Page 1

R Trademark

Please do not return unit to retailer.

Por favor, no devuelva el aparato al lugar de compra.

Veuillez ne pas retourner l’outil au détaillant.

1-800-554-6723

www.weedeater.com

Instruction Manual

Manual de Instrucciones

Manuel d’Instructions

XT260

FX26

ENGLISH ESPAÑOL

For Occasional Use Only

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en lesiones

graves.

AVERTISSEMENT:

Lire le manuel d’instructions et bien respecter tous les avertissements ettoutes les instructions de sécurité. Toutdéfaut de le faire

pourrait entraîner des blessures graves.

Electrolux Home Products, Inc.

250 Bobby Jones Expressway

Augusta, GA 30907

CopyrightE2003 Electrolux Home Products, Inc.

Electrolux Canada Corporation

6150 McLaughlin Road

Mississauga, Ontario L5R 4C2

530163906

10/20/03

FRANÇAIS

Page 2

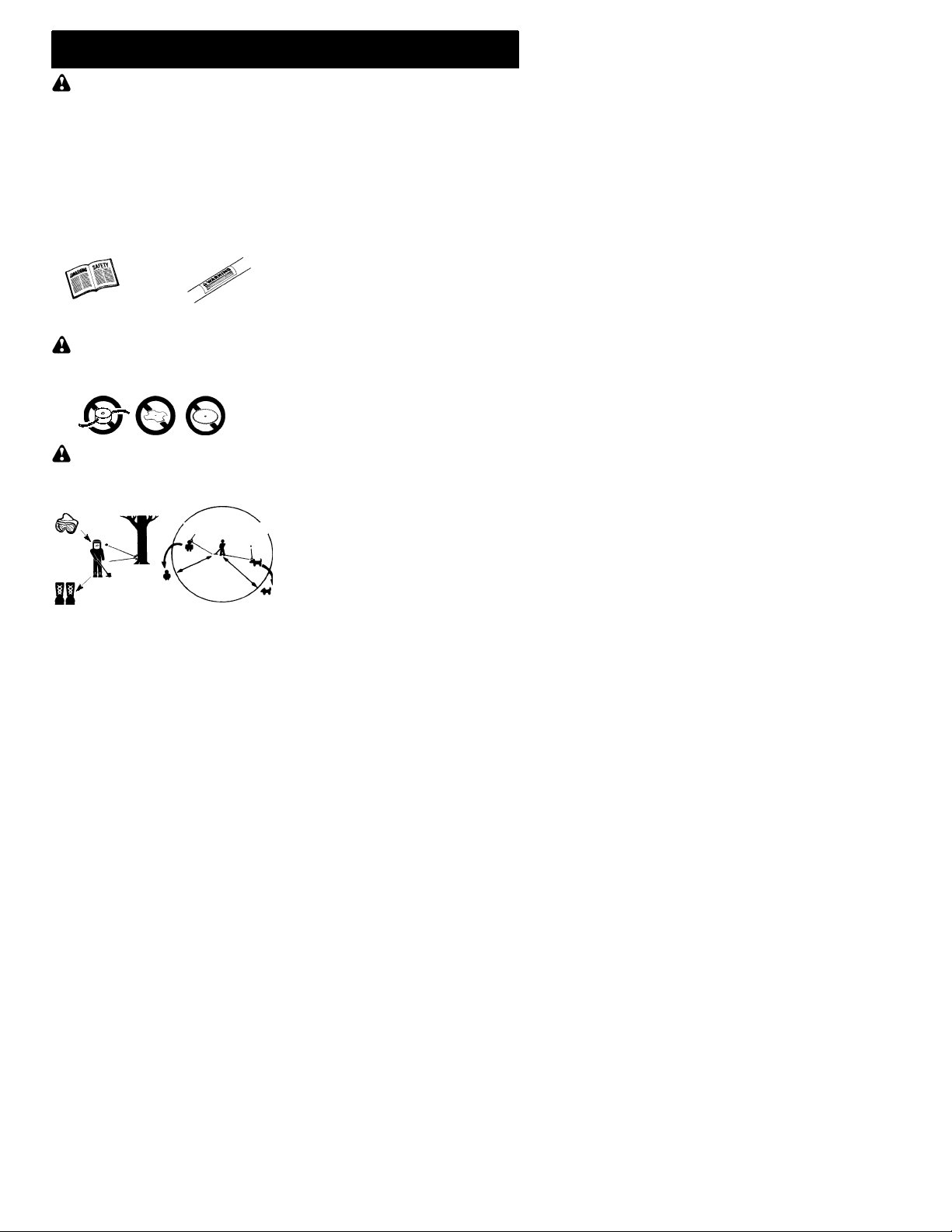

SAFETY RULES

WARNING:

appliances,basic safetyprecautionsmust alwaysbefollowedtoreducetherisk offireand

serious injury. Read and follow all instructions.

This power unit can be dangerous!

responsible for following instructions and warnings on unit and in manual. Read entire instruction manual before using unit! Be thoroughly familiarwiththecontrolsandtheprope ruseof the

unit. Restrict the use of this unit to persons who

have read, understand, and will follow the

instructions and warnings on the unit and in the

manual. Never allow children to operate this

unit.

INSTRUCTION

MANUAL

DANGER:

devices. This unit is designed forline trimmer

use only.Use of any other accessories or attachmentswill increase the risk of injury.

WARNING:

jects violently.Y ouand others can beblinded/injured. Wear eye and leg protection. Keep body

parts clear of rotating line.

Eye Protection

Boots

Keep children, bystanders, and animals 50 feet

(15 meters) away. If approached stop unit immediately.

