Page 1

Motors | Automation | Energy | Transmission & Distribution | Coatings

Frequency Inverter

Convertidor de Frecuencia

Inversor de Frequência

CFW700

User's Manual

Manual del Usuario

Manual do Usuário

Language: English, Spanish, Portuguese

Page 2

User's Manual

Series: CFW700

Language: English

Document: 10000771684 / 04

Models: Frame Sizes A...E

Date: 05/2015

Page 3

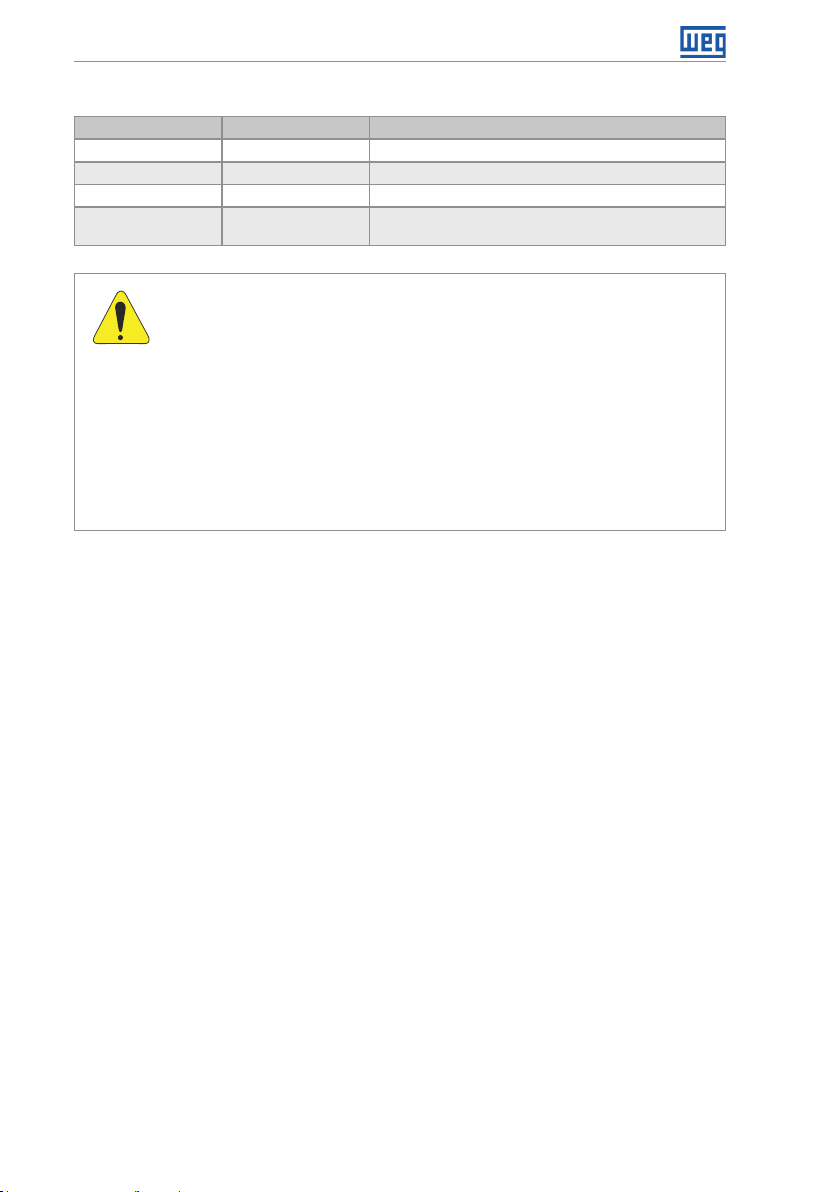

Summary of Revisions

The table below describes the revisions made to this manual.

Version Review Description

- R01 First edition

- R02 Cover update

- R03 General revision

- R04

Inclus ion of n ew fr ame s izes m ode ls D an d E

Update from IP54 to IP55 in frame sizes B and C

ATTENTION!

Parameters P0296 (Rated Line Voltage), P0400 (Rated Motor Voltage) and

P0403 (Rated Motor Frequency), were readjusted at the:

200...240 V / 220 / 230 V (S2, B2 and T2) models: P0296 = 0 (200 / 240 V),

P0400 = 220 V and P0403 = 60 Hz.

380...480 V (T4) models: P0296 = 3 (440 / 460 V), P0400 = 440 V and

P0403 = 60 Hz.

500...600 V (T5) models: P0296 = 6 (550 / 575 V), P0400 = 575 V and P0403

= 60 Hz.

For different values of line rated voltage and/or motor voltage and frequency,

set these parameters through the STARTUP menu, as presented in the user's

manual section 5.2 START-UP on page 48.

Page 4

Contents

1 SAFETY INSTRUCTIONS .................................................................... 1

1.1 SAFETY WARNINGS IN THE MANUAL .................................................... 1

1.2 SAFETY WARNINGS IN THE PRODUCT ................................................. 1

1.3 PRELIMINARY RECOMMENDATIONS ....................................................2

2 GENERAL INSTRUCTIONS ................................................................3

2.1 ABOUT THE MANUAL .............................................................................. 3

2.2 ABOUT THE CFW700 ................................................................................ 3

2.3 IDENTIFICATION .......................................................................................6

2.4 LIST OF AVAILABLE MODELS ................................................................ 8

2.5 IDENTIFICATION LABELS ........................................................................ 8

2.6 RECEIVING AND STORAGE .....................................................................9

3 INSTALLATION AND CONNECTION ................................................10

3.1 MECHANICAL INSTALLATION ...............................................................10

3.1.1 Installation Environment ...............................................................10

3.1.2 Mounting Considerations .............................................................10

3.2 ELECTRICAL INSTALLATION ................................................................11

3.2.1 Identification of the Power and Grounding Terminals ..............12

3.2.2 Power / Grounding Wiring and Fuses ......................................... 14

3.2.3 Power Connections .......................................................................15

3.2.3.1 Input Connections .............................................................15

3.2.3.2 Dynamic Braking (standard built-in for frame

sizes A, B, C and D and optional built-in for frame size

E - CFW700...DB...) ........................................................................16

3.2.3.3 Output Connections ......................................................... 17

3.2.4 Grounding Connections ...............................................................19

3.2.5 Control Connections ....................................................................19

3.2.6 Cable Distances ............................................................................23

3.3 INSTALLATION ACCORDING TO THE EUROPEAN DIRECTIVE

OF ELECTROMAGNETIC COMPATIBILITY ................................................24

3.3.1 Conformal Installation ..................................................................24

3.3.2 Emission and Immunity Levels ....................................................25

English

4 KEYPAD (HMI) AND BASIC PROGRAMMING ...............................26

4.1 INTEGRAL KEYPAD - HMI-CFW700 ......................................................26

4.2 APPLICATIONS ........................................................................................29

4.2.1 PID Regulator Application ............................................................29

4.2.1.1 Academic PID ..................................................................... 33

4.2.2 Electronic Potentiometer (EP) Application ...............................38

4.2.3 Multispeed Application ...............................................................40

4.2.4 3-Wire Start/Stop Command Application ..................................44

4.2.5 Forward/Reverse Run Application..............................................45

5 FIRST TIME POWER-UP AND START-UP .......................................48

5.1 PREPARE FOR START-UP ......................................................................48

5.2 START-UP.................................................................................................48

5.2.1 Oriented Start-up Menu ................................................................49

5.2.2 Basic Application Menu ..............................................................51

Page 5

Contents

6 TROUBLESHOOTING AND MAINTENANCE ...................................52

6.1 FAULTS AND ALARMS ............................................................................52

English

6.2 SOLUTIONS FOR THE MOST FREQUENT PROBLEMS ......................52

6.3 INFORMATION FOR CONTACTING TECHNICAL SUPPORT ..............53

6.4 PREVENTIVE MAINTENANCE................................................................53

6.5 CLEANING INSTRUCTIONS ..................................................................55

7 OPTION KITS AND ACCESSORIES ................................................. 57

7.1 OPTION KITS ............................................................................................ 57

7.1.1 Built-in RFI Filter (only for frame sizes A, B, C and D) -

CFW700...C3... ......................................................................................... 57

7.1.2 Dynamic Braking IGBT (only for frame size E in 220 / 230 V

and 380…480 V models and for frame sizes D and E in 500…600 V

models) - CFW700...DB... ...................................................................... 57

7.1.3 Nema1 Protection Degree (only for frame sizes A, B, C and E) -

CFW700...N1... .........................................................................................57

7.1.4 IP55 Protection Degree (only for frame sizes B and C) -

CFW700...N12... .......................................................................................57

7.1.5 IP21 Protection Degree (only for frame sizes A, B and C) -

CFW700...21... ..........................................................................................57

7.1.6 STO Function - CFW700...Y1... ......................................................57

7.1.7 24 Vdc External Control Power Supply - CFW700...W1... ..........58

7.2 ACCESSORIES .........................................................................................58

8 TECHNICAL SPECIFICATIONS ........................................................60

8.1 POWER DATA ...........................................................................................60

8.2 ELECTRICAL/GENERAL SPECIFICATIONS .........................................61

8.2.1 Codes and Standards ...................................................................63

APPENDIX A - DIAGRAMS AND FIGURES ......................................201

APPENDIX B - TECHNICAL SPECIFICATIONS ................................212

Page 6

Safety Instructions

1 SAFETY INSTRUCTIONS

This manual provides information for the proper installation and operation of the CFW700

frequency inverter.

Only trained personnel, with proper qualifications, and familiar with this kind of equipment

and associated machinery shall plan and implement the installation, starting, operation, and

maintenance of this equipment. The personnel shall follow all the safety instructions described in

this manual and/or defined by the local regulations. Failure to comply with the safety instructions

may result in death, serious injury, and equipment damage.

1.1 SAFETY WARNINGS IN THE MANUAL

DANGER!

The procedures recommended in this warning have the purpose of protecting

the user against death, serious injuries and considerable material damage.

ATTENTION!

The procedures recommended in this warning have the purpose of avoiding

material damage.

NOTE!

The text intents to supply important information for the correct understanding

and good operation of the product.

English

1.2 SAFETY WARNINGS IN THE PRODUCT

The following symbols are attached to the product, serving as safety notices:

High voltages are present.

Components sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to the protective ground (PE).

Connection of the shield to the ground.

Hot surface.

CFW700 | 1

Page 7

Safety Instructions

1.3 PRELIMINARY RECOMMENDATIONS

English

DANGER!

Always disconnect the main power supply before touching any electrical

device associated with the inverter. Several components may remain charged

with high voltage and/or in movement (fans), even after the AC power supply

has been disconnected or turned off. Wait at least 10 minutes to guarantee

the fully discharge of capacitors. Always connect the equipment frame to the

ground protection (PE).

NOTE!

Frequency inverters may cause inter ference in other electronic devices. Follow

the recommendations listed in chapter 3 INSTALLATION AND CONNECTION

on page 10, to minimize these effects.

Fully read this manual before installing or operating the inverter.

Do not perform a withstand voltage test on any part of the inverter!

If needed, please, consult WEG.

DANGER!

Crushing Hazard

In order to ensure safety in load lifting applications, electric and/or mechanical

devices must be installed outside the inverter for protection against accidental

fall of load.

2 | CFW700

DANGER!

This product was not designed to be used as a safety element. Additional

measures must be taken so as to avoid material and personal damages.

The product was manufactured under strict quality control, however, if installed

in systems where its failure causes risks of material or personal damages,

additional external safety devices must ensure a safety condition in case of a

product failure, preventing accidents.

Page 8

General Instructions

2 GENERAL INSTRUCTIONS

2.1 ABOUT THE MANUAL

The purpose of this manual is to provide the basic information needed to install, start-up in

the V/f control mode (scalar), and troubleshoot the most common problems of the CFW700

frequency inverter series.

ATTENTION!

The operation of this equipment requires installation instructions and detailed operation

provided in the user's manual, programming manual and communication manuals.

The user's manual and the parameters quick reference are supplied in a hard copy

together with the inverter. The user guides are also provided in a hard copy along

with the accessories. The other manuals are included on the CD supplied with the

inverter or can be downloaded from the WEG website at - www.weg.net. The CD

should always be kept with the equipment. A printed copy of the files available on the

CD can be ordered through your local WEG representative.

Some of the figures and tables are available in the appendixes. The APPENDIX A - DIAGRAMS

AND FIGURES on page 201 shows the figures and the APPENDIX B - TECHNICAL

SPECIFICATIONS on page 212 shows the technical specifications. The information is available

in three languages.

Please refer to the following technical manuals for further information:

CFW700 Programming Manual.

English

DeviceNet Communication Manual.

CANopen Communication Manual.

Profibus DP Communication Manual.

Modbus Communication Manual.

2.2 ABOUT THE CFW700

The CFW700 frequency inverter is a high performance product designed for speed and torque

control of threephase induction motors. The main characteristic of this product is the “Vectrue”

technology, which has the following advantages:

Scalar control (V/f), VVW or vector control programmable in the same product.

The vector control may be programmed as “sensorless” (which means standard motors

without using encoders) or as “vector control” with the use of an encoder.

The “sensorless” control allows high torque and fast response, even in very low speeds or at

the starting.

The “vector with encoder” control allows high speed precision for the whole speed range

(even with a standstill motor).

CFW700 | 3

Page 9

General Instructions

“Optimal Braking” function for the vector control, allowing the controlled braking of the motor

and avoiding external braking resistor for some applications.

English

“Self-Tuning” feature for vector control. It allows the automatic adjustment of the regulators

and control parameters from the identification (also automatic) of the motor parameters and

load.

