Wega Junior, Compatta User Manual

ENGLISH

technician

Via Santi, 9 - 40011 ANZOLA EMILIA (BO) - ITALY

Tel. +39.051.6500900 - Fax +39.051.733701

www.wega.it - commerciale@wega.it

R

SUMMARY follows

Summary

................................................................................................................

6

LEVER MACHINE

......................................................................................................................................................................................

6

DISTRIBUTION MACHINE

..........................................................................................................................................................................

6

TECHNICAL CHARACTERISTICS

.................................................................................................................................................................

INTERNAL COMPONENTS

........................................................................................................................................................................

8

2. PREPARATION OF THE MACHINE

............................................................................................................

9

2.1 UNPACKING

...............................................................................................................................................................

9

2.2 EQUIPMENT PREPARATION

......................................................................................................................................

9

Motor pump

.............................................................................................................................................................................................

9

Filter-holder

.............................................................................................................................................................................................

9

Spouts

.....................................................................................................................................................................................................

9

Softener

...................................................................................................................................................................................................

9

.......................................................................................................................

0

..........................................................................................................................................................

0

EPU - EVD - EVDT MACHINES

...............................................................................

.........................................................................................................

Warnings

..............................................................................................................................................................................................

LEVER MACHINE

.......................................................................................................................................................... .........................

........................................................................................................................... ...........

Machine with INTERNAL MOTOR PUMP

................................................................................................................................................

2

Machine with EXTERNAL MOTOR PUMP

...............................................................................................................................................

........................................................................................................................

2

.......................................................................................................................................

................................................................................................................

4. Distribution machine BOILER and EXCHANGERS

..................................................................................

4

4.1 ELECTRIC HEATING

.................................................................................................................................................

4.2 GAS HEATING

..........................................................................................................................................................

4.3 COMBINED GAS + ELECTRIC HEATING

...................................................................................................................

4

.................................................................................................................

........................................................................................................................................................

4

DELIVERY

GROUP

...................................................................................................................................................

.3

...............................................................................................................................................

6. Automatic Water Entry

..........................................................................................................................

6

7. VOLUMETRIC DOSING

...........................................................................................................................

6

8. PRESSURE SWITCH

...............................................................................................................................

6

9. ANTI-FLOODING DEVICE

.......................................................................................................................

7

..............................................................................................................................

7

....................................................................................................................................

................................................................................................................................

7

..................................................................................................................

7

...........................................................................................................

.......................................................................................................................................

8

Gas adjustment

....................................................................................................................................................................................

8

SUMMARY follows

........................................................................................................................................

9

Softener regeneration

..........................................................................................................................................................................

9

..............................................................................................................

0

..................................................................................................................................

2

0

.................................................................................................

0

........................................................................................................................

2

.....................................................................................................................

2

6

....................................................................................................................

2

2

7

CAPPU

CCIN

O MAKER

..........................................................................................................................

2

2

.........................................................................................................................

2

...........................................................................................................................................

Filter and filter-holder

.........................................................................................................................................................................

2

3

Perforated disk and containment ring

.................................................................................................................................................

2

3

Steam nozzles

.......................................................................................................................................................... ............................

3

Delivery groups (except for ALE version)

............................................................................................................................................

2

4

Body

.......................................................................................................................................................... ...........................................

Grinder-doser

.......................................................................................................................................................................................

2

4

Cappuccinatore

....................................................................................................................................................................................

20

..............................................................................................................

Machine

.......................................................................................................................................................... ......................................

2

................................................................................................................................................................................................

..........................................................................

.............................................................................................................................

...............................................................................................................................

...................................................................................................................................

.........................................................................................................

