Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

Ethernet

SCA06

User’s Guide

Page 2

Ethernet User’s Guide

Series: SCA06

Language: English

Document Number: 10004473905 / 00

Build 529

Publication Date: 09/2016

Page 3

Contents

Contents

About the Manual .. . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1 Equipment Characteristics in Ethernet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Modbus TCP specific characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 EtherNet/IP specific characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 PROFINET IO specific characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Ethernet Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Ethernet Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Interfaces Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Ethernet Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Indication LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Network Installation .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Communication Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Network Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Recommendations for Grounding Connection and Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Symbols for the Properties Description .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

P0202 – Operation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

P0662 – Communication Error Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

P0800 – Ethernet Module Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

P0801 – Ethernet Communication Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

P0803 – Ethernet Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

P0806 – Modbus TCP Watchdog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

P0810 – IP Address Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

P0811 – IP Address 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

P0812 – IP Address 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

P0813 – IP Address 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

P0814 – IP Address 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

P0815 – Subnet CIDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

P0816 – Gateway 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

P0817 – Gateway 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

P0818 – Gateway 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

P0819 – Gateway 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

P0820 ... P0831 – Ethernet Read Words #5 ... #16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

P0835 ... P0846 – Ethernet Write Words #5 ... #16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

P0849 – Update Ethernet Configuration .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 I/O Words with Specific Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Input Words – (Slave → Master) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1.1 1st– Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1.2 2nd– Motor Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1.3 3rd– Torque Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SCA06 | 3

Page 4

Contents

6.1.4 4th– Present Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Output Words – (Master → Slave) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.1 1st– Control Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.2 2nd– Speed Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.3 3rd– Torque Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.4 4th– Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Modbus TCP .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Indication LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Available Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3 Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.2 Memory Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4 Communication Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.5 Startup Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.5.1 Installing the Ethernet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.5.2 Configuring the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.5.3 Configuring the Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.5.4 Communication Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.5.5 Operation Using Process Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8 EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.1 Indication LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2 Cyclic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.3 Acyclic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.4 EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.5 Modbus TCP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.6 Startup Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.6.1 Installing the Ethernet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.6.2 Configuring the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.6.3 Configuring the Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.6.4 Communication Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.6.5 Operation Using Process Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9 PROFINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.1 Indication LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.2 Cyclic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.3 Acyclic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.4 XML File – GSDML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.5 Modbus TCP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.6 Startup Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.6.1 Installing the Ethernet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.6.2 Configuring the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.6.3 Configuring the Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.6.4 Communication Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.6.5 Operation Using Process Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10 WEB Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11 Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

F0047/A0147 - Ethernet Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SCA06 | 4

Page 5

Contents

F0048/A0148 - Ethernet interface access error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SCA06 | 5

Page 6

About the Manual

ABOUT THE MANUAL

This manual supplies the necessary information for theoperation of the SCA06 servo drive using the Ethernet interface.

This manual must be used together with the SCA06 user’s manual and programming manual.

SCA06 | 6

Page 7

Equipment Characteristics in Ethernet Network

1 EQUIPMENT CHARACTERISTICS IN ETHERNET NETWORK

Below are listed the main features for Ethernet communication module for SCA06 servo drive.

There are 3 different acessories, according to the specified communication protocol:

– ECO5: EtherNet/IP protocol.

– ECO6: Modbus TCP protocol.

– ECO7: PROFINET IO protocol.

The interface follows the Fast Ethernet 100BASE-TX standard.

It allows communication using the 10 or 100 Mbps rates in half or full duplex mode.

It has a built-in, two-port Ethernet switch.

The Ethernet ports work with Auto-MDIX (automatic medium-dependent interface crossover), a technology which

automatically detects the type of cable used and configures the connection accordingly, eliminating the need of

cross-over cables.

The interface also makes available a Web server (HTTP).

1.1 MODBUS TCP SPECIFIC CHARACTERISTICS

Operates as Modbus TCP server.

The server provides up to 4 simultaneous Modbus TCP connections.

Allows data communication for equipment operation and parameterization, as well as markers and data used for

SCA06 ladder programming.

1.2 ETHERNET/IP SPECIFIC CHARACTERISTICS

It is supplied with an EDS file for the network master configuration.

Allows up to 16 input words and 16 output words for cyclic data communication.

Acyclic data available for parameterization.

Device Level Ring (DLR) and linear network topology supported.

It features up to 2 Modbus TCP connections.

1.3 PROFINET IO SPECIFIC CHARACTERISTICS

It is supplied with a XML file for the network master configuration.

Allows up to 16 input words and 16 output words for cyclic data communication.

Acyclic data available for parameterization.

It features up to 2 Modbus TCP connections.

SCA06 | 7

Page 8

Ethernet Overview

2 ETHERNET OVERVIEW

Following it is presented general information about the Ethernet technology.

2.1 ETHERNET TECHNOLOGY

Ethernet is a technology for interconnecting local area networks (LAN) based on frames forwarding. It defines wiring

and electrical signals for the physical layer, the frame format and protocol for media access control layer (MAC) of the

OSI model.

Ethernet, however, mainly defines the physical medium and the frame format. Based on Ethernet, multiple protocols

and higher-level services were specified and developed in order to perform desired activities over a network, such as

packet routing, connection establishment, sending and receiving files, etc. Several of these protocols have also been

widely disseminated and employed, such as IP, TCP, UDP, FTP, HTTP.

Widely used to interconnect computers in the office environment, the Ethernet technology also started being used in

industrial environments for interconnection of field devices. For industrial environment also emerged different communication protocols based on Ethernet, among which we can mention Modbus TCP, EtherNet/IP, PROFINET.

SCA06 | 8

Page 9

Interfaces Description

3 INTERFACES DESCRIPTION

The SCA06 servo drive uses an accessory to provide a Ethernet interface for communication.

3.1 ETHERNET ACCESSORY

Supplied items:

– Installation guide.

– Ethernet accessory.

X

NOTE!

There are 3 different accessories, according to the specified communication protocol:

ECO5: EtherNet/IP protocol.

ECO6: Modbus TCP protocol.

ECO7: PROFINET IO protocol.

It is important to use the accessory model according to the desired protocol for application.

3.2 CONNECTORS

The accessory for Ethernet communication has two RJ45 connectors for network connection. The connector pin

out follows the Fast Ethernet 100BASE-TX standard, using two pairs of cables for data transmission and reception.