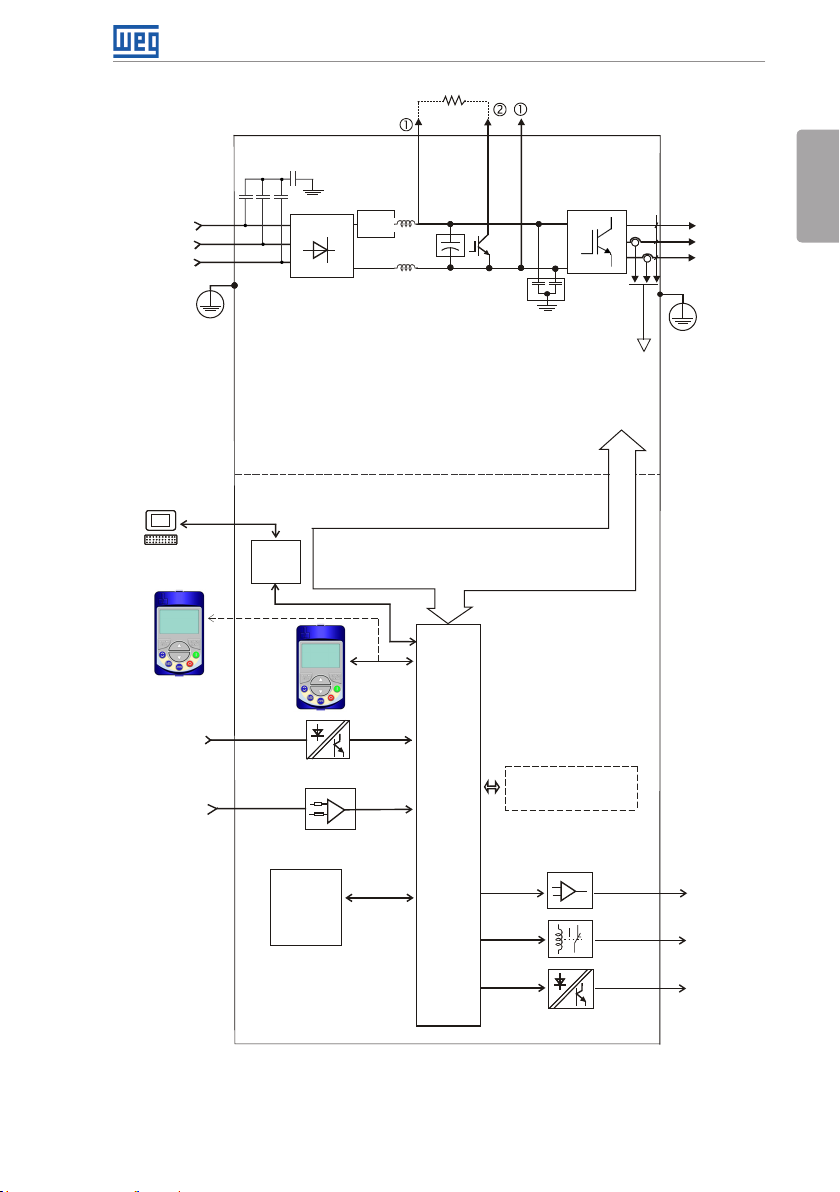

The main components of the CFW700 can be viewed in Figure A.1 on page 201.

4 | CFW700

Page 10

Mains power

supply

PC

R/L1/L

S/L2/N

T/L 3

PE

C3 RFI filter (*)

(available in

CFW700...C3...

Three-phase

rectifier

inverters)

Pre-

charge

DC+ DC-BR

DC link chokes

POWER

CONTROL

General Instructions

= DC bus connection

= Braking resistor

connection

U/T1

V/T2

Motor

W/T3

Inverter

with

RFI filter

DC link capacitor bank

CFW700...DB... inver ters)

Braking IGBT (available in

IGBT

transistors

Feedback:

- voltage

- current

PE

English

WPS software

WLP software

Keypad

(remote)

Digital inputs

DI1 to DI8

Analog

inputs

AI1 and AI2

RS-485

FLASH

memor y

module

(Slot 5)

Control power supply and interfaces

between power and control

Keypad

CC700

Control

board

with a

32 bits

"RISC"

CPU

Accessories

COMM 1

(Slot 3 - Green)

= Keypad (HMI)

(*) The capacitor to the ground of the C3 RFI filter (it is possible to meet the

requirements of category C2 with this filter on mechanics A models) must be

disconnected for IT net works and grounded delta power supplies. Please

refer to item 3.2.3.1 Input Connections on page 15.

Figure 2.1: Block diagram for the CFW700

Analog

outputs

AO1 and AO2

Digital output

DO 1 (R L1)

Digital outputs

DO2 to DO5

CFW700 | 5

Page 11

General Instructions

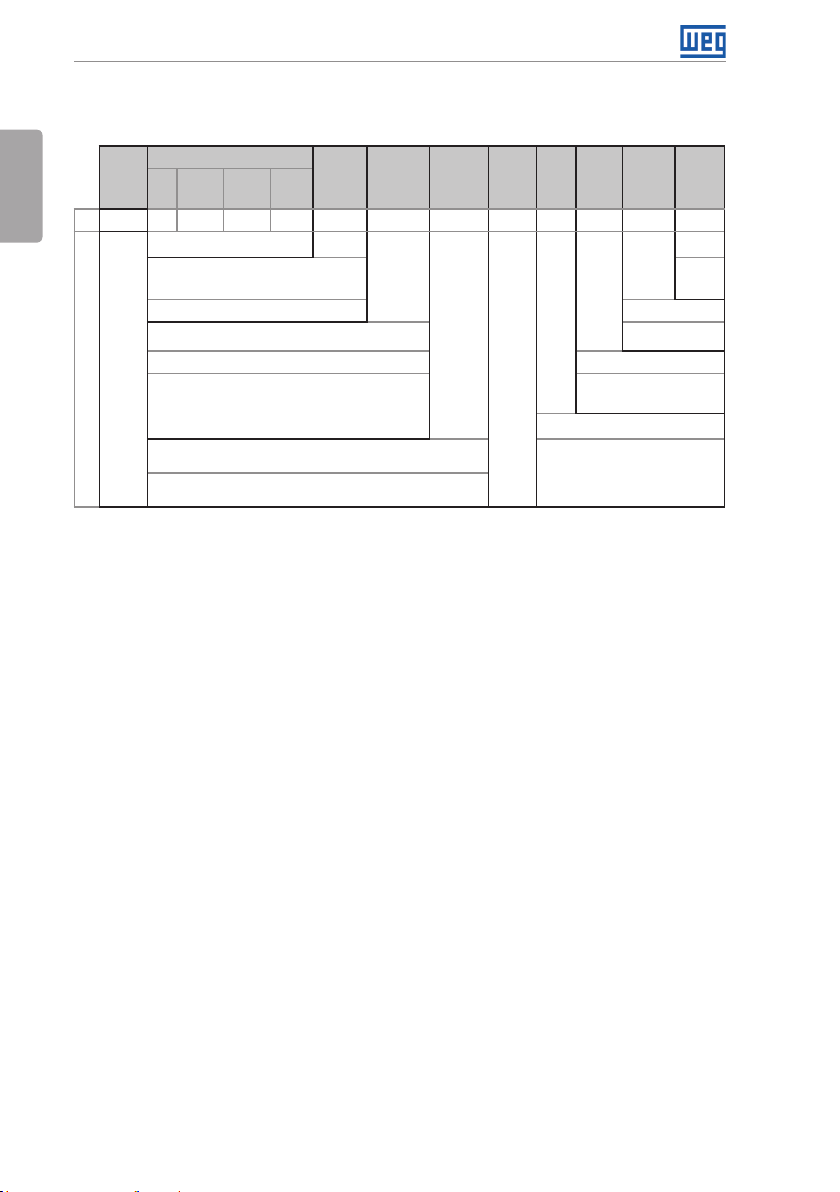

2.3 IDENTIFICATION

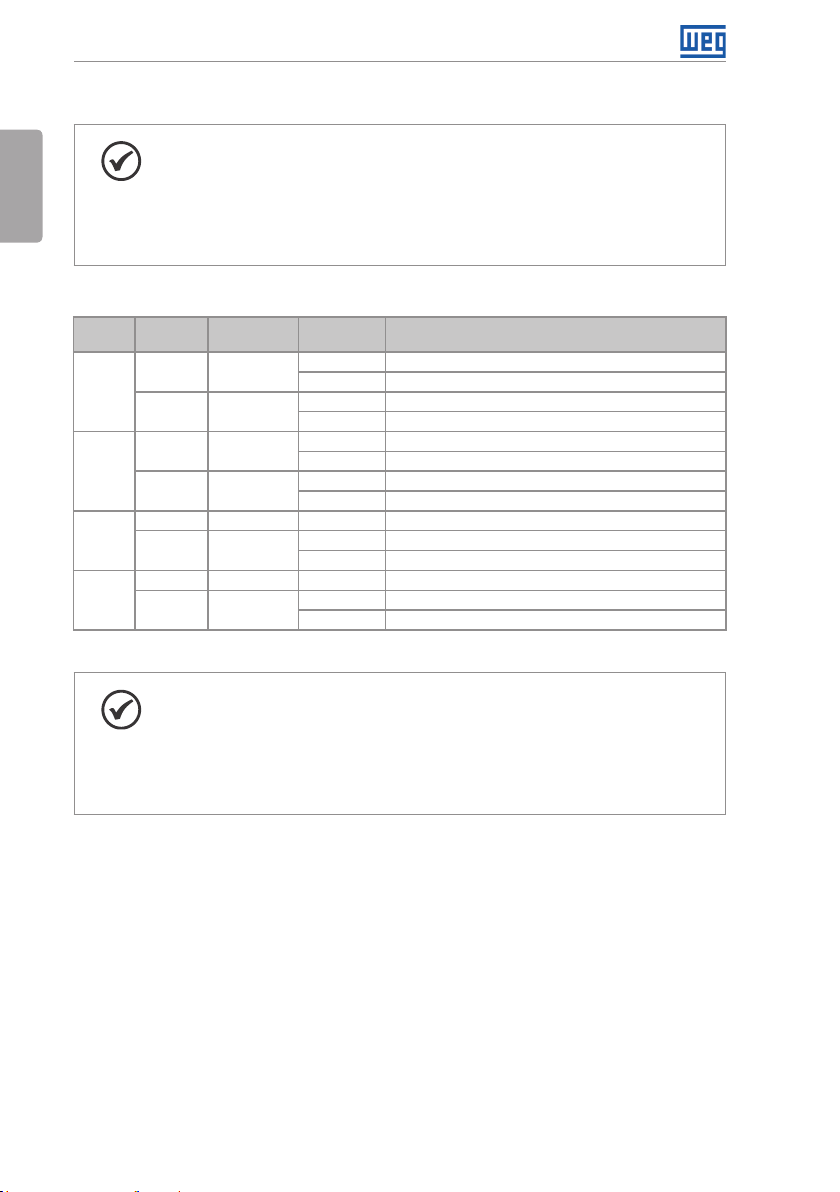

Table 2.1: Identification of the CFW700 inverters

English

Product

and

Series

Eg.: CFW700 A 03P6 T 4 DB 20 C3 DS Y1 W1 --- --

CFW700

Available options

Notes:

(1) The options available for each mo del are shown in Table 2.2 on p age 7.

(2) This option is not avai lable for frame size D inverters (the standard product is N ema1).

(3) This option is not availab le for frame size A inve rters with the N1 optio n (Nema1 enclosure) or I P21.

(4) It is pos sible to meet the req uirements of cate gory C2 with this f ilter on mechan ics A models. For fu rther detail s, see Table B.6 on page 226.

(5) Only applicabl e to models w ith degree of protection IP55, opt ion N12.

Model Identification

Rated

Output

Current

(4)

(2)

Number

of Power

Phases

Rated

Volta ge

Frame

Size

Refer to Table 2.2 on p age 7.

NB = withou t dynamic braki ng (valid only for

frame size E inverters).

DB = with dy namic braking. Blank = standard.

20 = IP20

21 = IP21 (not availa ble for frame size E inverter s). Blank = not available.

N1 = Nema1 enclos ure (UL Type 1) (protection de gree

accordi ng to IEC: IP21 for frame size s A, B and C and IP20

for frame s izes D and E).

N12 = IP55 (only for 200...240 V and 3 80...480 V models of

frame sizes B, C, D and E).

Blank = it i s not in acco rdance with the sta ndard conducted emissi on

levels.

C3 = accord ing to category 3 (C3) of IEC 61800-3, wi th built-in C3 RFI

fil ter.

Braking

(1)

Enclosure

Condu cted

(1)

Emission

Level

(1)

Safet y

Discon.

Stop

(5)

Switc h

(3)

Blank

= not

available

DS =

with

discon.

switch

Blank = not available.

Y1 = with STO function (Safe Torqu e Off)

accordi ng to EN 954-1/ISO 13849-1,

category 3.

External

Special

Control

Volta ge

W1 = 24 Vdc power supply,

indepe ndent of the control

voltage.

Special

Hardware

Software

Versi on

Versi on

Blank =

standard.

Sx =

special

software.

Hxx or K xx = special

hardware.

