Page 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

Serie: SSW-06

Software:version1.3X

0899.5579 E/6

SOFT-STARTER

MANUALSSW-06

ATTENTION!

It is very important to check if the

Soft-Starter Software is the same as

mentioned above.

12/2006

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 4

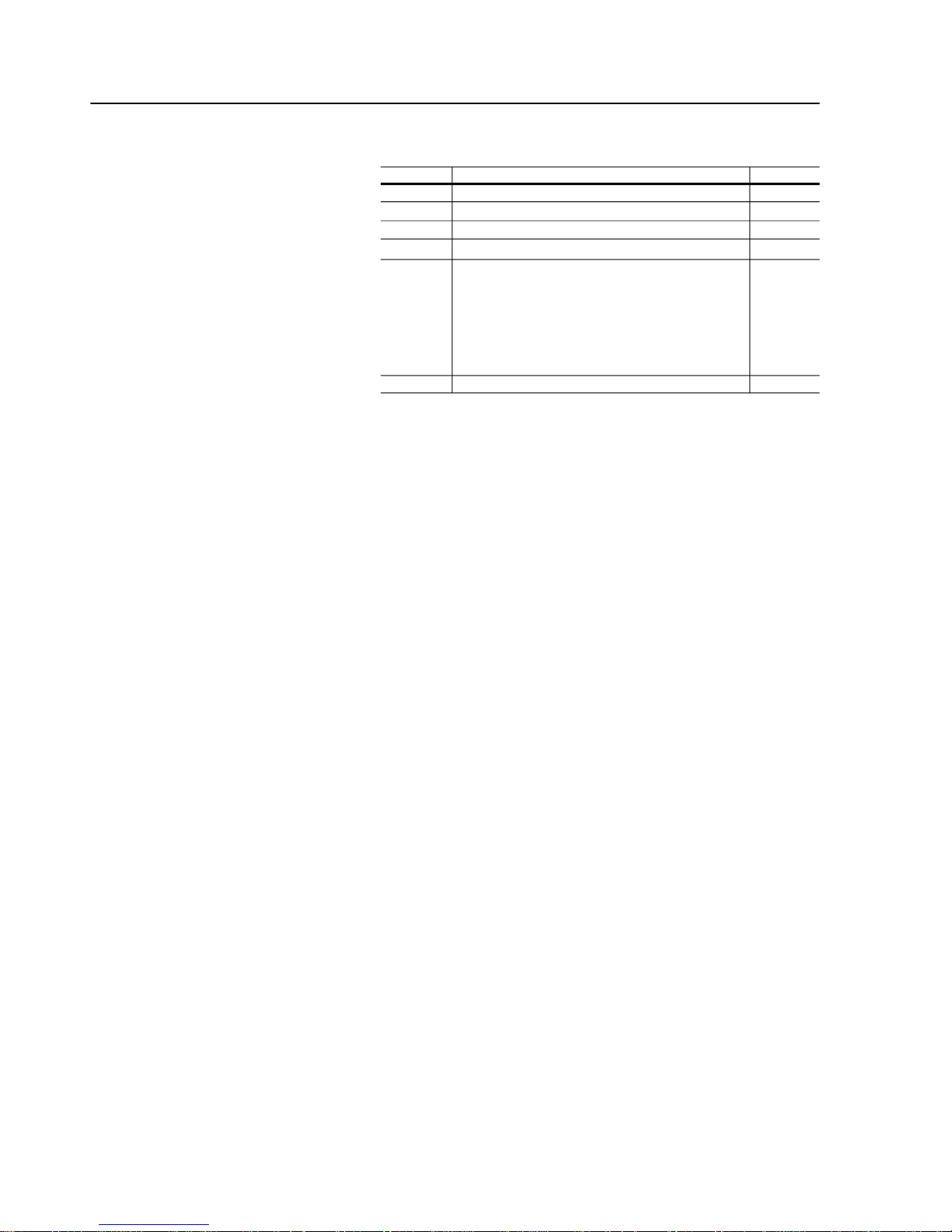

Summaryof Revisions

The tablebelowdescribes therevisions made to this manual.

Revision Description Section

1 FirstEdition 2 General Revision 3 General Revision 4 New Software Version 5 Implementation of the following current: 412A, Chap 3

480A, 604A, 670A, 820A, 950A, 1100A and 1400A. and 10

New software version with: braking methods 3, 4, 6

FWD/REVandJog. and 8

P140 was changed. E73 was eliminated.

E71 and E76 were changed.

6 General Revision -

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 5

Summary

Quick Parameter Reference,

Fault and Status Messages

I Parameters..................................................................................... 09

II FaultMessages.............................................................................. 17

III OtherMessages............................................................................. 17

CHAPTER 1

Safety Notices

1.1 Safety Notices inthe Manual.......................................................... 18

1.2 Safety Notice on the Product.......................................................... 18

1.3 PreliminaryRecommendations ....................................................... 19

CHAPTER 2

General Information

2.1 About this Manual .......................................................................... 20

2.2 SoftwareVersion............................................................................. 20

2.3 Aboutthe Soft-Starter SSW-06....................................................... 20

2.4 Soft-StarterSSW-06Identification .................................................. 23

2.5 ReceivingandStorage .................................................................... 25

CHAPTER 3

Installation and Connection

3.1Mechanical Installation ..................................................................... 26

3.1.1EnvironmentConditions .............................................................. 26

3.1.2Dimensions of the Soft-StarterSSW-06...................................... 26

3.1.3MountingSpecifications.............................................................. 27

3.1.3.1 Mounting inside a Panel .................................................... 28

3.1.3.2Mounting on a surface ....................................................... 30

3.2 Electrical Installation......................................................................... 31

3.2.1PowerTerminals ......................................................................... 32

3.2.2Locationof thePower/ Grounding, Control Connectionsand

Fan VoltageSelection ................................................................ 36

3.2.3RecommendedPower/GroundingCables ................................... 38

3.2.4AC InputConnection ................................................................... 39

3.2.4.1 Power Supply Capacity ..................................................... 40

3.2.4.2RecommendedFuses ....................................................... 40

3.2.5OutputConnection...................................................................... 41

3.2.5.1StandardThree-WireConnection(P150=0=Inactive).......... 41

3.2.5.2InsideDelta Motor Connection(P150=1=Active) ............... 42

3.2.6Grounding Connections .............................................................. 43

3.2.7Fan Connection and Selection of Fan Voltage ............................ 44

3.2.8Signaland Contro Connections .................................................. 45

3.2.9RS-232,X2SerialCommunicationConnection........................... 48

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 6

Summary

3.2.10RS-485,XC8 IsolatedSerialCommunication

Board Connection .................................................................... 48

3.2.11 XC6FieldbusCommunicationBoard Connection ...................... 48

3.3RecommendedSet-Ups.................................................................... 48

3.3.1Recommended Set-ups by Keypad(HMI) Command

with Isolating Contactor. Notes in 3 .3. ....................................... 50

3.3.2Recommended Set-ups by Keypad(HMI) Command

withCircuit-breaker.Notes in 3.3................................................ 50

3.3.3Recommended Set-ups withCommandviaTwo-wire

Digital Inputs. Notesin 3.3. ........................................................ 51

3.3.4RecommendedSet-upswithCommand viaThree-wire

Digital Inputs. Notesin 3.3. ........................................................ 51

3.3.5RecommendedSet-upswithCommand viaThree-wire

DigitalInput and Inside Delta Motor Connection. Notes in 3.3

and3.2.5.2. ................................................................................ 52

3.3.6RecommendedSet-upswithCommand viaThree-wire

DigitalInput or Serial Communication. Notes in 3.3. .................. 52

3.3.7RecommendedSet-upswithCommand viaThree-wire

DigitalInput or Fieldbus Communication. Notes in 3.3. .............. 53

3.3.8 RecommendedSetup withCommandvia DigitalInputs and

directionofrotation ..................................................................... 53

3.3.9 RecommendedSetup withCommandvia DigitalInputs and

ReverseBraking ......................................................................... 54

3.3.10Recommended Setup with Commandvia Digital Inputsand

Optimal Braking ....................................................................... 54

3.3.11Recommended SetupwithCommand viaDigitalInputsand

DC-Braking............................................................................... 55

3.3.12Recommended Setup with Commandvia Digital Inputsand

External By-pass Contactor ..................................................... 55

3.3.13 Symbols ................................................................................... 56

3.4 EuropeanDirectivesforElectromagneticCompatibility

Requirementsfor installation .......................................................... 57

3.4.1Installation .................................................................................. 57

CHAPTER 4

Keypad (HMI) Operation

4.1 Descriptionof the Keypad (HMI-SSW-06) ..................................... 59

4.2 Useof the Keypad (HMI) ................................................................ 61

4.2.1KeypadUse for Soft-StarterSSW-06 Operation ......................... 61

4.2.2HMI Display-Signalingindications............................................... 62

4.2.3ParameterViewingand Programming......................................... 63

CHAPTER 5

Start-up

5.1 Power-upPreparation ..................................................................... 65

5.2 InitialPower-up............................................................................... 66

5.3 Start-up........................................................................................... 73

5.3.1 Start-upOperationviaKeypad(HMI)-

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 7

Summary

Typeof Control:VoltageRamp .................................................. 74

CHAPTER6

Detailed Parameter Description

6.1 Access and Read-OnlyParameters - P000 to P099 ...................... 77

6.2 RegulationParameters - P100 toP199 ..........................................82

6.3 ConfigurationParameters-P200 to P299....................................... 91

6.4 Communication Parameters - P300to P399 .................................. 104

6.5 Motor Parameters - P400 to P499.................................................. 106

6.6 SpecialFunction Parameters - P500 to P599................................. 107

6.7 Protection Parameters - P600 to P699........................................... 113

CHAPTER7

Applications and Programming

7.1Applicationsand Programming ......................................................... 121

7.1.1Startingby VoltageRamp (P202=0)............................................ 123

7.1.2 Startingby Current Limit (P202=1)..............................................124

7.1.3StartingbyCurrentRamp (P202=4) ............................................ 125

7.1.4StartingbyCurrentRamp (P202=4) ............................................ 126

7.1.5StartingwithPump Control (P202=2) .......................................... 127

7.1.6Starting with TorqueControl(P202=3)......................................... 129

7.1.6.1Loads with constant torque (P202=3 and P120=1 point) .... 130

7.1.6.2 Loads with high initial torque (P202=3 and P120=3 points) 130

7.1.6.3Loads with constant torque and Sspeed curve

(P202=3 and P120=3 points) ............................................. 131

7.1.6.4Loads withquadratic torqueand Sspeed curve

(P202=3 and P120=2 points) ............................................. 131

7.1.6.5Loadswith quadratic torqueand linear speedcurve

(P202=3 and P120=3 points) ............................................. 132

7.1.6.6Loads withquadratic torqueand higherinitial torque

(P202=3 and P120=3 points) ............................................. 132

7.1.6.7Hydraulic pump load type (P202=3).................................... 133

7.2Protectionsand Programming .......................................................... 136

7.2.1ThermalClasses......................................................................... 136

7.2.1.1 Suggestions about thermal class setting............................ 136

7.2.1.2Example of how toprogram the Thermal Class .................. 137

7.2.1.3Time reductionwhenchanging from cold starting

to hot starting ..................................................................... 138

7.2.1.4ServiceFactor .................................................................... 138

CHAPTER8

Diagnosis and Troubleshooting

8.1 Faults and Possible Causes ............................................................. 139

8.2Troubleshooting ................................................................................ 143

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 8

Summary

8.3ContactingWEG Telephone/Fax/E-mailfor Contact (Servicing)........ 143

8.4PreventiveMaintenance .................................................................... 144

8.4.1CleaningInstructions .................................................................. 145

8.5 Spare Parts List ................................................................................ 145

CHAPTER 9

Options and Accessories

9.1Remote Keypad (HMI)and Cables.................................................... 146

9.2RS-485for theSoft-StarterSSW-06 ................................................. 148

9.2.1RS-485 Communication Kit for theSSW-06 ............................... 148

9.2.2OptionalMIW-02 Module ............................................................ 149

9.3 Fieldbus Communication Kits ........................................................... 149

9.3.1Fieldbus DeviceNet CommunicationKit for the SSW-06............. 149

9.3.2Fieldbus Profibus DP Communicationkit for the SSW-06 .......... 150

CHAPTER10

Technical Specifications

10.1 CurrentsandRatingsAccordingto Ul508 ....................................... 151

10.2 Currentsand Ratings for IP55,IV PoleWeg Motor ......................... 152

10.3 PowerData..................................................................................... 153

10.4 Electronics/Programming Data....................................................... 153

10.5 MechanicalData............................................................................. 155

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 9

9

SSW-06- QUICK PARAMETER REFERENCE

QUICK PARAMETER REFERENCE, FAULT AND STATUS MESSAGES

Software:V1.3X

Application:

Model:

SerialNumber:

PersonResponsible:

Date: / / .

