WEG MVW3000 A0040 V023, MVW3000 A0050 V023, MVW3000 A0090 V023, MVW3000 A0080 V023, MVW3000 A0100 V023 User Manual

...Page 1

User's Manual

Series: MVW3000

Language: English

Document: 10004823674 / 00

Please take this page out when

unpacking the product

13941741

Page 2

Page 3

Motors I Automation I Energy I Transmission & Distribution I Coatings

Medium Voltage Frequency Inverter

MVW3000

User's Manual

Page 4

Page 5

User’s Manual

Series: MVW3000

Language: English

Document: 10004823674 / 00

Publication Date: 03/2017

Page 6

Summary of Reviews

Vers ion Review Description

- R00 First edition

Page 7

Contents

1 SAFETY NOTICES ................................................................................1-1

1.1 SAFETY NOTICES IN THE MANUAL .........................................................................................1-1

1.2 SAFETY NOTICES ON THE PRODUCT .....................................................................................1-1

1.3 PRELIMINARY RECOMMENDATIONS ......................................................................................1-2

2 GENERAL INFORMATION ................................................................... 2-1

2.1 ABOUT THIS MANUAL ...............................................................................................................2-1

2.2 MVW3000 IDENTIFICATION LABEL ..........................................................................................2-2

2.3 RECEIVING AND STORAGE.......................................................................................................2-2

2.4 HOW TO SPECIFY THE MVW3000 MODEL ..............................................................................2-3

2.4.1 Available Models ...............................................................................................................2-5

3 PRODUCT CHARACTERISTICS .........................................................3-1

3.1 INPUT TRANSFORMER .............................................................................................................3-1

3.2 POWER CELLS ...........................................................................................................................3-3

3.3 CONNECTION OF THE CELLS ..................................................................................................3-5

3.4 CONTROL ....................................................................................................................................3-8

4 TECHNICAL DATA ..............................................................................4-1

4.1 MVW3000 PANEL ........................................................................................................................4-1

4.1.1 Panel Constructive Aspects .............................................................................................4-2

4.2 POWER CELLS ...........................................................................................................................4-4

4.2.1 Constructive Aspects .......................................................................................................4-4

4.2.2 Power Cell Boards and Connections ..............................................................................4-6

4.3 CONTROL RACK ........................................................................................................................4-6

4.4 OUTPUT FILTERS .......................................................................................................................4-7

5 SYNCHRONOUS MOTOR LINE ..........................................................5-1

5.1 ABSOLUTE ENCODER WITH RSSI BOARD .............................................................................5-1

5.1.1 Absolute Encoder ..............................................................................................................5-1

5.1.2 RSSI Board .........................................................................................................................5-2

5.2 FIELD EXCITATION SET (DC WITH BRUSHES) ........................................................................5-4

6 INSTALLATION, CONNECTION AND ENERGIZATION ......................6-1

6.1 MECHANICAL INSTALLATION ..................................................................................................6-1

6.1.1 Environmental Conditions ................................................................................................6-1

6.1.2 Handling Recommendations ............................................................................................6-2

6.1.3 Hoisting ..............................................................................................................................6-2

6.1.4 Moving ...............................................................................................................................6-3

6.1.5 Unpacking ..........................................................................................................................6-3

6.1.6 Positioning/Mounting........................................................................................................6-4

6.1.7 Insertion of the Power Cells .............................................................................................6-6

6.1.8 Electrical and Fiber Optic Connections on the Power Cells .........................................6-8

6.2 ELECTRICAL INSTALLATION ....................................................................................................6-10

6.2.1 Power Section ...................................................................................................................6-10

6.2.2 Input Cubicle ......................................................................................................................6-12

6.2.3 Low Voltage Auxiliary Supply ...........................................................................................6-13

6.3 ENERGIZATION, START-UP AND SAFE DE-ENERGIZATION .................................................6-14

6.3.1 Pre-power Checks ............................................................................................................6-14

6.3.2 Initial Power-up (Parameter Settings) ............................................................................6-15

6.3.3 Start-up .............................................................................................................................6-15

6.3.3.1 Start-up with HMI Operation and V/F 60 Hz Control Mode ................................6-15

6.3.4 Safe De-energization Instructions ...................................................................................6-17

Page 8

Contents

7 OPTIONAL ACCESSORIES AND BOARDS ........................................ 7-1

7.1 MVC4 SIGNAL AND CONTROL CONNECTIONS .....................................................................7-1

7.2 FUNCTION EXPANSION BOARDS ............................................................................................7-5

7.2.1 EBA (I/O Expansion Board A) ...........................................................................................7-5

7.2.2 EBB (I/O Expansion Board B) ...........................................................................................7-9

7.2.3 PLC2 ...................................................................................................................................7-12

7.3 INCREMENTAL ENCODER ........................................................................................................7-14

7.3.1 EBA/EBB Boards ...............................................................................................................7-14

7.3.2 EBC1 Board .......................................................................................................................7-16

7.4 SHORT UPS MODULE ................................................................................................................7-19

7.4.1 CFW10 Inverter Parameterization....................................................................................7-19

7.5 MVC3 CONTROL BOARD CONNECTIONS...............................................................................7-20

8 SPECIAL FUNCTIONS ......................................................................... 8-1

8.1 LOAD SHARE FUNCTION “MASTER/SLAVE” ..........................................................................8-1

8.2 SYNCHRONOUS TRANSFER FUNCTION .................................................................................8-3

8.3 CELL BYPASS .............................................................................................................................8-5

8.4 ANGLE ADJUSTMENT ...............................................................................................................8-6

9 COMMUNICATION NETWORKS ......................................................... 9-1

9.1 FIELDBUS KIT .............................................................................................................................9-1

9.1.1 Installation of the Fieldbus Kit .........................................................................................9-1

9.1.2 Profibus DP ........................................................................................................................9-2

9.1.3 DeviceNet ...........................................................................................................................9-5

9.1.4 DeviceNet Drive Profile .....................................................................................................9-7

9.1.5 Ethernet ..............................................................................................................................9-7

9.1.6 Fieldbus Application/MVW3000 Related Parameters ....................................................9-7

9.1.6.1 Variables Read From the Inverter .........................................................................9-8

9.1.6.2 Variables Written in Inverter ..................................................................................9-9

9.1.6.3 Error Indications .....................................................................................................9-11

9.1.6.4 MVW3000 Variable Addressing at the Fieldbus Devices ....................................9-12

9.2 WEGBUS SERIAL ........................................................................................................................9-12

9.2.1 Protocol Definitions ..........................................................................................................9-15

9.2.2 Variable Code ....................................................................................................................9-17

9.2.3 MVW3000 Special Parameters .........................................................................................9-21

9.2.4 RS-232 and RS-485 Physical Connection .......................................................................9-23

9.3 MODBUS-RTU ............................................................................................................................9-24

9.3.1 Introduction to the Modbus-RTU Protocol .....................................................................9-24

9.3.1.1 Transmission Modes ..............................................................................................9-24

9.3.1.2 RTU Mode Message Structure ..............................................................................9-25

9.3.2 Operation of the MVW3000 in the Modbus-RTU Network .............................................9-26

9.3.3 Detailed Description of the Functions .............................................................................9-30

9.3.3.1 Function 01 - Read Coils .......................................................................................9-30

9.3.3.2 Function 03 - Read Holding Register ...................................................................9-31

9.3.3.3 Function 05 - Write Single Coil .............................................................................9-32

9.3.3.4 Function 06 - Write Single Register ......................................................................9-32

9.3.3.5 Function 15 - Write Multiple Coils ........................................................................9-33

9.3.3.6 Function 16 - Write Multiple Registers .................................................................9-34

9.3.3.7 Function 43 - Read Device Identification .............................................................9-34

9.3.4 ModBus RTU Communication Error ................................................................................9-36

Page 9

MVW3000 | 1-1

11

Safety Notices

1 SAFETY NOTICES

This manual contains the necessary information for the correct use of the MVW3000 frequency inverter.

It has been written for qualified personnel with suitable training or technical qualifications to operate this type of

equipment.

This manual presents all the functions and parameters of the MVW3000. However, it is not intended to present

all the possible applications of the MVW3000. WEG will not take any liabilities for applications not described in

this manual.

1.1 SAFETY NOTICES IN THE MANUAL

Throughout this manual the following safety notes are used:

DANGER!

The procedures recommended in this warning have the purpose of protecting the user against dead,

serious injuries and considerable material damage.

DANGER!

Les procédures concernées par cet avertissement sont destinées à protéger l’utilisateur contre des

dangers mortels, des blessures et des détériorations matérielles importantes.

ATTENTION!

The procedures recommended in this warning have the purpose of avoiding material damage.

NOTE!

The text intents to supply important information for the correct understanding and good operation

of the product.

1.2 SAFETY NOTICES ON THE PRODUCT

The following symbols are attached to the product, serving as safety notices:

High voltages are present.

Components sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to the protective ground (PE).

Connection of the shield to the ground.

Hot surface.

Page 10

1-2 | MVW3000

1

Safety Notices

1.3 PRELIMINARY RECOMMENDATIONS

DANGER!

Only qualified personnel familiar with the MVW3000 frequency inverter and associated equipment

should plan or implement the installation, start-up and subsequent maintenance of this equipment

These personnel must follow all the safety instructions included in this manual and/or defined by local

regulations.

Failure to comply with these instructions can lead to death, serious injuries or considerable material

damage.

DANGER!

Seul le personnel qualifié et familier avec l’onduleur de fréquence MVW3000 et ses équipements

associés doit préparer et mettre en oeuvre l’installation, démarrer et ensuite entretenir cet équipement.

Ce personnel doit suivre toutes les instructions de sécurité comprises dans ce mode d’emploi et/ou

définies par la règlementation locale.

Le non respect de ces instructions peut causer la mort, des blessures graves ou d’importants dégâts

matériels.

NOTE!

For the purposes of this manual, qualified personnel are those trained to be able to:

1. Install, ground, energize and operate the MVW3000 according to this manual and the effective legal

safety procedures.

2. Use the protection equipments according to the established standards.

3. Give first aid services.

DANGER!

Always disconnect the input power before touching any electrical component associated to the

inverter.

Many components can remain charged with high voltages or remain in movement (fans) even after

that AC power is disconnected or switched off.

Wait at least 10 minutes to assure a total discharge of the capacitors.

Always connect the equipment frame to the protection earth (PE) at the suitable connection point.

DANGER!

Débranchez toujours l’alimentation générale avant de toucher un composant électrique associé au

convertisseur. Nombreux composants peuvent rester chargés avec haute tension et/ou en mouvement

(ventilateurs), même après que l’entrée d’alimentation CA a été débranchée ou coupée.

Attendez au moins 10 minutes pour s’assurer de la décharge totale des condensateurs.

Connectez toujours le boîtier de l’équipement à terre de protection (PE) au point adéquat pourça.

ATTENTION!

Electronic boards have components sensitive to electrostatic discharges. Do not touch directly

on components or connectors. If necessary, touch the grounded metallic frame before or use an

adequate grounded wrist strap.

Do not perform any high pot tests with the inverter!

If it is necessary consult WEG.

NOTE!

Frequency inverter may interfere with other electronic equipment. In order to reduce these effects,

take the precautions recommended.

NOTE!

Read the user’s manual completely before installing or operating the inverter.

Page 11

MVW3000 | 1-3

11

Safety Notices

DANGER!

This product was not designed to be used as a safety element. Additional measures must be taken

so as to avoid material and personal damages.

The product was manufactured under strict quality control, however, if installed in systems where its

failure causes risks of material or personal damages, additional external safety devices must ensure

a safety condition in case of a product failure, preventing accidents.

DANGER!

Ce produit n’est pas conçu pour être utilisé comme un élément de sécurité. Des précautions

supplémentaires doivent être prises afin d’éviter des dommages matériels ou corporels.

Ce produit a été fabriqué sous un contrôle de qualité conséquent, mais s’il est installé sur des

systèmes où son dysfonctionnement entraîne des risques de dommages matériels ou corporels,

alors des dispositifs de sécurité externes supplémentaires doivent assurer des conditions de sécurité

en cas de défaillance du produit, afin d’éviter des accidents.

Page 12

1-4 | MVW3000

1

Safety Notices

Page 13

MVW3000 | 2-1

2

MVW3000 | 2-1

General Information

2 GENERAL INFORMATION

This chapter defines the contents of this manual and describes the main characteristics of the MVW3000

frequency inverter and how to identify its components. It provides also additional information on the receiving

and storage of the product.

2.1 ABOUT THIS MANUAL

This manual presents 9 chapters, which have a logical sequence so that the user receives, installs, programs and

operates the MVW3000.

Chapter 1 SAFETY NOTICES on page 1-1.

Chapter 2 GENERAL INFORMATION on page 2-1.

Chapter 3 PRODUCT CHARACTERISTICS on page 3-1.

Chapter 4 TECHNICAL DATA on page 4-1.

Chapter 5 SYNCHRONOUS MOTOR LINE on page 5-1.

Chapter 6 INSTALLATION, CONNECTION AND ENERGIZATION on page 6-1.

Chapter 7 OPTIONAL ACCESSORIES AND BOARDS on page 7-1.

Chapter 8 SPECIAL FUNCTIONS on page 8-1.

Chapter 9 COMMUNICATION NETWORKS on page 9-1.

This user’s manual contains information about WEG MVW3000 medium voltage inverter. This document is

arranged in dedicated and specific chapters to explain the proper handling, installation, care, troubleshooting,

adaption to applications and functionalities of the equipment.

The characteristics and recommendations contained in this manual were based on models of the standard

MVW3000. However, it is possible to develop and provide customized solutions according to the customers’

needs and specific applications.

The MVW3000 product can be customized (engineered) to meet the needs and technical specifications of our

customers. Variations is sizes, technical recommendations, performance data and optional items can be changed

in relation to the information contained in this document.

The customer will receive the user’s manual, the programming manual and a detailed project of his product. This

project contains all the electrical and mechanical information, as well as instructions for the interface/installation

with other equipment regarding the MVW3000 supplied.

The MVW3000, as well as other WEG products, is in constant evolution in relation to both its internal parts

(hardware) and its programming (software/firmware). Any question about the equipment and its documentation

can be answered by means of WEG communication channels.

WEG is not liable for the improper use of the information contained in this manual.

