Page 1

GAS GRILL

Built-In LP Gas Grill Installation Guide

Tank Enclosure Installation - Pg 25

S-460

S-660

™

™

#43267

YOU MUST READ THIS OWNER’S GUIDE

BEFORE OPERATING YOUR GAS GRILL

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

Leaking gas may cause a fire or explosion

which can cause serious bodily injury or death,

or damage to property.

WARNING: Follow all leak-check procedures

carefully in this manual prior to barbecue

operation. Do this even if the barbecue was

dealer-assembled.

NOTICE TO INSTALLER: These instructions

must be left with the owner and the owner

should keep them for future use.

THIS GAS APPLIANCE IS DESIGNED FOR

OUTDOOR USE ONLY.

WARNING: Do not try to light this appliance

without reading the “Lighting Instructions”

section of this manual.

WARNING:

1. Do not store or use gasoline or other

flammable liquids or vapors in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall

not be stored in the vicinity of this or any

other appliance.

43267 US 08/06/08

LP

Page 2

2

WARNINGS

DANGER

Failure to follow the Dangers, Warnings and Cautions

contained in this Owner’s Manual may result in serious bodily

injury or death, or in a fire or an explosion causing damage to

property.

WARNINGS

Do not store a spare or disconnected liquid propane cylinder

under or near the barbecue.

Improper assembly may be dangerous. Please carefully

follow the assembly instructions in this manual.

Do not operate the Weber® gas barbecue if there is a gas leak

present.

Do not use a flame to check for gas leaks.

Combustible materials should never be within 24 (60.96cm)

inches of the top, bottom, back or sides of your Weber® gas

barbecue.

Do not put a barbecue cover or anything flammable on, or in

the storage area under the barbecue.

Your Weber® gas barbecue should never be used by children.

Accessible parts of the barbecue may be very hot. Keep

young children away while it is in use.

You should exercise reasonable care when operating your

Weber® gas barbecue. It will be hot during cooking or

cleaning and should never be left unattended, or moved

while in operation.

Liquid propane gas is not natural gas. The conversion or

attempted use of natural gas in a liquid propane unit or

liquid propane gas in a natural gas unit is dangerous and

will void your warranty.

Do not attempt to disconnect any gas fitting while your

barbecue is in operation.

Keep any electrical supply cord and the fuel supply hose

away from any heated surfaces.

Do not use this Weber® tank enclosure kit unless all parts are

in place. The unit must be properly assembled according

to the instructions outlined in the “Assembly Instruction”

section of the Owner’s Guide.

Proposition 65 Warning: Handling the brass material on

this product exposes you to lead, a chemical known to the

state of California to cause cancer, birth defects or other

reproductive harm.

(Wash hands after handling this product.)

LIQUID PROPANE GAS UNITS ONLY:

®

Use the regulator that is supplied with your Weber

Tank

Enclosure Kit.

Do not attempt to disconnect the gas regulator or any gas

fitting while your barbecue is in operation.

A dented or rusty liquid propane cylinder may be hazardous

and should be checked by your liquid propane supplier. Do

not use a liquid propane cylinder with a damaged valve.

Although your liquid propane cylinder may appear to be

empty, gas may still be present, and the cylinder should be

transported and stored accordingly.

If you see, smell or hear the hiss of escaping gas from the

liquid propane cylinder:

1. Move away from liquid propane cylinder.

2. Do not attempt to correct the problem yourself.

3. Call your fire department.

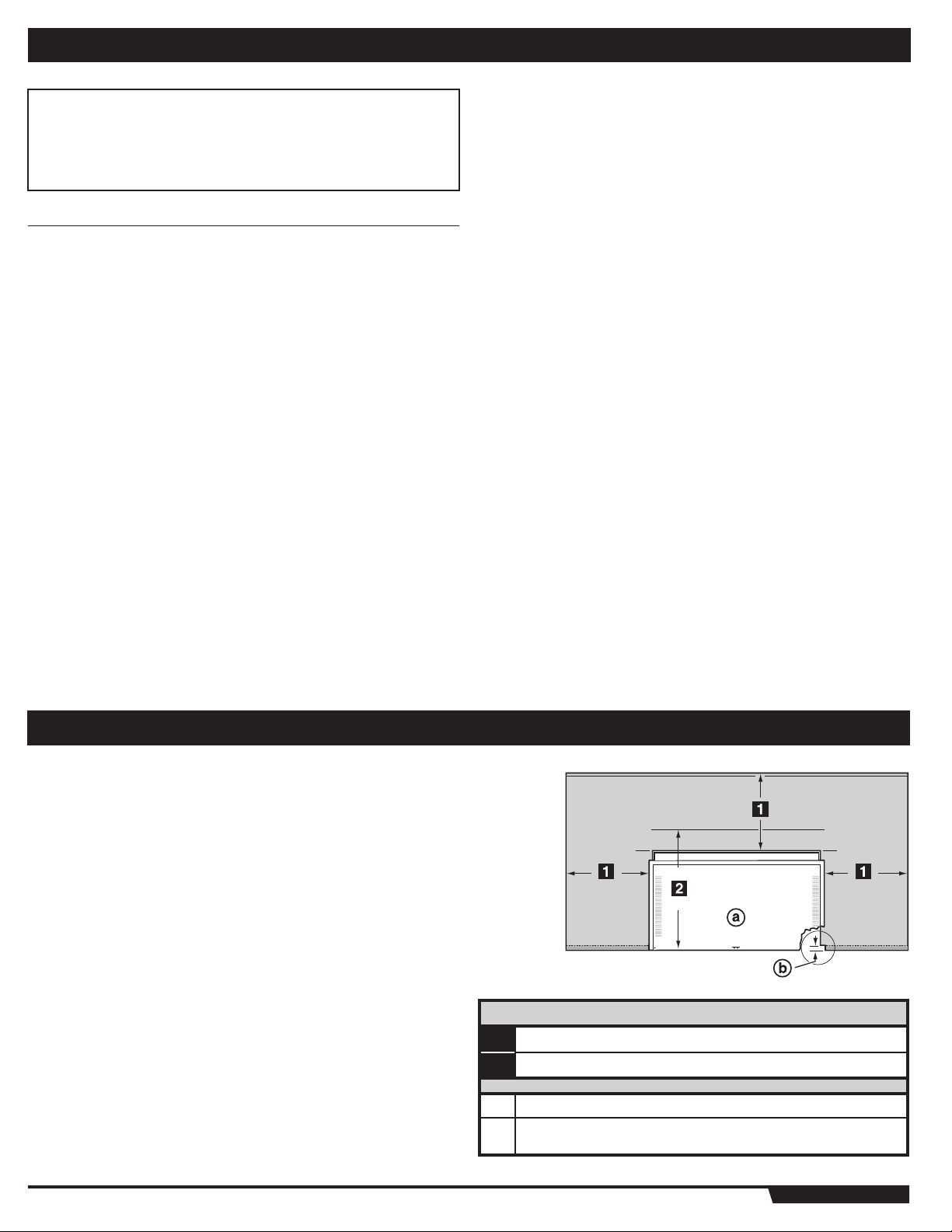

BUILT-IN CUTOUT DIMENSIONS

LOCATING YOUR GRILL

When determining a suitable location for your Summit® gas grill installation, give attention

to concerns such as exposure to wind, proximity to traffic paths, and keeping any

gas supply lines as short as possible. Never locate the Summit® gas grill in a garage,

breezeway, shed, under an unprotected overhang, or other enclosed area. Locate the grill

and structure so there is enough room to safely evacuate the area in case of a fire.

CLEARANCE FROM SURFACES OR STRUCTURES

WARNING: Clearance from any surface or structure is 24

inches (609.6 mm) from the back and sides of the grill.

Refer to “Typical Gas Supply Installation” before starting

installation.

WARNING: The structure, “island”, countertops, and adjacent

work areas for the built-in grill installation must be built from

noncombustible materials only.

NOTE: If you have questions on what materials are considered noncombustible, contact

your local building materials supplier or fire department.

CLEARANCES

24˝ inches (610 mm) Any Surface

1

27˝ inches (685.8 mm) min. for lid clearance

2

Grill Frame

a

Note: For a countertop treatment: Recommended 3/4˝ (19.1 mm)

b

overhang. Notch front edge for frame to fully slide in.