6 | CFW700

Page 12

General Instructions

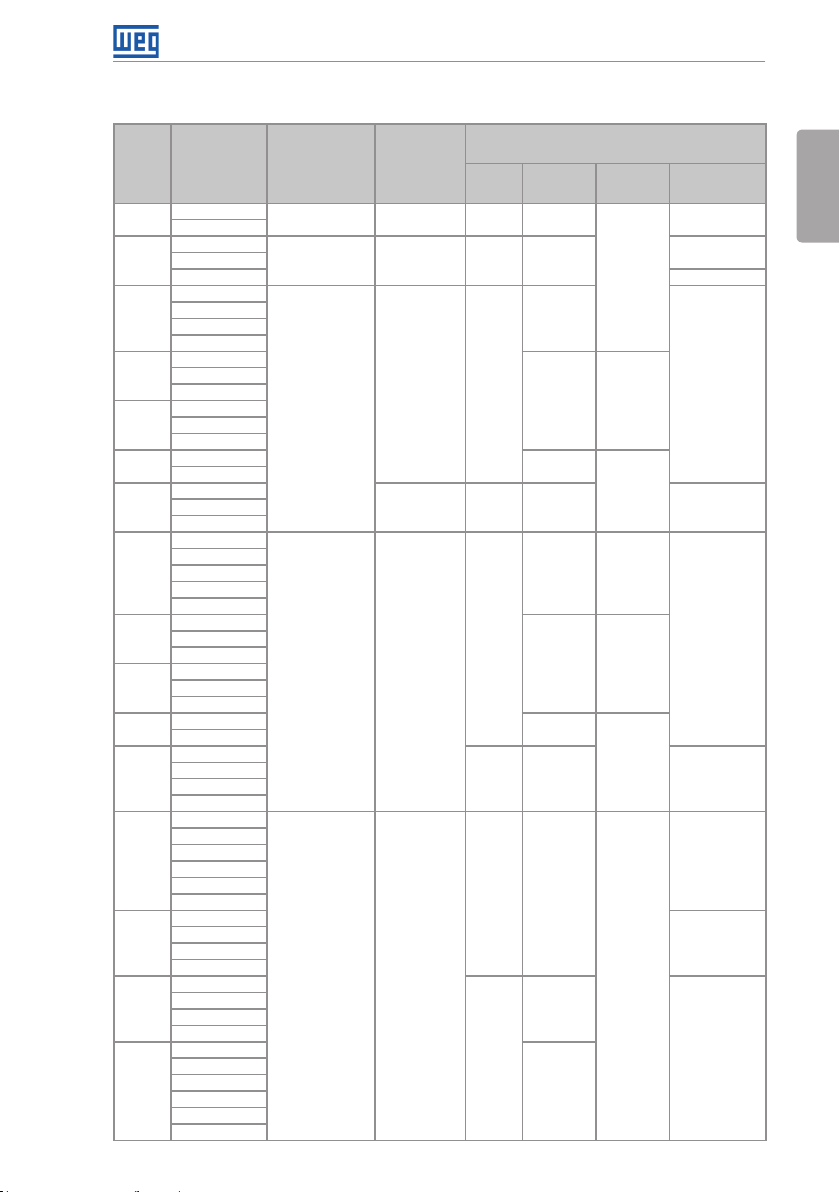

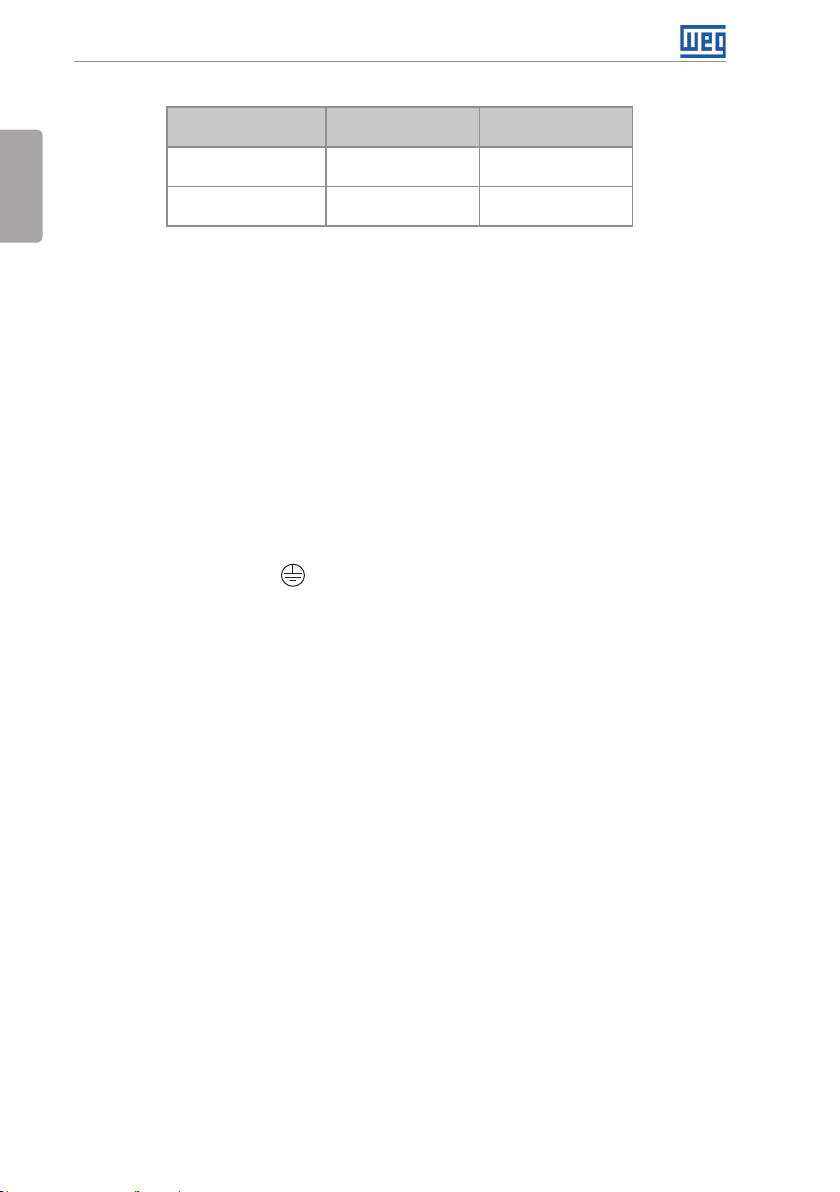

Table 2.2: Options available for each model according to the size, power supply, rated current and

voltage of the inverter

Frame

Size

A

A

A

B

C

D

E

A

B

C

D

E

B

C

D

E

Rated Output

Curre nt for ND

Overload

06P0 = 6.0 A

07P0 = 7.0 A

06P0 = 6.0 A

07P0 = 7.0 A

10P0 = 10 A Blank or C3

07P0 = 7.0 A

10P0 = 10 A

13P0 = 13 A

16P0 = 16 A

24P0 = 24 A

28P0 = 28 A

33P5 = 33.5 A

45P0 = 45 A

54P0 = 54 A

70P0 = 70 A

86P0 = 8 6 A

0105 = 105 A

0142 = 142 A

02 11 = 211 A

03P6 = 3.6 A

05P0 = 5.0 A

07P0 = 7.0 A

10P0 = 10 A

13P5 = 13.5 A

17P0 = 17 A

24P0 = 24 A

31P0 = 31 A

38P0 = 3 8 A

45P0 = 45 A

58P5 = 58.5 A

70P5 = 70.5 A

88P0 = 8 8 A

0105 = 105 A

0142 = 142 A

0180 = 180 A

02 11 = 211 A

02P9 = 2.9 A

04P2 = 4.2 A

07P0 = 7.0 A

10P0 = 10 A

12P0 = 12 A

17P0 = 17 A

22P0 = 22 A

27P0 = 27 A

32P0 = 32 A

44P0 = 44 A

22P0 = 22 A

27P0 = 27 A

32P0 = 32 A

44P0 = 44 A

53P0 = 53 A

63P0 = 63 A

80P0 = 80 A

0107 = 107 A

0125 = 125 A

0150 = 150 A

Number of

Power Phases

B = single-phase or

three-phase

S = Single-phase 2 = 200…240 V DB 20, 21 or N1

T = three-phase

T = three-phase 4 = 380 / 480 V

T = three-phase 5 = 50 0...600 V

Rated Voltage

2 = 200…240 V DB 20, 21 or N1

2 = 200…240 V DB

2 = 220…230 V

Available Options for the Remaining Identification

Braking

NB or

DB

DB

NB or

DB

DB 20, 21 or N1

NB or

DB

Codes o f the Inverte rs

(standard product is shown in bold)

Enclosure

(Protection

Degree)

20, 21 or N1

20, 21, N1

or N 12

21, N1 o r N12

20, N1 or N12 C30180 = 180 A

20, 21 or N1 Blank

20, 21, N1

or N 12

21, N1 o r N12

20, N1 or N12 C3

21 or N1

20 or N1

Discon.

Switch

Blank

Blank o r DS

Blank o r DS

Blank or DS

Blank or DS

Blank

Condu cted

Emission Level

Blank

Blank or C3

Blank or C3

Blank or C3

Blank or C3

CFW700 | 7

English

C3

C3

Page 13

General Instructions

2.4 LIST OF AVAILABLE MODELS

The available inverter models are listed in Table B.1 on page 212, Table B.2 on page 213

English

and Table B.3 on page 214.

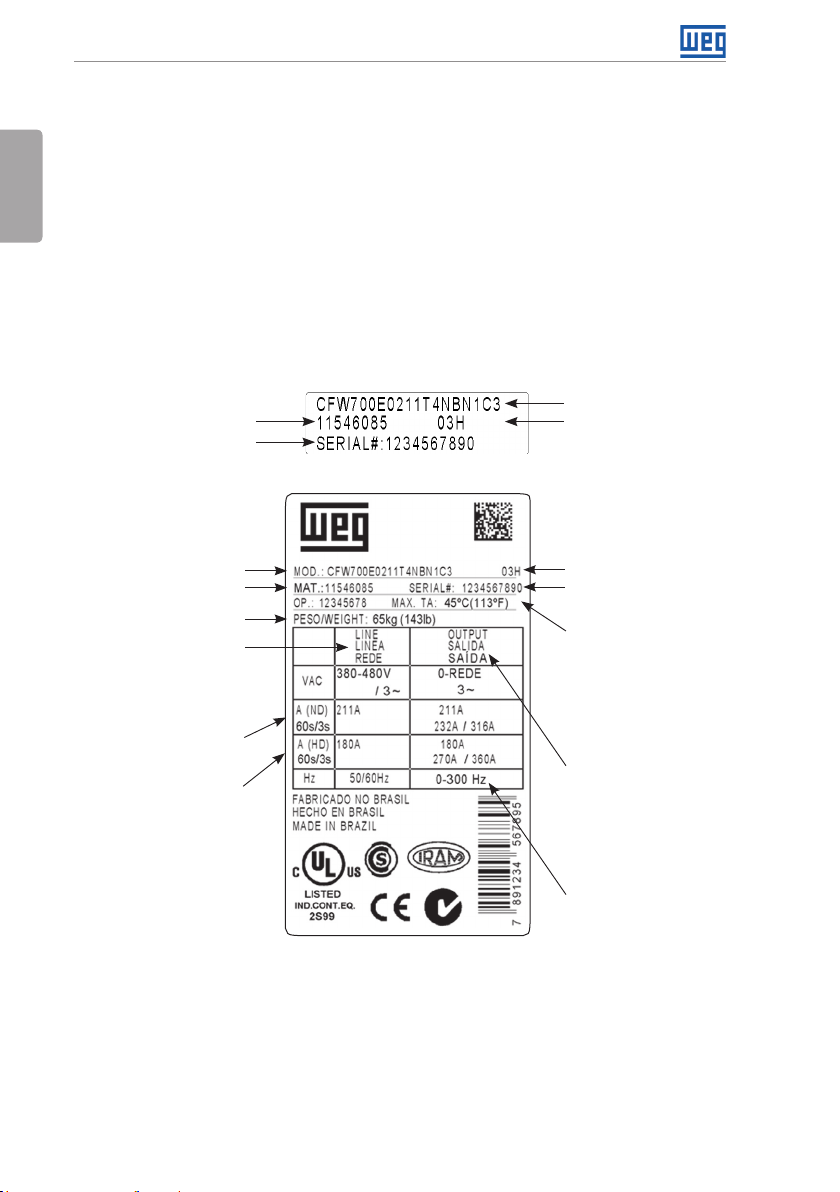

2.5 IDENTIFICATION LABELS

There are two nameplates on the CFW700: one complete nameplate is affixed to the side of the

inverter and a simplified one is located under the keypad. Please refer to Figure A.2 on page

202 to verify the position of these labels on the product. The nameplate under the keypad

allows the identification of the most important characteristics of the inverter even if they are

mounted side-by-side. When there is more than one inverter it is necessary to be careful not to

exchange the inverter covers (front cover in case of inverters frame sizes A, B or C and control

rack cover for inverters frame sizes D and E) because there are individual information labels

under the keypad of each inverter.

CFW700 model

Manufacturing dateWEG part number

Serial number

(a) Nameplate located under the keypad

CFW700 model

WEG part number

Inverter net weight

Input rated data (voltage,

number of phases, rated

currents for operation with

ND and HD overload cycles,

and frequency)

Current specifications

for operation with normal

overload cycle (ND)

Current specifications

for operation with heavy

overload cycle (HD)

(b) Nameplate affixed to the side of the inverter

Figure 2.2: (a) and (b) Nameplates

Manufacturing date

Serial number

Maximum ambient

temperature (without

derating) for ND overload

with open spaces for

ventilation around the

inverter (refer to the

dimensions A, B, C and D

in Figure B.3 on page 234)

Output rated data

(voltage, number of

phases, rated currents for

operation with ND and HD

overload cycles, overload

currents for 1 min and 3 s,

and frequency range)

The maximum output

frequency depends on the

settings of the motor rated

frequency, control mode

and inverter switching

frequency. For fur ther

details, see Table 8.1 on

page 61.

8 | CFW700

Page 14

General Instructions

2.6 RECEIVING AND STORAGE

The CFW700 comes packaged in a cardboard box up to frame size C inverter models. The

bigger models are packed in wooden box. There is an identification label affixed to the outside

of this package, the same one that is affixed to the side of the CFW700 inverter.

Follow the steps below to open the packaging of models larger than frame size C:

1. Put the shipping container over a flat and stable area with the assistance of another two

people.

2. Open the wood crate.

3. Remove all the packing material (the cardboard or styrofoam protection) before removing

the inverter.

Check the following items once the inverter is delivered:

Verify that the CFW700 nameplate corresponds to the model number on your purchase order.

Inspect the CFW700 for external damage during transportation.

Report any damage immediately to the carrier that delivered your CFW700 inverter.

If CFW700 is to be stored for some time before use, be sure that it is stored in a clean and dry

location that conforms to the storage temperature specification (between -25 °C and 60 °C

(-13 °F and 140 °F)). Cover the inverter to prevent dust accumulation inside it.

ATTENTION!

Capacitor reforming is required if drives are stored for long periods of time

without power. Refer to section 6.4 PREVENTIVE MAINTENANCE on page 53.

English

CFW700 | 9

Page 15

Installation and Connection

3 INSTALLATION AND CONNECTION

3.1 MECHANICAL INSTALLATION

English

3.1.1 Installation Environment

Avoid installing the inverter in an area with:

Direct exposure to sunlight, rain, high humidity, or sea-air.

Inflammable or corrosive gases or liquids.

Excessive vibration.

Dust, metallic particles, and oil mist.

Environment conditions for the operation of the inverter:

Inverter surrounding temperature: from -10 ºC up to Ta according to the Table B.4 on page 216.

For temperatures around the inverter greater than Ta and smaller than 60 °C (frame sizes

A, B, C and D), 40 °C (models with degree of protection IP55) and 55 °C (frame size E), it is

necessary to apply current reduction of 2 % for every degree Celsius (or 1.11 % each °F) up

to Ta.

Humidity: from 5 % to 95 % non-condensing.

Altitude: up to 1000 m (3,300 ft) - standard conditions (no derating required).

From 1000 m to 4000 m (3,300 ft to 13,200 ft) - current derating of 1 % each 100 m (or 0.3 %

each 100 ft) above 1000 m (3,300 ft) altitude.

From 2000 m to 4000 m (6,600 ft to 13,200 ft) above sea level - maximum voltage reduction

(240 V for 200...240 V models, 230 V for 220...230 V models, 480 V for 380...480 V models

and 600 V for 500...600 V models) of 1.1 % for each 100 m (330 ft) above 2000 m (6,600 ft).

Pollution degree: 2 (according to EN50178 and UL508C) with non-conductive pollution.

Condensation shall not originate conduction through the accumulated residues.