If situations occur which are not covered in

this manual, use care and good judgment. If

youneedassistance,contact yourauthorized

service dealer or call 1-800-554--6723.

OPERATOR SAFETY

Dress properly. Always wear safety glasses

S

or similar eye protection when operating, or

performing maintenance, on your unit (safety

glasses are available). Eye protection should

be marked Z87.

Alwayswearfa ceordust maskif operationis

S

dusty.

Always wear heavy,longpants, long sleeves,

S

boots, and gloves. Wearing safety legguards

is recommended.

When using gardening

Operator is

SAFETY INFORMATION

ON THE UNIT

Neverusebladesorflailing

Trim mer line throw sob-

HazardZone

50 ft.

(15 m)

Always wear foot protection. Do not gobare-

S

foot or wear sandals. Stay clear of spinning

line.

Securehairabove shoulder length. Secureor

S

remov elooseclothingorclothingwithloosely

hanging ties, straps, tassels, etc. They can

be caught in moving parts.

Being fully covered also helps protect you

S

from debris and pieces of toxic plants thrown

by spinning line.

Stay Alert. Do not operate this unit when you

S

aretired,ill, upsetorundertheinfluenceofalcoho l,drugs,or medication . Watchwhat you

are doing; use common sense.

Wear hearing protection.

S

Never start or run inside a closed room or

S

build ing. Breathing exhaust fum es can kill.

Keep handles free of oil and fuel.

S

UNIT / MAINTENANCESAFETY

Disconnect the spark plug before performing

S

maintenance except carburetor adjustments.

Look for and replace damaged or loose parts

S

before each use. Look for and repair fuel

leaks before use. Keep in good working

cond ition.

Replace trimmer head partsthatare chipped,

S

cracked, broken, or d amaged in any other

way before using the unit.

Maintain unit according to recommended pro-

S

cedures. Keep cutting line at proper length.

Use only 0.080!(2 mm) diameter Weed

S

Eater"brand line. Never use wire, rope,

string, etc.

Install required shield properly be fore using

S

the unit. Use only specified trimmer head;

makesureit isproperlyinsta lledandsecurely

fastened.

Make sure unit is assembled correctly as

S

shown in this manual.

Make carburetor adjustments with lower end

S

supported to prevent line from contacting any

object.

Keep others away when making carburetor

S

adjustments.

Use only recommended Weed Eater"ac-

S

cessories and replacement parts.

Have all maintenance and service not ex-

S

plained in this manual performedby an authorized service dealer.

FUEL SAFETY

Mix and pour fuel outdoors.

S

Keep away from sparks or flames.

S

Use a container approved for fuel.

S

Do not smoke or allow smoking near fuel or

S

the unit.

Avo idspillingfuel oroil. Wipeupallfuel spills.

S

Move at least 10 feet (3 meters) away from

S

fueling site before starting engine.

Stop engine and allow to cool before remov-

S

ingfuel cap.

Always store gasoline in a container ap-

S

proved for flam mable liquids.

2

Page 3

CUTTINGSAFETY

WARNING:

each use. Remove objects (rocks, broken

glass, nails, wire, etc.) which can be thrown

by or become entangled in line. Hard objects

can damagethetrimmer headand be thrown

causing serious injury.

Use only for trimming, scalping, mowing and

S

sweeping. Do not use for edging, pruning or

hedge trimming.

Keep firm footing and balance. Do not over-

S

reach.

Keep all parts of your body away from muffler

S

and spinning line. Keep engine below waist

level.A hotmufflercancause serious burns.

Cut from your right to your left. Cutting onleft

S

side of the shield will throw debris away from

the operator.

Use only in daylight or good artificial light.

S

Use only for jobs explained in this manual.

S

TRANSPORTINGAND STORAGE

Allow engine to cool; secure unit before stor-

S

ing or transporting in vehicle.

Empty the fuel tank before storing or trans-

S

porting theunit.Useupfuel left inthecarburetorbystartingtheengine and letting it run until

it stops.

Store unit and fuel in area where fuel vapors

S

cannotreachsparks oropenflames from water heaters, electric motors or switches, furnaces, etc.

Storeunitsolinelimiter blade cannotacciden-

S

tally cause injury.The unit can behung bythe

shaft.

Store unit out of reach of children.

S

Inspect the area before

ASSEMBLY

SAFETYNOTICE:

through prolonged use of gasoline powered

handtools could cause bloodvessel ornerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or abnormal swellings. Prolonged use in cold

weatherhasbeenlinkedto bloodvessel damagein otherwisehealthypeople. Ifsymptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinuethe useof this tooland seekmedical attention. An anti--vibrationsystem does

not guarantee the avoidance of these problems. Users who operate power tools on a

continual and regular basis must monitor

closely their physical conditionandthecondition of this tool.

SPECIALNOTICE:

with a temperaturelimiting muffler and spark

arresting screen which meets the requirementsof California Codes4442 and4443. All

U.S. forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey, Oregon, and Washington require by law that

many internal combustion engines be

equippedwithasparkarresting screen. Ifyou

operateinalocalewheresuchregulations exist, youarelegallyresponsibleformaintaining

theoperatingconditionof theseparts. Failure

to do so is a violation of the law. For normal

homeowneruse,themufflerandsparkarresting screen will not require any service. After

50 hours of use, we recommend that your

mufflerbeservicedorreplacedby yourauthorized service dealer.

Exposure tovibrations

This unit is equipped

WARNING:

repeatall stepstoensure yourunit is properly

assembled and all fasteners are secure.

Examine parts fordamage. Do not use damaged parts.

If you need assistance or find parts

NOTE:

missing or damaged, call 1-800-554-6723.