WWW.WEBER.COM

®

Page 3

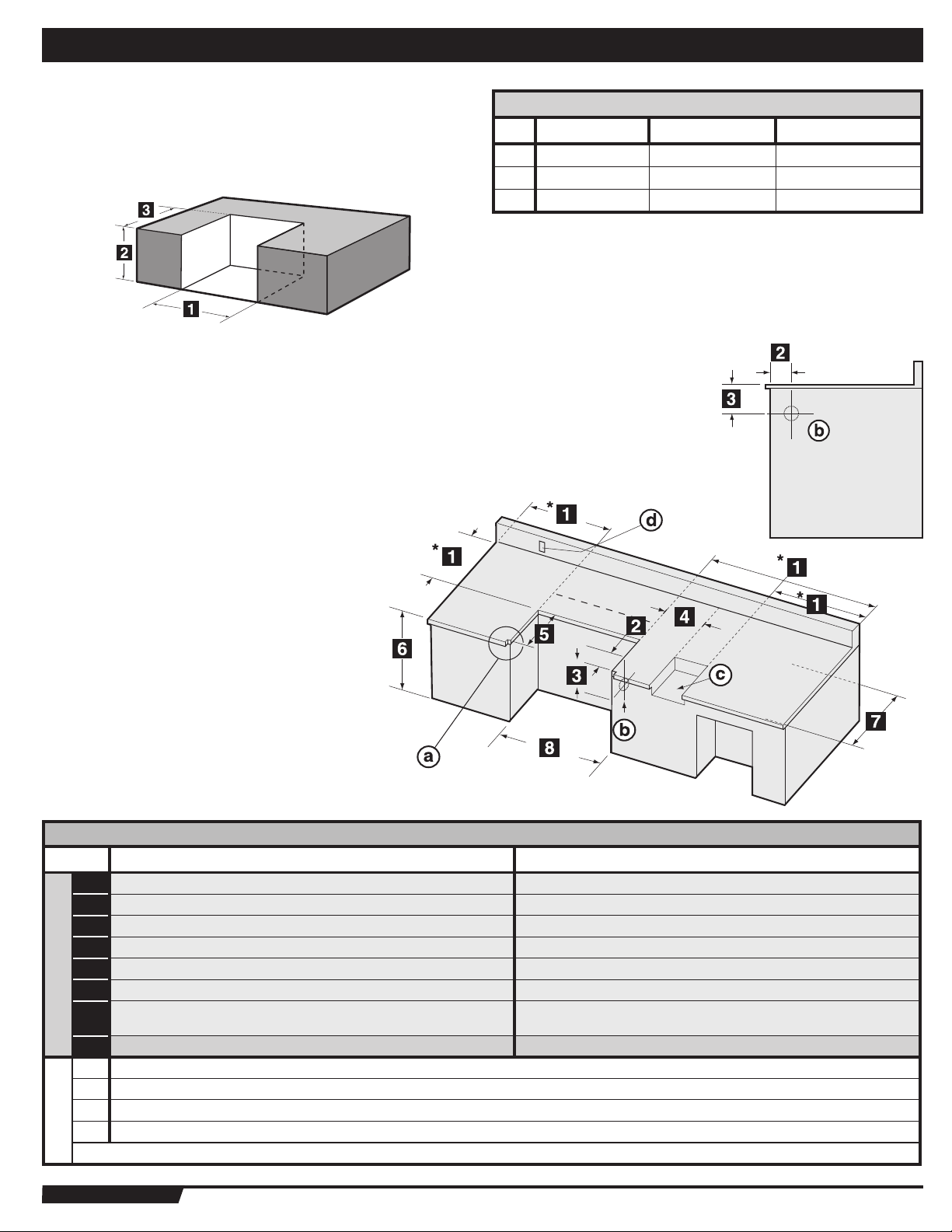

BUILT-IN CUTOUT DIMENSIONS

3

BUILT-IN STRUCTURE CUTOUT DIMENSIONS

ALL DIMENSIONS ARE TO FINISHED SURFACES.

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

GENERAL CONSTRUCTION DETAILS

Summit® Built-In unit and all other accessory units should be on site before construction

begins.

All dimensions have a tolerance of plus or minus (+/-) 1/

The grill frame rests directly on the Island Structure top finished surface. Make

sure this surface is level. Do not support the grill from the bottom.

If the supporting structure is going to have an electrical outlet for a

rotisserie, it should be on the left side of the structure.

inch (6.35 mm).

4

BUILT-IN CUTOUT DIMENSIONS

1 30

2 34

3 23˝ (584.2 mm) 23˝ (584.2 mm) +

S-460™ S-660™ TOLERANCES

1

˝ (768.35 mm) 38

/

4

3

/

˝ (873.13 mm) 34

8

1

˝ (971.55 mm) +

/

4

3

/

˝ (873.13 mm) +

8

3

1

1

˝ -

˝ (6.35mm)

/

/

4

4

1

1

/

/

˝ -

˝ (6.35mm)

4

4

1

1

˝ -

˝ (6.35mm)

/

/

4

4

BUILT-IN CUTOUT DIMENSIONS

S-460™ S-660™

1

2

3

4

5

6

DIMENSIONS

7

8

a

Note: For a countertop treatment: Recommended 3/4” (19.1 mm) overhang. Notch front edge for frame to fully slide in.

b

Gas Inlet

c

Side Burner Opening

d

Access for electric on left hand side

* Clearance from any surface or structure is at least 24” (609.6mm) from the back and sides of the grill or side burner.