3.1. 2 Mounting Considerations

External dimensions, fixing holes position and net weight of the inverter are presented at Figure

B.2 on page 232 and Figure B.3 on page 234. Please refer to Figure B.4 on page 235 to

Figure B.11 on page 242 for more details of each inverter size.

Install the inverter upright on a flat surface. First place the screws on the surface where the

drive is going to be installed, install the drive and then tighten the screws.

Frame size E inverters with N1 option (CFW700E...N1...):

After fixing the inverter, install the upper Nema 1 kit on the inverter using the two M8 screws

provided with the product.

10 | CFW700

Page 16

Installation and Connection

Let the minimum clearances specified in Figure B.3 on page 234 in order to allow air circulation

for cooling. It is possible to assembly frame sizes A, B and C inverters with IP20 protection

degree (CFW700… 20…) side by side without lateral spacing, i.e., with the D distance presented

in Figure B.3 on page 234 equal to zero.

Do not install heat sensitive components right above the inverter.

ATTENTION!

When arranging two or more inverters vertically, respect the minimum

clearance A + B (Figure B.3 on page 234) and provide an air deflecting

plate so that the heat rising up from the bottom inverter does not affect the

top inverter.

Provide conduit for physical separation of the signal, control, and power

conductors (refer to section 3.2 ELECTRICAL INSTALLATION on page 11).

Please refer to Figure B.3 on page 234 for surface and flange mounting data. The inverter

dissipated power at rated condition for surface and flange mounting is presented in Table B.4

on page 216. Remove the drive mounting brackets for flange mounting. The protection degree

of the inverter outside the panel is IP55 for flange mounting. It is necessary to provide proper

seal for the opening where the inverter is installed to ensure the protection degree of the panel.

Example: sealing with silicone.

Please refer to Figure A.4 on page 204 for more details on the access to the control and

power terminals.

3.2 ELECTRICAL INSTALLATION

English

DANGER!

The following information is merely a guide for proper installation. Comply

with applicable local regulations for electrical installations.

Make sure the AC power supply is disconnected before starting the

installation.

CFW700 | 11

Page 17

Installation and Connection

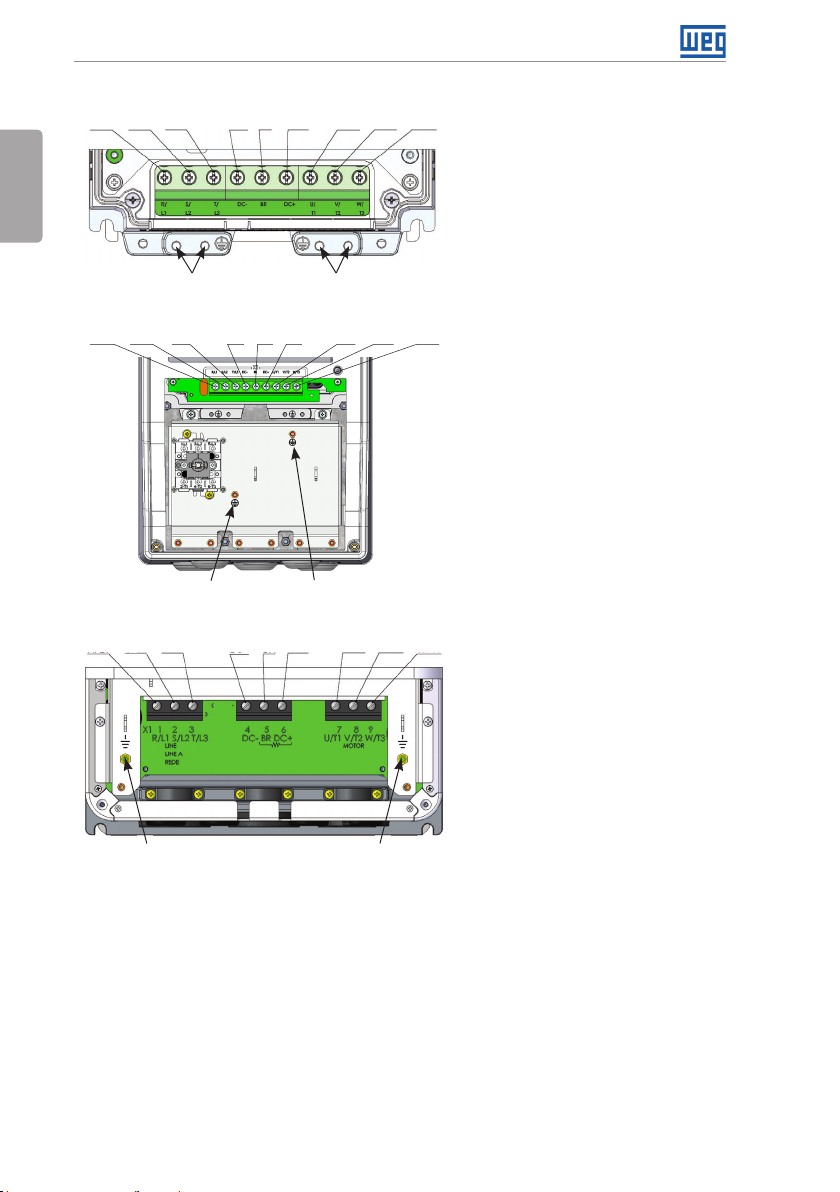

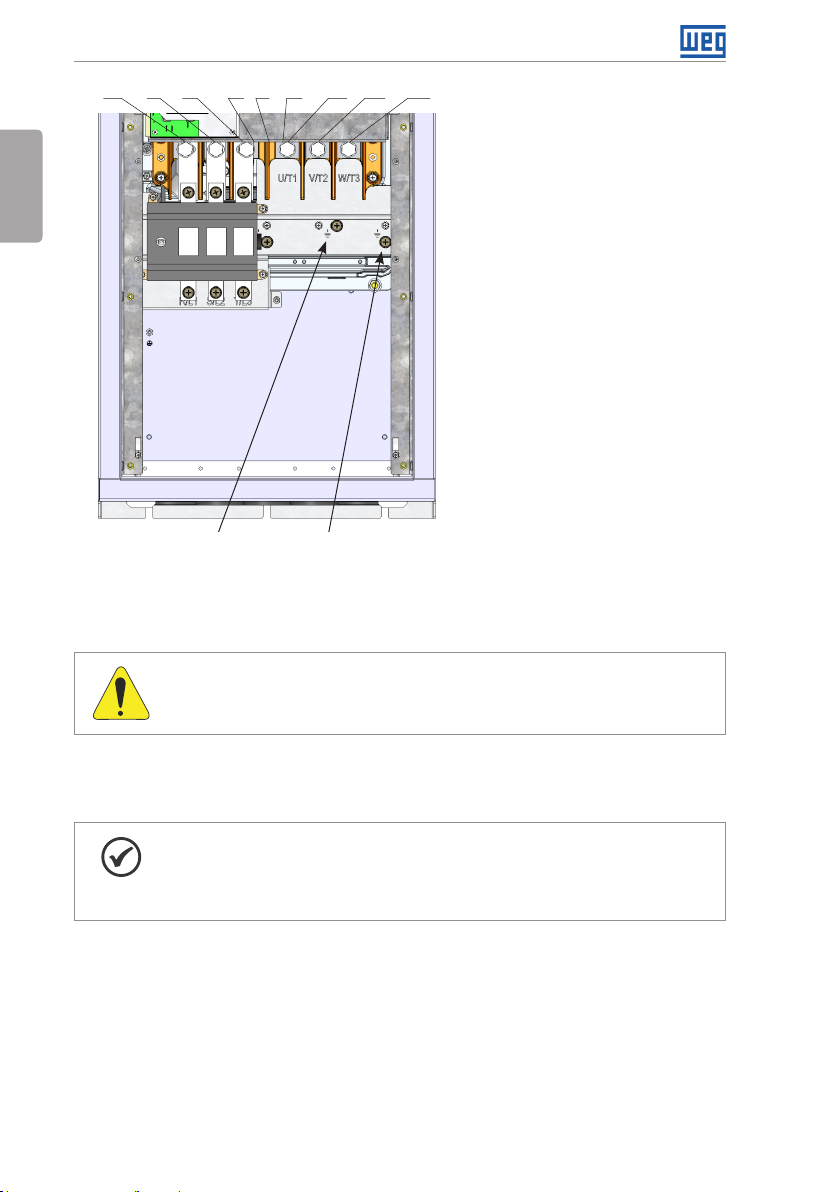

3.2 .1 Identification of the Power and Grounding Terminals

R/L1

S/L2

T/L 3

DC-

BR

DC+

U/T1

V/T2

W/T3

English

BR

BR

DC+

Ground

Ground

U/T1

V/T2

W/T3

Ground

(a) Frame sizes A, B and C

R/L1

S/L2

T/L 3

DC-

(b) Frame sizes B and C with degree of protection IP55

R/L1 S/L2 T/L 3 DC- DC+ U/T1 V/ T2 W/T3

Ground

Ground Ground

(c) Frame size D

R/L1, S/L2, T/L3: AC power supply.

DC-: this is the negative potential

terminal in the DC bus circuit.

BR: braking resistor connection.

DC+: this is the positive potential

terminal in the DC bus circuit.

U/T1, V/T2, W/T3: motor connection.

12 | CFW700

Page 18

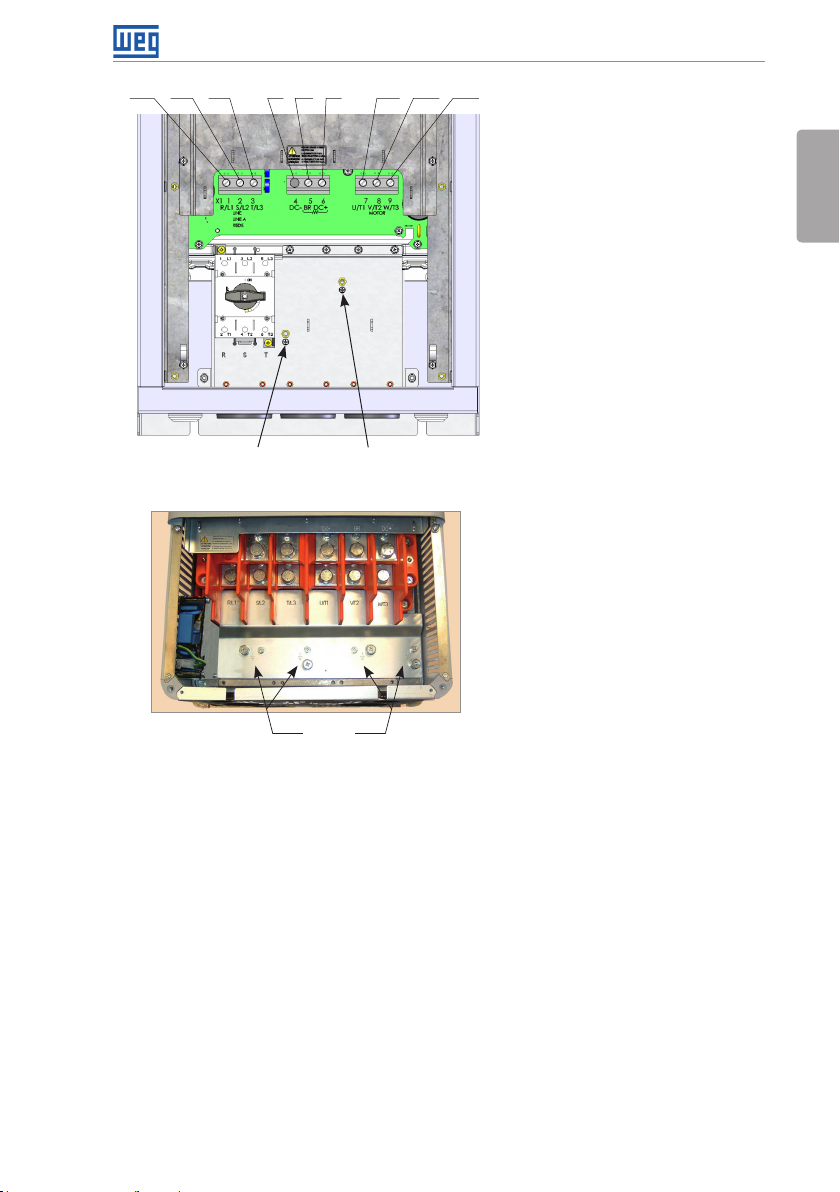

R/L1 S/L2 T/ L 3 DC- DC+ U/T1 V/ T2 W/T3BR

(d) Frame size D with degree of protection IP55

Ground

Ground

Installation and Connection

English

R/L1, S/L2, T/L3: AC power supply.

U/T1, V/T2, W/T3: motor

connwwection.

DC+: this is the positive potential

terminal in the DC bus circuit.

BR: braking resistor connection.

DC-: this is the negative potential

terminal in the DC bus circuit.

Ground

(4xM8, 4xM5)

(e) Frame size E

CFW700 | 13

Page 19

Installation and Connection

R/L1 S/L2 T/ L 3 DC- DC+ U/T1 V/ T2 W/T3BR

English

(f) Frame size E with degree of protection IP55

Ground

Figure 3.1: (a) to (f) Power terminals and grounding points - frame sizes A to E

Ground

3.2.2 Power / Grounding Wiring and Fuses

ATTENTION!

Use proper cable lugs for the power and grounding connection cables.

Refer to Table B.1 on page 212, Table B.2 on page 213 and Table B.3 on page 214 for the

recommended wiring and fuses and Table B.5 on page 223 for the specifications of the power

terminals.

NOTE!

The gauges values presented in Table B.1 on page 212, Table B.2 on page 213

and Table B.3 on page 214 are for reference only. Installation conditions and the

maximum permitted voltage drop shall be considered for the proper wiring sizing.

Input fuses

The fuses to be used at the input must be HS (High-Speed) type with I

value indicated in the Table B.1 on page 212, Table B.2 on page 213 and Table B.3 on

page 214 (consider extinction current value in cold situation (it is not the fusion value)), to

protect the inverter diode rectifiers and input wiring.

In order to meet UL requirements, use class J fuses at the inverter supply with a current not

higher than the values presented in Table B.1 on page 212, Table B.2 on page 213 and

Table B.3 on page 214.

2

t equal or lower the

14 | CFW700

Page 20

Installation and Connection

Optionally, slow blow fuses can be used at the input. They shall be sized for 1.2 x the rated

input current of the inverter. In this case, the installation is protected against short-circuit, but

not the inverter input rectifier. This may result in major damage to the inverter in the event of

an internal component failure.

