Page 1

Trademark

R

Instruction Manual

Manual de Instrucciones

Manuel d’Instructions

BV200 / BV1650 / BV1800

BV1850 / BV2000

LE Series

IMPORTANT MANUAL -- Do not throw away

MANUAL IMPORTANTE -- No lo descarte

MANUEL IMPORTANT -- À Conserver

ENGLISH

ESPAÑOL

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en lesiones

graves.

AVERTISSEMENT:

Veuillez lire le manuel d’instructions et bien respecter tous les

avertissements et toutes les instructions de sécurité. Tout défaut

de le faire pourrait entraîner des blessures graves.

Electrolux Home Products, Inc.

104 Warren Road

Augusta, GA 30907

CopyrightE2004 ElectroluxHome Products, Inc.

530163806

2/4/04

FRANÇAIS

Page 2

SAFETY RULES

WARNING:

Safety Rules and Precautions can result in

serious injury.

KNOW YOURUNIT

Readyour instructionmanualcarefullyuntil

S

you completely understand and canfollow

all warnings andsafety rulesbeforeoperating the unit.

Restrict unit to users who understand and

D

will follow all warnings and safety rules in

this manual.

WARNING:

ing unit. Remove all debris and hard objects

such as rocks, gla ss , wire, etc. that can ricochet, be thrown, or otherwise cause injury or

damage during operation.

Use your unit as a blower for:

Sweeping debris or grass clippings from

D

drivew ays, sidewalks, patio s,etc.

Blowing grass clippings, straw,or leaves into

D

piles, around joints, or betwee nbricks.

Use your unit as a vacuum for:

Picking up dry material such as leaves,

D

grass, small twigs, and bits of paper.

For best results during vacuum use, operate

D

your unit at high speed.

Moveslowly back and forthover the mate-

D

rial as you vacuum. Avoid forcing the unit

intoapileofdebrisas this canclog theunit.

Keep the vacuum tube about an inch above

D

thegroundforbestresults.

PLAN AHEAD

Always wear eye protection when operat-

D

ing, servicing, or performing maintenance

on unit. Wearing eye protectionwill helpto

preventrocksor debris from being blownor

ricocheting into eyes and face which can

result in blindness and/or serious injury.

Eye protection should be marked Z87.

Always wear foot protection. Do not go

D

barefoot or wear sandals.

Always wear respirator orface mask when

D

working with unit in dusty environments.

Secure hair above shoulder length. Secure

D

or remove jewelry, loose clothing, or clothing with loosely hanging straps, ties, tassels, etc. They can be caught in moving

parts.

Donotoperateunit whenyouaretired,ill, up-

D

set, or if you are under the influence of alcohol, drugs, or medication.

Keep children, bystanders, and animals

D

away from work area a minimum of 30 feet

(10meters) when starting or operatingunit.

Do not point the blower nozzle in the direction of people or pets.

HANDLEFUEL WITH CAUTION,IT IS

HIGHLY FLAMMABLE

Eliminate all sources of sparksor flame(in-

D

cluding smoking,open flames, or work that

cancausesparks)intheareaswherefuelis

mixed, poured, or stored.

Failure to follow all

Inspect area before start-

Mix and pour fuel in an outdoor area; store

D

fuel in a cool, dry,well ventilated place; use

an approved, marked container for all fuel

purposes.

Do not smoke while handling fuel or while

D

operating the unit.

Make sure the unit is properly assembled

D

and in good operating condition.

Do not fill fuel tank while engine is hot or

D

running.

Avoidspilling fuel or oil. Wipe up fuel spills

D

before starting engine.

Moveatleast 10 feet (3 meters)awayfrom

D

fuel and fueling site before starting engine.

Always store gasoline in a container ap-

D

proved for flammable liquids.

OPERATE YOUR UNIT SAFELY

WARNING:

opening the vacuum inlet door. The engine

must be stopped and the impeller blades no

longerturningtoavoid serious injury fromthe

rotating blades.

Inspect unit before each use for worn,

D

loose, missing, or damaged parts. Do not

use until unit is in proper working order.

Keep outside surfaces free of oil and fuel.

D

Never start or run engine inside a closed

D

room, building or other unventilated area.

Breathing exhaust fumes can kill.

To avoid static electricity shock, do not

D

wear rubber gloves or any other insulated

gloves while operating unit.

Do not set unit on any surface except a

D

clean, hard area while engine is running.

Debris such as gravel, sand, dust, grass,

etc.couldbe picked up by theair intakeand

thrown out through discharge opening,

damagingunit, property,or causing serious

injury to bystanders or operator.

Avoiddangerousenvironments.Donotuse

D

in unventilated areas or where explosive

vapors or carbon monoxide build up could

be present.

Do notoverreach or use from unstable sur-

D

faces such as ladders,trees, steep slopes,

rooftops,etc. Keepfirm footing andbalance

at all times.

Never place objects inside the blower

D

tubes; always direct the blowing debris

awayfrom people,animals,glass,andsolid

objects such as trees, automobiles, walls,

etc.Theforceofaircancauserocks, dirt,or

sticks tobethrownor toricochet which can

hurt people or animals, break glass, or

cause other damage.

