WEG WGM20 Installation, Operation & Manintenance Manual

Motors I Automation I Energy I Transmission & Distribution I Coatings

Three phase induction motors

cooled by water jacket

WGM20 line - Squirrel cage rotor

Horizontal and Vertical

Installation, Operation and Maintenance Manual

Installation, Operation and Maintenance Manual

Document Number: 10005256831

Material number: 14108242

Model: WGM20

Language: English

Revision: 01

March 2018

www.weg.net

Dear Customer,

Thank you for purchasing a WEG motor. Our products are developed with the highest standards of

quality and efficiency which ensures outstanding performance.

Since electric motors play a major role in the comfort and well-being of mankind, it must be identified

and treated as a driving machine with characteristics that involve specific care, such as proper

storage, installation and maintenance

All efforts have been made to ensure that the information contained in this manual is faithful to the

configurations and applications of the motor.

Therefore, we recommend that you read this manual carefully before proceeding with the installation,

operation or maintenance of the motor in order to ensure safe and reliable operation of your

equipment and facility. If you need any further information, please contact WEG.

Always keep this manual close to the motor, so that it can be consulted whenever necessary.

ATTENTION

1. It is imperative to follow the procedures contained in this manual for the warranty to be valid;

2. The motor installation, operation and maintenance procedures must be performed only by qualified

personnel.

NOTES

1. The total or partial reproduction of information supplied in this manual is authorized, provided that

reference is made to its source. If this manual is lost, an electronic PDF file is available at www.weg.net

or another printed copy may be requested.

WEG EQUIPAMENTOS ELÉTRICOS S.A.

14108242 Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line l 5

TABLE OF CONTENTS

www.weg.net

1 INTRODUCTION ............................................................................................... 11

1.1 SAFETY WARNINGS IN THE MANUAL ........................................................................................... 11

2 GENERAL INSTRUCTIONS ............................................................................... 12

2.1 QUALIFIED PERSONNEL ................................................................................................................ 12

2.2 SAFETY INSTRUCTIONS ................................................................................................................ 12

2.3 STANDARDS ................................................................................................................................... 12

2.4 ENVIRONMENTAL CONDITIONS .................................................................................................... 13

2.5 OPERATING CONDITIONS ............................................................................................................. 13

2.6 VOLTAGE AND FREQUENCY ......................................................................................................... 13

3 RECEIVING, HANDLING AND STORAGE ........................................................... 14

3.1 RECEIVING ..................................................................................................................................... 14

3.2 HANDLING ...................................................................................................................................... 14

3.2.1 Horizontal motor handling ................................................................................................................... 14

3.2.2 Vertical motor handling ....................................................................................................................... 15

3.2.3 Vertical motor positioning .................................................................................................................... 15

3.3 STORAGE ....................................................................................................................................... 15

3.3.1 Outdoor storage ................................................................................................................................. 15

3.3.2 Long term storage .............................................................................................................................. 15

3.3.2.1 Storage location .................................................................................................................. 16

3.3.2.1.1 Indoor storage ................................................................................................ 16

3.3.2.1.2 Outdoor storage ............................................................................................. 16

3.3.2.2 Separate parts .................................................................................................................... 16

3.3.3 Preservation during the storage ........................................................................................................... 16

3.3.3.1 Cooling system ................................................................................................................... 16

3.3.3.2 Space heater ....................................................................................................................... 16

3.3.3.3 Insulation resistance ............................................................................................................ 17

3.3.3.4 Exposed machined surfaces ................................................................................................ 17

3.3.3.5 Sealing ................................................................................................................................ 17

3.3.3.6 Bearings .............................................................................................................................. 17

3.3.3.7 Terminal boxes .................................................................................................................... 17

3.3.3.8 Cleanliness and conservation of the motor during storage ................................................... 17

3.3.3.9 Inspections and records during storage ............................................................................... 17

3.3.3.10 Predictive/preventive maintenance....................................................................................... 17

3.3.3.11 Maintenance plan during storage ......................................................................................... 18

3.3.4 Preparation for commissioning ............................................................................................................ 18

3.3.4.1 Cleaning .............................................................................................................................. 18

3.3.4.2 Bearing lubrication ............................................................................................................... 18

3.3.4.3 Insulation resistance verification ........................................................................................... 18

3.3.4.4 Cooling system ................................................................................................................... 18

3.3.4.5 Others ................................................................................................................................. 18

4 INSTALLATION ................................................................................................. 19

4.1 INSTALLATION SITE ....................................................................................................................... 19

4.2 SHAFT LOCK .................................................................................................................................. 19

4.3 ROTATION DIRECTION ................................................................................................................... 19

4.4 INSULATION RESISTANCE ............................................................................................................. 19

4.4.1 Safety Instructions .............................................................................................................................. 19

4.4.2 General considerations ....................................................................................................................... 19

4.4.3 Measurement on the stator windings................................................................................................... 19

4.4.4 Additional Information ......................................................................................................................... 20

4.4.5 Polarization Index ................................................................................................................................ 20

4.4.6 Conversion of the measured values ..................................................................................................... 20

4.4.7 Insulation assessment ......................................................................................................................... 20

4.5 PROTECTIONS ............................................................................................................................... 21

4.5.1 Thermal protections ............................................................................................................................ 21

4.5.2 Temperature limits for the windings ..................................................................................................... 21

4.5.3 Alarm and trip temperatures ................................................................................................................ 21

4.5.4 Installation of temperature sensors ...................................................................................................... 22