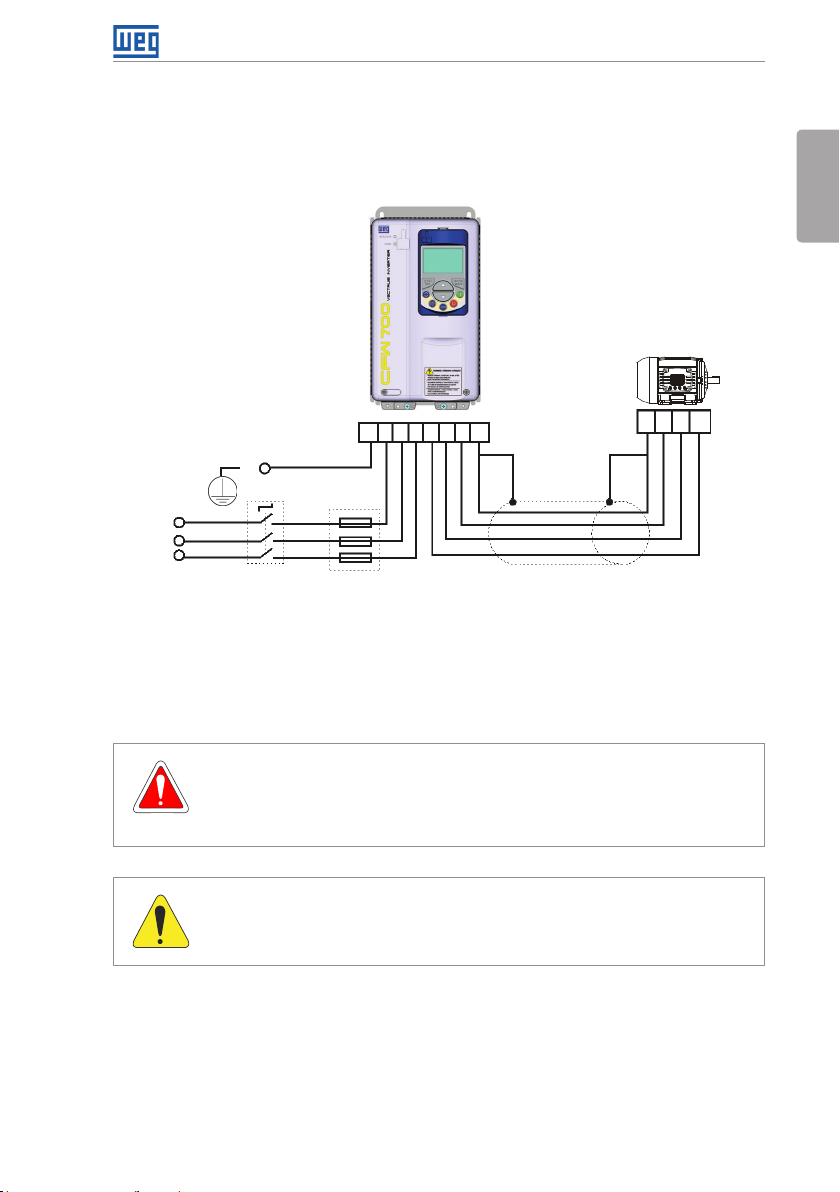

3.2.3 Power Connections

English

PE R S T U V W PE

PE

Shielding

R

S

T

Power

supply

The switch-disconnector is not necessary if the inverter has the DS optional item (with

Disconnect

switch

Fuses

Figure 3.2: Power and grounding connections

PE W V U

switch-disconnector).

3.2.3.1 Input Connections

DANGER!

Provide a disconnect device for the input power supply of the inverter.

This device shall disconnect the input power supply for the inver ter when needed

(for instance, during servicing).

ATTENTION!

The power supply that feeds the inverter shall have a solid grounded neutral.

In case of IT networks, follow the instructions described below.

CFW700 | 15

Page 21

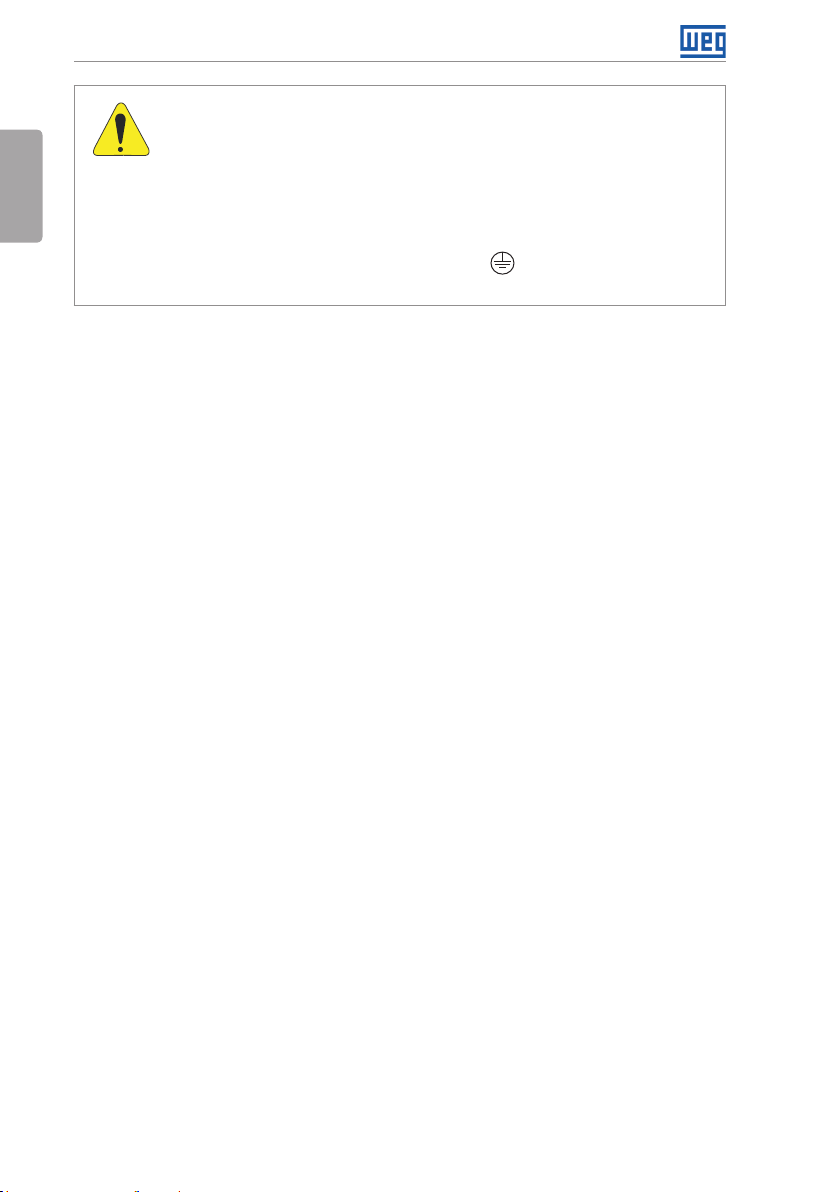

Installation and Connection

ATTENTION!

In order to be able to use the CFW700 with built-in C3 RFI filter (frame sizes A, B, C

English

and D with optional RFI f ilter and all frame size E inverter models – CFW700…C3…)

in IT networks (neutral conductor not grounded or grounded via a high ohmic value

resistor) or in corner-grounded delta systems, it is necessary to remove some RFI

filter components (capacitor for frame sizes A, B, C and D and capacitor and the

MOV for frame size E) connected to the ground by removing the screws indicated

in Figure A.8 on page 208 for inverter frame sizes A, B, C and D and changing the

position of the J1 jumper on the PRT1 board from (XE1) to “NC” (XIT), according

to the Figure A.8 on page 208 for inverter frame size E.

AC power supply considerations

Suitable for use on a circuit capable of delivering not more than 100.000 A

Ampères at 240 V, 480 V or 600 V maximum, when protected by Class J fuses (for 240 V

symmetrical

rms

and 480 V models) or special purpose fuses (for 600 V).

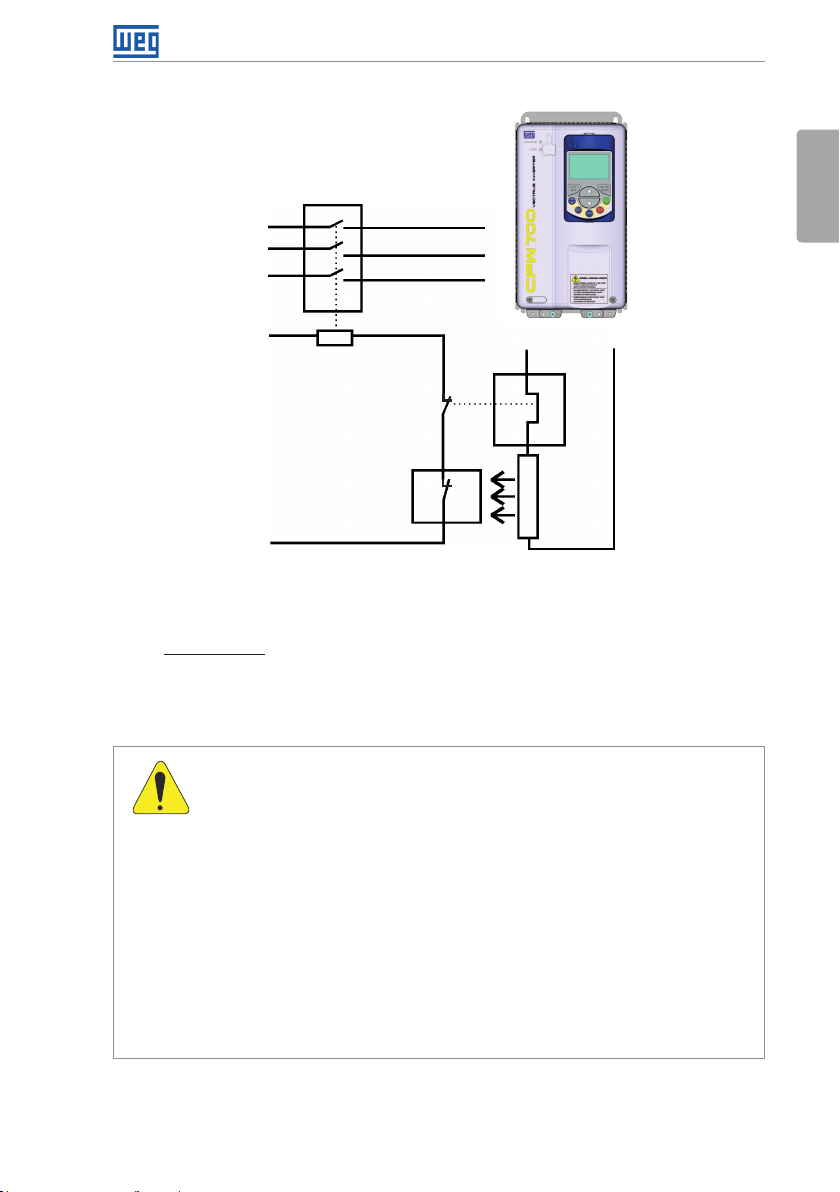

3.2.3.2 Dynamic Braking (standard built-in for frame sizes A, B, C and D and optional built-in for frame size E - CFW700...DB...)

Refer to Table B.1 on page 212, Table B.2 on page 213 and Table B.3 on page 214 for

the following dynamic braking specifications: maximum current, resistance, RMS current (*)

and cable gauges.

The power rating of the dynamic braking resistor is a function of the deceleration time, the load

inertia and the resistant torque.

Dynamic braking installing procedure:

Install the braking resistor between the power terminals DC+ and BR.

Use twisted cable for the connection. Separate these cables from the signal and control

cables.

Size the cables according to the application, respecting the maximum and effective currents.

If the braking resistor is installed inside the inverter cabinet, consider its additional dissipated

energy when sizing the cabinet ventilation.

The thermal protection of the dynamic brak ing resistor must be provided ex ternally using a thermal

relay in series with the resistor and/or a thermostat in contact with the resistor frame, connected

so as to switch the input power supply of the inverter, as shown in Figure 3.3 on page 17.

Set P0151 and P0185 to their maximum values (400 V or 800 V) when using dynamic braking.

The DC link voltage actuation level of the dynamic braking is set by parameter P0153 (Dynamic

Braking Level).

16 | CFW700

Page 22

Power

supply

Contactor

Installation and Connection

CFW700

R

S

T

English

BR

Thermal

Control power

supply

Thermostat

Figure 3.3: Connection of the braking resistor

relay

(*) The effective braking current can be calculated as follows:

I

. √tbr (min)

max

I

=

effect ive

5

3.2.3.3 Output Connections

ATTENTION!

The inverter has an electronic motor overload protection that shall be adjusted

according to the driven motor. When several motors are connected to the

same inverter, install individual overload relays for each motor.

The motor overload protection available for the CFW700 is in accordance

with UL508C as per the following information:

- "Trip" current equal to 1.25 times the motor rated current (P0401) adjusted

in the "Oriented Start-up" menu.

- The maximum value of P0398 (Motor Service Factor) is 1.15.

- Parameters P0156, P0157 and P0158 (Overload Current at 100 %,

50 % and 5 % of the rated speed, respectively) are automatically adjusted

when the parameters P0401 (Motor Rated Current) and/or P0406 (Motor

Ventilation) are changed on the “Oriented Start-up” menu. If the parameters

P0156, P0157 and P0158 are set manually, the maximum allowed value

is 1.05 x P0401.

DC+

Braking

resi stor

CFW700 | 17

Page 23

Installation and Connection

ATTENTION!

If a disconnect switch or a contactor is installed between the inverter and the

English

motor, never operate them with a spinning motor or with voltage at the inverter

output.

The characteristics of the cable used for the inverter and motor interconnection, as well as

the physical location are extremely important to avoid electromagnetic interference in other

equipment and to not affect the life cycle of motor windings and motor bearings controlled by

inverters.

Keep motor cables away from other cables (signal cables, sensor cables, control cables, etc.),

according to item 3.2.6 Cable Distances on page 23.

Connect a fourth cable between the motor ground and the inverter ground.

When using shielded cables for connecting the motor:

Follow the recommendations of IEC60034-25.

Use low impedance connection to high frequencies to connect the cable shield to ground.

Using parts supplied with the drive. See item below.

