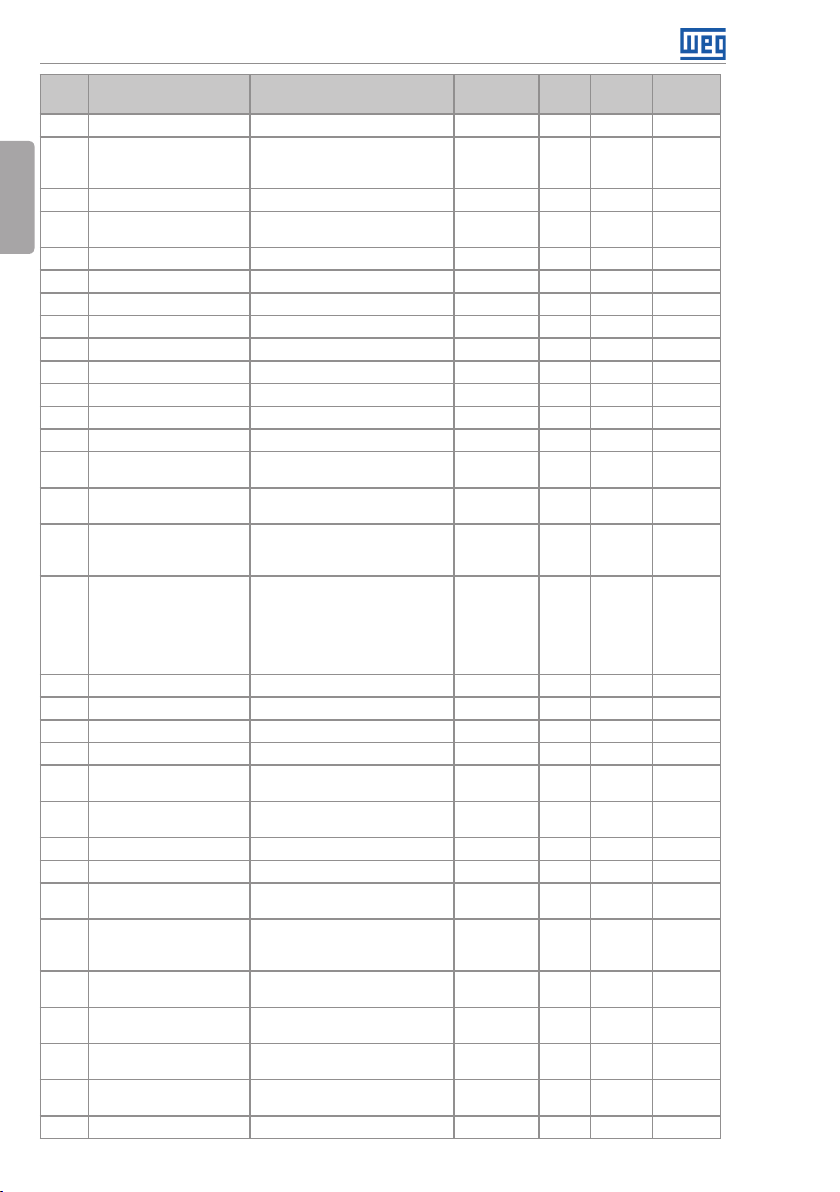

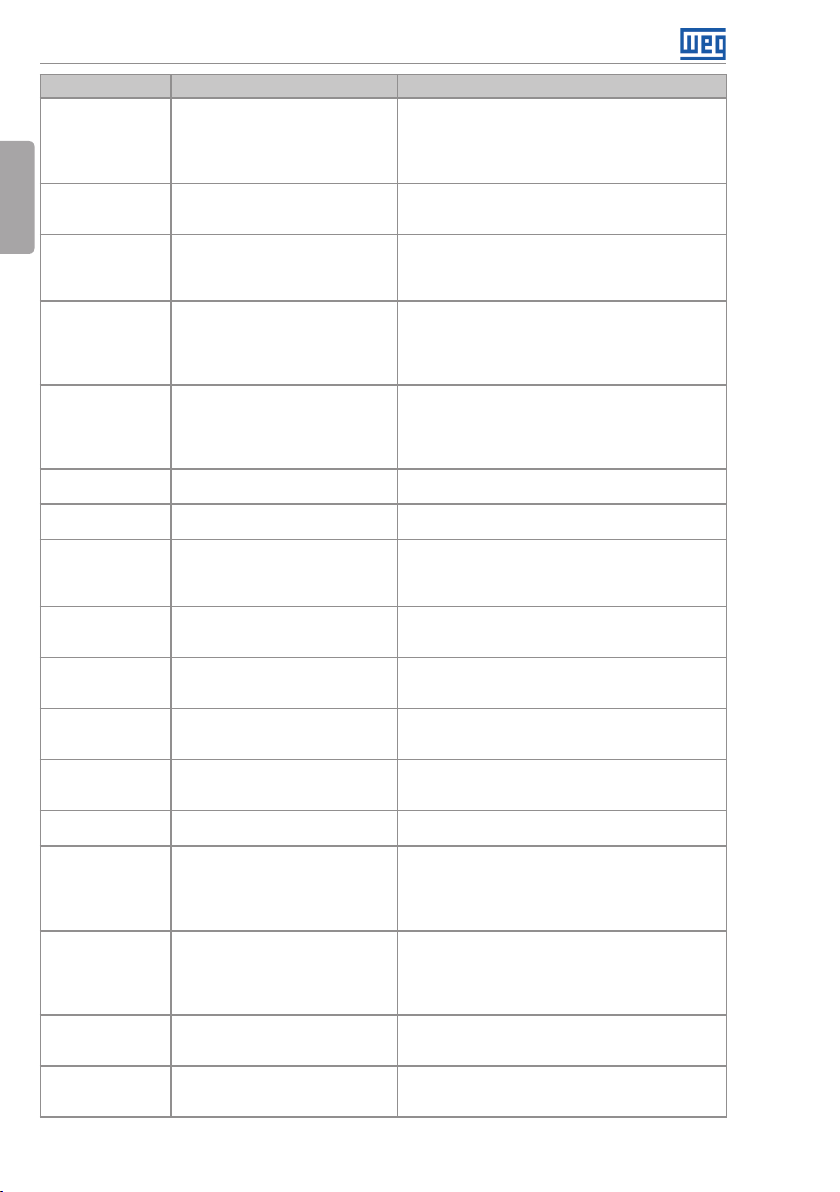

Quick Parameter Reference, Faults and Alarms

Param. Function

Adjustable

Range

P013 3 Minimum Speed 0 to 18000 rpm 90 (75) rpm BASIC

P013 4 Maximum Speed 0 to 18000 rpm 1800 (1500)

P013 5 Max. Output Current 0.2 to 2xI

nom-HD

P0136 Manual Torque Boost 0 to 9 1 V/f BASIC

P0137 Autom. Torque Boost 0.00 to 1.00 0.00 V/f

P013 8 Slip Compensation -10.0 to 10.0 % 0.0 % V/f

P013 9 Output Current Filter 0.0 to 16.0 s 0.2 s V/f, V VW

P0142 Max. Output Voltage 0.0 to 100.0 % 100.0 % cfg, Adj

P0143 Interm. Output Voltage 0.0 to 100.0 % 50.0 % cfg, Adj

P0144 3 Hz Output Voltage 0.0 to 100.0 % 8.0 % cfg, Adj

P0145 Field Weakening Speed 0 to 18000 rpm 180 0 r pm cfg, Adj

P0146 Intermediate Speed 0 to 18000 rpm 900 rpm cfg, Adj

P015 0 V/f DC Regulation Type 0 = Ramp Hold

1 = Ramp Accel.

