Page 1

ENC and ENC2 Encoder

Input Plug-in Module

Módulo Plug-in con Entrada

de Encoder ENC y ENC2

Módulo Plug-in com Entrada

de Encoder ENC e ENC2

CFW500

Installation, Configuration and Operation Guide

Guía de Instalación, Configuración y Operación

Guia de Instalação, Configuração e Operação

Motors | Automation | Energy | Transmission & Distribution | Coatings

Page 2

Page 3

Summary / Índice

English

EspañolPortuguês

SUMMARY

1 SAFETY INFORMATION ...............................5

1.1 SAFETY WARNINGS ...................................5

1.2 PRELIMINARY RECOMMENDATIONS .......5

2 GENERAL INFORMATION ...........................5

3 PACKAGE CONTENT ...................................5

4 ACCESSORY INSTALLATION .....................6

5 SETTINGS ...................................................... 6

APPENDIX A – FIGURES ...............................29

ÍNDICE

1 INFORMACIONES DE SEGURIDAD .........13

1.1 AVISOS DE SEGURIDAD ............................ 13

1.2 RECOMENDACIONES PRELIMINARES ... 13

2 INFORMACIONES GENERALES ............... 13

3 CONTENIDO DEL EMBALAJE ..................13

4 INSTALACIÓN DEL ACCESORIO..............14

5 CONFIGURACIONES ..................................14

ANEXO A – FIGURAS .....................................29

ÍNDICE

1 INFORMAÇÕES DE SEGURANÇA ............21

1.1 AVISOS DE SEGURANÇA .........................21

1.2 RECOMENDAÇÕES PRELIMINARES .......21

2 INFORMAÇÕES GERAIS ...........................21

3 CONTEÚDO DA EMBALAGEM ..................21

4 INSTALAÇÃO DO ACESSÓRIO .................22

5 CONFIGURAÇÕES......................................22

ANEXO A – FIGURAS .....................................29

Page 4

Page 5

ENC Encoder Input Plug-in Module

English

CFW500 | 5

1 SAFETY INFORMATION

1.1 SAFETY WARNINGS

NOTE!

Only use the (CFW500-ENC or CFW500-

ENC2) expansion plug-in module with

encoder input in CFW500 series WEG

inverters.

We recommend reading the inverter user´s

manual before installing or operating this

accessor y.

This guide contains important information

for the correct understanding and proper

operation of this module.

1.2 PRELIMINARY RECOMMENDATIONS

ATTENTION!

Always disconnect the general power

supply before connecting or disconnecting

the accessories on the frequency inverter.

Wait at least 10 minutes to guarantee

complete de-energization of the inverter.

2 GENERAL INFORMATION

This guide provides instructions for the installation,

configuration and operation of the plug-in expansion

module for encoder reader input (CFW500-ENC or

CFW500-ENC2).

The Plug-in module for encoder has two differential

channels, "A" and "B" designed up to 400 kHz

incremental encoder reader frequency. Moreover, it has a

configurable +5 V or +12 V output supply for quadrature

encoder operation.

3 PACKAGE CONTENT

When receiving the product, check if the package

contains:

Accessory in antistatic packaging.

Installation, configuration and operation guide.

Page 6

ENC Encoder Input Plug-in Module

English

6 | CFW500

4 ACCESSORY INSTALLATION

This accessory is easily installed or replaced. For correct

installation of the accessory execute the following steps:

Step 1: With the inverter de-energized, remove the front

cover of the Inverter (Figure A.1 on page 29).

Step 2: Remove the plug-in module connected to the

inverter, if there is any, as in Figure A.1 on page 29.

Step 3: Fit and press the accessory to be installed as

indicated in Figure A.1 on page 29 and then assemble

the front cover of the inverter.

Step 4: Power up the inverter and check if parameter

P0027 shows value 10 (P0027 = 10, for the model

CFW500-ENC) or 12 (P0027 = 12, for CFW500-ENC2).

If this information is not true, check if the module used

is actually the CFW500-ENC or CFW500-ENC2 and

repeat steps 1-4.

Step 5: After incremental encoder well installed and

connected to the inverter and motor. Verify if the speed

shown in P0038 and P0681 is alright.

5 SETTINGS

The CFW500-ENC or CFW500-ENC2, inputs signals

specifications match to the Dynapar incremental

encoder model HS35B. To use another type of encoder

check if the pins and signal sequence are equivalent to

the showed in the Figure 2 on page 10.

It is important to follow some recommendations during

assembly of the encoder on the motor:

1. The encoder must be coupled directly to the shaft

of the motor without torsional flexibility.

2. Both the shaft and metal frame of the encoder must

be electrically isolated from the motor (minimum

distance 3 mm).

3. Flexible and high quality coupling must be used to

avoid mechanic oscillation or backlash.

The Figure 1 on page 7 below shows the encoder

assembly of selfventilated and forced ventilated motors.