It is normal for the fuel filter to rattle in the

empty fuel tank.

Findingfuelor oil residueon muffler is normal

due to carburetor adjustments and testing

done by the manufacturer.

If received assembled,

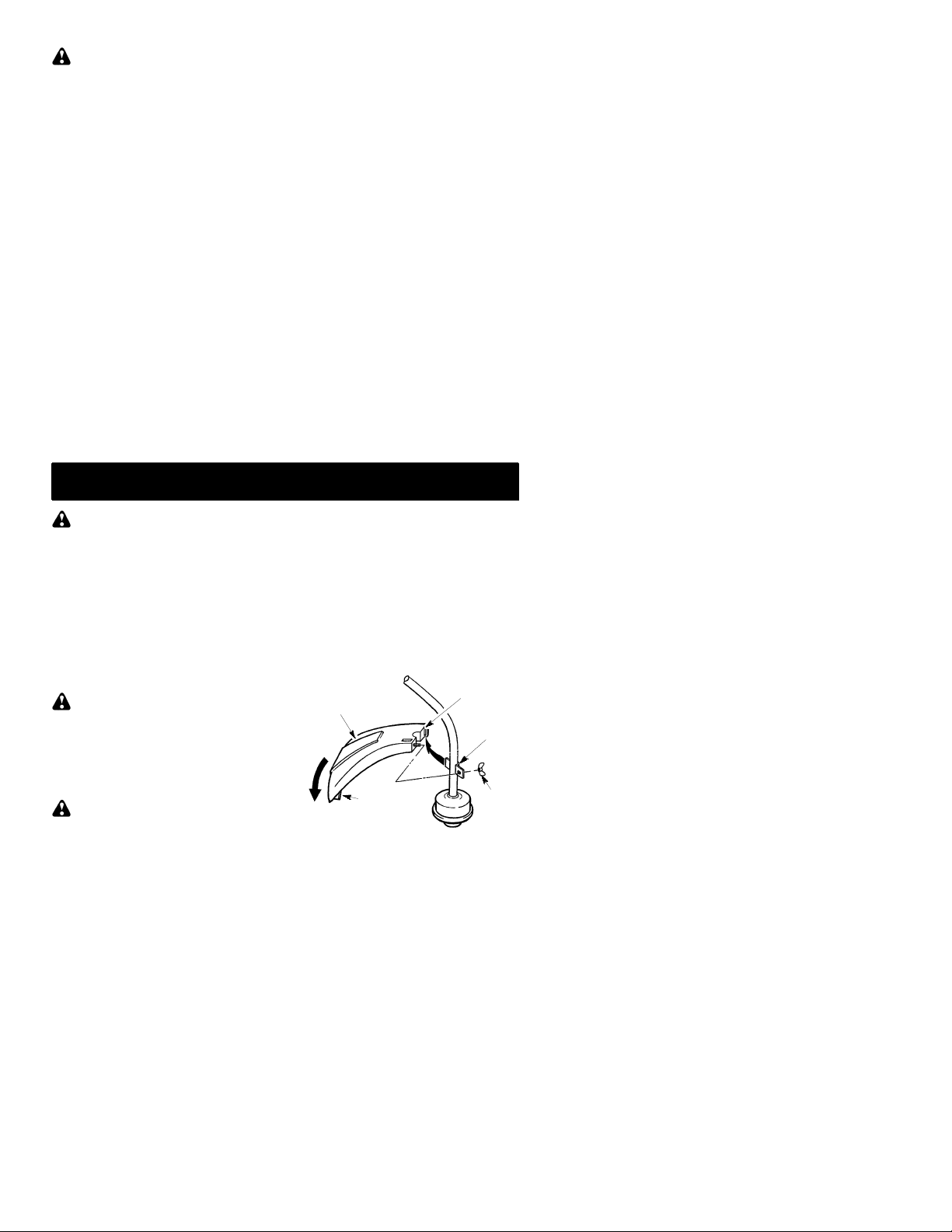

ADJUSTINGTHE HANDLE

WARNING:

handle,be sureit remains above the safety label

and below the mark or arrow on the shaft.

1. Loosen wing nut on handle.

2. Rotate thehandleonthe shaft to an upright

position; retighten wing nut.

Whenadjust ing theassist

ATTACHING SHIELD

WARNING:

erly installed. The shield provides partial protection from the risk of thrown objects to theopera-

The shield must be prop-

tor andothers andis equipped with a line limiter

blade which cuts excess line to the proper

length. The line limiter blade (on underside of

shield) is sharp and can cut you.

For proper orientation of shield, see KNOW

YOUR TRIMME R illustratio n in OPERATION

section.

1. Remove wing nut from shield.

2. In sert bracket into slot as shown.

3. Pivot shielduntil bolt passes through holein

bracket.