Never run unit without the proper equip-

D

ment attached. When using your unit as a

blower,always install blower tubes. When

usingyour unit as avacuum, always install

vacuumtubesand vacuum bagassembly.

Makesurevacuum bagassembly is completely zipped.

Check air intake opening, blower tubes,

D

vacuum tubes, and elbow tubefrequently,

always with engine stopped and spark

Stop the engine before

-- 2 --

Page 3

plug disconnected. Keep vents and discharge tubes free of debris which can accumulate and restrict proper air flow.

Never place any object in the air intake

D

opening as this could restrict proper air flow

and cause damage to the unit.

Never use for spreading chemicals, fertil-

D

izers, or othersubstanceswhich may contain toxic materials.

To avoid spreading fire, do not use near

D

leaf or brush fires, fireplaces, barbecue

pits, ashtrays, etc.

Use only for jobs explainedin this manual.

D

MAINTAIN YOUR UNIT PROPERLY

Have all maintenance other than the rec-

D

ommendedproceduresdescribedin theinstruction manual performed by an authorized service dealer.

Disconnect spark plug before performing

D

maintenance except for carburetor adjustments.

Use only recommended Weed Eater!re-

D

placement parts; use of any other parts

may void yourwarrantyandcause damage

to your unit.

Empty fuel tank before storing the unit. Use

D

upfuel left incarburetor by startingengineand

letting it run until it stops.

Do not use any accessory or attachment

D

other than those recommended by manufacturer for use with your unit.

Donotstore the unit or fuel in a closedarea

D

where fuel vapors can reach sparks or an

openflame from hotwaterheaters,electric

motors or switches, furnaces, etc.

Store in a dry areaout of reachof children.

D

ASSEMBLY

SPECIAL NOTICE:

tions throughprolongeduse of gasoline powered hand tools could cause blood vessel or

nerve damage in the fingers, hands, and

joints of people prone to circulation disorders

or abnormal swelling. Prolonged use in cold

weatherhasbeenlinked toblood vessel damagein otherwise healthypeople.Ifsymptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek

medical attention. An antivibration system

does not guarantee the avoidance of these

problems. Users who operatepower tools on

a continual and regular basis must monitor

closely their physical condition andthecondi-

Exposure to vibra-

tion of this tool.

SPECIAL NOTICE:

with a temperaturelimiting muffler and spark

arresting screen which meets the requirementsof CaliforniaCodes 4442and4443. All

U.S. forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey, Oregon, and Washington require by law that

many internal combustion engines be

equippedwithasparkarrestingscreen. Ifyou

operateinalocalewheresuch regulationsexist, youarelegally responsibleformaintaining

theoperatingconditionofthese parts. Failure

to do so is a violation of the law. Refer to the

MAINTENANCE section for information on

maintenance of the muffler and spark arrest-

This unit is equipped

ing screen.

WARNING:

the impeller blades have stopped turning before opening the vacuum inlet door or attempting to insert or remove the vacuum or

blower tubes. The rotatingblades can cause

serious injury. Always disconnect the spark

plug before performing maintenance or accessing movable parts.

WARNING:

assembled, check each step to insure your

unit is properly assembled and all fasteners

are secure. Follow all safety information in

the manual and on the unit.

A standard screwdriver is requiredfor as-

D

sembly.