Page 7

ENC Encoder Input Plug-in Module

English

CFW500 | 7

Encoder protection

cover

Flexible steel suporte/rack and

encoder fixture components

Encoder protection cover

fixture on the motor deflector

Encoder HS35B

Encoder HS35B

Figure 1: Encoder HS35B assembly for self-ventilated, or

with forced ventilated motor

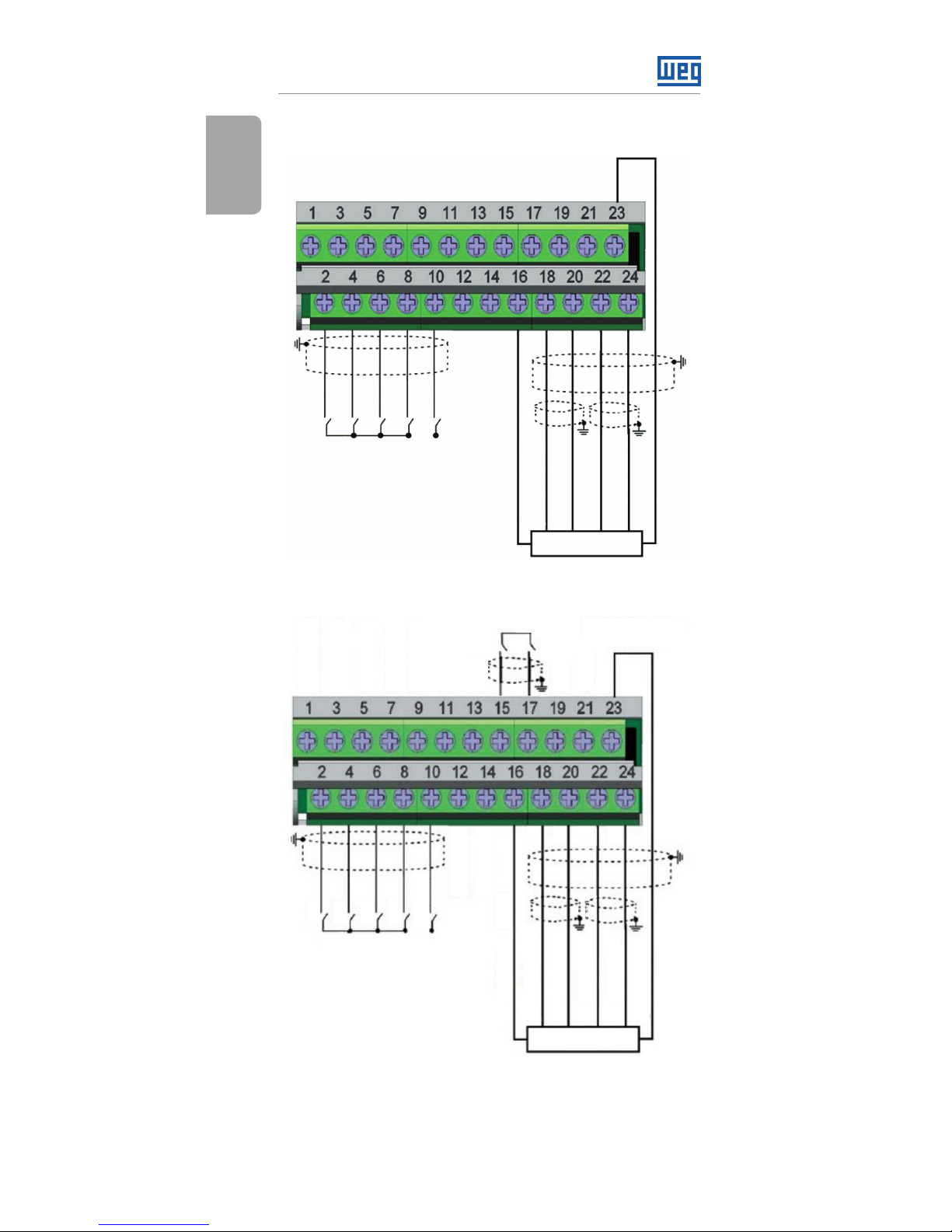

Controlling connections should be as presented in

Table 1 on page 8 for the CFW500-ENC module

or as per Table 2 on page 9 for the CFW500-ENC2

module. Figure 2 on page 10 presents the controlling

connection for the plug-in module and an example for

connecting the Dynapar model HS35B encoder.