Page 14

2-2 | MVW3000

2

General Information

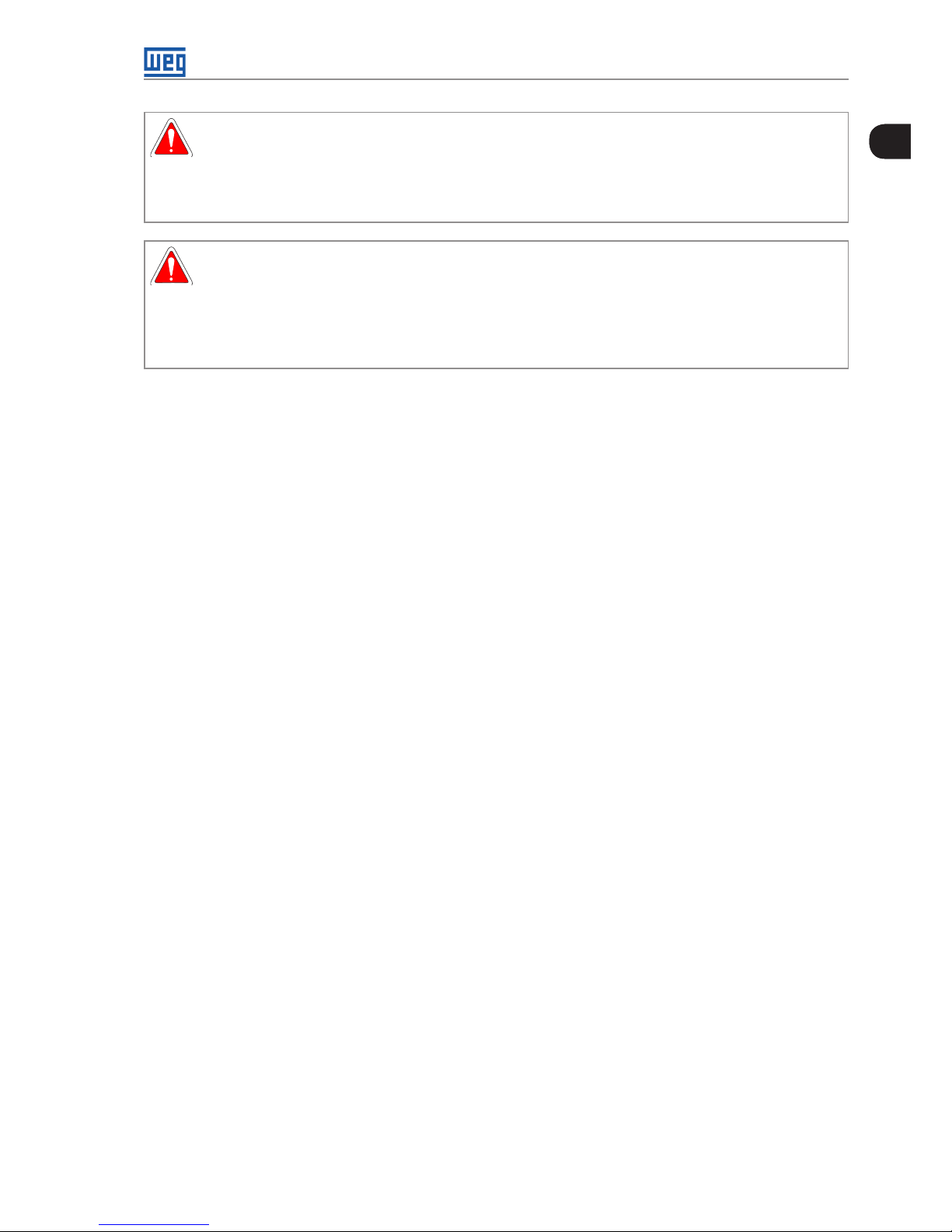

2.2 MVW3000 IDENTIFICATION LABEL

The MVW3000 identification label is positioned in the inner part of the Control Panel of the product. This label

describes important information about the inverter.

Figure 2.1: MVW3000 identification label (example)

2.3 RECEIVING AND STORAGE

The MVW3000 is supplied with the power cells separate from the panel and packed in sets of three cells per

package. The package is composed of OSB frame and injected foam shims. An identification label is affixed to

the outside of the package, identical to the label affixed to the side of the inverter. Compare the content of this

label to the purchase order.

In order to open the cells, see the procedures described in Item 6.1.5 Unpacking on page 6-3. If the MVW3000

cells are not install on the cabinet soon, store them in a clean and dry place (temperature between -25 °C ( -13 °F)

and 50 °C (122 °F) and humidity below 80 %), covered so as protect from dust accumulation and water splashes.

It is recommended to replace the silica gel every three months.

The MVW3000 cabinet has a dehumidifier module, which must remain turned on in case of storage for over thirty

days.

The MVW3000 cabinet is supplied in a cardboard and wood package. The directions for handling, transportation,

mechanical and electrical installations of the product are described in Chapter 6 INSTALLATION, CONNECTION

AND ENERGIZATION on page 6-1, in Item 6.1.5 Unpacking on page 6-3.

Page 15

MVW3000 | 2-3

2

MVW3000 | 2-3

General Information

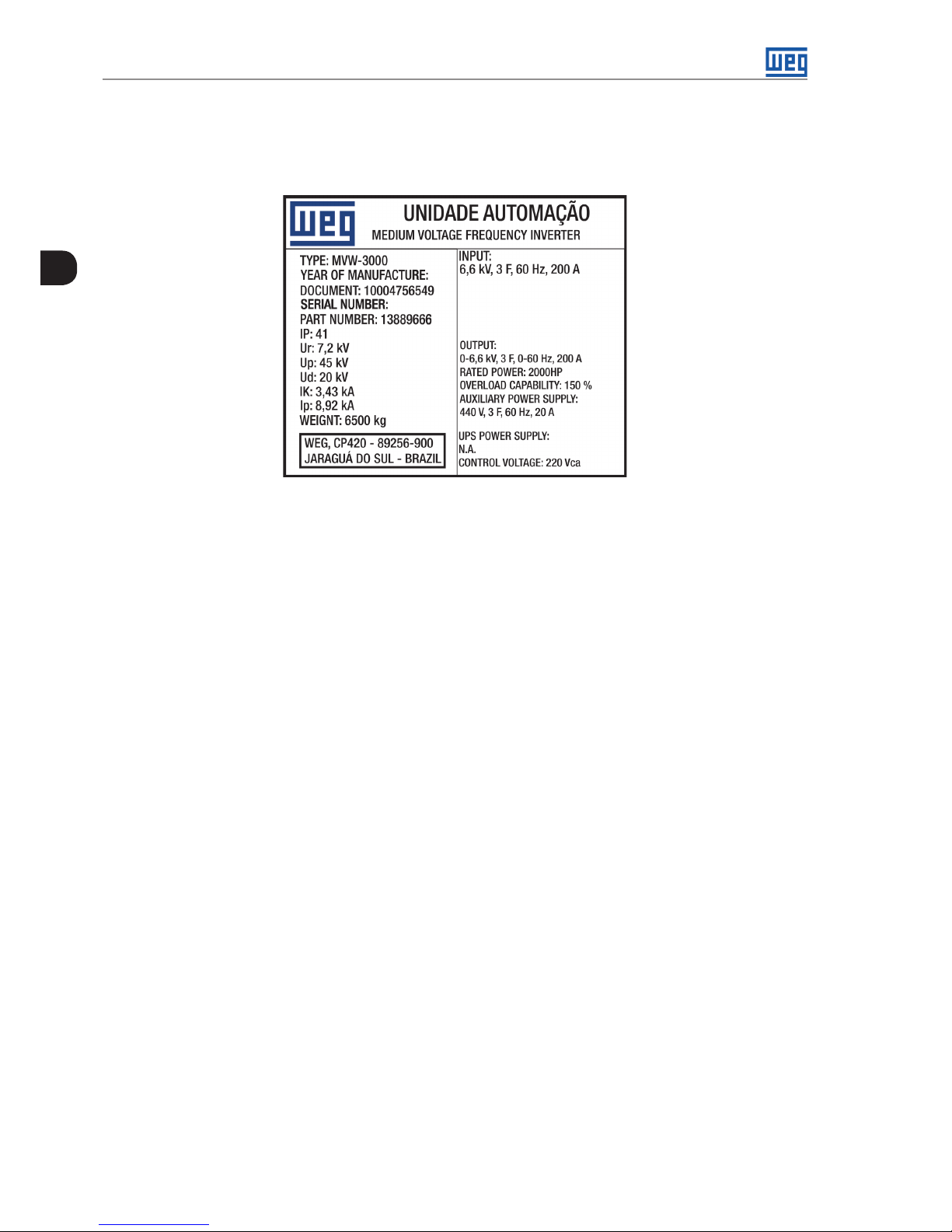

2.4 HOW TO SPECIFY THE MVW3000 MODEL

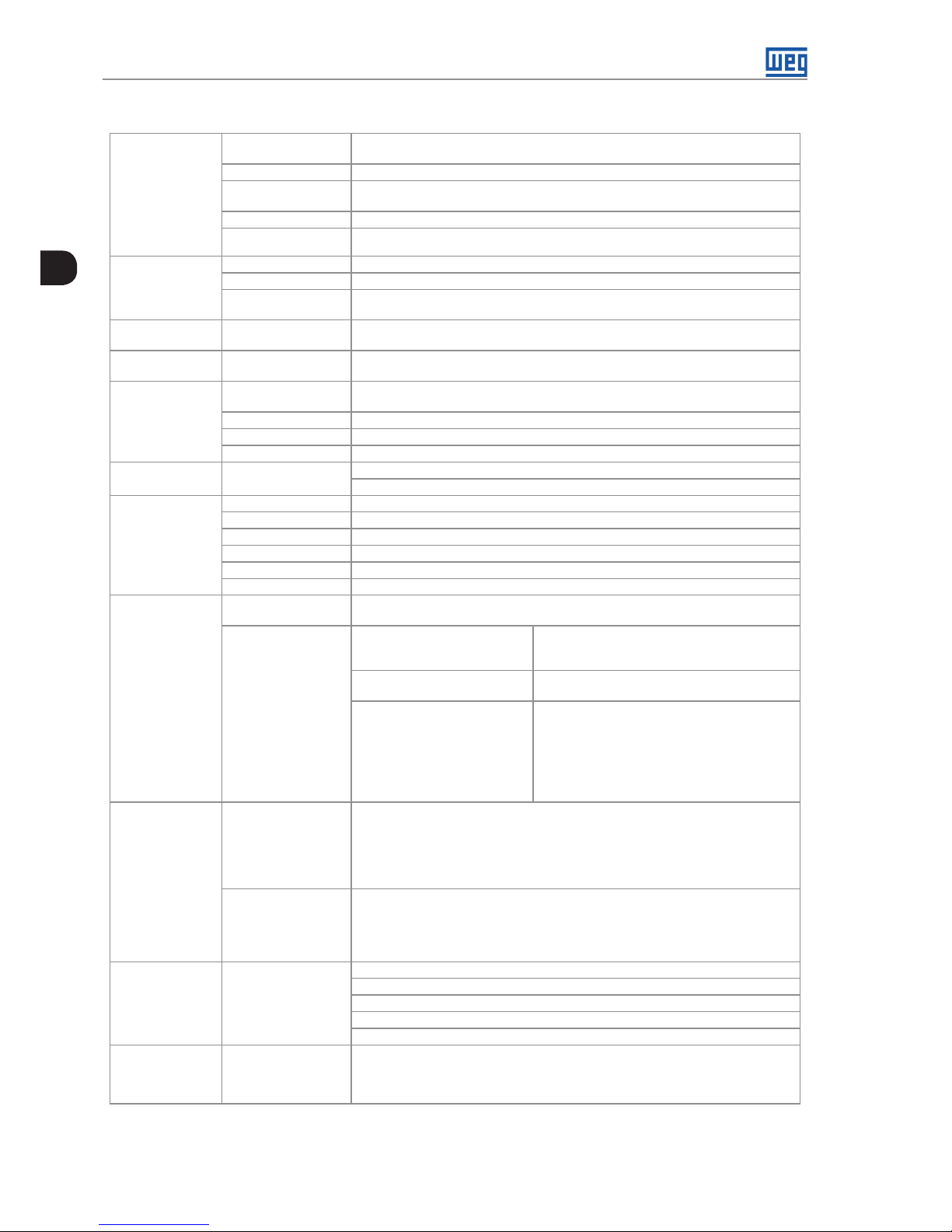

Table 2.1: MVW3000 Code

Lettering Line 1 2 3 4 5 6 7 8 9 10

Code Example

(¹)

MVW3000 A0140 V063 T5A 066 P A S E R D

1 2 3 4 5 6 7 8 9 10

Rated

Output

Current

Rated

Output

Volt age

Input

Transformer

Input

Rated

Volt age

Manual

Language

Cooling

System

Input

Cubicle

Capacitor

Typ e

Cell

Typ e

Rectifier

Typ e

40 A A0040 2300 V V023 Al - 50 Hz T5A 2300 V 023 English E Air A

Not

included

N Electrolytic E Standard S Diode D

50 A A0050 3300 V V033 Al - 60 Hz T6A 3300 V 033 Spanish S Water W Included S Film F Bypass B AFE A

60 A A0060 4160 V V041 Cu - 50 Hz T5C 416 0 V 0 41 Portuguese P - - - - - - Redundant R - -

70 A A0070 5500 V V055 Cu - 60 Hz T6C 5500 V 055 - - - - - - - - - - - -

80 A A0080 6300 V V063 - - 6000 V 060 - - - - - - - - - - - -

90 A A0090 6900 V V069 - - 6300 V 063 - - - - - - - - - - - -

100 A A0100 7200 V V072 - - 6600 V 066 - - - - - - - - - - - -

110 A A0110 8000 V V080 - - 6900 V 069 - - - - - - - - - - - -

125 A A0125 10000 V V10 0 - - 7200 V 072 - - - - - - - - - - - -

140 A A0140 11000 V V110 - - 8000 V 080 - - - - - - - - - - - -

160 A A0160 1320 0 V V132 - - 10000 V 100 - - - - - - - - - - - -

180 A A0180 138 00 V V138 - - 11000 V 110 - - - - - - - - - - - -

200 A A0200 - - - - 1320 0 V 132 - - - - - - - - - - - -

- - - - - - 1380 0 V 13 8 - - - - - - - - - - - -

(1) For available models, see Table 2.3 on page 2-5 to Table 2.10 on page 2-8.