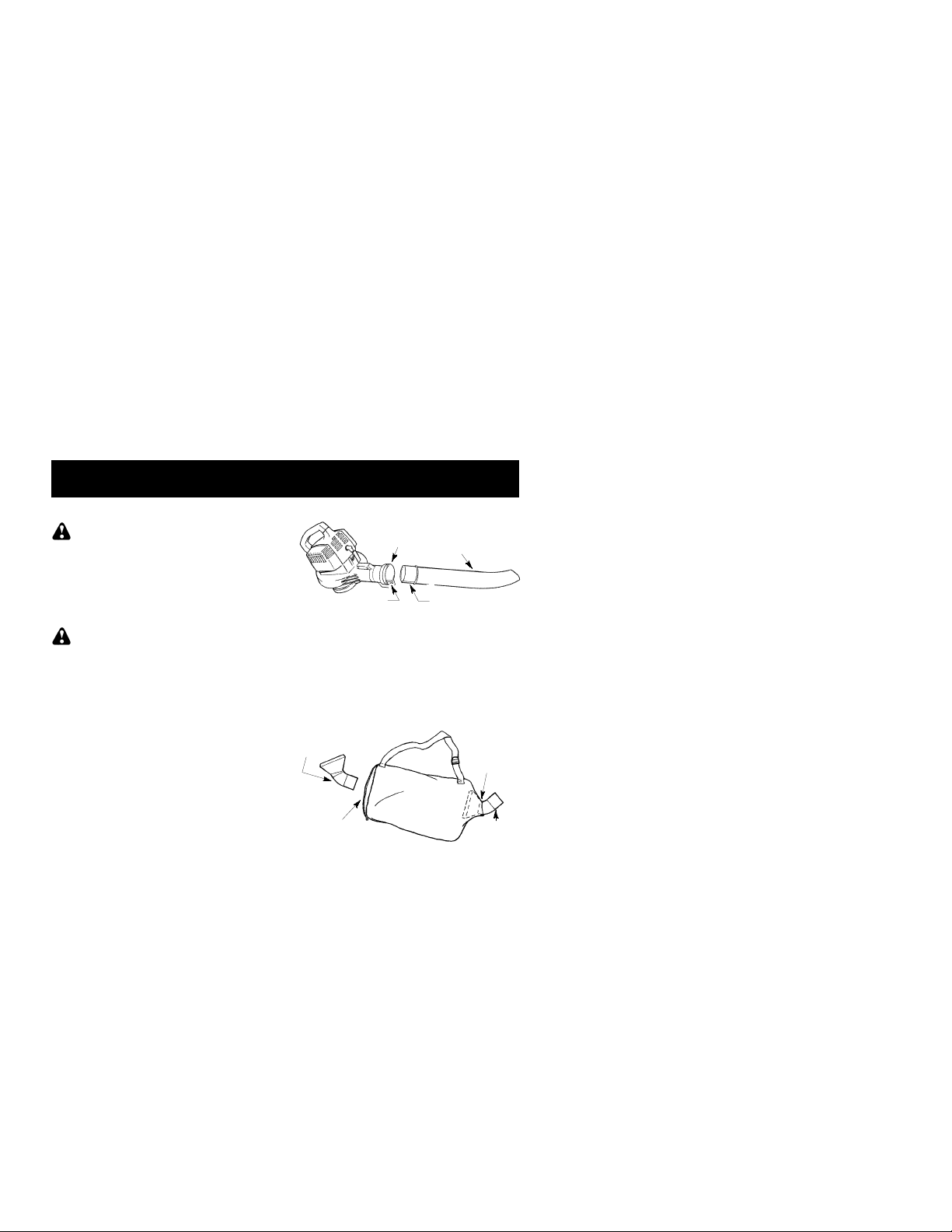

BLOWERTUBE ASSEMBLY

1. Align the rib on the blower tube with the

groove in the blower outlet; slide the tube

into place.

Knobmustbe looseenough toallow

NOTE:

blower tube to be inserted in blower outlet.

Loosen knob by turning counterclockwise.

Stop engine and be sure

If you receive your unit

Blower

Outlet

Groove

2. Securethe tubeby turningthe knob clockwise.

3. Toremovethetube, turntheknobcounterclockwise to loosen the tube; remove the

tube.

VACUUM BAG ASSEMBLY

1. Open the zipper on the vacuum bag and

insert the elbow tube.

2. Push the small end of the elbow tube

through the small opening in the bag.

Elbow

Tube

Blower

Tube

Rib

Zipper

Opening

-- 3 --

Small

Opening

Rib

Page 4

Makesureedgeof thesmallopening

NOTE:

is flush against the flared area of the elbow

tube, and the rib on the elbow tube is on the

bottom.

3. Closethe zipperon thebag.Makesurethe

zipper is closed completely.