4.5.5 Temperature and ohmic resistance of the PT100 thermoresistance ..................................................... 23

4.5.6 Space heater ...................................................................................................................................... 23

4.5.7 Water leak sensor ............................................................................................................................... 23

14108242 Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line l 7

www.weg.net

4.5.8 Water temperature sensor ...................................................................................................................23

4.6 COOLING ....................................................................................................................................... 24

4.6.1 Cooling system ...................................................................................................................................24

4.6.1.1 Cooling system characteristics ........................................................................................... 24

4.6.1.2 Cooling water characteristics .............................................................................................. 24

4.6.1.3 Cooling water temperature ................................................................................................. 24

4.6.1.4 Protective devices .............................................................................................................. 24

4.7 ELECTRICAL ASPECTS ................................................................................................................. 25

4.7.1 Electrical connections .........................................................................................................................25

4.7.1.1 Main electrical connections ................................................................................................. 25

4.7.1.2 Grounding .......................................................................................................................... 25

4.7.2 Connection diagram ............................................................................................................................25

4.7.3 Accessories connection diagram .........................................................................................................25

4.8 MECHANICAL ASPECTS ............................................................................................................... 25

4.8.1 Base ...................................................................................................................................................25

4.8.2 Base loads ..........................................................................................................................................26

4.8.3 Base types ..........................................................................................................................................26

4.8.3.1 Concrete base .................................................................................................................... 26

4.8.3.2 Sliding base ........................................................................................................................ 26

4.8.3.3 Metal base ......................................................................................................................... 26

4.8.3.4 Anchor bolts ....................................................................................................................... 26

4.8.4 Natural frequency of the base ..............................................................................................................26

4.8.5 Leveling ..............................................................................................................................................27

4.8.6 Alignment ............................................................................................................................................27

4.8.7 Doweling .............................................................................................................................................28

4.8.8 Couplings ...........................................................................................................................................28

4.8.8.1 Direct coupling ................................................................................................................... 28

4.8.8.2 Gear coupling ..................................................................................................................... 28

4.8.8.3 Belt drive ............................................................................................................................ 28

5 STARTING ........................................................................................................ 30

5.1 DIRECT ON-LINE STARTING ......................................................................................................... 30

5.2 DIRECT ONLINE STARTING FREQUENCY ..................................................................................... 30

5.3 LOCKED ROTOR CURRENT .......................................................................................................... 30

5.4 STARTING WITH REDUCED CURRENT ......................................................................................... 30

6 COMMISSIONING ............................................................................................. 31

6.1 PRELIMINARY INSPECTION .......................................................................................................... 31

6.2 FIRST STARTING ........................................................................................................................... 31

6.3 OPERATION ................................................................................................................................... 31

6.3.1 General ...............................................................................................................................................31

6.3.2 Temperatures......................................................................................................................................32

6.3.3 Bearings .............................................................................................................................................32

6.3.4 Cooling system ...................................................................................................................................32

6.3.5 Vibration .............................................................................................................................................32

6.3.6 Shutdown ...........................................................................................................................................32

7 MAINTENANCE ................................................................................................. 33

7.1 GENERAL ....................................................................................................................................... 33

7.2 GENERAL CLEANING .................................................................................................................... 33

7.3 WINDING INSPECTIONS ................................................................................................................ 33

7.4 WINDING CLEANING ..................................................................................................................... 33

7.4.1 Inspections .........................................................................................................................................33

7.4.2 Reimpregnation ...................................................................................................................................34

7.4.3 Insulation Resistance ...........................................................................................................................34

7.5 COOLING SYSTEM MAINTENANCE .............................................................................................. 34

7.5.1 Cleaning..............................................................................................................................................34

7.5.1.1 Motor end shield disassembly ............................................................................................. 34

7.5.1.2 Cooling heads disassembly ................................................................................................ 35

7.5.1.3 Inspection and cleaning of water channels .......................................................................... 35

7.5.1.4 End shields and cooling heads assembly ............................................................................ 35

7.6 VIBRATION ..................................................................................................................................... 35

7.7 MOTOR OUT OF OPERATION ....................................................................................................... 35

7.8 SHAFT GROUNDING DEVICE ........................................................................................................ 35

7.9 ENCODER MAINTENANCE ............................................................................................................ 36

8 l Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line 14108242

www.weg.net

7.10 BEARING MAINTENANCE .............................................................................................................. 36

7.10.1 Bearing data ....................................................................................................................................... 36

7.10.2 Instructions for lubrication ................................................................................................................... 36

7.10.3 Procedures for bearing lubrication ....................................................................................................... 36

7.10.4 Type and amount of grease ................................................................................................................ 37

7.10.5 Alternative greases .............................................................................................................................. 37

7.10.6 Procedure for changing the grease ..................................................................................................... 37

7.10.7 Low temperature greases ................................................................................................................... 38

7.10.8 Grease compatibility ........................................................................................................................... 38

7.10.9 Bearing disassembly ........................................................................................................................... 38

7.10.9.1 DE horizontal bearing disassembly ...................................................................................... 39

7.10.9.2 NDE horizontal bearing disassembly .................................................................................... 39

7.10.9.3 DE vertical bearing disassembly .......................................................................................... 40

7.10.9.4 NDE vertical bearing disassembly ........................................................................................ 40

7.10.9.5 Bearing assembly ................................................................................................................ 41

7.10.9.6 Bearing insulation ................................................................................................................ 41

7.10.10Rolling bearing replacement ................................................................................................................ 41

7.10.11Bearing protection .............................................................................................................................. 41