Page 8

ENC Encoder Input Plug-in Module

English

8 | CFW500

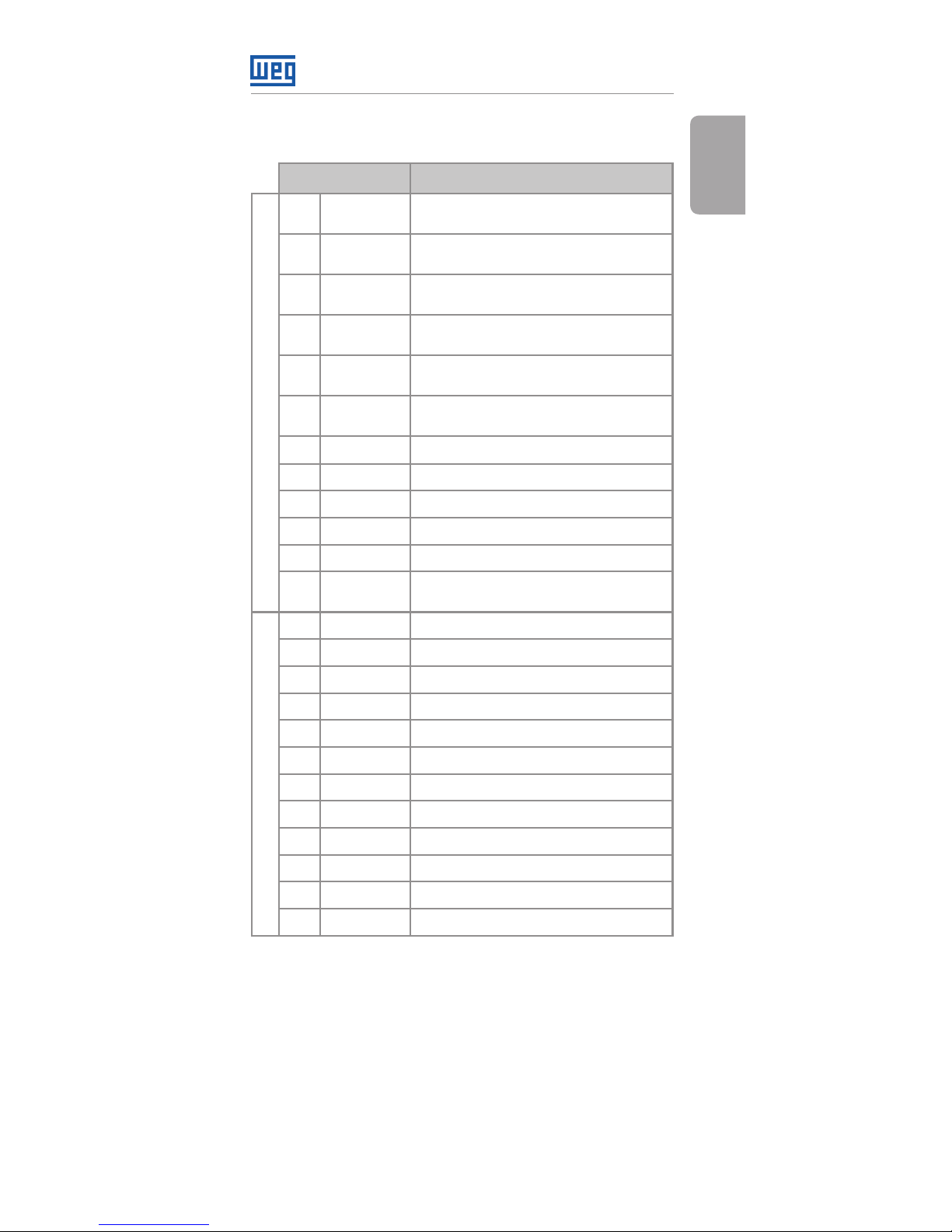

Table 1: CFW500-ENC signals from the control

connections

Connector Description

Superior Terminal

1 DO1-NO

Digital output 1

(NO contact of relay 1)

3 DO1-C

Digital output 1

(common point of relay 1)

5 D03-NO

Digital output 3

(NO contact of relay 3)

7 DO3-C

Digital output 3

common point of relay 3)

9 DO4-NO

Digital output 4

(NO contact of relay 4)

11 DO4-C

Digital output 4

(common point of relay 4)

13 GND Reference 0 V

15 AO1 Analogic output 1

17 AI1 Analogic input

19 DO2 Digital output 2 ( Transistor)

21 +24 V 24 Vdc Power supply (Transistor)

23 +VE

Output Power Supply +12 V

S2.1 = OFF) or +5 V (S2.1 = ON)

Inferior Terminal

2 DI1 Digital input 1

4 DI2 Digital input 2

6 DI3 Digital input 3

8 DI4 Digital input 4

10 DI5 Digital input 5 (NPN only)

12 RS-485 - A RS-485 (Terminal A)

14 RS-485 - B RS-485 (Terminal B)

16 GND Reference 0 V

18 A Non-inverting quadrature input A

20 /A Inverting quadrature input A

22 B Non-inverting quadrature input B

24 /B Inverting quadrature input B

Page 9

ENC Encoder Input Plug-in Module

English

CFW500 | 9

Table 2: CFW500-ENC2 signals from the control

connections

Connector Description

Superior Terminal

1 DO1-NO

Digital output 1

(NO contact of relay 1)

3 DO1-C

Digital output 1

(common point of relay 1)

5 D03-NO

Digital output 3

(NO contact of relay 3)

7 DO3-C

Digital output 3

common point of relay 3)

9 DO4-NO

Digital output 4

(NO contact of relay 4)

11 DO4-C

Digital output 4

(common point of relay 4)

13 GND Reference 0 V

15 DI6 Digital input 6

17 DI7 Digital input 7

19 DO2 Digital output 2 ( Transistor)

21 +24 V 24 Vdc Power supply (Transistor)

23 +VE

Output Power Supply +12 V

S2.1 = OFF) or +5 V (S2.1 = ON)

Inferior Terminal

2 DI1 Digital input 1

4 DI2 Digital input 2

6 DI3 Digital input 3

8 DI4 Digital input 4

10 DI5 Digital input 5 (NPN only)

12 RS-485 - A RS-485 (Terminal A)

14 RS-485 - B RS-485 (Terminal B)

16 GND Reference 0 V

18 A Non-inverting quadrature input A

20 /A Inverting quadrature input A

22 B Non-inverting quadrature input B

24 /B Inverting quadrature input B

Page 10

ENC Encoder Input Plug-in Module

English

10 | CFW500

Brown

Red

RS-485 - A

RS-485 - B

GND

GND

F A H B I D

DO4-RL-C

DI5 (NPN)

DI4

/B

DI3

B

DI2

/A

DI1

A

DO3-RL-C

DO4-RL-NO

DO3-RL-NO

DO1-RL-NO

DO1-RL-NC

AO1

AI1

DO2

+24 V

+VE

Blue

Yell o w

Green

White

GND / +24 V

Dynapar HS35B

S2.1 ON +5 V S2.1

OFF +12 V

+24 V

(a) Controlling connector signals for the

CFW500-ENC module

Red

GND

F A H B I D

DO4-RL-C

DO3-RL-C

DO4-RL-NO

DO3-RL-NO

DO1-RL-NO

DO1-RL-NC

DI6

DO2

+24 V

+VE

Blue

Yell o w

Green

White

S2.1 ON +5 V S2.1

OFF +12 V

DI4

DI3

DI2

DI1

DI5 (NPN)