4. Remove blower tube from engine.

Rib

Groove

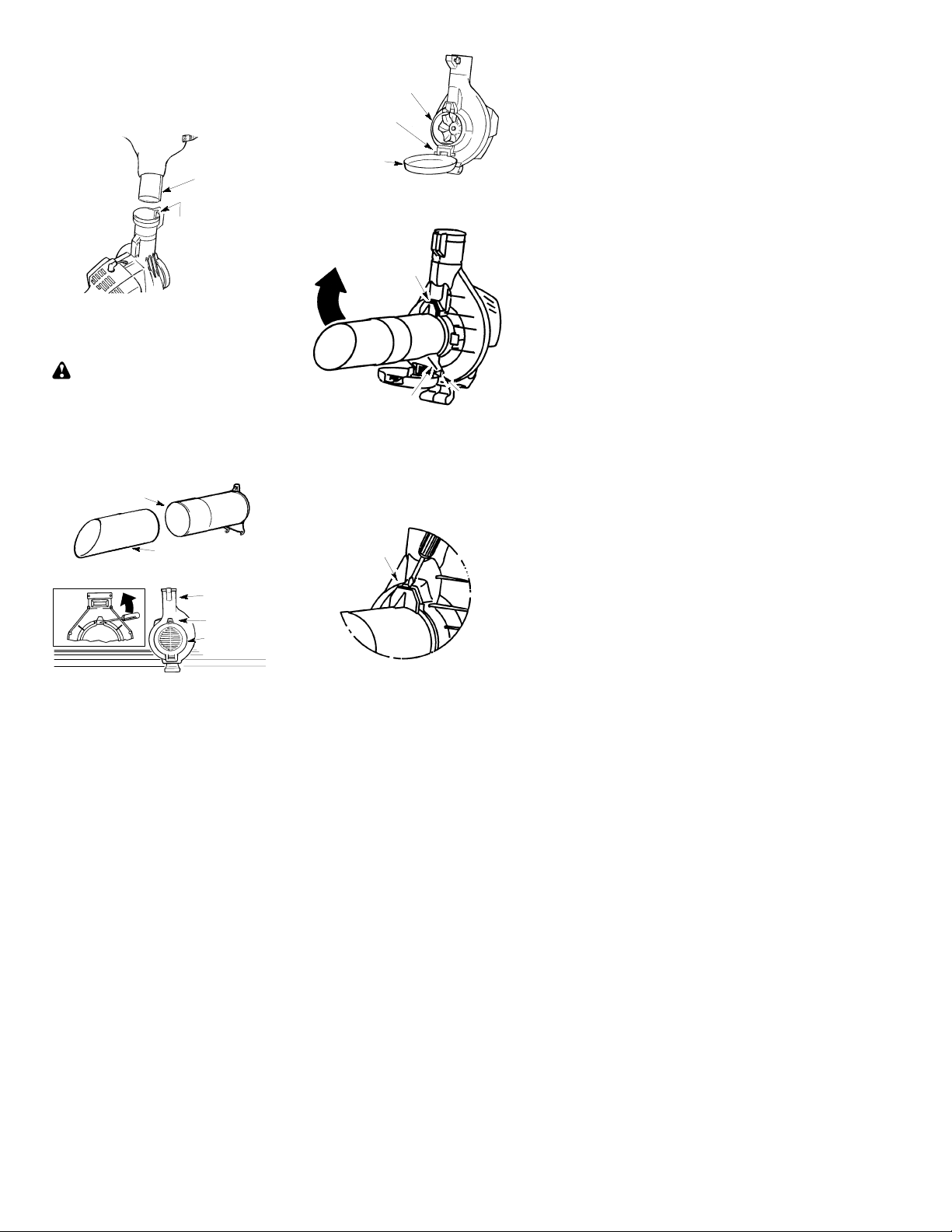

4. Hold the vacuum inlet cover open until upper vacuum tube is installed.

Vacuum Inlet

RetainingPost

Vacuum

Inlet

5. Place the hooksof theupper vacuum tube

6. Pivot the tube until it is secured to the

Cover

on the retaining posts of the unit.

blower unit by the vacuum inlet latch.

5. Inserttheelbowtubeinto theblower outlet.

Make sure elbow tube rib is aligned with

the blower outlet groove.

6. Turnknobclockwisetosecure elbowtube.

VACUUM TUBE ASSEMBLY

WARNING:

the impeller blades have stopped turning before opening the vacuum inlet door or attempting to insert or remove the vacuum or

blower tubes. The rotatingblades can cause

serious injury.

1. Align the lower vacuum tube as shown.

Push lower vacuum tube into uppervacuum tube.

Upper Vacuum

Tube

2. Insert thetip ofa screwdriverinto thelatch

area of the vacuum inlet.

Latch

Area

3. Gently tilt the handle ofthescrewdriver toward the back of the unit to release the

latch while pulling up on the vacuum inlet

cover with your other hand.

Stop engine and be sure

Lower Vacuum Tube

Blower

Outlet

Latch Area

Vacuum

Inlet Cover

PIVOT

Inlet Cover

Latch

Hook

Retaining

Post

HOW TO CONVERT UNIT FROM

VACUUM USE TO BLOWER USE

1. Remove the vacuum tubes by inserting

the tip of a screwdriver intothe latch area

of the vacuum inlet.

2. Gently tilt handle of screwdriver toward

the back of the unit to release the latch

whilepullingup on theupper vacuum tube

with your other hand.

Latch Area

3. Remove the vacuum bag.

4. Close the vacuum inlet cover and make

sure it is latched closed.

5. Reinstall the blower tube (see BLOWER

TUBE ASSEMBLY).

-- 4 --

Page 5

SHOULDERSTRAP ADJUSTMENT

1 Hold the unit as shown with the muffler side

facing away from your body and clothes.

2. Pass the shoulder strap over your head

and onto your right shoulder.

3. Extendyour left arm towardthe rear of the

vacuum bag.

4. Adjust shoulder strap until the vacuum

bag/shoulder strap seam lies between

your thumb and index finger.

5. Make sure air flows freely from the elbow

tubeinto bag. If bag is kinked, the unit will

not operate properly.

OPERATION

KNOW YOUR BLOWER

READTHIS INSTRUCTIONMANUALAND SAFETY RULES BEFORE OPERATINGYOURUNIT .

Comp aretheillustrations with yourunit to familiarizeyourselfwith thelocatio nof thevariou scontrols

and adjustments. Save this manual for future reference.

Lower

Vacuum Tube

Upper

Vacuum Tube

Vacuum Bag

Elbow Tube

Blower

Tube

THROTTLE LEVER

TheTHROTTLELEVER is usedto selectthe

desiredengine speedand to stop the engine.

Movethethrottlelever tothe

full speed operation. Move the throttle lever

tothe

engine, move the throttle lever to the STOP

position.

PRIMERBUTTON

The PRIMER BUTTON removes air from the

carburetorand fuellines andfills themwith fuel.

This allow s you to start the engine with fewer

pulls on the starter rope. Activate primer button

by pressing it and allowing it to return to its original position.

positionfor idle speed. Tostopthe

Spark Plug

position for

Primer Button

Throttle

Lever

CHOKE LEVER

The CHOKE helps to supply fuel to the engine

to aid in cold starting. Activate the choke by

moving the choke lever to the FULL CHOKE

position.Afterengineattemptstostart, movethe

choke lever to the HALF CHOKE position.