P0151 V/f DC Regulation Level 339 to 1000 V 800 V V/ f, V VW

P0152 DC Link Regul. P Gain 0.00 to 9.99 1.50 V/ f, V VW

P015 3 Dyn. Braking Level 339 to 1000 V 748 V

P015 6 100 % Speed Overload

Current

P0157 50 % Speed Overload

Current

P015 8 5 % Speed Overload

Current

P015 9 Motor Thermal Class 0 = Class 5

P016 0 Speed Regul. Config. 0 = Normal

0.1 to 1.5xI

0.1 to 1.5xI

0.1 to 1.5xI

1 = Class 10

2 = Class 15

3 = Class 20

4 = Class 25

5 = Class 30

6 = Class 35

7 = Class 40

8 = Class 45

nom-ND

nom-ND

nom-ND

1 = Saturated

P0161 Speed Prop. Gain 0.0 to 63.9 7.4 Vector

P0162 Speed Integral Gain 0.000 to 9.999 0.023 Vector

P016 3 LOC Reference Of fset -999 to 999 0 Vector

P016 4 REM Reference Offset -999 to 999 0 Vector

P016 5 Speed Filter 0.012 to 1.000 s 0.012 s Vector

P016 6 Speed Diff. Gain 0.00 to 7.99 0.00 Vector

P0167 Current Prop. Gain 0.00 to 1.99 0.50 Vector

P016 8 Current Integral Gain 0.000 to 1.999 0.010 Vector

P016 9 Max. + Torque Curr. 0.0 to 350.0 % 125.0 % Vector

P0170 Max. - Torque Curr. 0.0 to 350.0 % 125.0 % Vector

P0175 Flux Proport. Gain 0.0 to 31.9 2.0 Vector

P0176 Flux Integral Gain 0.000 to 9.999 0.020 Vector

P0178 Rated Flux 0 to 120 % 100 % Vector

P018 0 Iq* After I/f 0 to 350 % 10 % Sless

Factory

Setting

User

Setting

rpm

1.5xI

nom-HD

0 cfg, V/f,

1.05x I

nom-ND

0.9xI

nom-ND

0.65xI

nom-ND

1 cfg

0 cfg,

Propr. Groups

BASIC

V/f, V VW BASIC

VVW

Vector

English

CFW701| 5

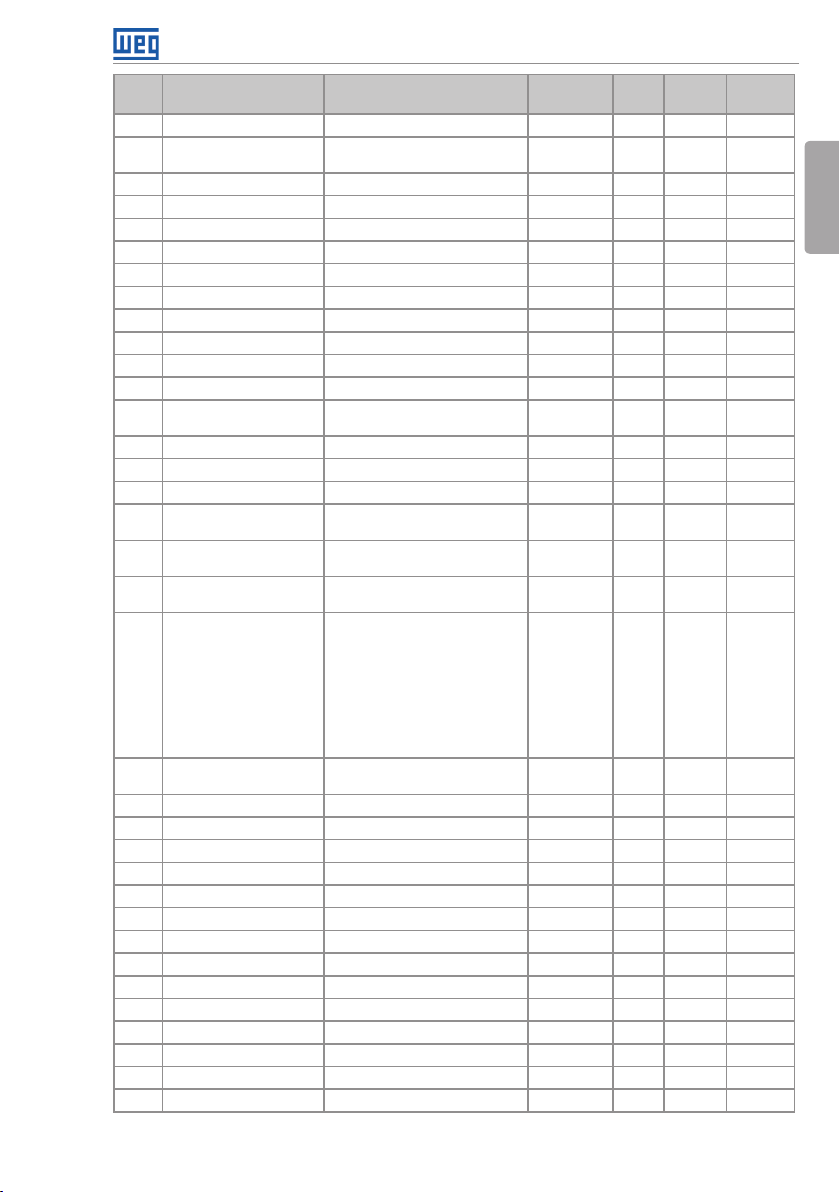

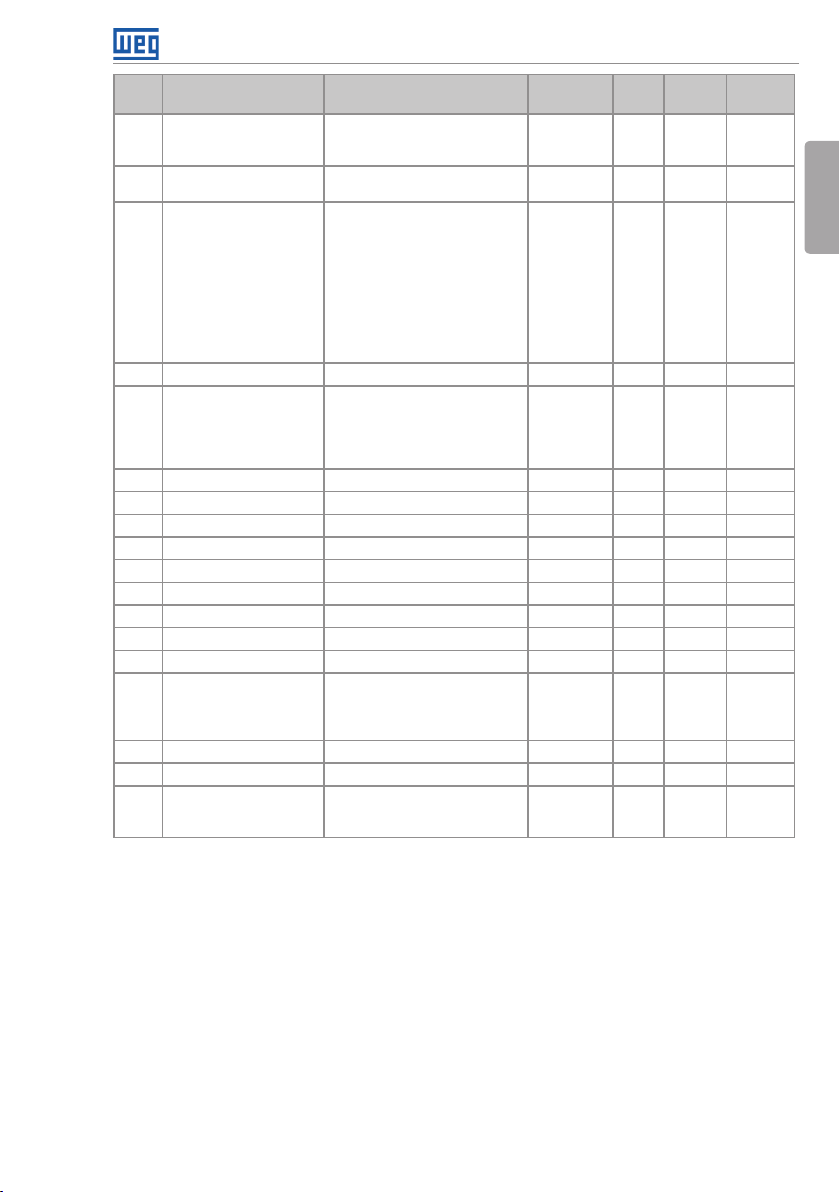

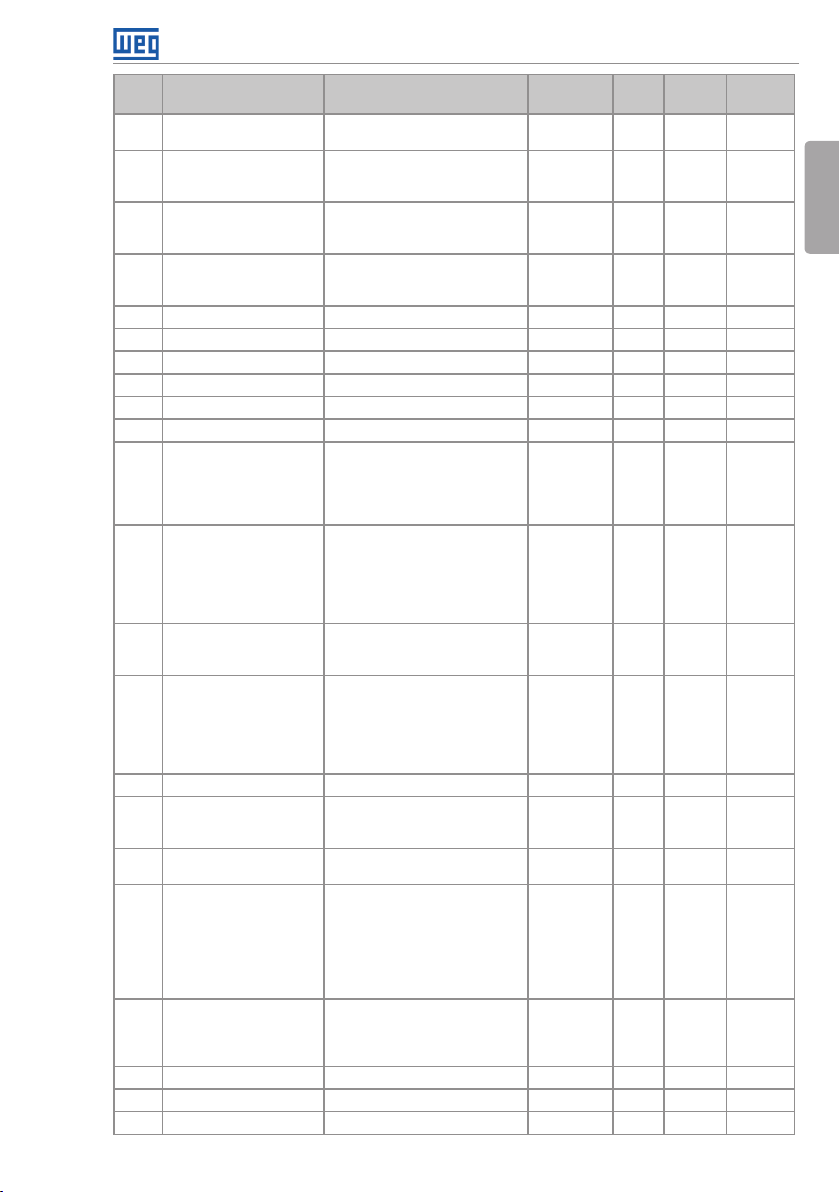

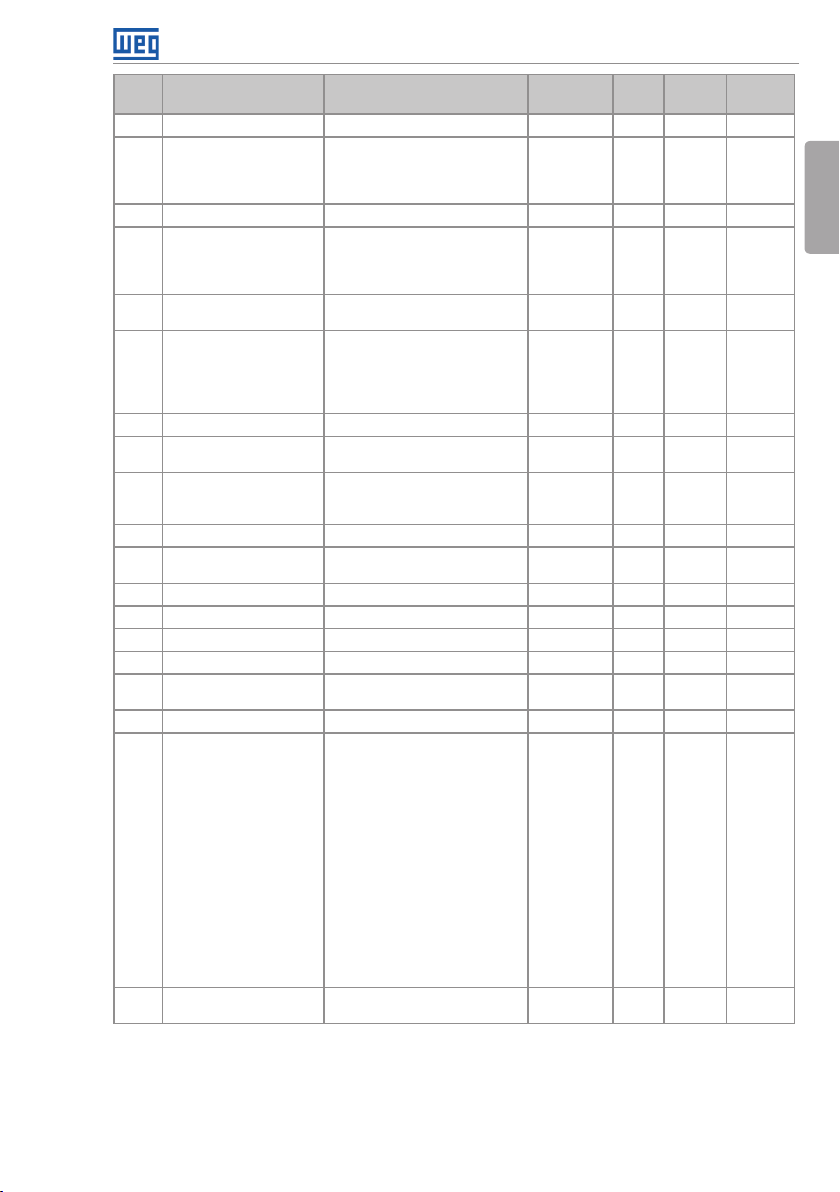

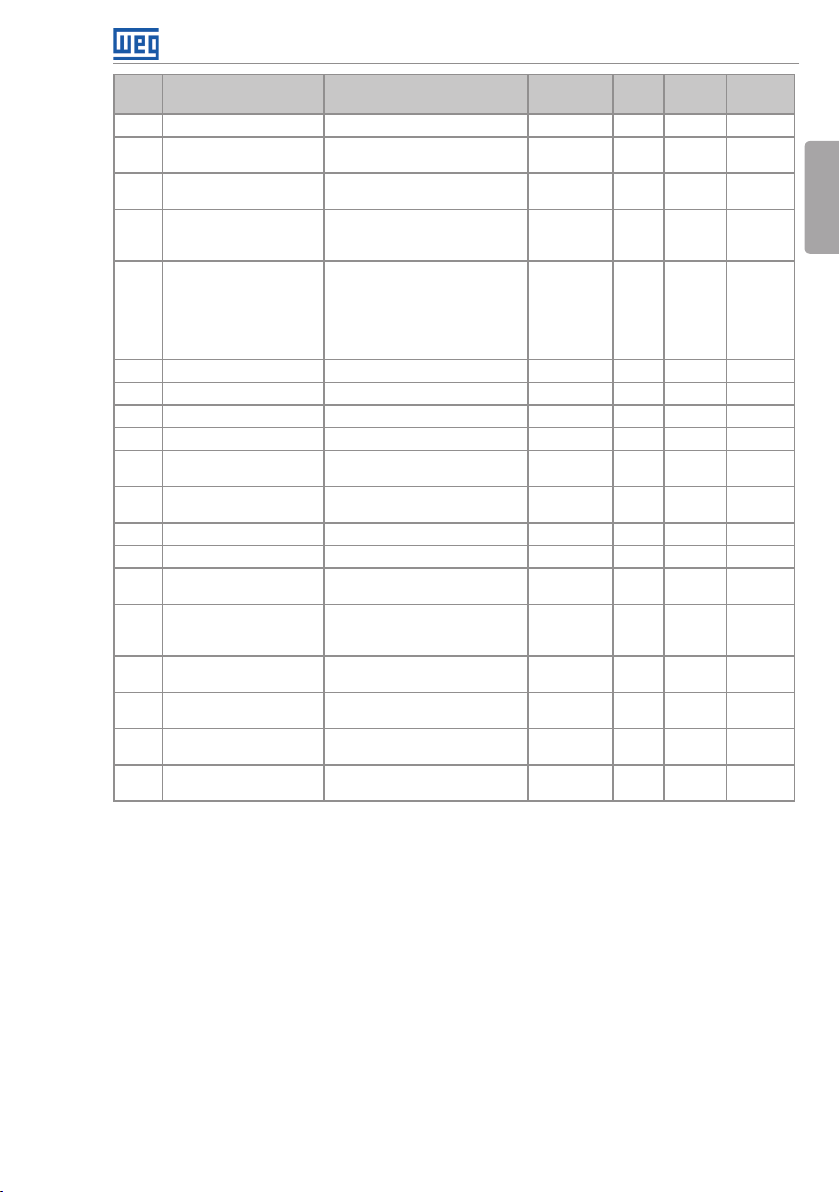

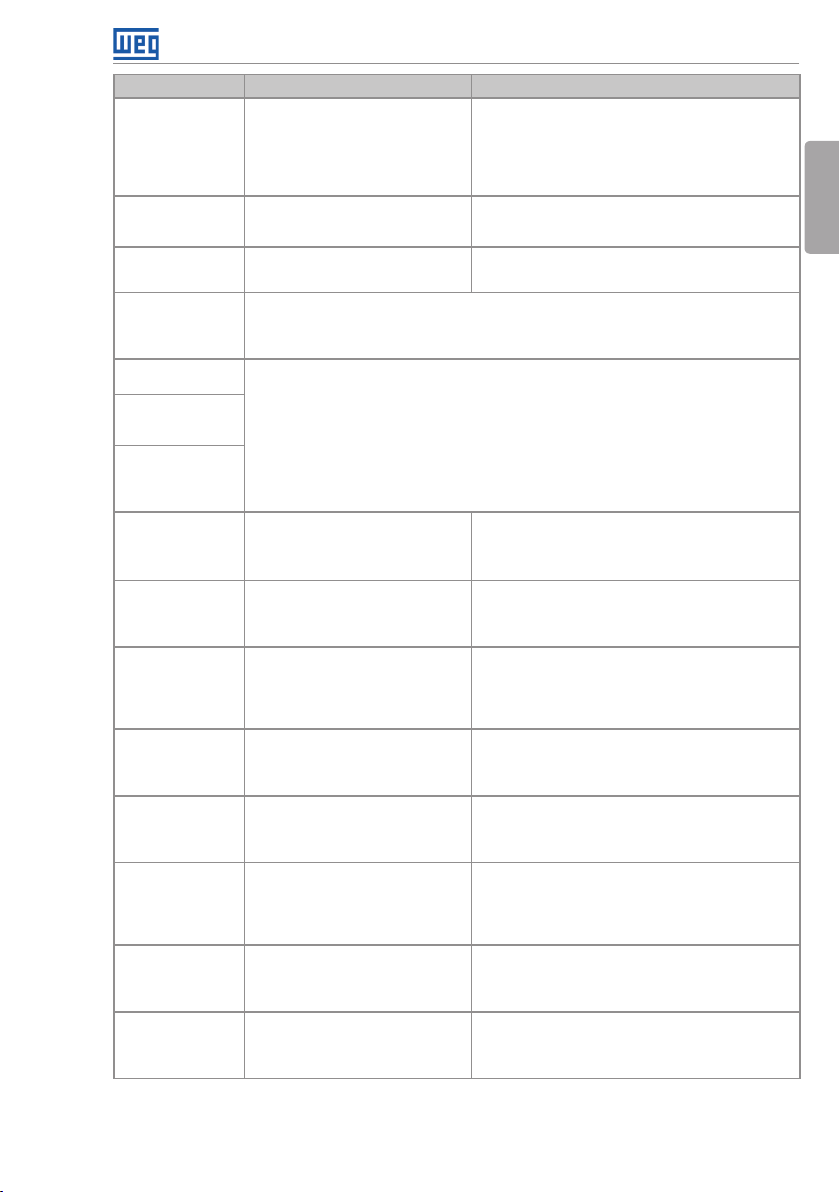

Quick Parameter Reference, Faults and Alarms

Param. Function

P0182 Speed for I/f Activ. 0 to 90 rpm 18 rpm Sless

P018 3 Current in I/f Mode 0 to 9 1 Sless

English

P018 4 DC Link Regul. Mode 0 = With losses

P018 5 DC Link Regul. Level 339 to 1000 V 800 V Vector

P018 6 DC Link Prop. Gain 0.0 to 63.9 26.0 Vector

P0187 DC Link Integral Gain 0.000 to 9.999 0.010 Vector

P019 0 Max. Output Voltage 0 to 600 V 440 V Ve ctor

P0200 Password 0 = Inactive

P0202 Control Type 0 = V/f 60 Hz

P0204 Load/Save Parameters 0 = Not Used

P0205 Main Display Parameter

Sel.

P0206 Secondary Display