GND

RS-485 - A

RS-485 - B

GND / +24 V

Brown

Dynapar HS35B

DI7

/B

B

/A

A

+24 V

GND / +24 V

(b) Controlling connector signals for the

CFW500-ENC 2 module

Figure 2: (a) and (b) Control connections

Page 11

ENC Encoder Input Plug-in Module

English

CFW500 | 11

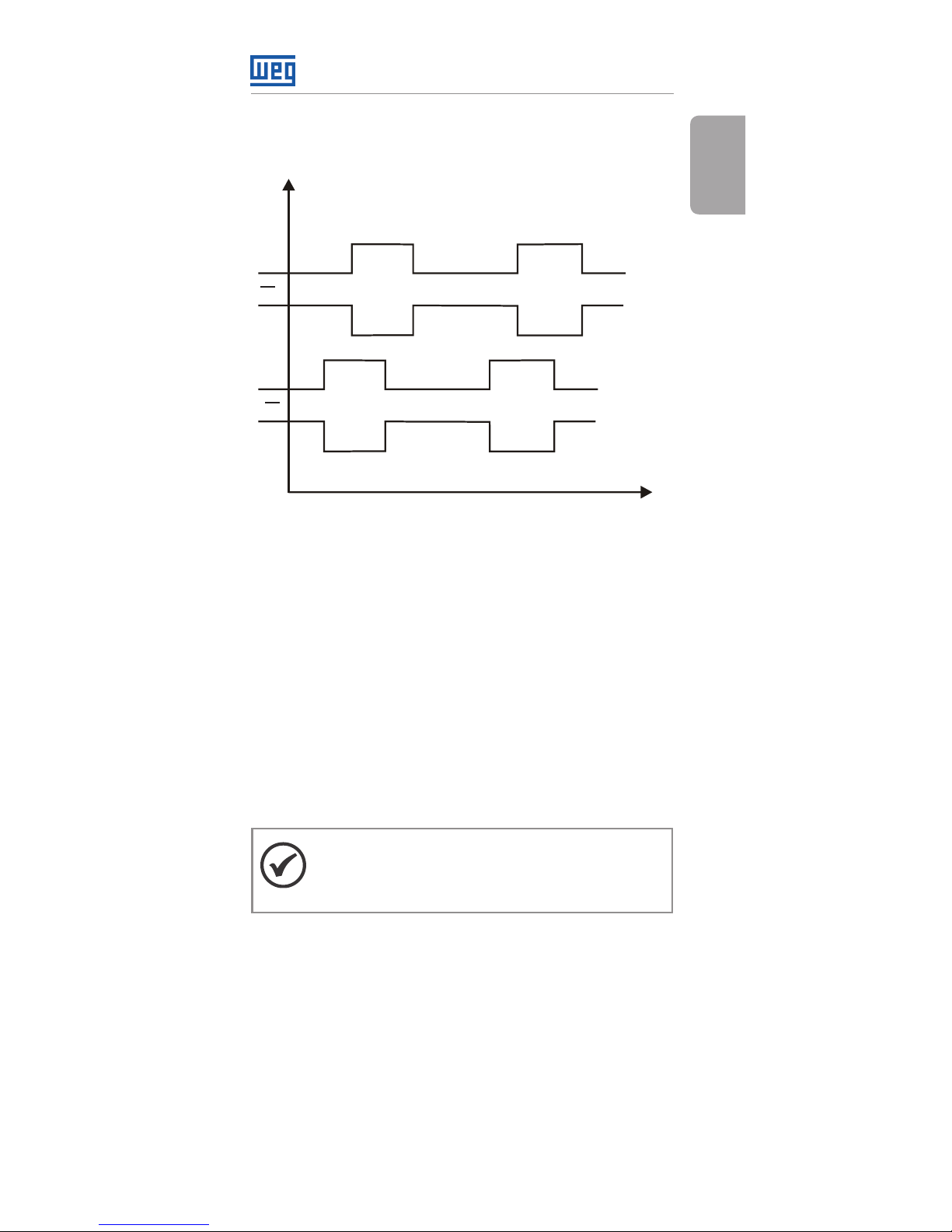

The Figure 3 on page 11 shows the phase sequence

signals of encoder to spin clockwise rotating direction.

Signal

A

A

B

B

Time

Figure 3: Standard phase of encoder signals

The location of the DIP switches to select the kind of

analog output and input signal can be better viewed in

Figure A.2 on page 30 and Figure A.3 on page 31.

To use the analog inputs and/ or outputs with current

signal, switch S1 and related parameters must be set

as indicated in Table 3 on page 12. To activate the

termination resistors of the RS-485 interface, see Table

4 on page 12. To set the power supply output for the

encoder + VE, see Table 5 on page 12.

For further details about the control connections see

chapter 3 Installation and Connection of the inverter.

NOTE!

The digital input signal DI5 is allways NPN

input instead of P0271 configuration.

Page 12

ENC Encoder Input Plug-in Module

English

12 | CFW500

Table 3 : Configurations switches for the analog input and

output

Input/

Output

Signal

Switch S1

Adjustment

Signal

Range

Parameter

Adjustment

AI1

Voltage S1.1 = OFF 0...10 V P0233 = 0 or 2

Current S1.1 = ON

0...20 mA P0233 = 0 or 2

4...20 mA P0233 = 1 or 3

AO1

Voltage S1.2 = ON 0...10 V P0253 = 0 or 3

Current S1.2 = OFF

0...20 mA P0253 = 1 or 4

4...20 mA P0253 = 2 or 5

Table 4 : Configurations switches for the RS-485 interface

Comunications Switch

Settings of the

Keys

Options

RS-485 S1

(*)

S1.3 = OFF and

S1.4 = OFF

RS-485

termination OFF

S1.3 = ON and

S1.4 = ON

RS-485

termination ON

(*) No other combinations of the switches are allowed.

Table 5: Configurations switches for the encoder supply

+VE

Encoder Supply Switch

Switch

Setting

Output

Voltage

+VE S2

S2.1 = ON 5 Vdc

S2.1 = OFF 12 Vdc

This module has a connector (Figure A.2 on page 30

and Figure A.3 on page 31) to enable the use of the

Flash Memory Module (CFW500-MMF), which allows

data transfer between inverters. For further details on

this accessory, refer to the installation, configuration

and operation guide of the CFW500-MMF.

Page 13

Módulo Plug-in con Entrada de Encoder ENC

CFW500 | 13

Español

1 INFORMACIONES DE SEGURIDAD

1.1 AVISOS DE SEGURIDAD

¡NOTA!

Solamente utilizar el módulo plug-in

con entrada de encoder (CFW500-ENC

o CFW500-ENC2) en los convertidores

WEG línea CFW500.

Se recomienda la lectura del manual del

usuario del convertidor antes de instalar

o operar este accesorio.

El contenido de esta guía ofrece

informaciones importantes para el correcto

entendimiento y buen funcionamento de

este módulo.

1.2 RECOMENDACIONES PRELIMINARES

¡ATENCIÓN!

Siempre desconecte la alimentación

general antes de conectar o desconectar

los accesorios en el convertidor de

frecuencia.

Aguarde por lo menos 10 minutos para

garantizar la desenergización completa

del convertidor.

2 INFORMACIONES GENERALES

Esta guía orienta en la instalación, configuración y

operación del módulo plug-in de expansión (CFW500-ENC

o CFW500-ENC2).

El módulo plug-in de encoder tiene dos canales

diferenciales "A" y "B" para lectura de las señales de un

encoder incremental con frecuencia de hasta 400 kHz.