Page 16

2-4 | MVW3000

2

General Information

Table 2.2: General specification

POWER SUPPLY

Voltage

2300 V, 3300 V, 4160 V, 5500 V, 6000 V, 6300 V, 6600 V, 6900 V, 7200 V, 8000 V

(± 10 %, -20 % with output power reduction)

Frequency 50 or 60 Hz (specify as necessary) ±3 %

Voltage imbalance

between phases

<3 %

Cos j >0.95

Overvoltage category

Category III

AUXILIARY

SUPPLY

Voltage 220, 380, 400, 415, 440, 460 or 480 V

Frequency 50 or 60 Hz (±3 %)

Voltage imbalance

between phase

<3 %

PROTECTION

DEGREE

Standard

IP41

DIMENSION

Width / Height / Depth

(mm)

16 distinct frames. For all available frames, see Figure 4.3 on page 4-3 and Table 4.2

on page 4-3 to Table 4.8 on page 4-4

ENVIRONMENTAL

CONDITIONS

Temperature

0 to 40 °C (32 °F to 104 °F) (up to 50 °C (122 °F) with 2.5 % reduction in the output

current/ °C)

Humidity 5 to 90 % without condensation

Altitude 0 to 1000 m ( up to 4000 m with derating of 10% / 1000 m )

Pollution degree 2

FINISHING Color

Gray ultra dull (Doors)

Blue ultra dull (Base, Roof, Shutters)

CONTROL

Microprocessor 32 bits

Control method Sinusoidal PWM

Control types Scalar (Imposed Voltage - V/F), Vector (encoder and sensorless)

Switching frequency 500 Hz

Frequency range 0 to 120 Hz

Allowed overload 115 % during 60 seconds, every 10 minutes

PERFORMANCE

Efficiency

Higher 96.5 % (with aluminum transformer)

Higher 97.0 % (with copper transformer)

Speed control

V/F Regulation: 1 % of the nominal speed with slip

compensation

Regulation: 1 rpm (keypad reference)

Sensorless Regulation: 0.5 % of the nominal speed

Speed variation range: 1:100

With Encoder

(using EBA, EBB or EBC board) )

Regulation:

±0.01 % of the nominal speed with a 14-bit analog

input (EBA)

±0.01 % of the nominal speed with digital reference

(keypad, Serial, Fieldbus, Electronic Potentiometer,

Multispeed)

±0.1 % of nominal speed with 10-bit analog input

INPUTS

OUTPUTS

Analogical

2 programmable differential inputs (10 bits ): 0 to 10 V, 0 to 20 mA or 4 to 20 mA

1 programmable bipolar input (14 bits ): -10 V to +10 V, 0 to 20 mA or 4 to 20 mA

1 programmable isolated input (10 bits ): 0 to 10 V, 0 to 20 mA or 4 to 20 mA

2 programmable outputs (11 bits ): 0 to 10 V

2 bipolar programmable outputs (14 bits ): (-10 to +10) V

2 programmable isolated outputs (11 bits): 0 to 20 mA or 4 to 20 mA

Digital Analog

Relay Transistor

8 programmable isolated inputs: 24 Vdc

1 programmable isolated input: 24 Vdc

1 programmable isolated input: 24 Vdc (for motor PTC thermistor)

5 programmable outputs, contacts NO/NC: 240 Vac, 1 A

2 programmable isolated open collector outputs: 24 Vdc, 50 mA

COMMUNICATION

Serial Interface

Fieldbus Networks

RS-232 (point to point)

RS-485, isolated, via EBA or EBB board (multipoint up to 30 inverters)

Modbus RTU (incorporated software) via RS-485 serial interface

Profibus DP or DeviceNet via additional kits

Ethernet and Profinet

SAFETY

Protections (memory

of the last 100 faults/

alarms with date and

time)

See fault in the programming manual available for download on: www.weg. net

Page 17

MVW3000 | 2-5

2

MVW3000 | 2-5

General Information

APPLICABLE

STA NDA RDS

Electromagnetic

compatibility

EMC directive 89 / 336 / EEC - industrial environment

EN 61800-3 Standard (EMC - Emission and Immunity)

CEI - IEC 61800

Adjustable Speed Electrical Power Drive System

Part 4 - General Requirements

Part 5 - Safety Requirements

HUMAN MACHINE

INTERFACE

(LCD DISPLAY)

Command

Start/Stop, Parameterization (Programming of general functions)

Increase/decrease the speed

JOG, Forward/Reverse selection, Local/Remote selection

Supervision (Reading)

Speed reference (rpm)

Motor speed (rpm)

Value proportional to the speed (e.g.: m/min)

Motor output frequency (Hz)

Voltage on the intermediate circuits (V)

Motor torque (%)

Output power (kW)

Energized time (h)

Operation time (h)

Motor current (A)

Motor voltage (V)

Inverter status

Digital input status

Digital output (transistor) status

Relay output status

Analog input values

100 last erros in the memory with date and time

Fault/alarm messages

AVAILABLE

RESOURCES/

FUNCTIONS

Options

Fieldbus network communication kits (installation inside the inverter)

SUPERDRIVE kit with RS-232 serial communication interface (Inverter - PC)

Kit Ethernet

Kit Expansão de I/Os Profibus DP

2.4.1 Available Models

The MVW3000 line of medium voltage inverters offers different models, classified according to their rated voltage

and current levels. Different models of the MVW3000 may have distinct frames, which are presented in Table 2.3

on page 2-5 with their respective codes. For the constructive aspects of the available frames, see Chapter 4

TECHNICAL DATA on page 4-1, Figure 4.3 on page 4-3 and Table 4.2 on page 4-3 to Table 4.8 on page

4-4. For models with rated voltage above 8000 V, contact WEG.