Once engine starts, move choke lever to the

RUN position.

Choke Lever

Fuel Mix

Fill Cap

Starter

Rope

Rear

Handle

-- 5 --

Page 6

OPERA TINGPOSITION

Eye

Protection

Blower

OPERA TINGTIPS

While vacuuming or blowing debris, hold

S

the unit with the muffler side facing away

from your body and clothes (seeOPERATING POSITION illustration above).

To reduce the risk of hearing loss

S

associated with sound level(s), hearing

protection is required.

T o reduce the risk of injury associated with

S

contacting rotating parts, stop the engine before installing or removing attachments. Do

not operate without guard(s) in place.

Operate power equipment only atreasonable

S

hours- -notearly in the morning or late at night

whenpeoplemight be disturbed.Comply with

times listed in local ordinances. Usual recommendations are 9:00 a.m. to 5:00 p.m.,

Monday though Saturday.

To reduce noise levels, limit the number of

S

pieces of equipmentused at any one time.

To reduce noise levels, operate power

S

blowers at the lowest possible throttle

speed to do the job.

Use rakes and brooms to loosen debris be-

S

fore blowing.

In dusty conditions, slightly dampen sur-

S

faces or use a mister attachmentwhen water is available.

Conserve water by using power blowers

S

instead of hoses for many lawn and garden

applications, including areas such as gutters,

screens, patios,grills, porches,andgard e ns.

Watchoutfor children, pets,openwindows,

S

or freshly washedcars. Blow debris away

safely.

Use the full blower nozzle extension so the

S

air stream can work close to the ground.

After using blowers and other equipment,

S

CLEAN UP! Dispose of debris in trash receptacles.

Vacuum

BEFORE STARTINGENGINE

WARNING:

information in the safety rules before you begin.If you do not understand the safety rules,

do not attempt to fuel your unit. Call

1-800-554-6723

Be sure to read the fuel

.

FUELING ENGINE

WARNING:

when refueling.

Remove fuel cap slowly

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good quality

synthetic 2-cycle air-cooled engine oil

designed to be mixed at a ratio of 40:1.

Poulan/Weed Eater brand synthetic oil is

recommended. Mix gasoline andoil at a ratio

of40:1. A40:1 ratio is obtainedby mixing 3.2

ounces (95 ml) of oil with 1 gallon (4 liters) of

unleaded gasoline. DO NOT USE

automotiveoil orboatoil.Theseoils willcause

engine damage. When mixing fuel, follow

instructions printed on container. Once oil is

added to gasoline, shake container

momentarily to assure that the fuel is

thoroughlymixed. Always readandfollow the

safetyrulesrelatingto fuel beforefuelingyour

unit.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol)can attract moisture which leads to

separation and formation of acids during

storage. Acidic gas can damage the fuel

systemofanenginewhile instorage.Toavoid

engine problems, empty the fuel system

beforestoragefor 30days or longer.Drainthe

gastank,starttheengine andlet it rununtil the

fuellines andcarburetorareempty.Usefresh

fuel next season. Never use engine or

carburetorcleaner products in thefueltankor

permanent damage may occur.

Unit must be placed on its side when

NOTE:

add ing fuel (see illustrationbelow).

TO STOP THE ENGINE

To stop the engine, move the throttle lever

D

to the STOP position.

BEFORE STARTINGTHE ENGINE

WARNING:

the tubes are secure before using the unit.

Fuel engine. Move at least 10 feet (3 me-

D

ters) away from the fueling site.

Hold the unit in the starting position as

D

shown. Make sure the blower end is directed away from people, animals, glass,

and solid objects.

YouMUSTmakesure

-- 6 --

Page 7

STARTING POSITION

Blower

Vacuum

WARNING:

holdtheunitasillustrated.Donotsetunitonany

surface except aclean, hard area when starting

engine or while engine is running. Debris such

as gravel, sand, dust, grass, etc. could be

picked up by the air intake and thrown out

through the discharge opening, damaging the

unit or property, or causing serious injury to bystanders or the operator.

When starting engine,

STARTING A COLD ENGINE

1. Move throttle lever to the position.

2. Move choke lever to the FULL CHOKE

position.

3. Slowly press the primer button 8 times.

Throttle Lever

4. Pull starter rope sharply until engine attemptstorun, butnomorethan5pulls(below 30_F, 8 pulls).

Primer Button

Choke Lever

If engine attempts tostart beforethe

NOTE:

th

pull, go to next step immediately.

5

5. Move the choke lever to the HALF

CHOKE position.

6. Pull the starter rope sharply until the engine runs, but nomore than 5 pulls (below

30_F, 10 pulls).

7. After a 5 second warm--up, move the

choke lever to the RUN position.

8. Allow the unit to run for 30 more seconds

at the RUN position before moving the

throttle lever to the

If engine has not started after 5 pulls (at HALF

CHOKE), repeat STARTING A COLD ENGINE

procedure. If engine still does not start, proceed

to STAR TING A FLOODED ENGINE.

9. Tostop the engine, move the throttle leverto

theSTOPposit ion.

position.