The housings of the Ethernet connectors, which are normally connected to the cable shield, have connections between themselves and to the protective earth via an RC circuit.

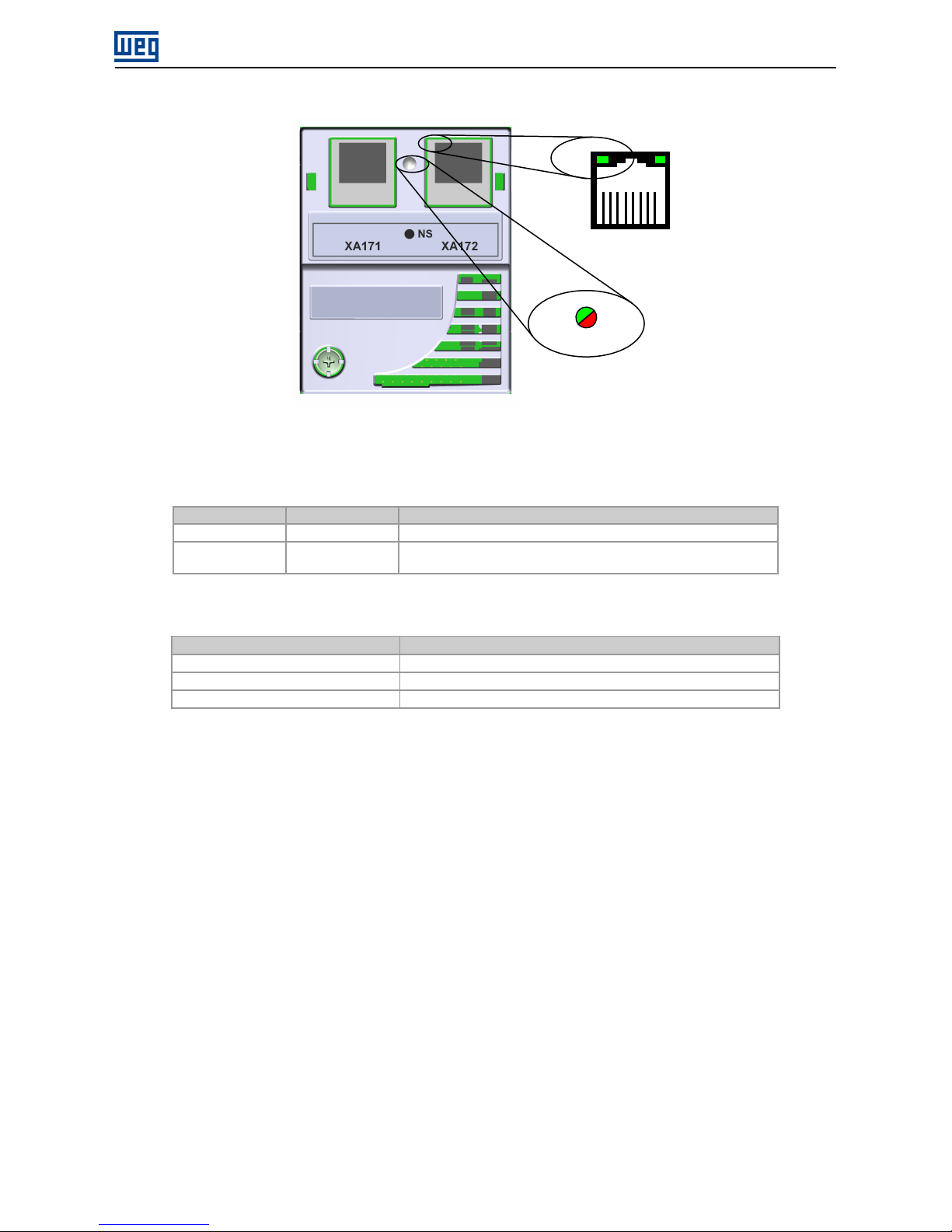

3.3 INDICATION LEDS

The Ethernet accessory has an LED indicator on the Ethernet port, and two bi-color status LEDs. These LEDs have

the following functions and indications:

SCA06 | 9

Page 10

Interfaces Description

Link

NS

Figure 3.1: Ethernet Connectors and LEDs

Table 3.1: Ethernet Indication LEDs

LED Color Function

Link Green LED for link and activity indication.

Network Status

(NS)

Bicolor

(Green/Red)

Has a different behavior depending on the communication protocol,

which is described in the section for each protocol.

Table 3.2: LED Link

State Description

Off No link or powered off.

Green, solid Link up, no activity.

Green, flashing Link up and activity.

SCA06 | 10

Page 11

Network Installation

4 NETWORK INSTALLATION

This chapter presents recommendations related to equipment installation in an Ethernet network.

4.1 IP ADDRESS

Every equipment in an Ethernet network needs an IP address and subnet mask.

The IP addressing is unique in the network, and each equipment must have a different IP. The subnet mask is used

to define which IP address range is valid in the network.

The SCA06 servo drive allows the use of two methods for programming these features, programmable via P0810:

DHCP: enable the configuration of the SCA06 via DHCP server. The DHCP can automatically assign IP addresses,

subnet mask, etc. to the devices on the network. The configurations performed via parameters are disregarded.

Parameters: uses the configurations of IP address, mask and gateway as programmed on equipment parameters.

X

NOTE!

After changing these properties, for the changes to take effect, the equipment must be turned off and

on again, or requesting the Ethernet settings update via P0849.

4.2 COMMUNICATION RATE

The Ethernet interfaces of the SCA06 servo drive can communicate using the 10 or 100 Mbps rates in half or full

duplex mode.

The baud rate is programmed at P0803.

X

NOTE!

It is important that, for each Ethernet connection made between two points, the baud rate and the

duplex mode are set to the same option. If the option AUTO is used in one of the points, you must

set the other point also to AUTO, or to half duplex mode.

For PROFINET IO interface, the baud rate is locked to 100 Mbps as required by the protocol.

4.3 CABLE

Recommended characteristics for the cable:

Standard Ethernet cable, 100Base-TX (FastEthernet), CAT 5e or higher.

Shielded cable.

Maximum length between devices: 100 m.

For installation, it is recommended the use of shielded Ethernet cables specific for use in industrial environment.