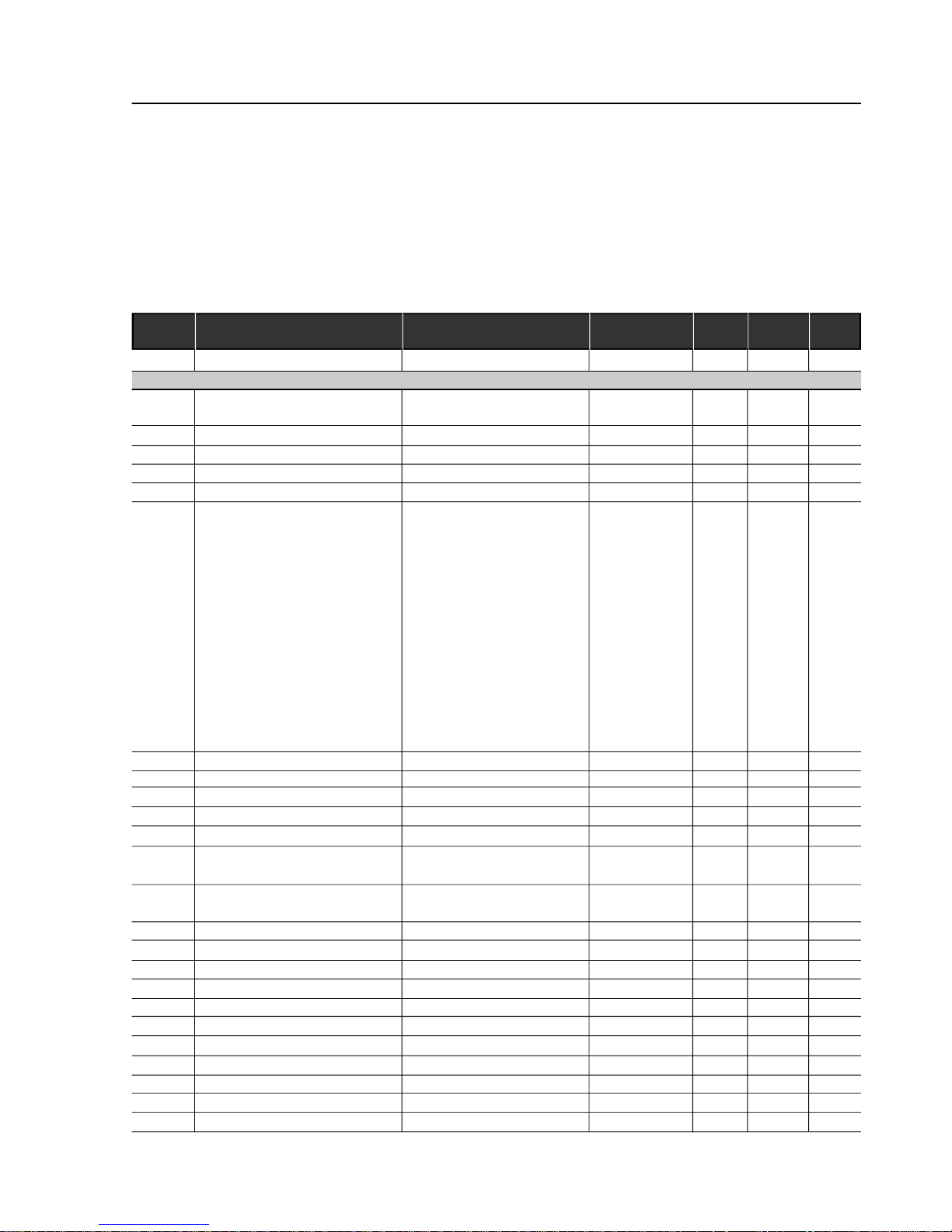

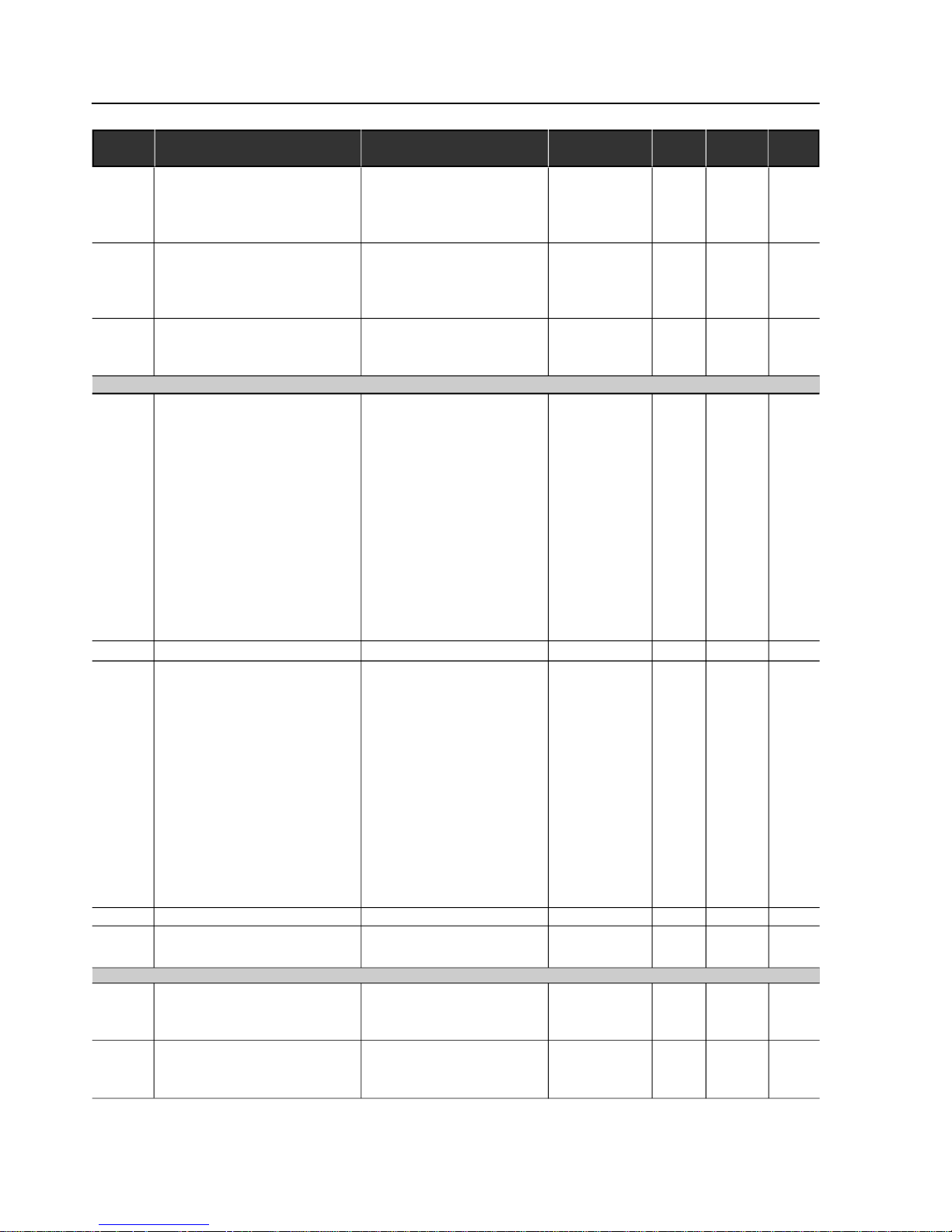

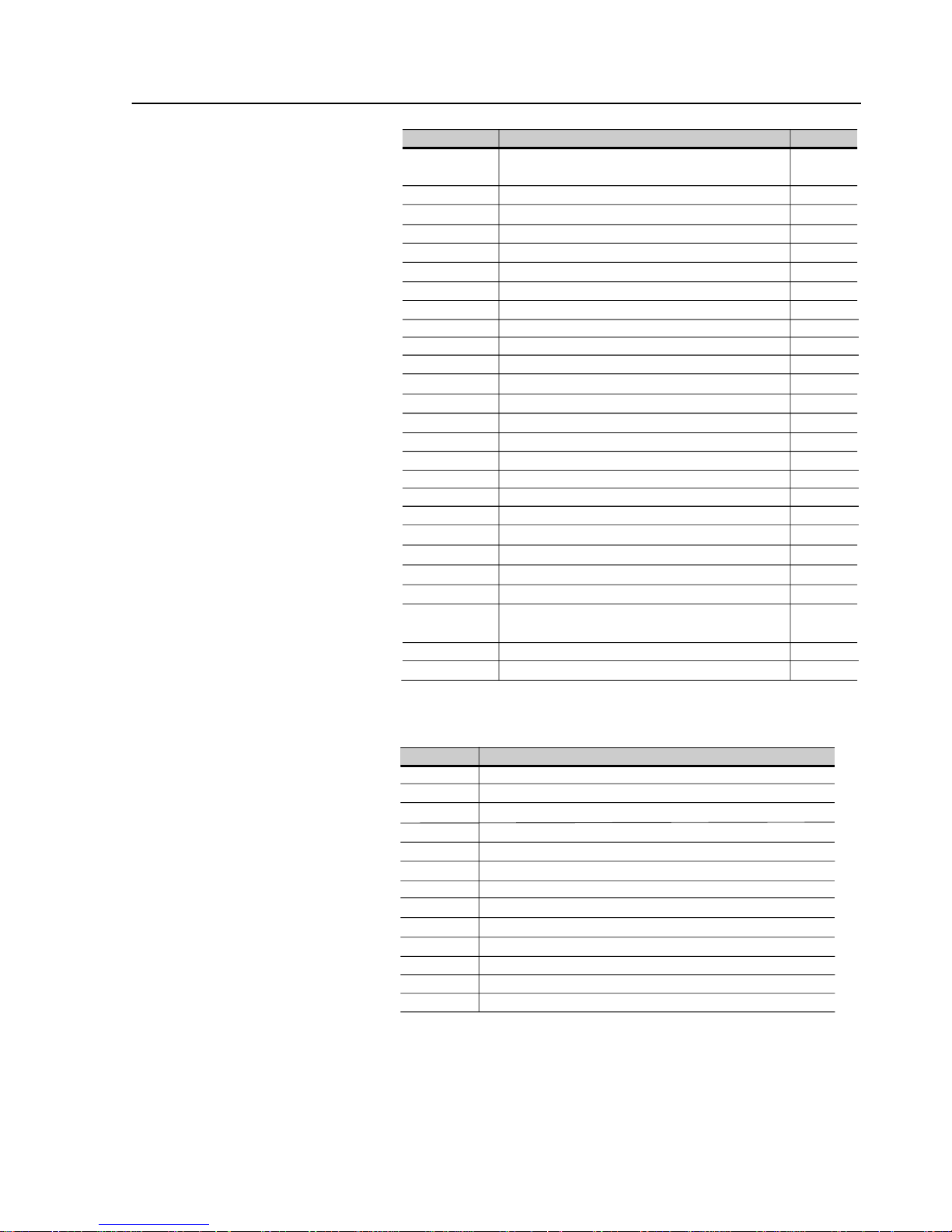

I.Parameters

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

Setting Setting

P000 Access Parameter 0 to 999 0 - 77

READONLY PARAMETERS P001 to P099

P001 Soft-Starter Current 0 to 999.9 - % 78

(%In of the Soft-Starter)

P002 Motor Current (%In of the Motor) 0 to 999.9 - % 78

P003 Motor Current 0 to 9999.9 - A 78

P004 Power Supply Voltage 0 to 999 - V 78

P005 Network Frequency 0 to 99.9 - Hz 78

P006 Soft-Starter Status 0=rdy - ready - - 78

1=Sub - Sub

2=Exx - Error

3=ruP - Run Up

4=FuLL- Full Volt.

5=PASS - By-pass

6=ECO - Reserved

7=rdo - Run Down

8=br - Braking

9=rE- FWD/REV

10=JOG-JOG

11=dly- Delay P630

12=G.di - Gen. Disable

P007 Output Voltage 0 to 999 - V 79

P008 Power Factor 0 to 1.00 - - 79

P009 Motor Torque (% Tn of the Motor) 0 to 999.9 - % 79

P010 Output Power 0 to 6553.5 - kW 79

P011 Apparent Output Power 0 to 6553.5 - kVA 79

P012 Digital InputStatusDl1 to Dl6 0 = Inactive - - 80

1 = Active

P013 Status RL1, RL2 and RL3 0 = Inactive - - 80

1 = Active

P014 Last Fault 03 to 77 - - 81

P015 Second Previous Fault 03 to 77 - - 81

P016 Third Previous Fault 03 to 77 - - 81

P017 Fourth Previous Fault 03 to 77 - - 81

P023 Software Version X.XX - - 81

P030 Current of Phase R 0 to 9999.9 - A 81

P031 Current of Phase S 0 to 9999.9 - A 81

P032 Current of Phase T 0 to 9999.9 - A 81

P033 R-S Line Voltage 0 to 999 - V 81

P034 S-T Line Voltage 0 to 999 - V 81

P035 T-RLine Voltage 0 to 999 - V 81

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 10

SSW-06- QUICK PARAMETER REFERENCE

10

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

Setting Setting

P042 Time Powered 0 to 65530 - h 81

P043 TimeEnabled 0 to 6553 - h 82

P050 MotorThermal Protection Status 0 to 250 - % 82

P085 FieldbusCommunication Board Status 0=Off - - 82

1=Board Inactive

2=Board Active and Offline

3=Board Active and Online

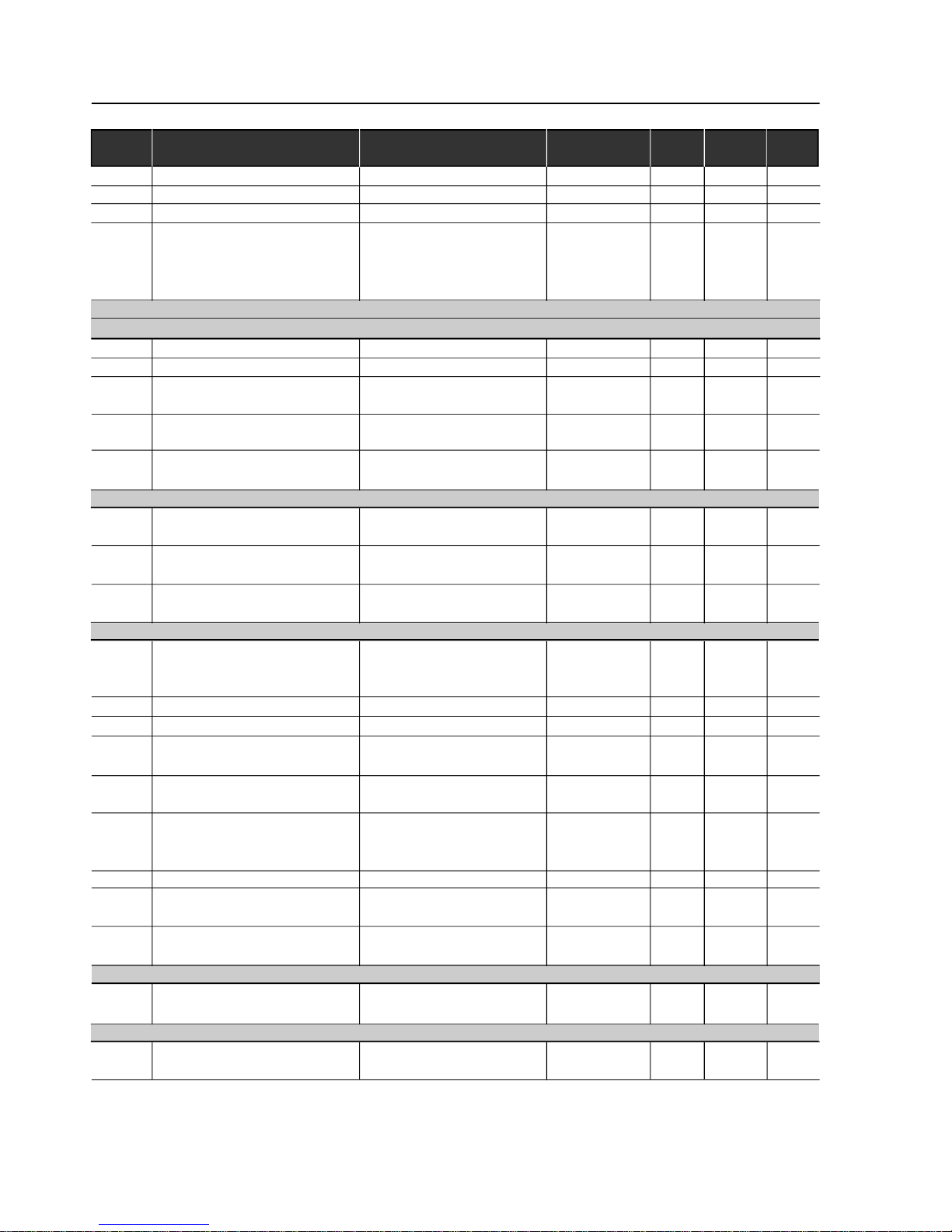

REGULATION PARAMETERS P100TO P199

Voltage Ramp

P101 Initial Voltage(% Un of the motor) 25 to 90 30 % 82

P102 Acceleration Ramp Time 1 to 999 20 s 83

P103 Deceleration Voltage Step 100=Inactive 100=Inactive % 84

(% Un of the motor) 99 to 60

P104 DecelerationRampTime 0=Inactive 0=Inactive s 84

1 to 299

P105 End Deceleration Voltage 30 to 55 30 % 84

(% Un of the Motor)

Current Limit

P110 CurrentLimit 150 to 500 300 % 84

(%In of the Motor current)

P111 Initial Current for the Current Ramp 150 to 500 150 % 85

(% In of the Motor)

P112 Time for the Current Ramp 1 to 99 20 % 85

(% of P102)

Torque Control

P120

(1)

Starting Torque Characteristics 1=Constant 1=Constant - 86

2=Linear

3=Quadratic

P121 Initial StartingTorque (% Tn of Motor) 10 to 400 30 % 87

P122 End Starting Torque(% Tn of Motor) 10 to 400 110 % 87

P123 MinimumStartingTorque 10 to 400 27 % 87

(% Tn of the Motor)

P124 Time for the Minimum Start Torque 1 to 99 20 % 87

(% of P102)

P125

(1)

Stopping Torque Characteristics 1=Constant 1=Constant - 88

2=Linear

3=Quadratic

P126 End Stop Torque(% Tn of the Motor) 10 to 100 20 % 88

P127 MinimumStopTorque 10 to 100 50 % 89

(% Tn of the Motor)

P128 Time for the Minimum StopTorque 1 to 99 50 % 89

(% of P104)

Pump Control

P130

(1)

PumpControl 0=PumpI 0=PumpI - 89

1=PumpII

By-pass

P140

(1)