WWW.WEBER.COM

27” (685.8 mm) minimum distance from front edge of

®

24” minimum* (610 mm) 24” minimum* (610 mm)

4 3/4” (120.65 mm) 4 3/4” (120.65 mm)

6 1/4” (158.75 mm) 6 1/4” (158.75 mm)

10 1/2” (266.7 mm) minimum 10 1/2” (266.7 mm) minimum

23” (584.2 mm) 23” (584.2 mm)

34 3/8” (873.13 mm) 34 3/8” (873.13 mm)

the cutout for open lid clearance

30 1/4” (768.35 mm) Built-In Frame 38 1/4” (971.55 mm) Built-In Frame

27” (685.8 mm) minimum distance from front edge of

the cutout for open lid clearance

Page 4

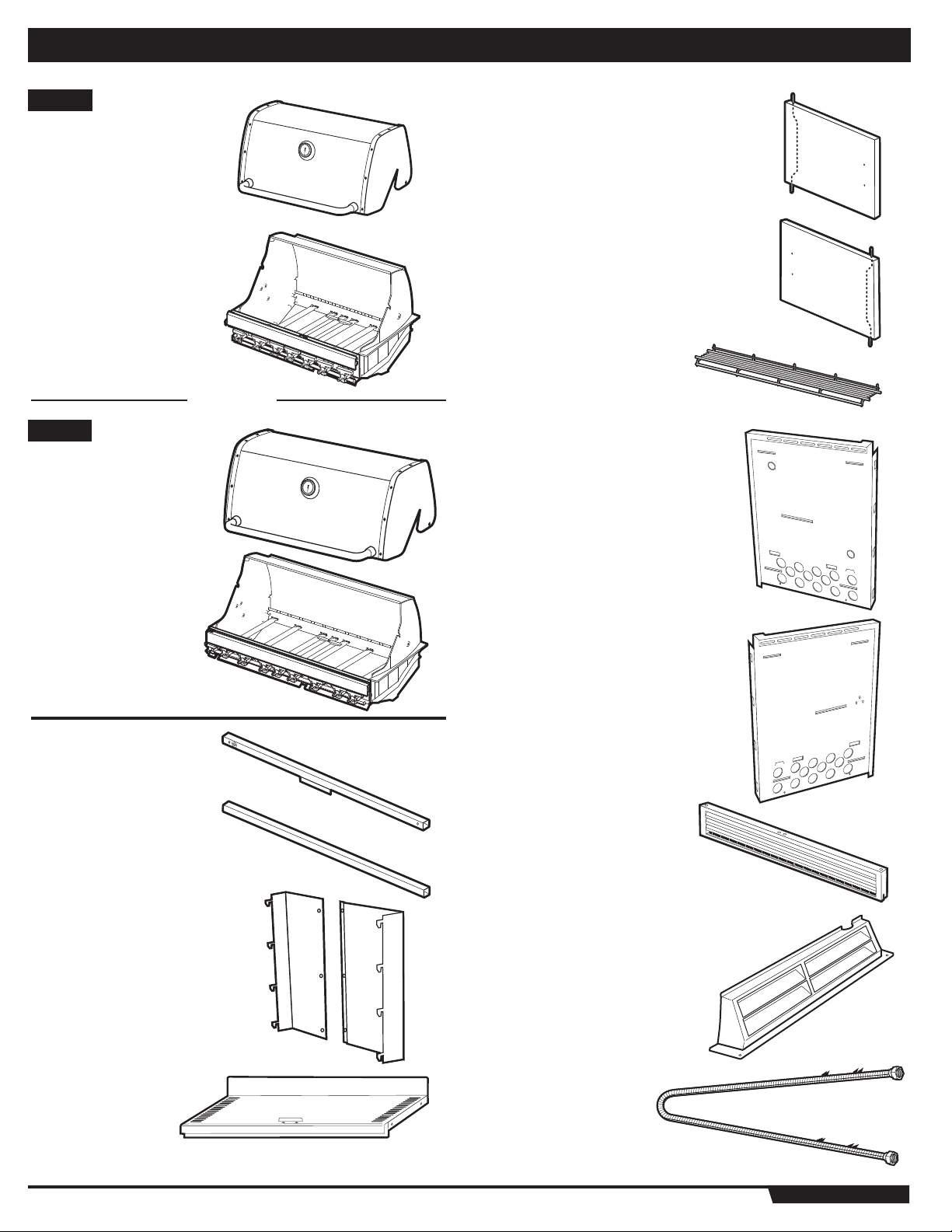

4

S-460

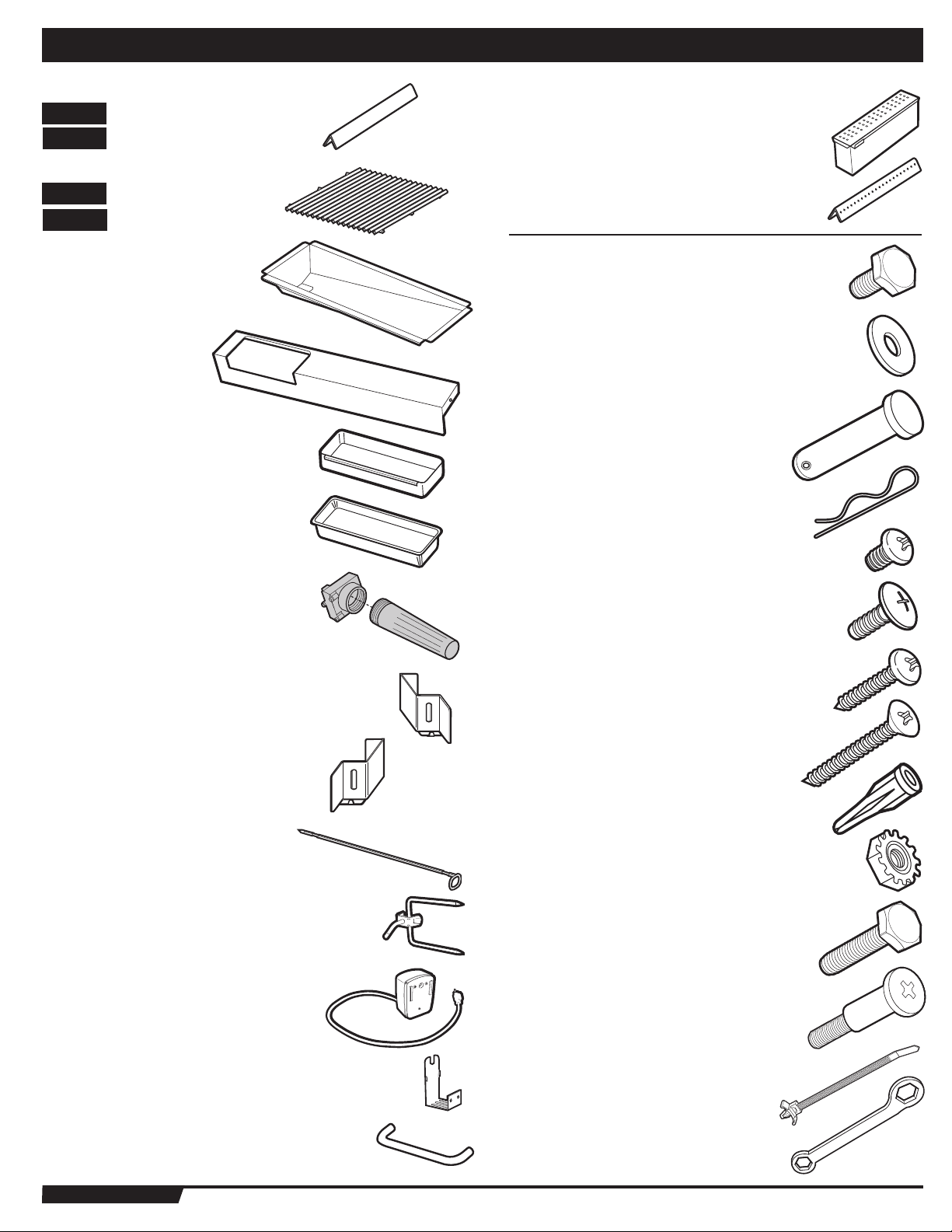

PARTS LIST

™

Lid - 1

Cookbox - 1

™

S-660

Lid - 1