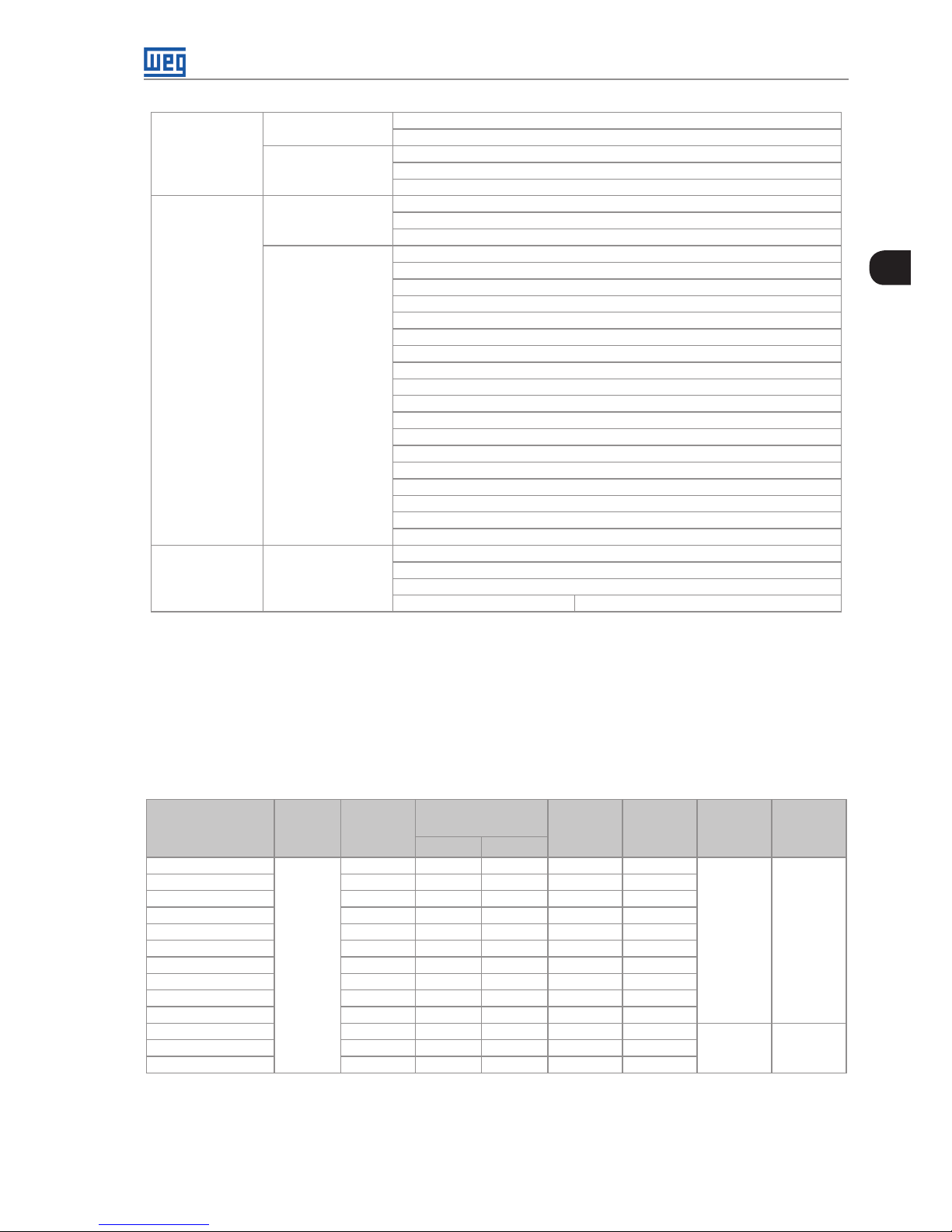

Table 2.3: MVW3000 2300 V models

Models

Nominal

Volt age [V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V023

2300

40 170 130 5.03 4.29

7062 CFM or

12000 m³/h

B2

MVW3000 A0050 V023 50 220 165 6.29 5.36

MVW3000 A0060 V023 60 265 200 7.54 6.43

MVW3000 A0070 V023 70 315 235 8.80 7.5 0

MVW3000 A0080 V023 80 355 265 10.06 8.58

MVW3000 A0090 V023 90 400 300 11.31 9.65

MVW3000 A0100 V023 100 445 335 12.57 10.72

MVW3000 A0110 V023 110 485 365 13.83 11.79

MVW3000 A0125 V023 125 560 420 15.71 13.40

MVW3000 A0140 V023 140 630 470 17.6 0 15.01

MVW3000 A0160 V023 160 715 535 20.11 17.15

8828 CFM or

15000 m³/h

C2MVW3000 A0180 V023 180 810 605 22.63 19.29

MVW3000 A0200 V023 200 895 670 25.14 21.44

Page 18

2-6 | MVW3000

2

General Information

Table 2.4: MVW3000 3300 V models

Models

Nominal

Volt age

[V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V033

3300

40 250 190 7.2 1 6 .15

7062 CFM or

12000 m³/h

B3

MVW3000 A0050 V033 50 320 240 9.02 7.6 9

MVW3000 A0060 V033 60 380 285 10.82 9.23

MVW3000 A0070 V033 70 445 335 12.63 10.77

MVW3000 A0080 V033 80 515 385 14.43 12. 30

MVW3000 A0090 V033 90 575 430 16.23 13.84

MVW3000 A0100 V033 100 640 480 18.04 15.3 8

MVW3000 A0110 V033 110 710 530 19.84 16.92

MVW3000 A0125 V033 125 800 600 22.54 19.22

MVW3000 A0140 V033 14 0 900 675 25.25 21.53

MVW3000 A0160 V033 160 1030 770 28.86 24.61

8828 CFM or

15000 m³/h

C3

MVW3000 A0180 V033 18 0 1155 865 32.46 2 7. 6 8

MVW3000 A0200 V033 200 1285 960 36.07 30.76

Table 2.5: MVW3000 4160 V models

Models

Nominal

Volt age

[V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V041

4160

40 320 240 9.09 7.76

77062 CFM

or

12000 m³/h

B4

MVW3000 A0050 V041 50 400 300 11.37 9.69

MVW3000 A0060 V041 60 480 360 13.64 11.63

MVW3000 A0070 V041 70 565 425 15.92 13.57

MVW3000 A0080 V041 80 650 485 18.19 15.51

MVW3000 A0090 V041 90 730 545 20.46 17. 4 5

MVW3000 A0100 V041 100 810 605 2 2.74 19.39

MVW3000 A0110 V041 110 890 665 25.01 21.33

MVW3000 A0125 V041 125 1015 760 28.42 24.23

MV W30 0 0 A0140 V041 140 1135 850 31. 83 2 7.14

MVW3000 A0160 V041 160 1300 970 36.38 31.02

8828 CFM or

15000 m³/h

C4

MVW3000 A0180 V041 180 1460 1090 40.92 34.90

MVW3000 A0200 V041 200 1625 1215 4 5.47 38.78

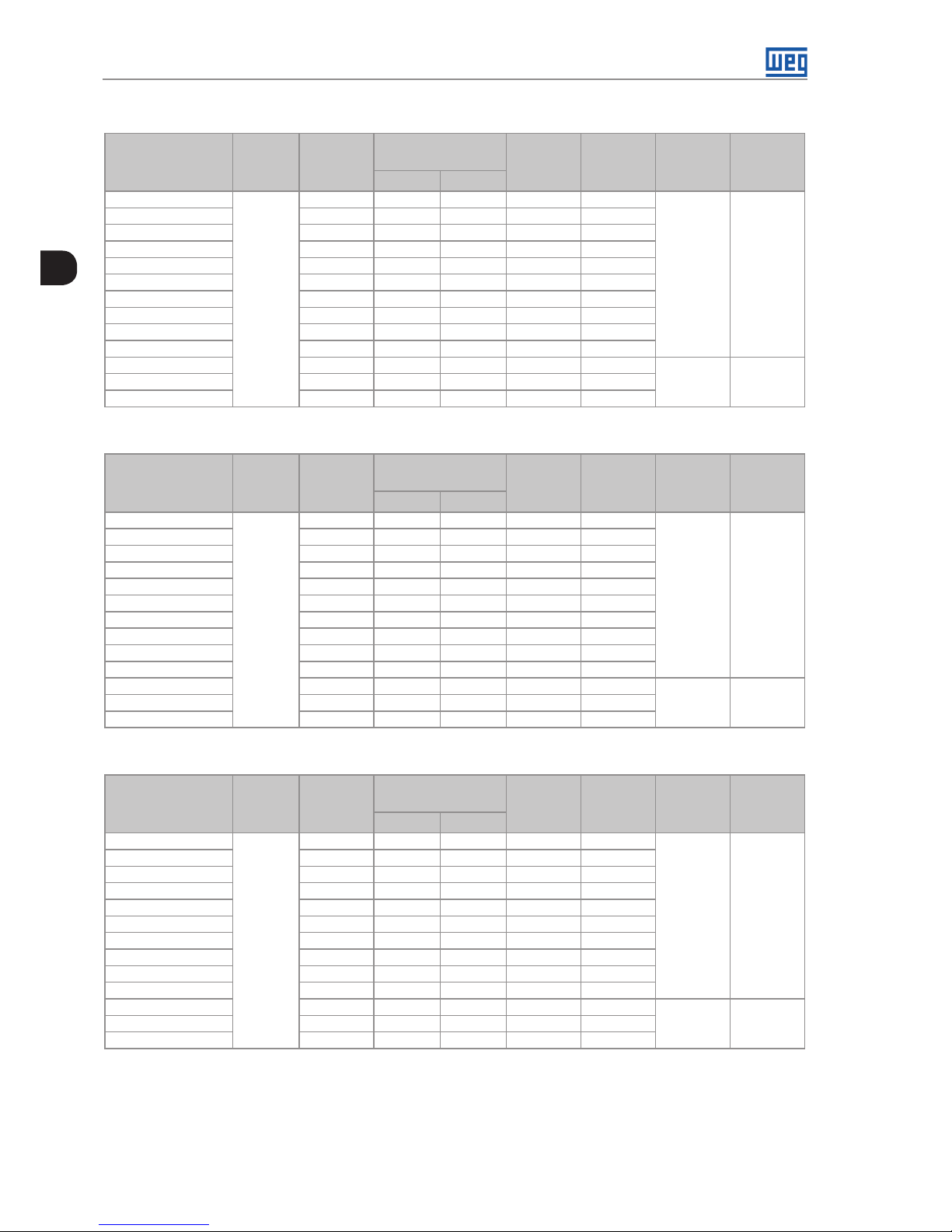

Table 2.6: MVW3000 5500 V models

Modelos

Nominal

Volt age

[V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V055

5500

40 425 320 12.02 10.25

7062 CFM or

12000 m³/h

B5

MVW3000 A0050 V055 50 535 400 15.03 12.82

MVW3000 A0060 V055 60 640 480 18.04 15.38

MVW3000 A0070 V055 70 750 560 21.0 4 17. 9 4

MVW3000 A0080 V055 80 855 640 24.05 20.51

MVW3000 A0090 V055 90 965 720 2 7. 0 5 23.07

MVW3000 A0100 V055 100 1070 800 30.06 25.63

MVW3000 A0110 V055 110 1175 880 33.07 28.20

MVW3000 A0125 V055 125 1340 1000 37. 5 7 32.04

MVW3000 A0140 V055 14 0 1505 1125 42.08 35.89

MVW3000 A0160 V055 160 1720 1285 4 8 .10 41.01

8828 CFM or

15000 m³/h

C5

MVW3000 A0180 V055 180 1935 1445 5 4.11 4 6 .14

MVW3000 A0200 V055 200 2150 1605 6 0 .12 51.27

Page 19

MVW3000 | 2-7

2

MVW3000 | 2-7

General Information

Table 2.7: MVW3000 6300 V models

Models

Nominal

Volt age

[V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V063

6300

40 485 485 13.77 11.74

7062 CFM or

12000 m³/h

B6

MVW3000 A0050 V063 50 615 615 17. 2 2 14.68

MVW3000 A0060 V063 60 735 735 20.66 17. 6 2

MVW3000 A0070 V063 70 855 855 24 .10 20.55

MVW3000 A0080 V063 80 985 985 2 7. 5 5 23.49

MVW3000 A0090 V063 90 1105 110 5 30.99 26.42

MVW3000 A0100 V063 100 1230 1230 34.43 29.36

MVW3000 A0110 V063 110 1350 1350 3 7. 8 8 32.30

MVW3000 A0125 V063 125 1540 1540 43.04 36.70

MVW3000 A0140 V063 14 0 1720 172 0 48.20 41.11

MVW3000 A0160 V063 16 0 1970 1970 55.09 46.98

8828 CFM or

15000 m³/h

C6

MVW3000 A0180 V063 18 0 2215 2215 61. 98 52.85

MVW3000 A0200 V063 200 2465 2465 68.86 58.72

Table 2.8: MVW3000 6900 V models

Models

Nominal

Volt age

[V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V069

6900

40 535 400 15.08 12.86

7062 CFM or

12000 m³/h

B6

MVW3000 A0050 V069 50 670 500 18.86 16.08

MVW3000 A0060 V069 60 810 605 22.63 19.29

MVW3000 A0070 V069 70 945 705 26.40 22.51

MVW3000 A0080 V069 80 1075 805 3 0.17 25.73

MVW3000 A0090 V069 90 1210 905 33.94 28.94

MVW3000 A0100 V069 100 1345 1005 3 7. 71 32.16

MVW3000 A0110 V069 110 1480 110 5 41.4 8 35.37

MVW3000 A0125 V069 125 1685 1260 4 7.14 40.20

MVW3000 A0140 V069 14 0 1890 1410 52.80 45.02

MVW3000 A0160 V069 16 0 2155 1610 60.34 51.4 5

8828 CFM or

15000 m³/h

C6

MVW3000 A0180 V069 18 0 2430 1815 67.8 8 5 7. 88

MVW3000 A0200 V069 200 2700 2015 75.42 64.31

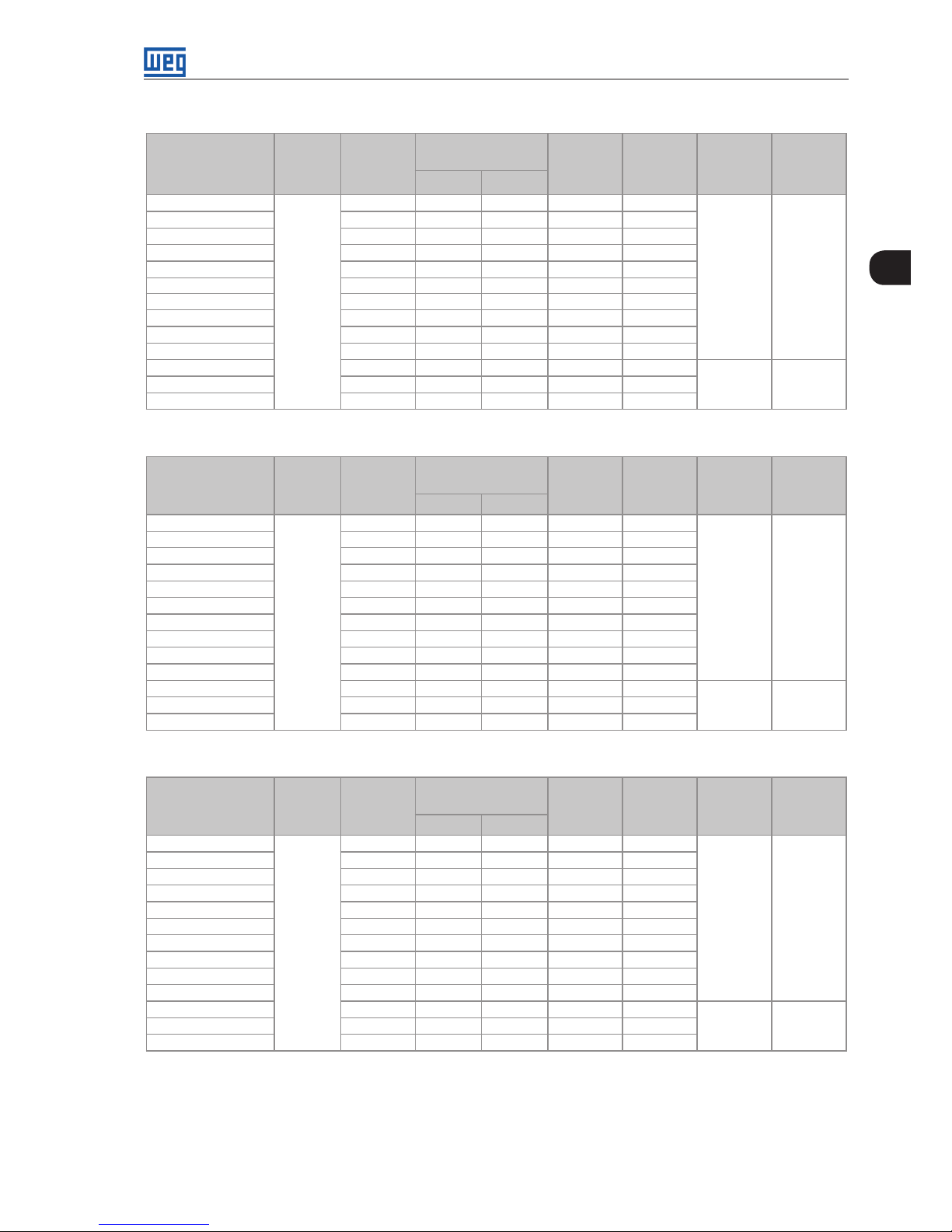

Table 2.9: MVW3000 7200 V models

Models

Nominal

Volt age

[V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V072

7200

40 560 420 15.74 13.42

10595 CFM or

18000 m³/h

B7

MVW3000 A0050 V072 50 700 525 19.68 16.78

MVW3000 A0060 V072 60 840 630 23.61 20.13

MVW3000 A0070 V072 70 985 735 27.5 5 23.49

MVW3000 A0080 V072 80 1125 840 31.48 26.84

MVW3000 A0090 V072 90 1265 945 35.42 30.20

MVW3000 A0100 V072 100 1405 1050 39.35 33.56

MVW3000 A0110 V072 110 1545 1155 43.29 36.91

MVW3000 A0125 V072 125 176 0 1315 49.19 41.94

MVW3000 A0140 V072 140 1970 1470 55.09 46.98

MVW3000 A0160 V072 160 2250 1680 62.96 53.69

13243 CFM or

22500 m³/h

C7

MVW3000 A0180 V072 180 2530 189 0 70.83 60.40

MVW3000 A0200 V072 200 2815 2100 78.70 6 7.11

Page 20

2-8 | MVW3000

2

General Information

Table 2.10: MVW3000 8000 V models

Models

Nominal

Volt age

[V]

Rated

Current

[A]

Motor Rated Power

(1)

Dissipated

Power

(2)

[kW]

Dissipated

Power

(3)

[kW]

Flow

Frame

Size

[HP] [kW]

MVW3000 A0040 V080

8000

40 620 465 17.49 14.91

10595 CFM or

18000 m³/h

B8

MVW3000 A0050 V080 50 775 580 21.8 6 18.64

MVW3000 A0060 V080 60 935 700 26.23 22.37

MVW3000 A0070 V080 70 1090 815 30.61 2 6 .10

MVW3000 A0080 V080 80 1250 935 34.98 29.83

MVW3000 A0090 V080 90 14 0 5 1050 39.35 33.56

MVW3000 A0100 V080 100 1560 116 5 43.72 37.28

MVW3000 A0110 V080 110 1720 1285 4 8 .10 41.01

MVW3000 A0125 V080 125 1955 1460 54.65 46.60

MVW3000 A0140 V080 140 2190 1635 61. 21 52.20

MVW3000 A0160 V080 160 2505 1870 69.96 59.65

13243 CFM or

22500 m³/h

C8

MVW3000 A0180 V080 180 2815 2100 78.70 67.11

MVW3000 A0200 V080 200 3130 2335 87.45 74.57

(1) The motor powers are only illustrative, and the correct inverter selection must be done as a function of the rated current of the motor to be used, as well

as the overloads related to the application. The motor rated output takes into account the operation with power factor 0.87 and 97 % of efficiency at full load.

(2) Dissipated power considering transformer with aluminum winding and operation under the conditions of Note (1).

(3) Dissipated power considering transformer with copper winding and operation under the conditions of Note (1).

Notes:

1 hp = 0.746 kW

1kW = 3412.14 BTU/hour for the dissipated power.

1 m³/h = 0.5885 CFM

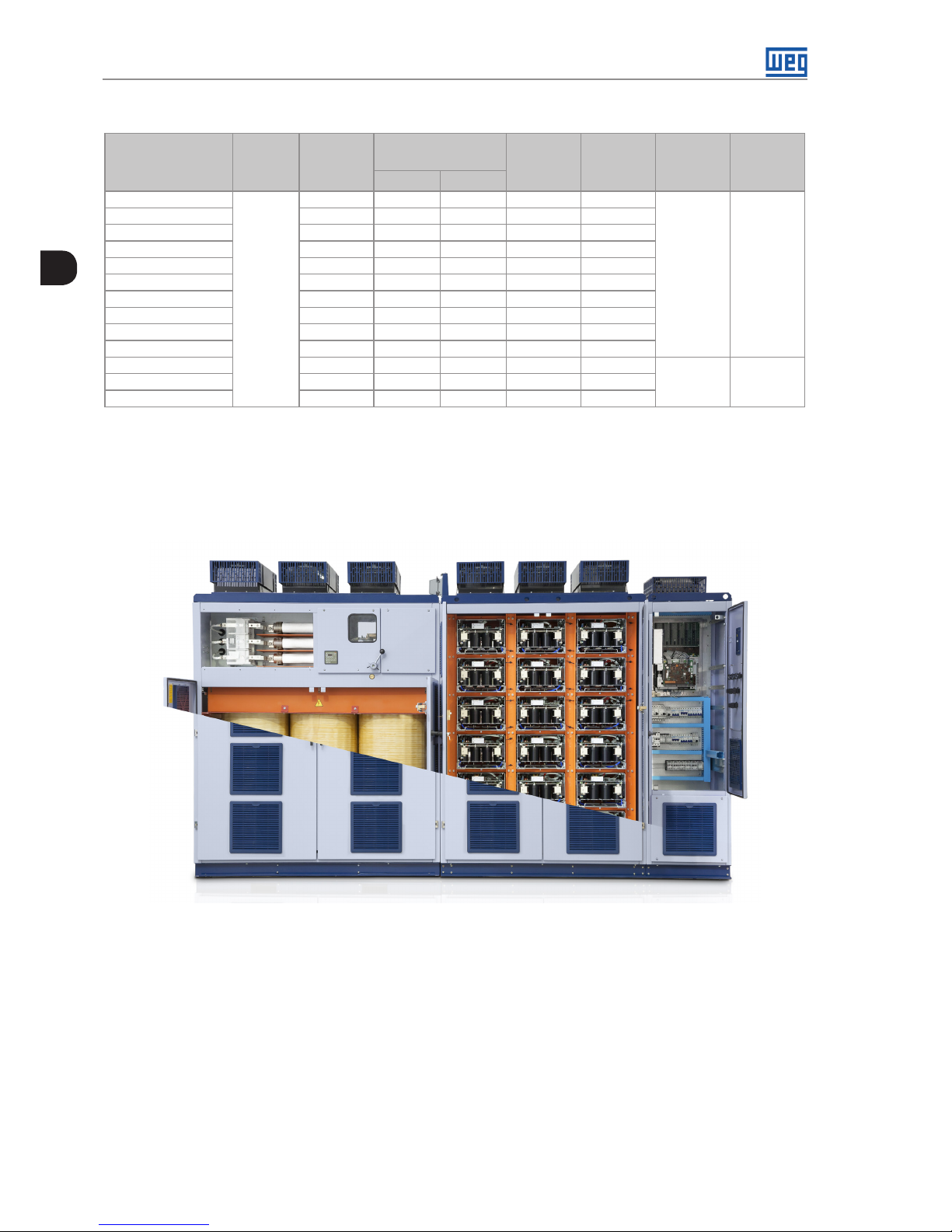

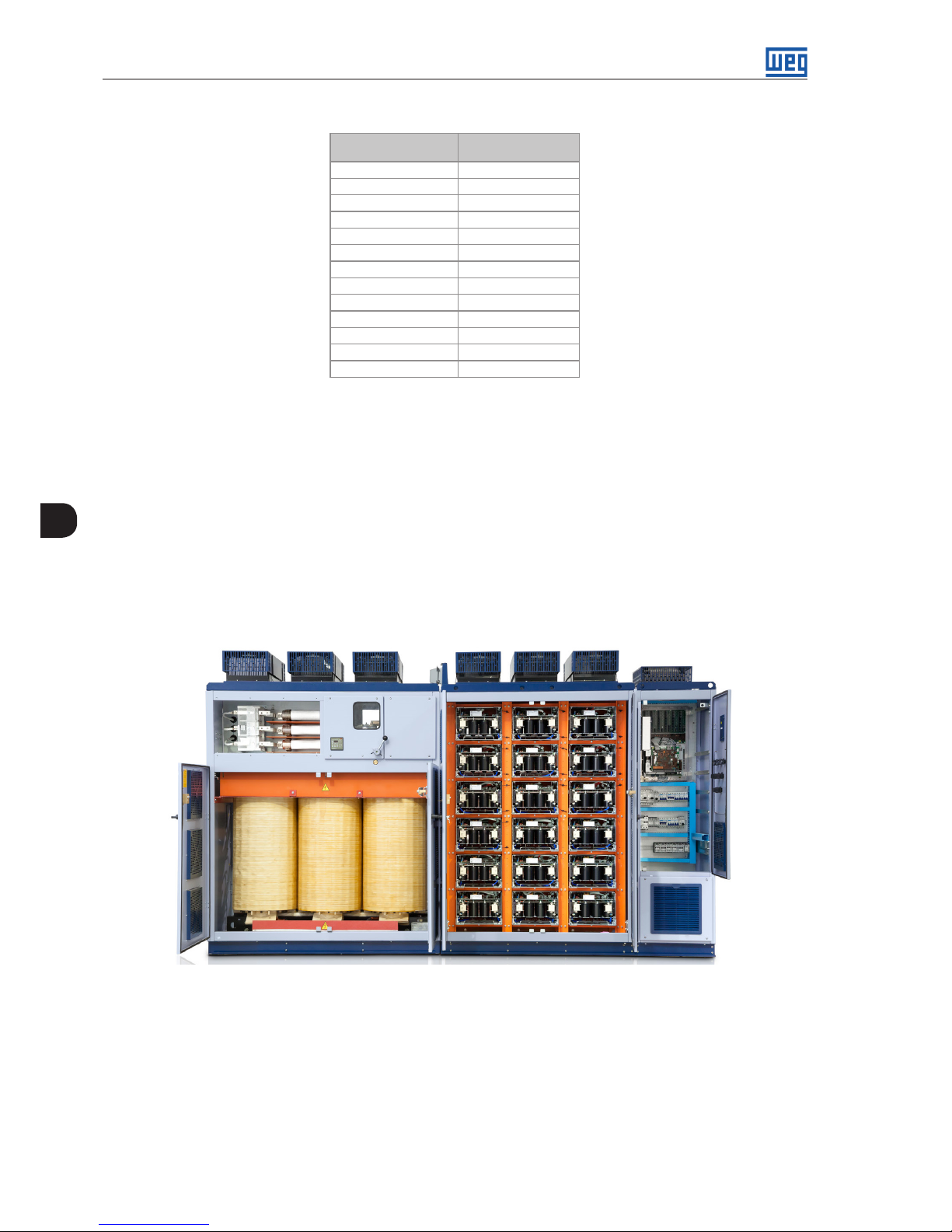

Figure 2.2: MVW3000 panel general view (Frame size B6)

Page 21

MVW3000 | 3-1

3

MVW3000 | 3-1

Product Characteristics

3 PRODUCT CHARACTERISTICS

A brief theoretical explanation about the operation and a simplified electrical scheme of the power cells and

their connections are presented below. The basic operation of the control system is presented at the end of this

chapte r.