SCA06 | 11

Page 12

Network Installation

4.4 NETWORK TOPOLOGY

To connect SCA06 servo drive in an Ethernet network, usually the star connection is made using an industrial switch.

Figure 4.1: Star topology

It is also possible to make the connection in daisy chain, allowing a topology equivalent to a bus.

Figure 4.2: Daisy chain topology

X

NOTE!

When the equipment is turned off, the built-in switch is also deactivated, preventing communication

with the subsequent equipment.

A switch with support to the redundancy technology enables the use of the ring topology.

Figure 4.3: Ring topology

SCA06 | 12

Page 13

Network Installation

4.5 RECOMMENDATIONS FOR GROUNDING CONNECTION AND CABLE ROUTING

The correct connection with the ground decreases problems caused by interference in an industrial environment. The

following are some recommendations about grounding and cable routing:

Always use shielded twisted pair Ethernet cables and connectors with metallic housing.

Connect the equipment grounding via grounding terminal. Avoid the cable connection on multiple grounding

points, especially where there are grounds with different potentials.

Pass signal cables and communication cables in dedicated pathways. Prevent laying these cables next to power

cables.

SCA06 | 13

Page 14

Parameterization

5 PARAMETERIZATION

Next, the SCA06 servo drive parameters related to the Ethernet communication will be presented.

5.1 SYMBOLS FOR THE PROPERTIES DESCRIPTION

RO Read-only parameter

RW Read/write parameter

CFG Parameter that can be changed only with motor stopped.

ETH Parameter visible on the HMI if the product has the Ethernet interface installed

P0202 – OPERATION MODE

Range: 1 = Torque Mode

2 = Speed Mode

3 = No function

4 = Ladder Mode

5 = CANopen/DeviceNet/EtherCAT

6 = Profibus DP/Ethernet

Default: 2

Properties: RW

Description:

This parameter defines the operating mode for SCA06 servo drive, allowing to program which mode is desired for

the motor control, and what is the control source for the device.

In order to control de equipment via Ethernet network, it’s necessary to use mode 6 = Ethernet. In case this mode

is programmed, commands and references for the product operation will be provided by cyclic data via Ethernet

network.

X

NOTE!

The control of equipment using these objects is only possible by selecting the desired option in this

parameter, but Ethernet communication can be used in any operating mode.

The Ethernet interface allows speed and torque control of the SCA06 servo drive. To perform positioning functions, the Ladder operating mode must be used, developing a Ladder application

program and using user’s parameters as the interface with the network master to control and monitor the equipment.

P0662 – COMMUNICATION ERROR BEHAVIOR

Range: 0 = Show Alarm

1 = Generate Fault

2 = Run STOP function

3 = Disable drive

Default: -

Properties: RW

Description:

This parameter allows selecting which action should be executed by the equipment, if it is controlled via network and

a communication error is detected.

SCA06 | 14

Page 15

Parameterization

Table 5.1: Option for parameter P0662

Option Description

0 = Show Alarm If a communication error occurs, only indicates alarm in the keypad. If the communica-

tion is reestablished, the alarm indication is automatically removed.

1 = Generate Fault Instead of an alarm, a communication error causes a fault in the equipment, and it is

necessary to reset the failure to return to normal operation.

2 = Run STOP function It will indicate an alarm along with the execution of the STOP command. To start oper-

ation again, it is necessary to run the fault reset or disable the drive.

3 = Disable drive It will indicate an alarm along with the execution of the disable command.

The following events are considered communication errors:

Ethernet communication:

Alarm A0147/Fault F0047: communication error with Ethernet master.

Alarm A0148/Fault F0048: Ethernet interface error.

P0800 – ETHERNET MODULE IDENTIFICATION

Range: 0 = Not Identified

1 = Modbus TCP

2 = EtherNet/IP

3 = PROFINET IO

Default: -

Properties: RO, ETH

Description:

It allows identifying the Ethernet module type connected to the equipment.

Table 5.2: P0800 indications

Indication Description

0 = Not Identified Module not connected / not identified.

1 = Modbus TCP Ethernet module for communication with Modbus TCP protocol.

2 = EtherNet/IP Ethernet module for communication with EtherNet/IP protocol.

3 = PROFINET IO Ethernet module for communication with PROFINET IO protocol.

P0801 – ETHERNET COMMUNICATION STATUS

Range: 0 = Setup

1 = Init

2 = Wait Comm

3 = Idle

4 = Data Active

5 = Error

6 = Reserved

7 = Exception

8 = Access Error

Default: -

Properties: RO, ETH

Description:

It allows identifying the Ethernet communication status.

SCA06 | 15

Page 16

Parameterization

Table 5.3: P0801 indications

Indication Description

0 = Setup Module identified, waiting configuration data (automatic).

1 = Init Module performing interface initialization procedure (automatic).

2 = Wait Comm Initialization finished, but no communication with master.

3 = Idle Communication with master established, but in Idle mode or Program mode.

4 = Data Active Communication with master established and performing normal I/O data handling. ”On-

line”.

5 = Error Communication error detected.

6 Reserved

7 = Exception Major fault detected by the Ethernet interface. Requires interface reinitialization.

8 = Access error Major fault detected between device and Ethernet interface. Requires interface reinitial-

ization.

P0803 – ETHERNET BAUD RATE

Range: 0 = Auto

1 = 10Mbit/s, half duplex

2 = 10Mbit/s, full duplex

3 = 100Mbit/s, half duplex

4 = 100Mbit/s, full duplex

Default:

0

Properties: RW, ETH

Description:

It allows to set the desired baud rate for the Ethernet interface.

X

NOTE!

For the changes in this parameter be effective, the equipment must be powered off and on again,

or an update must be performed by P0849.

For PROFINET interface, the baud is locked to 100Mbit/s as required by the protocol.

P0806 – MODBUS TCP WATCHDOG

Range: 0.0 to 65.5 s Default: 0.0

Properties: RW, ETH

Description:

It allows programming a time limit for the detection of Ethernet offline error, for Modbus TCP protocol. If the SCA06

remains without receiving valid telegrams longer than the time programmed in this parameter, it will be considered

that a communication error has occurred, the alarm A147 will be showed on the HMI and the option programmed in

P0662 will be executed.