For inverter frame sizes A, B and C there is an accessory called “Shielding kit for power

cables PCSx-01” (see section 7.2 ACCESSORIES on page 58), which can be mounted at

the bottom of the cabinet – the Figure 3.4 on page 18 shows an example. The shielding

kit for power cables PCSx-01 goes along with inverters with optional internal C3 RFI filter

(CFW700...C3...). The grounding for the motor cable shield on inverter frame sizes D and E is

already provided in the standard inverter cabinet. This is also provided on the “Nema1 Kits

(KN1x-01)” of the inverter frame sizes A, B and C.

For frame sizes B and C with degree of protection IP55, the accessory "PCSC-03 power

cable shield kit" is available, and for frame size D and E with degree of IP55 use the standard

accessories for shielding. The PCSC-03 shield kit comes with the inverter as optional item N12.

Figure 3.4: Motor cable shielding connection with PCSx-01 accessory

18 | CFW700

Page 24

Installation and Connection

3.2.4 Grounding Connections

DANGER!

The inverter shall be connected to a Protective Ground (PE).

Use the minimum ground wiring gauge as indicated in the Table B.1 on page

212, Table B.2 on page 213 and Table B.3 on page 214.

Connect the inverter grounding connections to a ground bus bar, to a single

ground point, or to a common grounding point (impedance ≤ 10 Ω).

The neutral conductor of the network shall be solidly grounded; however,

this conductor shall not be used to ground the inverter.

It is necessary to use a copper cable with 10 mm

2

minimum or 2 cables with

the same wire gauge as specified in Table B.1 on page 212, Table B.2 on

page 213 and Table B.3 on page 214 for connecting the inverter to the

ground protection to be in accordance with IEC61800-5-1 since the leakage

current is greater than 3.5 mA AC.

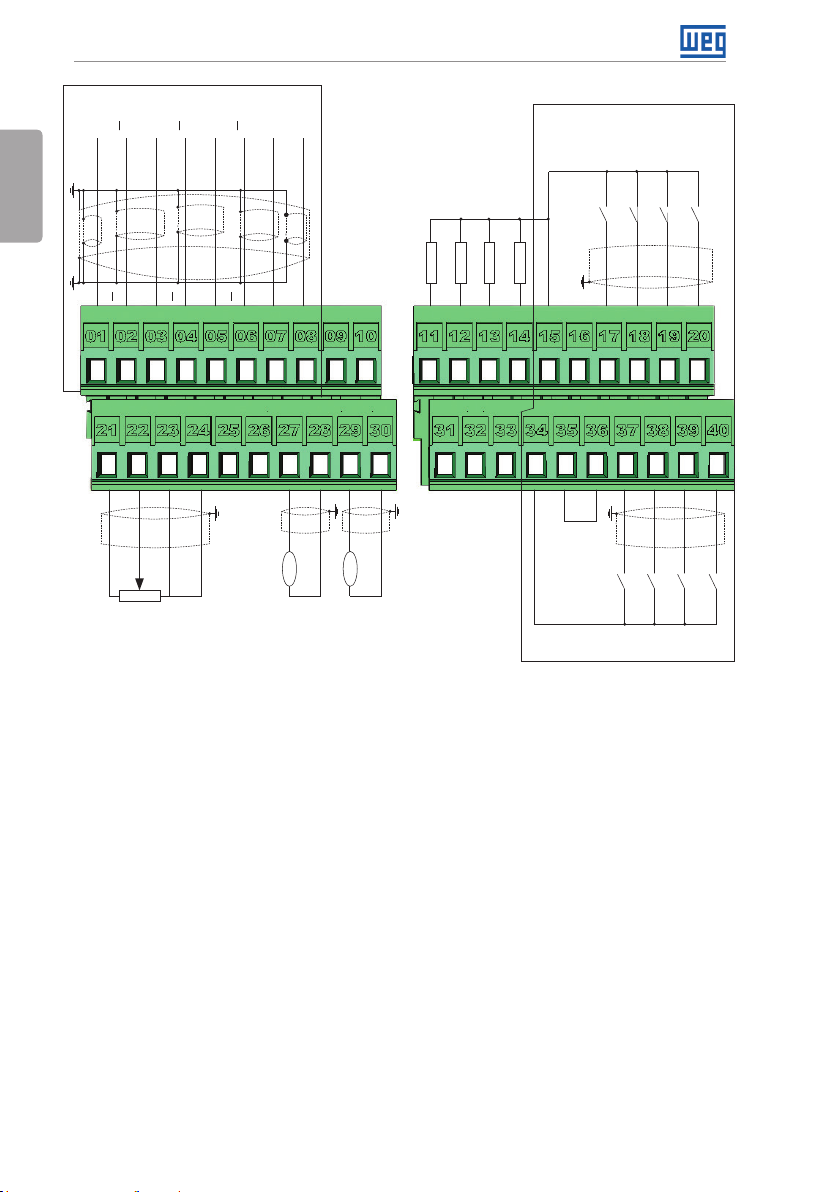

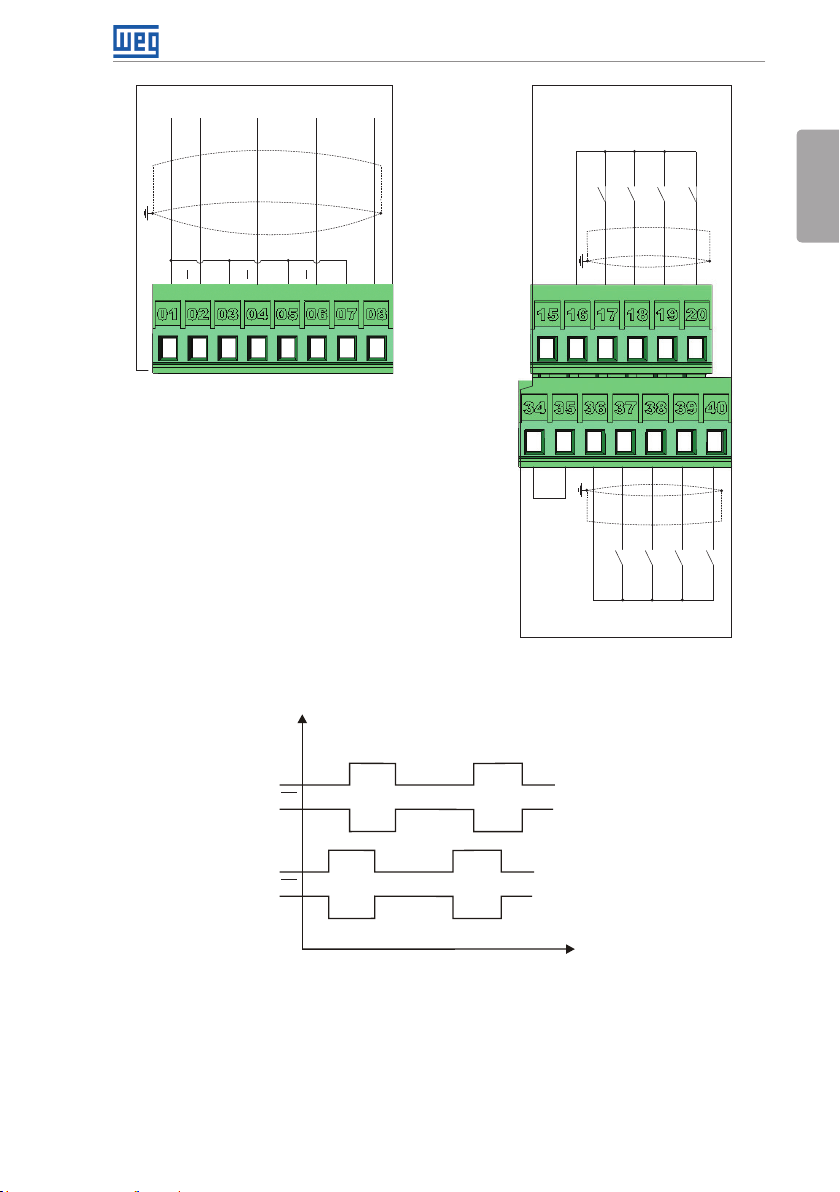

3.2.5 Control Connections

The control connections (analog inputs/outputs and digital inputs/outputs), shall be performed

in connector XC1 of the CC700 Control Board. Functions and typical connections are presented

in Figure 3.5 on page 21.

English

CFW700 | 19

Page 25

Installation and Connection

Linedrive encoder or push-pull

A

A

+V

English

Blue

White

A

+5 V-ENC

REF+

(1) Refer to Figure 3.5 on page 21 (b) for the open-collector encoder connection.

(2) Refer to Figure 3.5 on page 21 (c) for active low digital inputs connection.

B

Red

Green

Yel lo w

B

B

A

≥5 kΩ

AI1-

AI1+

REF-

(1)

Z

Z

B

Pink

Z

AI2+

GND

GreyZ

Brown

DO2

DO3

DO4

>300 Ω

>300 Ω

RL1-NF

>300 Ω

RL1-C

A - RS-485

GND-ENC

AI2-

rpm

AO1

B - RS-485

amp

AO2

AGND (24 V)

AGND (24 V)

+24 V

DO5

>300 Ω

RL1-N A

+24 V

Active high digital inputs

DI5

GND (24 V)

COM

GND (24 V)

DI1

(2)

DI6

DI7

DI8

DI2

DI3

DI4

(a) Linedrive encoder or push-pull and active high digital inputs

20 | CFW700

Page 26

Installation and Connection

Open collector encoder

+V(5 V )

A A

+5 V-ENC

Z

Z

Z

B

BBA

(b) Encoder with open collector

output

Figure 3.5: (a) to (c) XC1 connection terminals

Signal

Active low digital inputs

+24 V

DI5

DI6

DI7

GND (24 V)

DI8

English

GND-ENC COM

+24 V

COM

GND (24 V)

DI1

DI2

DI3

DI4

(c) Active low digital inputs

A

A

B

B

Time

Figure 3.6: Sequence of the encoder signals

Refer to Figure A.3 on page 202 to find the control board, the XC1 connector (control

signals), the S1 DIP-switches (to select the type of signal of the analog inputs and outputs)

and S2 (RS-485 network termination) and slots 3 and 5 for accessories (see section 7.2

ACCESSORIES on page 58).

The CFW700 inverters are supplied with the digital inputs configured as active high and the

CFW700 | 21

Page 27

Installation and Connection

analog inputs and outputs configured for voltage signal 0...10 V.

English

NOTE!

To be able to use the analog input and/or output as current signals, it is

necessary to change the switch S1 and the related parameters as per Table

3.1 on page 22. In order to set the analog inputs to bipolar voltage signal

(-10…10 V), it is necessary to set P0233 and P0238 according to Table 3.1 on

page 22. Refer to the CFW700 programming manual for more information.

Table 3.1: Configuration of the switch for the analog input and output signals selection

Input/

Output

Signal

Voltage S1.2 = OFF

AI1

Current S1.2 = ON

Voltage S1.1 = OFF

AI2

Current S1.1 = ON

Voltage S1.3 = ON

AO1

Current S1.3 = OFF

Voltage S1.4 = ON

AO2

Current S1.4 = OFF

(*) Factory setting.

S1 Switch

Settings

Signal

Range

(*)

0…10 V

(*)

-10…10 V P0233 = 4

P0233 = 0 (direct reference) or 2 (reverse reference).

Parameter Settings

0...20 mA P0233 = 0 (direct reference) or 2 (reverse reference).

4...20 mA P0233 = 1 (direct reference) or 3 (reverse reference).

(*)

0…10 V

(*)

-10…10 V P0238 = 4

P0238 = 0 (direct reference) or 2 (reverse reference).

0...20 mA P0238 = 0 (direct reference) or 2 (reverse reference).

4...20 mA P0238 = 1 (direct reference) or 3 (reverse reference).

(*)

0...10 V

(*)

P0253 = 0 (direct reference) or 2 (reverse reference).

0...20 mA P0253 = 0 (direct reference) or 2 (reverse reference).

4...20 mA P0253 = 1 (direct reference) or 3 (reverse reference).

(*)

0...10 V

(*)

P0256 = 0 (direct reference) or 2 (reverse reference).

0...20 mA P0256 = 0 (direct reference) or 2 (reverse reference).

4...20 mA P0256 = 1 (direct reference) or 3 (reverse reference).

NOTE!

Settings of the S2 switch:

S2.1 = ON and S2.2 = ON: RS-485 is ON.

S2.1 = OFF and S2.2 = OFF: RS-485 is OFF.

The factory default for the S2.1 and S2.2 switches are OFF.

Other combinations of switch S2 are not allowed.

Technical specifications for the encoder and the encoder cable as shown in Table 3.2 on page

23.

22 | CFW700

Page 28

Installation and Connection

Table 3.2: Technical specifications for the encoder and the encoder cable

Characteristics Specifications

Power supply 5 V

2 channels in qua drature (90º) + zero pulses with co mplementar y outputs

(differentials) or open-collector.

A, A, B, B, Z and Z

Available for 2 channels: A, A, B, B.

If the channel zis not used, leave the terminals XC1: 6 and 7 not

connected. Noother setting are necessary.

The cable shield must be connected to ground through devices on

control shield plate (see Figure 3.5 on page 21).

Encoder

Encoder

cable

Channels

Signals

Output circuit Linedrive type, push-pull or open-collector. Maximum voltage of 12 V.

Isolation Electronic circuit isolated from the encoder frame.

Pulses Recommended number of pulses per rotation = 1024 ppr.

Frequency Maximum allowed = 100 kHz.

Type of cable Balanced cable shield (for differential signals operation).

Connection

Distance ≥ 25 cm of other wiring.

Isolation Use metal conduit.

Length Maximum = 10 m.

Follow instructions below for the proper installation of the control wiring:

1. Wire gauge: 0.5 mm² (20 AWG) to 1.5 mm² (14 AWG).

2. Maximum tightening torque: 0.50 N.m (4.50 lbf.in).

3. Use shielded cables for the connections in XC1 and run the cables separated from the

remaining circuits (power, 110 V / 220 Vac control, etc.), according to item 3.2.6 Cable

Distances on page 23. If control wiring must cross other cables (power cables for instance),

make it cross perpendicular to the wiring and provide a minimum separation of 5 cm (1.9 in)

at the crossing point.

English

Refer to item 3.2.6 Cable Distances on page 23, for the proper cable distances.

Isolate with tape

Inverter

side

Do not ground

(a) Cable shield connection

Figure 3.7: (a) and (b) Shield connection

(b) Connection sample of the shield to

ground

4. Relays, contactors, solenoids or coils of electromechanical brakes installed close to the

inverter may eventually create interferences in the control circuitry. To eliminate this effect,

RC suppressors (with AC power supply) or free-wheel diodes (with DC power supply) shall

be connected in parallel to the coils of these devices.