Parameter Sel.

P0208 Main Display Scale Factor 0.1 to 1000.0 % 100.0 % HMI

Adjustable

Range

1 = Without losses

2 = Enab/Disab DIx

1 = Active

2 = Change Pass.

1 = V/f 50 Hz

2 = V/f Adjustable

3 = VV W

4 = Sensorless

1 = Not Used

2 = Reset P0045

3 = Reset P0043

4 = Reset P0044

5 = Load 60 Hz

6 = Load 50 Hz

7 = Load User 1

8 = Load User 2

9 = Save User 1

10 = Save User 2

0 to 1199 2 HMI

0 to 1199 3 HMI

Factory

Setting

User

Setting

1 cfg,

1 HMI

0 cfg

0 cfg

Propr. Groups

Vector

6 | CFW701

Param. Function

P0209 Main Display Eng. Unit 0 = None

1 = V

2 = A

3 = rpm

4 = s

5 = ms

6 = None

7 = m

8 = None

9 = None

10 = %

11 = °C

12 = None

13 = Hz

14 = None

15 = h

16 = W

17 = kW

18 = None

19 = None

20 = min

21 = °F

22 = bar

23 = mbar

24 = psi

25 = Pa

26 = kPa

27 = MPa

28 = mwc

29 = mca

30 = gal

31 = l

32 = in

33 = ft

34 = m³

35 = ft³

36 = gal/s

37 = gal/min

38 = gal/h

39 = l/s

40 = l/min

41 = l/h

42 = m/s

43 = m/min

44 = m/h

45 = ft/s

46 = ft/min

47 = ft/h

48 = m³/s

49 = m³/min

50 = m³/h

51 = ft³/s

52 = ft³/min

53 = ft³/h

54 = As per P0510

55 = As per P0512

56 = As per P0514

57 = As per P0516

Adjustable

Range

Quick Parameter Reference, Faults and Alarms

Factory

Setting

User

Setting

3 HMI

Propr. Groups

English

CFW701| 7

Quick Parameter Reference, Faults and Alarms

Param. Function

P0210 Main Display Decimal

Point

English

P02 11 Secondary Display Scale

Factor

P0212 Secondary Display

Decimal Point

P0216 HMI Backlighting 0 to 15 15 HMI

P0 217 Zero Speed Disable 0 = Inactive

P0218 Zero Speed Dis. Out 0 = Ref. or Speed

P0219 Zero Speed Time 0 to 999 s 0 s

P0220 LOC/REM Selection Src 0 = Always LOC

P0221 LOC Reference Sel. 0 = HMI

P0222 REM Reference Sel. See options in P0221 1 cfg I/O

P0223 LOC FWD/REV Selection 0 = Forward

P0224 LOC Run/Stop Sel. 0 = I,O Keys

P0225 LOC JOG Selection 0 = Disable

P0226 REM FWD/REV Sel. See options in P0223 4 cfg I/O

P0227 REM Run/Stop Sel. See options in P0224 1 cfg I/O

P0228 REM JOG Selection See options in P0225 2 cfg I/O

Adjustable

Range

0 = wxyz

1 = wxy.z

2 = wx.yz

3 = w.xyz

4 = As per P0511

5 = As per P0513

6 = As per P0515

7 = As per P0517

0.1 to 1000.0 % 100.0 % HMI

See options in P0210 1 HMI

1 = Active (N* and N)