The MVW3000 is a frequency inverter designed to control medium voltage motors at the rated values of 2.3 kV to

13.8 kV and for a power range of 150 HP to 5400 HP. Based on a topology where the low voltage cells (< 1000

V) are connected in series to form each inverter phase, its assembly is modular, enabling different configurations

if necessary to drive high power motors.

NOTE!

The characteristics contained in this manual were based on models of the standard MVW3000

intended for applications on 6.6 kV motors. Therefore, the MVW3000 used in the general illustrations

will contain 18 low voltage power cells (six in series per phase). Notice that the MVW3000 can be

engineered to meet the needs and technical specifications of our customers. Contact out technical

team for more details.

3.1 INPUT TRANSFORMER

The MVW3000 inverter has an input transformer, because the cascade cell topology demands the feeding of

each cell to be insulated from each other. This transformer is built so as to meet the different functions for the

MVW3000, such as the necessary insulation for the power cells, cancellation of the harmonic current coming

from the cell input rectifiers, and it also has an auxiliary winding responsible for the system pre-charge.

V phase cells

Medium voltage

input

Auxiliary input

(pre-charge)

W phase cells

U phase cells

U1

U2

Un

V1

V2

Vn

W1

W2

Wn

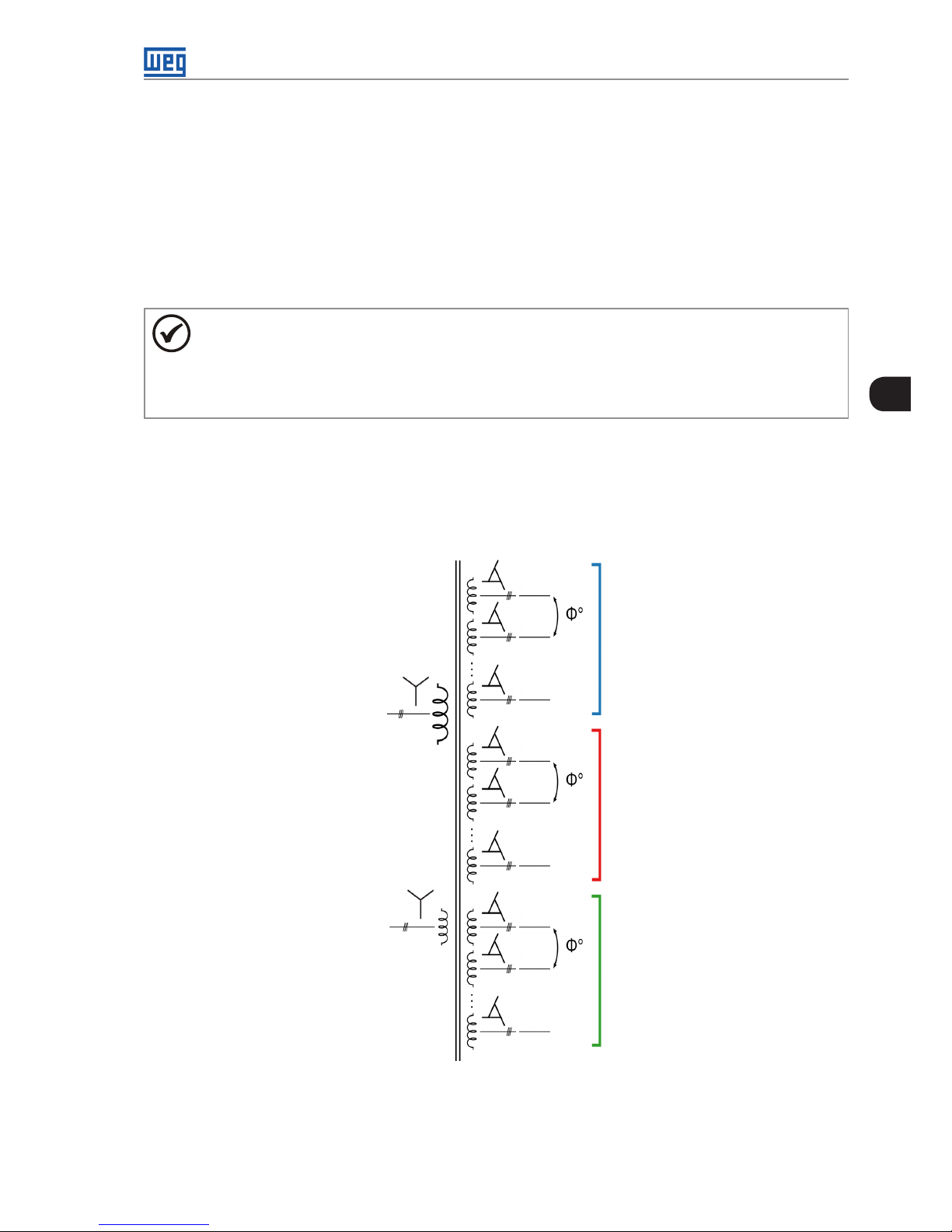

Figure 3.1: Input phase-shifting transformer diagram

Page 22

3-2 | MVW3000

3

Product Characteristics

The transformer configuration is made in star – extended delta, with phase-shifting angles j° between the

secondary windings of one same phase. The main primary windings (star connection) and the auxiliary input

windings (also star) do not present phase shifting between each other.

The transformer is designed according to the number of cells used on the inverter. 3x3xn windings (number of

motor phases x number of cell input phases x number of cells per phase) form n isolated secondary windings that

process 1/(3n) of the converter rated power, totalizing one secondary winding per cell.

Motor Voltage [kV] 2.3 3.3 4 .16 5.5 6-69 7. 2 8

Secondary Windings 3x2=6 3x3=9 3x4=12 3x 5 =15 3x 6 =18 3x7= 21 3x8=24

The transformer secondary windings have phase-shifting designed according to the number of cells and the

specified harmonic level, and it may be engineered upon the customer’s request The phase-shifting help cancel

the harmonic components coming from the non-controlled semiconductors devices. As each cell has a 6-pulse

diode rectifier at the input, and the secondary windings have a phase-shifting between each other, the transformer

primary winding perceives multiples of six pulses in its windings.

The bigger the number of pulses, the smaller the phase-shifting angle between the secondary windings, and

the smaller the Harmonic distortion rate observed by the transformer primary winding. Smaller phase-shifting

angles imply more complex manufacture and parameter control of the transformer. Thus, a good complexityperformance ratio is sought.

For the 18-cell MVW3000, the 36-pulse transformer Figure 3.2 on page 3-3 is used, which offers good

cost effectiveness with great performance regarding harmonic component cancellation and reduced cost, in

comparison to transformers with more pulses.

Table 3.1 on page 3-2 contains the possible input transformer configurations for different numbers of cells

installed on the MVW3000 panel.

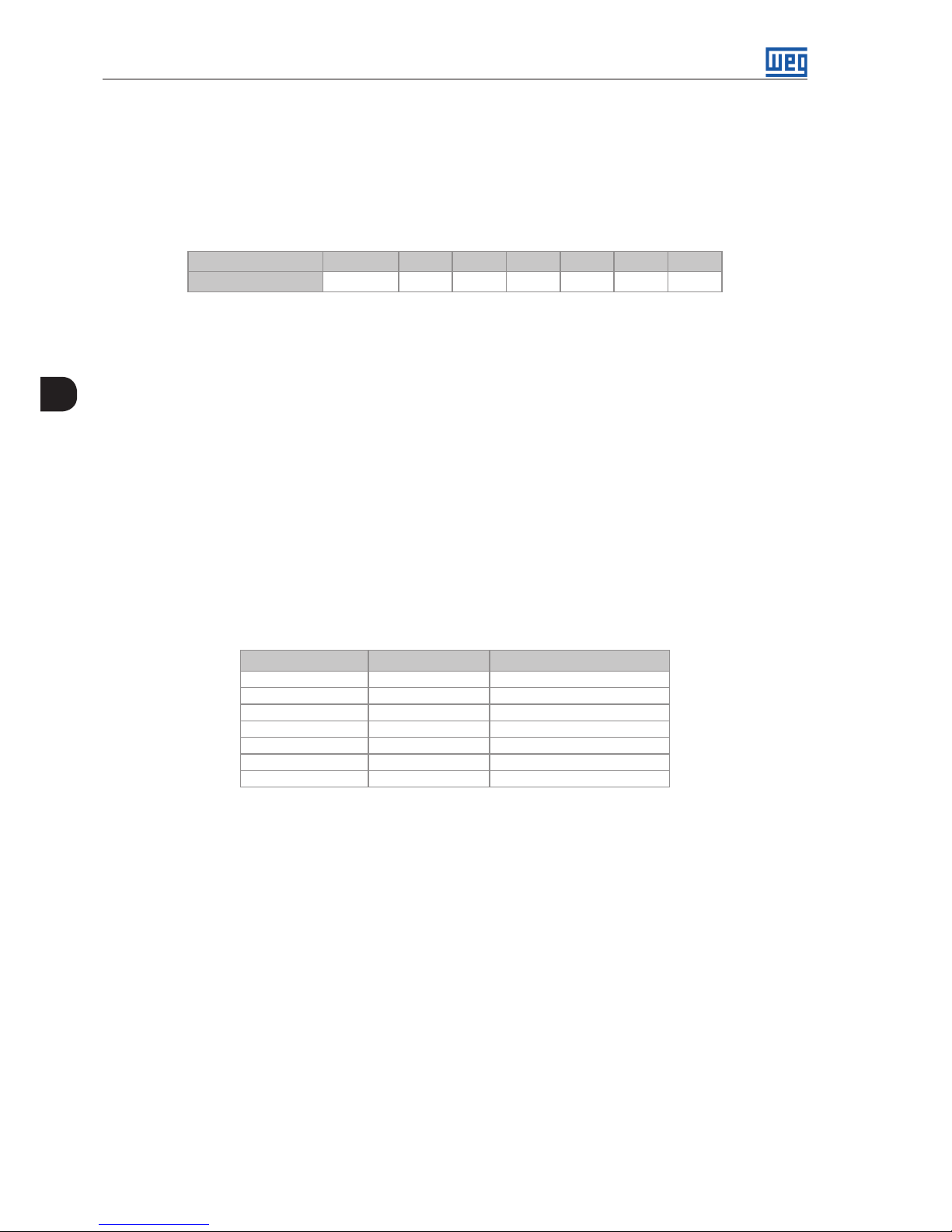

Table 3.1: Possible number of pulses to obtain in relation to the number of cells

Cells per Phase Total Cells Number of Pulses

2 6 36, 18

(1)

, 12, 6

3 9 54, 18

(1)

, 6

4 12 72, 36, 24

(1)

, 18, 12, 6

5 15 90, 30

(1)

, 18, 6

6 18 108, 54, 36

(1)

, 18, 12, 6

7 21 12 6, 126, 42

(1)

, 18, 6

8 24 144, 72, 48, 36

(1)

, 24, 18, 12, 6

(1) Stand ard op tion.

Figure 3.2 on page 3-3 indicates the connection points for the power cell inputs, in this case, the phases R, S

and T. The windings with 690 V

rms

of rated voltage process 1/18 of the converter rated power, in the case of the

18-cell MVW3000.

Page 23

MVW3000 | 3-3

3

MVW3000 | 3-3

Product Characteristics

R

S

T

Figure 3.2: Input transformer of the 18-cell MVW3000 (Frame B6)

Physically, the cells that form phases U, V and W are connected to the main transformer according to Figure 3.3

on page 3-3.

U phase cells

V phase cells

W phase cells

Figure 3.3: Cell connection area of each phase

The transformer has its own panel, being thus totally integrated to the MVW3000. For more details on the panels,

refer to Chapter 4 TECHNICAL DATA on page 4-1, Figure 4.3 on page 4-3, Table 4.2 on page 4-3 to Tabl e

4.8 on page 4-4.

3.2 POWER CELLS

The power cells used on the arms of the MVW3000 are single-phase low voltage inverters (output voltage of

690 V

rms

), in a topology known as H bridge or full bridge. A basic diagram of the rms power cell circuit can be seen

in Figure 3.4 on page 3-4. Each cell has the feeding of one own secondary winding (three-phase) of the main

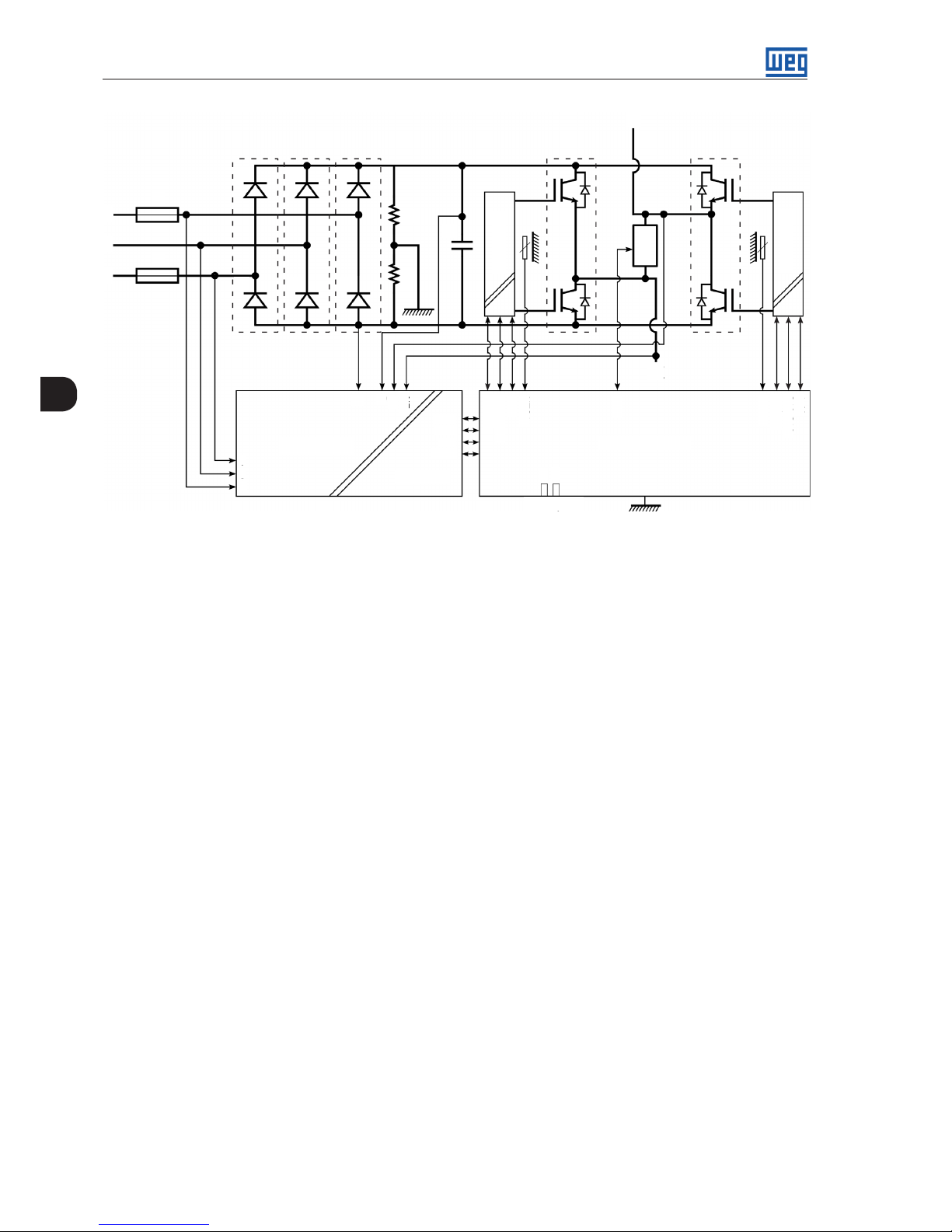

transformer, which ensures the converter medium voltage insulation.