4. Securely tighten wing nut onto bolt.

Shield

PIVOT

Line Limiter

Blade

Slot

Bracket

Wing

Nut

3

Page 4

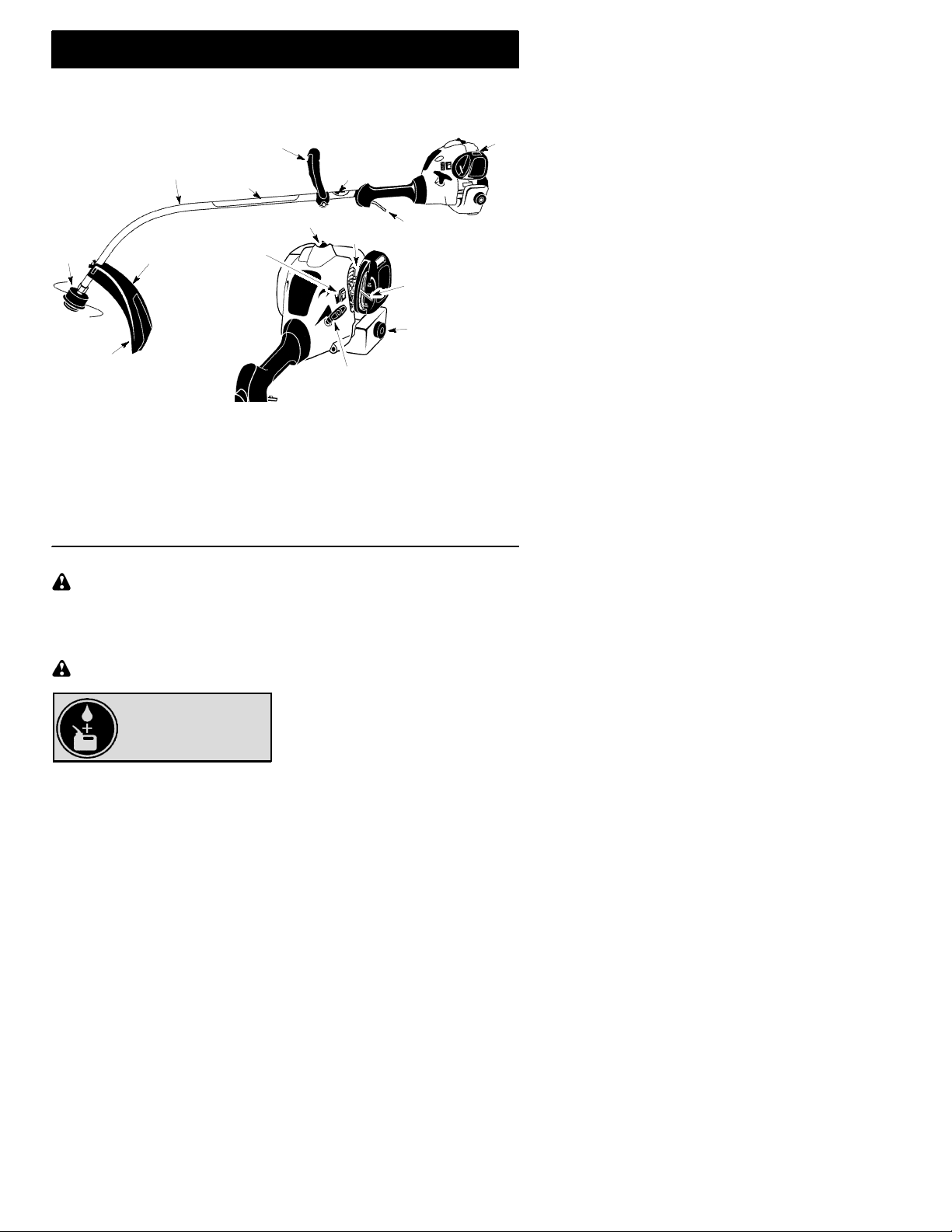

OPERATION

KNOW YOUR TRIMMER

READTHIS INSTRUCTIONMANUAL ANDSAFETYRULES BEFOREOPERATINGYOURUNIT.

Comp are the illustrationswith yourunit tofamiliarizeyourselfwith thelocationof thevariouscon trols

and adjustments. Save this manual for future reference.

Muffler

Shaft

Assist Handle

Safety Label

Shaft Mark

or Arrow

Spark Plug

Trimmer

Head

Line Limiter

Blade

STOP SWITCH

The STOP switch is usedto stopthe engine. To

stop the engine, push andhold theswitch in the

STOP position until the engine stops.

PRIMERBULB

ThePRIMER BULBremoves airfromthecarburetorand fuel lines and fills them with fuel.

This allows you tostart the engine with fewer

pulls on the starter rope. Activate the primer

bulb by pressing it and allowing it to return to

its original form.

Shield

STOP

Switch

BEFORE STARTINGENGINE

WARNING:

information in the safety rules before you

begin. If you do not understand the safety

rules, do not attempt to fuel your unit. Call

1-800-554-6723.

Besureto read thefuel

FUELING ENGINE

WARNING:

when refueling.

Removefuel cap slowly

HELPFUL TIP

Toobtainthe correct oilmix

ratio, pour 3.2 ounces of

2--cycle synthetic oil into

This engine is certified to operate on unleaded

gasoline. Before operation, gasoline must be

mixed with a go od quality synthetic 2-cycle

air-cooled engine oil designed to be mixed at a

ratio of 40:1. Poulan/Weed Eater brand

synthetic oil is recommended.Mix gasoline and

oilat ara tioof 40:1. A40:1 ratiois obtainedby

one gallon of fresh gas.

Primer

Bulb

Starter Handle

Throttle

Trigger

Choke Lever

Fuel Mix Fill Cap

CHOKE

The CHOKE helps to supply fuel to the engine

to aid in cold starting. Activate the choke by

moving the choke lever to the FULL CHOKE

position.Aftertheengineattempts tostart,move

the choke lever to the HALF CHOKE position.

Once engine has started, move the chokelever

to the RUN position.

mixing 3.2 ounces (95ml)ofoil with1gallon(4

liter s ) of unleaded gasoline. DO NOT USE

aut omotive oil or m arine oil. The se oils will

cause enginedamage.Whenmixing fuel, follow

instructions printed on container. Once oil is

addedto gasoline, shake containermomentarily

to a ssure that the fuel is thoroughly mixed.