External By-pass Contactor 0=Inactive 0=Inactive - 89

1=Active

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 11

11

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

Setting Setting

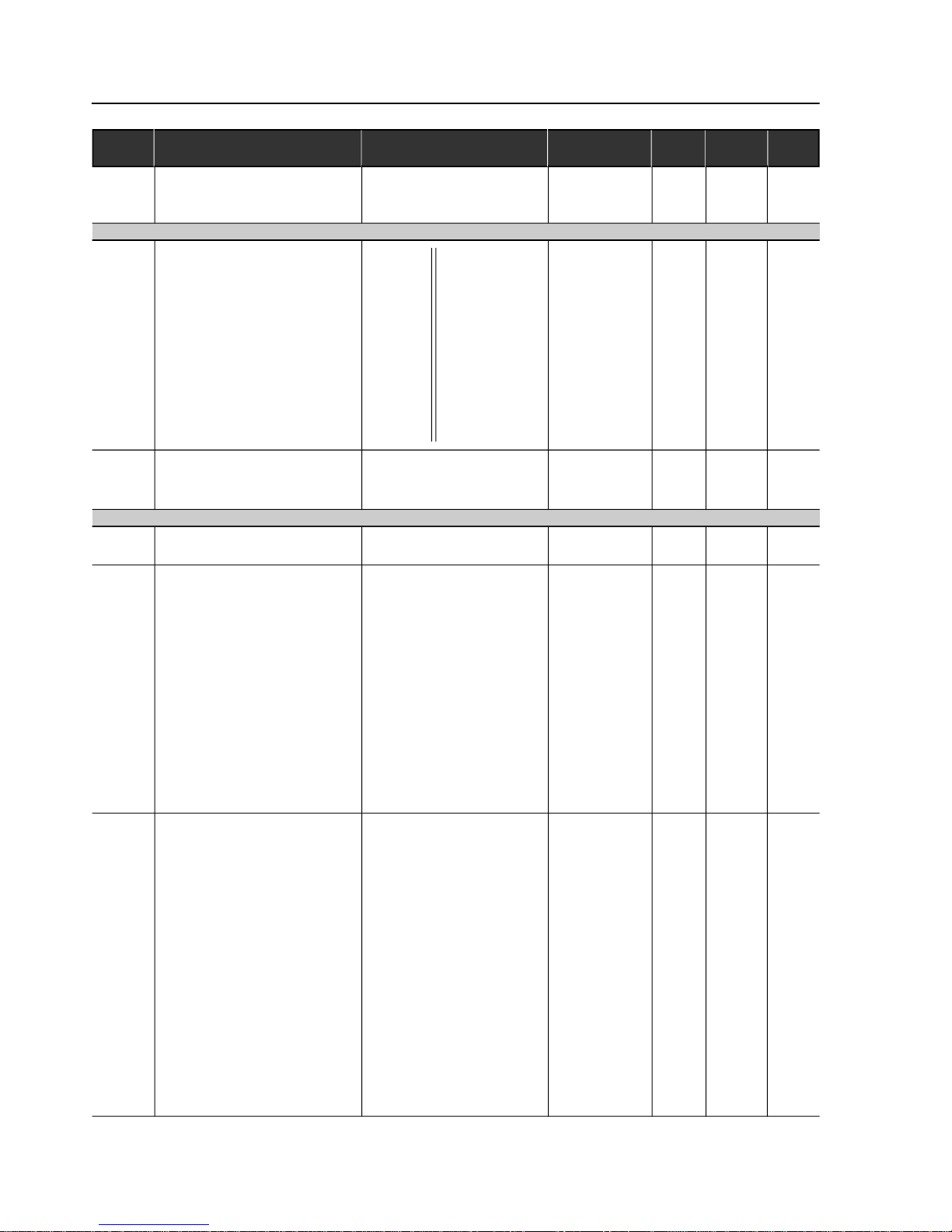

Inside Delta

P150

(1) (2)

Inside Delta Motor Connection 0=Inactive 0=Inactive - 90

1=Active

CONFIGURATION PARAMETERS P200 to P399

P200 Password 0=Inactive 1=Active - 91

1=Active

P201

(2)

Language Selection 0=Portuguese To be defined - 91

1=English by the user

2=Spanish

3=German

P202

(1)

Type of the Control 0=Voltage Ramp 0=Voltage Ramp - 91

1=Current limiting

2=PumpControl

3=Torque Control

4=CurrentRamp

P204

(1)

Load/Save Parameters 0=Not use 0=Not use - 94

1=Not use

2=Not use

3=ResetP043

4=Not use

5=Loads Factory Default

6=Not use

7=Loads User Default 1

8=Loads User Default 2

9=Not use

10=Saves User Default 1

11=Saves User Default 2

P205 Display Default Selection 0=P001 2=P003 - 95

1=P002

2=P003

3=P004

4=P005

5=P006

6=P007

7=P008

P206 Auto-Reset Time 0=Inactive 0=Inactive s 95

1 to 600

P215

(1)

Keypad Copy Function 0=Inactive 0=Inactive - 96

1=SSWHMI

2=HMISSW

P218 LCD Display Contrast Adjust. 0 to 150 127 - 97

Local/Remote Definition

P220

(1)

Local/Remote Source Selection 0=Always Local 2=HMI(L) - 97

1=Always Remote

2=HMI(L)

3=HMI(R)

4=DI4toDI6

5=Serial(L)

6=Serial(R)

7=Fieldbus(L)

8=Fieldbus(R)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 12

SSW-06- QUICK PARAMETER REFERENCE

12

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

Setting Setting

P229

(1)

LocalStatusCommand Selection 0=KeysHMI 0=KeysHMI - 97

1=DigitalInputs DIx

2=Serial

3=Fieldbus

P230

(1)

RemoteStatusCommandSelection 0=KeysHMI 1=DIxTerminals - 97

1=DigitalInputs DIx

2=Serial

3=Fieldbus

P231

(1)

FWD/REVSelection 0=Not used 0=Not used - 98

1=By Contactor

2=JOGOnly

Analog Outputs

P251 AO1 (0 to 10)V Output Function 0=Not used 0=Not used - 99

1= Current (%In of the SSW)

2=Input Voltage

(%Un of the SSW)

3=Output voltage

(%Un of the SSW)

4=Power Factor

5=ThermalProtection

6=Power (in W)

7=Power (in VA)

8=Torque (%Tn of Motor)

9=Fieldbus

10=Serial

P252 AO1 Analog Output Gain 0.000 to 9.999 1.000 - 99

P253 AO2 (0 to 20)mA or (4 to 20)mA 0=Not used 0=Not used - 99

Output Function 1= Current (%In of the SSW)

2=Input Voltage

(%Un of the SSW)

3=Output voltage

(%Un of the SSW)

4=Power Factor

5=ThermalProtection

6=Power (in W)

7=Power (in VA)

8=Torque (%Tn of the Motor)

9=Fieldbus

10=Serial

P254 AO2 Analog Output Gain 0.000 to 9.999 1.000 - 99

P255 AO2 Analog Output Selection 0=0 to 20 0=0 to 20 mA 99

1=4 to 20

Digital Inputs

P264

(1)

DI2Digital InputFunction 0=Not Used 2= Reset - 100

1=Stop (Three-Wire)

2=Reset

P265

(1)

DI3Digital InputFunction 0=Not Used 0=Not used - 100

1=GeneralEnable

2=Reset

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 13

13

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

Setting Setting

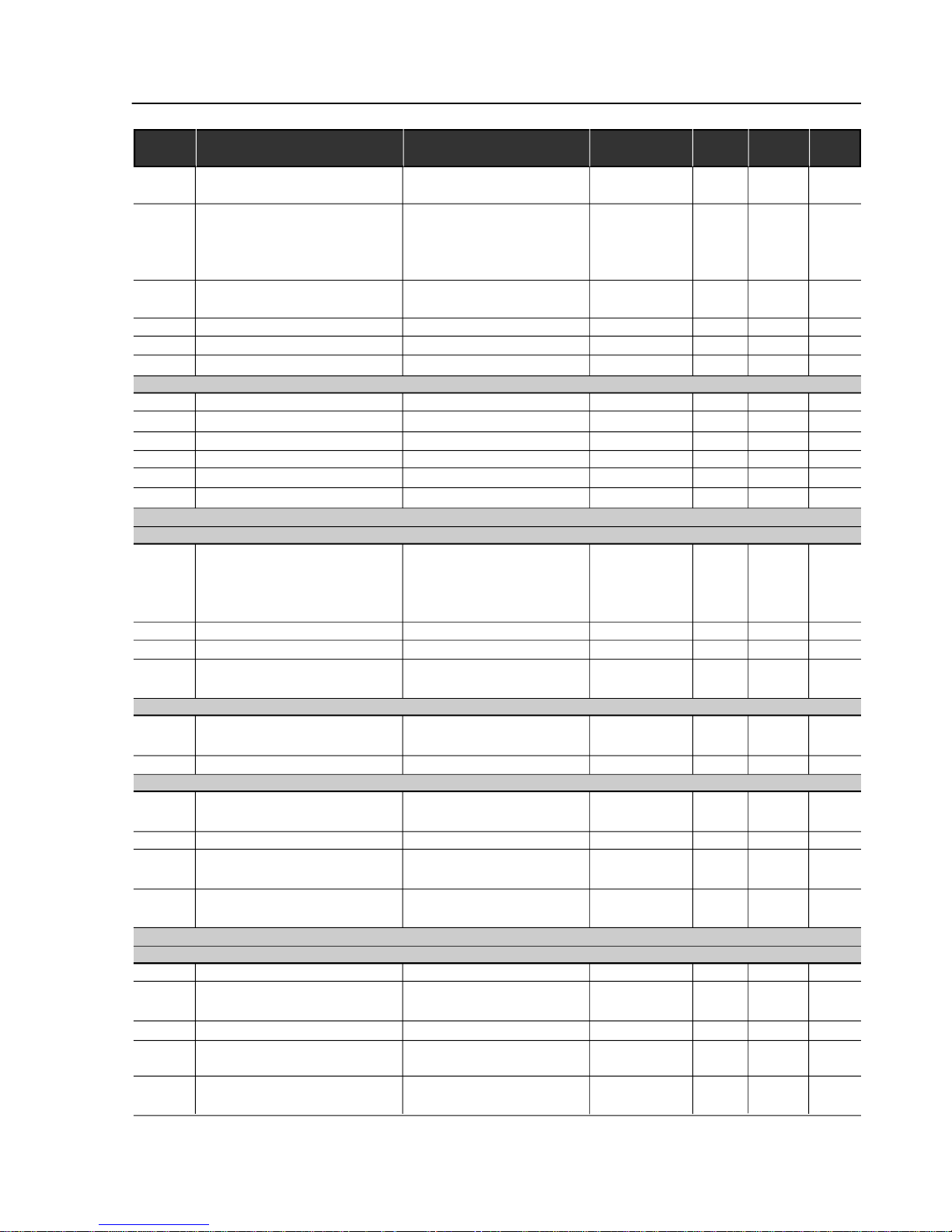

P266

(1)

DI4Digital InputFunction 0=Not Used 0=Not Used - 100

1=FWD/REV

2=Local/Remote

3=NoExternalFault

4=JOG

5=Brake Off

6=Reset

P267

(1)

DI5Digital InputFunction 0=Not Used 0=Not used - 101

1=FWD/REV

2=Local/Remote

3=NoExternalFault

4=JOG

5=Brake Off

6=Reset

P268

(1)

DI6Digital InputFunction 0=Not used 0=Not used - 101

1=FWD/REV

2=Local/Remote

3=No external Fault

4=JOG

5=Brake Off

6=Reset

7=MotorThermistor

Digital Outputs

P277

(1)

RL1 Relay Function 0=Not used 1=Running - 102

1=Running

2=Fullvoltage

3=External By-pass

4=FWD/REV-K1

5=DC-Brake

6=NoFault

7=Fault

8=Fieldbus

9=Serial

P278

(1)

RL2 Relay Function 0=Not used 2=FullVoltage - 102

1=Running

2=Fullvoltage

3=External By-pass

4=FWD/REV-K2

5=DC-Brake

6=NoFault

7=Fault

8=Fieldbus

9=Serial

P279

(1)

RL3 Relay Function 0=Inactive 6=NoFault - 102

1=Running

2=Fullvoltage

3=External By-pass

4= Not used

5=DC-Brake

6=NoFault

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 14

SSW-06- QUICK PARAMETER REFERENCE

14

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

Setting Setting

7=Fault

8=Fieldbus

9=Serial

Soft-Starter Data

P295

(1)(2)

SSW Rated Current 0=10A 11=312A According to A 103

1=16A 12=365A Soft-Starter

2=23A 13=412A Rated Current

3=30A 14=480A

4=45A 15=604A

5=60A 16=670A

6=85A 17=820A

7=130A 18=954A

8=170A 19=1100A

9=205A 20=1411A

10=255A

P296

(1) (2)

Rated Voltage 0=220/575V According to V 103

1=575/690V Soft-Starter

Voltage

PARÂMETROS DE COMUNICAÇÃO SERIAL P300 a P399

P308

(1)(2)

Soft-Starter Address on the Serial 1 to 247 1 - 104

Communication Network

P309

(1)(2)

FieldbusCommunication 0=Inactive 0=Inactive - 104

BoardEnabling 1=Profibus-DP

(1 Inputs and 1 Outputs)

2=Profibus-DP

(4 Inputs and 4 Outputs)

3=Profibus-DP

(7 Inputs and 7 Outputs)

4=DeviceNet

(1 Inputs and 1 Outputs)

5=DeviceNet

(4 Inputs and 4 Outputs)

6=DeviceNet

(7 Inputs and 7 Outputs)

P312

(1)(2)

Protocol Type and Serial 1=Modbus-RTU 1=Modbus-RTU 104

Communication Transfer Rate (9600bps, no parity) (9600bps,

2=Modbus-RTU no parity)

(9600bps, odd)

3=Modbus-RTU

(9600bps, even)

4=Modbus-RTU

(19200bps, no parity)

5=Modbus-RTU

(19200bps, odd)

6=Modbus-RTU

(19200bps, even)

7=Modbus-RTU

(38400bps, no parity)

8=Modbus-RTU

(38400bps, odd)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 15

15

SSW-06- QUICK PARAMETER REFERENCE

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

Setting Setting

9=Modbus-RTU

(38400bps, even)

P313 Serialand FieldbusCommunication 0=Inactive 0=Inactive 104

ErrorActions (E28, E29 and E30) 1=Disable

2=GeneralEnable

3=Changes to Local

P314

(1)

TimeoutTime for Serial 0 to 999 0= Inactive s 105

CommunicationTelegramReception

P315

(1)

Read Parameter via Fieldbus 1 0 to 999 0 - 105

P316

(1)

Read Parameter via Fieldbus 2 0 to 999 0 - 105

P317

(1)

Read Parameter via Fieldbus 3 0 to 999 0 - 105

MOTOR PARAMETERS P400 to P499

P400

(1)

Rated Motor Voltage 0 to 999 380 V 106

P401

(1)

Rated Motor Current 0.0 to 1500 20 A 106

P403

(1)

Rated Motor Speed 400 to 3600 1780 rpm 106

P404

(1)

Rated Motor Power 0.1 to 2650 75 kW 106

P405

(1)

Motor Power Factor 0 to 1.00 0.89 - 106

P406

(1)

Service Factor 0 to 1.50 1.00 - 106

SPECIAL PARAMETERS P500 to P599

Braking

P500

(1)

Braking Methods 0=Inactive 0=Inactive - 107

1=Reverse Braking

2=OptimalBraking

3=DC-Braking

P501 BrakingTime 1 to 299 10 s 110

P502 Braking Voltage Level 30 to 70 30 % 110

P503 Braking End Detection 0=Inactive 0=Inactive - 110

1=Automatic

JOG

P510

(1)

Jog 0=Inactive 0=Inactive - 111

1=Active

P511 Jog Level 10 to 100 30 % 111

Kick Start

P520

(1)

Kick Start TorquePulse 0=Inactive 0=Inactive - 112

(according to P202) 1=Active

P521 Kick StartPulseTime 0.1 to 2 0.1 s 112

P522 Kick Start Voltage Pulse Level 70 to 90 70 % 112

(% Un of the Motor)

P523 Kick Start Current Pulse Level 300 to 700 500 % 112

(% In of the Motor)

PROTECTION PARAMETERS P600 to P699

Voltage Protection

P600

(1)

Undervoltage (% Un of the motor) 0 to 30 20 % 113

P601

(1)

ImmediateUndervoltageTime 0=Inactive 1 s 113

1 to 99

P602

(1)

Overvoltage (% Un of the motor) 0 to 20 15 % 113

P603

(1)

ImmediateOvervoltageTime 0=Inactive 1 s 113

1 to 99

P604

(1)