7.10.11.1 Protection settings .............................................................................................................. 41

7.11 ACCESSORIES MAINTENANCE ....................................................................................................... 42

8 MOTOR DISASSEMBLY AND ASSEMBLY .......................................................... 43

8.1 HORIZONTAL MOTORS.................................................................................................................. 43

8.1.1 Disassembly ....................................................................................................................................... 43

8.1.2 Assembly ............................................................................................................................................ 43

8.2 VERTICAL MOTORS ....................................................................................................................... 44

8.2.1 Disassembly ....................................................................................................................................... 44

8.2.2 Assembly ............................................................................................................................................ 44

8.3 AIR-GAP MEASUREMENT .............................................................................................................. 45

8.4 TIGHTENING TORQUE ................................................................................................................... 45

8.5 SPARE PARTS ................................................................................................................................ 45

8.5.1 Necessary spare parts ........................................................................................................................ 45

8.5.2 Optional spare parts ........................................................................................................................... 45

9 MAINTENANCE PLAN ....................................................................................... 46

10 ABNORMALITIES, CAUSES AND SOLUTIONS ................................................... 47

11 ENVIRONMENTAL INFORMATION ..................................................................... 48

11.1 PACKAGE ....................................................................................................................................... 48

11.2 PRODUCT ....................................................................................................................................... 48

11.3 HAZARDOUS WASTE ..................................................................................................................... 48

12 DECLARATION OF CONFORMITY ..................................................................... 49

13 SERVICE NETWORK ........................................................................................ 50

14 WARRANTY TERM ........................................................................................... 50

14108242 Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line l 9

www.weg.net

1 INTRODUCTION

This manual contains information regarding low and high-voltage, three-phase induction motors.

Motors with special features can be supplied with specific documents (drawings, connection diagram, characteristic curves

etc.). Those documents, together with this manual, must be thoroughly evaluated before proceeding with the installation,

operation or maintenance of the motor.

In order to use a frequency inverter, it is mandatory to follow the instructions contained in the specific technical

documentation of the motor and in the manual of the frequency inverter.

If any additional explanation about motors with major special features is necessary, consult WEG. All procedures and

standards contained in this manual must be observed in order to ensure proper operation of the motor and the safety of the

personnel involved in its operation. Following these procedures is also important to ensure the validity of the motor warranty.

Thus, we recommend the careful reading of this manual before the installation and operation of the motor. If any further

information is still necessary, consult WEG.

1.1 SAFETY WARNINGS IN THE MANUAL

In this manual, the following safety warnings are used:

DANGER

Failure to observe the procedures recommend in this warning may result in death, serious injuries and

extensive equipment damage.

ATTENTION

Failure to observe the procedures recommend in this warning may result in equipment damage.

NOTE

This provides important information for correct understanding and proper operation of the product.

14108242 Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line l 11

www.weg.net

Thus, the operation with open terminal

ATTENTION

ATTENTION

IEC60034

-1

MG1

-

IEC60072

IEC60034

-2

Levels of

IEC60034

-6

IEC60034

-7

IEC60034

-9

Mechanical

IEC60034

-

14

Mechanical

2 GENERAL INSTRUCTIONS

All the personnel involved with the assembly, operation or maintenance of electrical installations must be permanently

informed and updated on the standards and safety instructions that guide the job and are advised to strictly comply with

them. Before beginning any job, the person in charge must make sure that all points have been duly observed and warn the

respective personnel about the danger inherent to the task to be performed.

Improper application, inadequate handled or maintenance of the generator, may cause serious injuries and/or material

damages.

Therefore, it is highly recommended that these services be always performed by qualified personnel.

2.1 QUALIFIED PERSONNEL

The term qualified personnel means those who, because

of their training, experience, education level, and

knowledge of the applicable standards, specifications,

accident prevention, safety standards and operating

conditions, have been authorized by the persons in charge

to execute the necessary tasks, and who are able to

recognize and avoid any possible danger.

Such qualified personnel must also know and be able to

provide first aid procedures if necessary.

The entire start-up, maintenance and repair tasks must

only be performed by qualified personnel.

2.2 SAFETY INSTRUCTIONS

DANGER

During normal operation of this equipment, a

hazard associated with energized or rotating

components with high voltage or elevated

temperatures exists.

boxes, unprotected couplings, improper

handling, or failure to comply with the

operating standards, may cause severe

personal injuries and material damages.

When devices and equipment are used

outside the industrial environment, the user

must ensure the safety of the equipment by

adopting proper protection and safety

measures during installation (for example,

keep people away, avoid contact of children,

etc.).

Those responsible for the safety of the installation must

ensure that:

Only qualified personnel install and operate the

equipment;

They have this manual and all other documents

supplied with the motor at hand, as well as that they

perform the tasks in strict compliance with the service

instructions, relevant standards and specific product

documentation;

Failure to comply with installation and safety

standards may void the product warranty.

Firefighting equipment and first aid notices

must be available in visible and easily

accessible locations at the work site.

You should also note:

All the technical data regarding the allowed applications

(operating conditions, connections and installation

environment), included in the catalog, in the purchase

order documents, in the operating instructions, in

manuals and all other documentation;

The specific regulations and conditions for the local

installation;

The use of suitable tools and equipment for handling

and transportation;

That the protective devices of the individual

components are removed shortly before installation.

Individual parts must be stored in vibration-free

environments, avoiding falls and ensuring their protection

against aggressive agents and/or that they do not

jeopardize people.