3.2.6 Cable Distances

The power cables and control cables must be separated (relay output cables and other control

cables) according to Table 3.3 on page 24.

CFW700 | 23

Page 29

Installation and Connection

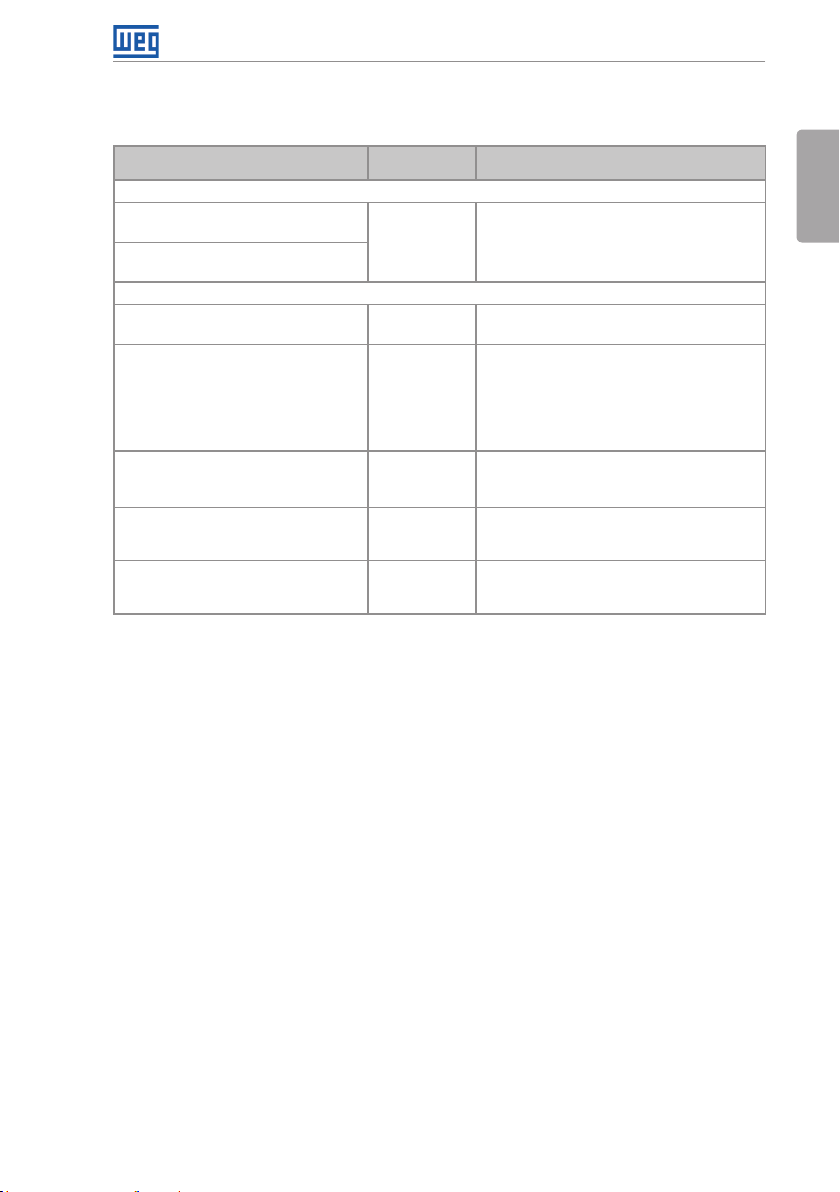

Table 3.3: Cable distances

Rated Output

English

Inverter Current

≤ 24 A

≥ 28 A

Cable Length(s)

≤ 100 m (330 ft)

> 100 m (330 ft)

≤ 30 m (100 ft)

> 30 m (100 ft)

Minimum Separation

Distance

≥ 10 cm (3.94 in)

≥ 25 cm (9.84 in)

≥ 10 cm (3.94 in)

≥ 25 cm (9.84 in)

3.3 INSTALLATION ACCORDING TO THE EUROPEAN DIRECTIVE OF ELECTROMAGNETIC COMPATIBILITY

The inverters with C3 option (CFW700...C3...) have internal C3 RFI filter to reduce electromagnetic

interference. These inverters, when properly installed, meet the requirements of “EMC Directive

89/336/EEC” with the 93/68/EEC supplement.

The CFW700 inverter series has been designed only for industrial applications. Therefore, the

emission limits of harmonic currents defined by the standards EN 61000-3-2 and EN 61000-3-2/A

14 are not applicable.

3.3.1 Conformal Installation

1. Inverters with built-in C3 RFI filter CFW700...C3...

2. Frame sizes A to D inverters with built-in C3 RFI filter capacitors grounding screws and frame

size E with J1 cable in the position (XE1). For more information see Figure A.8 on page

208.

3. Shielded output cables (motor cables) and connect the shield at both ends (motor and

inverter) with a low impedance connection for high frequency. Use PCSx-01 kit supplied with

frame sizes A, B and C inverters. For frame sizes B and C with degree of protection IP55,

use the PCSC-03 shield kit. For frame sizes D and E inverters use the clamps supplied with

the product. Ensure good contact between the cable shield and the clamps. Refer to Figure

3.4 on page 18 and keep the proper separation from other cables according to item 3.2.6

Cable Distances on page 23. The maximum motor cable length and conduction and

radiated emission levels are presented at Table B.6 on page 226. Use an external RFI filter

at the input of the inverter if necessary to have a lower emission level and/or a longer motor

cable length. For more information (RFI filter commercial reference, motor cable length and

emission levels) refer to Table B.6 on page 226.

4. Shielded control cables and separate the remaining cables according to item 3.2.6 Cable

Distances on page 23.

5. Inverter grounding according to the instructions on item 3.2.4 Grounding Connections on

page 19.

6. Grounded power supply.

24 | CFW700

Page 30

3.3.2 Emission and Immunity Levels

Table 3.4: Emission and immunity levels

EMC Phenomenon

Emission:

Mains Terminal Disturbance Voltage

Frequency Range: 150 kHz to 30 MHz)

Electromagnetic Radiation Disturbance

Frequency Range: 30 MHz to 1000 MHz)

Immunity:

Electrostatic Discharge (ESD) IEC 61000-4-2

Fast Transient-Burst IEC 61000-4-4

Conducted Radio-Frequency Common

Mode

Surge Immunity IEC 61000-4-5

Radio-Frequency Electromagnetic Field IEC 61000-4-3

Basic

Standard

IEC/EN61800-3

IEC 61000-4-6

Installation and Connection

Level

It depends on the inverte r model and the motor

cable length.

See Table B.6 on page 226.

4 kV for contact discharge and 8 kV for air

discharge.

2 kV / 5 kHz (coupling capacitor) power input

cables;

1 kV / 5 kHz control cables, and remote

keypad cables;

2 kV / 5 kHz (coupling capacitor) motor output

cables.

0.15 to 80 MHz; 10 V; 80 % AM (1 kHz).

Power supp ly cable, motor, control an d remote

keypad (HMI).

1.2/50 μs, 8/20 μs;

1 kV line-to-line coupling;

2 kV line-to-ground coupling.

80 to 1000 MHz;

10 V/m;

80 % AM (1 kHz).

English

Refer to Table B.6 on page 226 for conducted and radiated emission levels accomplished

with and without external RFI filter. The reference model for the external filter is also presented.

CFW700 | 25

Page 31

Keypad (HMI) and Basic Programming

4 KEYPAD (HMI) AND BASIC PROGRAMMING

4.1 INTEGRAL KEYPAD - HMI-CFW700

English

The integral keypad can be used to operate and program (view / edit all parameters) of the

CFW700 inverter. There are two operation modes in the keypad: monitoring and programming.

The key functions and display indications of the keypad may change according to the operation

mode. The programming mode consists of three levels.

- When in monitoring mode: press this key

- When in monitoring mode: press this

key to increase the speed.

- When in programming mode, level 1:

press this key to go back to the

previous group.

- When in programming mode, level 2:

press this key to go to the next

parameter.

- When in programming mode, level 3:

press this key to increase the

parameter value.

- When in programming mode, level

1: press this key to go back to the

monitoring mode.

- When in programming mode, level 2:

press this key to go back to the level 1.

- When in programming mode, level 3:

press this key to cancel the new value

(the value will not be saved) and it will

return to level 2 of the programming

mode.

- USB

communication port

(1)

to decrease the speed.

- When in programming mode, level 1:

press this key to go to the next group.

- When in programming mode, level 2:

press this key to go back to the previous

parameter.

- When in programming mode, level 3:

press this key to decrease the parameter

value.

- When in monitoring mode: press this

key to enter in the programming mode.

- When in programming mode, level 1:

press this key to select the desired

parameter group – it shows the

parameters of the selected group.

- When in programming mode, level 2:

press this key to show the parameter

– it shows the parameter value for its

modification.

- When in programming mode, level 3:

press this key to save the new parameter

value – it returns to level 2 of the

programming mode.

- Press this key to define the motor

rotation.

This option is active when:

P0223 = 2 or 3 in LOC and/or

P0226 = 2 or 3 in REM.

- Press this key to change between

LOCAL and REMOTE mode.

This option is active when:

P0220 = 2 or 3.

- Press this key to accelerate the motor up to the speed set in P0122. The motor speed is maintained

while the key is pressed. When the key is released the motor decelerates up to its complete stop.

This function is active when all the following conditions are met:

1. Start/Stop = Stop.

2. General Enable = Active.

3. P0225 = 1 in LOC and/or P0228 = 1 in REM.

(1) Available from the serial number 1024003697.

26 | CFW700

Figure 4.1: Operator keys

- Press this key to accelerate the motor

according to the acceleration ramp time.

This option is active when:

P0224 = 0 in LOC and/or

P0227 = 0 in REM.

- Press this key to decelerate the motor

according to the deceleration ramp time.

This option is active when:

P0224 = 0 in LOC and/or

P0227 = 0 in REM.

Page 32

NOTE!

It is necessary to set the password at P0000 for parameter modification.

Otherwise the parameters contents can only be viewed.

The default password for P0000 is 5. It is possible to change the password at

P0200. Refer to the CFW700 programming manual.

Local/Remote

(commands and

Motor rotation

Menu (parameters

group selection) –

only one parameter

group is shown at

each time.

Main display

references source)

Figure 4.2: Display sections

Parameter groups available at the Menu:

Keypad (HMI) and Basic Programming

English

Inverter status

Secondary display

Variable unit

(shows the value of

the main display)

Variable monitoring

bar graph

PARAM: all parameters.

READ: only the reading parameters.

MODIF: only the parameters changed compared to the factory default.

BASIC: basic application parameters.

MOTOR: parameters related to motor data control.

I/O: parameters related to the digital and analog inputs/outputs.

NE T: parameters related to the communication protocol.

HMI: parameters for the keypad configuration.

SPLC: parameters related to the SoftPLC function.

STARTUP: parameters for the Oriented Start-up.

CFW700 | 27

Page 33

Keypad (HMI) and Basic Programming

Inverter status:

LOC: local reference.

English

REM: remote reference.

: motor rotation according to the arrows.

CONF: configuration. It indicates that the inverter is in the Oriented Start-up routine or with

incompatible parameter programming. Refer section Incompatibility Between Parameters in

the programming manual of the CFW700.

SUB: DC link undervoltage.

RUN: inverter enabled and/or DC braking activated.

Monitoring Mode

It is the initial state of the keypad after power up and startup screen,

with the factory default values.

The Menu is not active in this mode.

Main display, secondary display and monitoring bar show the values of

the parameters defined at P0205, P0206 and P0207.

From the monitoring mode, pressing the ENTER/MENU key will switch

to the programming mode.

Programming Mode

Level 1:

This is the first level of the programming mode. It is possible to chose

the parameter group by using the and keys.

The main display, secondary display and monitoring bar are not shown

at this level.

Press the ENTER/MENU key to go to the second level of programming

mode - parameters selection.

Press the BACK/ESC key to go back to the monitoring mode.

Level 2:

The parameter number is displayed on the main display and its value

on the secondary display.

Use the and keys to find the desired parameter.

Press the ENTER/MENU key to go to level 3 of the programming mode

– parameters value changing.

Press the BACK /ESC key to return to level 1 of the programming mode.

Level 3:

The parameter values is shown at the main display and the parameter

number at the secondary display.

Use the and keys to change the valu e of the selected pa rameter.

Press ENTER/MENU key to confirm the modification (save the new

value) or BACK/ESC key to cancel the modification (do not save the

new value). In both cases, the keypad returns to the second level of the

programming mode.

Figure 4.3: Keypad operation modes

The keypad can be installed or removed from the inverter with or without AC power applied

to the inverter.

The HMI supplied with the product can also be used for remote command of the inverter. In

this case, use a cable with male and female D-Sub9 (DB-9) connectors wired pin to pin (mouse

28 | CFW700

Page 34

Keypad (HMI) and Basic Programming

extension type) or a market standard Null-Modem cable. Maximum length of 50 m (164 ft). It

is recommended the use of the M3 x 5.8 standoffs supplied with the product. Recommended

torque: 0.5 N.m (4.5 lbf.in).

Use the keypad frame accessory to assembly the keypad on the panel door or control table

(see section 7.2 ACCESSORIES on page 58, or perform the drilling as shown in Figure A.5

on page 205).

NOTE!

A list of parameters is supplied with the product, for additional information on

each parameter refer to the CFW700 programming manual provided in the

CD-ROM that accompanies the product or it can be downloaded at the WEG

homepage - www.weg.net.

4.2 APPLICATIONS

The CFW700 has some features that allow better matching the inverter commands to the

application. These features were grouped into a set of applications and can be as simple as the

forward and reverse command, or more elaborated such as a PID controller.The applications

were implemented using the SoftPLC function, in other words, ladder programming applicative

built-in to the CFW700 inverter. It allows the user that has the WLP and the built-in implemented

applicative to change it and use it as an user applicative.

Parameter P1003 allows selecting an application and uploading it to the CFW700. The CFW700

has following applications built-in:

PID Regulator.

English

Electronic Potentiometer (E.P.).

Multispeed.

3-Wire Start/Stop.

Forward/Reverse Run.

4.2.1 PID Regulator Application

The CFW700 has the PID REGULATOR application that can be used to control a closed loop

process. This application sets proportional, integral and derivative regulator superimposed to

the regular speed control of the CFW700 inverter.

The CFW700 will compare the setpoint with the process variable and control the motor speed

trying to eliminate any error and keeping the process variable equal to the setpoint. The setting

of the P, I and D gains determines how fast the inverter will respond to eliminate this error.

Application examples:

Flow control or pressure in a pipe system.

Temperature of a furnace or oven.