Alwaysread andfollow thesafetyrules rela ting

to fuel before fueling your unit.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol)can attractmoisturewhichleads to

separationandformationofacids duringstorage. Acidic gas can damage the fuel system

ofan enginewhile in storage. Toavoidengine

problems,emptythefuel system beforestoragefor 30 days or longer.Drainthegas tank,

startthe engineand letit rununtilthefuellines

andcarburetorare empty.Use freshfuel next

season. Never use engine or carburetorcleaner products in the fuel tank or permanent damagemayoccur. SeetheSTORAGE sectionfor

additional information.

4

Page 5

HELPFUL TIP

If your engine switch reads

“push to stop”, it is always

in the ON position.

HOW TO STOP YOUR UNIT

To stoptheengine,pushandholdtheSTOP

S

switch intheSTOPpositionuntilthe engine

stops.

If engine does notstop, move choke to the

S

FULL CHOKE position.

HOW TO STARTYOUR UNIT

WARNING:

turnwhilestartingthe engine. Avoid anycontact with the muffler.A hot muffler can cause

serious burns.

The trimmer head will

HELPFUL TIP

If your engine still does not

start after following these

instructions, please call

1--800--554--6723.

STARTINGA COLD ENGINE (or a

warm engine after running out of

fuel)

Starting Position

1. Setunitonaflatsurface.

2. Slowly press the primer bulb 6 times.

3. Move choke lever to the FULL CHOKE

position.

4. Squeeze the throttle trigger fully and hold

through

all remaining steps.

Primer Bulb

Choke

Lever

5. Pull starter rope handle sharply until engine

sounds as if it is trying to start, but do not

pullropemorethan6times.

6. As soonasenginesoundsas if it is trying to

start, move choke lever to HALF CHOKE

posit ion.

7. Pull starter rope sharply until engine runs,

but no more than 6 pulls.

If theengine doesn’t start after6

NOTE:

pulls (at the HALF CHOKE position),

move the choke lever to the FULL

CHOKE position and press the primer

bulb 6 times. Squeeze and hold the

throttle trigger and pull the starter rope2

more times. Move thechokelever to the

HALF CHOKEpositionandpull thestarterropeuntil the engineruns,but nomore

than 6 pulls. If the engine still doesn’t

start, it is probably flooded. Proceed to

STARTING A FLOODED ENGINE.

8. Oncetheenginestarts,allowittorun 10second s, then move the choke lever to the

RUN position. Allow the unit to run for 30

moresecond sat RUN beforereleasingthe

throttle trigger .

If engine dies with the choke le-

NOTE:

ver in the RUN position, move thechoke

lever to the HALF CHOKE position and

pull the rope until engine runs, but no

more than 6 pulls.

STARTINGA WARMENGINE

1. Move thechokelever tothe HALF CHOKE

posit ion.

2. Squeeze and hold the throttle trigger.Keep

throttle trigger fully squeezed until the engine runs smoothly.

3. Pull starter rope sharply until engine runs,

but no more than 6 pulls.

4. Allow engine to run 15 seconds, then move

the choke lever to RUN.

If engine has not started, pull starter

NOTE:

rope5morepulls. Ifenginestill doesnot run,it

is probably flooded.

ST ARTING A FLOODED ENGINE

Flooded engines can be started by placing the

choke lever in the RUN position; then, pull the

rope to clear the engine of excess fuel. This

could require pulling the starter handle many

times depending on how badly the unit is

flooded. If the unit still doesn’t start, refer to

TROUBLESHOOTING TABLE or call

1-800-554-6723.

Starter Handle

5

Page 6

OPERATING INSTRUCTIONS

It is recommended that the engine not be

operated for longer than 1 minute at full

throttle.

OPERA TINGPOSITION

ALWAYS WEAR:

Long pants

Heavy shoes

Cut from your right to your left.

Eye protection

WARNING:

diameter line. Other sizes of line will not advanceproperlyandwill resultin impropercuttinghead functionorcancauseseriousinjury.

Do not use other materials such as wire,

string, rope, etc. Wire can break off during

cutting and become adangerous missile that

can cause serious injury.

Use only 0.080!(2mm)

CUTTINGMETHODS

WARNING:

anddonotcrowdthe linewhen cuttingaround

hardobjects (rock, gravel, fence posts, etc.),

whichcan damagethetrimmerhead,become

entangled in the line, or be thrown causing a

serious hazard.

The tip of the line does the cutting. You will

S

achieve the best performance and minimum line wearbynot crowding the line into

the cutting area. Theright andwrongways

are shown below.

Tip of the Line

Does The Cutting

Use minimum speed

Line Crowded Into

Work Area

WARNING:

tion. Never lean over the trimmer head.

Rocks ordebris canricochet orbe throwninto

eyes and face and cause blindness or other

serious injury.

Do not run the engine at a higher speed than

necessary. The cutting line will cut efficien tly

when the engine is run at less than full throttle.

At lower speeds, there is less engine noise and

vibration.Th ecuttinglinewill lastlongerandwill

be less likely to “weld” onto the spool.

Always release the throttle trigger and allow the

engine to return to idle speed when not cutting.

To stop engine:

Release the throttletrigger.

S

Push and hold the STOP switch in the

S

STOP position until the engine stops.

TRIMMERLINEADVANCE

Thetrimmerlinewill advanceapproximately2

inches (5 cm) each time the bottom of the

trimmer headis tappedonthe groundwith the

engine running at full throttle.

The most eff icient line length is the maximum

length allowed by the line limiter.Always keep

the shield in place when the tool is being operated.

To advance line:

Operate the engine at full throttle.

S

Holdthetrimmer headparallel toandabove

S

the grassy area.