2.3 STANDARDS

The motors are specified, designed, manufactured and

tested according to the standards described in Table 2.1.

The applicable standards are specified in the commercial

contract, which may indicate other national or international

standards, depending on the application or installation

location.

Specification

Dimensions

Terminal marking

Tolerances

Table 2.1: Applicable standards

Tests

protection

Cooling

Mounting

Noise

Vibration

Balancing ISO1940 MG1-7

IEC / NBR NEMA

NBR 17094

NBR 15623

NBR 5383

IEC60034-5

NBR IEC 60034-5

NBR IEC 60034-6

NBR IEC 60034-7

NBR IEC 60034-9

NBR IEC 60034-14

IEC60034-8 / NBR 15367 MG1-2

ISO286 / NBR6158 MG1-4

1,10,20

MG1-4,11

MG1-12

MG1-5

MG1-6

MG1-4

MG1-9

MG1-7

12 l Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line 14108242

2.4 ENVIRONMENTAL CONDITIONS

ATTENTION

°C, antifreeze

The motor was designed according to the specific

environmental conditions (temperature and altitude) of

your application, and are described on the nameplate and

in the datasheet of the motor.

For the use of water-cooled motors in

ambient temperatures below +5

additives must be added to the water.

2.5 OPERATING CONDITIONS

In order for the product warranty to be valid, the motor

must be operated according to nominal data indicated on

its nameplate, observing all applicable standards and

information contained in this manual.

www.weg.net

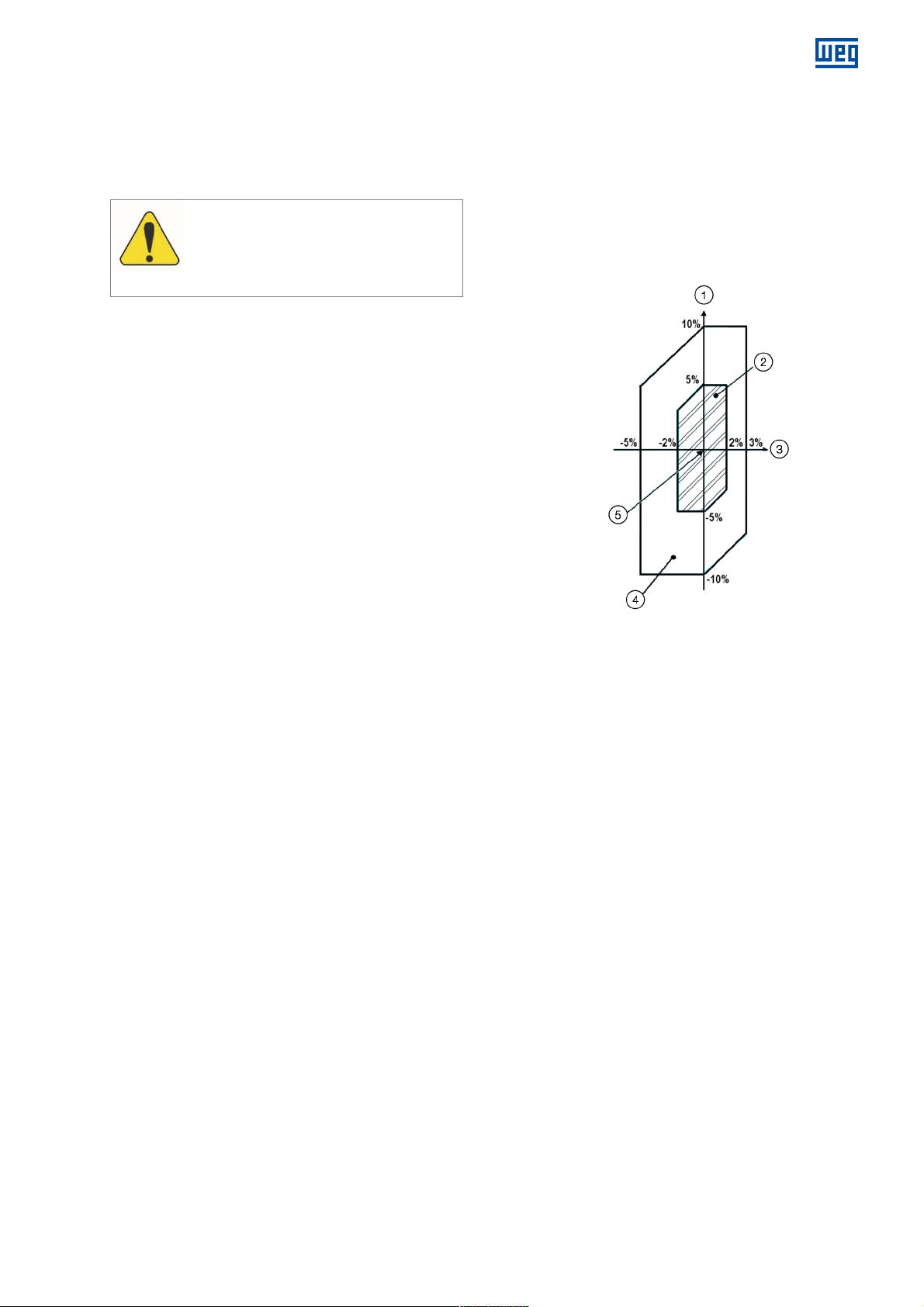

2.6 VOLTAGE AND FREQUENCY

It is very important to ensure a proper power supply for

the motor. The conductors and the entire protection

system must ensure the quality of the power supply at the

motor terminals within the limits, in accordance with the

IEC60034-1 standard:

Voltage: may vary within a range of ±10% of the rated

value;

Frequency: may vary within a range of -5% to +3% of

the rated value.