Voltage Imbalance Between Phases 0 to 30 15 % 114

(% Un of the motor)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 16

SSW-06- QUICK PARAMETER REFERENCE

16

Parameter Description Adjustable Range

Factory

Unit

User´s

Page

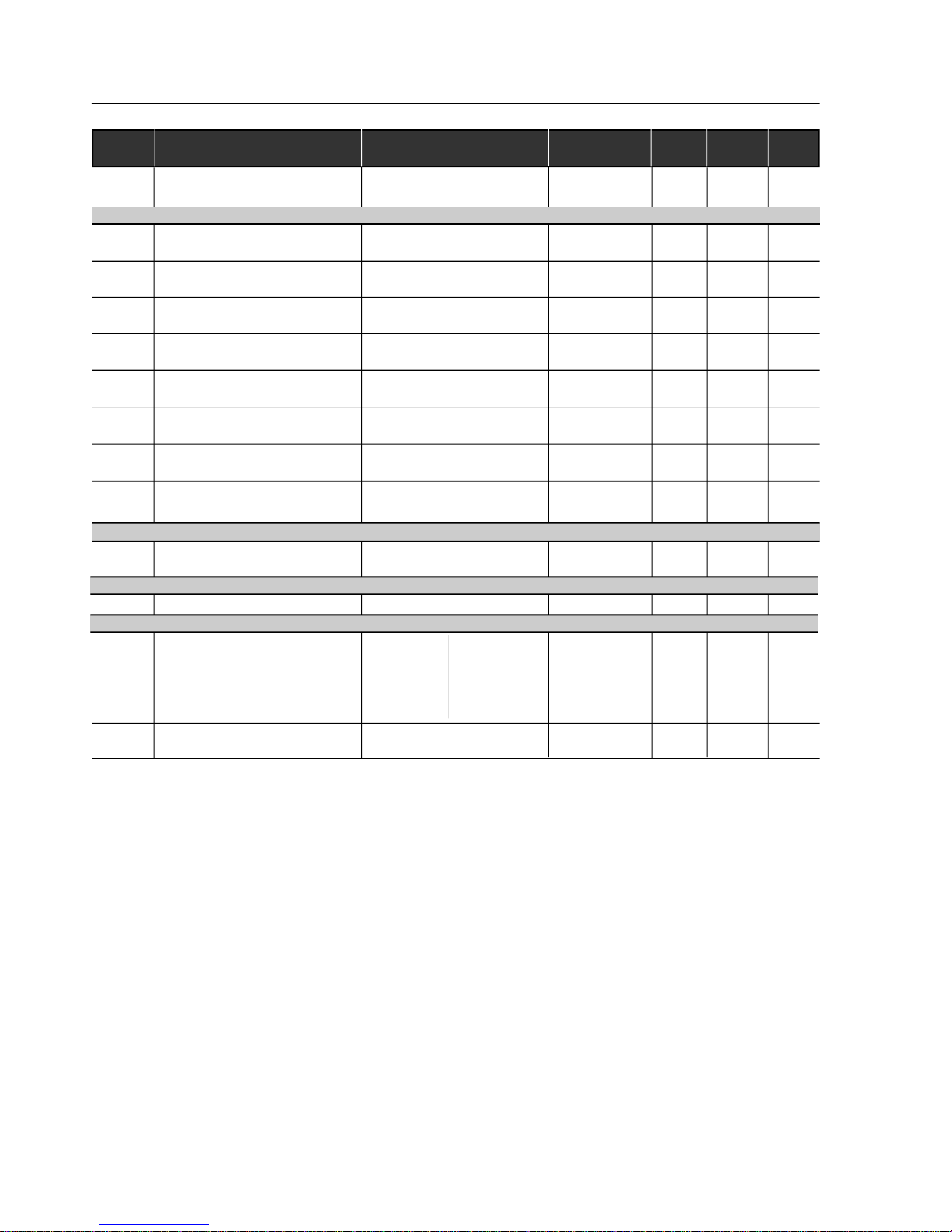

Setting Setting

Notes presented on quick parameter description:

(1) This parameter can only be changed with the motor stopped.

(2) This parameter does not change when factory defaults are loaded (P204=5).

P605

(1)

PhaseVoltage ImbalanceTime 0=Inactive 1 s 114

1 to 99

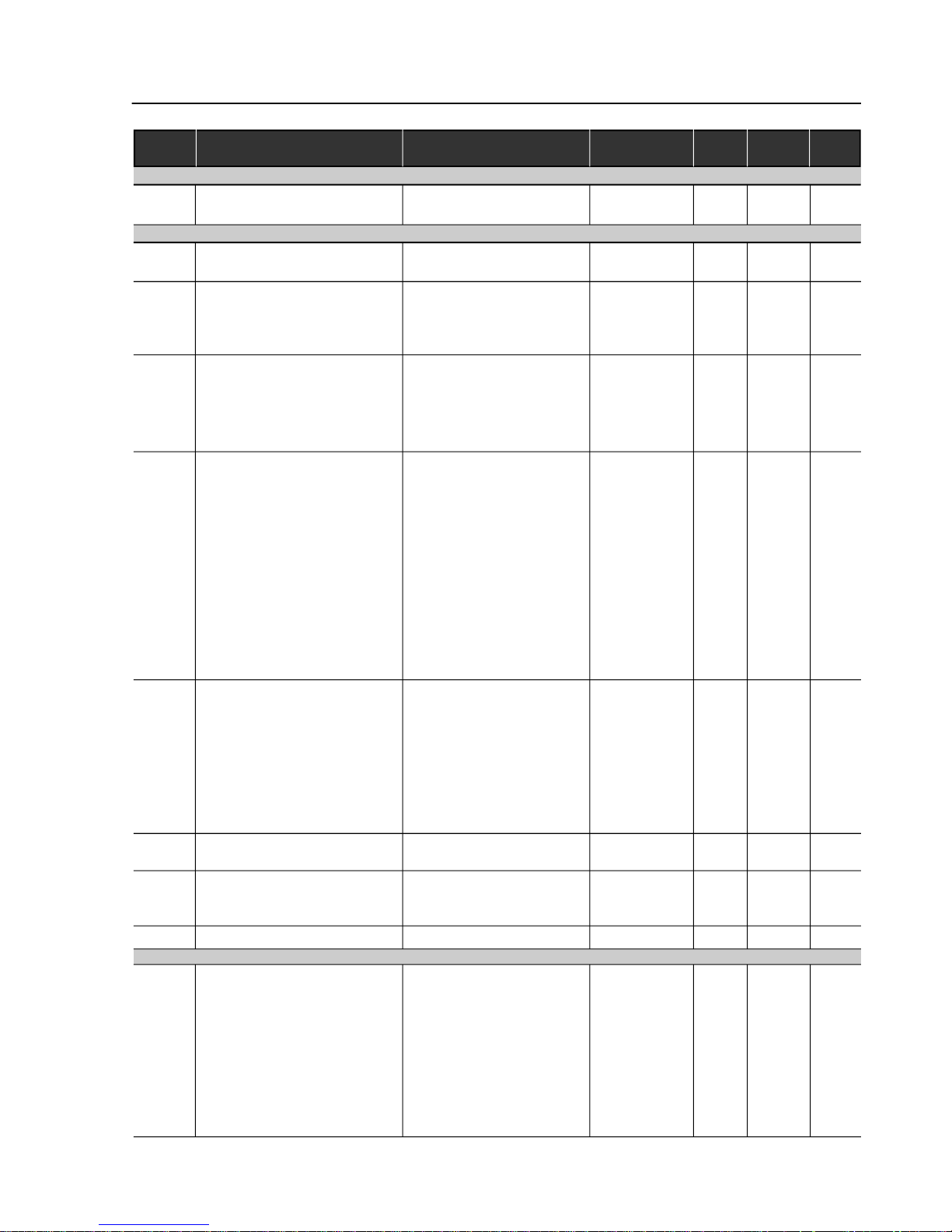

Current Protection

P610

(1)

Immediate Undercurrent 0 to 99 20 % 114

(% In of the motor)

P611

(1)

ImmediateUndercurrentTime 0=Inactive 0=Inactive s 114

1 to 99

P612

(1)

Immediate Overcurrent 0 to 99 20 % 114

(% In of the motor)

P613

(1)

ImmediateOvercurrentTime 0=Inactive 0=Inactive s 114

1 to 99

P614

(1)

Current Imbalance between Phases 0 to 30 15 % 115

(% In of the motor)

P615

(1)

Current Imbalance Between 0=Inactive 1 s 115

PhaseTimes 1 to 99

P616

(1)

Undercurrent before Closing 0=Inactive 1=Active - 115

of Internal By-pass 1=Active

P617 Motor Overcurrent before By-pass 0=Inactive 1=Active - 115

1=Active

Phase Sequence

P620

(1)

RST Phase Current Sequence 0=Inactive 0=Inactive - 115

1=Active

Interval between Starts

P630 Interval of Time after Stop 2 to 999 2 s 115

Motor Thermal Protection

P640

(1)

MotorProtection Thermal Class 0=Inactive 5=25 6=30 - 117

of Motor Protection 1=5 6=30

2=10 7=35

3=15 8=40

4=20 9=45

P641

(1)

Auto-Reset of thermal Memory 0=Inactive 0=Inactive s 120

1 to 600

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 17

17

SSW-06- QUICK PARAMETER REFERENCE

II.FaultMessages

III.OtherMessages

Display Description Page

E03 Undervoltage, Phase Fault or Phase 139

Unbalancing

E04 Overtemperature at the Power Assembly 139

E05 Motor Overload 139

E06 ExternalFault(DI) 139

E10 Copy Function Fault 139

E15 Motor is not Connected or SCRs in Short-circuit 139

E16 Overvoltage 139

E24 ProgrammingError 140

E28 Timeoutin the Telegram Reception 140

E29 FieldbusCommunication is Inactive 140

E30 Fieldbus Board is Inactive 140

E31 HMIConnectionFault 140

E32 Motor Overtemperature (DI) 140

E41 Self-Diagnosis Fault 140

E62 StartLimitingTime 140

E63 Locked Rotor 140

E65 Undercurrent 141

E66 Overcurrent 141

E67 Inverted Phase Sequence 141

E70 Undervoltage at the Electronics 141

E71 Bypass Contact is Open 141

E72 Overcurrent before By-pass Contact 141

E74 CurrentImbalance 141

E75 Frequency of Supply Line 141

out of Permitted Range

E76 Undercurrent before By-pass 141

E77 Bypass Contact is closed or SCRs in Short-circuit 141

For more details see table 8.1 in chapter 8.

Display Description

rdy Soft-Starter is ready to be enabled

ruP Soft-Starter is enabled according to “ramp up”

FuLL Soft-Starter is enabled at “full voltage”

PASS Soft-Starter is enabled with “By-pass”

rdo Soft-Starter is enabled according to “ramp down”

br Soft-Starter is enabled according to “braking”

rE Soft-Starter is enabled according to “reversing”

JOG Soft-Starter is enabled according to “jog”

Sub Soft-Starter under voltage fault

Exx Soft-Starter fault

dly Soft-Starter esperando o tempo após parada "delay"

G.di Soft-Starter com desabilita geral "general disable"

ECO Reserved

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 18

18

SAFETY NOTICES

ThisManualcontainsallnecessaryinformationforthecorrectinstallation

andoperationof theSSW-06 Soft-Starter.

TheSSW-06 InstructionManualhasbeenwrittenforqualifiedpersonnel

with suitable training or technical qualifications to operate this type of

equipment.

The following Safety Notices will be used in this Manual:

DANGER!

IftherecommendedSafetyInstructionsarenotstrictlyobserved,serious

orfatal injuries of personnel and/or equipmentdamage canoccur.

ATTENTION!

Failure to observe the recommended Safety Procedures can lead to

materialdamage.

NOTE!

ThecontentofthisManualsuppliesimportantinformationforthecorrect

understandingofoperationandproperperformanceof theequipment.

1.1 SAFETYNOTICES

INTHEMANUAL

1.2 SAFETYNOTICESON

THEPRODUCT

Thefollowingsymbolsmaybeattachedtotheproduct,servingasSafety

Notices:

High Voltages

Componentsaresensitivetoelectrostatic discharge.Donot touch

them without following proper grounding procedures.

Mandatory connection to ground protection (PE)

Shield connection to ground

CHAPTER 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 19

CHAPTER 1 - SAFETY NOTICES

19

NOTE!

In this Manual,qualified personnelare defined as people that are trained to:

1. Install, ground,power-up and operate the SSW-06 according tothis

Manual and the local required safety procedures;

2. Use of safety equipment according to the local regulations;

3. Administer First Aid Treatment.

DANGER!

Always disconnect the main power supply before touching any electrical

component associated to the SSW-06 Soft-Starter.

High voltages and spinningparts (fans) may bepresent even after switching

offthe power supply.Wait atleast3minutes forthecomplete dischargeof the

capacitors.

Always connect the equipment frame to the protection earth (PE) in the

appropriateplacefor this.

ATTENTION!

All electronic boards have components that are sensitive to electrostatic

discharges.Nevertouchanyoftheelectricalcomponentsorconnectorswithout

followingpropergroundingprocedures.If necessarytodoso,touchtheproperly

groundedmetallic frame oruse asuitable groundstrap.

NOTE!

Soft-StarterSSW-06can interfere with other electronicequipment.Inorder to

reduce this interference, adopt the measures recommended in Section 3

“Installation”.

NOTE!

Readthisentiremanualcarefullyandcompletelybeforeinstallingor operating

theSoft-StarterSSW-06.

Do not apply high voltage (High Pot) test on Soft-Starter SSW-06!

If this test is necessary, contact the manufacturer

DANGER!

Only qualified personnel should plan or implement the installation, start-up,

operationandmaintenanceofthisequipment.Personnelmustreviewthisentire

Manualbefore attemptingto install,operateortroubleshootthe SSW-06.

These personnel must follow all safety instructions included in this Manual

and/ordefined by local regulations.

Failuretocomply with these instructionsmayresultin personnel injuryand/or

equipmentdamage.

1.3 PRELIMINARY

RECOMMENDATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 20

20

GENERAL INFORMATION

This chapter defines the contents and purpose of this manual and

describes the main characteristics of the SSW-06 Soft-Starter.

Identification of theSSW-06, receiving and storage requirements are

alsoprovided.

This Manual is divided into 10 Chapters, providing information to the

user on how to receive, install, start-up and operate the Soft-Starter

SSW-06.

Chapter1- Safety Notices;

Chapter2- GeneralInformation;ReceivingandStoringoftheSSW-06;

Chapter3- InformationaboutInstallationandConnectionofthe

Soft-Starter SSW-06 power and control circuit), how to

installoptionsandrecommended drives;

Chapter4- Using the Keypad(HumanMachineInterface - HMI);

Chapter5- Information about runningandstepsto befollowed;

Chapter6- Detailed description of all Soft-StarterSSW-06

programmingparameters;

Chapter7- Information andsuggestions on how to program the

types of control and protections

Chapter8- InformationaboutDiagnosticsandTroubleshooting,

cleaninginstructionsandpreventivemaintenance;

Chapter9- SW-06 Soft-Starteroptionaldevices;

Chapter10- Tables and technical informationabout the powerlines

of the Soft-Starter SSW-06;

ThisManualprovidesinformationforthe correctuseof theSoft-Starter

SSW-06.Duetothevarious functionsoftheSoft-StarterSSW-06many

differentmodesof operation are possible.

As the Soft-Starter SSW-06 can be applied in several ways, it is

impossible to describe here all application possibilities, neither can

WEG assume anyresponsibility when the Soft-Starter SSW-06 is not

used according to this Manual.

No part of this Manual maybe reproduced in any form, without written

permissionfrom WEG.

It is important to notethe Software Version installed in the Soft-Starter

SSW-06,sinceitdefinesthefunctionsandtheprogrammingparameters

ofthe Soft-Starter.This Manualrefers to theSoftwareversion indicated

on the inside cover.For example, the Version1.0X applies to versions

1.00to1.09,where“X”isa variablethatwillchangeduetominorsoftware

revisions.

TheSoftware Versioncan be readthe ParameterP023.

TheSoft-StarterSSW-06 is ahigh performance Drive that permitsthe

start Control of three-phase AC induction motors. The Soft-Starter

SSW-06 prevents mechanical shocks on the load and current peaks

in the supply line.

Amongthe maincharacteristicsofthisproductis itslineandconnection

fault detection capacity thus enabling the customer tochose the best

way of protectinghis the motor,such as:

2.1 ABOUTTHISMANUAL

2.2 SOFTWARE VERSION

2.3 ABOUTTHE

SOFT-STARTER

SSW-06

CHAPTER 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 21

CHAPTER2 - GENERALINFORMATION

21

Programmableprotections againstlineundervoltageand

overvoltage,andlinephaseimbalance;

Thermal class maybeprogrammedup toClass45for largemotors.