Tap the bottom of the trimmer head lightly

S

on the ground one time. Approximately 2

inches (5 cm) of line will be advancedwith

each tap.

Always tap the trimmer head on a grassy

area. Tappingon surfaces such as concrete

or asphalt can cause excessive wear to the

trimmer head.

If the line is worn down to 2 inches (5 cm) or

less,morethanonetapwill berequired toobtain the most efficient line length.

Alwaysweareyeprotec-

Right Wrong

The line will easily remove grass and

S

weedsfromaroundwalls, fences,trees and

flower beds, but it also can cut the tender

bark oftrees orshrubs andscar fences. To

help avoid damage especially to delicate

vegetation or trees with tender bark,

shorten line to 4--5 inches (10--13cm) and

use at less than full throttle.

For trimming or scalping, use less than full

S

throttle to increase line life and decrease

head wear,especially:

During light duty cutting.

S

Near objects around which the line can

S

wrap such as small posts, trees or fence

wire.

Formowingor sweeping,use full throttlefor

S

a good clean job.

TRIMMING

headabout 3inches(8cm) above theground

andat anangle.Allowonlythe tipof thelineto

make contact. Do not force trimmer line into

work area.

Trimming

3 inches (8 cm)

above ground

SCALPING

moves unwanted vegetationdown to the

ground. Hold the bottom of the trimmer head

about 3 inches (8 cm) above the ground and

atanangle.Allowthetipofthe lineto strikethe

groundaround trees,posts,monuments,etc.

This technique increases line wear.

-- Hold the bottom of the trimmer

-- The scalping technique re-

6

Page 7

Scalping

MOWING

in places conventional lawn mowers cannot

reach. In the mowing position, keep the line

parallel to the ground. Avoid pressing the

head into the ground as this can scalp the

ground and damage the tool.

Mowing

-- Y ourtrimmer is ideal for mowing

MAINTENANCE

WARNING:

plug before performing maintenance except

for carburetor adjustments.

If any dealer other than an authorized

service dealer performs work on the

product, Electrolux Home Products,

Inc., may not pay forrepairs underwar-

ranty. Itis yourresponsibility tomaintain

and perform general maintenance.

CHECK FOR LOOSE

FASTENERSAND PARTS

Spark Plug Boot

S

Air Filter

S

Housing Screws

S

Assist Handle Screws

S

Debris Shield

S

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for replacement of damaged or worn parts.

STOPSwitch -- Ensure STOPswitch func-

S

tions properly by pushing and holding the

switch in theSTOP position.Makesureen-

gine stops. Restart engine and continue.

Fuel Tank -- Discontinue use of unit if fuel

S

tank shows signs of damage or leaks.

Debris Shield -- Discontinue use of unit if

S

debris shield is damaged.

INSPECTAND CLEAN UNIT AND

LABELS

After each u se, inspect complete un it for

S

loose or damaged parts. Clean the unit and

labels using a damp cloth with a mild deter-

gent.

Wipe off unit with a clean dry cloth.

S

Disconnect the spark

HELPFUL TIP

IMPORTANT:

repairs other than the recommended maintenance

described in the instruction

manual performed by an

authorized service dealer.

Have all

SWEEPING

ing line can be used for a quick and easy

clean up. Keep the line parallel to and above

the surfaces being swept and move the tool

from side to side.

Sweeping

CLEAN AIR FILTER

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the air filter cover and the area

2. Open air filter cover by pushing button

NOTE:

producingharmfulevaporativeemissions, do

not clean filter in gasoline or otherflammable

solvent.

3. Washthe filter in soap and water.

4. Allow filter to dry.

5. Replace air filter and close cover.

-- Thefanningaction oftherotat-

around it to keep dirt from falling into the

carburetor chamber when the cover is

opened.

(see illustration). Remove air filter.

To avoid creating a fire hazard or

Button

Air Filter

Air Filter Cover

MUFFLER AND SPARKARRESTING SCREEN

WARNING:

uct contains chemicals known to the State of

California to cause cancer.

As yourunitisused,carbon depositsbuildup

on the muffler and spark arresting screen.

For normal homeowner use, however, the

mufflerandspark arrestingscreenwill not require any service. After 50 hours of use, we

recommend that your muffler be serviced or

replaced by your authorized service dealer.

The muffler on this prod-

7

Page 8

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Set

spark plug gap at 0.025 inch (0.6 mm). Ignition timing is fixed and nonadjustable.

SERVICE AND ADJUSTMENTS

LINE REPLACEMENT

1. Remove spool by firmly pulling on tap

button.

2. Clean entire surface of hub and spool.

3. Replace with a pre-wound spool, or cut two

leng ths of

ameter Weed Eaterrbrand line.

WARNING:

string,etc.,which canbreak offandbecomea

dangerous missile.

4. Insertends of the lines about 1/2 inch (1

cm) into the small holes on the inside of

spool.

Spool

Line exit holes

feet of 0.080!(2 mm) di-

12-1/2

Never use wire, rope,

Line in Notch

Small

Holes

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 inch

(19 mm) socket wrench.

4. Reinstall the spark plug boot.

CARBURETOR ADJUSTMENT

WARNING:

making idle speedadjustments. Thetrimmer

head will be spinning during this procedure.

Wearyourprotectiveequipmentandobserve

all safety precautions.

The carburetor has been carefully set at the

factory.Adjustments maybenecessaryifyou

notice any of the following conditions:

Engine will not idle when the throttle is re-

S

leased.

Make adjustments with the unit supported so

the cutting attachment is off the ground and

will not make contact with any object. Hold

theunit byhand whilerunningandmaking adjustments. Keepall parts of your body away

from the cutting attachment and muffler.