Figure 2.1: Voltage and frequency variation limits

Figure 2.1 legend:

1. Voltage

2. Zone A

3. Frequency

4. Zone B (outside zone A)

5. Voltage with rated characteristics

The motor must be able to perform its main function

continuously in Zone A, but it may not fully meet its

performance characteristics at rated voltage and

frequency (refer to the point with rated characteristics in

Figure 2.1), when it may present some deviations. The

temperature rises may be above those at rated voltage

and frequency.

The motor must be able to perform its main function in

Zone B, but regarding the performance characteristics at

rated voltage and frequency, it may present deviations

greater than those of Zone A. The temperature rises may

be higher than those observed at rated voltage and

frequency, and they will most likely be higher than those in

Zone A.

Prolonged operation in the periphery of Zone B is not

recommended.

14108242 Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line l 13

www.weg.net

ATTENTION

Any damage must be photographed,

documented and reported immediately to the

ATTENTION

ATTENTION

or transport the motor, the

must be able

lifting

LIFTING LUGS

3 RECEIVING, HANDLING AND STORAGE

3.1 RECEIVING

All motors were tested and are in perfect operating

conditions. The machined surfaces are protected against

corrosion. The package must be inspected upon receipt

for occasional damages during transportation.

carrier, the insurer and WEG. The noncommunication of this damage will void the

warranty.

Parts supplied in additional packages must be

checked upon receipt.

When lifting the package (or container), the proper

hoisting points, the weight indicated on the package or

on the nameplate and the operating capacity and

conditions of the hoisting equipment must be observed;

Motors packed in wooden crates must always be lifted

by their own lifting lugs or by a proper forklift; they must

never be lifted by the package;

The package can never be overturned. Place it on the

floor carefully (without impact) in order to avoid damage

to the bearing;

Do not remove the grease for protection against

corrosion from the shaft end, or the closing plugs

present in the terminal box holes. These protections

must remain in place until the moment of the final

assembly.

A complete visual inspection of the motor must be

arried out after removing the package;

c

The shaft locking system must be removed just before

the installation and stored to be used in future

transportation of the motor.

3.2 HANDLING

In order to move

shaft must be locked with the locking

device supplied with the motor.

Lifting equipment and devices

to withstand the motor weight.

Failure to comply with these

recommendations may cause damage to the

equipment, personal injuries or both.