STARTING A WARMENGINE

If fuel tank is empty, add fuel; then,

NOTE:

follow STARTING A COLD ENGINE procedure. Do not fill fuel tank while engine is hot.

1. Move throttle lever to the

2. Pull starter rope sharplyuntil engine runs,

but no more than 5 pulls.

If engine has not started, pull starter

:

NOTE

rope5 morepulls. If engine still does notrun,

it is probably flooded.

3. Tostop the engine, move the throttle leverto

theSTOPposit ion.

position.

ST ARTING A FLOODED ENGINE

Flooded engines can be started by placing the

choke lever in the RUN position. Move throttle

lever to the fast positio n

until engine starts. After engine starts, move the

throttle lever to the slow position

eng ine to idle.

Star ting could require pu lling the starter rope

many times depending on how badly the unit is

flooded.

If unit still doesn’t start refer to the TROUBLESHOOTING TABLE or call 1-800-554-6723.

; then, pull rope

toallow

MAINTENANCE

WARNING:

unless engine and muffler are cold. A hot

muffler can cause serious burns.

WARNING:

the impeller blades have stopped turning before opening the vacuum inlet door or attempting to insert or remove the vacuum or

blower tubes. The rotatingblades can cause

serious injury. Always disconnect the spark

plug before performing maintenance or accessing movable parts.

GENERALRECOMMENDATIONS

Thewarrantyonthisunit doesnotcover items

that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, the operator must maintain unit as

Avoid touching muffler

Stop engine and be sure

instructed in this manual. Various adjustments will need to be made periodically to

properly maintain your unit.

CHECK FOR LOOSE

FASTENERSAND PARTS

Spark Plug Boot

S

Air Filter

S

Housing Screws

S

Muffler

S

CHECK FOR DAMAGED OR WORN

PARTS

Contact an authorized service dealer for replacement of damaged or worn parts.

Fuel Tank -- Do not use unit if fuel tank shows

S

signs of damage or leaks.

VacuumBag -- Do not use vacuum bag if it

S

is torn or damaged.

-- 7 --

Page 8

INSPECTAND CLEAN UNIT AND

DECALS

After each use, inspect complete unit for

S

looseordamagedparts. Clean the unitand

decals using adampcloth witha mild detergent.

Wipe off unit with a clean dry cloth.

S

CLEAN AIR FILTER

Fuel Line

Fuel Filter

Air Filter

Cover

Air Filter

Cleaning the air filter:

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean or replace

air filter after every 5 hours of operation or

yearly, whichever comes first.

1. Clean the cover and the area around it to

keepdebris from fallinginto thecarburetor

chamber when the cover is removed.

2. Remove parts as illustrated.

Donotclean filter in gasoline orother

NOTE:

flammable solvent. Doingsocancreateafire

hazardorproduceharmfulevaporativeemissions.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Apply a few drops of oil to the filter;

squeeze filter to distribute oil.

6. Replace parts.

REPLACE SPARKPLUG

Replace spark plug each year to ensure the

engine starts easier and runs better. Set

sparkpluggap at 0.025inch.Ignitiontimingis

fixed, nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 inch

socket wrench.

4. Reinstall the spark plug boot.

REPLACE FUEL FILTER

Toreplacefuel filter,drainunit byrunningit dry

of fuel, then removefuel cap/retainerassembly from tank. Pull filter from tank andremove

itfromthefuel line. Installnew fuelfilter onfuel

line; reinstall parts.

Screws

CHECK MUFFLER MOUNTING

SCREWS

Once each year, ensure muffler mounting

screws are secure and tightened properly to

prevent damage.

Muffler Cover

Screws

1. Loosenand removethe 2 screws fromthe

muffler cover.

2. Remove the muffler cover.

3. Tightenthe 2 muffler mountingscrews securely.

4. Reinstall muffler cover and 2 screws.

Tighten securely.

INSPECT MUFFLER AND SPARK

ARRESTINGSCREEN

WARNING:

uct contains chemicals known to the State of

California to cause cancer.

As the unit is used, carbon deposits build up

on the muffler and spark arresting screen,

andmust be removedto avoid creating a fire

hazard or affecting engine performance.

VIEW OF MUFFLER

Spark arresting

screen

Exhaust

Diverter

Screws

Replace the spark arrestingscreen every 50

hoursof operation orif any damage orbreaks

in the screen are noted.

The muffler on this prod-

-- 8 --

Mounting

Screw

Holes

Page 9

Donot attempttocleanthe spark ar-

NOTE:

resting screen.

1. Loosenand removethe 2 screws fromthe

muffler cover. Remove the muffler cover.

2. Loosen and remove bothscrews from the

exhaust diverter.

3. Remove the exhaust diverter and spark

arresting screen.

4 Install new spark arresting screen.

5. Reinstall exhaust diverter and both

screws. Tighten screws securely.

6. Reinstall muffler cover and 2 screws.

Tighten securely.

If any part of the muffler is cracked,

NOTE:

broken or damaged, we recommend thatthe

muffler be replaced.

STORAGE

WARNING:

steps after each use:

Allow engine to cool, and secure the unit

S

before storing or transporting.

Store unit and fuel in a well ventilated area

S

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

Store unit with all guards in place. Position

S

unit so that any sharp object cannot accidentally cause injury.