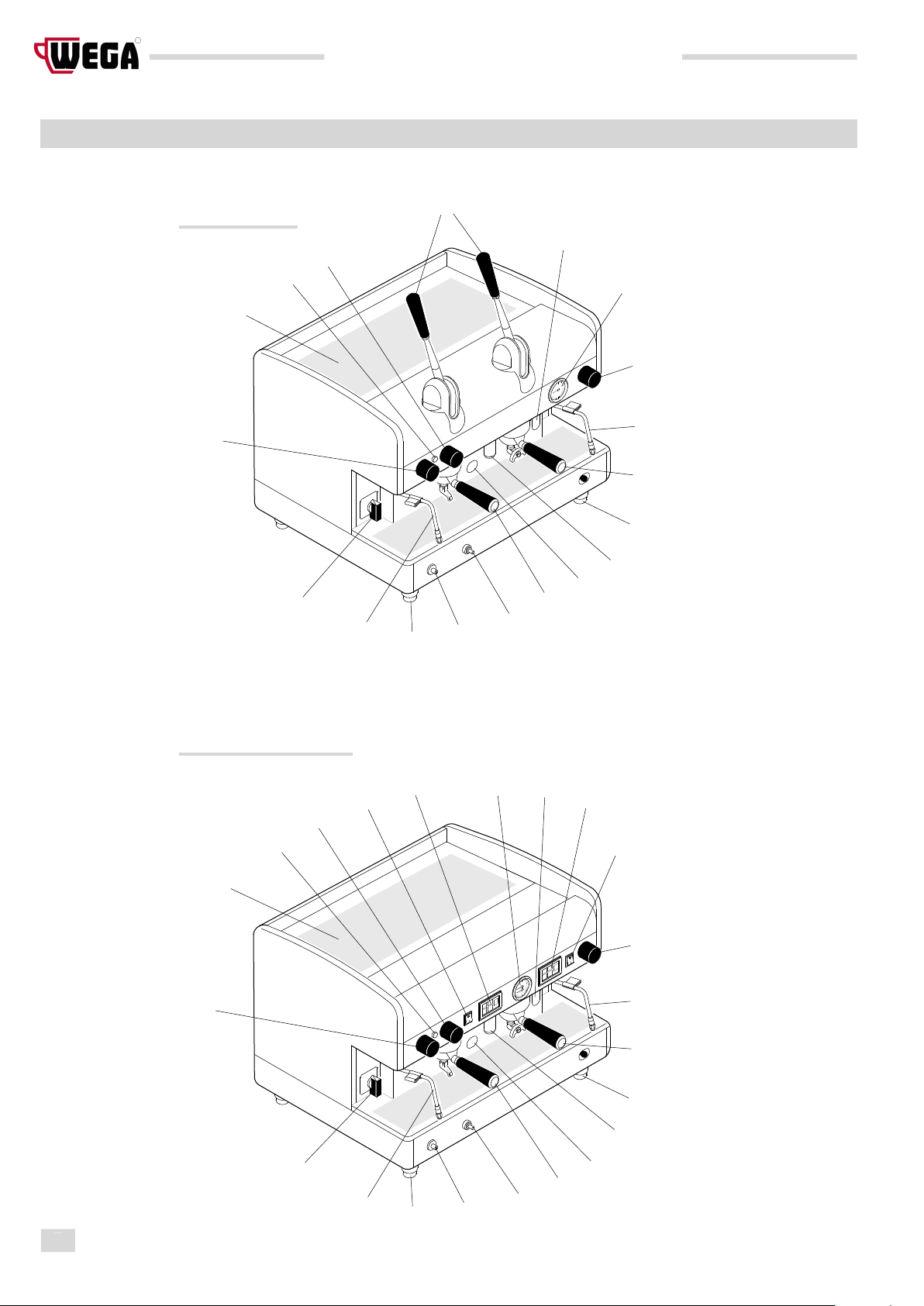

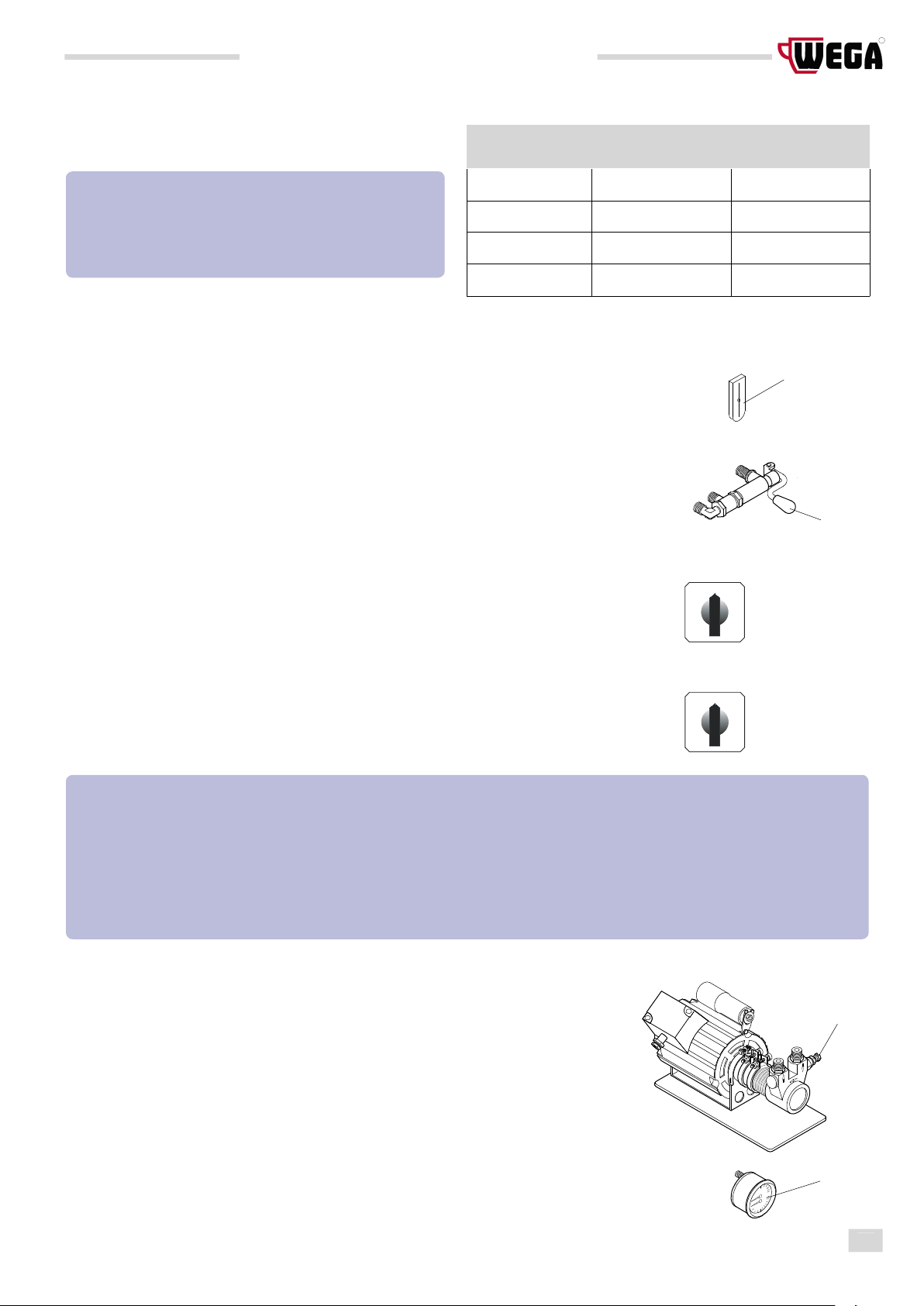

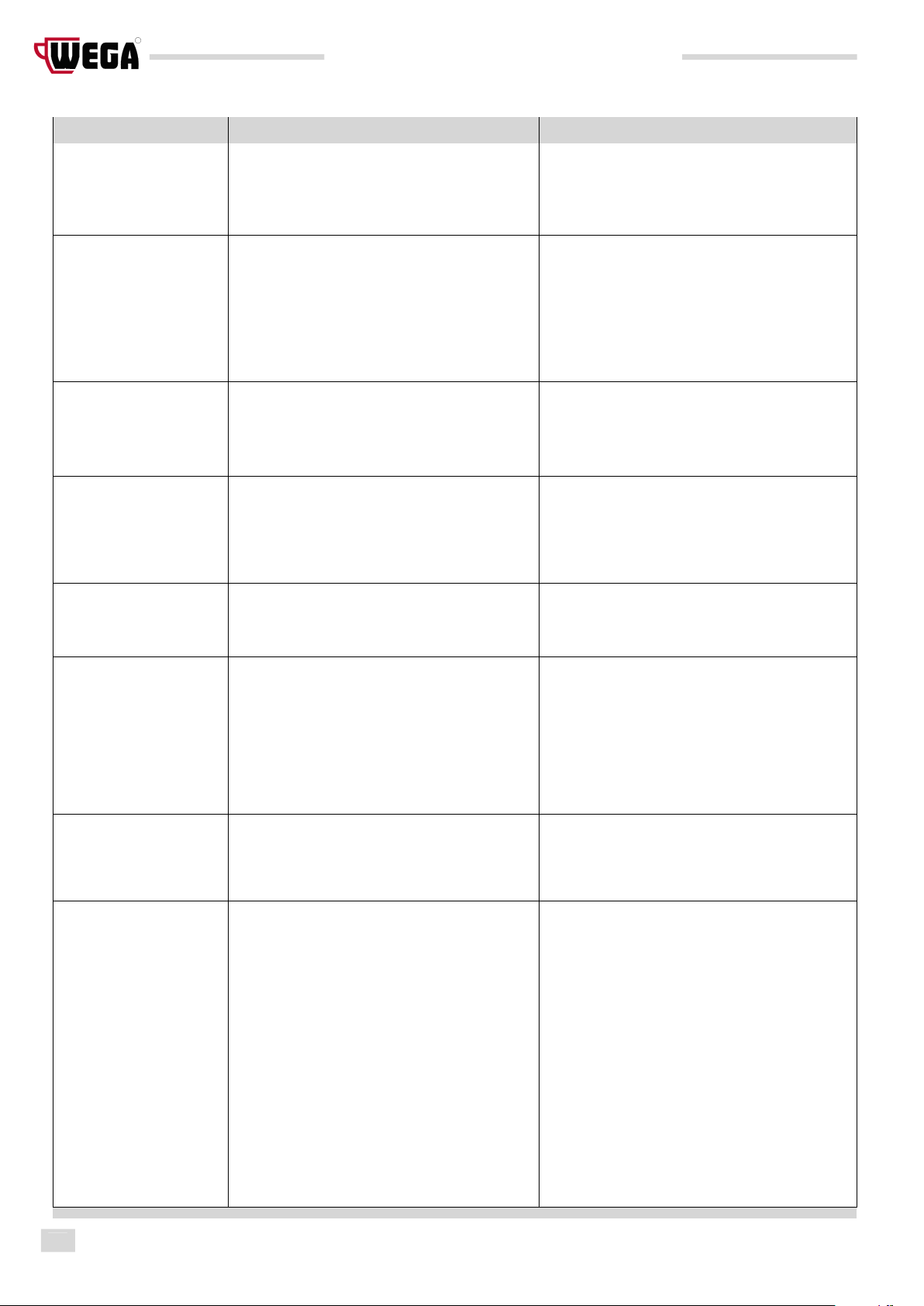

ESPRESSO COFFEE MACHINE

1. TECHNICAL CHARACTERISTICS

DISTRIBUTION MACHINE

LEVER MACHINE

14

16

12

13

2

10

4

4

1

3

11

8

7

6

6

15

3

5

9

18

12

3

15

4

1

3

10

4

11

8

7

6

6

2

14

13

15

17

18

5

9

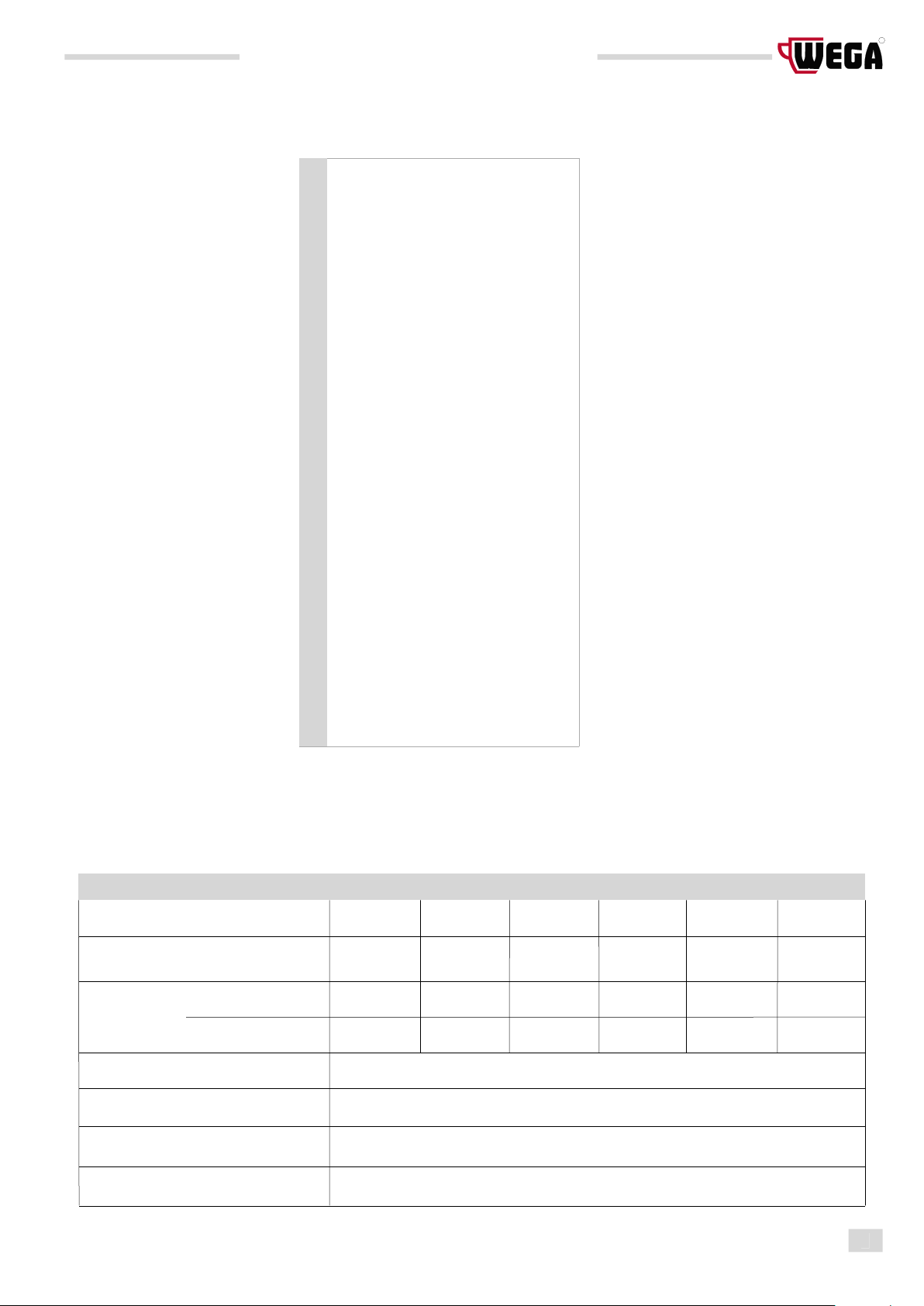

TECHNICAL CHARACTERISTICS

1 Boiler level-check window

2 Gauge

3 Steam gauge

4 Steam nozzle

5 2-cup filter holder

6 Adjustable foot

7 Hot water dispensing spout

8 Gas burner viewing window (if included)

9 1-cup filter holder

10 Gas safety (if included)

11 Gas ignition push button (if included)

12 Machine main switch

13 Cup rest grille

14 Machine on indicator light

15 Hot water knob

16 Lever groups

17 Manual delivery switches

18 Push button panels (for version EVD)

Boiler capacity (lt)

Power supply voltage (V)

Boiler pressure (bar)

Safety valve calibration (bar)

Supply water pressure (bar)

Coffee dispensing pressure (bar)

3,5 5 12 16 22

240 240 - 400 240 - 400

240 - 400

120 - 230 120 - 230 120 - 230

2

1,5 - 5 MAX

8 - 9

Version JUNIOR 1 Group 2 Groups 3 Groups 4 Groups

0,8 - 1,4 MAX

240 - 400

230

7

240

120 - 230

COMPATTA

120 V

1500 2000 2600 ---- ----2000

230 - 240 - 400 V

1500 2600 3400 5000 60002600

Power (W)