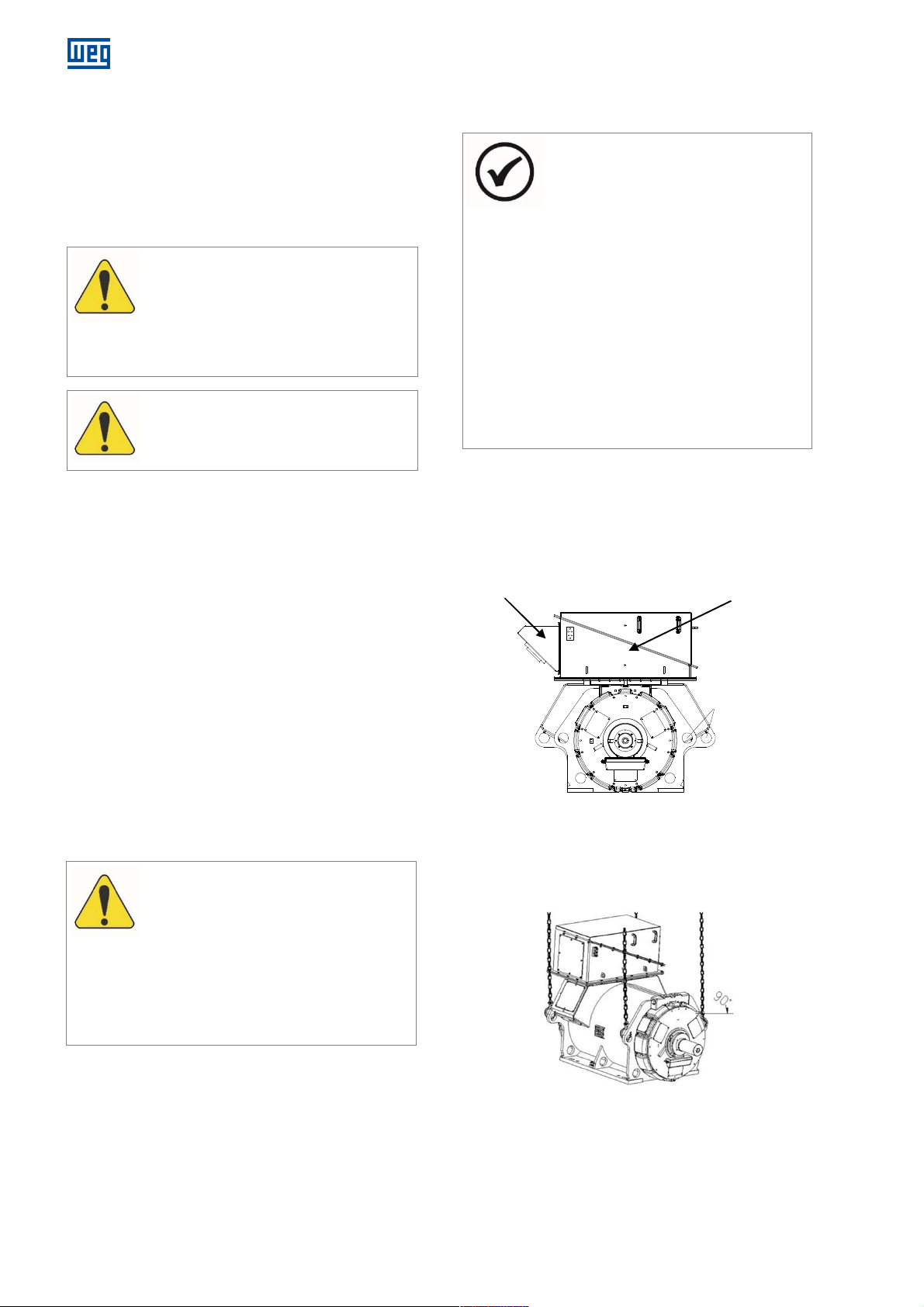

3.2.1 Horizontal motor handling

Horizontal motors must be handled as shown in Figure

3.2.

In order to lift the motor, use only the lifting lugs provided

for that purpose.

CABLES GUIDE TERMINAL BOX

Remove the cable guide and lift the motor, as shown in

Figure 3.2.

NOTES

Observe the indicated weight. Do not lift

the motor causing jolts or put it down

abruptly on the floor, because this may

cause damage to the bearings;

In order to lift the motor, use only the

lugs provided for that purpose. If

necessary, use a crossbeam to protect

parts of the motor.

The lifting lugs on the heat exchanger, end

shields, bearings, radiator, terminal box,

etc. are designed to handle these

components only separately;

Never use the shaft to lift the motor;

The frame lifting lugs are intended to lift

nly the motor. Never use them to lift the

o

motor-driven machine set.

Figure 3.1: Horizontal motor handling

14 l Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line 14108242

Figure 3.2: Motor handling

ATTENTION

recommendations may cause damage to the

ATTENTION

Any damage to the paint

ATTENTION

To assure that the motor warranty be valid, it

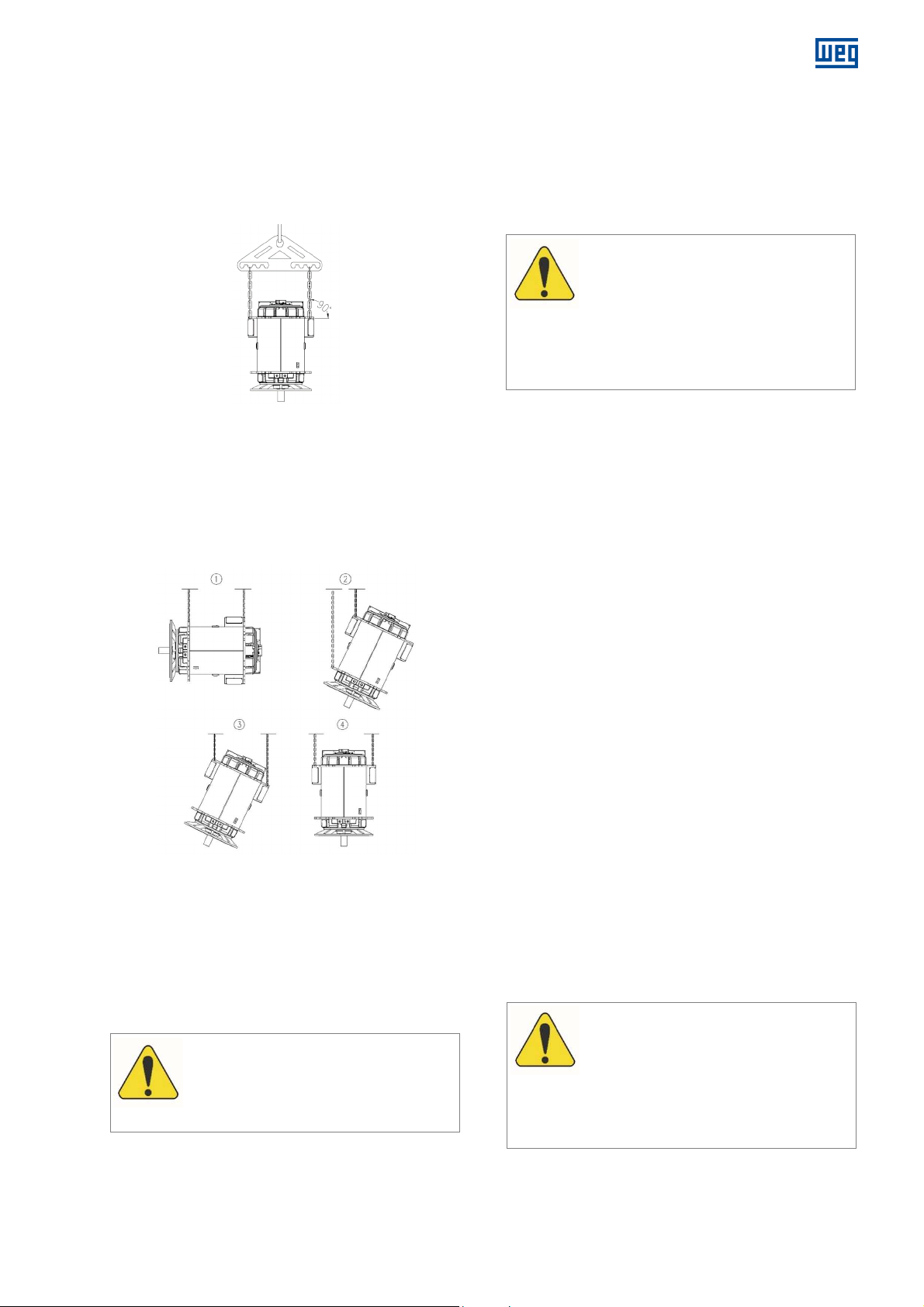

3.2.2 Vertical motor handling

Vertical motors must be handled as shown in Figure 3.3;

Always use the upper lifting lugs of the motor for handling

it in the vertical position, making sure the chains and

cables are also in the vertical position, avoiding too much

stress on the lifting lugs.

www.weg.net

3.3 STORAGE

If the Motor is not installed immediately after reception, it

must remain inside the package and stored in a location

protected against moisture, vapors, sudden changes in

temperature, rodents and insects.