The three-phase voltages of the input of the modules are then rectified by a Graetz bridge using non-controlled

semiconductor devices (diodes), forming one own DC link (direct current) with the addition of the capacitors to

the cell (represented by symbol C1). They can be electrolytic or plastic film capacitors, depending on the model

of the used cell.

Page 24

3-4 | MVW3000

3

Product Characteristics

R

S

T

F1

F2

D1

D3 D5

D2 D4

D6

R1

R2

C1

Gate driver

Bypass

Gate driver

FA

NE

Measurement

Supply

Fiber optic

Local control

R

T

S

N

P

FA

NE

24 V

15 V

5 V

GND

NTC1

GND

S1n, S2n

15 v

XC3

15 v

GND

NTC2

S1f, S2f

Tx

Rx

Figure 3.4: Basic diagram of a power cell

IGBT (Insulated Bipolar Gate Transistor) controlled semiconductor devices are used to implant the inverter bridge

in H; thus, each power cell has four IGBTs in the configuration shown above. During operation, the voltage

between FA and NE output terminals has three possible voltage levels. Considering that the DC link voltage of

each cell is VDC and that only two IGBTs can be operating simultaneously (due to short circuit protection), when

S1f and S2n are operating, the voltage between FA and NE will be + VDC, whereas if S1n and S2f start operating,

the voltage between FA and NE will be –VDC. If S1n and S1f or S2n and S2f are turned on, the voltage, in both

cases, will be equal the zero.

To protect the modules, two fuses F1 and F2 are connected to the input phases R and T, as shown in Figure 3.1

on page 3-1. In case a module presents some fault, the bypass system, when available, will be responsible for

circumventing the fault, removing it from the series and enabling the operation to continue.

When that occurs, control strategies will be applied so that the load remains operating. Further information can

be found in Chapter 8 SPECIAL FUNCTIONS on page 8-1, in Section 8.3 CELL BYPASS on page 8-5.

Each power cell has one local control module. This module communicates with the main control module by

means of an optical-fiber interface, necessary to obtain, in addition to the insulation degree required for the

communication, noise immunity, greater robustness and reliability, characteristics necessary for the application.

The local control makes acquisitions and monitors relevant magnitudes for the cell operation.

Some of the monitored magnitudes are the line voltages of the power cell, temperature of the diode modules and

IGBTs, voltage of the DC link capacitors, voltage of the cell power supplies, among others.

The local control is also responsible for local activations, such as the switching of the IGBTs and the trigger of

the bypass system. In case the cell presents readings out of the expected operation standards, for example,

temperatures close to damaging the semiconductors, overvoltage on the DC link, or other faults predicted by

the control, the bypass system may be activated for protection against a possible cell failure or for removing an

already damaged cell from operation.

Page 25

MVW3000 | 3-5

3

MVW3000 | 3-5

Product Characteristics

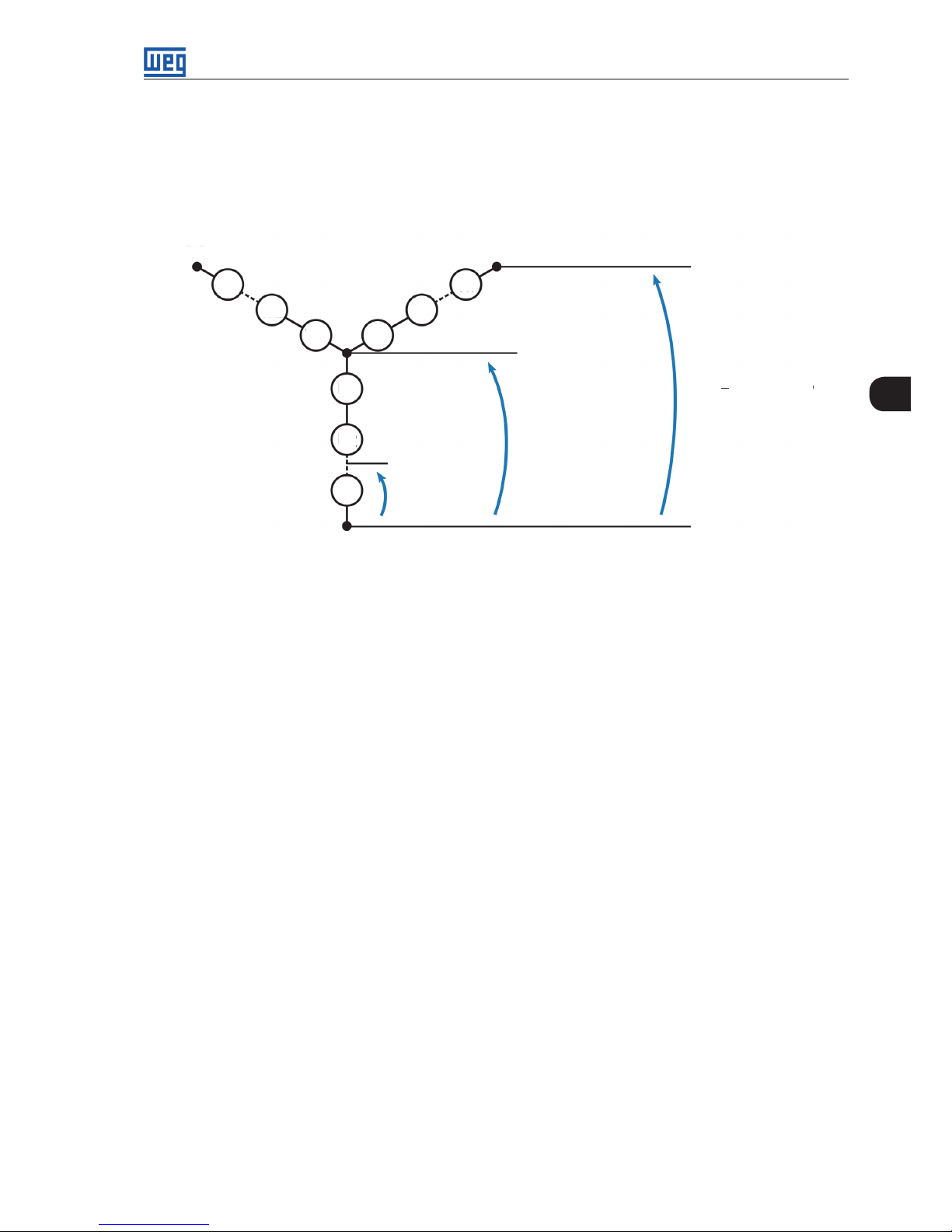

3.3 CONNECTION OF THE CELLS

To form a three-phase output, a number “n” of power cells that operate with 690 “V

rms

” of output are rms grouped

in series per phase. The cell sets that represent phases U, V and W are connected in star configuration, with a

floating neutral in common with the phases, as indicated in Figure 3.5 on page 3-5.

n x 690 V

690 V

V

W

U

√3 x n x 690 V

Vn

V2

V1W1

W2

Wn

U1

U2

Un

Figure 3.5: Cell-to-phase connection diagram

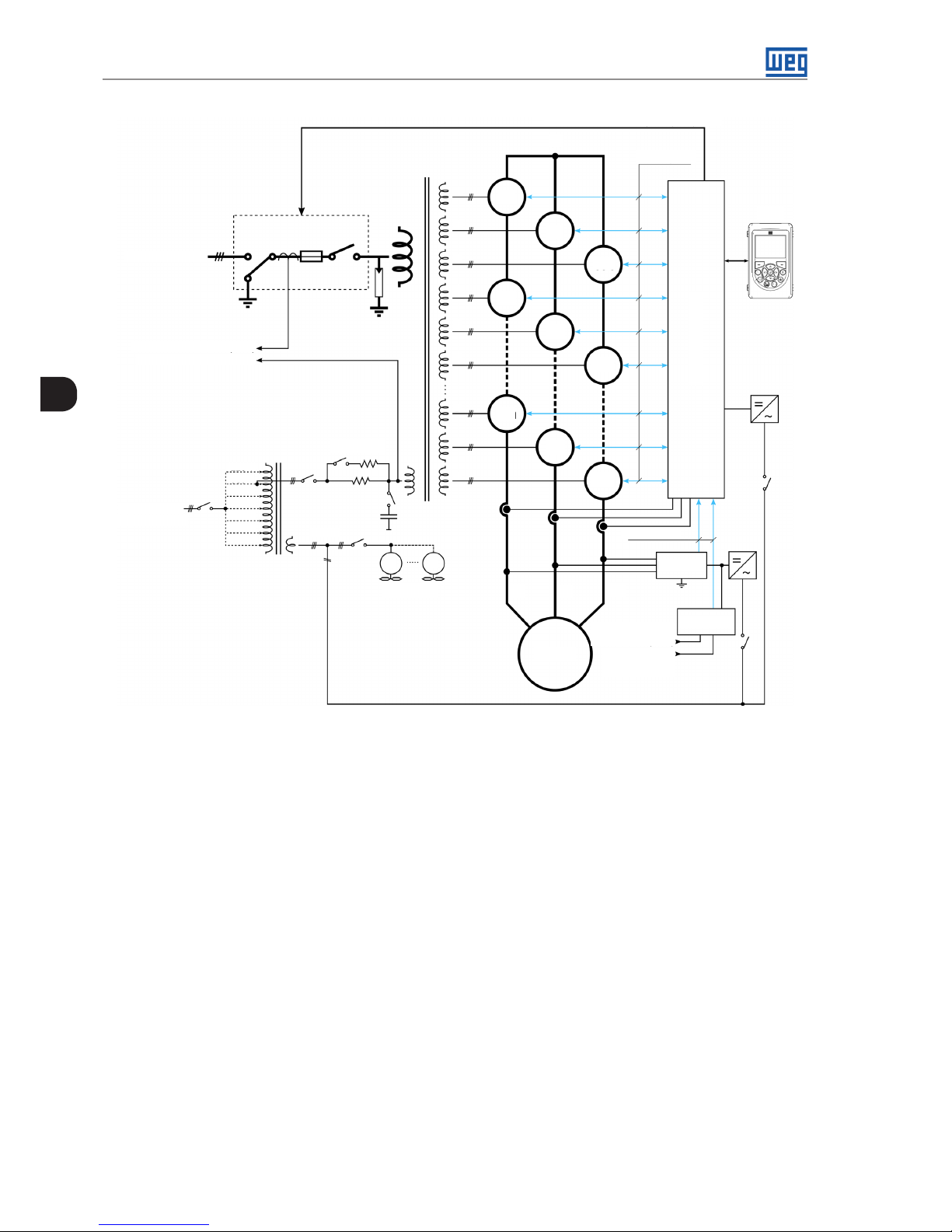

Figure 3.6 on page 3-6 shows the transformer, input switchgear and secondary winding connected to each

cell. This association in series enables more voltage levels at the inverter output. Locally, each cell produces three

voltage levels; however, at the converter three-phase output, it is possible to obtain 2n + 1 levels on the phase

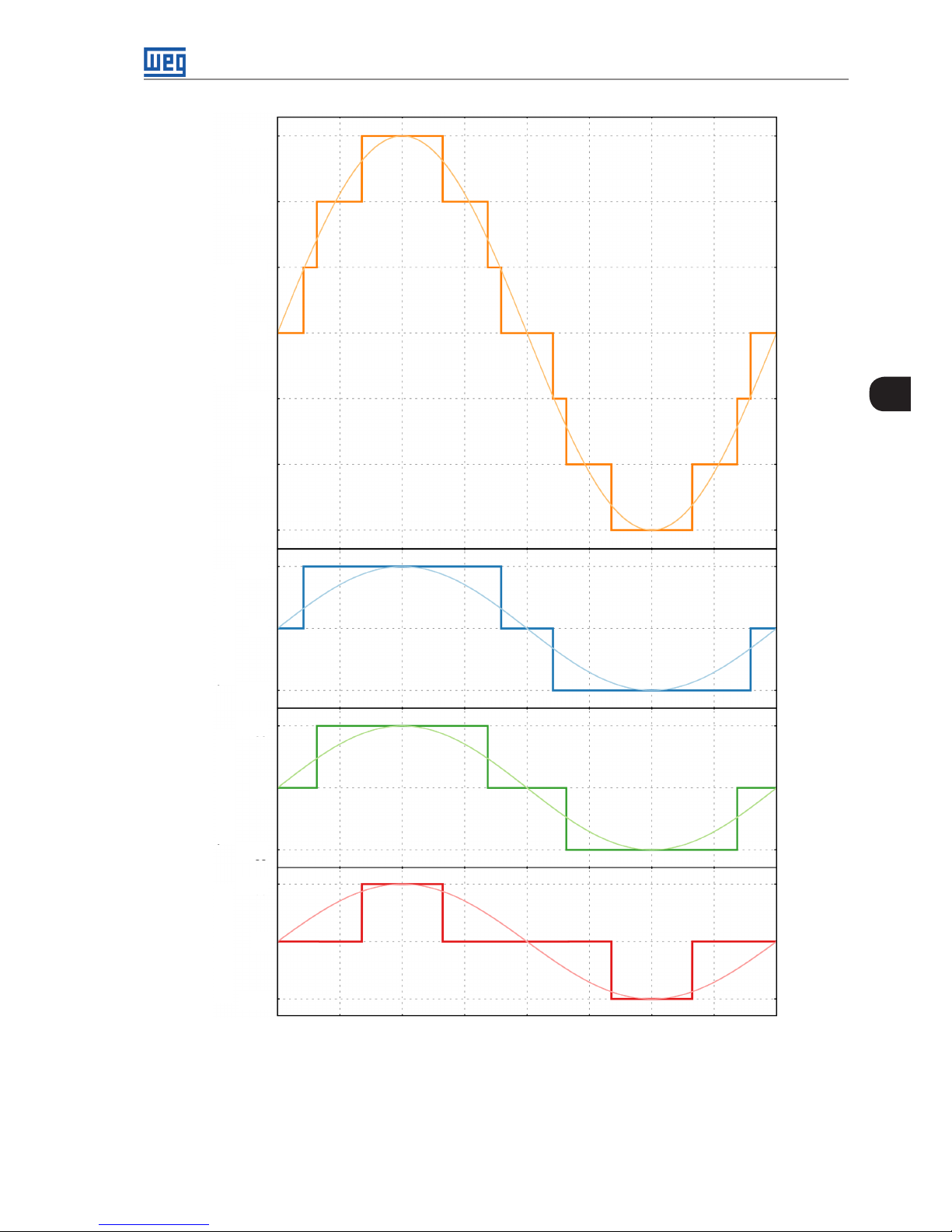

voltage and 4n+1 levels on the line voltage.