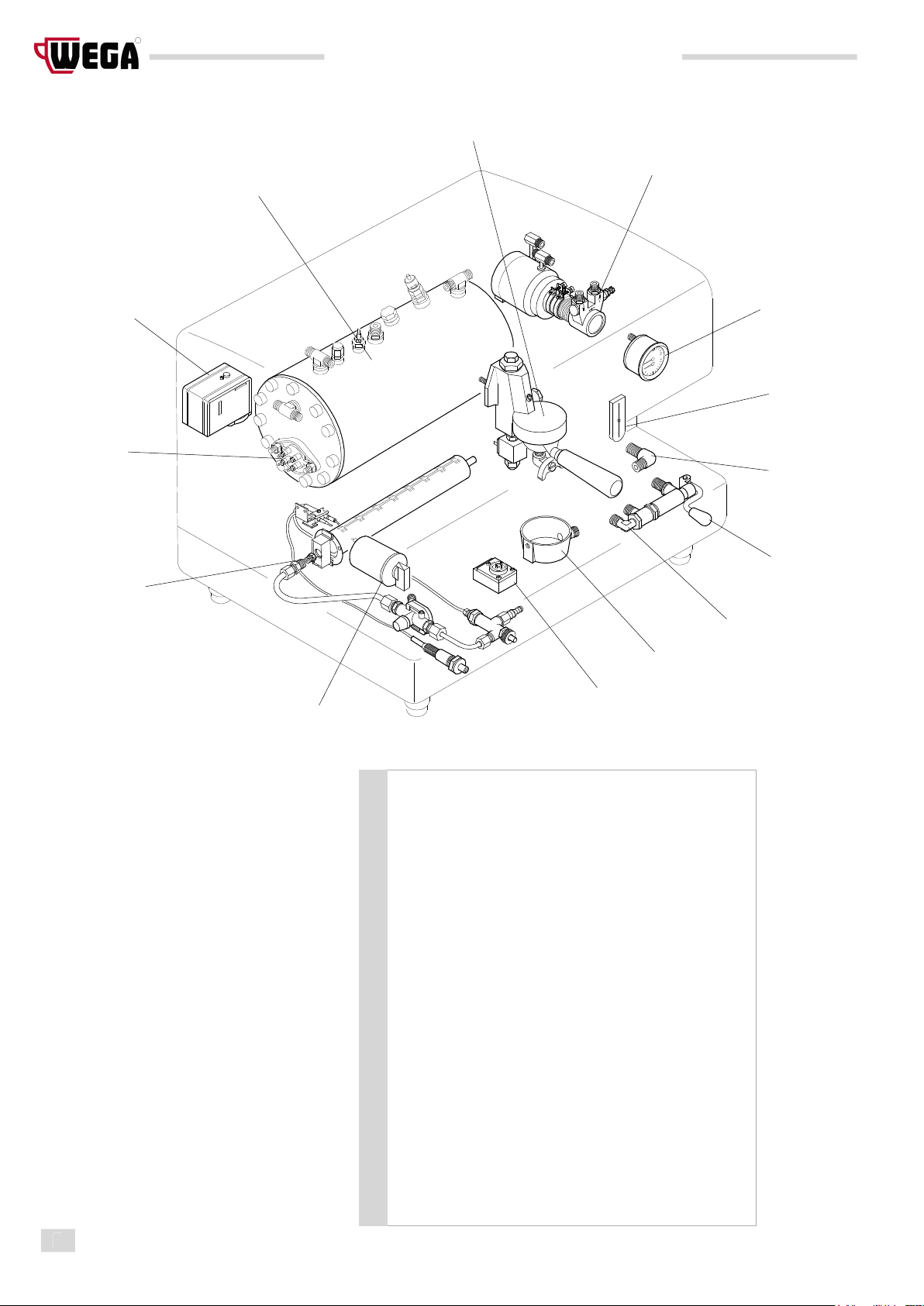

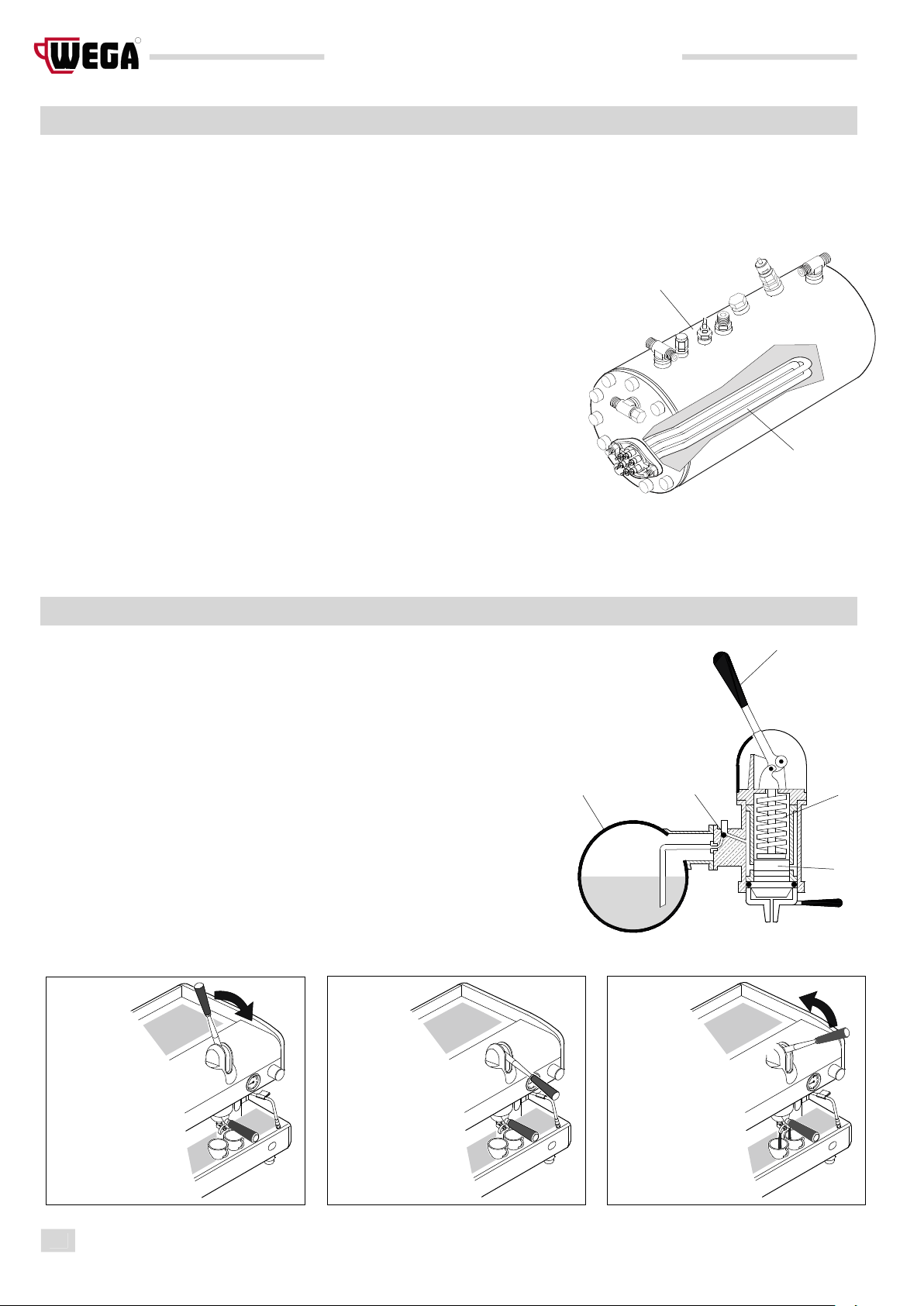

INTERNAL COMPONENTS

1 Boiler

2 Delivery group

3 Internal motor pump (if included)

4 Boiler / motor pump pressure gauge

5 Boiler level-check window

6 Internal pump water attachment connection (if included)

7 Manual water pump

8 External pump water attachment connection

9 Drain tub

10 Volumetric dosing device (EVD)

11 Machine main switch

12 Gas system (if included)

13 Electrical heating element

14 Pressure switch

1

3

4

5

14

9

10

2

11

6

12

13

7

8

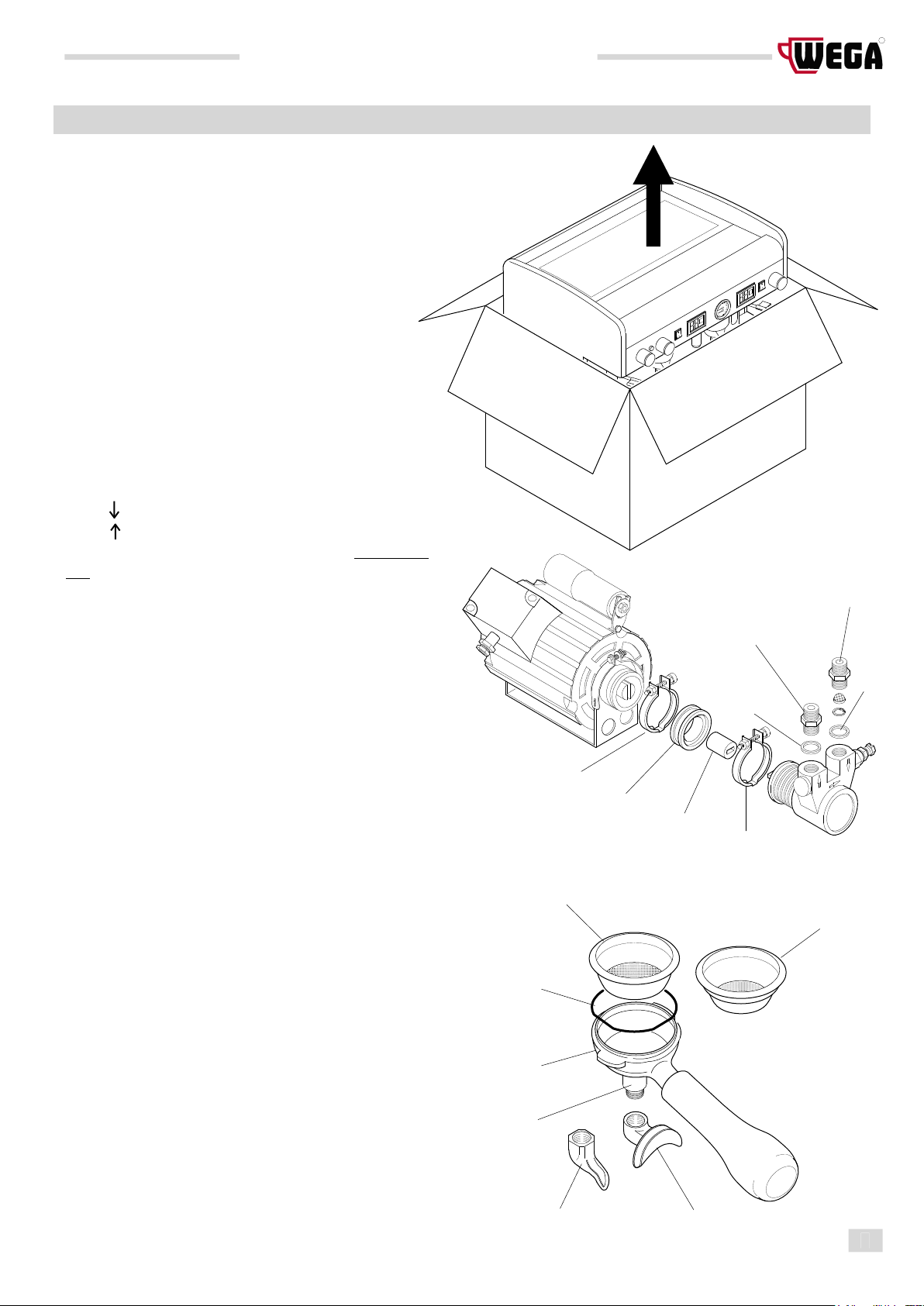

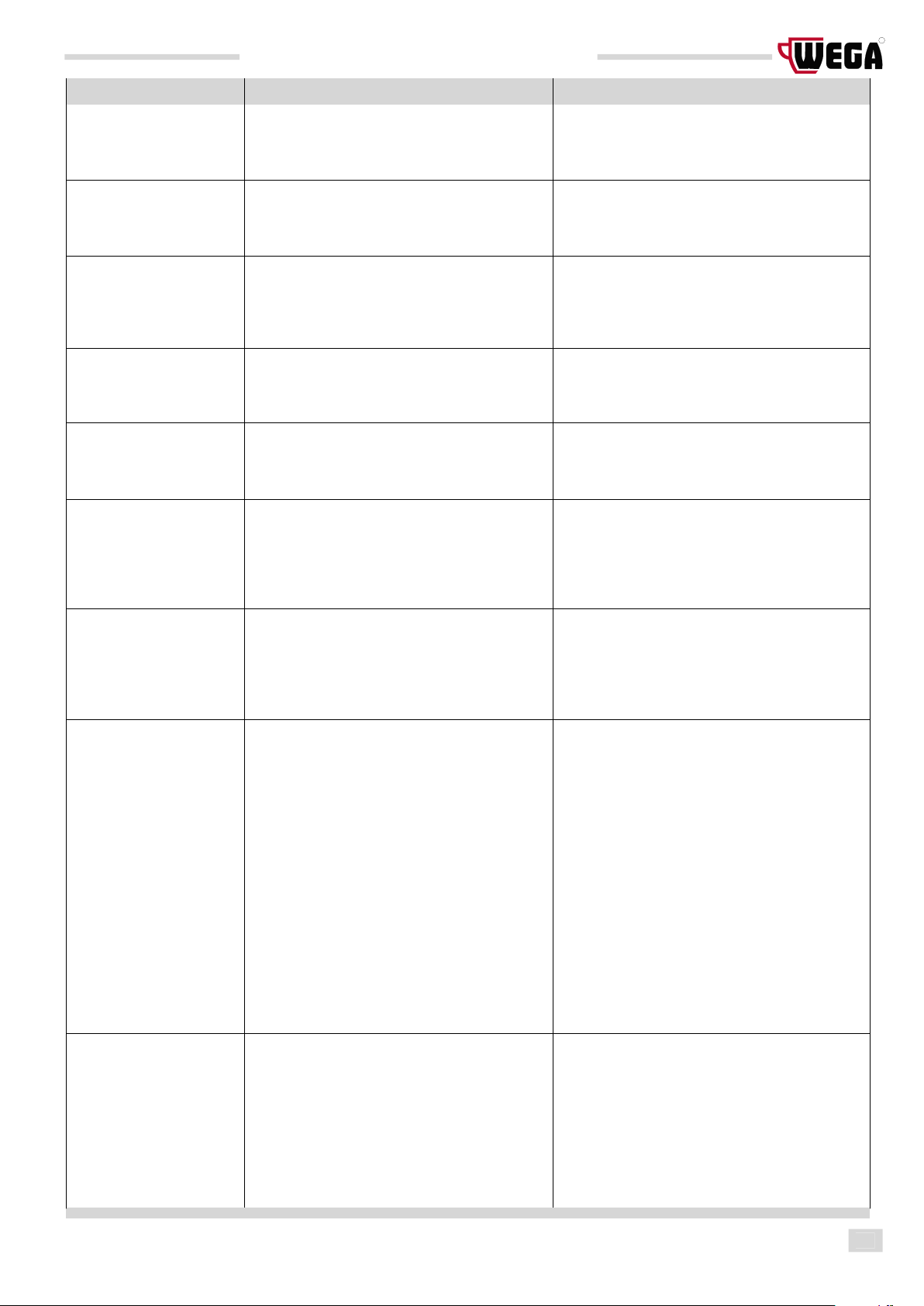

2. PREPARATION OF THE MACHINE

2.1 UNPACKING

Open the packaging, taking care not to damage it. Remove the

machine protections and the equipment contained in the package.

Take the machine out.

If there is an external motor pump, the motor and the pump are

provided in separate packaging.

2.2 EQUIPMENT PREPARATION

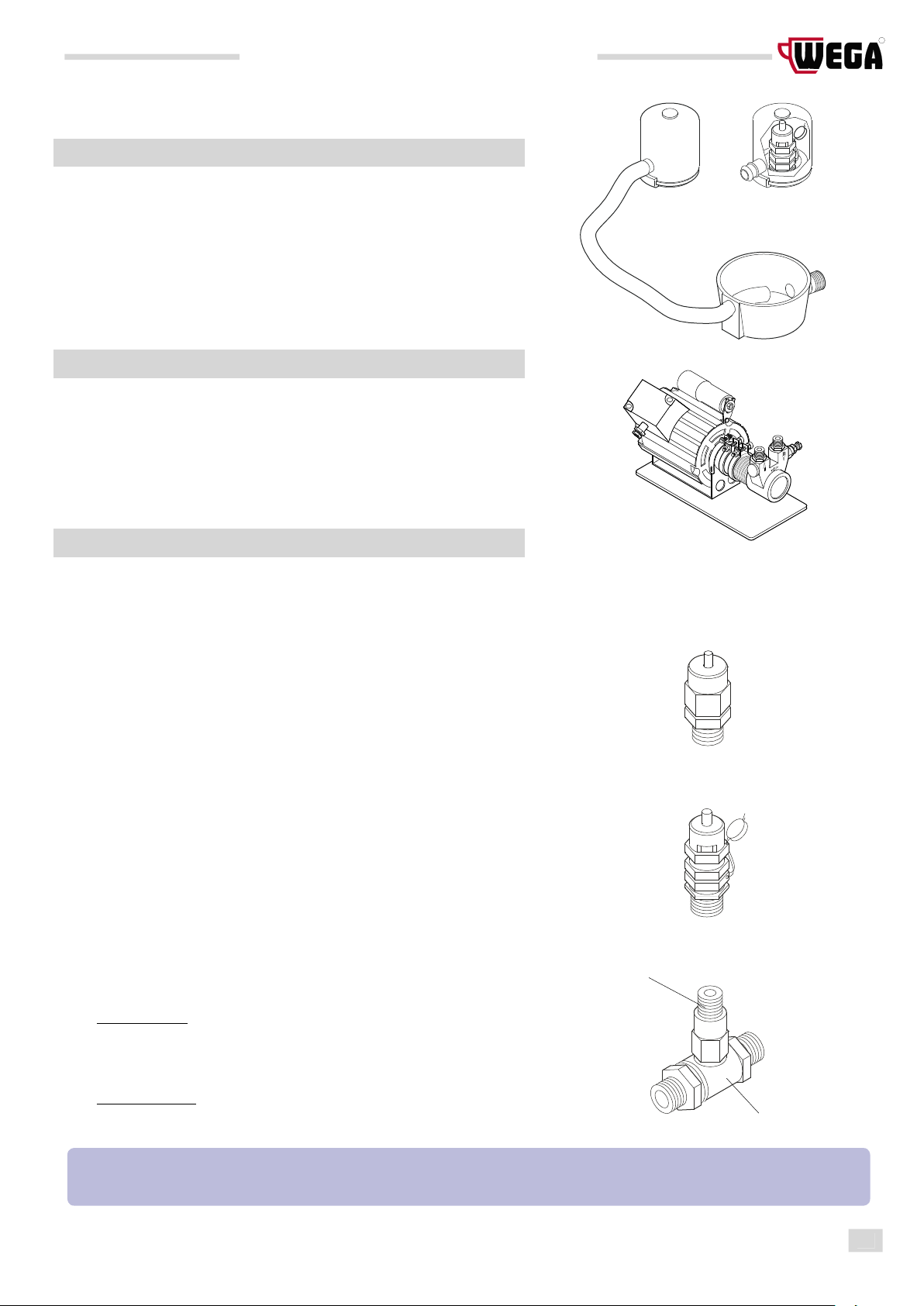

Motor pump

In machines with an external motor, it is necessary to prepare

the pump and the motor.

Fit the 3/8 gas connection with filter (2) at the pump inlet

(arrow ) and the plain 3/8 connection (1) at the pump outlet

(arrow ).

Attention: install the connection with filter (2) at the pump

inlet.

Use the special washers (3) provided for the seal.

To correctly couple the pump and motor, use the appropriate

joint (4) and the spacer ring (5). Lock all of this with the two

clamps

(6).

The pump-motor joint is also installed in machines with an internal

motor, with the exception of the Junior version and the Zecchin

type motors.

Filter-holder

In the housing of the filter holder (7), place the filter clamp spring

(8). Take the two-cup (9) or one-cup (10) filter and press it

firmly into the filter holder.

Spouts

Complete the filter holder by installing the two-cup (12) or one-

cup (13) spout.

In Italy provide for an extension cord (11).

Attention: install the spout on the relative filter holder: one-cup

spout on one-cup filter, etc.

Softener

The resin softener is standard equipment on versions EVD-EVDT.

It is furnished on request in versions ALE-EPU.

For further information, refer to the “Softeners” chapter.

7

8

9

10

11

12

13

2

1

3

4

5

6

3

6

3.1 POSITIONING

Prepare an ample suppor t base for the machine that is suitable to suppor t its weight (1). It is impor tant for all terminals of connections to

the water mains (2), to the electrical mains (3) and to the gas mains (in included), to be easily reachable and in any case in the immediate

vicinity of the machine.

Make sure that there is sufficient space for placing and correctly using the appliance. The grinding-dosing machine (4) must be placed in the

immediate vicinity of the appliance in order to allow for comfortable use of the machine.

It is advisable to equip the working base of the machine with a drawer (5) for used coffee grounds. Preferably this would also have a rubber

device to tap the filter holder against.

3. MACHINE INSTALLATION

1

2

3

4

6

7

8

9

10

11

12

13

14

15

5

WARNING

For correct operation, the machine must rest on a perfectly horizontal surface.

Any alignment adjustments of the ma-

chine must be done by adjusting the feet.(6)

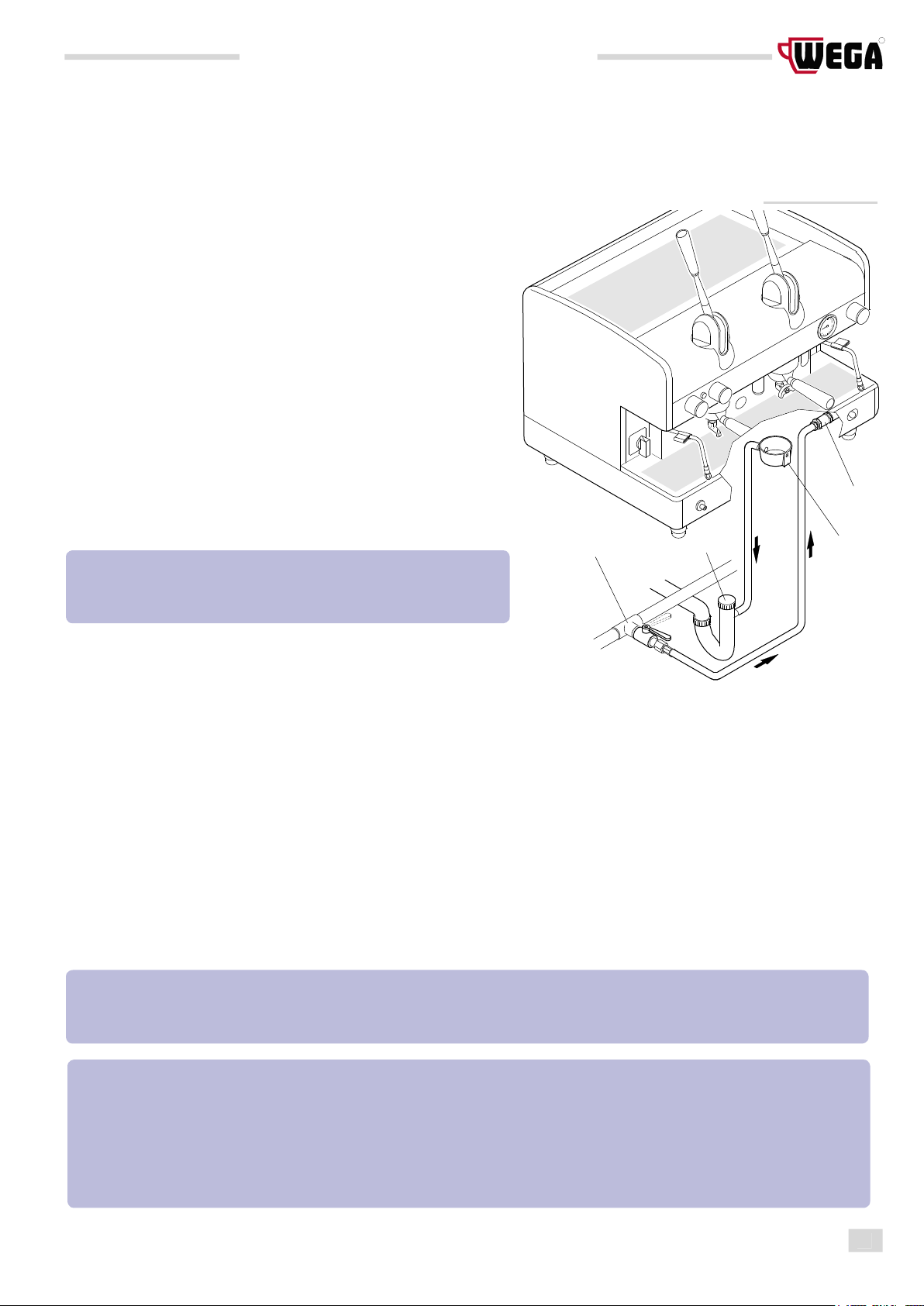

DISTRIBUTION MACHINE

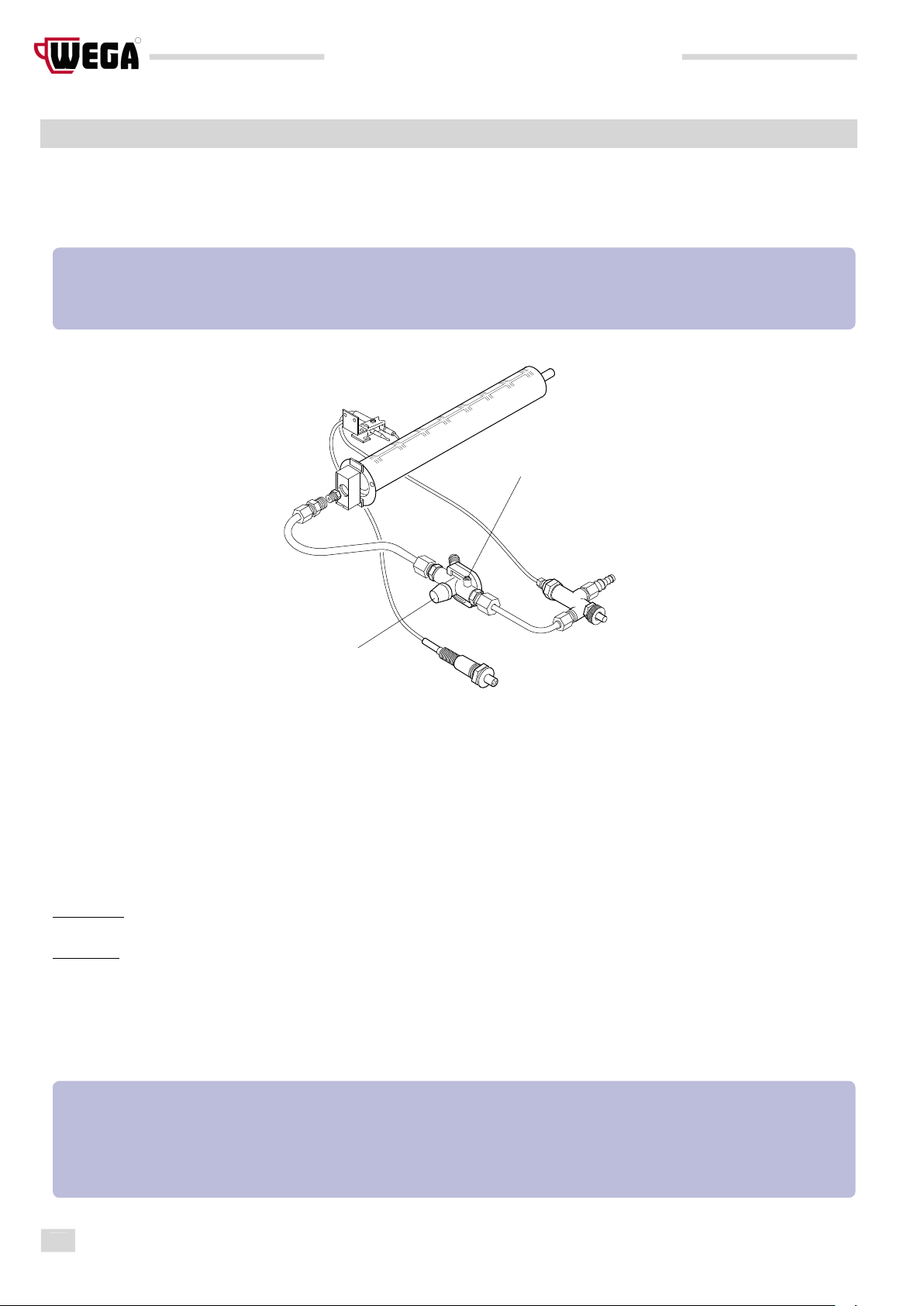

3.2 HYDRAULIC CONNECTION FOR EPU - EVD - EVDT MACHINES

1) Remove any rubber plugs which may be inserted in the tap fixtures of the softener.