Dosing of chemicals in tanks.

CFW700 | 29

Page 35

Keypad (HMI) and Basic Programming

The following example defines the terms used by the PID controller.

A pump used in a water pumping system where is necessary to control the pressure of the

pipe. A pressure transducer is installed in the pipe and supplies an analog feedback signal

English

to the CFW700, which is proportional to the water pressure. This signal is called the process

variable, and can be visualized at the parameter P1012. A setpoint is programmed in the

CFW700 via keypad (P1025), through an analog input (such as a 0-10 V or 4-20 mA signal) or

via communication network. The setpoint is the desired water pressure value that the pump is

supposed to produce, regardless of the consumption variations at the pump output at any time.

It is necessary to set the parameter P0221 or P0222 to 7 = SoftPLC for the operation of the

PID Regulator application.

Definitions:

The Function 1 of the Application at parameters P0231 or P0236 represents the value of the

PID Setpoint.

The Function 2 of the Application at parameters P0231 or P0236 represents the value of the

PID Feedback.

The Function 1 of the Application at parameters P0251 or P0254 represents the value of the

PID Setpoint.

The Function 2 of the Application at parameters P0251 or P0254 represents the value of the

PID Feedback.

The Function 1 of the Application at parameters P0263 or P0270 represents the value of the

Manual/Auto command.

The Function 1 of the Application at parameters P0275 to P0279 represents the VP>VPx

logical condition.

The Function 2 of the Application at parameters P0275 to P0279 represents the VP<VPy

logical condition.

The PID setpoint can receive an analog input signal (AI1 or AI2). It is necessary to set P1016

to 1 = AIx and select which analog input will be used. The analog inputs are set at P0231 (AI1)

or P0236 (AI2) and it is necessary to program it to 5 = Function 1 of the Application in order to

enable the analog inputs for the operation. The following alarm message will be displayed in

case it is not properly done: “A770: Set AI1 or AI2 for Function 1 of the Application”.

The PID setpoint value can be presented via analog output AO1 or AO2. It is necessary to set

P0251 (AO1) or P0254 (AO2) to 17 = Function 1 of the Application. The full scale value of the

variable is 100.0 % and corresponds to 10 V or 20 mA.

The PID feedback can receive an analog input signal (AI1 or AI2). It is necessary to set P0231

(AI1) or P0236 (AI2) to 6 = Function 2 of the Application in order to enable the analog inputs for

the operation. The following alarm message will be displayed in case it is not properly done:

“A772: Set AI1 or AI2 for Function 2 of the Application”.

In case the analog inputs (AI1 and AI2) are programmed with the same function, PID Setpoint

or Feedback, the following alarm message will be displayed and the application will not be

enabled: “A774: AI1 and AI2 were set for the same function”.

30 | CFW700

Page 36

Keypad (HMI) and Basic Programming

The value of the PID feedback can be presented via analog output AO1 or AO2. It is necessary

to set P0251 (AO1) or P0254 (AO2) to 18 = Function 2 of the Application. The full scale value of

the variable is 100.0 % and corresponds to 10 V or 20 mA.

The Manual/Auto control is done by a digital input (DI1 to DI8). It is necessary to set one of the

DI parameters (P0263 to P0270) to 20 = Function 1 of the Application. If more than one digital

input is set for this function, the logic operation will consider only the command of the high

priority level digital input, where: DI1>DI2>DI3>DI4>DI5>DI6>DI7> DI8. If any of the digital inputs

is set, the PID controller will work only in automatic (Auto) mode.

The Manual/Auto input is active when it is in 24 V indicating automatic control and it is inactive

in 0 V indicating manual operation.

The digital outputs (DO1 to DO5) can be programmed to trigger comparison logics with the

process variable (PV). In order to do that, it is necessary to set one of the DO’s parameters

(P0275 to P0279) to 34 = Function 1 of the Application (VP>VPx) or 35 = Function 2 of the

Application (VP<VPy).

English

CFW700 | 31

Page 37

Keypad (HMI) and Basic Programming

English

Manual

(Open DIx)

P0121

Reference

(Refer to the

Speed Reference

P013 3, P0134

0 = Direct

P1024

manual)

the CFW700

figure 13.8 of

programming

Automatic

(Closed DIx)

Academic PID

Enable

Ac tio n Typ e

1 = Reverse

PID Regulator

-1

DIx

+

+

+

P1022

P1020

Academic PID

P1021

Setpoint Definition (reference of

32 | CFW700

P1011

Enable

P1023

P1016 = 0

P1025

the process variable)

P1016 > 0

Setpoint Reference

+

-

P1012

P0231 = 6

P0236 = 6

AI1'

AI2'

Figure 4.4: PID Regulator block diagram

Page 38

Keypad (HMI) and Basic Programming

4.2.1.1 Academic PID

The PID controller implemented in CFW700 is the academic type. The equations that characterize

the Academic PID, which is the base of this function algorithm, are presented next.The transfer

function in the Academic PID regulator frequency dominion is:

y(s) = Kp x e(s) x [1 + 1 + sTd ]

By replacing the integrator by a sum and the derivative by the incremental quotient, one gets

an approximation for the discrete transfer equation (recursive) presented next:

y(k) = y(k-1) + Kp[(1 + Ki.Ta + Kd/Ta).e(k) – (Kd/Ta).e(k-1)]

Being:

y(k): current PID output, can vary from 0.0 to 100.0 %;

y(k-1): PID previous output;

Kp (Proportional gain): Kp = P1020;

Ki (Integral gain): Ki = P1021 x 100 = [1/Ti x 100];

Kd (Differential gain): Kd = P1022 x 100 = [Td x 100];

Ta = 0.05sec (PID regulator sampling time);

e(k): current error [SP*(k) – X(k)];

e(k-1): previous error [SP*(k-1) – X(k-1)];

SP*: reference, can vary from 0.0 to 100.0 %;

X: process variable (or feedback), read through one of the analog inputs (AIx), can vary from

0.0 to 100.0 %.

The parameters related to this application are:

sTi

English

P1010 – Version of the PID Regulator Application

Adjustable

Range:

Properties: ro

Access Groups

via HMI:

Description:

Read only parameter that presents the software version of the PID regulator application

developed for the SoftPLC function of the CFW700.

0.00 to 10.00 Factory

Setting:

SPLC

-

P1011 – PID Setpoint

Adjustable

Range:

Properties: ro

Access Groups

via HMI:

Description:

Read only parameter that presents, in the wxy.z form without engineering unit, the feedback

value of the PID regulator according to the scale defined at P1018.

0.0 to 3000.0 Factory

Setting:

SPLC

-

CFW700 | 33

Page 39

Keypad (HMI) and Basic Programming

P1012 – PID Feedback

Adjustable

English

Range:

Properties: ro

Access Groups

via HMI:

Description:

Read only parameter that presents, in the wxy.z form without engineering unit, the feedback

value or the process variable of the PID regulator according to the scale defined at P1018.

0.0 to 3000.0 Factory

Setting:

SPLC

P1013 – PID Output

Adjustable

Range:

Properties: ro

Access Groups

via HMI:

Description:

Read only parameter that presents, in percentage (%), the PID regulator output value.

0.0 to 100.0 % Factory

Setting:

SPLC

P1016 – PID Setpoint Selection

Adjustable

Range:

Properties: ro

Access Groups

via HMI:

0 = HMI

1 = AIx

2 = Serial/USB

3 = CO/DN/DP

SPLC

Factory

Setting:

-

-

0

Description:

Defines the source of the PID regulator setpoint.

Notes:

“HMI” means that the PID regulator setpoint will be the value of P1025 parameter.

“AI” means that the PID regulator setpoint will come from an analog input. It is necessary

to set P0231 (AI1) or P0236 (AI2) to 5 = Function 1 of the Application in order to enable its

operation. The following alarm message will be displayed in case it is not properly done:

“A770: Set AI1 or AI2 for Function 1 of the Application”.

“Serial/USB” means that the setpoint of the PID will be the value of P0683 proportionally

referenced to the percentage value with one decimal point, i.e., 100.0 % corresponds to

1000 in P0683.

34 | CFW700

Page 40

Keypad (HMI) and Basic Programming

“CO/DN/DP” means that the setpoint of the PID regulator will be the value of P0685

proportionally referenced to the percentage value with one decimal point, i.e., 100.0 %

corresponds to 1000 in P0685.

P1018 – PID Feedback Scale

Adjustable

Range:

0.0 to 3000.0 Factory

Setting:

100.0

Properties: Access Groups

SPLC

via HMI:

Description:

Defines how the PID Feedback or Process Variable will be presented in P1012 (as well as

the PID setpoint in P1011), i.e., the full scale of the PID feedback or process variable that

corresponds to 100.0 % in the analog input used as the PID regulator feedback.

The variable will always be with one decimal point “wxy.z”, i.e., one place after the dot.

Example: The pressure transducer is a 4-20 mA with 0-25 bar range. Set P1019 to 25.0.

P1020 – PID Proportional Gain

P1021 – PID Integral Gain

P1022 – PID Differential Gain

Adjustable

Range:

Properties: Access Groups

via HMI:

0.000 to 30.000 Factory

Setting:

SPLC

P1020 = 1.000

P1021 = 0.430

P1022 = 0.000

English

Description:

These parameters define the PID regulator application gains and they should be set according

to the application being controlled.

Examples of initial settings for some applications are presented in Table 4.1 on page 35.

Table 4.1: Recommended settings for the PID regulator gains

Variable

Pneumatic system Pressure 1 0.430 0.000

Pneumatic system flow 1 0.370 0.000

Hydraulic system Pressure 1 0.430 0.000

Hydraulic system flow 1 0.370 0.000

Temperature 2 0.040 0.000

Level 1 - See note bellow 1 See note below 0.000

Proportional

P1020

Gains

Integral

P1021

Derivative

P1022

CFW700 | 35

Page 41

Keypad (HMI) and Basic Programming

NOTE!

For the level control, the integral gain settings will depend on the time it takes

English

for the reservoir to go through the minimum acceptable level to the desired

level, with the following conditions:

1. The time for the direct action should be measured with the maximum input

flow and minimum output flow.

2. The time for the reverse action should be measured with minimum input

flow and maximum output flow.

An equation to calculate the initial value of P1021 as a function of the system response time

is presented next:

P1021 = 5.00 / t,

Where: t = time (in seconds)

P1023 – PID Setpoint Filter

Adjustable

Range:

0.00 to 650.00 s Factory

Setting:

3.0 s

Properties: Access Groups

SPLC

via HMI:

Description:

This parameter sets the value of the constant time of the setpoint filter of the PID regulator

and has the purpose of reducing abrupt changes in the PID setpoint value.

P1024 – PID Regulator Action Type

Adjustable

Range:

Properties: Access Groups

via HMI:

Description:

The PID action type should be selected as “Direct” when it is necessary that the motor speed is

increased in order to increment the process variable. Otherwise, the “Reverse” should be selected.

This characteristic varies with the process type, but direct feedback is most used.

0 = Direct

1 = Reverse

Factory

Setting:

SPLC

Table 4.2: Selecting the PID action type

Motor Speed Process Variable Selection

Increases

Increases Direct

Decreases Reverse

0

For temperature control or level process, the selection of the action type will depend on the

configuration.

Example: if the inverter runs the motor that removes fluid from the reservoir in a control

level, the action type is reverse as the inverter should increase the motor speed in order to

decrease the level of fluid. In case the inverter is running the motor that is adding fluid in the

reservoir, the action type is Direct.

36 | CFW700

Page 42

Keypad (HMI) and Basic Programming

P1025 – PID Setpoint via Keypad Keys (HMI)

Adjustable

Range:

Properties: Access Groups

via HMI:

Description:

This parameter allows the adjustment of the PID regulator setpoint through the keypad keys,

since P1016 = 0 and it is operating in Auto mode. If the operation is in Manual mode, the

keypad reference is set in P0121.

The value of P1025 is kept with the last value set (backup) even after disabling or resetting

the inverter (with P1027 = 1 - Active).

0.0 to 100.0 % Factory

Setting:

SPLC

0.0 %

P1026 – Automatic Setting of the PID Setpoint via Keypad (P1025)

Adjustable

Range:

Properties: cfg

Access Groups

via HMI:

Description:

When the PID regulator setpoint is done via the keypad (P1016 = 0) and P1026 is 1 (active),

when switching from manual to automatic, the percentage value of the manual setpoint that

corresponds to the PID regulator output from 0.0 to 100.0 % will be loaded at P1025. It avoids

PID oscillations when switching from manual to automatic.

0 = Inactive

1 = Active

SPLC

Factory

Setting:

1

English

P1027 – PID Setpoint Backup via Keypad (P1025)

Adjustable

Range:

Properties: Access Groups

via HMI:

Description:

This parameter sets whether the backup function of the PID setpoint via keypad is active or

inactive.

If P1027 = 0 (Inactive), the inverter will not save the value of the PID setpoint when disabled.

Therefore, when the inverter is enabled again, the PID setpoint value is 0.0 %.

0 = Inactive

1 = Active

SPLC

Factory

Setting:

1

CFW700 | 37

Page 43

Keypad (HMI) and Basic Programming

P1028 – PID Output N = 0

Adjustable

English

Range:

Properties: -

Access Groups

via HMI:

Description:

The P1028 parameter works together with the P0218 parameter (Condition to Leave the

Zero Speed Disable), providing additional requirement for leaving the condition. Thus, it is

necessary that the error of the PID controller (the difference between the control setpoint

and process variable) is greater than the value programmed in P1028 for the inverter to

operate the motor again, this state is known as “wake up”.

0.0 to 100.0 % Factory

Setting:

SPLC

P1031 – X Process Variable Value

P1032 – Y Process Variable Value

Adjustable

Range:

Properties: Access Groups

via HMI:

Description:

These parameters are used at the digital outputs functions for signaling/alarm, and will show:

Process Variable > VPx (Function 1 of the Application) and

Process Variable < VPy (Function 2 of the Application).

0.0 to 100.0 % Factory

Setting:

SPLC

0.0 %

P1031 = 90.0 %

P1032 = 10.0 %

4.2.2 Electronic Potentiometer (EP) Application

The CFW700 has the Electronic Potentiometer (E.P.) function that allows the speed reference to

be adjusted via two digital inputs, one for accelerating and another for decelerating the motor.

With the inverter enabled and the DIx digital input set to “Function 1 of the Application

(Accelerate)” activated, the motor is accelerated according to the programmed acceleration

ramp up to the maximum speed. If only the DIx digital input set to “Function 2 of the Application

(Decelerate)” is active and the inverter is enabled, the motor speed is decreased according to