2 = Active (N*)

1 = Reference

1 = Always REM

2 = LR Key LOC

3 = LR Key REM

4 = DIx

5 = Serial LOC

6 = Serial REM

7 = SoftPLC LOC

8 = SoftPLC REM

1 = AI1

2 = AI2

3 = AI3

4 = Sum AIs > 0

5 = Sum AIs

6 = Serial

7 = SoftPLC

1 = Reverse

2 = FR Key FWD

3 = FR Key REV

4 = DIx

5 = Serial FWD

6 = Serial REV

7 = SoftPLC FWD

8 = SoftPLC RE V

9 = AI2 Polarity

1 = DIx

2 = Serial

3 = SoftPLC

1 = JOG Key

2 = DIx

3 = Serial

4 = SoftPLC

Factory

Setting

User

Setting

0 HMI

0 cfg

0

2 cfg I/O

0 cfg I/O

2 cfg I/O

0 cfg I/O

1 cfg I/O

Propr. Groups

8 | CFW701

Quick Parameter Reference, Faults and Alarms

Param. Function

P0229 Stop Mode Selection 0 = Ramp to Stop

P0230 Dead Zone (AIs) 0 = Inactive

P0231 AI1 Signal Function 0 = Speed Ref.

P0232 AI1 Gain 0.000 to 9.999 1.000 I/O

P0233 AI1 Signal Type 0 = 0 to 10 V / 20 mA

P0234 AI1 Offset -100.00 to 100.00 % 0.00 % I/O

P0235 AI1 Filter 0.00 to 16.00 s 0.15 s I/O

P0236 AI2 Signal Function See options in P0231 8 cfg I/O

P0237 AI2 Gain 0.000 to 9.999 1.000 I/O

P0238 AI2 Signal Type See options in P0233 0 cfg I/O

P0239 AI2 Offset -100.00 to 100.00 % 0.00 % I/O

P024 0 AI2 Filter 0.00 to 16.00 s 0.15 s I/O

P0 241 AI3 Signal Function See options in P0231 9 cfg I/O

P0242 AI3 Gain 0.000 to 9.999 1.000 I/O

P0243 AI3 Signal Type 0 = 0 to 20mA

P024 4 AI3 Offset -100.00 to 100.00 % 0.00 % I/O

P024 5 AI3 Filter 0.00 to 16.00 s 0.15 s I/O

P024 6 Frequency Input

Configuration

Adjustable

Range

1 = Coast to Stop

2 = Fast Stop

1 = Active

1 = No Ramp Ref.

2 = Max. Torque Cur

3 = SoftPLC

4 = PTC

5 = Main PID Feedback 1

6 = Main PID Feedback 2

7 = Main PID Feedback 3

8 = External PID 1 Feedback

9 = External PID 2 Feedback

1 = 4 to 20 mA

2 = 10 V / 20 mA to 0

3 = 20 to 4 mA

4 = -10 to +10 V

1 = 4 to 20 mA

2 = 20 to 0 mA

3 = 20 to 4 mA

0 = Off

1 = DI3

2 = DI4

Factory

Setting

User

Setting

0 cfg

0 I/O

5 cfg I/O

0 cfg I/O

0 cfg I/O

0 cfg

Propr. Groups

English

CFW701| 9

Quick Parameter Reference, Faults and Alarms

Param. Function

P0251 AO1 Function 0 = Speed Ref.

English

P0252 AO1 Gain 0.000 to 9.999 1.000 I/O

P0253 AO1 Signal Type 0 = 0 to 10 V / 20 mA

P0254 AO2 Function See options in P0251 17 I/O

P0255 AO2 Gain 0.000 to 9.999 1.000 I/O

P0256 AO2 Signal Type See options in P0253 0 cfg I/O

P0263 DI1 Function 0 = Not Used

P0264 DI2 Function See options in P0263 4 cfg I/O

P0265 DI3 Function See options in P0263 0 cfg I/O

P0266 DI4 Function See options in P0263 20 cfg I/O

P0267 DI5 Function See options in P0263 21 cfg I/O

P0268 DI6 Function See options in P0263 22 cfg I/O

P0269 DI7 Function See options in P0263 0 cfg I/O

P0270 DI8 Function See options in P0263 0 cfg I/O

Adjustable

Range

1 = Total Ref.

2 = Real Speed

3 = Torque Cur. Ref

4 = Torque Current

5 = Output Current

6 = Active Current

7 = Output Power

8 = Torque Cur. > 0

9 = Motor Torque

10 = SoftPLC

11 = PTC

12 = Motor Ixt

13 = P0696 Value

14 = P0697 Value

15 = Id* Current

16 = External PID 1 Output

17 = External PID 2 Output

1 = 4 to 20 mA

2 = 10 V / 20 mA to 0

3 = 20 to 4 mA

1 = Run/Stop

2 = General Enable

3 = Fast Stop

4 = FWD/REV

5 = LOC/REM

6 = JOG

7 = SoftPLC

8 = Ramp 2

9 = Speed/Torque

10 = JOG+

11 = JOG12 = No Ext. Alarm

13 = No Ext. Fault

14 = Reset

15 = Disab.FlyStart

16 = DC Link Regul.

17 = Progr. Off

18 = Load User 1

19 = Load User 2

20 = Main PID Aut/Man

21 = External PID 1 Aut/Man

22 = External PID 2 Aut/Man

23 = Bypass Mode

24 = Fire Mode

Factory

Setting

16 I/O

User

Setting

0 cfg I/O

1 cfg I/O

Propr. Groups

10 | CFW701

Quick Parameter Reference, Faults and Alarms

Param. Function

P0275 DO1 Function (RL1) 0 = Not Used

Adjustable

Range

1 = N* > Nx

2 = N > Nx

3 = N < Ny

4 = N = N*

5 = Zero Speed

6 = Is > Ix

7 = Is < Ix

8 = Torque > Tx

9 = Torque < Tx

10 = Remote

11 = Run

12 = Ready

13 = No Fault

14 = No F0070

15 = No F0071

16 = No F0006/21/22

17 = No F0051

18 = No F0072

19 = 4-20 mA OK

20 = P0695 Value

21 = Forward

22 = Ride-Through

23 = Pre-Charge OK

24 = Fault

25 = Enabled Time > Hx

26 = SoftPLC

27 = N>Nx/Nt>Nx

28 = F > Fx (1)

29 = F > Fx (2)

30 = STO

31 = No F0160

32 = No Alarm

33 = No Fault/Alarm

34 = Dry Pump Alarm/Fault

35 = Broken Belt Alarm/Fault

36 = Filter Mainten. Alarm/

Fault

37 = Sleep Mode

38 = Not Used

39 = Drive Bypass Contactor

40 = Mains Bypass Contactor

41 = Fire Mode

42 = Self-Tuning

P0276 DO2 Function (RL2) See options in P0275 24 cfg I/O

P0277 DO3 Function See options in P0275 0 cfg I/O

P0278 DO4 Function See options in P0275 0 cfg I/O

P0279 DO5 Function See options in P0275 0 cfg I/O

P0281 Fx Frequency 0.0 to 300.0 Hz 4.0 Hz

P0282 Fx Hysteresis 0.0 to 15.0 Hz 2.0 Hz

P0287 Nx/Ny Hysteresis 0 to 900 rpm 18 (15) rpm

P0288 Nx Speed 0 to 18000 rpm 120 (100)

P0289 Ny Speed 0 to 18000 rpm 1800 (1500)