2) Connect the water mains

(2) to the softener inlet (7) using the provided hose.

3) rinse resins

from the softener and check that the water, which initially comes out yellowish, comes out clean

4) connect the softener outlet (8) to the external motor pump inlet (9);

5) connect the outlet of the motor pump

(10) to the inlet of the machine (11);

WARNING

If hydraulic connection is not to the water mains but to an external tank, it is advisable to place a non-return valve between the

machine and the tank. The connection pipe between the machine and the external tank must not be greater than 150 cm.

NOTE

In all machines equipped with automatic water fi lling, there is an automatic time control device which allows the boiler to

be fi lled with water within a maximum period of time. This function keeps water from coming out of the valve of the boiler

(fl ooding) and keeps the motor pump from overheating.

If the maximum time is not enough for the boiler to fi ll up completely (machines installed with 3 or 4 groups), turn the machine off and then back on, and repeat the operations shown above.

When the machine is started for the fi rst time, it is advisable to fi ll the boiler manually using the knob (14)

NOTE

All fi lling connections are 3/8 male gas type. The drain tub is connected

with a tube with an internal diameter of 16mm.

6) connect the drain tub of the machine (12) to the sewer discharge (13)

using the special tube provided. Take care to avoid overly tight bends or

kinks, and make sure that there is sufficient inclination for water to flow

out of the drain.

3.3 HYDRAULIC CONNECTION OF ALE MACHINES

1) Remove any rubber plugs which may be inserted in the tap fixtures of

the softener.

2) connect the water mains

(2) to the inlet of the machine (11);

3)

connect the drain tub of the machine (12) to the sewer discharge (13)

using the special tube provided. Take care to avoid overly tight bends or

kinks, and make sure that there is sufficient inclination for water to flow out

of the drain.

Warnings

1)

The water mains must provide cold water for human consumption (potable water) at a pressure between 1 and 5 bar inclusive If the pressure

is greater than 5 bar, connect a pressure reducer upstream from the pump.

2) insert a tap (2) on the water mains supply so that it will be possible to cut off water flow to the machine;

3)

in order to prevent damage to the outer covering, to the valves or to the taps, install the softener where it will be protected from accidental blows;

4)

to prevent the water from freezing, install the softener in rooms with an ambient temperature of more than 0°C;

5)

if there is no softener, connect the water mains (2) directly to the inlet of the external motor pump(9);

6)

if there is an internal motor pump, connect the outlet of the softener (8) (if there is one) or the water mains (2) directly to the machine inlet (11);

7) when connecting the tub of the machine to the sewer drain, avoid overly tight curves or kinks, and make sure that there is sufficient

inclination for water to flow out of the drain.

8)

the drain must be connected to an inspectionable siphon that can be periodically cleaned in order to avoid the backflow of unpleasant odours;

9) to avoid oxidization and damage to the machine over time, do not use iron connections for the hydraulic connections, even if they are

galvanized.

2

11

12

13

LEVER MACHINE

3.5 GAS CONNECTION (if provided for)

Install a pressure reducer upstream from the gas system. When operating on

gas, the machine emits combustion fumes directly into the surroundings where

it is being used. Therefore, gas-powered machines must not be installed in

rooms with a volume of less than 12 m

3

, as described in standards UNI 7129

and UNI 7131.

On the pipe works upstream from the machine, a cut-off cock must be installed.

If flexible hoses rather than stiff pipes are used for connections, they must be

compliant with standard UNI 7140. These hoses must not be more than one

metre long, and they must be firmly attached to the hose connection with a safety

clamp (UNI 7141). They must not be placed near potential heat sources, they

must not reach a temperature greater than 50°C, they must not be subjected

to traction or twisting stress, and they must not have any kinks in them. It must

be possible to inspect them along their entire length, and they must not come

into contact with sharp objects or sharp corners.

The machine is assembled with the methane gas nozzle already installed.

The nozzle for city gas or gas cylinders is provided. Check that the nozzle

is appropriate to the type of gas being used before lighting the burner. The

incoming gas pipe must be equipped with a cut-off cock near the machine (see

the provided gas diagram).

At the cock outlet there will as necessary be installed a flexible hose or a stiff

copper pipe. Pipe connections to the machine must be made in accordance with

current standards in the country of installation. If connection is made with a

flexible hose, first of all inser t the hose into the gas safety hose connection.

If instead you would like to make a stiff connection, you can use a soft copper

pipe Ø6x8, equipped with a 1/4 gas nipple at the gas safety (remove the hose

connection first).

1. Hose connection tube

2. Gas ignition push button

3. Gas self-regulator

4. Gas safety

5. Nozzle

6. Burner

NOTE

To adjust the gas system, refer to chapter12.

The water in the boiler can be heated in various ways: only electrically (machines without gas system), only with gas (version ALE), with a combined

system of gas and electricity (machines with gas system).

6

5

3

2

4

1

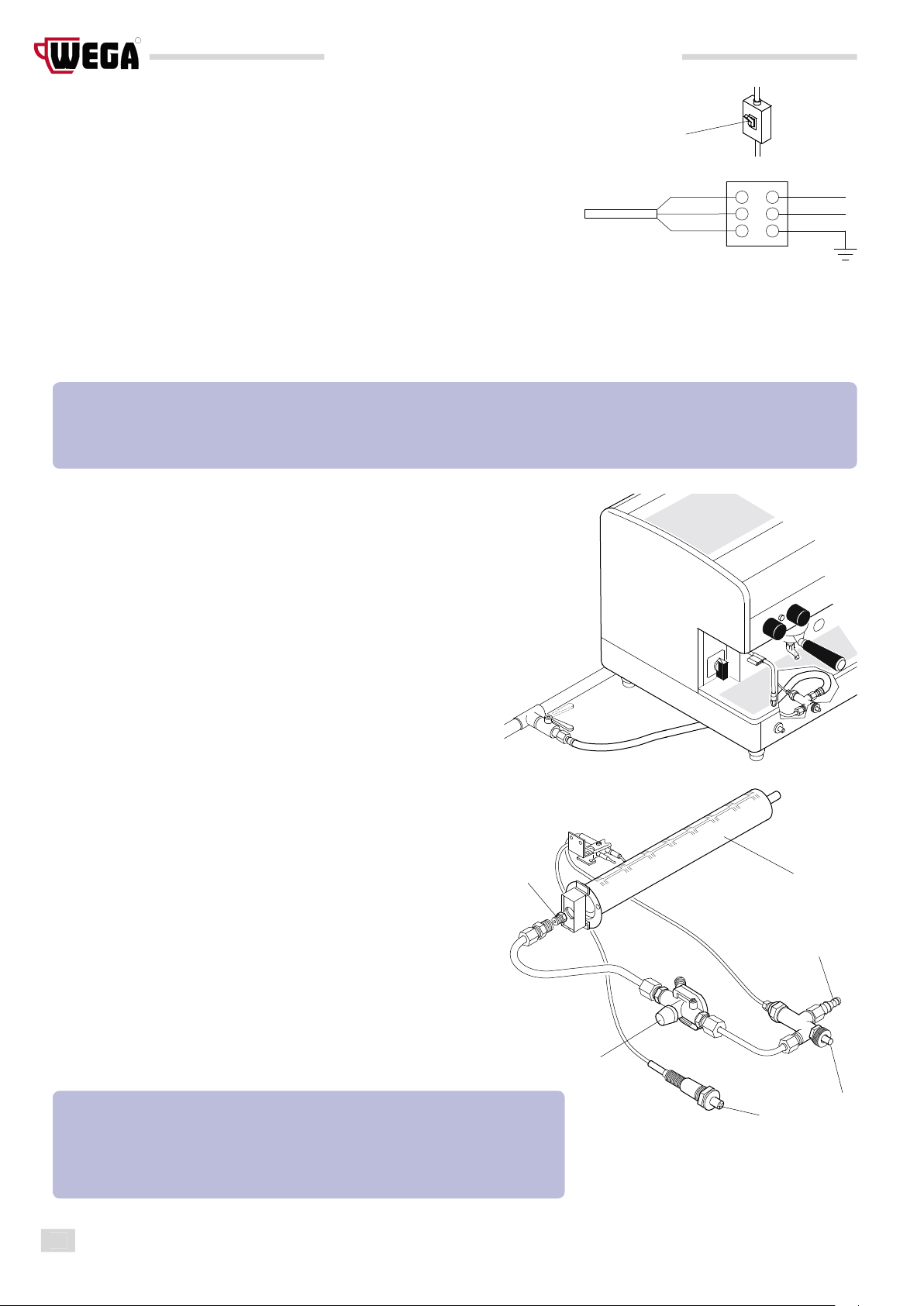

WARNING

Always connect the motor pump cable before the machine power supply cable, in accordance with the diagram provided.

Failure to comply with the instructions given above may cause serious damage to the machine an/or to the motor pump

and will invalidate any guarantee. Carry out all electrical connections with the power supply disconnected.

3.4 ELECTRICAL CONNECTION

On the electrical mains, it is advisable to install a main protection switch (A)

Machine with INTERNAL MOTOR PUMP

Connect the power cable as set forth in the chapter “Electrical diagrams” (the cable has a

cross-section and number of wires based on the power and voltage of the machine).

Machine with EXTERNAL MOTOR PUMP

1) Connect the cable to the motor pump (with lesser cross section) to the connector

as shown in the diagram shown alongside.

2) Connect the machine power cable (with greater cross section) as set for th in the

chapter “Electrical diagrams”.

C

B

M

GV

B

M

GV

MP

C Motor pump power cable

MP Motor pump terminal

B Blue

M Brown

GV Yellow-green

A

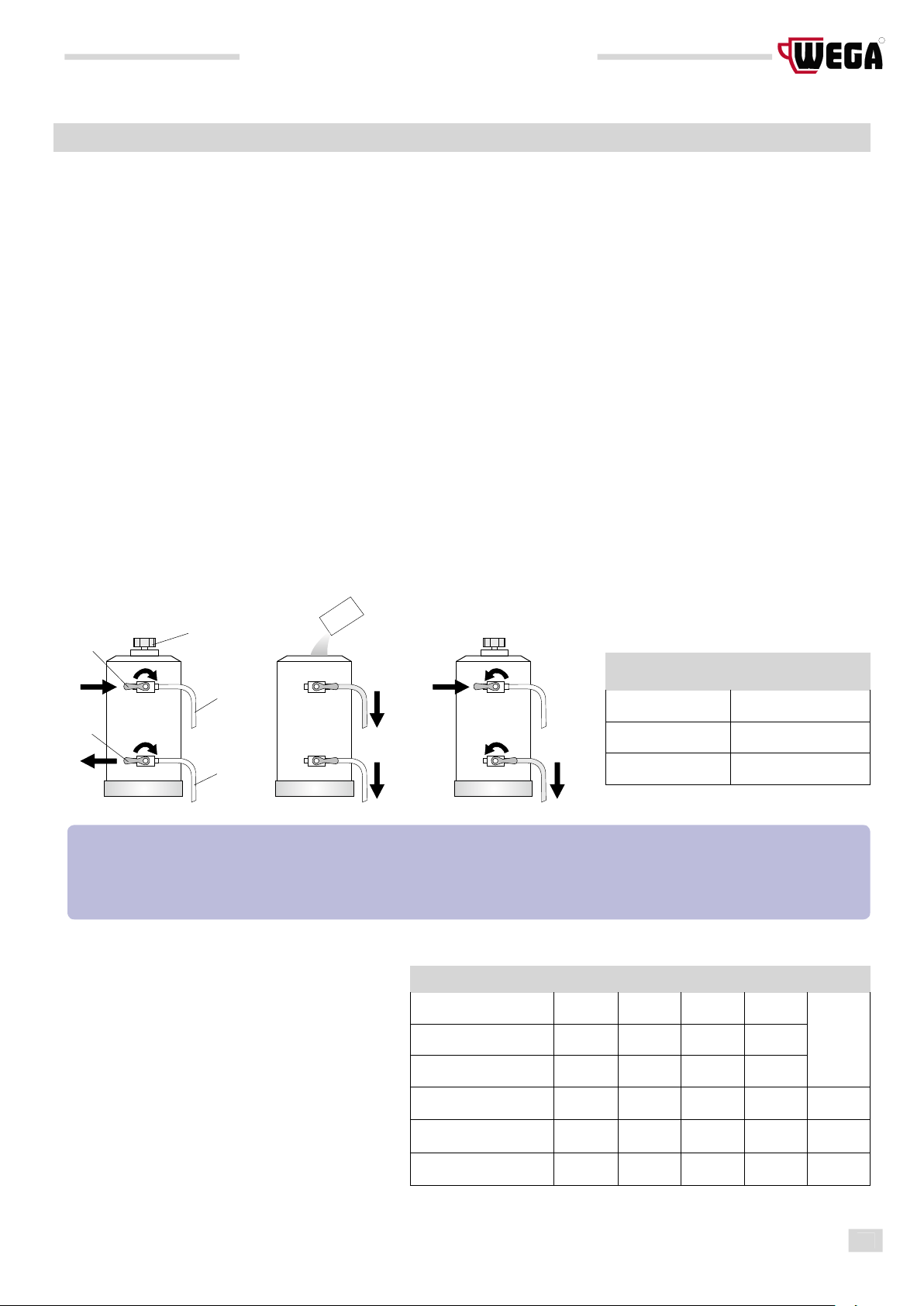

3.6 STARTING THE MACHINE

Before starting the machine, make sure that the level of water in the boiler is higher than the

minimum level on the level-check window (1). If there is no water (first installation or after boiler

maintenance), it is necessary to fill the boiler in advance, so as to prevent overheating of the

heating element. Proceed as follows:

Switch

Open the water tap of the water mains and of the softener.

Using manual fill (2) fill the boiler with water until the optimal level is restored.

Turn the switch to position “1” and wait for the machine to warm up completely.

Commutator

Open the water tap of the water mains and of the softener.

Turn the switch to position “

1” (electrical power supplied to the pump for automatic boiler filling

and machine services) and wait for the boiler to be automatically filled with water.

Turn the switch to position “

2” (full electrical power supplied, including the heating element in the

boiler) and wait for the machine to warm up completely.

For the installation of the most suitable injector, see the table shown

alongside.

WARNING

Do not under any circumstances attempt to light the gas

without fi rst installing the proper injector. As soon as connection is complete, check for any gas leaks by placing a

soapy solution on all connections.