The thermal memory is saved on EEPROM even in case of an

electronic supplyfault.

Specialfunctions such as:

Displayof the number ofhours,runningtime,supplyvoltagephase,

motor current per phase, motor current in amperes, motor current

asa%oftheSoft-StarterSSW-06ratedcurrentandtheratedcurrent

asa %of the motorcurrent, statusof the digital inputs and outputs;

Setting sequence after reset to factory default;

Veryflexibleselectionof start/stopcontroltype,enablingthefollowing

selections: VoltageRamp, Constant Current Limitingor by Ramp,

PumpControland Constant,LinearorQuadraticTorqueControl;

TotallyflexibleTorque Control providingveryhighperformancefor

themost demanding applications;

Possibility of using all digital inputs, digital outputs and analog

outputsas remote PLCvia Fieldbuscommunication;

Possibilityof monitoringthepowersupplyvoltagemeasurementsin

aPLC networkvia Fieldbus communication.

Control Hardware:

Keypad, referred to as the Human Machine Interface (HMI) with

Liquid-CrystalDisplayandeasyprogramming.Faultconditionscan

bedisplayedinseveral languages.

32Bit Microprocessor calculates the True rms voltage and current;

Measurementof thevoltage and current inthe three phases;

Isolated digitalinput for the motor PTC;

Fieldbus boards and RS-485 as options.

Power Hardware:

Compact size;

Power Supply input and output connections:

Models85A to 820A- Input through the top andoutput through the

bottom of the SSW-06.Models 950A to 1400A - Input and output

throughthe bottom.

Easy assembly and maintenance services;

Measurements of heat sink temperature in models 255A to 820A

through two thermostats:One thermostat to switch-on the internal

fansand the otherto monitorover-heating.

Soft-Starter SSW-06 can be coupled to the motor by a standard

connection or an inside delta motor connection without requiring

optionaldevices.

Incorporated By-pass contactor makes the Soft-Starter SSW- 06

(85Ato 820A):

More resistantto supply line oscillations after starting;

Save energy that would be dissipated through the thyristors after

thestart,thus reducingthenumberoffansrequiredfor controlpanel

cooling.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 22

CHAPTER2 - GENERALINFORMATION

22

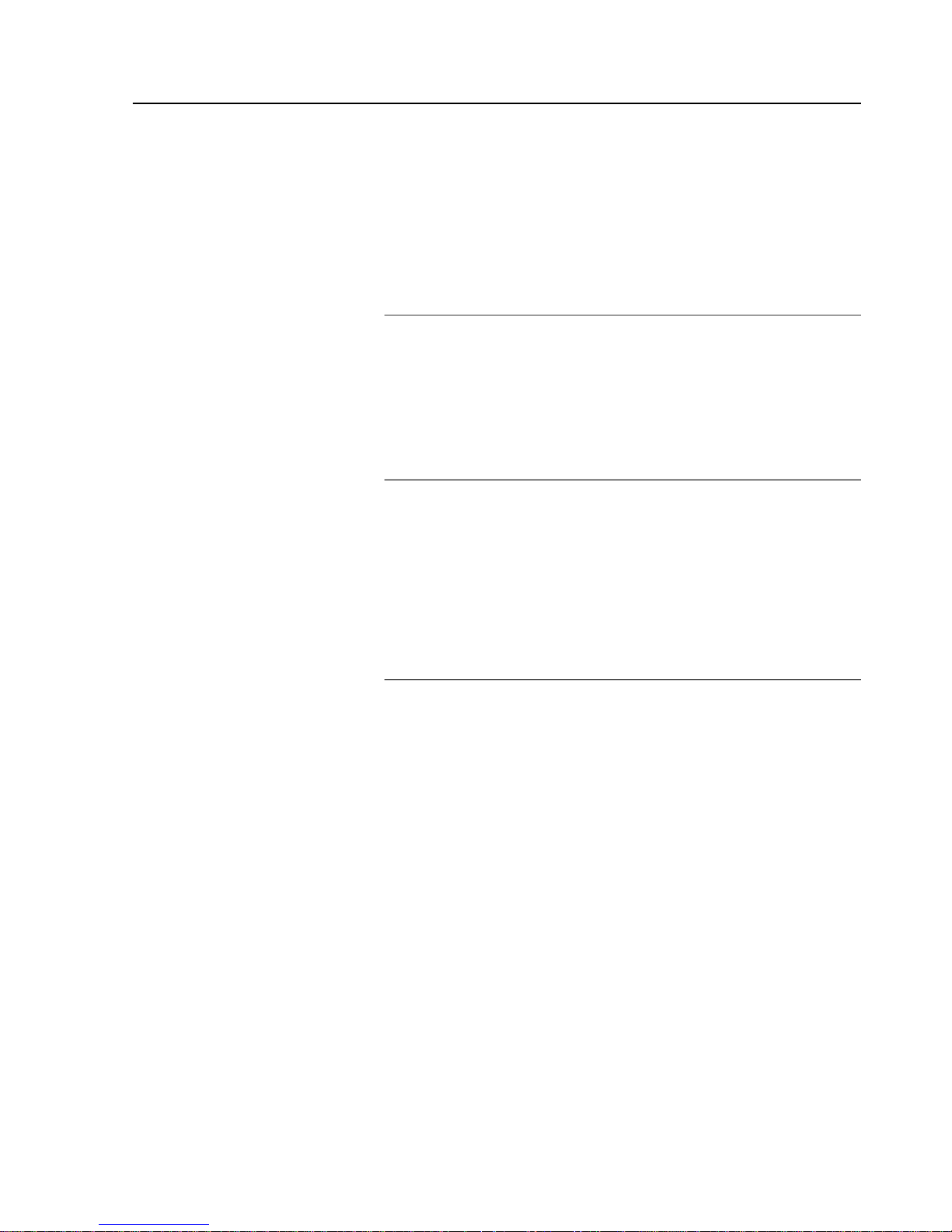

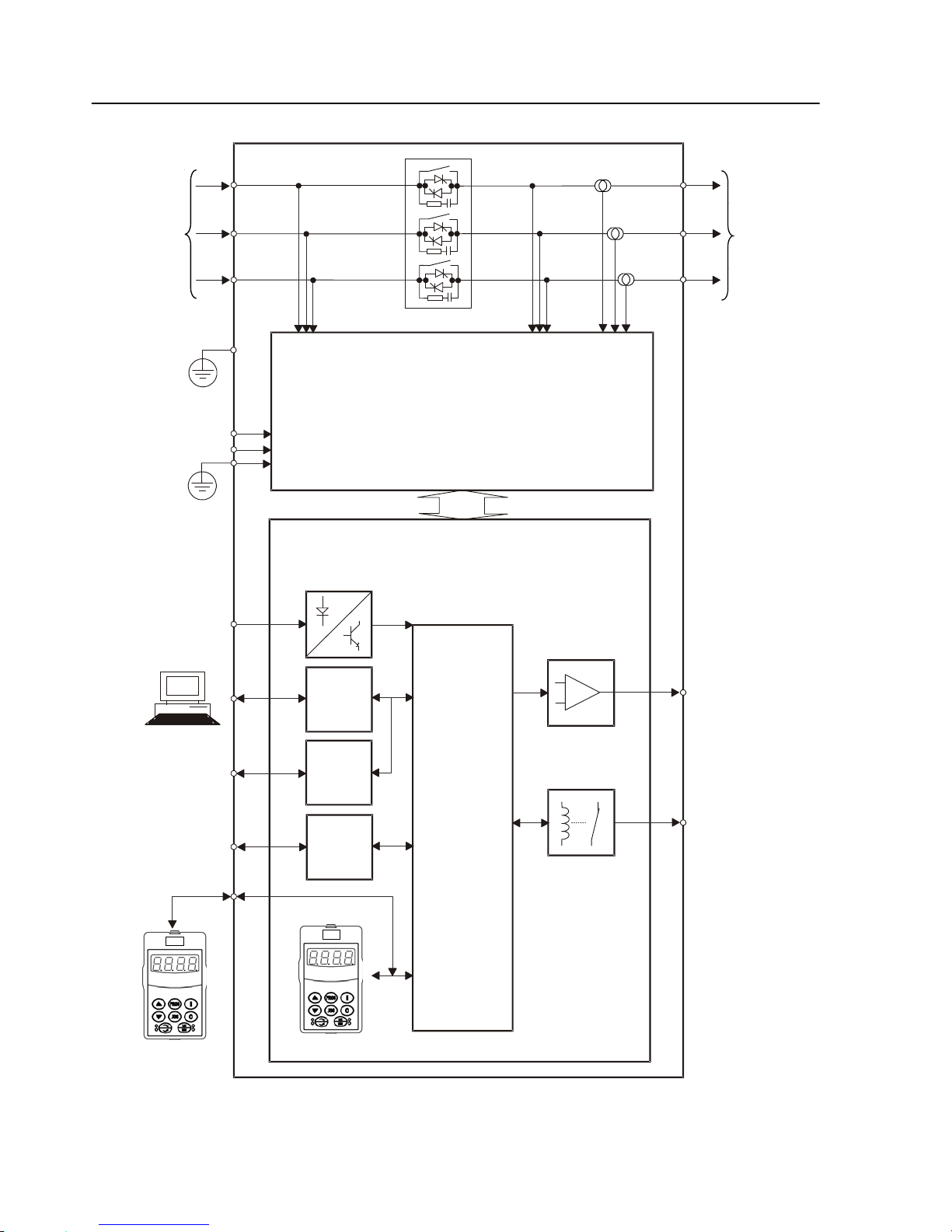

Figure 2.1 - Soft-Starter SSW-06 block diagram

Three-Phase

Power Supply

CONTROL BOARD

Control

Supply

DigitalInputs

Serial

Interface

RS-232

Serial

Interface

(optional)

RS-485

Fieldbus

(optional)

ProfibusDP

DeviceNet

Analog Outputs

DigitalOutputs

Programmable

Analog Outputs

AO1 and AO2

Programmable

DigitalOutputs

RL1...RL3

Programmable

DigitalInputs

DI1...DI6

PC,PLC,MFW,

Super Drive,

ModBUS-RTU

PC,PLC

Three-Phase

Motor

Output

Voltage

Input Voltage

Current

Supply

POWERBOARD

HMI

(Remote)

HMI

(1)

(1)

(1)

CPU

PE

PE

(1) Models 950, 1100 and 1400 do not have an internal By-pass contactor.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 23

CHAPTER2 - GENERALINFORMATION

23

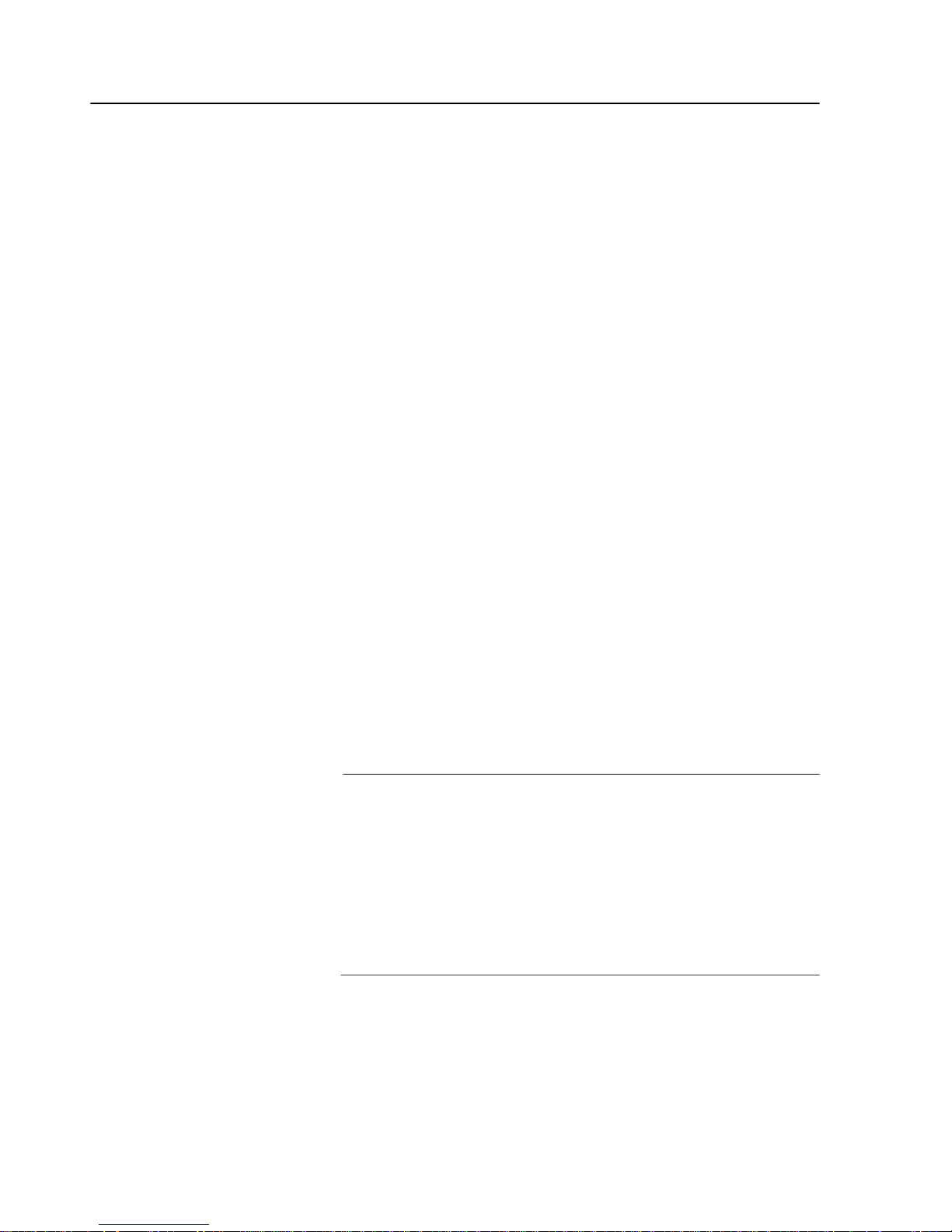

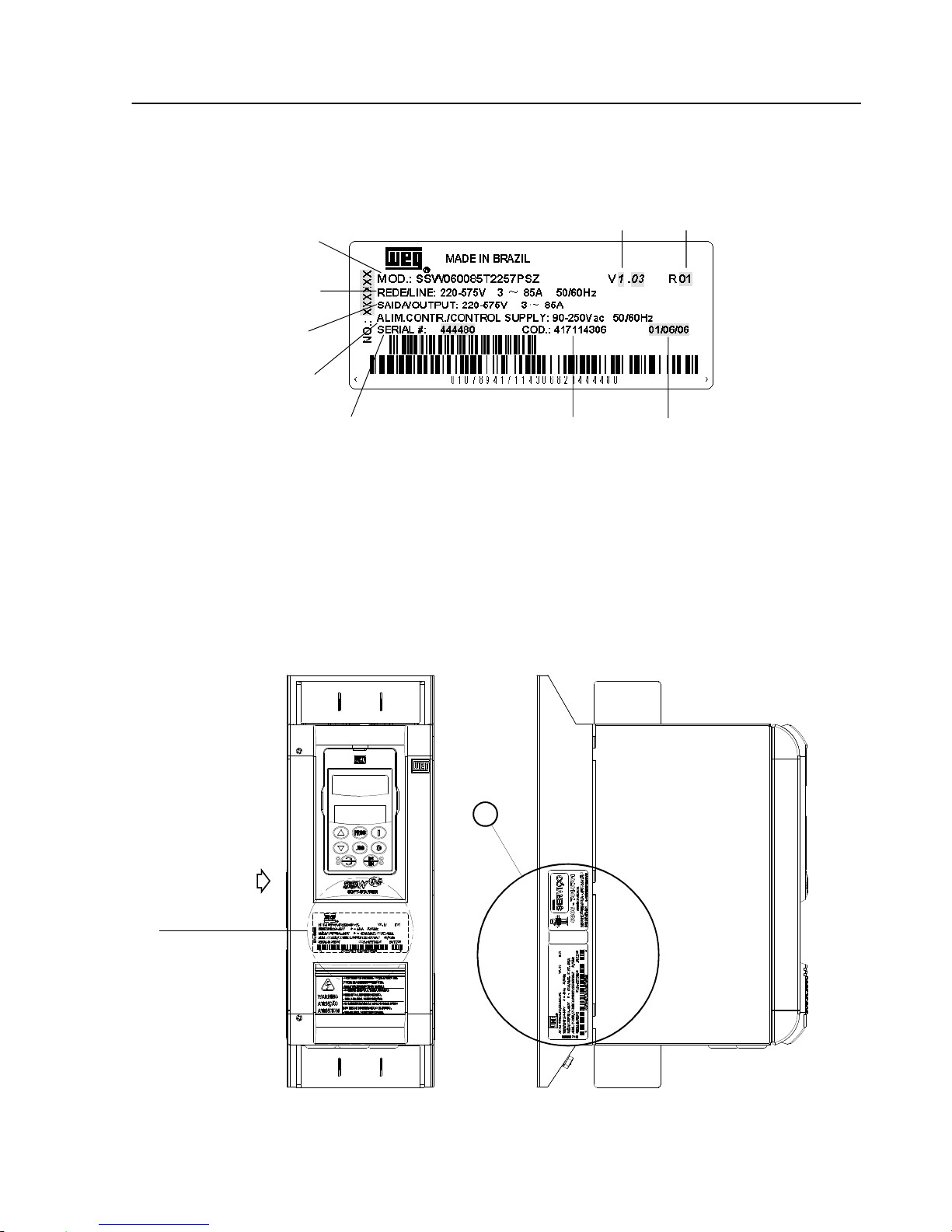

2.4 SOFT-STARTER SSW-06

IDENTIFICATION

Figure 2.2 - Soft-Starter SSW-06 nameplate

LocationofSoft-Starter SSW-06 nameplate:

Figure 2.3 - Detail of the Soft-Starter SSW-06 nameplate

VER DETALHE "A"

X

FRONTAL

A

VISTA DE X

SSW-06 Model

Input Data (Voltage, Number of

Phases, Current, Frequency)

Output Data (Voltage, Number

of Phases, Current)

Control Power Supply Data

(Voltage, Frequency)

SerialNumber

Software

Version

Hardware

Revision

Manufacturing

Date

View Detail A

Identificationnameplate

of the SSW-06

(Internal Cover)

FRONT VIEW VIEWX

WEGItem

Number

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 24

CHAPTER2 - GENERALINFORMATION

24

Rated

Output

Current:

0085=85A

0130=130A

0170=170A

0205=205A

0255=255A

0312=312A

0365=365A

0412=412A

0480=480A

0604=604A

0670=670A

0820=820A

0950=950A

1100=1100A

1400=1400A

Thee-phase

Power

Supply

Power Supply

Voltage:

2257=

(220 to 575)V

Manual

Language:

P= portuguese

E=English

S=Spanish

G=German

Human-

Machine

Interface

(Keypad):

Blank =

standard

SI= without

keypad

HOW TO SPECIFY THE SSW-06 MODEL:

SSW-06 0023 T 2257 P O _ _ _ _ _ _ Z

Special

Software:

Blank =

standard

S1=Special

Software

Special

Hardware:

Blank =

standard

H1 = 115V

Ventilation

(Model950A)

H2 = 230V

Ventilation

(Models

950A,1100A

and1400A)

Soft-Starter

SSW-06

WEG Series

End of

Code

NOTES!

The option field (S or O) defines if the Soft-Starter SSW-6 is a standard version or if it is equipped with any optional devices. If the standard version is

required, the code ends here. The model number alwayshas the letter Z at the end. For example:

SSW060085T2257ESZ = StandardSoft-StarterSSW-06 with current of 85Aand 220V to 575V with Manual in English.

If there are accessories, the spaces must be filled out in the correct sequence until the code ends with the letter zero.

Thestandard productis defined as described here:

Degreeof protection:IP00from 85Ato1400A

Human-Machine-Interface: HMI-SSW06 (withLCDandLEDdisplays).

Obs.: The communication kits are optional, see chapter 9.

Options:

S=Standard

O=with options

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 25

CHAPTER2 - GENERALINFORMATION

25

2.5 RECEIVINGAND

STORAGE

The SSW-06 is supplied in packaging according to the model:

-Models 85A to 205A in a cardboard box;

-Models255A to 365Ain a cardboard boxover a woodenbox;

-Models 412A to 1400A ina woodenbox.

The outside of the packing container has a nameplate that is identical

tothaton the Soft-StarterSSW-06.Pleasecheck if thenameplatedata

matches the ordered data.

Themodels upto 205A must be placedand opened on atable with the

helpof two or more people,open thebox, remove thefoam protection

andremoveSoft-StarterSSW-06.

Themodels up to 205Amust be placed and openedonatablewiththe

helpof twoor more persons.

Open the box, remove the foam protection and remove Soft-Starter

SSW-06 with the help of two or more persons.

Models greater than 255A must be openedon the floor. Open the box

and,removetheboltsthatfastentheSoft-StarterSSW-06 onthepallet.

The Soft-Starter SSW-06 must be handled with a hoist.

Check if:

The Soft-Starter SSW-06 nameplate data matches the purchase

order;

Theequipmenthas not beendamagedduring transportation.If any

problem is detected, contact the carrier immediately.

If the Soft-StarterSSW-06is notto be installedimmediately, storeit

within its original cardboard boxin a clean and dry room (Storage

temperaturesbetween - 10°C(14ºF)and65°C(149ºF)).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 26

26

CHAPTER 3

3.1 MECHANICAL

INSTALLATION

INSTALLATION AND CONNECTION

Thischapterdescribestheelectricandmechanic installationprocedures

of the SSW-06 Soft-Starters. The orientations and suggestions must

befollowedfor correct productfunctioning.

3.1.1Environment Conditions

The location of the Soft-Starter SSW-06 installation is an important

factorto assure good performance andhigh product reliability.

Forproperinstallationof theSSW-06Soft-Starter,wemakethefollowing

recommendations:

Avoiddirectexposuretosunlight,rain,excessivehumidityor marine

environment;

Gases or explosive or corrosiveliquids;

Excessive vibration, dust or metallic and/or oil particles in the air.

Allowed Environment Conditions:

Temperature: 0ºC to 55ºC (32ºF to 131ºF) – Rated conditions for

models 85A to 820A;

0ºC to 40ºC (32ºF to 104ºF) – Ratedconditions for models950A to

1400A.

2%CurrentreductionforeachdegreeCelsiusabovethespecification

in the ratedconditions.

RelativeAir Humidity:5% to 90%, non-condensing.

MaximumAltitude:1000m ( 3,300 ft) - rated conditions.

From1000mto4000m(3,300ftto13,200ft)-with1%currentreduction

foreach100m(330ft)above1000m(3,300ft).

Degree of Pollution:2 (accordingto UL508).

Water,condensationor conductivedust/particlesare notallowedin

the air.

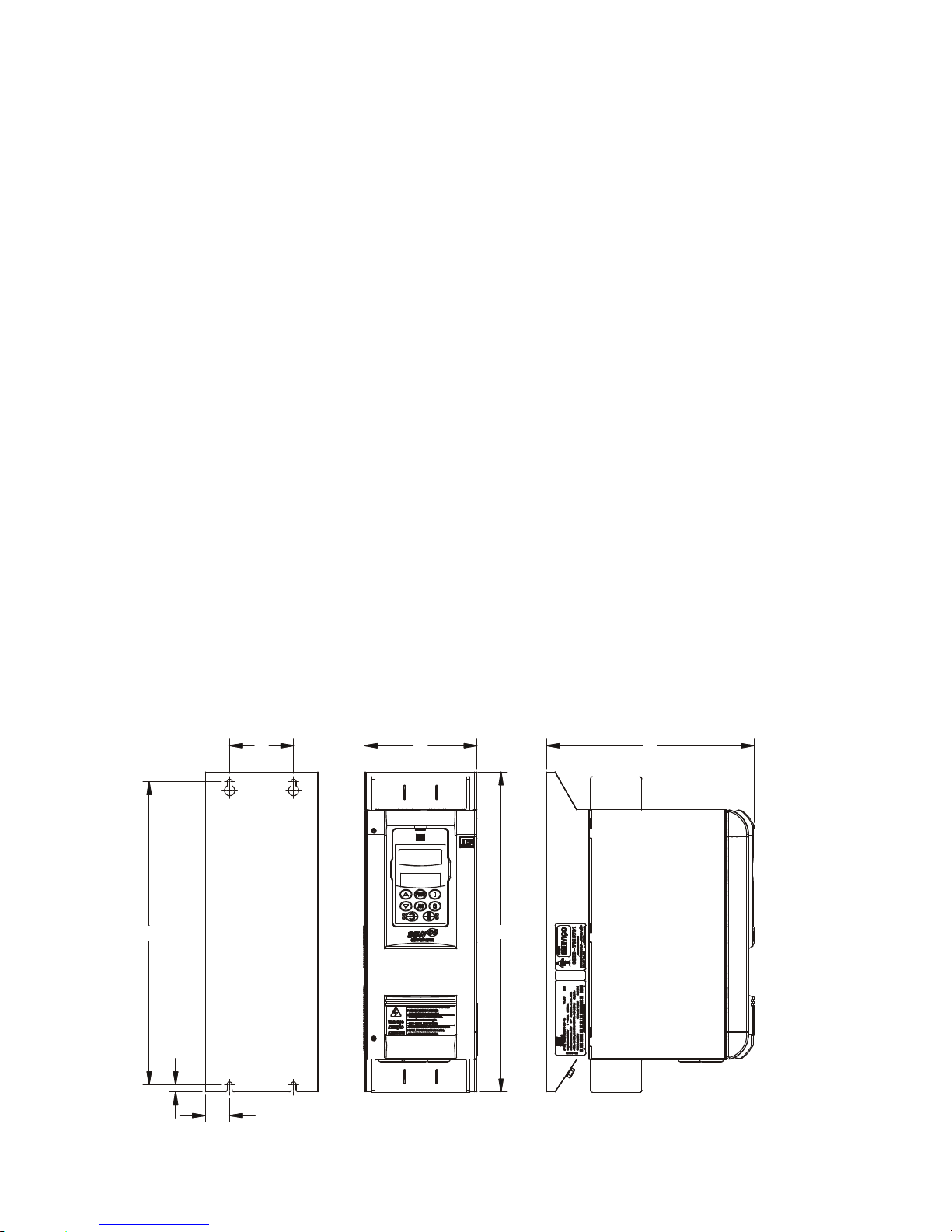

3.1.2 Dimensionsof the

Soft-StarterSSW-06

ExternaldimensionsandmountingholesfollowFigure3.1andTable3.1.

Figure 3.1 - Dimensional Drawings of the Soft-Starter SSW-06

A

W

D

C

B

D2

H

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 27

CHAPTER3 - INSTALLATIONANDCONNECTION

27

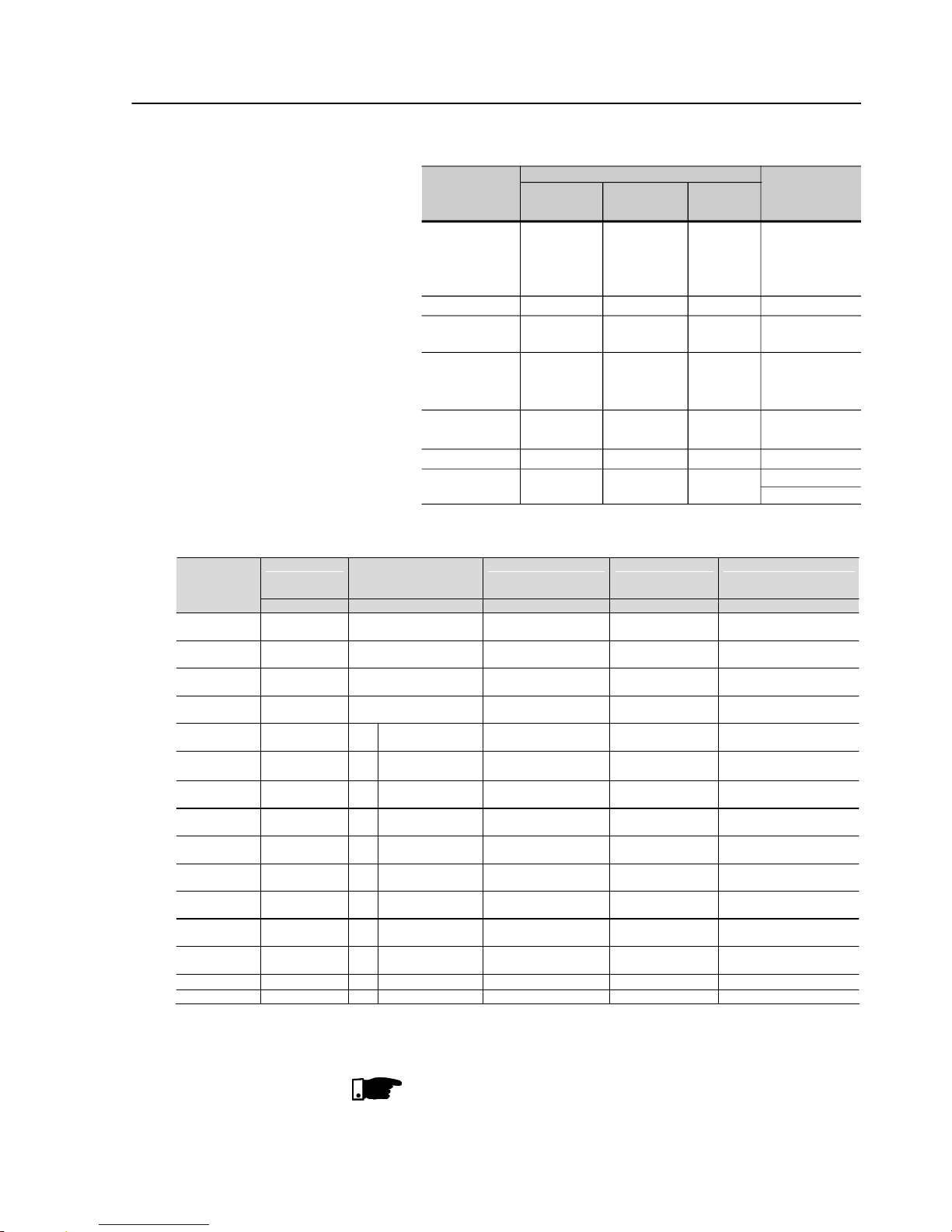

Model

Height Width Depth.