P0290 Ix Current 0 to 2xI

nom-ND

P0291 Zero Speed 0 to 18000 rpm 18 (15) rpm

P0292 N = N* Band 0 to 18000 rpm 18 (15) rpm

Factory

Setting

User

Setting

Propr. Groups

11 cfg I/O

rpm

rpm

1.0xI

nom-ND

English

CFW701| 11

Quick Parameter Reference, Faults and Alarms

Param. Function

P0293 Tx Torque 0 to 200 % 100 %

P0294 Hx Time 0 to 6553 h 4320 h

English

P0295 ND/HD VFD Rated Curr. 0 = 2 A / 2 A

P0296 Line Rated Voltage 0 = 200 / 240 V

P0297 Switching Frequency 0 = 1.25 kHz

Adjustable

Range

1 = 3.6 A / 3.6 A

2 = 5 A / 5 A

3 = 6 A / 5 A

4 = 7 A / 5.5 A

5 = 7 A / 7 A

6 = 10 A / 8 A

7 = 10 A / 10 A

8 = 13 A / 11 A

9 = 13.5 A / 11 A

10 = 16 A / 13 A

11 = 17 A / 13.5 A

12 = 24 A / 19 A

13 = 24 A / 20 A

14 = 28 A / 24 A

15 = 31 A / 25 A

16 = 33.5 A / 28 A

17 = 38 A / 33 A

18 = 45 A / 36 A

19 = 45 A / 38 A

20 = 54 A / 45 A

21 = 58.5 A / 47 A

22 = 70 A / 56 A

23 = 70.5 A / 61 A

24 = 86 A / 70 A

25 = 88 A / 73 A

26 = 105 A / 86 A

27 = 105 A / 88 A

28 = 142 A / 115 A

29 = 180 A / 142 A

30 = 211 A / 180 A

31 = 2.9 A / 2.7 A

32 = 4.2 A / 3.8 A

33 = 7 A / 6.5 A

34 = 10 A / 9 A

35 = 12 A / 10 A

36 = 17 A / 17 A

37 = 22 A / 19 A

38 = 27 A / 22 A

39 = 32 A / 27 A

40 = 44 A / 36 A

41 = 53 A / 44 A

42 = 63 A / 53 A

43 = 80 A / 66 A

44 = 107 A / 90 A

45 = 125 A / 107 A

46 = 150 A / 122 A

1 = 380 V

2 = 400 / 415 V

3 = 440 / 460 V

4 = 480 V

5 = 500 / 525 V

6 = 550 / 575 V

7 = 600 V

1 = 2.5 kHz

2 = 5.0 kHz

3 = 10.0 kHz

4 = 2.0 kHz

Factory

Setting

According

to inverter

model

According

to inverter

model

User

Setting

Propr. Groups

ro READ

cfg

cfg

12 | CFW701

Quick Parameter Reference, Faults and Alarms

Param. Function

P0298 Application 0 = Normal Duty

P0299 DC-Braking Start Time 0.0 to 15.0 s 0.0 s V/f,

P0300 DC-Braking Stop Time 0.0 to 15.0 s 0.0 s V/f,

P0301 DC-Braking Speed 0 to 450 rpm 30 rpm V/f,

P0302 DC-Braking Voltage 0.0 to 10.0 % 2.0 % V/f, V VW

P0303 Skip Speed 1 0 to 18000 rpm 600 rpm

P0304 Skip Speed 2 0 to 18000 rpm 900 rpm

P0305 Skip Speed 3 0 to 18000 rpm 1200 rp m

P0306 Skip Band 0 to 750 rpm 0 rpm

P0308 Serial Address 1 to 247 1 NET

P0310 Serial Baud Rate 0 = 9600 bits/s

P0311 Serial Bytes Config. 0 = 8 bits, no, 1

P0 312 Serial Protocol 2 = Modbus RTU

P0313 Comm. Error Action 0 = Off

P0 314 Serial Watchdog 0.0 to 999.0 s 0.0 s NET

P0316 Serial Interf. Status 0 = Off

P0 317 Oriented Start-up 0 = No

P0318 Copy Function MMF 0 = Off

P0320 FlyStart/Ride-Through 0 = Off

P0321 DC Link Power Loss 178 to 770 V 505 V Vector

P0322 DC Link Ride-Through 178 to 770 V 490 V Vector

P0323 DC Link Power Back 178 to 770 V 535 V Vector

Adjustable

Range

1 = Heavy Duty

1 = 19200 bits/s

2 = 38400 bits/s

3 = 57600 bits/s

4 = Reser ved

1 = 8 bits, even, 1

2 = 8 bits, odd, 1

3 = 8 bits, no, 2

4 = 8 bits, even, 2

5 = 8 bits, odd, 2

3 = BACnet

4 = N2

1 = Ramp Stop

2 = General Disab.

3 = Go to LOC

4 = LOC Keep Enab.

5 = Cause Fault

1 = On

2 = Watchdog Error

1 = Yes

1 = VFD → MMF

2 = MMF → VFD

3 = Sync VFD → MMF

4 = Format MMF

5 = Copy SoftPLC Program.

6 = SoftPLC Program Save

1 = Flying Start

2 = FS/RT

3 = Ride-Through

Factory

Setting

User

Setting

0 cfg

1 NET

1 NET

2 NET

1 NET

0 cfg STAR TUP

0 cfg

0 cfg

Propr. Groups

VV W,

Sless

VV W,

Sless

VV W,

Sless

ro NET

CFW701| 13

English

Quick Parameter Reference, Faults and Alarms

Param. Function

P0325 Ride-Through P Gain 0.0 to 63.9 22.8 Vector

P0326 Ride-Through I Gain 0.000 to 9.999 0.128 Ve ctor

English

P0327 F.S. I/f Current Ramp 0.000 to 1.000 s 0.070 s Sless

P0328 Flying Start Filter 0.000 to 1.000 s 0.085 s Sless

P0329 Frequency Ramp F. S. 2.0 to 50.0 20.0 Sless

P0331 Voltage Ramp 0.2 to 60.0 s 2.0 s V/f, V VW

P0332 Dead Time 0.1 to 10.0 s 1.0 s V/f, V V W

P0340 Auto-reset Time 0 to 255 s 0 s

P0 341 AIPTC Configuration 0 = Off

P0343 Ground Fault Config. 0 = Off

P0344 Current Lim. Conf. 0 = Hold

P0348 Motor Overload Conf. 0 = Off

P0349 Ixt Alarm Level 70 to 100 % 85 % cfg

P0350 IGBTs Overload Conf. 0 = F, w/ SF rd.

P0 351 Motor Overtemp. Conf. 0 = Off

P0352 Fan Control Config. 0 = HS-OFF, Int-OFF

P0353 IGBTs/Air Overtemp. Cfg 0 = HS-F/A, Air-F/A

P0354 Fan Speed Config. 0 = Inactive

P0355 F0185 Fault Config. 0 = Off

P0356 Dead Time Compens. 0 = Off

Adjustable

Range

1 = Fault/Alarm

2 = Fault

3 = Alarm

1 = On

1 = Decel.

1 = Fault/Alarm

2 = Fault

3 = Alarm

1 = F/A, w/ SF rd.

2 = F, no SF rd.

3 = F/A, no SF rd.

1 = Fault/Alarm

2 = Fault

3 = Alarm

1 = HS-ON, Int-ON

2 = HS-CT, Int-CT

3 = HS-CT, Int-OFF

4 = HS-CT, Int-ON

5 = HS-ON, Int-OFF

6 = HS-ON, Int-CT

7 = HS-OFF, Int-ON

8 = HS-OFF, Int-CT

9 = HS-CT, Int -CT *

10 = HS-CT, Int -OFF *

11 = HS-CT, Int -ON *

12 = HS-ON, Int -CT *

13 = HS-OFF, Int -CT *

1 = HS-F/A, Air-F

2 = HS-F, Air-F/A

3 = HS-F, Air-F

4 = HS-F/A, Air-F/A *

5 = HS-F/A, Air-F *

6 = HS-F, Air-F/A *

7 = HS-F, Air-F *

1 = Fault

1 = On

1 = On

Factory

Setting

User

Setting

0 cfg I/O

1 cfg

1 cfg, V/f,

1 cfg

1 cfg

1 cfg

2 cfg

0 cfg

1 cfg

1 cfg

1 cfg

Propr. Groups

VVW

14 | CFW701

Quick Parameter Reference, Faults and Alarms

Param. Function

Adjustable

Range

P0357 Line Phase Loss Time 0 to 60 s 3 s

P0360 Speed Hysteresis 0.0 to 100.0 % 10.0 % Vector

P0361 Time with Speed Different

from Reference

0.0 to 999.0 s 0.0 s Vector

P0372 DC-Braking Curr. Sless 0.0 to 90.0 % 40.0 % Sless

P0397 Slip Compens. Regen. 0 = Off

1 = On

P0398 Motor Service Factor 1.00 to 1.50 1.00 cfg MOTOR

P0399 Motor Rated Eff. 50.0 to 99.9 % 67.0 % cfg,

P0400 Motor Rated Voltage 0 to 600 V 440 V cfg MOTOR

P0401 Motor Rated Current 0 to 1.3xI

nom-ND

P0402 Motor Rated Speed 0 to 18000 rpm 1750 (1458)

P0403 Motor Rated Frequency 0 to 300 Hz 60 (50) Hz cfg MOTOR

P0404 Motor Rated Power 0 = 0.33 hp / 0.25 kW

P0406 Motor Ventilation 0 = Self-Vent.

1 = 0.5 hp / 0.37 kW

2 = 0.75 hp / 0.55 kW

3 = 1 hp / 0.75 kW

4 = 1.5 hp / 1.1 kW

5 = 2 hp / 1.5 kW

6 = 3 hp / 2.2 kW

7 = 4 hp / 3 kW

8 = 5 hp / 3.7 kW

9 = 5.5 hp / 4 kW

10 = 6 hp / 4.5 kW

11 = 7.5 hp / 5.5 kW

12 = 10 hp / 7.5 kW

13 = 12.5 hp / 9 kW

14 = 15 hp / 11 kW

15 = 20 hp / 15 kW

16 = 25 hp / 18.5 kW

17 = 30 hp / 22 kW

18 = 40 hp / 30 kW

19 = 50 hp / 37 kW

20 = 60 hp / 45 kW

21 = 75 hp / 55 kW

22 = 100 hp / 75 kW

23 = 125 hp / 90 kW

24 = 150 hp / 110 kW

25 = 175 hp / 130 kW

1 = Separate Vent.

2 = Optimal Flux

3 = Extended Protection

P0407 Motor Rated Power Fac 0.50 to 0.99 0.68 cfg, V/f,

P0408 Run Self-Tuning 0 = No

1 = No Rotation

2 = Run for I

m

P0409 Stator Resistance 0.000 to 9.999 Ω 0.000 Ω cfg,

P0 410 Magnetization Current 0 to 1.25xI

nom-ND

P0411 Leakage Inductance 0.00 to 99.99 mH 0.00 mH cfg,

Factory

Setting

User

Setting

1 cfg,

Propr. Groups

VVW

VVW

1.0xI

Motor

nom-ND

rpm

max-ND

cfg MOTOR

cfg MOTOR

cfg MOTOR

0 cfg MOTOR

VVW

0 cfg,

I

nom-ND

VV W,

Vector

VV W,

Vector

Vector

MOTOR

MOTOR

MOTOR

MOTOR

MOTOR

MOTOR

English

CFW701| 15

Quick Parameter Reference, Faults and Alarms

1 = V

2 = A

3 = rpm

4 = s

5 = ms

6 = None

7 = m

8 = None

9 = None

10 = %

11 = °C

12 = None

13 = Hz

14 = None

15 = h

16 = W

17 = kW

18 = None

19 = None

20 = min

21 = °F

22 = bar

23 = mbar

24 = psi

25 = Pa

26 = kPa

27 = MPa

28 = mwc

29 = mca

30 = gal

31 = l

32 = in

33 = ft

34 = m³

35 = ft³

36 = gal/s

37 = gal/min

38 = gal/h

39 = l/s

40 = l/min

41 = l/h

42 = m/s

43 = m/min

44 = m/h

45 = ft/s

46 = ft/min

47 = ft/h

48 = m³/s

49 = m³/min

50 = m³/h

51 = ft³/s

52 = ft³/min

53 = ft³/h

1 = wxy.z

2 = wx.yz

3 = w.xyz

1 = wxy.z

2 = wx.yz

3 = w.xyz

Adjustable

Range

Param. Function

P0 412 Tr Time Constant 0.000 to 9.999 s 0.000 s Vector MOTOR

P0 413 Tm Time Constant 0.00 to 99.99 s 0.00 s Vector MOTOR

English

P0 510 Ind. Eng. Unit 1 0 = None

P0511 Ind. Decimal Point 1 0 = wxyz

P0 512 Ind. Eng. Unit 2 See options in P0510 11 HMI

P0 513 Ind. Decimal Point 2 0 = wxyz

16 | CFW701

Factory

Setting

22 HMI

User

Setting

1 HMI

1 HMI

Propr. Groups

Quick Parameter Reference, Faults and Alarms

Param. Function

P0 514 Ind. Eng. Unit 3 See options in P0510 10 HMI

P0 515 Ind. Decimal Point 3 0 = wxyz

P0 516 Ind. Eng. Unit 4 See options in P0510 13 HMI

P0 517 Ind. Decimal Point 4 0 = w xyz

P0579 Reference to Fire Mode 0 to 18000 rpm 1800 (1500)

P0580 Fire Mode Configuration 0 = Disabled

P0581 Fire Mode PID Setpoint -32768 to 32767 0 HVAC

P0582 Auto-reset Configuration 0 = Limited

P0583 Bypass Mode

Configuration

P0584 Bypass Contactor Time 0.00 to 300.00 s 0.30 s HVAC

P0585 Short Cycle Protection

Config.