WARNING

• during the machine’s warm-up phase (roughly 20 minutes), the negative pressure valve will release steam for a few seconds until the

valve itself closes

• before using the machine, run deliveries dry with the filter holder attached for a few seconds to release any air which may be in the

circuit, so that the delivery groups are completely heated

• before using the machine, dispense a few servings of coffee to test the grinding and to check the operating pressure of the machine

1 2

0

3

1 Group ø 1.00 (1.75 kW)

2 Groups

ø 1.10 (2.25 kW)

3 Groups ø 1.35 (3.20 kW)

4 Groups

ø 1.45 (4.00 kW)

Version

METHANE gas

(18 mbar)

ø 0.60 (1.50 kW)

ø 0.65 (1.75 kW)

ø 0.80 (2.50 kW)

ø 0.85 (3.00 kW)

LPG

(28/37 mbar)

1

0

1

2

Switch

Commutator

3.7 EXTERNAL MOTOR PUMP ADJUSTMENT

To adjust operating pressure proceed as follows:

• Use a coffee delivery switch.

• Adjust the pressure by turning the screw located on the pump

(3) so as to obtain a pressure

of between 8 and 9 bar. Tightening the screw increases pressure, and loosening it reduces

pressure. Check the pressure by means of the gauge

(4) located on the front part of the

machine;

• turn off the delivery switch;

4

4. Distribution machine BOILER and EXCHANGERS

The boiler is constructed in copper sheet metal (1), to which the heat exchangers are assembled which in turn are connected to the delivery

group. Water for coffee delivery is taken directly from the heat exchanger. During delivery cold water is sent to the inside of the exchanger

by means of the motor pump. Inside the heat exchanger, cold water and the pre-existing hot water are mixed, thus obtaining optimal water

temperature for coffee infusion. The ALE does not have a heat exchanger, therefore water is taken directly from the boiler.

4.1 ELECTRIC HEATING

5. COFFEE DELIVERY GROUPS

The delivery group and the heat exchanger are the fundamental components in obtaining

espresso coffee. Specifically, the purpose of the group is to dispense the coffee.

The water is heated in the boiler by means of an electrical heating element that is immerged in the

water(2).

4.2 GAS HEATING

Gas heating is obtained by supplying the flame of the burner located under the boiler.

4.3 COMBINED GAS + ELECTRIC HEATING

In machines equipped with both systems, it is possible to combine the heating types.

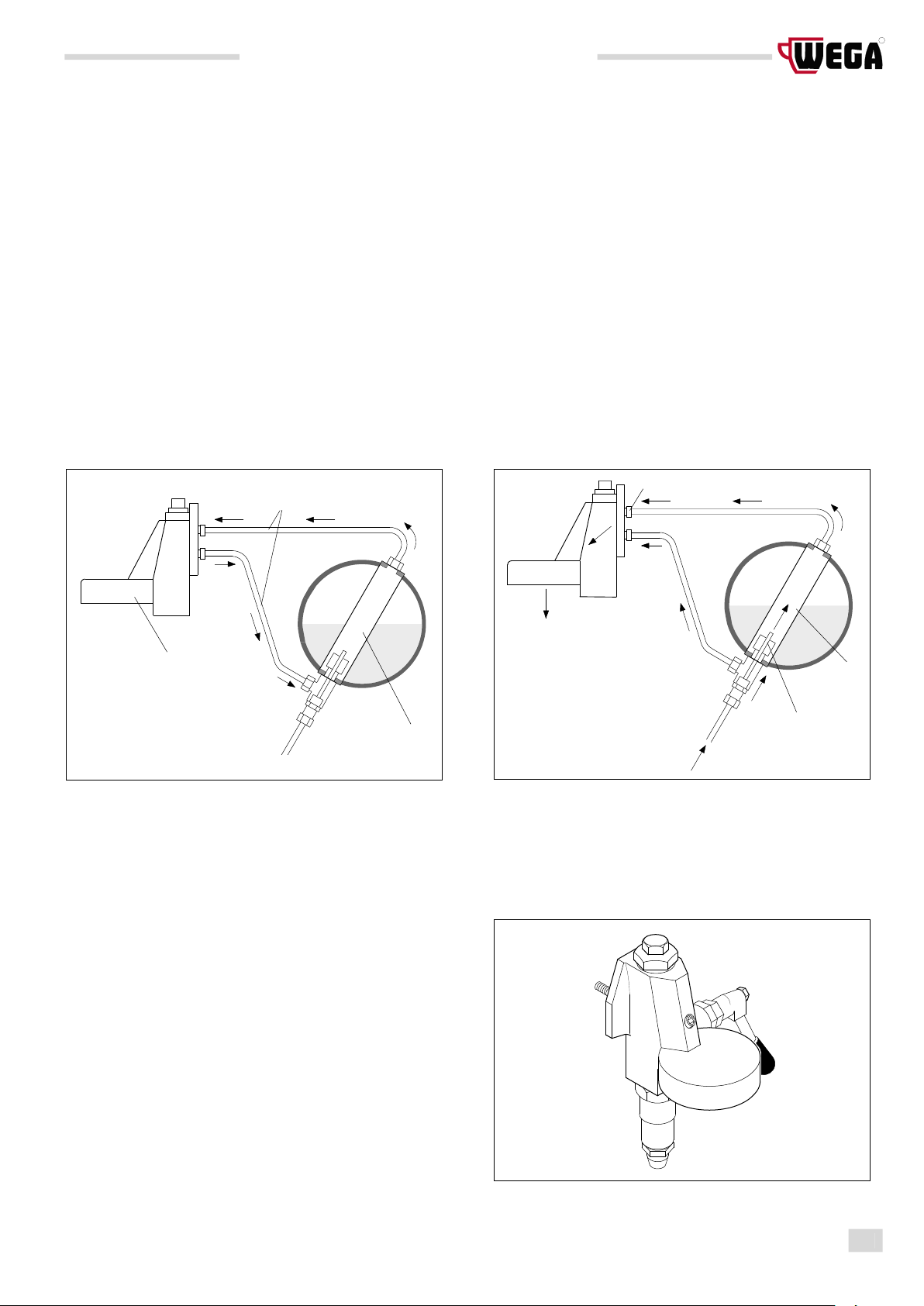

5.1 LEVER GROUP

The lever group uses the boiler pressure and water. This system does not require heat

exchangers.

When the lever (1) is lowered, the spring (2) inside the group is compressed: the piston

(3) raises, allowing water to enter the pre-infusion jacket. When the lever is released,

the piston compresses the water to 8-10 bar, allowing delivery of espresso coffee. The

non-return ball valve

(4) keeps water from flowing back into the boiler (5).

2

1

3

2

4

5

1

Phase 1

Lowering the lever.

Phase 2

Pre-infusion for

3÷5 seconds.

Phase 3

Release of lever

and delivery

of the coffee.

5.2 DELIVERY GROUP

In this system, the delivery group (1) is heated by a thermosiphon circuit (2) connected to the heat exchanger (3). The same water is used

for coffee delivery, thus ensuring the same temperature for all coffee servings.

• activation of the solenoid valve and of the pump allow cold water to enter the exchanger (3) through the injector (4).

• from the exchanger

(3) the boiler water is carried to the group (4) for delivery;

• the pump allows the increase of the pressure of the water flow up to 8-9 bar for delivery.

The injector

(4) and the flow reducer (5) are impor tant components for the operation of the delivery group.

To increase the coffee extraction temperature, remove the flow reducer (5) or replace it with one of a greater diameter. To decrease the

temperature, replace it with one of a smaller diameter.

If necessary, the exchangers can be replaced by removing the flange and disconnecting the relative pipes of the hydraulic circuit. These operations should be carried out after the machine has been switched down and has cooled off. Always replace the seals.

inlet

water

delivery

coffee

in delivery

3

4

5

at rest

1

2

3

5.3 DELIVERY DELIVERY

This group functions with a double-outlet type exchanger.

The delivery is controlled with a manual valve system. The opening and

the closing of the valves for the passage of the water is operated by

a lever placed beside the group which, in turn, operates a cam inside

the group, opening and closing the water.

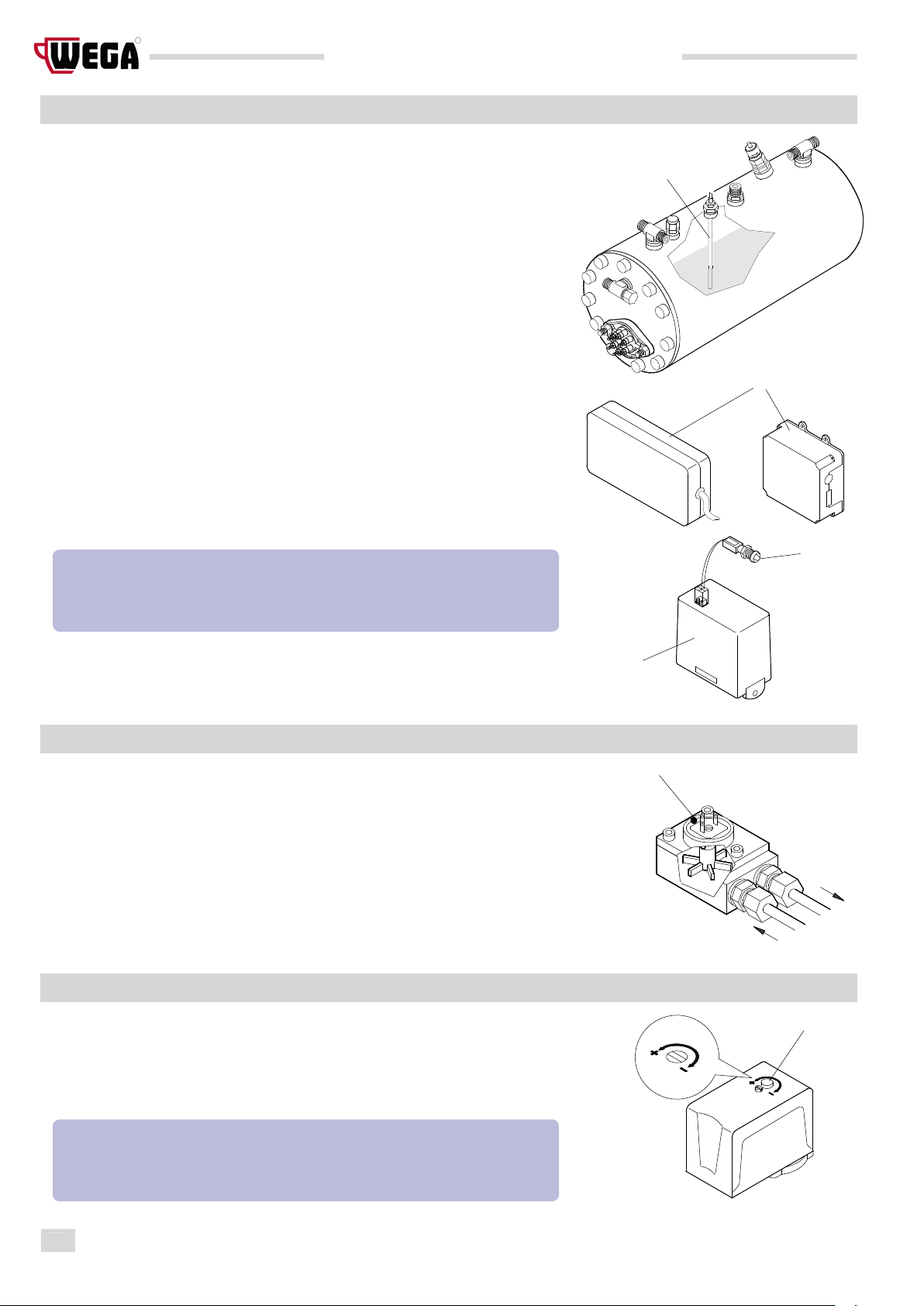

6. Automatic Water Entry

The AEA system (Automatic Water Entry) is for checking the boiler level. It is composed of:

• sensor inserted in the boiler (1), composed of a stainless steel rod;

• control unit (2) standard on EVD machines, electronic level regulator on other

versions

(3);

• hydraulic circuit with a solenoid valve controlled by the regulator.

The electronic control unit controls the level of water in the boiler. When the level of water

in the boiler drops, the contact with the probe is interrupted. The control unit sends and

impulse to the entry solenoid valve (1) and to the motor pump (2), which act to restore

the normal level of water in the boiler.

To avoid possible flooding due to machine malfunctions or leaks in the hydraulic circuit, the

electronic control unit includes a timing device that cuts off automatic filling after a certain

time (roughly 30 seconds). The LED

(4) located on the front of the machine body comes

on to indicate activation of this system. During the installation of machines with three or

four groups the initial water filling time may exceed the established time limit. In this event,

just switch the machine off and then back on to restore normal operating conditions.

7. VOLUMETRIC DOSING

The volumetric dosing device installed on the EVD electronic machines serves the purpose

of measuring the quantity of water sent to the group of espresso delivery.

The dosing device generates an electrical impulse which is sent to the electronic control

unit. This impulse is read by the control unit and memorized during the programming of

the dose.

The flashing of the LED

(5) indicates that the electrical impulse has been sent from the

dosing device to the control unit.

8. PRESSURE SWITCH

The pressure switch makes it possible to control boiler pressure by activating or bypassing

the heating element in the boiler.

Any calibration of the pressure switch which may be required can be carried out with the machine in operation by means of the screw (6) located on the body of the component.

1

2

3

4

5

6

WARNING

Always check the level of the water in the boiler by means of the level-check

window placed on the front of the machine.

WARNING

The internal contacts of the pressure switch may be subject to oxidization. It

is recommended to periodically clean the contacts with anti-oxidant spray.

11. VALVE GROUP

The valves are devices whose purpose is to ensure the safety and proper operation

of the machine.

10. PUMPING SYSTEM

This is a component that serves the purpose of feeding the machine, raising the

water pressure to 8-9 bar for the delivery of the coffee and for automatic filling

of the boiler.

9. ANTI-FLOODING DEVICE

The cover installed on the pressure modulating switch makes it possible, by means

of the special tube, to collect and carry to the drain tub any water which may exit

the boiler to due any malfunction of the machine.

11.1 NEGATIVE PRESSURE VALVE

The purpose of the negative pressure valve is to prevent the backflow of liquids

through the steam nozzle when they are being heated. Fur thermore, the excess

air is eliminated inside the boiler during the heating phase of the machine.

11.2 SAFETY OR PRESSURE RELIEF VALVE

The pressure relief valve guarantees that the pressure in the boiler does not go

above 2 bar. If there is a malfunction, the capacity of the valve is such that it can

eliminate all of the excess pressure in the valve.

11.3 EXPANSION VALVE - NON-RETURN VALVE

This is a valve consisting of an expansion valve and a non-return valve.

• Expansion valve: the cold water sent from the pump to the heat exchangers

is heated. This heating causes an increase in the volume of water. To limit

increases of pressure in the hydraulic circuit, the valve limits the maximum

internal pressure of the circuit to 12 bar.

• non-return valve: Its function is that of preventing the back flow of water

from the exchangers in the hydraulic circuit.

NOTE

On all machines with four groups, two pressure relief valves are installed.

valve

EXPANSION

valve

NON-RETURN

12. GAS SYSTEM

The gas system is useful in heating the water in the boiler. It does not, except in special cases, substitute the electrical heating system, but

rather works along with it.

For machines with levers, operation may be either electric or gas.

Gas adjustment

• Lighting the burner

• loosen the locknut

(1);

• give the screw two turns and place the minimum regulator pin

(2) so as to have maximum opening of the gas minimum passage;

• wait for boiler pressure to reach 1.4 bar (see boiler gauge);

• turn the minimum pin

(2) clockwise until the burner flame is barely visible (pilot flame);

• lower the pressure in the boiler down to 1 bar;

• turn the adjustment screw for the maximum clockwise until the flame is up to maximum;

• tighten the locknut thus locking the screw.

The operation described above places the machine in an operating range of 1.2-1.3 bar. If you want to increase or decrease operating pressure

in the boiler, proceed as above, varying the parameters as follows:

to decrease:

• set the maximum to 1.3 bar and the minimum to 0.9 bar. You will obtain pressure in the boiler of 1.1-1.2 bar.

to increase:

• adjust the maximum to 1.5 bar and the minimum to 1.1 bar. You will obtain a pressure in the boiler of 1.3-1.4 bar (this is the maximum

recommended pressure limit)

1

2

WARNING

If you decide to use only the gas heating system, no electrical devices are active, including automatic boiler fi lling.