This effect occurs, because the voltage of each phase is instantaneously given by the addition of the voltages at

terminals FA and NE of each cell pertaining to the analyzed phase. Figure 3.7 on page 3-7 shows the sum of

the voltages of each cell to form the phase voltage in a 9-cell MVW3000 (3 per phase).

Page 26

3-6 | MVW3000

3

Product Characteristics

Input MT 3~

Currents (S andT)

Voltages (R, S and T)

Line BT 3~

220 V...480 V

220 V

380 V

400 V

415 V

440 V

440 V

440 V

Pre-load

Ventilation

220 V

M

M

zº

yº

zº

zº

yº

yº

xº

xº

xº

Fiber optic

Input switchgear command

HMI

N

U1

V1

W1

U2

V2

W2

Un

Vn

Wn

Fiber optic

Currents

(S and T)

Voltages

(R, S and T)

ISOC.22

ISOC2.00

Main control

Motor

U

V

W

Figure 3.6: MVW3000 simplified diagram for n power cells

Therefore, increasing the number of cells per phase, in addition to enabling the drive of motors with higher

voltages and powers, a better sinusoidal shaped wave is obtained. Thus, the converter provides a smaller THD

(total harmonic distortion), reduction of noises and vibration on the motor, operating with high efficiency.

Page 27

MVW3000 | 3-7

3

MVW3000 | 3-7

Product Characteristics

Voltage on phase U

+3 V

CC

Voltage on cell U1Voltage on cell U2

Voltage on cell U3

+2 V

CC

+V

CC

-V

CC

0

-2 V

CC

-3 V

CC

+V

CC

0

-V

CC

+V

CC

0

-V

CC

+V

CC

0

-V

CC

Figure 3.7: Wave form of the phase voltage for a CHB of 3 cells per phase

The diagram also shows the medium voltage input switchgear, the low voltage auxiliary winding to perform the

pre-charge of the cell capacitors, as well as the fiber optic interface between the main control and the local

control of the power cells.

Page 28

3-8 | MVW3000

3

Product Characteristics

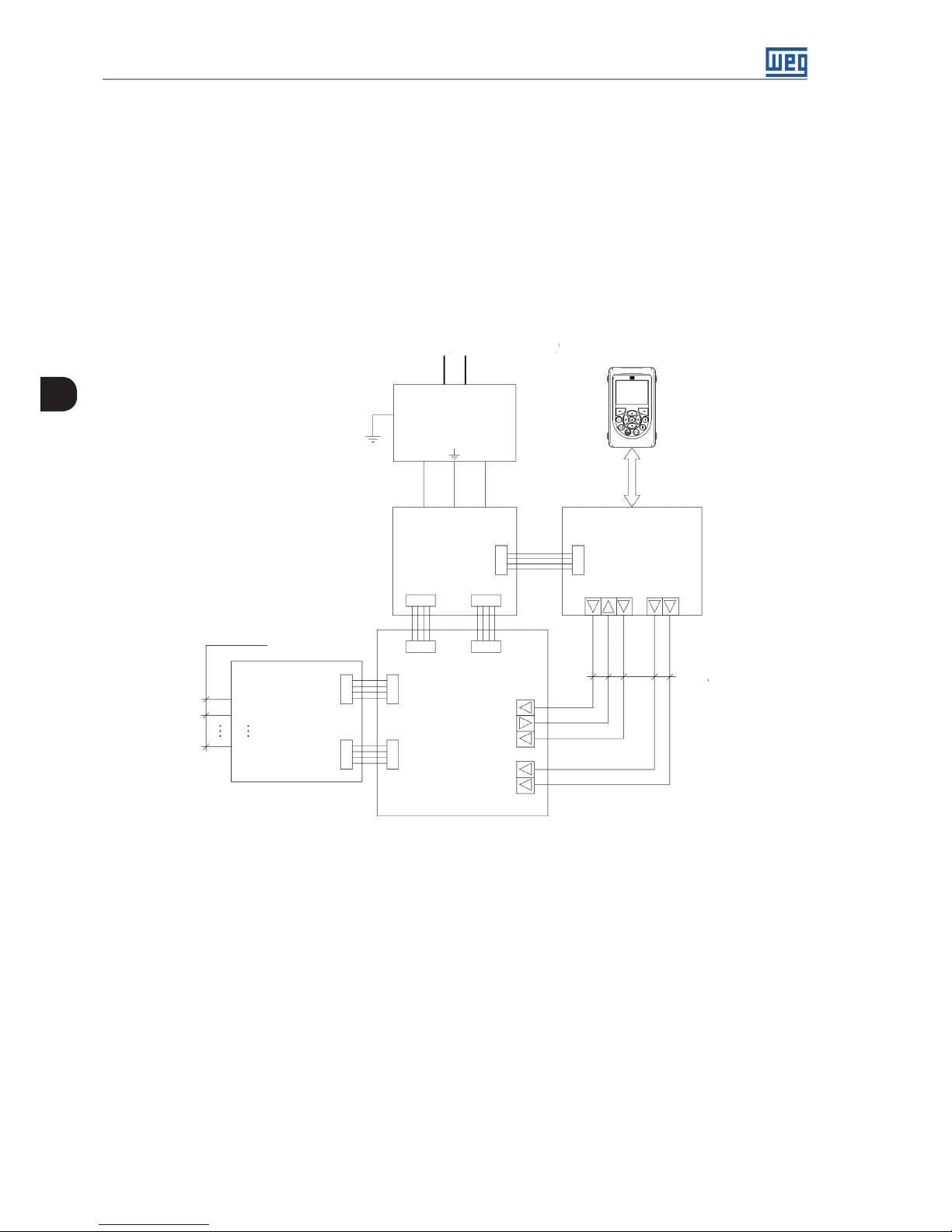

3.4 CONTROL

The MVW3000 has protections against overload, short circuit, current limit, under and overvoltage,

overtemperature, ground fault and monitoring of the individual faults of each power cell. The control type can be

selected by the user between: scalar control (constant V/f ratio) or vector control (sensorless or with feedback by

speed sensor).

The MVW3000 inverter uses the PWM modulation technique (Pulse Width Modulation); from the direct voltage

of each independent DC links, it synthesizes an alternate voltage with variable frequency and amplitude at the

output terminals. The medium voltage level is obtained at the converter output terminals from the association of

“n” low voltage cells in series. For further information on the central control, refer to Section 4.3 CONTROL RACK

on page 4-6.

HMI

MVC4PIC

PS24

24 V 0 V

MVC3

F.O .

F.O .

U1

U2

Wn

FOI3.02

Input BT (220 V 1~ or 3~)

Figure 3.8: Central control simplified diagram

The output currents of the three phases (motor currents) are measured using the Hall-effect CTs (current

transformers). Those current signals are sent to the central control board. The measurement is done for indication

on the HMI and for implanting the converter control and protection functions.

The pre-charge is done by means of an auxiliary winding of the input transformer, which is driven by the inverter

auxiliary supply circuit via current limiter elements. In order to prevent high starting current levels on the inverter,

activation of protection systems or even damages to its own components, the cell capacitor pre-charge must be

done through and auxiliary winding of the input transformer. The auxiliary supply is also responsible for feeding

the control circuit and fans for the panel cooling.

Page 29

MVW3000 | 4-1

4

MVW3000 | 4-1

Technical Data

4 TECHNICAL DATA

This chapter contains technical information on the MVW3000, cabinet details, input transformer, power cell and

control rack. It also provides information about the available output filters for the MVW3000.

4.1 MVW3000 PANEL

The MVW3000 is assembled as coupled panels forming four distinct compartments. In the first column of the

panel, to the left, are the input safety devices, such as fuses and the input circuit breaker/contactor (if installed).

This part also shows the input transformer temperature on the temperature display. Below the safety devices, in

a separate section, is the main medium voltage input transformer. In the central section, the inverter power cells

are installed; each of the three columns shown in Figure 4.2 on page 4-2 represents each of the three inverter

phases: U, V and W.

Transformer and Circuit

Inverter

Control

Figure 4.1: Closed panel of the 18-cell MVW3000 (Frame B6)

The handles of average tension that feed the cells of the invertor come from the secondary ones of the transforming

one of entrance. The number of cables and conductor diameter varies according to the number and current of

the cells installed on the MVW3000.

Each cell receives the input supply from and independent secondary winding insulated from the main transformer.

In the right panel, in the upper compartment, is the control compartment, containing the main control, user

interface, HMI, command and signalling, which are exclusively supplied by low voltage circuits.

The converter three-phase medium voltage output is located in the compartment below the control, and this

compartment can also be used to install optional output filters.

The standard panels of the models equipped with drive system and input protection feature medium voltage

fuses in order to protect the system against short circuit. The fuses must match the rated voltage of the input

medium voltage circuit.

Table 4.1 on page 4-2 presents the fuse models recommended for the standard inverters where the input and

output voltage are the same; for applications with voltage values different between input and output, the fuse

model will be informed upon request.

Page 30

4-2 | MVW3000

4

Technical Data

Table 4.1: Recommended fuses

Inverter Rated

Current (A)

Fuse

40 3R

50 3R

60 3R

70 5R

80 5R

90 5R

100 5R

110 12R

125 12R

140 12R

160 12R

180 18R

200 18R

The standard panels supplied for the MVW3000 are suitable for connection to medium voltage circuits capable

to supply a maximum symmetrical short circuit current of 40 kA.

The standard panels supplied for the MVW3000 are suitable for connection to medium voltage circuits capable

to supply a maximum symmetrical short circuit current of 40 kA.

4.1.1 Panel Constructive Aspects

The panel is made with steel sheets painted and processed (cutting, holes, folding, chemical treatment, painting

and finishing) by WEG, ensuring the quality in all the levels of the manufacture process. The inverter parts that

are not painted are zinc plated or have another suitable treatment in order to assure their resistance against

corrosion.

Transformer and Circuit Inverter

Control

Figure 4.2: Panel of the 18-cell MVW3000 (Frame B6)

The MVW3000 panel is supplied, in its standard structure, with degree of protection IP41 (openings smaller than

10 mm and protected against ingress of vertical drops). They can be supplied with distinct degrees of protection

according to the customer’s needs.

The panel cooling is done by means of forced convection. The air enters through the opening on the panel front

doors, goes through the transformer windings and also the power heatsinks located in each power cell. The

hot air leaves through the top do painel, of the panel, where the exhaust fans are located, allowing maintenance

without the need to open the inverter doors.

Page 31

MVW3000 | 4-3

4

MVW3000 | 4-3

Technical Data

Filter cleaning or replacement can be done by removing the external grid with no need to open the doors and to

interrupt the inverter operation. The internal grid with openings smaller than 10 m prevents the access to the

medium voltage compartment.

The MVW3000 complies with the international standards, such as harmonic limits, contained in IEEE-519 and

G5/4-1 standards, and also electromagnetic emission (EMC), contained in IEC61800-3 standard.

The medium voltage compartments are mechanically and electrically interlocked so as to prevent the access

to all the components that may present risk of electric shock with the system energized. Only after closing the

transformer and inverter panel doors is it possible to open the grounding system and close the input switch

disconnector.

In case of unlocking of the doors, the inverter will block the operation and turn off the input circuit breaker. The

control panel is fed by an auxiliary power supply (220 V – 480 V), which may be blocked to prevent its activation.

Bottom view

P

H

V

Top view

L

H

L

T

L

I

L

C

Figure 4.3: Panel constructive aspects

Table 4.2: Frame sizes available for 2300 V MVW3000

Frame Size LT [mm] LI [mm] LC [mm] L [mm] H [mm] HV [mm] P [mm]

Weight

kg (lb)

B2

150 0 1500 600 3900 2063 2405 110 0

2600 (5732)

C2 3250 ( 7165)

Table 4.3: Frame sizes available for 3300 V MVW3000

Frame size LT [mm] LI [mm] LC [mm] L [mm] H [mm] HV [mm] P [mm]

Weight

kg (lb)

B3

180 0 1500 600 3900 2063 2405 1100

3150 (6944)

C3 3950 (8708)

Page 32

4-4 | MVW3000

4

Technical Data

Table 4.4: Frame sizes available for 4160 V MVW3000

Frame size LT [mm] LI [mm] LC [mm] L [mm] H [mm] HV [mm] P [mm]

Weight

kg (lb)a [kg]

B4

180 0 1500 600 3900 2063 2405 1100

3550 (7826)

C4 4500 (9920)

Table 4.5: Frame sizes available for 5500 V MVW3000

Frame size LT [mm] LI [mm] LC [mm] L [mm] H [mm] HV [mm] P [mm]

Weight

kg (lb)

B5

180 0 1500 600 3900 2063 2405 1100

4200 (9259)

C5 54 50 (12015 )

Table 4.6: Frame sizes available for 6600 V and 6900 V MVW3000

Frame size LT [mm] LI [mm] LC [mm] L [mm] H [mm] HV [mm] P [mm]

Weight

kg (lb)

B6

180 0 1500 600 3900 2063 2405 1100

4850 (106 92)

C6 6350 (13999)

Table 4.7: Frame sizes available for 7200 V MVW3000

Frame size LT [mm] LI [mm] LC [mm] L [mm] H [mm] HV [mm] P [mm]

Weight

kg (lb)

B7

3600 3000 600 7200 2063 2405 1100

6100 (13448)

C7

78 50 (17306)

Table 4.8: Frame sizes available for 8000 V MVW3000

Frame size LT [mm] LI [mm] LC [mm] L [mm] H [mm] HV [mm] P [mm]

Weight

kg (lb)

B8

3600 3000 600 7200 2063 2405 1100

6550 (14440)

C8 8400 (18518)

4.2 POWER CELLS

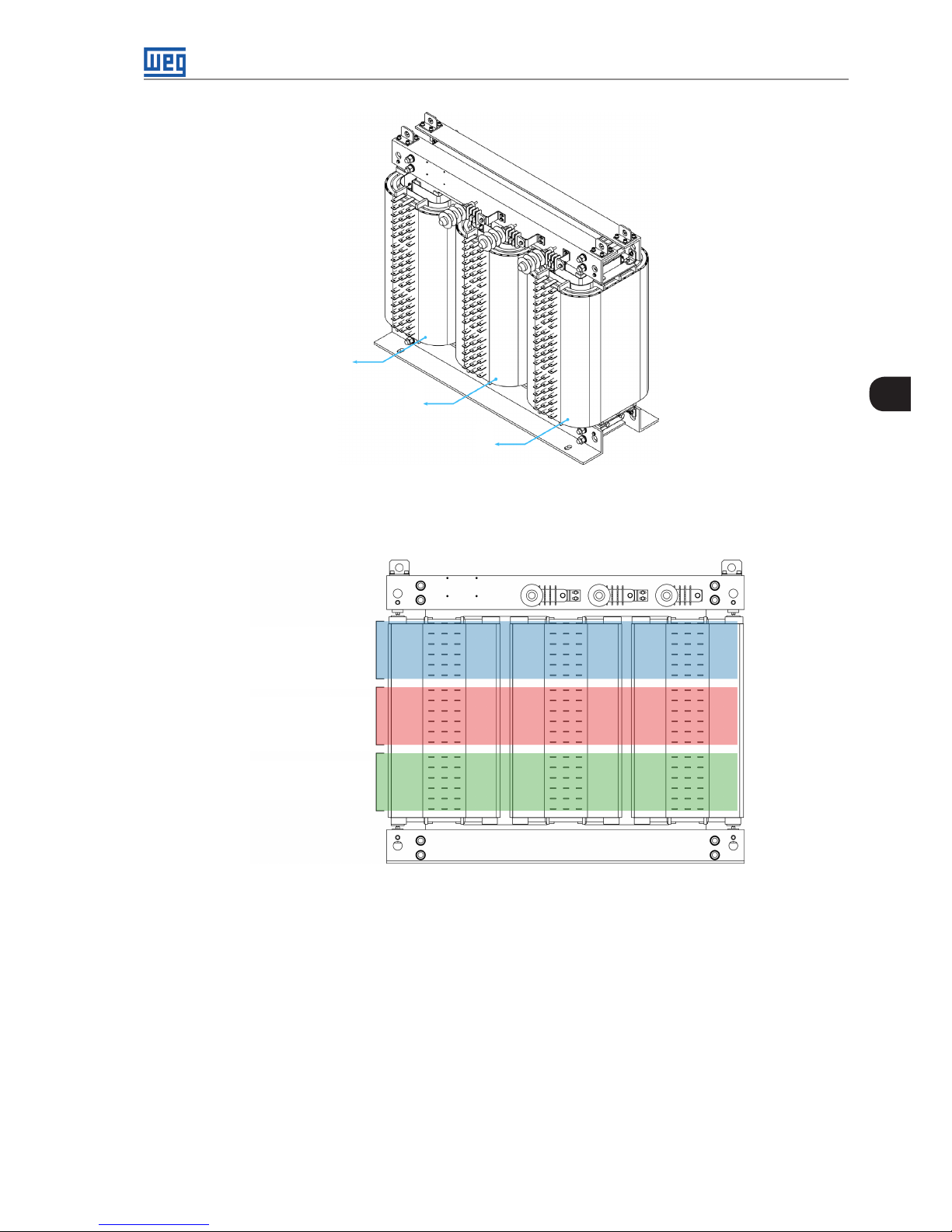

4.2.1 Constructive Aspects

The power cells of the same MVW3000 have two frames available. The 140 A cell, of frambe “B”, has 9 plastic

film capacitors for the DC link. And the 200 A cell, of fram “C”, with 12 capacitors. Information about power cell

models and dimensions may be seen in Table 4.9 on page 4-5, as well as a cell illustration in Figure 4.4 on page

4-4.