P0586 Minimum RUN Time 0.00 to 650.00 s 5.00 s HVAC

P0587 Minimum STOP Time 0.00 to 650.00 s 5.00 s HVAC

P0588 Maximum Torque Level 0 to 85 % 0 % cfg, V/f H VAC

P0589 Energy Saving Min. Mag. 40 to 80 % 40 % cfg, V/f HVAC

P0590 Energy Saving Min.

Speed

P0591 Energy Saving Histeresis 0 to 30 % 10 % cfg, V/f HVAC

P0680 Logical Status Bit 0 = Not Used

P0681 Speed in 13 bits -32768 to 32767 ro READ,

Adjustable

Range

1 = wxy.z

2 = wx.yz

3 = w.xyz

1 = wxy.z

2 = wx.yz

3 = w.xyz

1 = Enabled

2 = Enabled/P0579

3 = Enabled/P0581

4 = Enabled/Gen. Disable

1 = Unlimited

0 = Off

1 = On/DIx

2 = On/DIx+Fault

0 = Off

1 = On

0 to 18000 rpm 600 (525)

Bit 1 = Run Command

Bit 2 = Fire Mode

Bit 3 = Bypass

Bit 4 = Quick Stop ON

Bit 5 = 2nd Ramp

Bit 6 = Config. Mode

Bit 7 = Alarm

Bit 8 = Running

Bit 9 = Enabled

Bit 10 = Forward

Bit 11 = JOG

Bit 12 = Remote

Bit 13 = Subvoltage

Bit 14 = Not Used

Bit 15 = Fault

Factory

Setting

rpm

rpm

User

Setting

1 HMI

1 HMI

0 cfg HVAC

0 cfg HVAC

0 cfg HVAC

0 cfg HVAC

Propr. Groups

cfg, V/f H VAC

ro READ,

HVAC

NET

NET

English

CFW701| 17

Quick Parameter Reference, Faults and Alarms

Param. Function

P0682 Serial Control Word Bit 0 = Ramp Enable

English

P0683 Serial Speed Ref. -32768 to 32767 ro READ,

P0695 DOx Value Bit 0 = DO1

P0696 AOx Value 1 -32768 to 32767 0 NET

P0697 AOx Value 2 -32768 to 32767 0 NET

P0760 BACnet Dev Inst High 0 to 419 0 NET

P0761 BACnet Dev Inst Low 0 to 9999 0 NET

P0762 Max. Number of Master 0 to 127 127 NET

P0763 MS/TP Max. Info Frame 1 to 65535 1 NET

P0764 I-AM Msg Transmition 0 = Power Up

P0765 Token RX Qtde 0 to 65535 ro READ,

P1000 SoftPLC Status 0 = No Application

P1001 SoftPLC Command 0 = Stop Application

P100 2 Scan Cycle Time 0.0 to 999.9 ms ro READ,

P100 3 SoftPLC Appl. Sel. 0 = User

P1010 Version of the HVAC

Application

P1011 Main PID Aut. Setpoint -32768 to 32767 0 HVAC

P1012 SoftPLC Parameter 3 -32768 to 32767 0 HVAC

P1013 SoftPLC Parameter 4 -32768 to 32767 0 HVAC

P1014 Main PID Man. Setpoint 0.0 to 100.0 % 0.0 % H VAC

P1015 Main PID Process

Variable

P1016 MainPID Output 0.0 to 100.0 % ro READ,

P10 17 MainPID Act. Control 0 = Disable PID

Adjustable

Range

Bit 1 = General Enable

Bit 2 = Run Forward

Bit 3 = JOG Enable

Bit 4 = Remote

Bit 5 = 2nd Ramp

Bit 6 = Quick Stop

Bit 7 = Fault Reset

Bit 8 to 12 = Reserved

Bit 13 = Internal PID

Bit 14 = External PID 1

Bit 15 = External PID 2

Bit 1 = DO2

Bit 2 = DO3

Bit 3 = DO4

Bit 4 = DO5

1 = Continuos

1 = Install. App.

2 = Incompat. App.

3 = App. Stopped

4 = App. Running

1 = Run Application

2 = Delete Application

1 = HVAC

0.00 to 10.00 ro HVAC

-32768 to 32767 ro RE AD,

1 = Direct Mode

2 = Reverse Mode

Factory

Setting

Bit 4 NET

User

Setting

0 NET

1 HVAC

1 cfg HVAC

0 cfg HVAC

Propr. Groups

ro READ,

ro READ,

NET

NET

NET

HVAC

HVAC

HVAC

HVAC

18 | CFW701

Quick Parameter Reference, Faults and Alarms

Param. Function

P1018 Main PID Operation Mode 0 = AlwaysAutomatic

P1019 Main PID Sampling Time 0.10 to 60.00 s 0.10 s HVAC

P1020 Main PIDP. Gain 0.000 to 32.767 1.000 HVAC

P1021 Main PIDI. Gain 0.000 to 32.767 0.430 H VAC

P1022 Main PIDD. Gain 0.000 to 32.767 0.000 HVAC

P1023 Main PID Output Min.

Value

P1024 Main PID Output Max.

Value

P1025 SoftPLC Parameter 16 -32768 to 32767 0 HVAC

P1026 Main PID Feedback Conf. 0 = Sum Feed. 1, 2 and 3

P1027 Main PID Min. Feedback -32768 to 32767 0 HVAC

P1028 Main PID Ma x. Feedback -32768 to 32767 1000 HVAC

P1029 SoftPLC Parameter 20 -32768 to 32767 0 HVAC

P1030 Main PID Fdbck Alarms

Conf.

P1031 M. PID Fdbck Alarm

Low V.

P1032 M. PID Fdbck Alarm

Lo w T.

P103 3 M. PID Fdbck Alarm

Hi gh V.

P103 4 M. PID Fdbck Alarm

Hi g T.

P103 5 SoftPLC Parameter 26 -32768 to 32767 0 HVAC

P103 6 Sleep Mode Speed 0 to 18000 350 H VAC

P1037 Sleep Mode Time 0.00 to 650.00 s 5.00 s HVAC

P103 8 Wake Up Main Deviation 0.0 to 100.0 % 5.0 % HVAC

P103 9 Wake Up Main Time 0.00 to 650.00 s 10.00 s HVAC

P1040 HVAC Fun. Log. Status 0000h to FFFFh ro READ,

P10 41 Sof tPLC Parameter 32 -32768 to 32767 0 HVAC

P1042 Dry Pump Config. 0 = Disable

P104 3 Dry Pump Speed 0 to 18000 400 HVAC

P1044 Dry Pump Torque 0.0 to 350.0 % 20.0 % HVAC

P104 5 Dry Pump Time 0.00 to 650.00 s 20.00 s HVAC

P1046 Broken Belt Config. 0 = Disable

P1047 Broken Belt Speed 0 to 18000 400 HVAC

P104 8 Broken Belt Torque 0.0 to 350.0 % 20.0 % HVAC

Adjustable

Range

1 = Always Manual

2 = A/M DI w/o bumpless

3 = A/M Net w/o bumpless

4 = A/M DI w/ bumpless

5 = A/M Net w/ bumpless

0.0 to 100.0 % 0.0 % HVAC

0.0 to 100.0 % 100.0 % HVAC

1 = Difference Feed. 1 and 2

2 = Average Feed. 1, 2 and 3

3 = Minimum Feed. 1, 2 and 3

4 = Maximum Feed. 1, 2 and 3

0 = Disable

1 = Enable Alarm

2 = Enable Fault

-32768 to 32767 50 HVAC

0.00 to 650.00 s 5.00 s HVAC

-32768 to 32767 900 HVAC

0.00 to 650.00 s 5.00 s HVAC

1 = Enable Alarm

2 = Enable Fault

1 = Enable Alarm

2 = Enable Fault

Factory

Setting

User

Setting

0 HVAC

0 cfg HVAC

0 HVAC

0 cfg HVAC

0 cfg HVAC

Propr. Groups

HVAC

CFW701| 19

English

Quick Parameter Reference, Faults and Alarms

Param. Function

P1049 Broken Belt Time 0.00 to 650.00 s 20.00 s HVAC

P1050 Filter Mainten. Alarm

English

Conf.

P1051 Filter Mainten. Alarm Time 0 to 32000 h 5000 h HVAC

P1052 Filter Mainten. Alarm

Counter

P105 3 SoftPLC Parameter 44 -32768 to 32767 0 HVAC

P105 4 SoftPLC Parameter 45 -32768 to 32767 0 HVAC

P1055 SoftPLC Parameter 46 -32768 to 32767 0 HVAC

P1056 SoftPLC Parameter 47 -32768 to 32767 0 HVAC

P1057 SoftPLC Parameter 48 -32768 to 32767 0 HVAC

P1058 SoftPLC Parameter 49 -32768 to 32767 0 HVAC

P1059 SoftPLC Parameter 50 -32768 to 32767 0 HVAC

P106 0 Ext. PID 1 Aut. Setpoint -32768 to 32767 0 HVAC

P1061 Ext. PID 1 Man. Setpoint 0.0 to 100.0 % 0.0 % HVAC

P106 2 Ext. PID 1 Feedback -32768 to 32767 ro READ,

P106 3 Ext. PID 1 Output 0.0 to 100.0 % ro READ,

P106 4 Ext. PID 1 Act. Control 0 = Disable PID

P106 5 Ext. PID 1 Operation

Mode

P106 6 Ext. PID 1 Sampling Time 0.10 to 60.00 s 0.10 s HVAC

P1067 Ext. PID 1 P. Gain 0.000 to 32.767 1.000 HVAC

P106 8 Ext. PID 1 I. Gain 0.000 to 32.767 0.430 HVAC

P106 9 Ext. PID 1 D. Gain 0.000 to 32.767 0.000 HVAC

P1070 Ext. PID 1 Output Min.

Value

P1071 Ext. PID 1 Output Ma x.