Store unit and fuel well out of the reach of

S

children.

SEASONALSTORAGE

Prepareunit forstorageat endofseason or if

it will not be used for 30 days or more.

If your unitis to be storedfor a period of time:

Clean the entire unit before lengthy stor-

S

age.

Store in a clean dry area.

S

Lightly oil external metal surfaces.

S

FUEL SYSTEM

Under FUELING ENGINE in the OPERATIONsectionof this manual,seemessagelabeled IMPORTANT regarding the use of gasohol in your engine.

Perform the following

CARBURETOR ADJUSTMENTS

Thereis no screw for idle adjustment on your

blower. The throttle lever is used to control

engine speed. The throttle lever can be

placed in one of four positions: STOP, IDLE

, FULL THROTTLE or , and one

or

intermittentposition. Ifyourenginewill notrun

properly or you require further assistance,

contact an authorized service dealer or call

1--800--554--6723.

Fue l stabilizer is an acce ptab le alterna tive in

minimizing the formation of fuel gum deposits

during storage. Addstabilizerto gasolinein fuel

tank or fuel storage container. Follow the mix

instruction s found on stabilizer contain e r. Run

eng ineat least 5 minutes afteraddingstabilize r.

ENGINE

Remove spark plug and pour1teaspoonof

S

40:1,2-cycle engine oil (air cooled) through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

Replacespark plug with new one ofrecom-

S

mended type and heat range.

Clean air filter.

S

Check entire unit for loose screws, nuts,

S

and bolts. Replace any damaged, broken,

or worn parts.

At the beginning of the next season, use

S

only freshfuelhavingthepropergasolineto

oil ratio.

OTHER

Do not store gasoline from one season to

S

another.

Replaceyourgasolinecan if it starts torust.

S

-- 9 --

Page 10

TROUBLESHOOTINGTABLE

WARNING:

recommended remedies below other than remedies that require operation of the unit.

TROUBLE

Enginewill not

start.

Enginewill not

idle properly.

Enginewill not

accelerate,

lacks power, or

dies under a

load.

Engine smokes

excessively.

Engine runs hot.

Always stopunitanddisconnect spark plug before performingany of the

CAUSE REMEDY

1. Engine flooded.

2. Fuel tank empty.

3. Spark plug not firing.

4. Fuel not reaching

carburetor.

5. Compressionlow.

1. Fuel not reaching

carburetor.

2. Carburetor requires

adjustment.

3. Crankshaft seals worn.

4. Compressionlow.

1. Air filter dirty.

2. Fuel not reaching

carburetor.

3. Spark plug fouled.

4. Carburetor requires

adjustment.

5. Carbon build up.

6. Compressionlow.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build up.

1. See “Starting a Flooded Engine”

in Operation section.

2. Fill tank with correct fuel mixture.

3. Install new spark plug.

4. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

5. Contact an authorized service dealer.

1. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer

4. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

3. Clean or replace spark plug

and re-gap.

4. Contact an authoriz ed service dealer.

5. Contact an authoriz ed service dealer.

6. Contact an authoriz ed service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer.

1. See “Fueling Engine” in Operation

section.

2. Replace with correct spark plug.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

-- 1 0 --

Page 11

LIMITED WARRANTY

ELECTROLUX HOME PRODUCTS, INC.,

warrantsto theoriginal purchaser that eachnew

Weed Eater

is free from defects in material and workmanship and agrees to repair or replace under this

warranty any defective gasoline product or attachment as follows from the original date of

purchase

2 YEARS--

household purposes.

90 DAYS --

commercial, professional, or income producing

purposes.

30 DAYS --

purposes.

This warranty is not transferable and does not

cover dama ge or liability caused by imprope r

handling, improper maintenance, or the use of

accessories and/or attachments not specifically

recommended by

PRODUCTS, INC.,

this warranty does not cover tune-ups, spark

plugs, filters, starter ropes, starter springs, cutting line, or rotatingheadparts thatwill wearand

require replacement with reasonable useduring

the warranty period. This warranty does not

brand gasoline tool or attachment

:

Parts and Labor, when used for

Parts and Labor, when used for

Parts and Labor , if used for rental

ELECTROLUX HOME

for this tool. Additionally,

U.S. EPA/CALIFORNIA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGA-

The U.S. Environmental Protection

TIONS:

Agency/California Air Resources Board and

ELECTROLUXHOME PRODUCTS, INC., are

pleasedtoexplaintheemissionscontrolsystem

warranty on your year 2002- -2004 small off- road engine. In California, all new small off--road

engines must be designed, built, and equipped

to meet the State’s stringent anti- -smog standards. ELECTROLUX HOME PRODUCTS,

INC.,mustwarranttheemissioncontrolsystem

on your small off- -road engine for the periods of

time listed below provided there has been no

abuse, neglect, or improper maintenance of

your small off- -road engine engine. Your emission control system includes parts such as the

carb u reto r an d the ignition system. Where a

warrantable condition exists, ELECTROLUX

HOMEPRODUCTS,INC., will repair yoursmall

off--road engine engine at no cost to you. Expenses covered under warranty includediagnosis, parts and labor.