Left Door - 1

Right Door - 1

Warming Rack - 1

OR

Right Enclosure Panel - 1

Cookbox - 1

Front Frame Rail - 1

Rear Frame Rail - 1

Rear Panel Assembly - 1

Left Enclosure Panel - 1

Front Vent Panel - 1

Rear Vent - 1

Bottom Shelf - 1

Corrugated Gas Line - 1

WWW.WEBER.COM

®

Page 5

PARTS LIST

5

Flavorizer® Bars

™

S-460

S-660

Stainless Steel Cooking Grates

S-460

S-660

Collection Tray - 1

Catch-Pan Holder - 1

Catch-Pan - 1

Disposable Drip Pans - 2

- 8

™

- 12

™

- 2

™

- 3

Smoker - 1

5

Smoker Bar - 1

1/2 inch Bolts (¼-20 x 1/2 inch Bolt) - 10

Nylon Washer - 10

Hinge Pin - 2

Hair Pin Cotter - 2

#10-32 x 1/4 inch Steel Screw - 5

Battery Housing - 1

Right Front Vent Clip - 1

Left Front Vent Clip - 1

Rotisserie - 1

Rotisserie Fork - 4

Rotisserie Motor - 1

¼-20 x 1/2 inch Truss Head Screw - 2

#10 Sheet Metal Screw - 3

Flat Head Screw - 2

Plastic Anchors - 5

Keps Nuts (1/4 x 20 Keps Nut) - 2

1 inch Bolt (¼-20 x 1 inch Bolt) - 2

Handle Hardware - 4

Rotisserie Bracket - 1

Handle - 2

WWW.WEBER.COM

Wire Tie - 1

7/16 inch Wrench - 1

®

Page 6

6

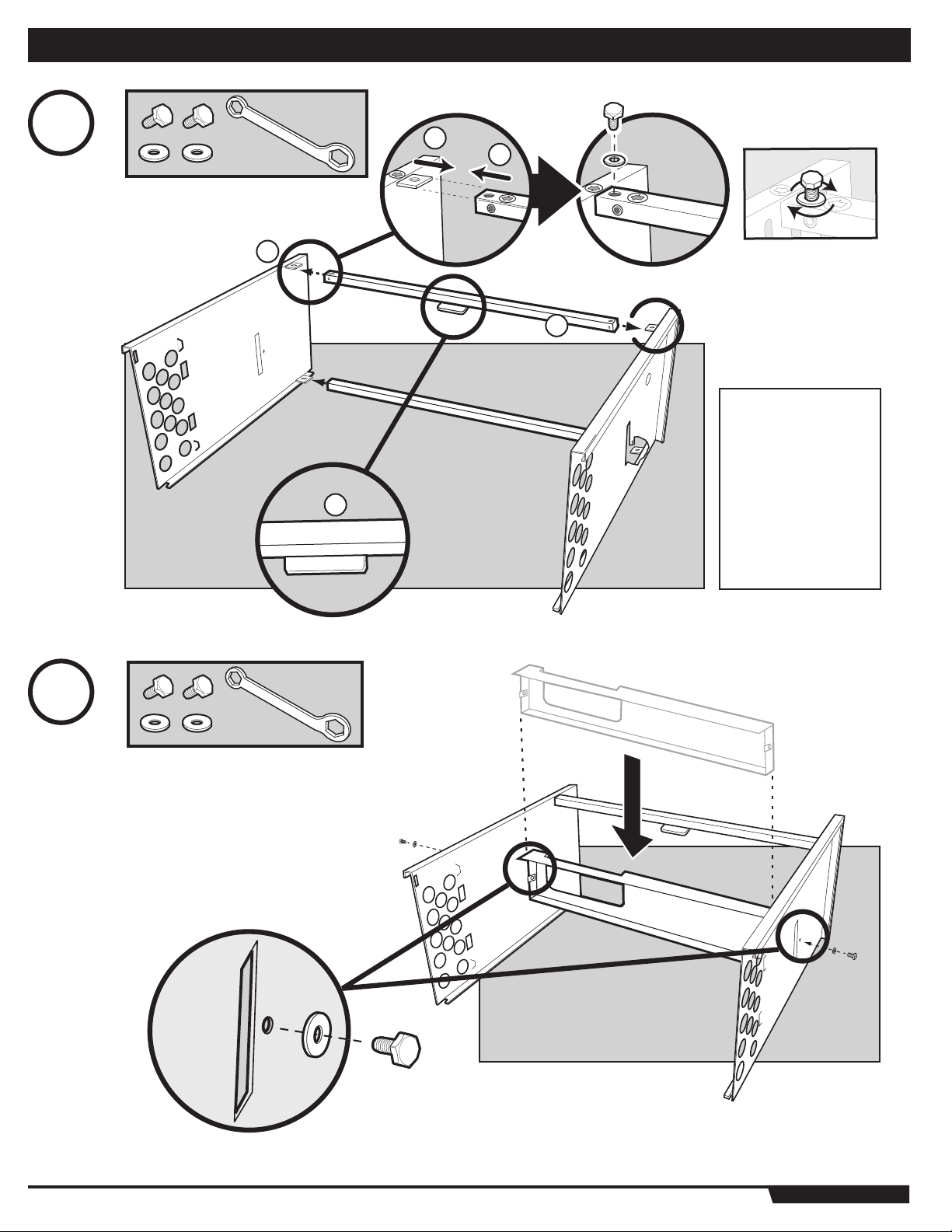

1

1

2

2

3

1

ASSEMBLY

Arrow stickers

on Frame Rail

(1) and Left Side

Panel (2) should

point toward each

other (shown

above). Door Stop

Bracket (3) should

be positioned as

shown (left).