Idle Speed Adjustment

Allow enginetoidle.Adjustspeed untilengine

runs without stalling (idle speed too slow).

Turn idle speed screw clockwise to in-

S

creaseenginespeedifenginestalls ordies.

Turnidle speedscrew counterclockwise to

S

decrease engine speed.

Keepothersaway when

Idle Speed Screw

Hub

5. Wind the line evenly and tightly onto the

spool. Wind in the direction of the arrows

found on the spool.

6. Pushthe lines into thenotches, leaving 3

to 5 inches (7 -- 12 cm) unwound.

7. Insert the lines into the the exit holes in

the hubas shownin the illustration.

8. Align thenotches with the line exit holes.

9. Push spool into hub until it snaps into

place.

10. Pullthe lines extendingoutside ofthehub

to release the lines from the notches.

Line in Notch

Air Filter Cover

Ifyou requirefurtherassistance orareunsure

about performing this procedure, contact an

authorized service dealer or call

1--800--554--6723.

8

Page 9

STORAGE

WARNING:

steps after each use:

Allow engine to cool, and secure the unit

S

before storing or transporting.

Store unit and fuel in a well ventilated area

S

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

Store unit with all guards in place. Position

S

unit so that any sharp object cannot accidentally cause injury.

Store unit and fuel well out of the

S

children.

SEASONALSTORAGE

Prepareunit for storage atend of season orif

it will notbeusedfor 30 days or more.

If your unitis to be storedfor a period of time:

Clean the entire unit before lengthy storage.

S

Store in a clean dry area.

S

Lightly oil external metal surfaces.

S

FUEL SYSTEM

Under FUELING ENGINE in the OPERATIONsectionof thismanual,seemessagelabeled IMPORTANTregarding the use of gasohol in your engine.

Fuel stabilizer is an acceptable alternativein

minimizing the formation of fuelgum deposits

during storage. Add stabilizer to the gasoline

in the fuel tank or fuel storage container.Follow the mix instructions found on stabilizer

container.Run engineat least 5 minutesafter

adding stabilizer.

Perform the following

reach of

HELPFUL TIP

During storageof yourgas/

oilmixture,theoil will separate from the gas.

We recommend that you

shake the gas can weekly

toinsureproper blendingof

the gas and oil.

ENGINE

Remove spark plugand pour1 teaspoonof

S

40:1,2-cycle engine oil (aircooled)through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

Replacesparkplugwith new oneof recom-

S

mended type and heat range.

Clean air filter.

S

Check entire unit for loose screws, nuts,

S

and bolts. Replace any damaged, broken,

or worn parts.

At the beginning of the next season, use

S

only freshfuel havingthepropergasolineto

oil ratio.

OTHER

Do not store gasoline from one season to

S

another.

Replaceyourgasoline canifit startstorust.

S

9

Page 10

TROUBLESHOOTINGTABLE

WARNING:

recommended remedies below except remedies that require operation of the unit.

Alwaysstopunitanddisconnectsparkplugbeforeperformingall ofthe

TROUBLE CAUSE REMEDY

Enginewill not

start.

Enginewill

not idle

properly.

Enginewill not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Engine runs

hot.

1. Engine flooded.

2. Fuel tank empty.

3. Spark plug not firing.

4. Fuel not reaching

carburetor.

5. Carburetor requires

adjustment.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compressionlow.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compressionlow.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

1. See “Starting a Flooded Engine in

Operation Section.

2. Fill tank with correct fuel mixture.

3. Install new spark plug.

4. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

5. Contact an authorized service dealer.

1. See “Carburetor Adjustment” in

Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Clean or replace plug

and regap.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

5. Contact an authorized service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer.

1. See “Fueling Engine” in Operation

section.

2. Replace with correct spark plug.

3. Contact an authorized service dealer

.

4. Contact an authorized service dealer.

10

Page 11

LIMITED WARRANTY

ELECTROLUX HOME PRODUCTS, INC.,

warrantsto the original purchaser thateach new

WeedEater

is free from defects in material and

workmanship and agrees to repair or replace

under this warranty any defective gasoline

product or attachment as follows from the

original date of purchase.

2 YEARS

household purposes.

60 DAYS

commercial, professional, or income producing

purposes.

30 DAYS

purposes.

This warranty is not transferable and does not

cover damage or liability caused by impro per

handling, improper maintenance, or the use of

accessories and/orattachments notspecifically

recommended by

PRODUCTS, INC.,

this warranty does not cover tune--ups, spark

plug s, filters, starte r ropes, starter sprin gs,

cutting line, or rotating head parts that will wear

and require replacement with reasonable use

during the warranty period. This warranty does

not cover predelivery setup or normal

adjustments expla inedin theinstructionmanual.

brandgasoline tool orattachment

r

-- Parts and Labor, when used for

-- Parts and Labor, when used for

-- Parts and Labor, if used for rental

ELECTROLUX HOME

for this tool. Additionally,

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY HAVE

OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE

EXPRESSLYSTIPULATED HEREIN.

SOME STA TES DO NOT ALLOW

LIMITATIONS ON HOW LONG ANIMPLIED

WARRANTY LASTS OR THE EXCLUSION

OR LIMITATIONS OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS OR EXCLUSION

MAY NOT APPLYTOYOU.

The policy of

PRODUCTS, INC.,

improve its products. Therefore,

ELECTROLUX HOME PRODUCTS, INC.,

reserves the right to change, modify, or

discontinue models, designs, specifications,

and accessories of all products at any time

without notice or obligation to any purchaser.