After being powered up, the SCA06 starts counting this time from the first received valid telegram. The value 0.0

disables this function.

X

NOTE!

For the changes in this parameter be effective, the equipment must be powered off and on again, or

an update must be performed by P0849.

SCA06 | 16

Page 17

Parameterization

P0810 – IP ADDRESS CONFIGURATION

Range: 0 = Parameters

1 = DHCP

Default: 1

Properties: RW, ETH

Description:

It allows to choose how to set the IP address for the Ethernet modules.

Table 5.4: P0810 options

Option Description

0 = Parameters The settings for IP address, sub-net mask and gateway shall be done by means of

parameters P0811 to P0819.

1 = DHCP Enables DHCP function. A DHCP server should set the IP address, sub-net mask and

gateway through network.

X

NOTE!

For the changes in this parameter be effective, the equipment must be powered off and on again, or

an update must be performed by P0849.

P0811 – IP ADDRESS 1

P0812 – IP ADDRESS 2

P0813 – IP ADDRESS 3

P0814 – IP ADDRESS 4

Range: 0 ... 255 Default: 192.168.0.10

Properties: RW, ETH

Description:

If P0810 = 0 (parameters), these parameters allow you to program the IP address of the Ethernet module. For other

option of P0810, these parameters have no function.

Each parameter programs one octet of the IP address, where the P0811 is the most significant octet. The programmed IP address, then, has the format “P0811.P0812.P0813.P0814”.

X

NOTE!

For the changes in this parameter be effective, the equipment must be powered off and on again, or

an update must be performed by P0849.

P0815 – SUBNET CIDR

Range: 1 ... 31 Default: 24

Properties: RW, ETH

Description:

If P0810 = 0 (parameters), this parameters allow you to program the sub-net mask for the Ethernet module. The

subnet mask can usually be programmed using a notation with 4 octets separated by dots, or CIDR notation, in

which the value is the number of bits with value “1” in the subnet mask. For other option of P0810, this parameter

has no function.

SCA06 | 17

Page 18

Parameterization

The following table shows the allowed values for the CIDR notation and equivalent dot notation for the subnet mask:

Table 5.5: P0815 options

CIDR Sub-net mask CIDR Sub-net mask

1 128.0.0.0 17 255.255.128.0

2 192.0.0.0 18 255.255.192.0

3 224.0.0.0 19 255.255.224.0

4 240.0.0.0 20 255.255.240.0

5 248.0.0.0 21 255.255.248.0

6 252.0.0.0 22 255.255.252.0

7 254.0.0.0 23 255.255.254.0

8 255.0.0.0 24 255.255.255.0

9 255.128.0.0 25 255.255.255.128

10 255.192.0.0 26 255.255.255.192

11 255.224.0.0 27 255.255.255.224

12 255.240.0.0 28 255.255.255.240

13 255.248.0.0 29 255.255.255.248

14 255.252.0.0 30 255.255.255.252

15 255.254.0.0 31 255.255.255.254

16 255.255.0.0

X

NOTE!

For the changes in this parameter be effective, the equipment must be powered off and on again, or

an update must be performed by P0849.

P0816 – GATEWAY 1

P0817 – GATEWAY 2

P0818 – GATEWAY 3

P0819 – GATEWAY 4

Range: 0 ... 255 Default: 0.0.0.0

Properties: RW, ETH

Description:

If P0810 = 0 (parameters), these parameters allow you to program the IP address of the default gateway for the

Ethernet modules. For other option of P0810, these parameters have no function.

Each parameter programs one octet of the gateway address, where the P0816 is the most significant octet. The

programmed gateway IP address, then, has the format “P0816.P0817.P0818.P0819”.

X

NOTE!

For the changes in this parameter be effective, the equipment must be powered off and on again, or

an update must be performed by P0849.

P0820 ... P0831 – ETHERNET READ WORDS #5 ... #16

Range: 0 ... 9999 Default: 0

Properties: RW, ETH

Description:

These parameters allow programming the number of read words (inputs: slave → master), as well as the content of

SCA06 | 18

Page 19

Parameterization

each word.

The first four read words are pre-defined, representing the value of the status word, motor speed, torque current

and present control mode (refer to item 6.1), and are always sent to the network master. The words #5 to #16 can

be programmed by the user. By using these parameters it is possible to program the number of another parameter

whose content must be made available at the network master input area. If, for instance, one wants to read from the

SCA06 servo drive the motor current in Amps, one must program the value 3 in one of these parameters, because

the parameter P0003 is the one that contains this information. It is worthwhile to remind that the value read from any

parameter is represented with a 16 bit word. Even if the parameter has decimal resolution, the value is transmitted

without the indication of the decimal places. E.g., if the parameter P0003 has the value 4.7A, the value supplied via

the network will be 47.

The number of read words is defined by programming zero in the last parameter required for communication. Besides

the four predefined words, it will also be added to the input area the words programmed in these parameters if the

contents programmed for these parameters is different from zero. The first parameter set to zero disables the use of

itself and the other parameters in the sequence. For example, if you set P0820 = 0, only four predefined read words

(state, speed, torque current and present control mode) will be communicated with the master.

Table 5.6: Read words programming

Input

Number of read words

(slave → master)

Fixed

Status word

4

5

6

7

16

Motor speed

Torque current

Present control mode

Programmable

Programmable in P0820

Programmable in P0821

Programmable in P0822

.

.

.

Programmable in P0831

The same number of words programmed into the equipment must be programmed in the master when configuring

the network.

X

NOTE!

If, after parameter settings, the number of words changes, to make the new configuration effective the

equipment must be powered off and on again, or an update must be performed by P0849.

P0835 ... P0846 – ETHERNET WRITE WORDS #5 ... #16

Range: 0 ... 9999 Default: 0

Properties: RW, ETH

Description:

These parameters allow programming the number of write words (outputs: master → slave), as well as the content

of each word.

The first four write words are pre-defined, representing the value of the control word, speed reference, torque reference

and control mode (refer to item 6.2), and are always received from the network master. The words #5 to #16 can

be programmed by the user. By using these parameters it is possible to program the number of another parameter

whose content must be made available at the network master output area. If, for instance, one wants to write to

the SCA06 servo drive the ramp for STOP function, one must program the value 105 in one of these parameters,

because the parameter P0105 is the one to program this information. It is worthwhile to remind that the value written

from any parameter is represented with a 16 bit word. Even if the parameter has decimal resolution, the value is

transmitted without the indication of the decimal places. E.g., if the parameter P0105 has the value 5.0s, the value

supplied via the network will be 50.