WARNING

When operating on gas, the machine emits combustion fumes directly into the surroundings where it is being used. Therefore, gas-powered machines must not be installed in rooms with a volume of less than 12 m

3

, as described in standards

UNI 7129 and UNI 7131.

In closed rooms, always provide ventilation openings to release any possible gas leaks.

13. SOFTENERS

Mains water contains insoluble salts, which cause the build-up of lime scale deposits in the boiler and in other parts of the machine. The

softener makes it possible to eliminate or substantially reduce the presence of these mineral salts.

The resin softener has the proper ty of retaining the calcium contained in the water. For this reason after a certain period the resins are

saturated and are to be regenerated with coarse kitchen salt (NaCL, sodium chloride) or special water softening salt. It is very important to

regenerate the softener within the established times.

The regeneration is to be done regularly every 15 days. However, in locations with very hard water, it will be necessary to regenerate more

frequently. The same is true of places in which there is a large consumption of hot water for tea or other uses.

Softener regeneration

Proceed as follows:

• move levers

(2) and (5) from left to right;

• Remove the lid by loosening the knob

(1).

• Release enough water through the pipe

(3) to make room for the amount of salt as required depending on the model (see table).

• Clean any salt or resin residue from the gasket located on the lid.

• Put the lid back in place by screwing the knob

(1) down securely and move the lever (2) back from right to left.

• Let the salt water drain from the small tube

(4) until the water is no longer salty (about 30-60 minutes). The salt allows the accumulated

mineral salts to be released.

• Bring the lever

(5) from right to left back to its initial position.

1

2

3

4

5

In order to keep the softener and hence the machine in

perfect operating condition, it is necessary to perform

regeneration periodically based on the use of the softener

and the hardness of the water that is used.

The table alongside shows the values of the quantity of

softened water based on the hardness of the water in the

various units of measure:

- F°: French degree

- D°: German degree

- mg CaCO

3

For further information on installation, start-up and regeneration of the softener, refer to the relative instruction manual.

WARNING

The build-up of lime scale in the hydraulic circuit and boiler inhibit thermal exchange, thus compromising proper operation

of the machine. Heavy incrustation in the boiler may cause long machine shutdowns and in any case invalidate any guarantee, because this symptom indicates that regeneration has been neglected.

8 litres 1.0 kg

12 litres

1.5 kg

16 litres 2.0 kg

Model

softener

Amount

of salt

F° 30°

D° 16.5°

mg CaCO

3

300

8 litres

1000 lt

Amount of softened water based on hardness

40°

22°

400

900 lt

60°

33°

600

700 lt

80°

44°

800

500 lt 1.0 kg

salt

12 litres

1500 lt 1350 lt 1050 lt 750 lt 1.5 kg

16 litres

2100 lt 1800 lt 1400 lt 1000 lt 2.0 kg

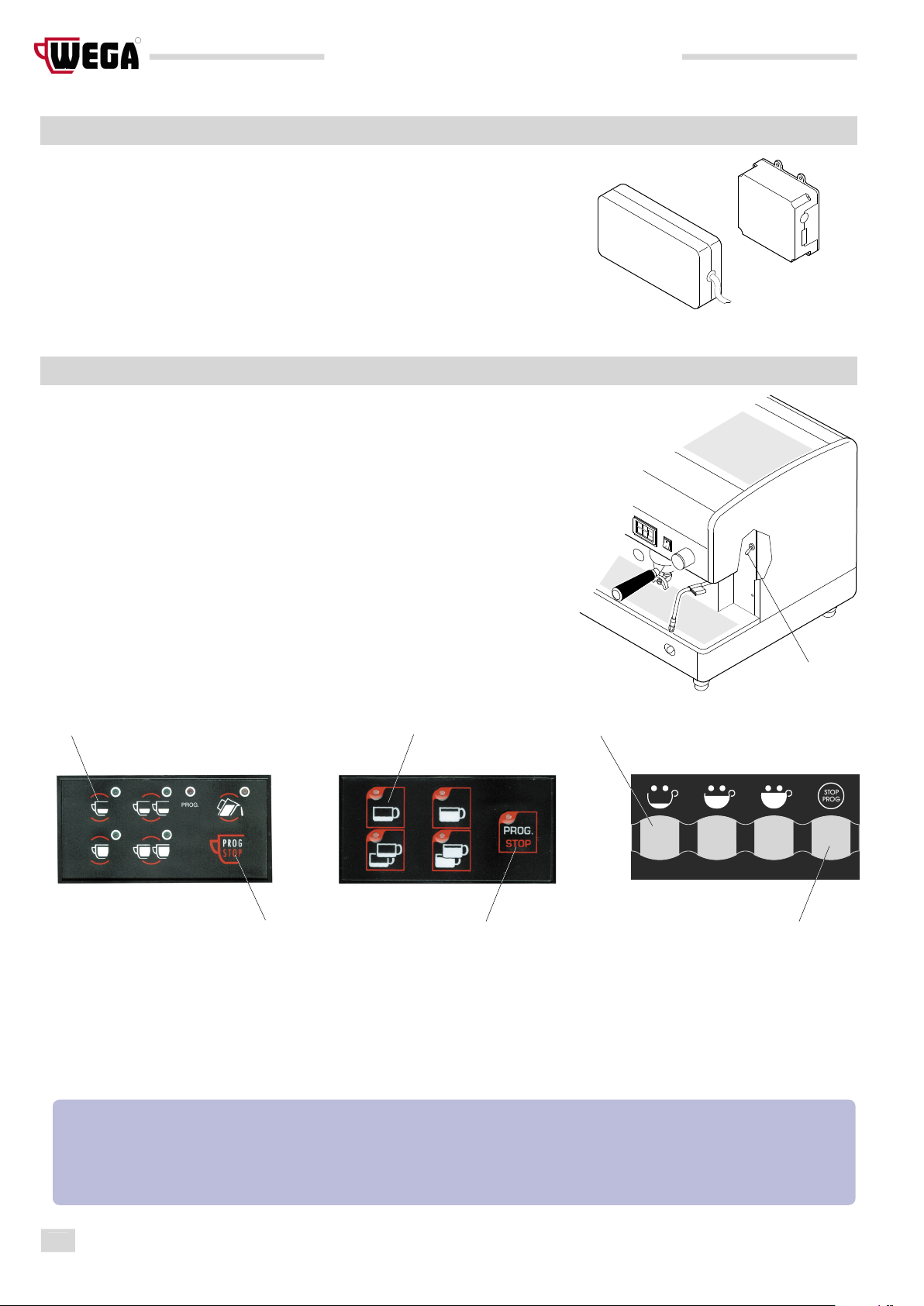

14. ELECTRONIC CONTROL UNIT

The electronic control unit is installed on machines with volumetric dosing. Its purpose is to control the dose of coffee electronically by means of the water flowing

through the dosing device and to check filling of the water entry in the boiler.

This control unit is set up to be connected to the delivery accounting systems by

means of a specific interface device.

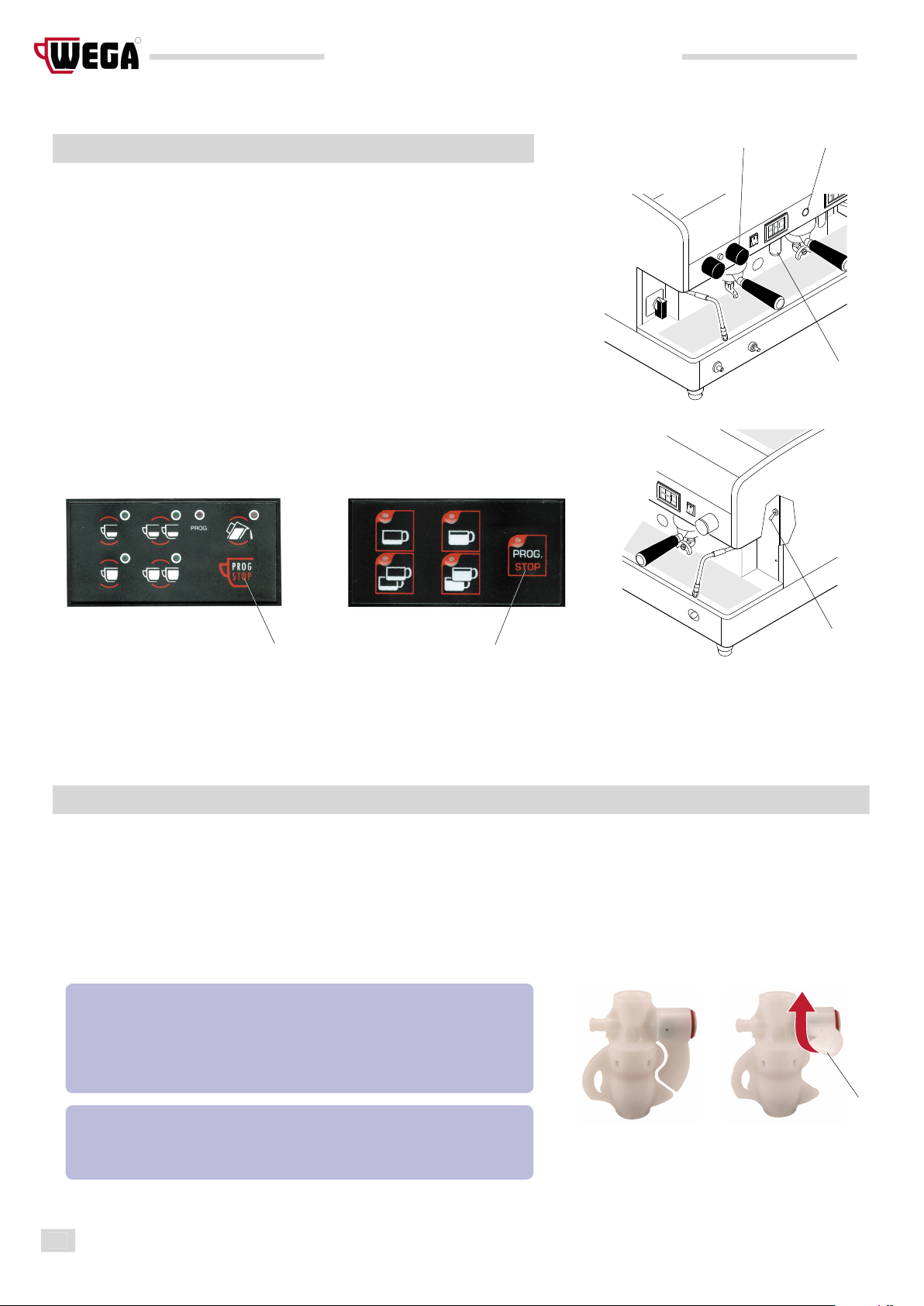

15.1 EVD PUSH BUTTON PANEL

The push button panel is connected to the control unit which allows selection and programming of the doses of coffee.

Programming is carried out in the following way:

• Place the programming lever (1) in the ON position. It is located under the front

right-hand panel of the body;

• put the coffee cup under the dispensing spout.

• press the PROG/STOP key

(2) and all dose key LED will come on;

• press the desired dose key

(3);

• when the desired dose has been attained, confirm by pressing the PROG/STOP key (2)

;

• Repeat this operation for the other dose keys.

• upon completion of programming, place the programming lever

(1) back in the OFF

position.

1

In some models, the programming lever has been eliminated because to access program, and it is enough to press the PROG/STOP key for

at least 5 seconds with all push button panel LED coming on. Also, confirmation of the dose can be given by pressing either the PROG/STOP

key or the selected dose key.

In other models to access programming it is necessary to use a special key switch.

To exit programming it is sufficient to wait a few seconds.

NOTE

The programming of every dose must be done with ground coffee and not with previously used grounds.

With machines having two or three groups, by fi rst programming the right-hand push buttons the others are automatically

programmed. It is however both possible and advisable to program the push button panels independently, always starting

from the right-hand push button panel.

15. ELECTRONIC PUSH BUTTON PANELS

3

2

3

2

STOP

PROG

3

2

15.2 TH JUNIOR PUSH BUTTON PANEL

This push button panel is installed mainly on JUNIOR models and on some EVD volumetric dosing machines.

Programming is carried out in the following way:

• put the coffee cup under the dispensing spout.

• Press the PROG/STOP key

(1) for at least 5 seconds until all dose key LED are on.

• Press the desired dose key

(2).

• To confirm the dose press the dose key

(2) or the PROG/STOP key again (1).

• Repeat this operation for the other dose keys.

• Programming will be terminated automatically after a few seconds.

15.3 EVDT TIMER PUSH BUTTON PANEL

The timer is installed on EVDT machines and controls delivery time of the coffee.

Programming is carried out in the following way:

1) Press and hold down the STOP/PROG key (1) for 5 seconds and check that all of the LED on the push button panel come on. This confirms

correct entry into the programming phase.

2) Press on of the two dose keys

(2) to program. The LED corresponding to the CONT key (continue) and to the key of the dose being

programmed stay on.

3) When the desired amount of coffee in the cup has been reached, press the STOP/PROG key (1) or the key of the dose being programmed

to stop delivery and memorize the new value (the duration of the dose of coffee is calculated in seconds). At the same time, the LED for

the dose which is still to be programmed comes back on, while the LED for the programmed dose stays off.

4) Proceed with the programming of the other coffee dose by pressing the other dose key. Once the desired amount of coffee in the cup

has been reached, press the dose key or the STOP/PROG again

(1).

5) To exit programming, press and hold down the STOP/PROG (1) key for more than 5 seconds.

NOTE

It is possible to re-program the coffee dose that you have just fi nished programming (LED off) without necessarily having

to turn the system off and back on or exiting the programming phase.

The system automatically exits programming status approximately 10 seconds after the last operation.

1

2

1

2

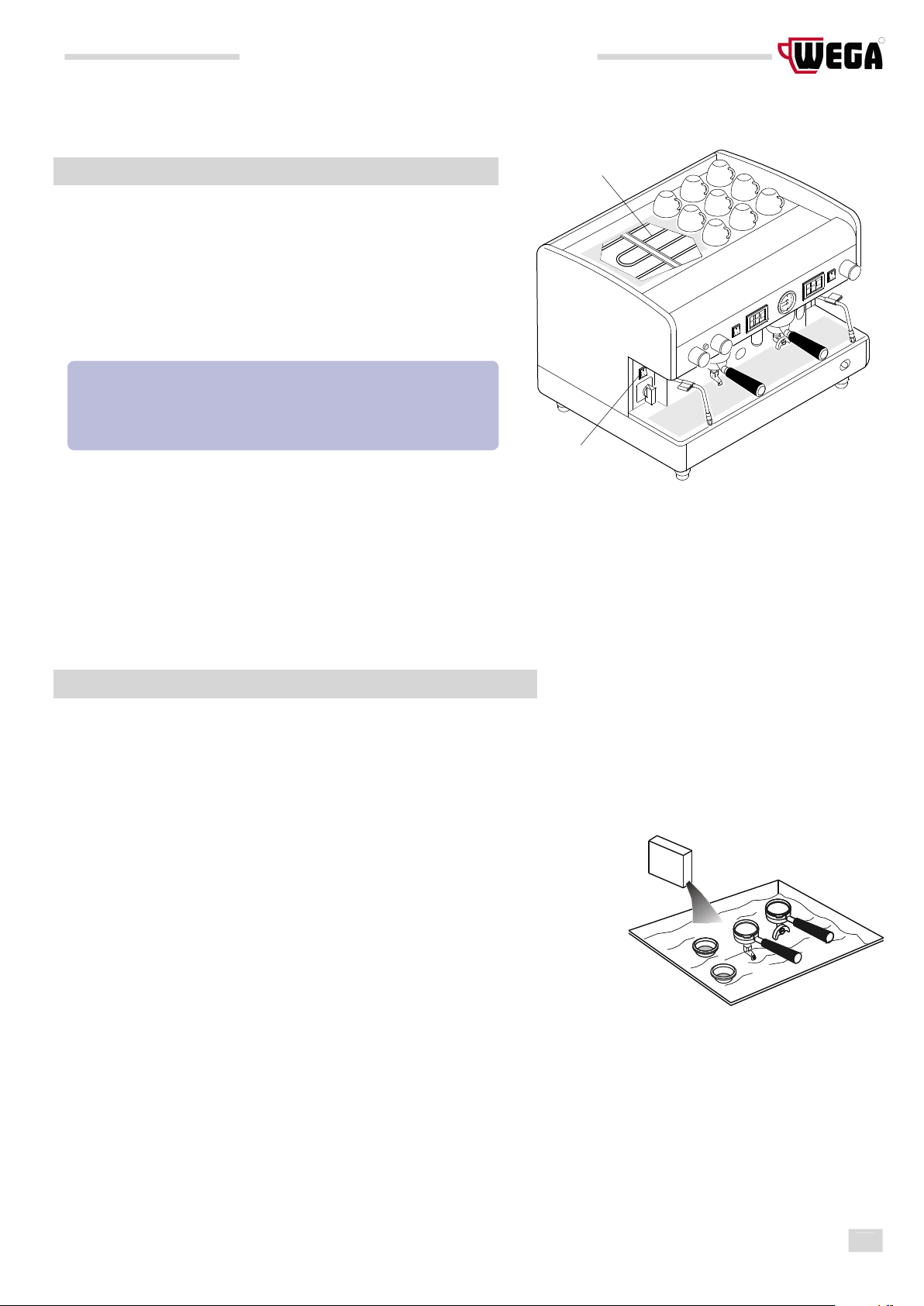

Programming

• Place the programming lever in the ON position (1) it is located under the

front right panel of the body

;