H

W

L

Figure 4.4: Dimensions of the cell of power of MVW3000

Page 33

MVW3000 | 4-5

4

MVW3000 | 4-5

Technical Data

Table 4.9: Dimensions of the different frames available

Frame Size H = Height (mm) W = Width (mm) L = Length (mm)

Weight

kg (lb)

B 255 361 505 35 ( 7 7.16 )

C 255 361 595 40 ( 8 8 .18)

The power cells may also contain a bypass system, at the costumer’s discretion, which provides greater safety

and robustness for the applications. Thus, a power cell of the standard MVW3000 contains:

9 or 12 capacitors (according to the model).

6 diodes with blocking voltage of 1.6k V.

4 IGBTs with blocking voltage of 1.7 kV.

1 heatsink for heat exchange.

2 gate driver electronic boards.

1 switched-mode power supply electronic board.

1 local control electronic board with fiber optic interface.

2 input protection fuses.

2 temperature sensors.

The listed items can be found in Figure 4.4 on page 4-4 and Figure 4.6 on page 4-6.

Diodes

IG BTs

Gate driver

Heatsink

Gate driver

IG BTs

Fuse

Fuse

Capacitor

Figure 4.5: Position of the components of the MVW3000 140 A power cell

The mechanical structure of each cell is basically formed by galvanized steel plates, and it is easy to install due to

the connection clamp system and the insertion and extraction mechanism present in the the set.

As the connection and mounting of the cell to the MVW3000 do not require tools, a cell can be changed in few

minutes, reducing the downtime. For further information about cell installation and replacement, refer to Chapter

6 INSTALLATION, CONNECTION AND ENERGIZATION on page 6-1.

Page 34

4-6 | MVW3000

4

Technical Data

4.2.2 Power Cell Boards and Connections

The electrical connection inside the cell is done by means of laminated busbars, insulated between each other

by means of insulating material compatible with the applied voltage level.

Gate driver

RX/TX fiber optic

Supply

Gate driver

Local controll

NE

R

S

T

FA

Figure 4.6: Standard power cell boards and connections of the MVW3000 (frame B)

The local control and power supply electronic boards are in the upper part of the cell, above the laminated

busbars, insulated and fastened to a metal base. The serial communication between the cell and the main control

module occurs by means of the local control board via the fiber optic interface.

The modulation signals leave the local control and go to the gate driver boards by via multiway flat cables. The

power supply provides the voltages of: 5 V, 15 V, -15 V, 24 V that feed all the cell control part (local control, gate

drivers and bypass system).

The celll connection to the link is carried out by means of clamps, located in the back part of the cell. There are

five connections per cell, connecting it to the transformer three-phase secondary winding (terminals R, S and T)

and to the serial circuit of the phase applied by terminals FA and NE (phase and neutral).

ATTENTION!

Electronic boards have components sensitive to electrostatic discharges. Do not touch directly

on components or connectors. If necessary, touch the grounded metallic frame before or use an

adequate grounded wrist strap.

4.3 CONTROL RACK

For the control power supply, the auxiliary voltage (220 Vac - 480 Vac) must have available and connected to the

specific terminal strip, located in the control panel. The provided transformer has taps for different voltages in the

primary winding and supplies 220 Vac in the secondary winding to feed all the low voltage circuits and exhaust

fans present in the product.

The MVW3000 control rack has four electronic boards, grouped in a mechanical assembly that enables better

visualization and access to the analog, digital and fiber optic interfaces. For this assembly, MVC3, MVC4, FOI3

and PIC2 boards are represented.

Page 35

MVW3000 | 4-7

4

MVW3000 | 4-7

Technical Data

1

2

3

4

Figure 4.7: MVW3000 standard control rack

Lettering 1 2 3 4

Board Code MVC4 FOI3 MVC3 PIC2

Description

User’s

functions

board

Fiber optic

interface

board

Control board

Control I/O

and power

supply board

The control rack is supplied with 24 Vdc by the PS24 power supply, whose input is at 220 V, single-phase or threephase. The control rack is composed of the interface and power supply board (PIC2), one control board (MVC3),

the user’s function board (MVC4) and the fiber optic interface board (FOI3). The MVC3 board is responsible for the

motor and inverter control, and the MVC4 for the user’s interface tasks. Both boards are supplied with isolated

low voltages provided by the PIC2 board, where there are also opto-isolated digital inputs and relay outputs (220

Vac) for internal use of the MVW3000.

Optional Fieldbus communication and function expansion boards (EBA, EBB or EBC) can be connected to the

MVC4 control board. The connections between the MVC3 board and the power stages are made with fiber-optic

cables through the FOI interface boards.

ATTENTION!

Electronic boards have components sensitive to electrostatic discharges. Do not touch directly

on components or connectors. If necessary, touch the grounded metallic frame before or use an

adequate grounded wrist strap.

4.4 OUTPUT FILTERS

Depending on the installation conditions, it may be necessary the addition of an output filter. For drives with

cables between 200 and 500 m, it is recommended to use output filter on the motor phases. For drives with

long cables, above 500 m, or for motors not able to operate with PWM modulation (retrofitting applications), it is

recommended to use filter type 2 (contact WEG).

The available filter models follow the voltage and current informed in Table 2.3 on page 2-5 to Table 2.10 on

page 2-8.

Page 36

4-8 | MVW3000

4

Technical Data

Ground loop

Shield

cables

Motor

PE

PE

PE

Inverter

L

(a) Filter type 1, for applications with cable length between 200 and 500 m.

Shield

cables

Motor

Inverter

PE

PEPE

Ground loop

C

C

C

L

L

L

(b) Filter type 2, for applications with cable length above 500 m and retrofitting.

Figure 4.8 (a) and (b): Output filters for MVW3000 inverters

Page 37

MVW3000 | 5-1

5

MVW3000 | 5-1

Synchronous Motor Line

5 SYNCHRONOUS MOTOR LINE

In order to allow driving synchronous motors, the MVW3000 introduces a number of software functions and new

hardware elements for commanding and controlling these motors.

Figure 5.1 on page 5-1 presents the general diagram for driving the synchronous motor using the MVW3000.

For more details on the excitation control system and the direct connection of the motor to the line, refer to the

electrical project of the inverter.

Supply line

Auxiliary line

E

Y

Y

-

+

MS

Interlocked

AC/DC converter

Excitation

control

system

Crowbar

MVW3000

MVC3

MVC4

RSSI

Figure 5.1: General diagram of the inverter for synchronous motor

5.1 ABSOLUTE ENCODER WITH RSSI BOARD

In synchronous machine drive applications, it is necessary to use an absolute encoder so as to obtain the exact

rotor position in relation to the stator, since the incremental encoder is not able to provide such information.

5.1.1 Absolute Encoder

The synchronous motor control requires the use of an absolute encoder, which must follow the following

specifications:

Synchronous Serial Interface (SSI) communication protocol with RS-485 communication channel, with clock and

16 bit word size in the following format:

14 data bits

1 ZERO bit

1 even parity bit

Page 38

5-2 | MVW3000

5

Synchronous Motor Line

Clock

Data

MSB

BIT 13 BI T 12 BI T 11 BIT 0 Zero Pa r.

LSB Zero Parity

t1 T

nT

t2

Figure 5.2: Clock specification and data transfer for the absolute encoder

Supply voltage of 15 V, with consumption lower than 300 mA.

Resolution of 14 bits per turn, which ensures a dynamic equivalent to the conventional incremental encoder;

When mounting the encoder next to the motor, it is recommended:

Coupling the encoder directly to the motor shaft (using a flexible coupling, however without torsional flexibility).

Both the shaft and the metallic frame of the encoder must be electrically isolated from the motor (minimum

distance of 3 mm).

Use good quality flexible couplings that prevent mechanical oscillations or “backlash”.

NOTE!

The standard absolute encoder recommended for the MVW3000 is the Baumer MHAP 400 B5

XXXXSB14EZ D.

The maximum encoder cable length is 120 m.

Refer to the motor project to define the type of encoder mounting.

5.1.2 RSSI Board

The use of absolute encoder implies the need for an SSI data interface (Synchronous Serial Interface) between

the encoder and the inverter. The RSSI board was developed for the encoder specification previously described.

This board has the following features:

Supply voltage of 24 V DC, with consumption of up to 700 mA.

RS485 communication channel for data transmission and clock according to SSI standard with absolute encoder;

2 fiber optic communication channels for use with up to two boards, MVC3 control and FOI3.

For electric connection, use shielded cables, keeping them at least 25 cm away from the other cables (power,

control, etc.). Preferably inside a metal conduit.

Page 39

MVW3000 | 5-3

5

MVW3000 | 5-3

Synchronous Motor Line

Encoder

Connector

CLK + CLK +3

DATA + DATA +8

DATA - DATA -7

DGND DGND6

6 9

51

Shield Shield Ground

Reference

Power supply

Absolute

Encoder

Signals

Description

RSSI-XC2 Connector

MVW3000 RSSI

board

XC2 connector

(DB0 - Male)

5

Shield

Brown

White

Pink

Gray

Blue

Red

Vdc Vdc4

CLK - CLK -2

Figure 5.3: RSSI - Encoder connection cable

NDO1 - FOI3 RDA

RDB

N3_CHA

N3_CHB

N2_CHA

N2_CHB

NDO1 - FOI3

N2 - MVC 3

N2 - MVC 3

+ 24 V 1

Ground 2 XC1

XC2

Encoder

GND 3

N3 - MV C3

N3 - MV C3

MVW3000

(B)

RSSI

MVW3000

Figure 5.4: Diagram of the connection with MVC3 and FOI3 boards

1

1

1

2

2

2

1

2

XC1

XC3

ON

1

2

XC2

RDB RDA

3

3

3

3

RSSI

8

7

6

9

6

5

5

4

4

4

4

4

4

1

1

4

1

1

1

1

1

D1

CTRL Com (Common)

Com (Common)

12119560 (GBR R02)

N3_CHA N2_CHA N3_CHB N2_CHB

+5 V (+Output)

-15 V (-Aux)

+15 V (+Aux)

-Vi (-Input)

+Vi (+Input)

B1

S1

Figure 5.5: RSSI board

Page 40

5-4 | MVW3000

5

Synchronous Motor Line

5.2 FIELD EXCITATION SET (DC WITH BRUSHES)

The field excitation of the synchronous motor can be done through an AC-DC converter that presents the

possibility of being controlled by a control loop, and that has an input for current reference and presents an

analogue output with the information of its output current (feedback for the MVW3000).

Specifications:

Current reference input AC-DC: 0 V to 10 V (AC-DC 5 V = 1 PU, observe P0462);

Feedback of the output current for the MVW3000: 0 V to 10 V (MVW3000 5 V = 1 PU, observe P0462 and P0744).

NOTE!

The MVC3 board has only voltage signals, in order to use current signals an external current

transducer must be used.

Example of configuration of the field current reference and paremeter setting of the inverter is presented in

Figure 5.6 on page 5-4. The parameters presented are described in the programming manual available for

download on: www.weg.net.

Field current

reference

P0180

|m|

P0177 P0450

P0178 P0449P0175/ P 0176P0182/P 0183

∑ ∑

φ

|φ|

+ -

+ -

if*

|m| = modulation index modulus

φ = stator flux,

|φ| = module

i

*

f

= field current reference

Figure 5.6: Parameters used by the inverter in the calculation of the of the field current reference

NOTE!

Information presented in Chapter 5 SYNCHRONOUS MOTOR LINE on page 5-1 of this manual

refers to the operation of synchronous machines with DC excitation and with brushes.

In order to drive synchronous machines with other types of excitation, consult WEG.

Page 41

MVW3000 | 6-1

6

Installation, Connection and Energization

6 INSTALLATION, CONNECTION AND ENERGIZATION

This chapter describes the electrical and mechanical installation procedures for the MVW3000. The presented

guidance and suggestions must be followed in order to assure the proper inverter operation.

ATTENTION!

The handling of the MVW3000 and its mechanical and electrical installation must be carried out

by persons trained and qualified by WEG.

STORAGE OF THE MVW3000 PANEL AND CELLS:

After receiving the equipment, remove the plastic film in order to prevent moisture condensation.

Do not store exposed to sunshine and to temperatures above 40 °C (104 °F).

Store in a clean and protected place with the air relative humidity not above 80 %.

During all the storage period the conditions mentioned earlier must be satisfied, but when components are

stored for more than one year, measures must be taken to dehumidify the storage location.

When using equipment after a long storage period, verify whether the equipment is free of scratches, dirt, rust

and other damages.

The inverter performance and reliability can be impaired if the inverter or the power arms were stored in an

environment out of the conditions listed previously.

DANGER!

The procedures recommended in this warning have the purpose of protecting the user from death,

severe personal injury and considerable property damage.

Power supply isolating switches: equipment for isolating the inverter power and auxiliary supplies

must be planed. They must cut off the inverter supplies (e.g., during installation maintenance tasks).

This equipment cannot be used as emergency stop mechanism.

Make sure that the power supply is disconnected before starting the wiring.

The following information is intended to be a example for a proper installation. Comply with applicable

local regulations for electrical installations.

DANGER!

Les procédures recommandées dans cet avertissement visent à protéger l’utilisateur de la mort,

de blessures graves et de dégâts matériels importants.

Interrupteurs d’isolement de l’alimentation : Le matériel d’isolement de l’alimentation de l’onduleur

et des alimentations auxiliaires doit être prévu. Il doit couper les alimentations de l’onduleur (par

ex.: pendant les tâches de maintenance de l’installation).