Así como una fuente configurable en +5 Vcc o +12 Vcc

para alimentación del encoder incremental.

3 CONTENIDO DEL EMBALAJE

Al recibir el producto, verifique si el embalaje contiene:

Accesorio en embalaje antiestático.

Guía de instalación, configuración y operación.

Page 14

Módulo Plug-in con Entrada de Encoder ENC

14 | CFW500

Español

4 INSTALACIÓN DEL ACCESORIO

El accesorio puede ser fácilmente instalado o sustituido.

Para la correcta instalación del accesorio, ejecute los

siguientes pasos:

Paso 1: Con el convertidor desenergizado, retire la tapa

frontal del mismo (Figura A.1 en la página 29).

Paso 2: Retire, si existe, el accesorio (módulo plug-in

conectado) conforme la Figura A.1 en la página 29.

Paso 3: Encaje y presione el accesorio a ser instalado

conforme indicado en la Figura A.1 en la página 29 y

después conecte la tapa frontal del convertidor.

Paso 4: Energice el convertidor y verifique si el

parámetro P0027 indica el valor 10 (P0027 = 10

para CFW500-ENC) o el valor 12 (P0027 = 12, para

CFW500-ENC2). En caso de que esa información no sea

verdadera, verifique si el módulo utilizado realmente es el

CFW500-ENC o CFW500-ENC2 y repita los pasos 1-4.

Paso 5: Después de que plug-in y encoder incremental

haya sido bien instalado y conectado al convertidor y al

motor. Verifique si la velocidad que se muestra en P0038

y P0681 está correcta.

5 CONFIGURACIONES

Las especificaciones de apagar señales para las

entradas de encoder incremental del módulo CFW500ENC o CFW500-ENC2, son válidas para los modelos de

encoder HS35B de la Dynapar. Para el uso de otro tipo

de encoder verificar si los terminales y la secuencia de

las señales son las mismas que el modelo presentado.

Conforme muestra la Figura 2 en la página 18.

Durante el montaje del encoder en el motor es muy

importante seguir algunas recomendaciones:

1. El encoder debe ser acoplado directamente al eje

del motor sin tener flexibilidad de torsión.

2. Tanto el eje cuanto el armazón metálico del encoder

deben estar eléctricamente aislados del motor

(separasión mínimo de 3 mm).

Page 15

Módulo Plug-in con Entrada de Encoder ENC

CFW500 | 15

Español

3. Deben ser utilizados acoplamientos flexibles y de

buena calidad que eviten oscilaciones mecánicas o

“backlash”.

La Figura 1 en la página 15 muestra el montaje del

encoder para motores autoventilados y con ventilación

forzada.

Tapa de protección

del encoder

Soporte flexible de acero y

componentes de fijación del

encoder

Fijación de la tapa de protección

del encoder sobre la deflectora

del motor

Encoder HS35B

Encoder HS35B

Figura 1: Montaje del encoder HS35B para motor

autoventilado o con ventilación forzada

Las conexiones de control deben ser hechas en el

conector, conforme la Tabla 1 en la página 16, para

el módulo CFW500-ENC, o la Tabla 2 en la página 17

para el módulo CFW500-ENC2.

Page 16

Módulo Plug-in con Entrada de Encoder ENC

16 | CFW500

Español

Tabla 1: Señales del conector de control CFW500-ENC

Conector Descripción

Borne Superior

1 DO1-NO

Salida digital 1

(contacto NA del relé 1)

3 DO1-C

Salida digital 1

(punto común del relé 1)

5 DO3-NO

Salida digital 3

(contacto NA del relé 3)

7 DO3-C

Salida digital 3

(punto común del relé 3)

9 DO4-NO

Salida digital 4

(contacto NA del relé 4)

11 DO4-C

Salida digital 4

(punto común del relé 4)

13 GND Referencia 0 V

15 AO1 Salida analógica 1

17 AI1 Entrada analógica 1

19 DO2 Salida digital 2 (Transistor)

21 +24 V Fuente +24 V (150 mA)

23 +VE

Fuente encoder

+12 V (S2.1 = OFF) o +5 V (S2.1 = ON)

Borne Inferior

2 DI1 Entrada digital 1

4 DI2 Entrada digital 2

6 DI3 Entrada digital 3

8 DI4 Entrada digital 4

10 DI5 Entrada digital 5 (NPN sólo)

12 RS-485 - A RS-485 (Terminal A)

14 RS-485 - B RS-485 (Terminal B)

16 GND Referencia 0 V

18 A Entrada en cuadratura A

20 /A Entrada en cuadratura A invertida

22 B Entrada en cuadratura B

24 /B Entrada en cuadratura B invertida

Page 17

Módulo Plug-in con Entrada de Encoder ENC

CFW500 | 17

Español

Tabla 2 : Señales del conector de control CFW500-ENC2

Conector Descripción

Borne Superior

1 DO1-NO Salida digital 1 (contacto NA del relé 1)

3 DO1-C

Salida digital 1

(punto común del relé 1)

5 DO3-NO Salida digital 3 (contacto NA del relé 3)

7 DO3-C

Salida digital 3

(punto común del relé 3)

9 DO4-NO Salida digital 4 (contacto NA del relé 4)

11 DO4-C

Salida digital 4

(punto común del relé 4)

13 GND Referencia 0 V

15 DI6 Entrada digital 6

17 DI7 Entrada digital 7

19 DO2 Salida digital 2 (Transistor)

21 +24 V Fuente +24 V (150 mA)

23 +VE

Fuente encoder

+12 V (S2.1 = OFF) o +5 V (S2.1 = ON)

Borne Inferior

2 DI1 Entrada digital 1

4 DI2 Entrada digital 2

6 DI3 Entrada digital 3

8 DI4 Entrada digital 4

10 DI5 Entrada digital 5 (NPN sólo)

12 RS-485 - A RS-485 (Terminal A)

14 RS-485 - B RS-485 (Terminal B)

16 GND Referencia 0 V

18 A Entrada en cuadratura A

20 /A Entrada en cuadratura A invertida

22 B Entrada en cuadratura B

24 /B Entrada en cuadratura B invertida

Page 18

Módulo Plug-in con Entrada de Encoder ENC

18 | CFW500

Español

Marrón

Rojo

RS-485 - A

RS-485 - B

GND

GND

F A H B I D

DO4-RL-C

DI5 (NPN)