• put the cup under the hot water nozzle (2);

• press the PROG/STOP key (3) and all dose key LED will come on;

• press the key to dispense hot water (4);

• when the desired dose has been attained, confirm by pressing the PROG/STOP

key

(3)

;

•

upon completion of programming, place the programming lever

(1)

back in

the OFF position

33

2

1

4

1

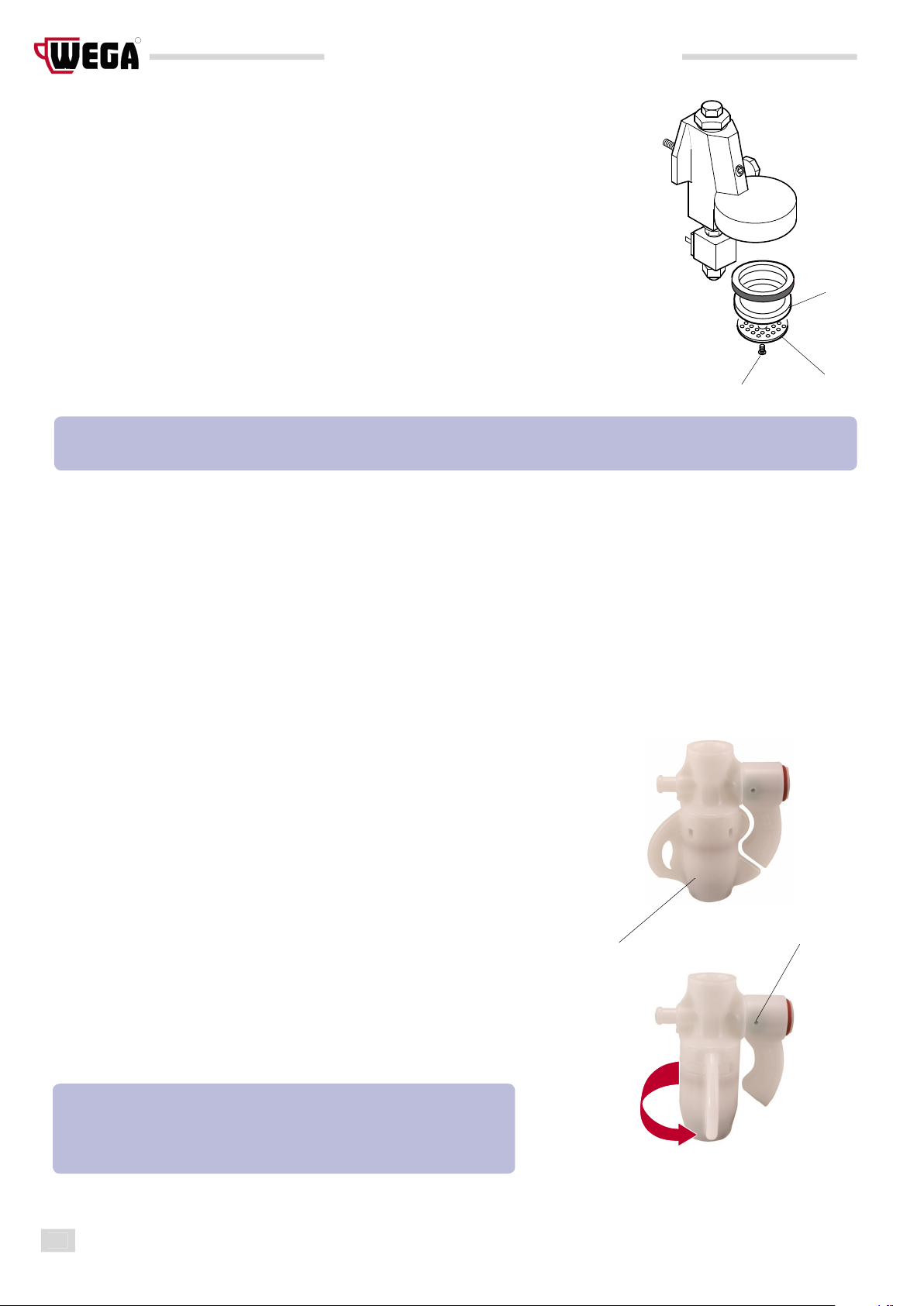

WARNING

Be sure to keep the cappuccino maker clean at all times as described

in the chapter “Cleaning”.

• Put the suction tube in the milk;

• place the pitcher under the spout of the cappuccino maker;

• turn the steam tap counter-clockwise. When the desired level is reached, close the steam tap;

• pour the foamed milk into the cups with the coffee.

NOTE

To obtain warm milk without foam, lift the tab (1) upwards. For best

results, we recommend not dispensing directly into the coffee cup,

but rather into a pitcher. From there, pour the foamed milk into the

coffee.

1

CAPPUCCINO position WARM MILK position

16. DISPENSING HOT WATER

17. CAPPUCCINO MAKER

19. CLEANING

For perfect cleaning and efficiency of the appliance, several simple cleaning operations are necessary on the functional parts and accessories

as well as the body panels.

The indications given here are applicable for normal use of the coffee machine. If the machine is heavily used then cleaning should be performed more frequently.

Filter and filter-holder

The filters and the relative filter-holders must be cleaned daily in hot water. The best thing to do is to

let them soak in hot water overnight so that the fatty coffee deposits can dissolve.

It is advisable to add an envelope or tablet of special detergent to the water, and then to rinse

everything off with water.

Failure to clean the filters and filter holders daily will compromise the quality of the coffee and will

also cause problems such as bad extraction and coffee grounds at the bottom of the cup.

Perforated disk and containment ring

Both the shower plate (4) and its containment ring (3) should be cleaned weekly in hot water. To

do this loosen the screw (5) and remove the two elements from the dispensing unit.

Steam nozzles

The steam pipes must be kept clean at all times. Check the ends of the steam nozzles and clean

them monthly, clearing out the exit holes with a small needle.

1

2

18. CUP HEATING DEVICE

The cup heating device is for heating cups before they are used.

• Place the cups on the upper surface

(1) of the coffee machine.

• Start the electric heating element with the switch

(2) or with the push

button panel (e.g. VENUS).

WARNING

For safety reasons we advise against putting cloths or other

objects on the upper surface of the machine as they could obstruct

normal air circulation.

Delivery groups (except for ALE version)

The cleaning of the internal parts of the delivery groups is to be performed weekly in the following

manner:

• replace the normal filter of the filter-holder with a solid one;

• pour a teaspoon of a suitable detergent powder on the solid filter, and attach the filter-holder

to the group;

• use the delivery switch to set the group in operation;

• repeat the above operations until the water comes out clean;

• turn off and remove the filter-holder from the group;

• rinse a final time, so as to remove any residual detergent.

WARNING

Do not use a solid fi lter to clean the machines with a lever group (ALE)

Body

The body panels should be cleaned with a cloth soaked in warm water. Do not use abrasive detergents since the panels could get scratched.

Grinder-doser

Every week clean the bell jar and the dosing device with a cloth soaked in lukewarm water, both inside and out

.

4

5

3

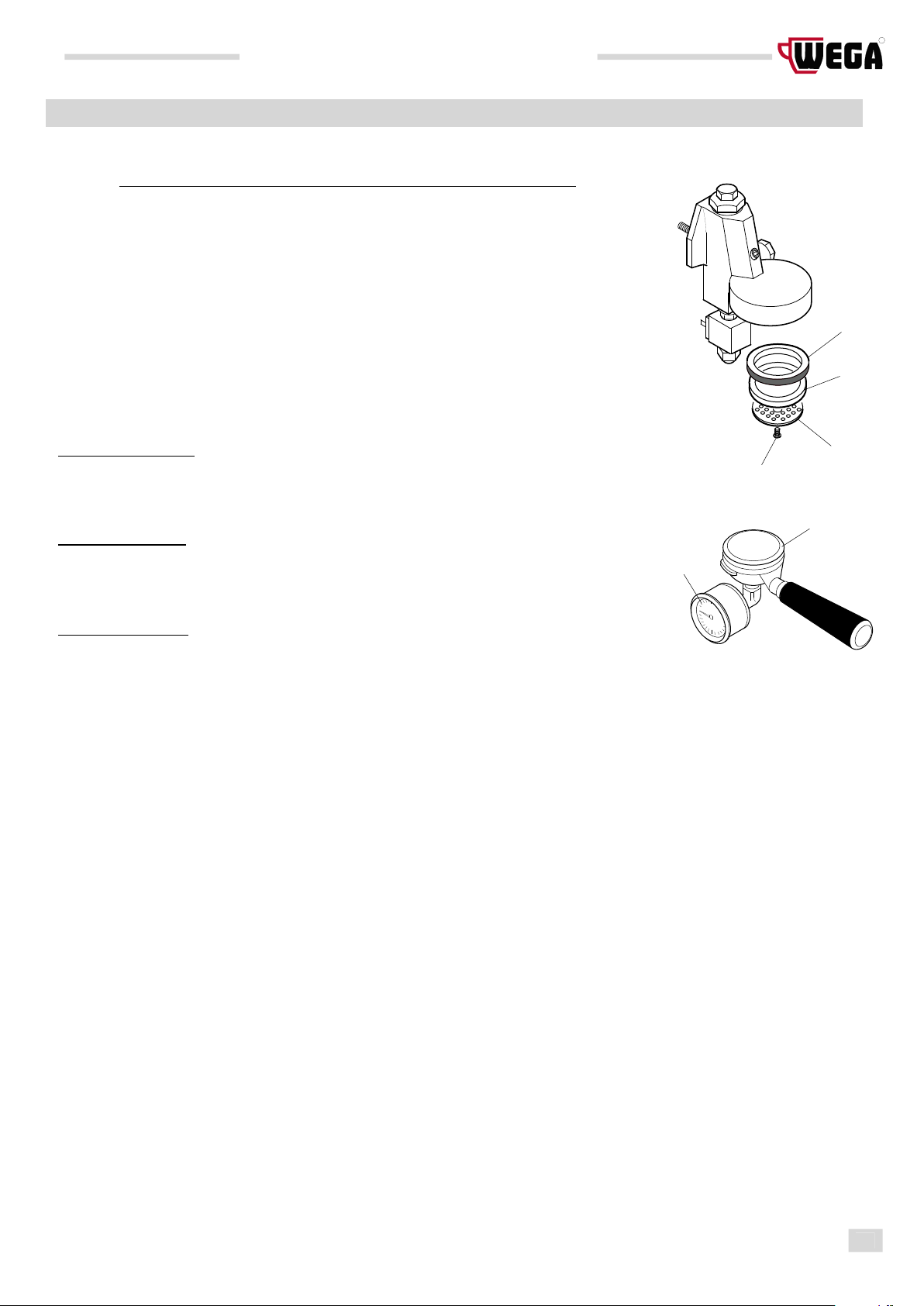

Cappuccinatore

Si raccomanda una par ticolare cura nella pulizia del cappuccinatore seguendo le

modalità qui riportate

:

• eseguire un primo lavaggio immergendo il tubo di aspirazione in acqua ed

effettuare una erogazione

per qualche secondo;

• ruotare il corpo rotante (1) di 90° in pos. B (chiusura del condotto di

fuoriuscita del latte);

• tenendo il tubo di aspirazione latte in aria, effettuare l’erogazione di vapore

(funzionamento a vuoto del cappuccinatore);

• attendere circa 20 secondi in modo da permettere la pulizia e sterilizzazione

interna del cappuccinatore

;

•

chiudere il vapore e riportare il corpo rotante in

pos. A

;

• nel caso di ostruzione del foro di prelievo dell’aria (2), liberatelo delicatamente con uno spillo.

ATTENZIONE

Si consiglia di effettuare la pulizia del cappuccinatore dopo ogni uso

continuativo in modo da evitare anomalie di funzionamento e garantire

un elevato grado di igienità del sistema.

2

1

pos. A

pos. B

negative pressure valve

- Turn the machine off;

-

by means of the steam valves, release all pressure in the boiler;

- turn the machine back on and check closure of the valve.

pressure limiting valve

- Lock the pressure switch contacts.

- wait for pressure in the boiler to rise and check for intervention

of the valve at a maximum pressure of 2 bar.

Non-return drain valve

- Activate the delivery groups for about 30 seconds;

- attach a filter holder

(5) with a gauge (available on request) to the delivery group;

- activate the delivery group, and use the gauge

(6) to monitor pressure increase up to 8-9 bar;

- check the increase of pressure due to the expansion of the heated water up to a value of approximately 12 bar: reaching this value

confirms proper operation of the valve and the seal of the gaskets and solenoid valves;

- de-activate the deliveries;

- repeat the control on the other delivery groups.

• Periodically check water pressure during coffee delivery. Check the pressure indicated on the gauge, which must be between 8 and 9 bar

inclusive.

• Monitor the boiler pressure value as explained in chapter 1, “Technical characteristics”.

• Periodically check the condition of the filters. Check for any damage on the edge of the filters and check whether any coffee grounds

settle in the coffee cup.

• At least once a year, check for proper operation of the gauge and pressure switch;

• At least once a year check for lime scale deposits on the heating element, on the exchanger (inside and out) and on the hydraulic circuit.

When replacing any components, always replace the relative gasket as well.

• At least once a year, check the condition of the solenoid valve of the delivery group.

• At least once a year check for trace water leaks on the counter. Also check the condition of the discharge tub and its connection to the

sewer system.

Grinder-doser

Periodically check the dose of ground coffee (inclusive between 6 and 7 gr. per stroke) and check the degree of grinding. The grinders

must always have sharp cutting edges. Their deterioration is indicated by the presence of too much powder in the grounds. It is advisable to

replace the grinders after every 400/500 kg of coffee.

Softener

The build-up of lime scale deposits in the hydraulic circuit of the machine indicates that regeneration has been neglected. Carry out maintenance of the boiler and of the hydraulic circuit, replacing any components as required.

Use care in areas where the water is very hard. It will be necessary to regenerate at more frequent intervals; likewise if there is high consumption of hot water for tea and so forth.

20. CHECKS AND MAINTENANCE

To ensure perfect safety and efficiency of the machine over time, it is necessary to carry out routine, preventive and special maintenance. In

particular, it is advisable to carry out an overall check of the machine at least once a year.

Machine

• Carry out cleaning as described in the previous chapter on a daily basis.

• Every four months replace the perforated disk

(2) and the undercup seal (4) of the delivery group

(use only original spare parts) proceeding as follows:

- loosen the screw

(1);

- remove the containment ring

(3);

- replace the group perforated disk

(2) and the rubber undercup seal (4);

- put the components back in place.