A B C D2

Mounting

Weight

Degree of

H W D

mm mm mm mm

screw

Kg

Protection

mm mm mm

(in) (in) (in) (in)

mm

(lb)

(in) (in) (in)

(in)

SSW-06.0085 370 132 244 75 350 28.5 8.5 M5 8.5

IP00

SSW-06.0130 (14.57) (5.20) (9.61) (2.95) (13.78) (1.12) (0.33) (1/4") (18.74)

SSW-06.0170 440 223 278 150 425 36.5 5.9 M6 18.5

SSW-06.0205 (17.32) (8.78) (10.94) (5.91) (16.73) (1.44) (0.23) (1/4") (40.79)

SSW-06.0255 550 370 311 200 527.5 84.8 10 M6 39.5

SSW-06.0312 (21.65) (14.57) (12.24) (7.87) (20.77) (3.34) (0.39) (1/4") (87.08)

SSW-06.0365

SSW06.0412 650 369.5 347 200 627.5 84.75 11.25 M6 55.0

SSW06.0480 (25.59) (14.55) (13.67) (7.87) (24.7) (3.33) (0.44) (1/4") (121.27)

SSW06.0604

SSW06.0670 795 540 357.12 250 775 145 10 M8 120.0

SSW06.0820 (31.3) (21.26) (14.06) (9.84) (30.51) (5.71) (0.39) (5/16") (264.60)

SSW06.0950 894.5 568.2 345.15 400 810 84.1 10 M8 107.0

(35.22) (22.37) (13.59) (15.75) (31.89) (3.31) (0.39) (5/16") (235.93)

SSW06.1100 1234.8 685 432.94 500 1110 92.5 15 M8 217.5

SSW06.1400 (48.61) (26.97) (17.04) (19.68) (43.7) (3.64) (0.59) (5/16") (479.59)

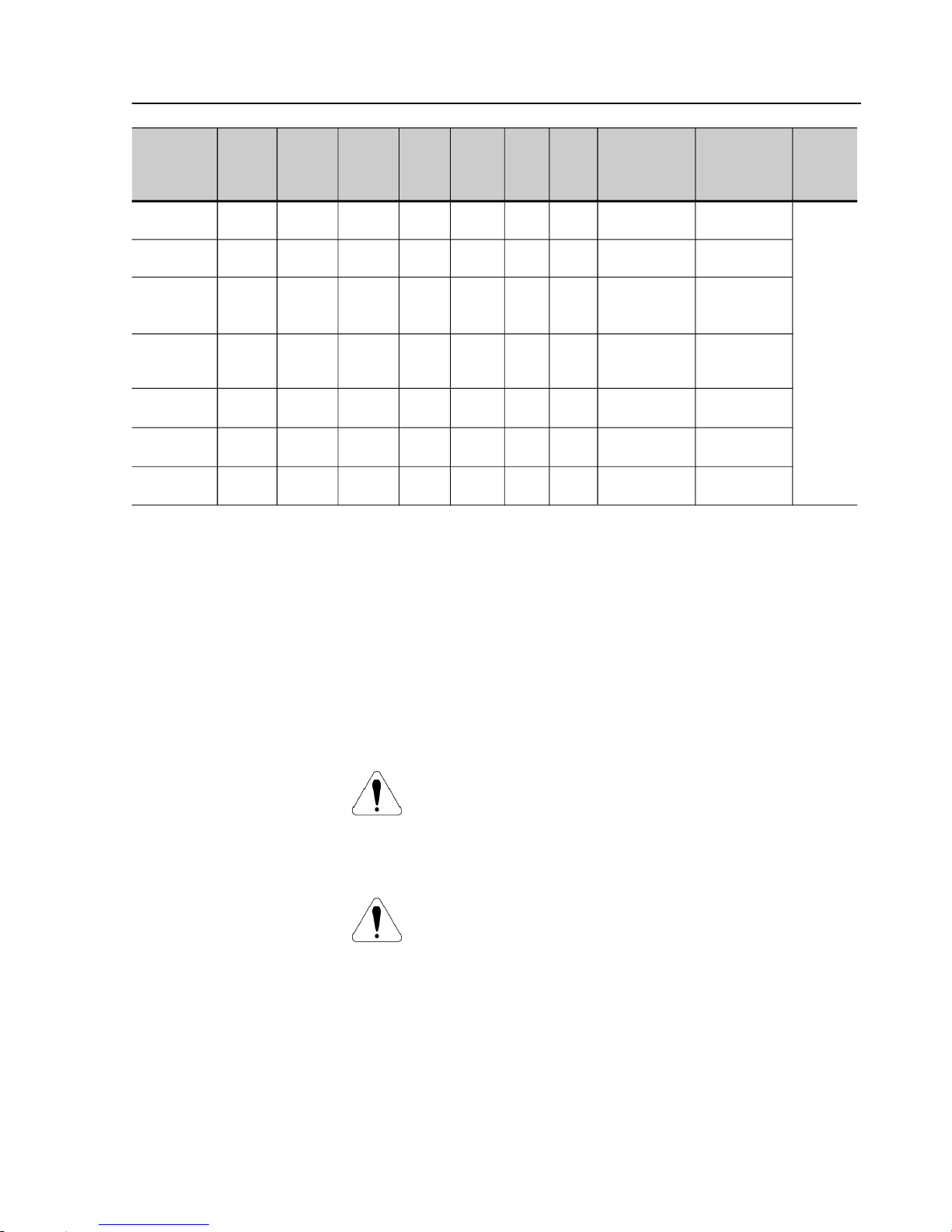

Table 3.1 - Installation Data with dimensions in mm (in)

At least the spaces around the soft-starter must be left open for the

installation of the SSW-06 Soft-Starter, according to Figure 3.2, as

follows.The dimensions of each space are described intable 3.2.

InstalltheSoft-Starter SSW-06inthe verticalpositionaccordingtothe

followingrecommendations:

1) Install the SSW-06 Soft-Starteron a flat surface;

2)Donot place heat sensitivecomponentsontopof theSSW-06 SoftStarter;

ATTENTION!

If the Soft-Starters are installed one next to the other, use minimum

distance B.

WhenaSoft-Starterisinstalledontopof another,useminimum distance

A+Candavoidto the Soft-Starterabovethe hotairthatcomesfrom the

Soft-Starterbelow.

ATTENTION!

Foreseeindependentconduits or electroducts for physicallyseparating

the signal, control and power conductors (see item 3.2, electrical

installation).

3.1.3 Positioning / Fixing

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 28

CHAPTER3 - INSTALLATIONANDCONNECTION

28

Figure 3.2 - Free spaces for cooling

CAY

B

B

Table 3.2 - Recommended free spaces

Air Flow Outlet

Air Flow Inlet

A

mm(in)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

Model

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

B

mm(in)

30 (1.18)

30 (1.18)

30 (1.18)

30 (1.18)

30 (1.18)

30 (1.18)

100 (3.93)

C

mm(in)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

150 (5.90)

Y

mm(in)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

50 (1.96)

WhentheSoft-StarterSSW-06areinstalledinpanelsor closedmetallic

boxes, adequate cooling is required to ensure that the temperature

aroundtheinverterwillnotexceedthemaximum allowedtemperature.

See Dissipated Power in the table 3.4.

3.1.3.1Mounting insideaPanel

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 29

CHAPTER3 - INSTALLATIONANDCONNECTION

29

Use the minimum recommended panel dimensions and its cooling

requirements:

Table 3.3 - Panel Dimensions and Cooling Requirements

Table 3.4 - Power losses for panel fan dimensioning

NOTE!

Thefans abovearerecommended fordutiesof 10starts/hourwith3 x In

oftheSoft-Starterduring30s.

Power Losses

In the

eletronics

Fan Power

Total Power losses in

the SCRs in Full

Voltage

Average power

losses-10 starts/h

3xln@30s

Total average power

losses-10 starts/h

3xIn@30s

Model

W W W W W

SSW-06.0085 33 - 0 = By-pass 76.5 109.5

SSW-06.0130 33 - 0 = By-pass 117.0 150.0

SSW-06.0170 33 - 0 = By-pass 153.0 186.0

SSW-06.0205 33 - 0 = By-pass 184.5 217.5

SSW-06.0255 33

58

528mA@110Vac

264mA@220Vac

0 = By-pass 229.5 320.5

SSW-06.0312 33

58

528mA@110Vac

264mA@220Vac

0 = By-pass 280.8 371.8

SSW-06.0365 33

58

528mA@110Vac

264mA@220Vac

0 = By-pass 328.5 419.5

SSW-06.0412 33

58

528mA@110Vac

264mA@220Vac

0 = By-pass 370.8 461.8

SSW-06.0480 33

58

528mA@110Vac

264mA@220Vac

0 = By-pass 432.0 523.0

SSW-06.0604 33

58

528mA@110Vac

264mA@220Vac

0 = By-pass 543.6 634.6

SSW-06.0670 33

87

396mA@110Vac

972mA@220Vac

0 = By-pass 603.0 723.0

SSW-06.0820 33

87

396mA@110Vac

1391mA@220Vac

0 = By-pass 738.0 858.0

SSW-06.0950 33

160

727mA@110Vac

955mA@220Vac

3420 427.5 3898.0

SSW-06.1100 33

210

955mA@220Vac 3960 495.0 4533.0

SSW-06.1400 33 210 955mA@220Vac 5040 630.0 5703.0

CoolingCFM

(m3/min)

-

-

-

-

-

1757.30 (49.80)

1757.30 (49.80)

2648.44 (75.00)

Model

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

PanelDimensions

Width Hiegth Depth

mm(in) mm (in) mm(in)

600 1200 400

(23.62) (47.24) (15.75)

600 (23.62) 1600 (63.00) 600 (23.62)

600 2000 600

(23.62) (78.74) (23.62)

600 2000 600

(23.62) (78.74) (23.62)

800 2000 600

(31.50) (78.74) (23.62)

800 (31.50) 2000 (78.74) 600 (23.62)

800 2000 600

(31.50) (78.74) (23.62)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 30

CHAPTER3 - INSTALLATIONANDCONNECTION

30

Thetotal power lossescan be determinedthroughthe equationbelow:

where:

Pe = power losses at the electronics (W)

tc = working cycle time (s)

Ip = start current (A)

tp = start time (s)

In = current at rated duty(A), with By-pass In=0

tr = rated duty time (Full Voltage) (s)

Ptd = total power losses (W)

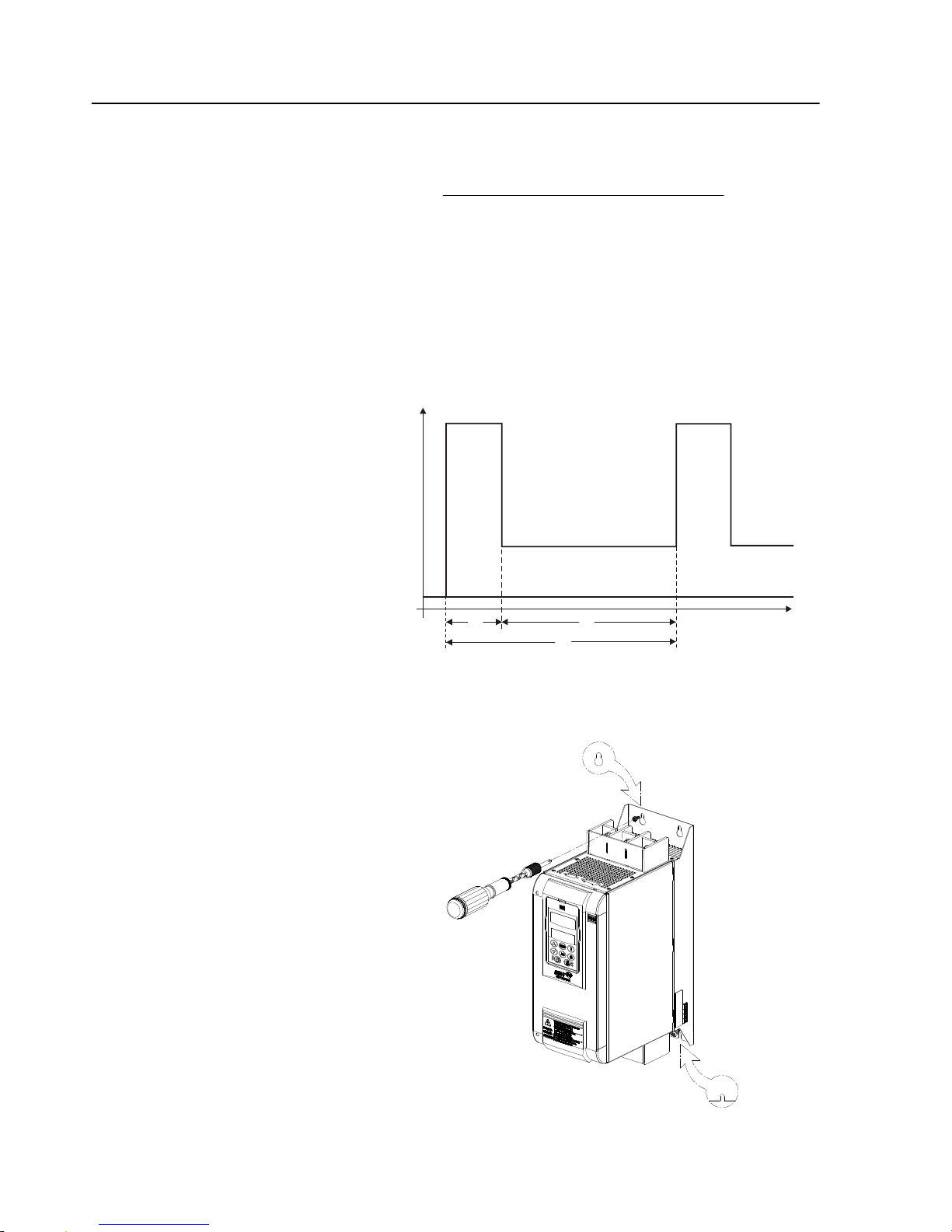

Figure 3.3 - Soft-Starter SSW-06 working cycle for

power loss determination

Ptd

tc

trInVtpIpVtcPe

)32.1()32.1()(

The figure 3.4 shows the installation of the Soft-StarterSSW-06 on a

mountingplate.

3.1.3.2 MountingonaSurface

Figure 3.4 - Mounting procedures for the SSW-06 on a flat surface

P(W)

I(A)

Ip

0

tp

tr

tc

Pe

In

t(s)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 31

CHAPTER3 - INSTALLATIONANDCONNECTION

31

First install and partiallytighten the mountingbolts, inagreement with

figures3,1 and 3,4and table3.1,then installthe Soft- StarterSSW-06

and tighten the mouthing bolts.

Figure 3.5 - Procedures for HMI removal and front cover

opening of the control connections

3.2 ELECTRICAL

INSTALLATION

DANGER!

TheSoft-StarterSSW-06cannotbeusedasanemergencystopdevice.

DANGER!

Be sure that the AC input power is disconnected before making any

terminalconnections.

ATTENTION!

The information belowwill be a guide to achieve a proper installation.

Also follow all applicable local standards for electrical installations.

Provideatleasta 0.25m(10in)spacebetweenthe sensitiveequipment

andwiring from the Soft-Starter SSW-06, andthe cables betweenthe

Soft-StarterSSW-06andthemotor.Example:PLC,temperaturewiring,

thermocouple cables, etc.

Figure 3.6 - Standard power/grounding connections

R/1L1

S/3L2

T/5L3

Circuit-breaker

Line

Fuses

T

S

R

U/2T1 PEV/4T2 W/6T3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 32

CHAPTER3 - INSTALLATIONANDCONNECTION

32

The power connection terminals can be of different sizes and

configurations,dependingontheSoft-StarerSSW-06modelasshown

in Figures 3.8 and 3.9.

Terminals:

R / 1L1, S / 3L2and T / 5L3 :AC supply line

U / 2T1, V / 4T2 and W /6T3: Motor connection.