SCA06 | 19

Page 20

Parameterization

The number of write words is defined by programming zero in the last parameter required for communication. Besides

the four predefined words, it will also be added to the output area the words programmed in these parameters if the

contents programmed for these parameters is different from zero. The first parameter set to zero disables the use of

itself and the other parameters in the sequence. For example, if you set P0835 = 0, only four predefined write words

(control, speed reference, torque reference and control mode) will be communicated with the master.

Table 5.7: Write words programming

Output

Number of write words

(master → slave)

Fixed

Control word

4

5

6

7

16

Speed reference

Torque reference

Control mode

Programmable

Programmable in P0835

Programmable in P0836

Programmable in P0837

.

.

.

Programmable in P0846

The same number of words programmed into the equipment must be programmed in the master when configuring

the network.

X

NOTE!

If, after parameter settings, the number of words changes, to make the new configuration effective the

equipment must be powered off and on again, or an update must be performed by P0849.

P0849 – UPDATE ETHERNET CONFIGURATION

Range: 0 = Normal Operation

1 = Update configuration

Default: 0

Properties: RW, ETH

Description:

It allows you to force a reset of the Ethernet interface, to update the settings made in the device parameters. When

setting this parameter to “1”, the Ethernet interface is restarted, resulting in loss of communication during this process.

After the process is complete, the parameter switch automatically to “0”.

SCA06 | 20

Page 21

I/O Words with Specific Function

6 I/O WORDS WITH SPECIFIC FUNCTION

The servo drive SCA06 can communicate from 4 to 16 input/output words (I/O). The first four I/O words have predefined functions, whose formats and functions are described below.

6.1 INPUT WORDS – (SLAVE → MASTER)

6.1.1 1st– Status Word

Word that indicates the equipment status, providing information about licenses, faults, etc.

Bit

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Function

Limit switch

counterclockwise active

Limit switch clockwise

active

Reserved

In Alarm

Safety function active

In Stop

Energized Power

In Fault

Enabled

Reserved

Table 6.1: Functions of the bits for the specific status word of the SCA06

Bit Value/Description

Bit 0 ... 1 Reserved

Bit 2

Enabled

0: Drive disabled.

1: Drive enabled, it is driving the motor according to the control mode.

Bit 3

In Fault

0: No fault in the drive.

1

: Drive in fault status.

Bit 4

Power Energized

0: No power on the power circuit or in undervoltage.

1: Power circuit of the drive fully energized, ready to enable.

Bit 5

In Stop

0: STOP function inactive.

1: STOP function active.

Bit 6

Safety Stop Active

0: Safety stop function (STO) inactive.

1: Safety stop function (STO) inactive.

Bit 7

In Alarm

0: No alarm.

1: Drive with some active alarm.

Bit 8 ... 13 Reserved

Bit 14

Limit switch clockwise active

0: No limit switch clockwise signal.

1: Limit switch clockwise signal was activated.

Bit 15

Limit switch counterclockwise active

0: No limit switch counterclockwise signal.

1: Limit switch counterclockwise signal was activated.

6.1.2 2nd– Motor Speed

Word that indicates the motor speed. Specific motor speed of the SCA06, where the value 7FFFh (32767) corresponds to 18750 rpm. Negative values represent the motor spinning counterclockwise.

X

NOTE!

In this word, it is indicated the instant speed value, without filter. For this reason, it is normal the

oscillation of the value read around the operation point.

SCA06 | 21

Page 22

I/O Words with Specific Function

6.1.3 3rd– Torque Current

Word that indicates the torque current, proportional to the equipment current that generates torque. The indication

is done in ampere (A), with one-decimal place resolution. Example: If the current value is 4.7A, the value read via

network will be 47. Negative values represent negative torque current.

6.1.4 4th– Present Control Mode

It indicates which control mode is selected for the equipment:

Bit

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Function

Reserved

Control Mode

Table 6.2: Functions of the bits for the control mode of the SCA06

Bit Value/Description

Bit 0 ... 3

Control Mode

It defines present control mode of the equipment:

0: Torque mode.

1: Velocity mode.

3: Position mode.

Bit 4 ... 15 Reserved

6.2 OUTPUT WORDS – (MASTER → SLAVE)

6.2.1 1st– Control Word

Word that allows sending command to the equipment. Only used by the SCA06 if the operating mode is set for

Ethernet (P0202 = 6).

Bit

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Function

Reserved

Fault Reset

Reserved

Enable

Activate STOP

Reserved

Table 6.3: Functions of the bits for specific control word of the SCA06

Bit Value/Description

Bit 0 ... 1 Reserved

Bit 2

Activate STOP

0: No STOP function.

1: Activates STOP function.

Bit 3

Enable

0: Disable drive.

1: Enable Drive.

Bit 4 ... 6 Reserved

Bit 7

Fault Reset

0: No function.

0 → 1: Resets the equipment faults.

Bit 8 ... 15 Reserved

SCA06 | 22

Page 23

I/O Words with Specific Function

6.2.2 2nd– Speed Reference

Word for programming the motor speed reference. Specific motor speed of the SCA06, where the value 7FFFh

(32767) corresponds to 18750 rpm. Negative values represent counterclockwise reference.

6.2.3 3rd– Torque Reference

Word that allows programming the reference for the torque current of the servoconverter. The reference is programmed in ampere (A), with one-decimal place resolution. Example: when sending the value 47, the drive will take

a reference equal to 4.7A. Negative values represent negative referece for the torque current.

6.2.4 4th– Control Mode

Allows programming the equipment control mode:

Bit

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Function

Reserved

Control Mode

Table 6.4: Functions of the bits for the control mode of the SCA06

Bit Value/Description

Bit 0 ... 3

Control mode

It defines the present control mode of the equipment:

0: Torque mode.

1: Velocity mode.

Other values are reserved.

Bit 4 ... 15 Reserved

X

NOTE!