The motor must be stored in vibration-free locations in

order to avoid bearing damage.

Figure 3.3: Vertical motor handling

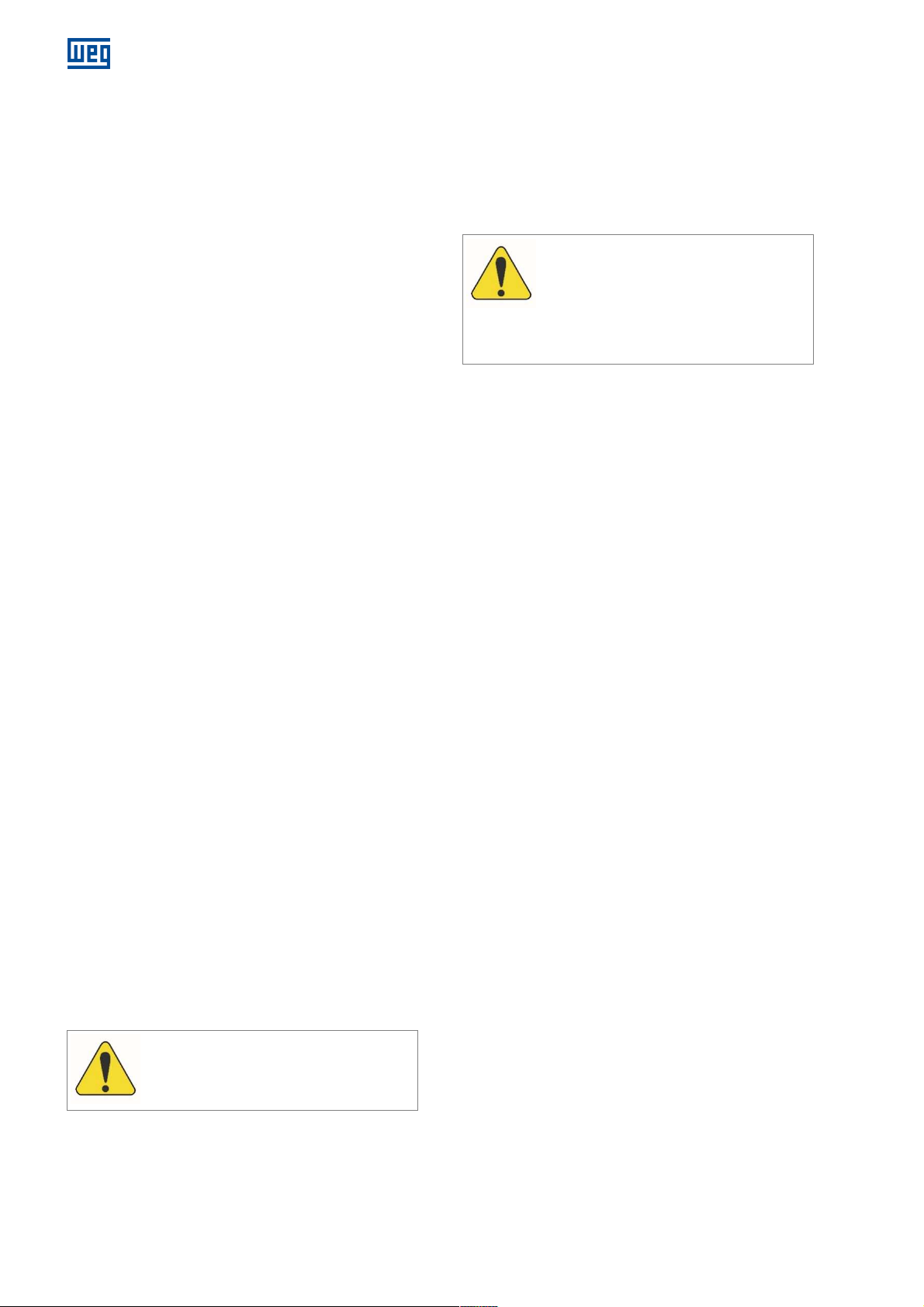

3.2.3 Vertical motor positioning

Vertical motors are supplied with lifting lugs at the drive

end DE and non-drive end NDE.

Some motors are transported in the horizontal position

and need to be moved to the original position. The

following procedure shows how to move motors from the

horizontal position to the vertical position and vice versa.

Figure 3.4: Vertical motor positioning

1. Lift the motor with the side lifting lugs using two hoists;

2. Lower the motor drive end (DE) and lift the non-drive

end (NDE) at the same time until balance is reached;

3. Loosen the DE cables and turn the motor 180º in

order to enable the connection of these cables to the

other lifting lugs of the NDE;

4. Connect the loose cables to the NDE lifting lugs and

lift them until the motor reaches the vertical position.