Value

P1072 Sof tPLC Parameter 63 -32768 to 32767 0 HVAC

P1073 Ext. PID 1 Min. Feedback -32768 to 32767 0 HVAC

P1074 Ext. PID 1 Max.

Feedback

P1075 Ext. PID 1 Fdbck Alarms

Conf.

P1076 Ext. PID 1 Fdbck Alarm

Low V.

P1077 Ext. PID 1 Fdbck Alarm

Lo w T.

P1078 Ext. PID 1 Fdbck Alarm

Hi gh V.

P1079 Ext. PID 1 Fdbck Alarm

Hi g T.

P1080 Ext. PID 2 Aut. Setpoint -32768 to 32767 0 HVAC

Adjustable

Range

0 = Disable

1 = Enable Alarm

2 = Enable Fault

0 to 32000 h ro READ,

1 = Direct Mode

2 = Reverse Mode

0 = AlwaysAutomatic

1 = Always Manual

2 = A/M DI w/o bumpless

3 = A/M Net w/o bumpless

4 = A/M DI w/ bumpless

5 = A/M Net w/ bumpless

0.0 to 100.0 % 0.0 % HVAC

0.0 to 100.0 % 100.0 % HVAC

-32768 to 32767 1000 HVAC

0 = Disable

1 = Enable Alarm

2 = Enable Fault

-32768 to 32767 2 HVAC

0.00 to 650.00 s 5.00 s HVAC

-32768 to 32767 900 HVAC

0.00 to 650.00 s 5.00 s HVAC

Factory

Setting

User

Setting

0 cfg HVAC

0 cfg HVAC

0 HVAC

0 HVAC

Propr. Groups

20 | CFW701

HVAC

HVAC

HVAC

Quick Parameter Reference, Faults and Alarms

Param. Function

P1081 Ext. PID 2 Man. Setpoint 0.0 to 100.0 % 0.0 % HVAC

P1082 Ext. PID 2 Feedback -32768 to 32767 ro READ,

P108 3 Ext. PID 2 Output 0.0 to 100.0 % ro READ,

P108 4 Ext. PID 2 Act. Control 0 = Disable PID

P108 5 Ext. PID 2 Operation

Mode

P108 6 Ext. PID 2 Sampling Time 0.10 to 60.00 s 0.10 s HVAC

P1087 Ext. PID 2 P. Gain 0.000 to 32.767 1.000 HVAC

P108 8 Ext. PID 2 I. Gain 0.000 to 32.767 0.430 HVAC

P108 9 Ext. PID 2 D. Gain 0.000 to 32.767 0.000 HVAC

P109 0 Ext. PID 2 Output Min.

Value

P1091 Ext. PID 2 Output Max.

Value

P1092 SoftPLC Parameter 83 -32768 to 32767 0 HVAC

P109 3 Ext. PID 2 Min. Feedback -32768 to 32767 0 HVAC

P109 4 Ext. PID 2 Max.

Feedback

P109 5 Ext. PID 2 Fdbck Alarms

Conf.

P109 6 Ext. PID 2 Fdbck Alarm

Low V.

P1097 Ext. PID 2 Fdbck Alarm

Lo w T.

P109 8 Ext. PID 2 Fdbck Alarm

Hi gh V.

P109 9 Ext. PID 2 Fdbck Alarm

Hi g T.

Notes:

ro = Read-only parameter

rw = Reading/writing parameter

cfg = Configuration parameter, it can be changed only with stopped motor

V/f = Parameter available in V/f mode

Adj = Parameter available only in adjustable V/f mode

VVW = Parameter available in V V W mode

Vector = Parameter available in vector mode

Sless = Parameter available only in sensorless mode

Adjustable

Range

1 = Direct Mode

2 = Reverse Mode

0 = AlwaysAutomatic

1 = Always Manual

2 = A/M DI w/o bumpless

3 = A/M Net w/o bumpless

4 = A/M DI w/ bumpless

5 = A/M Net w/ bumpless

0.0 to 100.0 % 0.0 % HVAC

0.0 to 100.0 % 100.0 % HVAC

-32768 to 32767 1000 HVAC

0 = Disable

1 = Enable Alarm

2 = Enable Fault

-32768 to 32767 2 HVAC

0.00 to 650.00 s 5.00 s HVAC

-32768 to 32767 900 HVAC

0.00 to 650.00 s 5.00 s HVAC

Factory

Setting

User

Setting

0 cfg HVAC

0 HVAC

0 HVAC

Propr. Groups

HVAC

HVAC

English

CFW701| 21

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

F0006:

Input Voltage

Imbalance or Phase

Loss

English

F0 021:

DC Link

Undervoltage

F0022:

DC Link Overvoltage

A0046:

High Load at the

Motor

A0 0 47:

IGBT Overload

Alarm

F0048:

IGBT Overload Fault

A0050:

IGBT High

Temperature

F0 0 51:

IGBT

Overtemperature

F0070:

Overcurrent/

Short-circuit

F0 071:

Output Overcurrent

The mains voltage imbalance is too

high or phase loss at the supply line

has occurred.

Note:

- This fault may not occur if the

load at the motor shaf t is too low or

nonexistent.

P0357 sets the time for the trip, and

P0357 = 0 disables this fault.

A DC link undervoltage condition has

occurred.

A DC link overvoltage condition has

occurred.

It is the motor overload alarm.

Note:

It can be disabled by setting

P0348 = 0 or 2.

It is the IGBT overload alarm.

Note:

It can be disabled by setting

P0350 = 0 or 2.

It is the IGBT overload fault. The inverter output current is too high.

The NTC temperature sensors

located in the IGBTs detected a high

temperature alarm.

Note:

It can be disabled by setting

P0353 = 2 or 3.

The NTC temperature sensors

located in the IGBTs detected a high

temperature fault.

An overcurrent or a short-circuit at

the output, at the DC link or at the

braking resistor, has occurred.

An output overcurrent has occurred. Excessi ve load inerti a or too short acc eleration ramp.

A Phase Loss at the inverter input.

The input voltage imbalance is > 5 %.

The input voltage is too low and the DC link voltage

dropped below the minimum permitted value (monitor

the P0004 parameter value):

Ud < 223 V - 200 / 240 V three-phase input voltage;

Ud < 170 V - 200 / 240 V single-phase input voltage

(CFW701XXXXS2 or CFW701XXXXB2 models)

(P0296 = 0);

Ud < 385 V - 380 V input voltage (P0296 = 1);

Ud < 405 V - 400 / 415 V input voltage (P0296 = 2);

Ud < 446 V - 440 / 460 V input voltage (P0296 = 3);

Ud < 487 V - 480 V input voltage (P0296 = 4);

Ud < 530 V - input voltage 500 / 525 V (P0296 = 5);

Ud < 580 V - input voltage 550 / 575 V (P0296 = 6);

Ud < 605 V - input voltage 600 V (P0296 = 7).

Phase loss at the inverter input.

Pre-charge circuit failure.

Parameter P0296 was set to a value higher than the

power supply rated voltage.

Too high input voltage, resulting in a DC link voltage

higher than the maximum permitted value:

Ud > 400 V - 220 / 230 V models (P0296 = 0);

Ud > 800 V - 380 / 480 V models (P0296 = 1, 2, 3, or 4);

Ud > 1000 V - 500 / 600 V models (P0296 = 5, 6 or 7).

The inertia of the driven-load is too high or the

deceleration time is too short.

The parameter P0151, P0153 or P0185 setting is

too high.

The settings of P0156, P0157 and P0158 are too low

for the used motor.

There is excessive load at the motor shaft.

The inverter output current is too high.

High surrounding air temperature (>50 °C (122 °F))

and high output current.

Blocked or defective fan.

Very dirty heatsink.

Short-circuit between two motor phases.

Short-circuit between the dynamic braking resistor

connection cables.

Shorted IGBT modules.

P0135, or P0169 and P0170 settings are too high.

22 | CFW701

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

F0072:

Motor Overload

F0 074:

Ground Fault

F0078:

Motor

Overtemperature

F0080:

CPU Watchdog

F00 84:

Auto-Diagnosis Fault

A0090:

External Alarm

F0 0 91:

External Fault

A0098:

Activate General

Enable

F0099:

Invalid Current

Offset

A0 110:

High Motor

Temperature

A0128:

Serial

Communication

Timeout

F015 0:

Motor Overspeed

F0151:

FLASH Memory

Module Fault

The motor overload protection has

tripped.

Note:

It can be disabled by setting

P0348 = 0 or 3.

A ground fault occurred either in the

cable between the inverter and the

motor or in the motor itself.

Note:

It can be disabled by setting

P0343 = 0.

Fault related to the PTC temperature

sensor installed in the motor.

Note:

- It can be disabled by setting

P0351 = 0 or 3.

- An analog input and an analog

output must be set for the PTC

function.

Microcontroller watchdog fault. Electrical noise.

Auto-Diagnosis Fault. Defect in the inverter internal circuitry.

External alarm monitored through a

digital input.

Note:

It is necessar y to program a digital

input for “No external alarm”.

External fault monitored through a

digital input.

Note:

It is necessar y to program a digital

input for “No external fault”.

General Enable signal is missing

during the self-tuning.

The current measurement circuit is

presenting an abnormal value for null

current.

Fault detected through PTC type

temperature sensors installed in the

motor.

Note:

- It can be disabled by setting

P0351 = 0 or 2.

- An analog input and an analog

output must be set for the PTC

function.

It indicates that the inverter stopped

receiving valid telegrams during a

certain period.

Note:

It can be disabled by setting

P0314 = 0.0 s

Overspeed fault.

It trips when the actual

speed exceeds the value of

(100 % + P0132)

P013 4 x

than 20 ms.

FLASH Memory Module (MMF-01)

fault.

100%

for more

The settings of P0156, P0157 and P0158 are too low

for the used motor.

There is excessive load at the motor shaft.

Short-circuit to the ground in one or more output

phases.

Motor cable capacitance is too large, resulting in

current peaks at the output.

Excessive load at the motor shaft.

Severe duty cyc le (too many star ts / stops per minu te).

Too high surrounding air temperature.

Loose conne ction or shor t-circuit (re sistance < 100 Ω) in

the wiring connected to the motor thermistors.

Not installed motor thermistors.

Blocked motor shaft.

Firmware incompatible with an accessory.

A d igital input ( DI1 to DI8) programm ed for “No exter nal

alarm” is open.

A d igital input ( DI1 to DI8) programm ed for “No exter nal

fault” is open.

The digital input programmed for “General Enable”

is open.

Defect in the inverter internal circuitry.

Excessive load at the motor shaft.

S evere duty cycl e (too many starts / s tops per minute).

Too high surrounding air temperature.

Not installed motor thermistors.