The Ethernet interface allows speed and torque control of the servoconverter SCA06. To perform

positioning functions, the Ladder operating mode must be used, developing a Ladder application

program and using the user’s parameter as interface with the network master to control and monitor

the equipment.

SCA06 | 23

Page 24

Modbus TCP

7 MODBUS TCP

This chapter shows operating characteristics of the servo drive SCA06 using the accessory for communication as

Modbus TCP server.

7.1 INDICATION LEDS

The NS LED have the following information for Modbus TCP protocol:

Table 7.1: Network Status LED (NS)

State Description

Off No power or no IP address.

Green, solid Connection established.

Green, flashing Waiting for connections.

Red, solid Duplicate IP address, or fatal error (interface must be reinitialized).

Red, flashing Modbus communication timed out.

7.2 AVAILABLE FUNCTIONS

In the Modbus specification are defined the functions used to access different types of data. In the SCA06, in order

to access those data the following services (or functions) have been made available:

Table 7.2: Supported Modbus Functions

Code Name Description

01 Read Coils Reading of bit blocks of the coil type.

02 Read Discrete Inputs Reading of bit blocks of the discrete input type.

03 Read Holding Registers Reading of register blocks of the holding register type.

04 Read Input Registers Reading of register blocks of the input register type.

05 Write Single Coil Writing in a single bit of the coil type.

06 Write Single Register Writing in a single register of the holding type.

15 Write Multiple Coils Writing in bit blocks of the coil type.

16 Write Multiple Registers Writing in register blocks of the holding register type.

43 Read Device Identification Identification of the device model.

7.3 MEMORY MAP

The servo drive SCA06 has different types of data accessible through the Modbus communication. These data are

mapped at data addresses and access functions as described in the following items.

7.3.1 Parameters

The SCA06 Modbus communication is based on the reading/writing of the equipment parameters. All the drive

parameters list is made available as 16-bit holding registers type. The data addressing is done with the offset equal

to zero, which means that the parameter number corresponds to the register number. The following table illustrates

the parameters addressing, which can be accessed as holding register:

SCA06 | 24

Page 25

Modbus TCP

Table 7.3: Parameters Access - Holding Registers

Parameter Modbus data address (decimal)

P0000 0

P0001 1

.

.

.

.

.

.

P0100 100

.

.

.

.

.

.

It is necessary to know the device list of parameters to be able to operate the equipment. Thus, it is possible to

identify what data are needed for the status monitoring and the control of the functions. The main parameters are:

Monitoring (reading):

P0002 (holding register 2): Motor speed

P0052 (holding register 52): Fractions of revolution

Command (writing):

P0099 (holding register 99): Enable

P0121 (holding register 121): Speed reference

P1100 (holding register 1100): User parameter 1100

Refer to the Programming Manual for a complete parameter list of the equipment.

X

NOTE!

All the parameters are treated as holding registers. Depending on the master that is used, those

registers are referenced starting from the base address 40000 or 4x. In this case, the address

that must be programmed in the master for a parameter is the address showed in the table above

added to the base address. Refer to the master documentation to find out how to access holding

registers.

It should be noted that read-only parameters can only be read from the equipment, while other

parameters can be read and written through the network.

7.3.2 Memory Markers

Besides the parameters, other types of data as bit markers, word or float, can also be accessed using the Modbus

protocol. Those markers are used mainly by the SoftPLC function, available for the SCA06. Refer to the SoftPLC

documentation for the description of those markers, as well as for the addresses via Modbus.

7.4 COMMUNICATION ERRORS

Communication errors may occur in the transmission of telegrams, as well as in the contents of the transmitted

telegrams. Transmission and connection errors are directly processed by the Ethernet interface and by the TCP/IP

protocol.

In the event of a successful reception, during the treatment of the telegram, the server may detect problems and send

an error message, indicating the kind of problem found:

SCA06 | 25

Page 26

Modbus TCP

Table 7.4: Error codes for Modbus

Error Code Description

1 Invalid function: the requested function is not implemented for the equip-

ment.

2 Invalid data address: the data address (register or bit) does not exist.

3 Invalid data value:

Value out of the allowed range.

Writing on data that cannot be changed (read only register or bit).

X

NOTE!

It is important that it be possible to identify at the client what type of error occurred, in order to be able

to diagnose problems during the communication.

7.5 STARTUP GUIDE

The following items describe main steps for SCA06 commissioning using the Modbus TCP protocol. These steps

represent an example of use. Refer to specific chapters for details on the steps.

7.5.1 Installing the Ethernet Module

1. Install the Ethernet communication module, as indicated in the installation guide supplied with the module.

2. Connect the Ethernet cable to the module, considering the recommended instructions in network installation,

as described in item 4:

Use shielded cable.

Properly ground network equipment.

Avoid laying communication cables next to power cables.

7.5.2 Configuring the Drive

1. Follow the recommendations described in the user’s manual to program the device parameters related to motor

settings, desired operation mode, I/O signs, etc.

2. Program command sources as desired for application.

3. Program communication parameters such as DHCP, IP address, baud rate, etc.

4. Program the timeout for Modbus TCP communication in parameter P0806.

5. Define which parameters will be read and written at SCA06 servo drive, based on its parameter list. It is not

necessary to define I/O words. The Modbus TCP protocol enables direct access to any device parameter, and

does not distinguish between cyclic and acyclic data. The main parameters that can be used to control the

device, we can mention:

P0002 - Motor speed

P0052 - Fractions of revolution

P0099 - Enable

P0121 - Speed reference

P1100 - User parameter 1100

6. If necessary, restart the Ethernet module using P0849.

SCA06 | 26

Page 27

Modbus TCP

7.5.3 Configuring the Master

The way you do the network setup is highly dependent on the network master and the network configuration tool.

It is important to know the tools used to perform this activity. In general, the following steps are required to perform

the network configuration.

1. Program the master to read and write holding registers, based on the defined equipment parameters to read

and write. The register number is based on the parameter number, as shown in table 7.3.

2. It is recommended that reading and writing are done in a cyclic manner, allowing detection of communication

errors by timeout.

7.5.4 Communication Status

Once you install the network and program the master, you can use the LEDs and equipment parameters to identify

some states related to communication.

The LEDs ”NS” and ”Link” provide information about the state of the interface and communication.

The parameter P0801 indicates the status of communication between the device and the network master.