• At least once a year, check for proper operation of the negative pressure valve, pressure limiting valve

and non-return drain valve. In the event of malfunction they must be replaced. For the checks, proceed

as follows:

5

6

2

1

3

4

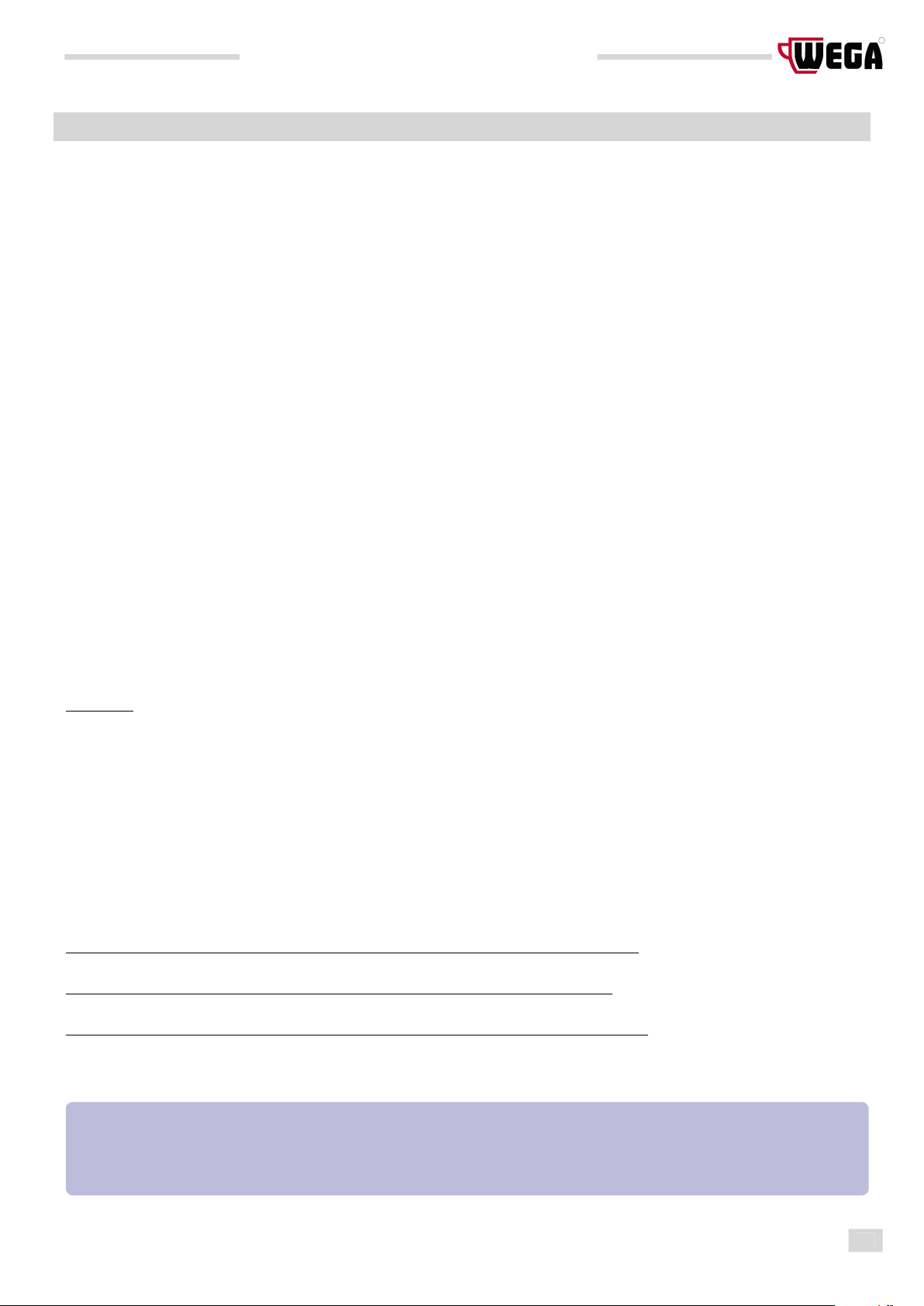

21. MALFUNCTIONS AND CORRESPONDING SOLUTIONS

Indication Cause Solution

NO POWER

TO MACHINE

1)

The machine commutator is in position “0” or “1”

2) The machine switch is defective

3) The mains power supply switch is in the OFF position

4) The connection to the electrical mains is defective

1) Replace the solenoid valve of the automatic level device

2) Replace the heat exchanger

3) Check the level probe, the earth of the

frame and the operation of the electronic control unit

NO WATER

IN BOILER

1) The water mains tap is closed

2) The cut-off tap of the automatic level device is in the

closed position

3) The pump filter is closed

4) The motor pump is disconnected or blocked

5) The water filling solenoid is defective

6)

The water inlet solenoid valve filter is clogged

1) Open the water mains tap

2) Open the automatic level device tap

3) Replace the pump filter

4) Check the motor pump

5) Replace the water filling solenoid valve

6) Clean or replace the filter of the solenoid valve

EXCESSIVE WATER

IN BOILER

1) The solenoid of the automatic level device is defective

2) The heat exchanger is perforated

3) The manual valve remains inser ted

1) Turn the machine commutator to position “2”

2) Replace the main switch

3) Place the mains switch in the ON position

4) Check for any defective connections

STEAM DOES NOT COME

OUT OF NOZZLES

1) The electrical heating element is defective

2) The pressure switch contacts are oxidized

3) The heating element protection thermostat has cut in

4) The nozzle sprayer is clogged

5) Machine switch in position “1”

1) Replace the electrical heating element

2) Clean the contacts or replace the pressure switch

3) Reset the heating element protection

4) Clean the steam nozzle sprayer

5) Turn the machine switch to position “2”

STEAM MIXED WITH WATER

COMES OUT OF

THE NOZZLES

1)The boiler level is too high 1) Check the status of the level probe:

verify correct position and check for

presence of any surface lime scale

NO DELIVERY

1) No water mains

2) Group solenoid valve is defective

3) The pump is blocked

4) The control unit fuse is burned out

5) The injector is clogged

6)

The group solenoid valve is clogged or dirty

7) The group filter is clogged

8) The volumetric dosing device is blocked

1) Check that there is water in the mains

2) Replace the group solenoid valve

3) Replace the pump

4)

Replace the solenoid valve protection fuse (1A)

5) Clean or replace the injector

6) Clean or replace the solenoid valve

7) Clean or replace the filter

8) Check/replace the dosing device

WATER LEAKS

FROM THE MACHINE

1) The tub does not drain

2) The drain tube is detached or broken or has

obstruction to water flow

3) Hydraulic leaks in the hydraulic circuit

1) Check the sewer drain

2) Check and restore the connection of the

drain tube to the tub

3) Identify and eliminate hydraulic leaks

COFFEE IS

TOO COLD

1) The electrical heating element is defective

2) The electrical connection is defective

3) Lime scale on the exchangers and/or heating element

4) The pressure switch contacts are oxidized

5) The heating element protection thermostat has cut in

6) Machine switch in position “1”

7) The lime scale has reduced the

circulation of water

8) The delivery group is cold

1) Replace the electrical heating element

2) Check for any defective connections

3) Clean the machine

4) Clean the contacts or replace the pressure switch

5) Reset the heating element protection

6) Turn the machine switch to position “2”

7) Clean the connections of the exchanger, and clean or

replace the two circulation tubes

8) Eliminate air pockets in the

hydraulic circuit in the following manner:

- disconnect the electrical power supply to the pump

- close the water tap of the softener

-

perform a dry run of delivery for a few minutes

- reconnect the electrical power supply to the pump

- open the water outlet tap of the softener

- perform delivery until water comes out

- wait a few minutes for heating

COFFEE IS

TOO HOT

Indication Cause Solution

1) Boiler temperature is too high

2) The flow reducer of the group is not suitable

1) Reduce pressure in the boiler by turning the appropriate screw

on the pressure switch

2) Replace the injector with one of a smaller diameter

DELIVERY

OF COFFEE

IS TOO FAST

1) The coffee is ground too coarsely

2) The diameter of the injector is too large

3) Boiler temperature is too high

1) Adjust the grinding of the coffee

2) Replace the injector with one of a smaller diameter

3) Reduce pressure in boiler

1) Coffee is ground too finely

2) The injector is clogged

3) The delivery group is clogged

4) The filter holder is dirty

1) Adjust the grinding of the coffee

2) Replace the injector

3) Check and clean the delivery group

4) Clean and if necessary replace the filters

COFFEE GROUNDS ARE

WET

1) The group solenoid valve discharge is clogged

2) The delivery group is too cold

3) Coffee is ground too finely

1) Clean the group drain

2) Wait for group to heat up completely

3) Adjust the grinding of the coffee

GROUNDS

IN CUP

1) The gauge is defective

2) Incorrect pressure switch calibration.

3) Incorrect motor pump calibration.

1) Replace the gauge

2) Adjust the calibration of the pressure switch

3) Adjust the calibration of the motor pump

THE GAUGE SHOWS AN

UNACCEPTABLE

PRESSURE

1) The filter holder is dirty

2) The filter holes are worn

3) The coffee is not ground evenly

4) The undercup seal is worn

5)

The temperature of the delivery water is high

1) Clean the filter holder

2) Replace the filter

3) Replace the grinders

4) Change the seal

5) Check the causes and eliminate the problem

for EVD:

COFFEE DELIVERY

ONLY BY MEANS OF

MANUAL KEY

1) The control unit fuse is burned out

2) The coil of the solenoid valve does not work

correctly or has shor ted out

1) Check for proper connection of the

volumetric dosing device connector

2) Check for proper connection of the

8-pole connector of the electronic control unit

3)

Remove the connector of the volumetric dosing device

and thoroughly dry the contacts

4) Replace the heads of the volumetric dosing device

or replace the dosing device

5) Adjust the grinding suitably

and if necessary check the grinders

6) Check and if necessary replace the

non-return valve

7) Check and if necessary replace the

drain valves

8) Clean and if necessary replace

the solenoid valve

9) Clean or replace the volumetric dosing device

for EVD:

INCORRECT

COFFEE DELIVERY

THE COFFEE DOSE IS NOT

MET

THE LED OF THE

DOSE PUSH BUTTON

FLASHES

1) The connection of the volumetric dosing device

is defective

2) The connection of the electronic control unit

is defective

3) The connector of the volumetric dosing device

has humidity on it

4) The volumetric dosing device is defective: during

delivery the dosing device LED does not flash

5) The coffee is ground too finely: there is not

sufficient water flow in the dosing device

6) The non-return valve loses pressures

(the dose is too small)

7) The drain valves lose pressure

(the dose is too small)

8) Water leakage from the group solenoid valve during

coffee delivery or when at rest

9) The volumetric dosing device is partially obstructed

for EVD:

ALL THE LED OF ALL THE

PUSH BUTTON PANELS

FLASH

for EPU-EVDT:

THE FRONT LED

FLASHES

After a few minutes, automatic filling with water is stopped:

1) Time control device has cut in

2) No water in mains

3) The tap for the automatic level device is closed

4) Some of the tubes in the circuit are clogged

5) The probe and/or the earth are disconnected

1) Turn the machine off and then back on

2) Open the water mains tap

3) Open the automatic level device tap

4) Check and replace the defective tubes

5) Check and restore connections

1) Replace the control unit fuse (1A)

2) Replace the coil of the solenoid valve

DELIVERY

OF COFFEE

TOO SLOW

THE PUMP WORKS ONLY

WITH THE MANUAL DELIVERY KEY

Indication Cause Solution

1) The pump fuse of the electronic control unit

is burned out

1) Replace pump fuse of the electronic control

unit (10 A)

SHUTDOWN OF

ELECTRONIC

SYSTEM

1) The control unit fuse is burned out

2) The volumetric dosing device has a contact

of the positive pole to the earth

1) Replace the main fuse (125 mA)

2) Check for proper connection of the volumetric

dosing device

THE PUMP

LEAKS WATER

1) Poor mechanical seal of the shaft or

of the O-ring

2) The inlet and outlet connections are loose

3) The hex nut of the pressure relief valve

or of the filter are loose

4)

The gasket or the O-ring of the pressure relief valve

or of the filter are defective.

1) Check the status of the pump

and take any corrective action which may be required

2) Tighten the connections

3) Tighten the hex connection of the modulating

valve and of the filter

4)

Replace the gasket and the O-ring. Take care

not to change the calibration of the valve

THE PUMP FUNCTIONS

BELOW THE NOMINAL

CAPACITY

1) The inlet is clogged, perhaps only partially

2) The pump rotates in the wrong direction.

3) The pressure relief valve is not properly calibrated

4) The motor runs at low RPM

5) The inside of the pump is damaged

due to the infiltration of foreign bodies

1) Clean the filter holder

2) Check the motor

3) Calibrate the pressure relief valve

4) Check the voltage or replace the motor

5) Replace the pump

1) The pump and the engine are not aligned.

2) The gasket or the O-ring of the pressure relief valve

or of the filter are defective.

3) The joint, the coupling screw or the

V-shaped clamp are loose.

4) The inlet is clogged, perhaps only partially

5) The hex nut of the pressure relief valve

or of the filter is loose

1) Install the pump-motor joint

2)

Replace the gasket and the O-ring. Take care

not to change the calibration of the valve

3) Align and tighten the components which are

loose

4) Clean the filter holder

5) Tighten the hex connection of the pressure relief

valve and of the filter

THE MOTOR STOPS

SUDDENLY OR

THE THERMAL PROTECTION

CUTS IN DUE TO

AN OVERLOAD

1) Lime scale and mineral build-ups in the

pump have caused it to jam

2) The pump and the engine are not aligned.

3) The motor is defective

4) The motor is connected with a voltage that

is not correct

1) Check the status of the pump

and if necessary replace it

2) Install the pump-motor joint

3) Replace the motor

4) Ascertain that the power supply voltage

of the motor is the right one

THE PUMP

IS NOISY

1) Steam pockets in the delivery system

2) Air pockets in the hydraulic circuit

3) Coffee is ground too finely

4) The flow reducer of the group is not suitable

1) Reduce water temperature

2) Check the cause and eliminate the problem

3) Adjust the grinding suitably

4) Replace the flow reducer

THE CUP IS

DIRTIED BY

SPLASHES OF COFFEE

22. LIST OF HAZARDS

This chapter describes possible hazards for the user if the specific safety standards described in this booklet are not adhered to.

The appliance must be connected to an efficient grounding system

If this is not done, the appliance can be a source of dangerous electrical discharges in that it is no longer able to discharge electricty to

earth.

Do not use running water to wash

The use of pressurized water directly on the machine can seriously damage electrical appliances. Never use water jets to wash any part of

the appliance.

Be careful with the steam nozzles and hot water

During use, the steam nozzles and hot water may overheat, thus becoming a source of danger. Handle such parts carefully. Never direct

steam or hot water jets directly on parts of the body.

Do not intervene on the machine when it is supplied with electrical power.

Before carrying out any intervention on the machine you must turn it off by means of the main network switch or better yet, disconnecting the

connection terminals in the network. Never remove any body panel when the machine is supplied with electrical power.

Never work on the hydraulic system before having emptied it.

All work regarding the hydraulic system and the relative boiler are to be avoided when there is still water and pressure in the system. You

must therefore empty it beforehand, closing the mains cock and dry-running the delivery group for a shor t time. Switch off the machine and

open all the steam and water cocks and taps. With the pressure zero, completely empty the boiler, unscrewing the special pipe fitting situated

on the lower part of it.

If the above procedure is not correctly carried out, opening any part of the hydraulic system can cause a sudden outlet of overheated water

under pressure.

Lever machines

Never lower the lever if there is no coffee in the filter, or if the filter holder is not installed on the group: the sudden upwards movement of the

lever may damage the appliance and injure individuals.

Gas machines

Periodically check for gas leaks in the system by applying a soapy solution to the ducts.

For safety reasons, close the gas heating system when the machine is not in use (at night or during hours of closure)

Use of the appliance

This espresso coffee machine is an appliance exclusively for professional use. Any other type of use is considered wrong and therefore dangerous. Never allow children or incapable persons to use the machine.

Non-observance of the above-described standards can cause serious damage to people or animals

.

Never work on the electronic apparatus when the machine is still supplied with electrical energy.

Shut down the machine completely by unplugging it from the mains before carrying out any operation.

WARNING

Any action taken by a technician on the electronics of the machine when the machine is still supplied with electrical power

automatically invalidates any guarantee.

The technician needs to be aware that the machine is electrically connected and act accordingly.

Loading...

Loading...