DI4

/B

DI3

B

DI2

/A

DI1

A

DO3-RL-C

DO4-RL-NO

DO3-RL-NO

DO1-RL-NO

DO1-RL-NC

AO1

AI1

DO2

+24 V

+VE

Azul

Amarillo

Verde

Blanco

GND / +24 V +24 V

Dynapar HS35B

S2.1 ON +5 V S2.1

OFF +12 V

(a) Señales del conector de control para el módulo

CFW500-ENC

Rojo

GND

F A H B I D

DO4-RL-C

DO3-RL-C

DO4-RL-NO

DO3-RL-NO

DO1-RL-NO

DO1-RL-NC

DI6

DO2

+24 V

+VE

Azul

Amarillo

Verde

Blanco

S2.1 ON +5 V S2.1

OFF +12 V

DI4

DI3

DI2

DI1

DI5(NPN)

GND

RS-485 - A

RS-485 - B

GND / +24 V +24 V

Marrón

Dynapar HS35B

DI7

/B

B

/A

A

GND / +24 V

(b) Señales del conector de control para el modulo

CFW500-ENC2

Figura 2: (a) y (b) Las conexiones de control

Page 19

Módulo Plug-in con Entrada de Encoder ENC

CFW500 | 19

Español

La Figura 3 en la página 19 muestra la secuencia

de fase de las señales del encoder para la rotación del

motor en sentido horario.

Señal

A

A

B

B

Tiempo

Figura 3: Señales del encoder para sentido giro horario

La localización de las DIP-switches para selección del

tipo de señal de la entrada y salida analógica puede ser

mejor visualizada en la Figura A.2 en la página 30 y en

la Figura A.3 en la página 31. Para utilizar las entradas

y/u salidas analógicas con señal en corriente, se debe

ajustar el interruptor S1 y los parámetros relacionados

conforme Tabla 3 en la página 20. Para activar las

resistencias de terminación de la interfaz RS-485,

consulte la Tabla 4 en la página 20. Para ajustar

la potencia de salida del codificador + EV, véase la

Tabla 5 en la página 20. Para más detalles sobre las

conexiones de control consulte el capítulo 3 Instalación

y Conexion del manual del usuario del convertidor.

¡NOTA!

La señal de la entrada digital DI5 es siempre

NPN, independientemente de la configuración

en P0271.

Page 20

Módulo Plug-in con Entrada de Encoder ENC

20 | CFW500

Español

Tabla 3 : Configuraciones de los interruptores para

selección del tipo de señal en la entrada y salida analógica

Entrada/

Salida

Señal

Ajuste del

Interruptor

S1

Rango de

la Señal

Ajuste de

Parámetros

AI1

Tensión S1.1 = OFF 0...10 V P0233 = 0 o 2

Corriente S1.1 = ON

0...20 mA P0233 = 0 o 2

4...20 mA P0233 = 1 o 3

AO1

Tensión S1.2 = ON 0...10 V P0253 = 0 o 3

Corriente S1.2 = OFF

0...20 mA P0253 = 1 o 4

4...20 mA P0253 = 2 o 5

Tabla 4 : Configuraciones de los interruptores para

configuración de la RS-485

Comunicación Llave

Ajuste de los

Interruptores

Opción

RS-485 S1

(*)

S1.3 = OFF y

S1.4 = OFF

Terminación

RS-485 apagada

S1.3 = ON y

S1.4 = ON

Terminación

RS-485 encendida

(*) Cualquier otra combinación de los interruptores no está

permitida.

Tabla 5: Configuración de la alimentación del encoder +VE

Alimentación Llave

Ajuste de la

Llave

Tensión de

salida

+VE S2

S2.1 = ON 5 Vdc

S2.1 = OFF 12 Vdc

Este módulo posee un conector (Figura A.2 en la página

30 y en la Figura A.3 en la página 31) para utilización

del Módulo de Memória Flash (CFW500-MMF), el cual

permite la transferencia de datos entre los convertidores.

Para más detalles sobre este accesorio consulte la guía de

instalación, configuración y operación del CFW500-MMF.

Page 21

Módulo Plug-in com Entrada de Encoder ENC

CFW500 | 21

Português

1 INFORMAÇÕES DE SEGURANÇA

1.1 AVISOS DE SEGURANÇA

NOTA!

Somente utilizar o módulo plug-in com

entrada de encoder (CFW500-ENC ou

CFW500-ENC2) nos inversores WEG

linha CFW500.

Recomenda-se a leitura do manual do

usuário do inversor antes de instalar ou

operar esse acessório.

O conteúdo deste guia fornece

informações importantes para o correto

entendimento e operação deste módulo.

1.2 RECOMENDAÇÕES PRELIMINARES

ATENÇÃO!

Sempre desconecte a alimentação geral

antes de conectar ou desconectar os

acessórios no inversor de frequência.

Aguarde pelo menos 10 minutos para

garantir a desenergização completa do

inversor.

2 INFORMAÇÕES GERAIS

Este guia orienta na instalação, configuração e operação

do módulo plug-in de expansão com entrada para

leitura de encoder incremental (CFW500-ENC ou

CFW500-ENC2).

O modulo plug-in de encoder tem dois canais diferenciais

"A" e "B" para leitura dos sinais de um encoder

incremental com frequência de até 400 kHz. Bem como

uma fonte configurável em +5 Vcc ou +12 Vcc para

alimentação do encoder incremental.

3 CONTEÚDO DA EMBALAGEM

Ao receber o produto, verificar se a embalagem contém:

Acessório em embalagem anti-estática.

Guia de instalação, configuração e operação.

Page 22

Módulo Plug-in com Entrada de Encoder ENC

22 | CFW500

Português

4 INSTALAÇÃO DO ACESSÓRIO

O acessório é facilmente instalado ou substituído.

Para a correta instalação do acessório execute os

passos a seguir:

Passo 1: Com o inversor desenergizado, retire a tampa

frontal do Inversor (Figura A.1 na página 29).