The network master must also provide information about communication with slave.

7.5.5 Operation Using Process Data

Once communication is established, data is written and read by the Modbus TCP network master automatically.

Using these parameters, the master is able to control the equipment and monitor its operation. It is important to

know the device parameters to program the master as desired for the application.

SCA06 | 27

Page 28

EtherNet/IP

8 ETHERNET/IP

Following it shows operating characteristics of the SCA06 servo drive using the accessory for EtherNet/IP communication.

8.1 INDICATION LEDS

The NS LED present on the Ethernet accessory, have the following information for EtherNet/IP protocol:

Table 8.1: Network Status LED (NS)

State Description

Off No power or no IP address.

Green, solid Connection established.

Green, flashing Waiting for connections.

Red, solid Duplicate IP address, or fatal error (interface must be reinitialized).

Red, flashing One or more I/O connection timed out.

8.2 CYCLIC DATA

Cyclic data is the data normally used for status monitoring and equipment control. For EtherNet/IP protocol, the

interface supports an I/O connection that allows communication up to 16 input words and 16 output words.

It is necessary the configuration to be made both at the slave and master.

8.3 ACYCLIC DATA

In addition to the cyclic data, the interface also provides acyclic data via explicit messaging. Using this type of communication, you can access any equipment parameter. Access to this type of data is commonly done using instructions

for reading or writing data, which should indicate the class, instance, and attribute to the desired parameter. The

following table describes how to address the parameters for SCA06 servo drive.

Table 8.2: Parameter Addressing

Parameter Class Instance Atribute

P0001 162 (A2h) 1 5

P0002 162 (A2h) 2 5

P0003 162 (A2h) 3 5

.

.

.

.

.

.

.

.

.

.

.

.

P0400 162 (A2h) 400 5

.

.

.

.

.

.

.

.

.

.

.

.

The data is transmitted as an integer value, without the indication of the decimal places.

8.4 EDS FILE

Each device on an EtherNet/IP network has an EDS configuration file, which contains information about the device

functions on the network. This file is used by a master or configuration software to program devices present at

EtherNet/IP network.

SCA06 | 28

Page 29

EtherNet/IP

The EDS file is available from WEG website (http://www.weg.net). It is important to note if the EDS configuration file

is compatible with the firmware version of the SCA06 servo drive.

8.5 MODBUS TCP CONNECTIONS

The accessory for EtherNet/IP also provides up to 2 Modbus TCP connections. These connections can be used for

parameterization, as well as access to markers and data used for SCA06 ladder programming.

8.6 STARTUP GUIDE

Next it describes the main steps for commissioning SCA06 servo drive on Ethernet network using the EtherNet/IP

protocol. These steps represent an example of use. Refer to specific chapters for details on the steps.

8.6.1 Installing the Ethernet Module

1. Install the Ethernet communication module, as indicated in the installation guide supplied with the module.

2. Connect the Ethernet cable to the module, considering the necessary care in network installation, as described

in section 4:

Use shielded cable.

Properly ground the network devices.

Avoid laying communication cables next to power cables.

8.6.2 Configuring the Drive

1. Follow the recommendations described in the user’s manual to program the related to device settings, motor

parameters, desired functions for I/O signs, etc..

2. Program command sources as desired for application.

3. Program communication parameters such as DHCP, IP address, baud rate, etc.

4. Set the desired action for communication errors, through the P0662.

5. Set number of I/O words as well as the contents of each word using parameters P0820 to P0831 and P0835

to P0846.

6. If necessary, restart the Ethernet module using P0849.

8.6.3 Configuring the Master

The way you do the network setup depends largely on the master and the configuration tool. It is important to know

these tools to perform this activity. In general, the following steps are required to do the network configuration.

1. Load the EDS file1to the list of devices in the network configuration tool.

2. Select SCA06 servo drive from the available list of devices on the network configuration tool. This can be done

manually or automatically, if allowed by the tool.

1

The EDS file is available from WEG website (http://www.weg.net). It is important to note if the EDS configuration file is compatible with the

firmware version of the SCA06 servo drive.

SCA06 | 29

Page 30

EtherNet/IP

3. For the master configuration, in addition to the IP address used by the EtherNet/IP module, you must indicate

the number of instances of I/O and the amount of data exchanged with the master in each instance. For the

communication module for EtherNet/IP, the following values must be programmed:

Input instance: 100

Output instance: 150

4. The EtherNet/IP module is described as “Generic Ethernet Module” on the device list. Using these settings you

can program the network master to communicate with the equipment.

8.6.4 Communication Status

Once you install the network and program the master, you can use the LEDs and equipment parameters to identify

some states related to communication.

The LEDs ”NS” and ”Link” provide information about the state of the interface and communication.

The parameter P0801 indicates the status of communication between the device and the network master.

The network master must also provide information about the communication with slave.

8.6.5 Operation Using Process Data

Once the communication is established, the data mapped in the I/O area is automatically updated between master

and slave. Among the main parameters that can be used to control the device, we can mention:

Status Word

Motor Speed

Torque Current

Present Control Mode

Control Word

Speed Reference

Torque Reference

Control Mode

It is important to know these parameters to program the master as desired for the application.

SCA06 | 30

Page 31

PROFINET

9 PROFINET

Following it shows operating characteristics of the servo drive SCA06 using plug-in module for PROFINET communication.

9.1 INDICATION LEDS

The NS LED present on the Ethernet accessory, have the following information for PROFINET protocol:

Table 9.1: Network Status LED (NS)

State Description

Off No power or no connection with controller.

Green, solid Connection with controller established, controller in RUN mode.

Green, flashing Connection with controller established, controller in STOP mode.

9.2 CYCLIC DATA

Cyclic data is the data normally used for status monitoring and equipment control. For PROFINET protocol, the

interface supports an I/O connection that allows communication up to 16 input words and 16 output words.

It is necessary the configuration to be made both at the slave and master.

9.3 ACYCLIC DATA

In addition to the cyclic data, the PROFINET protocol also provides acyclic data, mainly used to communicate diagnoses data, parameterization and configuration. For the SCA06 servo drive using the Ethernet module, the parameter

list is available using this communication method.