U.S. EPA/CALIFORNIA/ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGA-

The U.S. Environmental Protection

TIONS:

Agency, California Air Resources Board, Environment Canada and ELECTROLUX HOME

PRODUCTS, INC., are pleased to explain the

emissionscontro lsystemwarrantyonyouryear

2002--2004 small off--road engine. In California,

all small off--road engines must be designed,

built, and equipped to meet the State’s stringent

anti- -smog standards. ELECTROLUX HOME

PRODUCTS, INC., must warrant the emission

control system on yoursmall off--roadenginefor

the periods of time listed below provided there

has been no abuse, neglect, or improper maintenance of your small off--road engine. Your

emissioncontrol system includes parts such as

the carburetor and the ignition system. Wherea

warrantable condition exists, ELECTROLUX

HOMEPRODUCTS,INC., will repairyoursmall

off--road engine engine at no cost to you. Expenses coveredunderwarranty includediagnosis, parts and labor.

WARRANTY COVERAGE:

related part on your eng ine (as listed under

EmissionsControl Warranty PartsList)isdefective or a defect in the materials or workmanship

ofthe enginecauses thefailure ofsuchan emission related part, the part will be repaired or replaced by ELECTROLUX HOME PRODUCTS, INC.

RESPONSIBILITIES:

gine engine owner, you are responsible for the

performance of the required maintenance listed

MANUFACTU RER’S

If any emissions

OWNER’S WARRANTY

As thesmall off--roaden-

in your instruction manual. ELECTROLUX

HOME PRODUCTS, INC., recommends that

you retain all receipts covering maintenance on

your small off- -road engine, but ELECTROLUX

HOME PRODUCTS, INC., cannot deny warranty solely for the lack of receipts or for your

failure to ensure the performance of all scheduled maintenance. As the small off--road engine engine owner, you should be aware that

ELECTROLUX HOME PRODUCTS, INC.,

may deny you warranty coverage if your small

off--road engine engine or a part of it has failed

due to abuse, neglect, improper maintenance,

unapproved modifications, or the use of parts

not made or approved by the original equipment

manufacturer. Youareresponsible for presentingyoursmalloff--roadengineto anELEC TROLUX HOME PRODUCTS, INC., autho rizedrepair center as soon as a problem exists.

Warrant yrepa irs shouldbe completedin a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rightsandresponsibilities,you sho uld contact your nearest authorized service center or

call ELECTROLUXHOME PRODUCTS, INC.,

at 1--800--554--6723.

MENCEMENTDATE:

gins on the date the small off--road engine is

purchased.

warranty shall be for a period of two years from

the initial date of purchase.

ERED: REP AIR OR REPLACEMENT OF

PART S.

LENGTH OF COVERAGE:

Repair or replacement of any war-

11

ELECTROLUX HOME

is to continuously

WARRANTY COM-

The warranty period be-

This

WHAT IS COV-

Page 12

rantedpart will beperformedat no charge to the

owner at an approved ELECTROLUX HOME

PRODUCTS,INC.,servicingcenter.Ifyou

have any questions regarding your warranty

righ ts and responsibilities, you should contact

your nearest authorized service center or call

ELECTROLUX HOME PRODUCTS, INC., at

1--800--554--6723.

warranted part which is not scheduled for replacement as requiredmaintenance,or whichis

scheduled only for regular inspection to the effect of “repair or replace as necessary” shall be

warrantedfor 2years. Anywarranted part which

is scheduled for replacement as required maintenanceshall be warrantedfor theperiodof time

up to the first scheduled replacement point for

that part.

charged for diagnostic labor which leads to the

determination that a warranted part is defective

if the diagnostic work is performed at an approved ELECTROLUX HOME PRODUCTS,

INC., servicing center .

DAMAGES:

UCTS, INC., may beliable for damagesto other

engine components caused by the failure of a

warranted part still under warranty.

NOT COVERED

neglect, or improper maintenance are not covered.

ADD--ON OR MODIFIED PARTS:

The information on the product label indicates to which standard your engine is certified.

Example: (Year) EPA Phase I or Phase II and/or CALIFORNIA.

WARRANTYPERIOD:

DIAGNOSIS:

The owner shall not be

ELECTROLUX HOME PROD-

CONSEQUENTIAL

: All failures caused by abuse,

WHAT IS

use of add--on or modified parts can be grounds

for disallowin g a warra nty c laim. ELECTROLUX HOME PRODUCTS, INC., is not liable to

cover failures of warranted parts caused by the

use of add--on or modified parts.

ACLAIM:

your warranty rights and respo nsibilities, you

Any

should contact your nearest authorized service

center or call ELECTROLUX HOME PRODUCTS, INC., at 1--800--554--6723.

GET WARRANTY SERVICE:

vices or repairs shall be provided at all ELECTROLUX HOME PRODUCTS, INC., service

centers. Call: 1--800- -554--6723.

NANCE, REPLACEMENT AND REPAI R OF

EMISSION RELATED PARTS

TROLUXHOME PRODUCTS, INC.,approved

replacement part used in the performance of

any warranty maintenance or repair on emission related parts will be provided without

charge tothe owner if thepart is underwarranty.

EMISSION CONTROL WARRANTY P ARTS

LIST :

(covered up to maintenance schedule), Ignition

Module, Muffler including catalyst.

NANCE STATEMENT:

ble for the performance of all required maintenance as defined in the instruction manual.

The

If you have any questions regarding

Carburetor, Ignition System: Spark Plug

Theowneris resp onsi-

HOW TOFILE

WHERETO

Warranty ser-

: Any ELEC-

MAINTE-

MAINTE-

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

12

Loading...

Loading...