Passo 2: Retire, se houver, o acessório (módulo plug-in

conectado) conforme a Figura A.1 na página 29.

Passo 3: Encaixe e pressione o acessório a ser instalado

conforme indicado na Figura A.1 na página 29 e após

conecte a tampa frontal do inversor.

Passo 4: Energize o inversor e verifique se o parâmetro

P0027 indica o valor 10 (P0027 = 10, para CFW500ENC) ou o valor 12 (P0027 = 12, para CFW500-ENC2).

Caso essa informação não for verdadeira, verifique se

o módulo utilizado realmente é o CFW500-ENC ou

CFW500 ENC2 e repita os passos 1-4.

Passo 5: Após a instalação e conexão do plug-in e

do encoder, verifique também se as funções dos

parâmetros P0038 e P0681 relacionadas ao encoder

estão funcionando corretamente.

5 CONFIGURAÇÕES

As especificações dos sinais para as entradas de

encoder incremental do módulo CFW500-ENC ou

CFW500-ENC2, são válidas para os modelos de encoder

HS35B da Dynapar. Para o uso de outro tipo de encoder

verifique se a pinagem e sequência de sinais equivalem

ao modelo apresentado. Conforme mostra a Figura 2

na página 26.

Na montagem do encoder ao motor é importante seguir

algumas recomendações:

1. O encoder deve ser acoplado diretamente ao eixo

do motor sem flexibilidade torsional.

2. Tanto o eixo quanto a carcaça metálica do encoder

devem estar eletricamente isolados do motor

(espaçamento mínimo de 3 mm).

Page 23

Módulo Plug-in com Entrada de Encoder ENC

CFW500 | 23

Português

3. Devem ser utilizados acoplamentos flexíveis e de

boa qualidade que evitem oscilações mecânicas

ou "backlash".

A Figura 1 na página 23 abaixo mostra a montagem

do encoder em motores auto-ventilados e com

ventilação forçada.

Tampa de proteção

do encoder

Suporte flexível da chapa de

aço e componentes de fixação

do encoder

Fixação da tampa de proteção

do encoder sobre a deflectora

do motor

Encoder HS35B

Encoder HS35B

Figura 1: Montagem do Encoder HS35B para o motor

auto-ventilado, ou com ventilação forçada

As conexões de controle devem ser feitas no conector

conforme Tabela 1 na página 24 para o modulo

CFW500-ENC ou Tabela 2 na página 25 pa ra o

modulo CFW500-ENC2. A Figura 2 na página 26

mostra a conexão de controle para o modulo plug-in e

um exemplo de conexão ao enconder Dynapar HS35B.

Page 24

Módulo Plug-in com Entrada de Encoder ENC

24 | CFW500

Português

Tabela 1: Sinais do conector de controle CFW500-ENC

Conector Descrição

Borne Superior

1 DO1-NO

Saída Digital 1 (Contato NA do

Rel é 1)

3 DO1-C

Saída Digital 1 (Ponto comum do

Rel é 1)

5 D03-NO

Saída Digital 3 (Contato NA do

Relé 3)

7 DO3-C

Saída Digital 3 (Ponto comum do

Relé 3)

9 DO4-NO

Saída Digital 4 (Contato NA do

Relé 4)

11 DO4-C

Saída Digital 4 (Ponto comum do

Relé 4)

13 GND Referência 0 V

15 AO1 Saída analógica 1

17 AI1 Entrada analógica 1

19 DO2 Saída digital 2 (Transistor)

21 +24 V

Fonte de alimentação 24 Vdc

(150 mA)

23 +VE

Fonte de Alimentação do Encoder

12 V (S2.1 = OFF) ou 5 V (S2.1 = ON)

Borne Inferior

2 DI1 Entrada Digital 1

4 DI2 Entrada Digital 2

6 DI3 Entrada Digital 3

8 DI4 Entrada Digital 4

10 DI5 Entrada Digital 5 (NPN somente)

12 RS-485 - A RS-485 (Terminal A)

14 RS-485 - B RS-485 (Terminal B)

16 GND Referência 0 V

18 A Entrada em quadratura A

20 /A Entrada em quadratura A invertida

22 B Entrada em quadratura B

24 /B Entrada em quadratura B invertida

Page 25

Módulo Plug-in com Entrada de Encoder ENC

CFW500 | 25

Português

Tabela 2: Sinais do conector de controle CFW500-ENC2

Conector Descrição

Borne Superior

1 DO1-NO

Saída Digital 1 (Contato NA do

Rel é 1)

3 DO1-C

Saída Digital 1 (Ponto comum do

Rel é 1)

5 D03-NO

Saída Digital 3 (Contato NA do

Relé 3)

7 DO3-C

Saída Digital 3 (Ponto comum do

Relé 3)

9 DO4-NO

Saída Digital 4 (Contato NA do

Relé 4)

11 DO4-C

Saída Digital 4 (Ponto comum do

Relé 4)

13 GND Referência 0 V

15 DI6 Entrada Digital 6

17 DI7 Entrada Digital 7

19 DO2 Saída digital 2 (Transistor)

21 +24 V

Fonte de alimentação 24 Vdc

(150 mA)

23 +VE

Fonte de Alimentação do Encoder

12 V (S2.1 = OFF) ou 5 V (S2.1 = ON)

Borne Inferior

2 DI1 Entrada Digital 1

4 DI2 Entrada Digital 2

6 DI3 Entrada Digital 3

8 DI4 Entrada Digital 4

10 DI5 Entrada Digital 5 (NPN somente)

12 RS-485 - A RS-485 (Terminal A)

14 RS-485 - B RS-485 (Terminal B)

16 GND Referência 0 V

18 A Entrada em quadratura A

20 /A Entrada em quadratura A invertida

22 B Entrada em quadratura B

24 /B Entrada em quadratura B invertida

Page 26

Módulo Plug-in com Entrada de Encoder ENC

26 | CFW500

Português

Marrom

Vermelho

RS-485 - A

RS-485 - B

GND

GND

F A H B I D

DO4-RL-C

DI5 (NPN)