WARRANTY COVERAGE:

related part on your engine (as listed under

EmissionsControl WarrantyParts List) is defective or a defect in the materials or workmanship

ofthe enginecauses thefailure of such an emission related part, the part will be repaired or replaced by ELECTROLUX HOME PRODUCTS, INC.

SPONSIBILITIES:

gine engine owner, you are responsible for the

performance of the required maintenance listed

in your instruction manual. ELECTROLUX

HOME PRODUCTS, INC., recommends that

you retain all receipts covering maintenanceon

MANUFACTU RER’S

If any emissions

OWNER’S WARRANTY RE-

As the small off--road en-

cover predelivery setup or normal adjustments

explained in the instruction manual.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MA Y HAVE

OTHER RIGHTS WHICH VARY FROM

STA T E TO STA TE.

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EXPRESSLY STIPULATED HEREIN.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OR

LIMIT ATIONS OF INCIDENT AL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS OR EXCLUSION MAY NOT

APPLY TO YOU.

ELECTROLUX HOME PRODUCTS, INC.,

policy is to continuously improve its products.

Therefore,

UCTS,INC.,

ify, or discontinue models, designs, specifications, and accessories of all products at any

time without notice or obligation to any purchaser.

your small off- -road engine, but ELECTROLUX

HOME PRODUCTS, INC., cannot deny warranty solely for the lack of receipts or for your

failure to ensure the performance of all scheduled maintenance. As the small off- -road engine engine owner, you should be aware that

ELECTROLUX HOME PRODUCTS, INC.,

may deny you warranty coverage if your small

off--road engine engine or a part of it has failed

due to abuse, neglect, improper maintenance,

unapproved modifications, or the use of parts

not made or approved by the original equipment

manufacturer. You are responsible for presentingyoursmalloff--roadengin etoanELECTROLUX HOME PRODUCTS, INC., authorized repair center as soon as a problem exists. Warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If

you have any questions regarding your warrantyrightsandrespons ibilities,youshouldcontact

your nearest authorized service center or call

ELECTROLUX HOME PRODUCTS, INC., at

1--800- -554--6723.

MENCEMENTDATE:

gins on the date the small off--road engine is

purchased.

warranty shall be for a period of two years from

the initial date of purchase.

ERED: REP AIR OR REPLACEMENT OF

PART S.

rantedpartwill be performedat no charge tothe

owner at an approved ELECTROLUX HOME

PRODUCTS, INC., servicing center. If you

have any questions regarding your warranty

rights and resp onsibilit ies, you shou ld contact

your nearest authorized service center or call

ELECTROLUX HOME PROD-

reserves the right to change, mod-

WARRANTY COM-

The warranty period be-

LENGTH OF COVERAGE:

WHAT IS COV-

Repair or replacement of any war-

-- 11 --

This

Page 12

ELECTROLUX HOME PRODUCTS, INC., at

1--800- -554--6723

warranted part which is not scheduled for replacement as requiredmaintenance,or which is

scheduled only for regular inspection to the effect of “repair or replace as necessary” shall be

warrantedfor 2 years. Any warrantedpartwhich

is scheduled for replacement as required maintenanceshall be warranted for the period of time

up to the first scheduled replacement point for

that part.

charged for diagnostic labor which leads to the

determination that a warranted part is defective

if the diagnostic work is performed at an approved ELECTROLUX HOME PRODUCTS,

INC., servicing center.

DAMAGES:

UCTS, INC., may beliable for damages toother

engine components caused by the failure of a

warranted part still under warranty.

NOT COVERED

neglect, or improper maintenance are not covered.

ADD--ON OR MODIFIED PARTS:

use of add--on or modified parts canbe grounds

for disallowing a warranty claim. ELECTROLUX HOME PRODUCTS, INC., is not liable to

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

WARRANTYPERIOD:

DIAGNOSIS:

ELECTROLUX HOME PROD-

The owner shall not be

CONSEQUENTIAL

: All failures caused by abuse,

WHAT IS

cover failures of warranted parts caused by the

Any

use of add--on or modified parts.

ACLAIM:

your warranty rights and responsib ilities, you

should contact your nearest authorized service

center or call ELECTROLUX HOME PRODUCTS, INC., at 1--800- -554--6723.

GET WARRANTY SERVICE:

vices or repairs shall be provided at all ELECTROLUX HOME PRODUCTS, INC., service

centers. call: 1--800--554--6723

NANCE, REPLACEMENT AND REPAIR OF

EMISSION RELATED PARTS

TROLUXHOME PRODUCTS, INC., approved

replacement part used in the performance of

any warranty maintenance or repair on emission related parts will be provided without

charge to the owner if the part is under warranty.

EMISSION CONTROL WARRANTY PART S

LIST :

(covered up to maintenance schedule), Ignition

Module, Muffler including catalyst.

The

NANCE STA TEME NT:

ble for the performance of all required maintenance as defined in the instruction manual.

If you have any questions regarding

Carburetor, Ignition System: Spark Plug

HOW TOFILE

WHERETO

Warranty ser-

MAINTE-

: Any ELEC-

Theowner is responsi-

MAINTE-

-- 1 2 --

Loading...

Loading...