Space heaters must remain powered during

storage in order to avoid moisture

condensation inside the motor.

protection of the machined parts must be

repaired.

or corrosion

3.3.1 Outdoor storage

The motor must be stored in a dry location, free of

flooding and vibrations.

Repair any damages on the package before storing the

motor, which is needed to ensure proper storage

conditions.

Place the motor on platforms or foundations that ensure

protection against humidity from the ground and prevent it

from sinking into the soil. Free air circulation underneath

the motor must be assured.

The cover used to protect the motor against the bad

weather must not be in contact with its surfaces. In order

to ensure free air circulation between the motor and such

covers, place wooden blocks as spacers.

3.3.2 Long term storage

When the motor is stored for a long period of time (two

months or more) before start-up, it is exposed to

external agents, such as temperature variations,

moisture, aggressive agents, etc.

The empty spaces inside the motor – such as rolling

bearings, terminal boxes, and windings – are exposed to

humidity, which can cause condensation, and,

depending on the degree of air contamination,

aggressive substances may also penetrate these empty

spaces.

Consequently, after long periods of storage, the winding

insulation resistance may drop below the acceptable

values, internal components, such as rolling bearings,

may oxidize, and the lubricant power of the lubricant

agent in the bearings may be adversely affected.

All of these influences increase the risk of damages

before starting the motor.

Failure to comply with these

equipment, personal injuries or both.

14108242 Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line l 15

is necessary to make sure that all preventive

measures described in this manual, such as

constructive aspects, maintenance,

packaging, storage, and periodical

inspections, are followed and recorded.

www.weg.net

ATTENTION

ATTENTION

The instructions for long term storage are valid for motors

that remain stored for long periods (two months or more)

before start-up or motors already installed that are in a

prolonged stoppage, considering the same period.

3.3.2.1 Storage location

In order to ensure the best storage conditions for the

motor during long periods, the chosen location must

strictly meet the criteria described in sections 3.3.2.1.1

and 3.3.2.1.2.

3.3.2.1.1 Indoor storage

In order to ensure better storage conditions for the motor,

the storage site must comply strictly with the criteria

described below:

The storage site must be closed, covered, dry, free

air contaminants (moisture, vapor, dust, particles and

aggressive fumes) and free of flooding;

The site should be protected against sudden

temperature variations, humidity, rodents and insects;

Vibration-free location, to avoid damaging to the motor

bearings;

The floor must be of leveled concrete with resistant

structure to support the motor weight;

Must have system to fire detection and extinguishing;

Be provided with electricity for supplying the space

heaters with power failure detection system;

Exclusive site to store electrical machines (do not mix

with other equipment and/or products that could

prejudice the correct motor storage);

Site with facilities of cargo handling services, suitable to

allow the motor handling and removal;

There must be no gas present, such as chlorine, sulfur

dioxide or acids;

The site must have ventilation system with air filter;

Ambient temperature between 5°C and 50°C, and

should not present sudden temperature variation;

Relative air humidity <50%;

Must have prevention against dirt and dust depositio

The motor should be stored on a suitable metal base

that prevents the absorption of moisture from the floor.

If any of these requirements is not met in the storage site,

WEG suggests that additional protections be added to the

motor package during the storage period, as follows:

A closed wooden crate or the like with an electrical

installation that allows the energization of the space

heaters;

If there is a risk of infestation and fungus formation, the

package must be protected in the storage place by

spraying it or painting it with appropriate chemicals;

The package preparation must be prepared carefully by

an experienced person.

of

n;

3.3.2.1.2 Outdoor storage

moisture and other odd materials, using resistant

canvas or plastic.

The package must be placed on platforms or

f

oundations that ensure protection against dirt and

moisture and prevent it from sinking into the soil;

After the package is covered, a shelter must be erected

to protect it against direct rain, snow and excessive sun

heat.

In case the motor remains stored for long

periods (two months or more), it is

recommended to inspect it regularly as

specified in the section 3.3.3.11 of this

manual.

3.3.2.2 Separate parts

If parts are supplied separately (terminal boxes, heat

exchanger, end shields, etc.), these parts must be

mounted on motor to store it;

Spare parts must be stored in an adequate place, as

specified in sections 3.3.2.1.1 and 3.3.2.1.2 of this

manual.

The relative humidity inside the package must not

exceed 50%.

Rolling bearings must not be subject to shocks, falls or

storage with vibration or humidity, which can cause

marks on the internal tracks or on the balls, reducing

their useful life.

3.3.3 Preservation during the storage

3.3.3.1 Cooling system

After the motor operation, to preserve the cooling system

during long term storage, the following criteria must be

strictly observed:

Blow hot air in one of the holes for 15 to 20 minutes

eliminate the moisture from inside the frame inner

channels;

After drying, the water inlet and outlet should be closed.

, to

3.3.3.2 Space heater

Space heaters must remain powered during storage to

avoid moisture condensation inside the motor and ensure

that the winding insulation resistance remains within

acceptable levels.

The space heaters drive circuit must be unique and the

voltage and current of this circuit must be measured and

recorded monthly.

It is recommended that a signal be installed near the

motor to indicate that the space heaters are energized.

In case outdoor storage is unavoidable, the motor must be

packed in specific packaging for such conditions, as

follows:

For outdoor storage (exposed to the weather), besides

16 l Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line 14108242

Outdoor storage of the motor is not

recommended.

the packaging recommended for indoor storage, the

package must be covered with protection against dust,

Loading...

Loading...