DI4

/B

DI3

B

DI2

/A

DI1

A

DO3-RL-C

DO4-RL-NO

DO3-RL-NO

DO1-RL-NO

DO1-RL-NC

AO1

AI1

DO2

+24 V

+VE

Azul

Amarelo

Verde

Branco

GND / +24 V +24 V

Dynapar HS35B

S2.1 ON +5 V S2.1

OFF +12 V

(a) Sinais do conector de controle para modulo

CFW500-ENC

Vermelho

GND

F A H B I D

DO4-RL-C

DO3-RL-C

DO4-RL-NO

DO3-RL-NO

DO1-RL-NO

DO1-RL-NC

DI6

DO2

+24 V

+VE

Azul

Amarelo

Verde

Branco

S2.1 ON +5 V S2.1

OFF +12 V

GND / +24 V

DI4

DI3

DI2

DI1

DI5 (NPN)

GND

RS-485 - A

RS-485 - B

GND / +24 V +24 V

Marrom

Dynapar HS35B

DI7

/B

B

/A

A

(b) Sinais do conector de controle para modulo

CFW500-ENC2

Figura 2: (a) e (b) Conexões de controle

Page 27

Módulo Plug-in com Entrada de Encoder ENC

CFW500 | 27

Português

A Figura 3 na página 27 mostra a sequência de fase

dos sinais do encoder para a rotação do motor em

sentido horário.

Sinal

A

A

B

B

Tempo

Figura 3: Sinais de encoder para sentido de giro horário

A localização das DIP-switches para seleção do tipo de

sinal da entrada e saída analógica podem ser melhor

visualizadas na Figura A.2 na página 30 e na Figura

A.3 na página 31. Para utilizar as entradas e/ou saídas

analógicas com sinal em corrente deve-se ajustar a

chave S1 e os parâmetros relacionados conforme

Tabela 3 na página 28. Para ativar os resistores de

terminação da interface RS-485, veja a Tabela 4 na

página 28. Para configurar a saída de alimentação

do encoder +VE, veja a Tabela 5 na página 28. Para

mais detalhes sobre as conexões de controle consulte

o capítulo 3 do manual do usuário do inversor.

NOTA!

O sinal da entrada digital DI5 é sempre NPN,

independente da configuração em P0271.

Page 28

Módulo Plug-in com Entrada de Encoder ENC

28 | CFW500

Português

Tabela 3: Configurações das chaves para seleção do tipo

de sinal na entrada e saída analógica

Entrada/

Saída

Sinal

Ajuste da

Chave S1

Faixa do

Sinal

Ajuste de

Parâmetros

AI1

Tensão S1.1 = OFF 0...10 V P0233 = 0 ou 2

Corrente S1.1 = ON

0...20 mA P0233 = 0 ou 2

4...20 mA P0233 = 1 ou 3

AO1

Tensão S1.2 = ON 0...10 V P0253 = 0 ou 3

Corrente S1.2 = OFF

0...20 mA P0253 = 1 ou 4

4...20 mA P0253 = 2 ou 5

Tabela 4: Configurações das chaves para configuração

da RS-485

Comunicação Chave

Ajuste das

Chaves

Opção

RS-485 S1

(*)

S1.3 = OFF e

S1.4 = OFF

Terminação

RS-485 desligada

S1.3 = ON e

S1.4 = ON

Terminação

RS-485 ligada

(*) Qualquer outra combinação das chaves não é permitida.

Tabela 5: Configuração da alimentação do encoder +VE

Alimentação Chave

Ajuste da

Chave

Tensão de

Saída

+VE S2

S2.1 = ON 5 Vdc

S2.1 = OFF 12 Vdc

Este módulo possui um conector (Figura A.2 na página

30 e Figura A.3 na página 31) para utilização do

Módulo de Memória Flash (CFW500-MMF), o qual

permite a transferência de dados entre inversores.

Para mais detalhes sobre esse acessório consulte

o guia de instalação, configuração e operação do

CFW500-MMF.

Page 29

Appendix A - Anexo A

CFW500 | 29

APPENDIX A – FIGURES

ANEXO A – FIGURAS

(a) Removal of front cover and accessory

(a) Remoción de la tapa frontal y de lo accesorio

(a) Remoção da tampa frontal e do acessório

(b) Accessory connection

(b) Conexión de lo accesorio

(b) Conexão do acessório

Figure A.1: (a) to (b) Installation of accessory

Figura A.1: (a) a (b) Instalación de lo accesorio

Figura A.1: (a) a (b) Instalação do acessório

Page 30

Appendix A - Anexo A

30 | CFW500

66.3

(2.6)

62.3

(2.5)

22.6

(0.9)

Figure A.2: CFW500-ENC dimensions in mm [in],

DIP-switches location and MCard connector

Figura A.2: Dimensiones del CFW500-ENC en mm [in],

localización de las DIP-switc hes y conectador de MCard

Figura A.2: Dimensões do CFW500-ENC em mm [in],

localização das DIP-switches e conector

Page 31

Appendix A - Anexo A

CFW500 | 31

66.3

(2.6)

62.3

(2.5)

22.6

(0.9)

Figure A.3: CFW500-ENC2 dimensions in mm [in],

DIP-switches location and MCard connector

Figura A.3: Dimensiones del CFW500-ENC2 en mm [in],

localización de las DIP-switc hes y conectador de MCard

Figura A.3: Dimensões do CFW500-ENC2 em mm [in],

localização das DIP-switches e conector

Page 32

NOTES / NOTAS / ANOTAÇÕES

Page 33

NOTES / NOTAS / ANOTAÇÕES

Page 34

NOTES / NOTAS / ANOTAÇÕES

Page 35

Page 36

Document: 10002552668 / 03

11771113

WEG Drives & Controls - Automação LTDA.

Jaraguá do Sul - SC - Brazil

Phone 55 (47) 3276-4000 - Fax 55 (47) 3276-4020

São Paulo - SP - Brazil

Phone 55 (11) 5053-2300 - Fax 55 (11) 5052-4212

automacao@weg.net

www.weg.net

Loading...

Loading...