3.2.1 PowerTerminals

U/2T1 V/4T2 W/6T3 PE

R/1T1 S/3T2 T/5T3

PE

Figure 3.7 - Power/Grounding connections for inside delta motor

connection

R/1L1

S/3L2

T/5L3

Circuit-breaker

Line

Fuses

T

S

R

*Dimensions in mm (in)

a) Models: 85A and 130A

Figura 3.8 a) - Maximum tightening torque for power connection

79.5

(3.13)

25

(0.98)

24.5

(0.96)

20

(0.79)

30.6

(1.20)

20

(0.79)

39

(1.54)

39

(1.54)

27

(1.06)

InputTerminal

Power

Stell M6 (6x)

OutputTerminal

Power

79.5

(3.13)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 33

CHAPTER3 - INSTALLATIONANDCONNECTION

33

*Dimensions in mm (in)

b) Models: 170A and 205A

Figura 3.8 b) c) – Power terminals

55.3

(2.18)

56.3

(1.30)

56.3

(1.30)

39.5

(1.56)

InputTerminal

Power

OutputTerminal

Power

40

(1.57)

Stell M8 (6x)

20

(0.79)

29.4

(1.16)

112

(4.41)

20

(0.79)

132

(5.20)

35

(1.38)

30

(1.18)

80

(3.15)

59.8

(2.35)

41

(1.30)

63.5

(2.50)41(1.30)

63.5

(2.50)

41

(1.30)

InputTerminal

Power

OutputTerminal

Power

Stell M10 (12x)

179.5

(7.07)

179.5

(7.07)

25

(0.98)

25

(0.98)

*Dimensions in mm (in)

c) Models: 225A, 312A, 365A, 412A, 480A and 604A

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 34

CHAPTER3 - INSTALLATIONANDCONNECTION

34

d) Models: 670A and 820A

23.9

(0.94)

120

(4.72)

95

(3.74)

60

(2.36)

85

(3.35)

InputTerminal

Power

OutputTerminal

Power

Stell M12 (12x)

214.3

(8.44)

25

(0.98)

25

(0.98)

60

(2.36)

85

(3.35)

60

(2.36)

29.7

(1.17)

214.3

(8.44)

*Dimensions in mm (in)

e) Models: 950A

*Dimensions in mm (in)

22

(0.87)

66.1

(2.60)

51.7

(2.04)

49.5

(1.95)

53.4

(2.10)

156

(6.14)

22

(0.87)

156

22

(0.87)

50

(1.97)

Output Bus Bar

Power

22

(0.87)

14

(0.55)

212.2

(8.35)

98.8

(3.89)

49.7

(1.96)

110.3

(4.34)

49.7

(1.96)

100

(3.94)

110.3

(4.34)

49.7

(1.96)

Input Bus Bar

Power

40

(1.57)

20

(0.79)

Figura 3.8 d) e) – Power terminals

Stell M12 (12x)

Stell M10 (6x)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 35

CHAPTER3 - INSTALLATIONANDCONNECTION

35

f) Models: 1100Aand 1400A

*Dimensions in mm (in)

50

(1.97)

89

(3.50)

60.3

(2.37)

58

(2.28)

104.5

(4.11)

163

(6.42)

100

(3.94)

Output Bus Bar

Power

262

(10.31)

129.4

(5.09)

40

(1.57)

158

(6.22)

40

(1.57)

120

(4.72)

158

(6.22)

40.7

(1.57)

Input Bus Bar

Power

40

(1.57)

20

(0.79)

Stell M12 (12x)

50

(1.97)

Stell M12 (12x)

163

(6.42)

50

(1.97)

40

(1.57)

20

(0.79)

Figura 3.8 f) – Power terminals

Table 3.5 - Maximum tightening Torque for power connection

Bolt

M6

(1/4")

M8

(5/16")

M10

(3/8")

M10

M12

M12

M12

SSW-06

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

Torque

Nm(lb.in)

8.3

(74.38)

19

(166.25)

37

(328.12)

37

61

61

61

Bolt

M6

(1/4")

M6

(1/4")

M10

(3/8")

M10

M10

M10

M10

Torque

Nm(lb.in)

8.3

(74.38)

8.3

(74.38)

37

(328.12)

37

37

37

37

Line / Motor Grounding

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 36

CHAPTER3 - INSTALLATIONANDCONNECTION

36

3.2.2 Locationof the Power/Grounding,

ControlConnections andFanVoltageSelection

Figura 3.9 a) to e) - Location of the Power/ Grounding, Control Connections and Fan Voltage Selection

a) Models 85A and 130A b) Models 170A and 205A c) Models 255A ,312A and 365A

d) Models 412A,480A and 640A

e) Models 670A and 820A

Grounding

Grounding

Grounding

IntputTerminal

Power

IntputTerminal

Power

IntputTerminal

Power

Power

Control

Power

Control

FanSupply

Control

Power

Fan

VoltageSelection

110/220V

OutputTerminal

Power

OutputTerminal

Power

OutputTerminal

Power

Control

Power

FanSupply

Fan

VoltageSelection

110/220V

OutputTerminalPower

Intputterminal

Power

Grounding

Control

Power

FanSupply

Fan

VoltageSelection

110/220V

Output TerminalPower

Intputterminal

Power

Grounding

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 37

CHAPTER3 - INSTALLATIONANDCONNECTION

37

Figure 3.9 f) and g) – Location of the Power, Grounding, Control and Selection Connections

Control

Power

FanSupply

IntputTerminal

Power

OutputTerminal

Power

Control

Power

FanSupply

OutputTerminal

Power

IntputTerminal

Power

f) Model 950A

g) Models 1100Ato 1400A

Grounding

Grounding

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 38

CHAPTER3 - INSTALLATIONANDCONNECTION

38

3.2.3 RecommendedPower/

GroundingCables

Thedescribed specificationsin tables 3,6 and 3,7 arevalid only for the

followingconditions:

Copper wires with PVC 70°C (158ºF) PVC insulation, for room

temperature of 40°C (104ºF) , installed in perforated and nonagglomeratedconduits

Naked or silvercoaredcopperbusbarswithroundedges and radius

equal to 1 mm with room temperature of 40°C (104ºF) and bus

temperatureof 80°C (176ºF).

Obs.: When external By-pass contactors are applied, use the same

cablesor busbar applied for the motor connection.

NOTE!

Forcorrect cabledimensioning,consider the installationconditionand

themaximum permitted line voltagedrop.

Current

100% In

(A)

85

130

170

205

255

312

365

412

480

604

670

820

950

1100

1400

Model

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

Cables

(mm²)

25

50

70

95

120

185

240

240

300

2 x 150

2 x 185

2 x 240

2 x 300

4 x 150

4 x 185

Bus

(mmxmm)

12 x 2

20 x 3

20 x 3

20 x 3

25 x 5

25 x 5

25 x 5

30x5

40x5

40x5

40x10

40x10

50x10

60x10

80x10

Grounding

Cables

(mm²)

10

25

35

50

70

95

120

120

150

150

185

240

300

2 x 150

2 x 185

Table 3.6 - Minimum specification of cables and busbars for standard

connection

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 39

CHAPTER3 - INSTALLATIONANDCONNECTION

39

Current

100% In

(A)

147

225

294

355

441

540

631

713

831

1046

1160

1420

1645

1905

2424

Model

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

Line

Cables

(mm²)

70

95

150

185

300

400

500

2 x 185

2 x 240

4 x 120

4 x 150

4 x 185

4 x 240

4 x 300

4 x 500

Line

Bus

(mmxmm)

20 x 3

20 x 3

25 x 5

25 x 5

30 x 5

40 x 5

60 x 5

40x10

40x10

50x10

60x10

80x10

100x10

120x10

160x10

Motor

Cables

(mm²)

25

50

70

95

120

185

240

240

300

2 x 150

2 x 185

2 x 240

2 x 300

4 x 150

4 x 185

Motor

Bus

(mmxmm)

12 x 2

20 x 3

20 x 3

20 x 3

25 x 5

25 x 5

25 x 5

30x5

40x5

40x5

40x10

40x10

50x10

60x10

80x10

Grounding

Cables

(mm²)

10

25

35

50

70

95

120

120

150

150

185

240

300

2 x 150

2 x 185

Table 3.7 - Recommended cables for inside delta motor connection

DANGER!

TheAC inputvoltagemust becompatiblewiththeSoft-StarterSSW-06

ratedvoltage.

DANGER!

Providepowersupplydisconnectingswitch.This disconnectingswitch

must disconnect the AC input voltage from the Soft-Starter SSW-06,

always when required(forinstanceduringmaintenanceservices).

DANGER!

If a disconnect switch or a contactor is inserted in the motor supply

line,DO NOT operate these deviceswithrunning motor or when

Soft-Starter SSW-06 is enabled.

ATTENTION!

Controlof overvoltageinthe line thatsupplies the Soft-Startermustbe

madeusingsurgeprotectionwithavoltageof680 Vac(phasetophase

connection) and energy absorption capacity of 40 joules (for models

from 85Ato 205A) or 80 joules (for models from 255A to 1400A).

NOTE!

Use wire sizing and fuses as recommended in Table 3.6, 3.7 and 3.9.

The connector tighteningtorque is as indicated in Table 3.5. Use 70ºC

(158ºF)copper wiresonly.

3.2.4 Connectionof the Power

Supplytothe Soft-Starter

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 40

CHAPTER3 - INSTALLATIONANDCONNECTION

40

The SSW-06 Soft-Starter is suitable to use in a circuit capable of

supplying at most the current (symmetric Arms) established for each

model, and, respective voltage (V) according to table 3.8. This, when

protected by highspeed semiconductor fuses.

3.2.4.1 Power SupplyCapacity

Standard

Connection

220-575V (kA)

10

10

10

10

18

18

18

30

30

42

42

85

85

85

85

Model

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

Inside - Delta

Connection

220-575V (kA)

10

18

18

18

30

30

42

42

42

85

85

85

100

100

125

Table 3.8 - Maximum current capacity of the power supply

The fuses to beused in the inputmust be high speed semiconductor

fuses with l2t lower of equal to 75% of the SCR value indicated above

(A2s).

These fuses will protect the SRCs in case of a short-circuit. Normal

fuses can also be used, instead of the high speed, which will protect

the installationfrom short-circuits, but the SCRs will not be protected.

3.2.4.2 RecommendedFuses

Standard

Connection

In (A)

200

250

450

500

500

500

550

700

900

900

900

1400

1600

1600

2000

Model

SSW-06.0085

SSW-06.0130

SSW-06.0170

SSW-06.0205

SSW-06.0255

SSW-06.0312

SSW-06.0365

SSW-06.0412

SSW-06.0480

SSW-06.0604

SSW-06.0670

SSW-06.0820

SSW-06.0950

SSW-06.1100

SSW-06.1400

Delta - Inside

Connection

In (A)

315

350

500

550

700

700

700

1250

1400

1600

1600

2000

2200

2500

3000

I²t of the SCR

(kA²s)

80

84

245

320

238

238

320

1452

4250

4250

4250

4250

14000

14000

15125

Table 3.9 - Recommended Fuses.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 41

CHAPTER3 - INSTALLATIONANDCONNECTION

41

DANGER!

Powerfactor correctioncapacitorsshouldneverbeinstalledat theoutput

of the Soft-Starter SSW-06 (U / 2T1, V / 4T2 and W /6T3).

ATTENTION!

Fortheprotectionsbasedonthe current readingand indicationto work

correctly, in case of overloadprotection, the rated current of the motor

cannot be lower than30% of the ratedcurrent of the SSW-06

Soft-Starter.

It is not recommended to use motors with the load working duty lower

than 50% of its rated current.

NOTE!

Use wire sizing and fuses as recommended in Table 3.6, 3.7 and 3.9.

The connector tighteningtorque is as indicated in Table3.5. Use 70ºC

(158ºF)copper wiresonly.

NOTE!

Soft-Starter SSW-06 is provided with anelectronic protection against

motor overload. This protection must be set according to the specific

motor. When several motors are connected the same Soft-Starter

SSW-06, use individual overload relaysfor each motor.

The SSW-06 Soft-Starter can be connected to the motor in two

ways, according to 3.2.5.1 and 3.2.5.2.

3.2.5 Connectionofthe

SSW-06Soft-Starter

tothe motor

3.2.5.1 StandardThree-Wire

Connection

(P150=0=Inactive)

The standard 3 wires connection allows the SSW-06 Soft-Starter line

current to be equal to the motor current.

Figure 3.10 - Soft-Starter SSW-06 with standard connection

1/U1

4/U2

2/V1

5/V2

6/W2

3/W1

2/V1

5/V2

1/U1

4/U2

6/W2

3/W1

R

S

T

N

PE

R

S

T

N

PE

R

U

S

V

W

T

R

U

S

V

T

W

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 42

CHAPTER3 - INSTALLATIONANDCONNECTION

42

3.2.5.2 Inside Delta

MotorConnection

(P150=1=Active)

Inthis kind ofconnection,the SSW-06 Soft-Starterlinecurrent is equal

to approximately58% of the rated current of the motor.

Figure 3.11 - Soft-Starter SSW-06 Inside Delta Motor Connection

Figure 3.12 - Soft-Starter SSW-06 Inside Delta Motor Connection - motor

with double delta series connected.

S

S

V

W

R

R

T

T

U

R

S

T

N

PE

2/V1

5/V2

6/W2

3/W1

8/V3

11/V4

7/U3

10/U4

12/W4

9/W3

1/U1

4/U2

Figure 3.13 - Soft-Starter SSW-06 Inside Delta Motor Connection - motor

with double delta parallel connected.

1/U1

4/U2

2/V1

5/V2

6/W2

3/W1

R

S

T

N

PE

S

S

V

W

R

R

T

T

U

2/V1

5/V2

6/W2 3/W1

8/V3

11/V4

12/W4 9/W3

7/U3

10/U4

1/U1

4/U2

R

S

T

N

PE

R

S

W

T

S

R

T

V

U

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 43

CHAPTER3 - INSTALLATIONANDCONNECTION

43

ATTENTION!

Fortheconnectioninside the delta of the motor,themotor must have a

deltaconnection in the desired voltage.

NOTES!

1) In the motor inside delta connection, the SSW-06 Soft-Starter

connection cables to the power supply, fuses and/or the main

contactor must support the rated current of the motor. The motor

connection cables to the Soft-Starter and/or the external By-pass

contactor connection must support 58% of the rated current of the

motor.

2) Due to the presence of high currents and large cable sizes

requirements, we also recommend the use of copper busbars for

connecting the Soft-StarterSSW-06 to the power supply.

3) During the start of the motor current in relation to the Soft-Starteris

1.50. However in full voltage condition (after the start time of the

motor) the current relation is 1.73.

ATTENTION!

Payattentiontotheconnectionofthemotortothe SSW-06Soft-Starter,

respecttheconnectiondiagrams shown in thefiguresaboveaccording

to the type of motor windings. If it is necessary to change the motor

speeddirection,onlyinverttheSSW-06 Soft-Starterconnectionstothe

powersupply.

Maintainthe electronics turned off during the connectionchanges.

ATTENTION!

Ensurecorrectsettingof Parameter P150 before the motor is switched

ON.Soft-StarterSSW-06maybedamaged,whenthisparametersetting

is not correct

P150 Action

0 (Inactive) Soft-Starter SSW-06 with standard connection to motor

1 (Active) Soft-Starter SSW-06 inside of the delta motor connection

DANGER!

TheSoft-Starter SSW-06 must begroundedfor safetypurposes(PE).

Theearthorgroundconnectionmust complywiththelocalregulations.

Forgrounding,usecables withcross sectionasindicatedinTable 3.6.

Make the ground connection to a grounding bar or to the general

groundingpoint (resistance 10 ohms).

DANGER!

TheACinput for the Soft-StarterSSW-06 must be grounded.

DANGER!

Donotusetheneutralconductorforgroundingpurpose.Useaspecific

groundconductor.

ATTENTION!

Do notshare the ground wiring with otherequipment that operate with

highcurrents(forinstance,highvoltagemotors,weldingmachines,etc).

Whenmorethanoneself-starterSSW-06used,see3.14figure.

3.2.6 GroundingConnections

Table 3.10 - Connection of the Soft-Starter to the motor

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 44

CHAPTER3 - INSTALLATIONANDCONNECTION

44

EMI – Electromagnetic interference:

TheSoft-StarterSSW-06isdeveloped to beusedinindustrialsystems

(ClassA) as per NormEN60947-4-2.

It’s necessary to have a distance of 0,25m (10in) between the SoftStarter SSW-06and the cablesbetweentheSoft-StarterSSW-07and

themotor.Example:PLCwiring,temperaturecontrollers,thermocouple

cables, etc.

Grounding the motor frame:

Alwaysgroundthe motorframe. Ground the motor inthe panelwhere

the Soft-StarterSSW-06 is installed.The Soft-StarterSSW-06 output

wiring to the motor must be laid separately from the input wiring, as

well as from thecontrol and signal cables.

Figure 3.14 - Grounding connections for more than one

Soft-StarterSSW-06

Groundingbar

Internalto thePanel

Groundingbar

Internalto thePanel

3.2.7 FanConnections

Available in models 255A to 820A. The rated voltage of the fans can

also be selected.

Figura 3.15 – Selection of the Fan Voltage

X1E

ALIMEN TA ÇÃO

VEN TILA DO R

SEL EÇÃO

DE T ENSÃO

110 /220 V

ATENÇÃO!

SELECIONE A TEN SÃO DOS VENTI LADORES

DEACO RDO CO M A TENS ÃO APLICA DA AOS

BORNES X1:33 E X1:34

ATTENTION!

SELECT THE FAN VOLTAGE IN AC CORDANCE

WITHTH E VOLTA GE APPLI ED TO THE

TERMINALS X1: 33 AND X1: 34

ATENCION!

SELECCIONAR L A TENSIO N DE LOS VENTILA DORES

DEACU ERDO C ON LA TE NSION AP LICADA A LOS

BORNES X1:33 Y X1:34

!

Voltage Selection

110/220V

Fan

Fan Power Supply

Connector X1E pins 33 and 34. More details see figure 3.16.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 45

CHAPTER3 - INSTALLATIONANDCONNECTION

45

3.2.8 SignalandControl

Connections