Blocked motor shaft.

Check the wiring and the ground installation.

Make sure that the inverter has sent a new message

within the time interval set at P0314.

Wrong settings of P0161 and/or P0162.

Problem with a hoist-type load.

Defective FLASH memory module.

Check the connection of the FLASH memory module.

English

CFW701| 23

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

A0152:

High Internal Air

Temperature

English

F015 3:

Internal Air

Overtemperature

F015 6:

Undertemperature

F0157:

Parameter Table

Data Loss

F015 8:

Parameter Table

Fault

A0159:

Incompatible HMI

F0160:

Safety Stop Relays

A0163:

AI1 Broken Cable

This alarm indicates that the internal

air temperature is too high.

Note:

It can be disabled by setting

P0353 = 1 or 3.

It indicates internal air

overtemperature fault.

The temperature sensors located in the

IGBTs or in the rectifier detected a low

temperature, below -30 °C ( -22 °F ),

fault.

There was a problem during the

initialization, during the parameter

table loading routine. Some recent

parameter modifications may have

been lost.

There was a problem during the

initialization, during the parameter

table loading routine. All the

parameters were lost and the factory

settings were loaded.

Incompatible HMI HMI of another product being used.

Safety stop relay fault. One of the relays is defective or it does not have +24 V

It indicates that the AI1 current (4-20 mA

or 20-4 mA) reference is out of the 4

to 20 mA range.

High surrounding air temperature (>50 °C (122 °F))

and high output current.

Defective internal fan (if existent).

High temperature (> 45 ºC) inside the cabinet.

High surrounding air temperature (>50 °C (122 °F))

and high output current.

Defective internal fan (if existent).

Surrounding air temperature ≤ -30 °C (-22 °F).

The control was switched off very fast while a

parameter was being modified.

Firmware updating fault.

Defective control board.

applied to its coil.

Broken AI1 cable.

Bad contact at the connection of the signal to the

terminal strip.

A0164:

AI2 Broken Cable

A0165:

AI3 Broken Cable

A0168:

Speed Error too

High

F0169:

Speed Error too

High

A0170:

Safety Stop

A0177:

Fan Replacement

F0179 :

Heatsink Fan Speed

Fault

F0182:

Pulse Feedback

Fault

F018 3:

IGBT Overload +

Temperature

24 | CFW701

It indicates that the AI2 current (4-20 mA

or 20-4 mA) reference is out of the 4

to 20 mA range.

It indicates that the AI3 current (4-20 mA

or 20-4 mA) reference is out of the 4

to 20 mA range.

Difference between speed reference

and effective speed greater than the

setting in P0360.

Difference between speed reference

and effective speed greater than the

setting in P0360 for longer than P0361.

The Safety Stop function is active. The CFW701 went to the STO state.

Fan replacement alarm (P0045 >

50000 hours).

Note:

This function can be disabled by

setting P0354 = 0.

This fault indicates a problem with the

heatsink fan.

Note:

This function can be disabled by

setting P0354 = 0.

It indicates a fault in the output

pulses feedback.

Overtemperature related to the IGBT

overload protection.

Broken AI2 cable.

Bad contact at the connection of the signal to the

terminal strip.

Broken AI3 cable.

Bad contact at the connection of the signal to the

terminal strip.

Inverter in torque current limitation.

Inverter in torque current limitation for too long.

The heatsink fan maximum number of operating hours

has been reached.

Dirt on the blades and in the bearings of the fan.

Defective fan.

Defective fan power supply connection.

Defect in the inverter internal circuitry.

Too high inverter surrounding temperature.

Operation with frequencies < 10 Hz with overload.

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

F018 5:

Pre-Charge

Contactor Fault

A0210:

Drive in Bypass

mode

A0 211:

Drive in Fire Mode

F0228:

Serial

Communication

Timeout

A0702:

Disabled Inverter

A0704:

Two Enabled

Movements

A0706:

Reference not

Programmed for

SoftPLC

F0 711:

Fault in the

Execution of the

SoftPLC

A0750:

Programming AIx for

Main PID Controller

Feedback

A0752:

Programming DIx for

Main PID Controller

Automatic/Manual

Selection

A0754:

Programming Local

Reference (P0221)

for SoftPLC

A0756:

Programming

Remote Reference

(P0222) for SoftPLC

A0758:

Programming

Indirect Engineering

Unit 4 (P0516) for Hz

or rpm

A0760:

Low Level for Main

PID Controller

Feedback

F0761:

Low Level for Main

PID Controller

Feedback

It indicates a fault at the pre-charge

contactor.

Indicates that the drive is in Bypass

mode.

Indicates that the drive is in Fire

Mode.

Defective pre-charge contactor.

Open command fuse.

Phase loss at the L1/R or L2/S input.

P0355 = 1 (incorrect setting for mechanical models

“E” powered by the DC Link. For these models should

be set P0355 = 0).

The digital input programmed for activating the Bypass

mode is active.

The digital input programmed for activating the Fire

Mode is active.

Refer to the RS-232 / RS-485 Serial Communication Manual.

Refer to the SoftPLC Manual.

Fault in the execution of the SoftPLC. Incompatible applicative.

It indicates to the user there is not

analog input programmed for Main

PID controller feedback.

It indicates to the user there is not

digital input programmed for Main

PID controller

Automatic/Manual selection.

It indicates to the user that the origin

of the speed reference in the Local

situation is not programmed for

SoftPLC.

It indicates to the user that the origin

of the speed reference in the Remote

situation is not programmed for

SoftPLC.

It indicates to the user that the

engineering unit parameters for

motor speed is not programmed for

Hz or rpm.

It indicates to the user that the Main

PID controller feedback is low.

It indicates to the user that the Main

PID controller feedback is low.

Fault during upload of the applicative.

Parameter P0231 or P0236 or P0241 is not

programmed in 5, 6 or 7.

Parameter P0263 or P0264 or P0265 or P0266

or P0267 or P0268 or P0269 or P0270 is not

programmed in 20.

Main PID controller is enabled (P1017 in 1 or 2) and

CFW701 frequency inverter run the motor in Local

situation and parameter P0221 is not programmed in 7.

Main PID controller is enabled (P1017 in 1 or 2) and

CFW701 frequency inverter run the motor in Remote

situation and parameter P0222 is not programmed in 7.

Parameter P0516 is not programmed in 13 (Hz) or 3 (rpm).

Parameter P1030 is programmed in 1 and the Main

PID controller feedback value is remaining below the

value programmed in P1031 for the time programmed

in P1032.

Parameter P1030 is programmed in 2 and the Main

PID controller feedback value is remaining below the

value programmed in P1031 for the time programmed

in P1032.

English

CFW701| 25

Quick Parameter Reference, Faults and Alarms

Fault/Alarm Description Possible Causes

A0762:

High Level for Main

PID Controller

Feedback

English

F0763:

High Level for Main

PID Controller

Feedback

A0764:

CFW701 in Sleep

Mode

A0766:

Dry Pump Detected

F0767:

Dry Pump Detected

A0768:

Broken Belt

Detected

F0769:

Broken Belt

Detected

A0770:

Filter Maintenance

F0771:

Filter Maintenance

A0780:

Programming

AIx for External

PID Controller 1

Feedback

A0782:

Programming

DIx for External

PID Controller 1

Automatic/Manual

Selection

A0784:

Programming AOx

for External PID

Controller 1 Output

A0786:

Low Level for External

PID Controller 1

Feedback

F0787:

Low Level for External

PID Controller 1

Feedback

It indicates to the user that the Main

PID controller feedback is high.

It indicates to the user that the Main

PID controller feedback is high.

It indicates to the user that the

CFW701 frequency inverter is in

Sleep mode.

It indicates to the user that the dry

pump condition was detected for the

pump driven by CFW701 frequency

inverter.

It indicates to the user that the dry

pump condition was detected for the

pump driven by CFW701 frequency

inverter.

It indicates to the user that the

broken belt condition was detected

for the motor driven by CFW701

frequency inverter.

It indicates to the user that the

broken belt condition was detected

for the motor driven by CFW701

frequency inverter.

It indicates to the user that the need

to change the filter system.

It indicates to the user that the need

to change the filter system.

It indicates to the user there is

not analog input programmed for

External PID controller 1 feedback.

It indicates to the user there is not

digital input programmed for External

PID controller 1 Automatic/Manual

selection.

It indicates to the user there is not

analog output programmed for

External PID controller 1 output.

It indicates to the user that the

External PID controller 1 feedback

is low.

It indicates to the user that the

External PID controller 1 feedback

is low.

Parameter P1030 is programmed in 1 and the Main

PID controller feedback value is remaining above the

value programmed in P1033 for the time programmed

in P1034.

Parameter P1030 is programmed in 2 and the Main

PID controller feedback value is remaining above the

value programmed in P1033 for the time programmed

in P1034.

Main PID controller is enabled and in Automatic mode

and the motor speed is remaining below the speed

value programmed in P1036 for the time programmed

in P10 37.

Parameter P1042 is programmed in 1 and the pump

driven by CFW701 frequency inverter is running faster

than speed programmed in P1043 and the motor torque

is remaining below the torque value programmed in

P1044 for the time programmed in P1045.

Parameter P1042 is programmed in 2 and the pump

driven by CFW701 frequency inverter is running faster

than speed programmed in P1043 and the motor torque

is remaining below the torque value programmed in

P1044 for the time programmed in P1045.

Parameter P1046 is programmed in 1 and the motor

driven by CFW701 frequency inverter is running faster

than speed programmed in P1047 and the motor torque

is remaining below the torque value programmed in

P1048 for the time programmed in P1049.

Parameter P1046 is programmed in 2 and the motor

driven by CFW701 frequency inverter is running faster

than speed programmed in P1047 and the motor torque

is remaining below the torque value programmed in

P1048 for the time programmed in P1049.

Parameter P1050 is programmed in 1 and the operation

time of motor driven by CFW701 frequency inverter

displayed in P1052 is greater than the time programmed

in P10 51.

Parameter P1050 is programmed in 2 and the operation

time of motor driven by CFW701 frequency inverter

displayed in P1052 is greater than the time programmed

in P10 51.

Parameter P0231 or P0236 or P0241 is not

programmed in 8.

Parameter P0263 or P0264 or P0265 or P0266

or P0267 or P0268 or P0269 or P0270 is not

programmed in 21.

Parameter P0251 or P0254 is not programmed in 16.

Parameter P1075 is programmed in 1 and the External

PID controller 1 feedback value is remaining below the

value programmed in P1076 for the time programmed

in P10 77.

Parameter P1075 is programmed in 2 and the External

PID controller 1 Feedback value is remaining below the

value programmed in P1076 for the time programmed

in P10 77.

26 | CFW701

Loading...

Loading...