The PROFINET protocol defines the following structure to address the components for network configuration:

AR (Application Relation)

API (Application Process Identifier)

Slot

Subslot

The AR and API are used to identify the Ethernet module during the network configuration steps. Slot/subslot are not

relevant for accessing acyclic data. Once the module is identified, the parameters are accessed indicating the index

and the data length:

Index: represents the parameter number;

Length: the length of data, in bytes. All device parameter are 2 bytes in length (Word).

The data is transmitted as an integer value, without the indication of the decimal places.

9.4 XML FILE – GSDML

Each device on an PROFINET network has an GSDML configuration file, which contains information about the device

functions on the network. This file is used by a master or configuration software to program devices present at

PROFINET network.

SCA06 | 31

Page 32

PROFINET

The GSDML file is available from WEG website (http://www.weg.net). It is important to note if the GSDML configuration

file is compatible with the firmware version of the SCA06 servo drive.

9.5 MODBUS TCP CONNECTIONS

The plug-in module for PROFINET IO also provides up to 2 Modbus TCP connections. These connections can be

used for parameterization, as well as access to markers and data used for SCA06 ladder programming. The available

Modbus functions and communication data are described in item 7.

9.6 STARTUP GUIDE

Next it describes the main steps for commissioning SCA06 servo drive on Ethernet network using the PROFINET

protocol. These steps represent an example of use. Refer to specific chapters for details on the steps.

9.6.1 Installing the Ethernet Module

1. Install the Ethernet communication module, as indicated in the installation guide supplied with the module.

2. Connect the Ethernet cable to the module, considering the necessary care in network installation, as described

in section 4:

Use shielded cable.

Properly ground the network devices.

Avoid laying communication cables next to power cables.

9.6.2 Configuring the Drive

1. Follow the recommendations described in the user’s manual to program the related to device settings, motor

parameters, desired functions for I/O signs, etc..

2. Program command sources as desired for application.

3. Program communication parameters such as DHCP, IP address, baud rate, etc.

4. Set the desired action for communication errors, through the P0662.

5. Set number of I/O words as well as the contents of each word using parameters P0820 to P0831 and P0835

to P0846.

6. If necessary, restart the Ethernet module using P0849.

9.6.3 Configuring the Master

The way you do the network setup depends largely on the master and the configuration tool. It is important to know

these tools to perform this activity. In general, the following steps are required to do the network configuration.

1. Load the GSDML file2to the list of devices in the network configuration tool.

2. Select SCA06 servo drive from the available list of devices on the network configuration tool. This can be done

manually or automatically, if allowed by the tool.

2

The GSDML file is available from WEG website (http://www.weg.net). It is important to note if the GSDML configuration file is compatible with

the firmware version of the SCA06 servo drive.

SCA06 | 32

Page 33

PROFINET

3. For the master configuration, you must indicate the number of I/O words exchanged with the master. It is

necessary to select word by word, first selecting all input words and then all output words.

4. The PROFINET module is recognized as ”SCA06”, at the ”General” category. Using these settings you can

program the network master to communicate with the equipment.

9.6.4 Communication Status

Once you install the network and program the master, you can use the LEDs and equipment parameters to identify

some states related to communication.

The LEDs ”NS” and ”Link” provide information about the state of the interface and communication.

The parameter P0801 indicates the status of communication between the device and the network master.

The network master must also provide information about the communication with slave.

9.6.5 Operation Using Process Data

Once the communication is established, the data mapped in the I/O area is automatically updated between master

and slave. Among the main parameters that can be used to control the device, we can mention:

Status Word

Motor Speed

Torque Current

Present Control Mode

Control Word

Speed Reference

Torque Reference

Control Mode

It is important to know these parameters to program the master as desired for the application.

SCA06 | 33

Page 34

WEB Server

10 WEB SERVER

Besides the communication protocol, the Ethernet interface also provides a WEB server with a simple HTML page to

access SCA06 servo drive data. If the IP address is known, you can use a web browser by typing the IP address in

the browser address bar, and it will present a web page with links to interface settings and device data.

Figure 10.1: WEB page for interface configuration

In the interface settings, it presents several fields for programming the IP address, subnet, DHCP, among others. The

parameter list of the equipment can also be accessed through the WEB browser via ”Parameter Data” link. This list

is presented in a simplified format, with only the integer values, with no indication of decimal places.

SCA06 | 34

Page 35

Faults and Alarms

11 FAULTS AND ALARMS

F0047/A0147 - ETHERNET OFFLINE

Description:

Indicates communication failure between the slave and the network controller.

Actuation:

It occurs when, once established communication between the slave and the network master, there is an interruption

in this communication. The method for detecting the interruption of communication depends on the network:

Modbus TCP: not receiving a valid Modbus TCP telegram by preset period at P0806.

EtherNet/IP: timeout in I/O connection, or master goes to IDLE state.

PROFINET: timeout on the cyclic communication between master and slave, or master goes to STOP state.

In this case, the device will show in the HMI an alarm message A0147 - or fault F0047, depending on the P0662

programming. In case of alarm, the indication will automatically disappear at the moment when the communication

is reestablished.

Possible Causes/Correction:

Verify whether the network master is properly configured and operating normally.

Search for short-circuit or bad contact in the communication cables.

Verify the entire network installation – cable laying, grounding.

F0048/A0148 - ETHERNET INTERFACE ACCESS ERROR

Description:

Indicates error in data exchange between SCA06 servo drive and Ethernet module.

Actuation:

It occurs whenthe controlboard cannot exchange data with the Ethernet module, when the Ethernet module identifies

some internal error, or when there is a hardware incompatibility.

In this case, the device will show in the HMI an alarm message A0148 - or fault F0048, depending on the P0662

programming. You must reboot the Ethernet module, power cycling the product or using P0849.

Possible Causes/Correction:

Check if Ethernet module is properly connected to product.

Check it the device firmware version supports this module.

Hardware errors caused by the improper handling or installation of the accessory can cause this error. If possible,

test it by replacing the communication module.

SCA06 | 35

Page 36

WEG Drives & Controls - Automação LTDA.

Jaraguá do Sul – SC – Brazil

Phone 55 (47) 3276-4000 – Fax 55 (47) 3276-4020

São Paulo – SP – Brazil

Phone 55 (11) 5053-2300 – Fax 55 (11) 5052-4212

automacao@weg.net

www.weg.net

Loading...

Loading...