2

WWW.WEBER.COM

®

Page 7

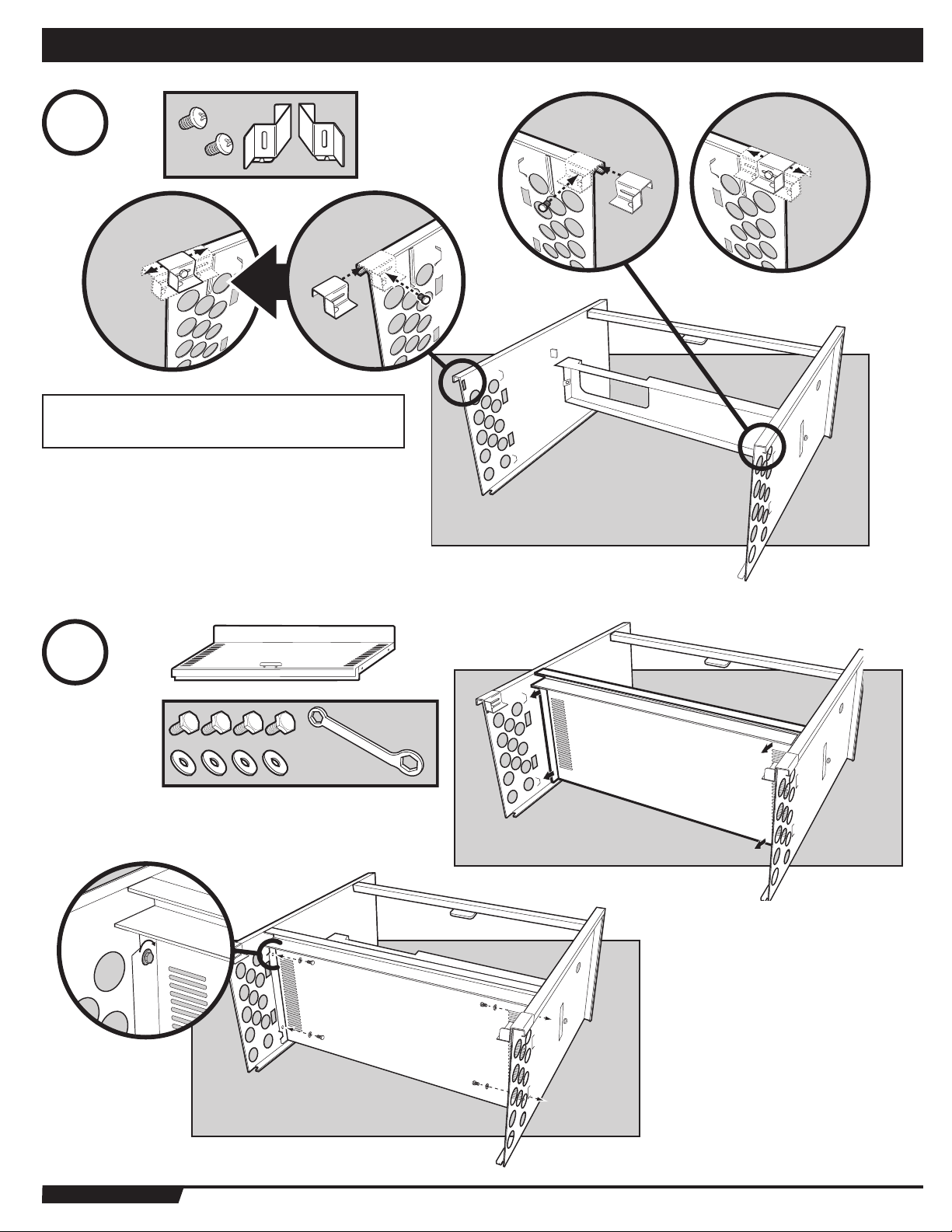

3

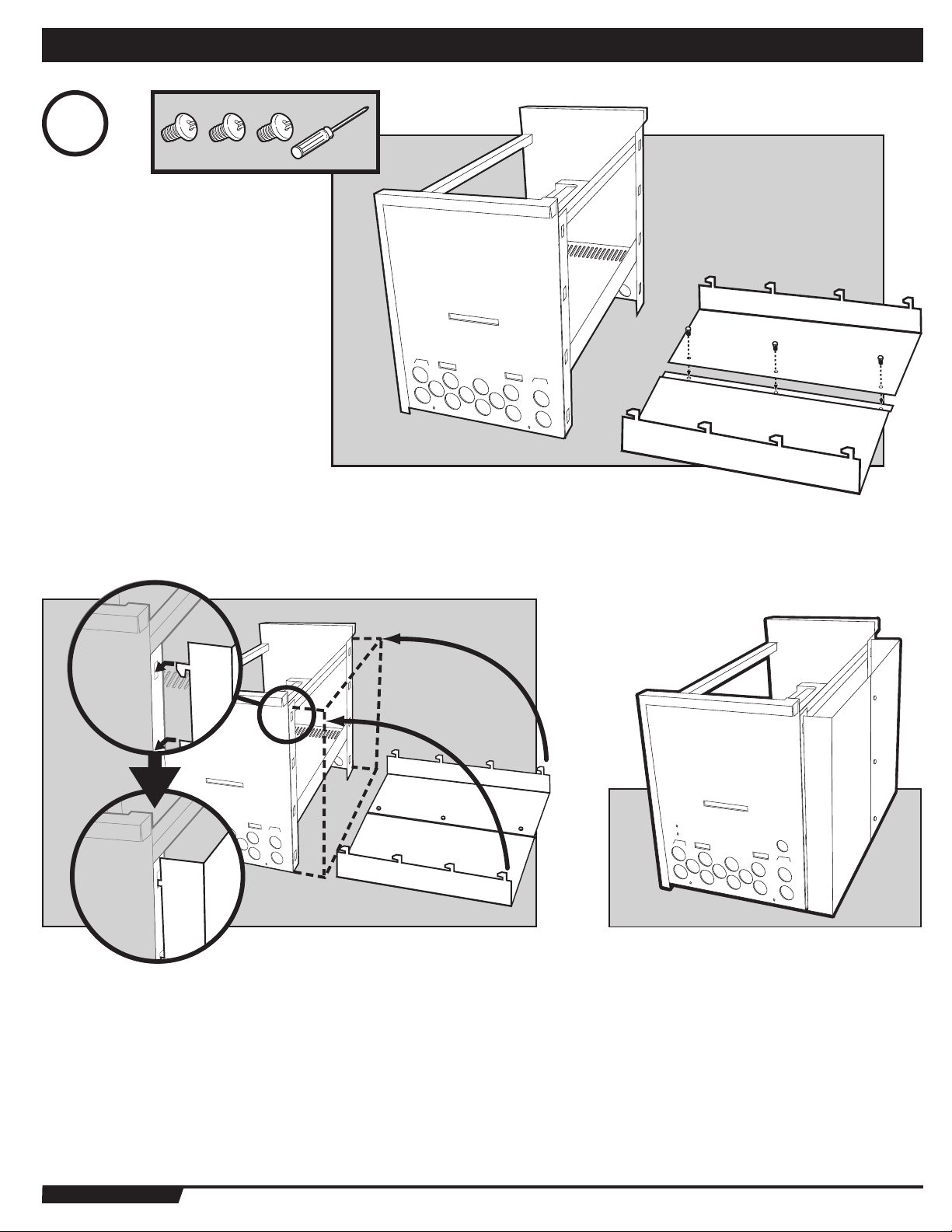

ATTENTION! Do not fully tighten screws.

Clips should slide freely when installed.

ASSEMBLY

7

7

4

WWW.WEBER.COM

®

Page 8

8

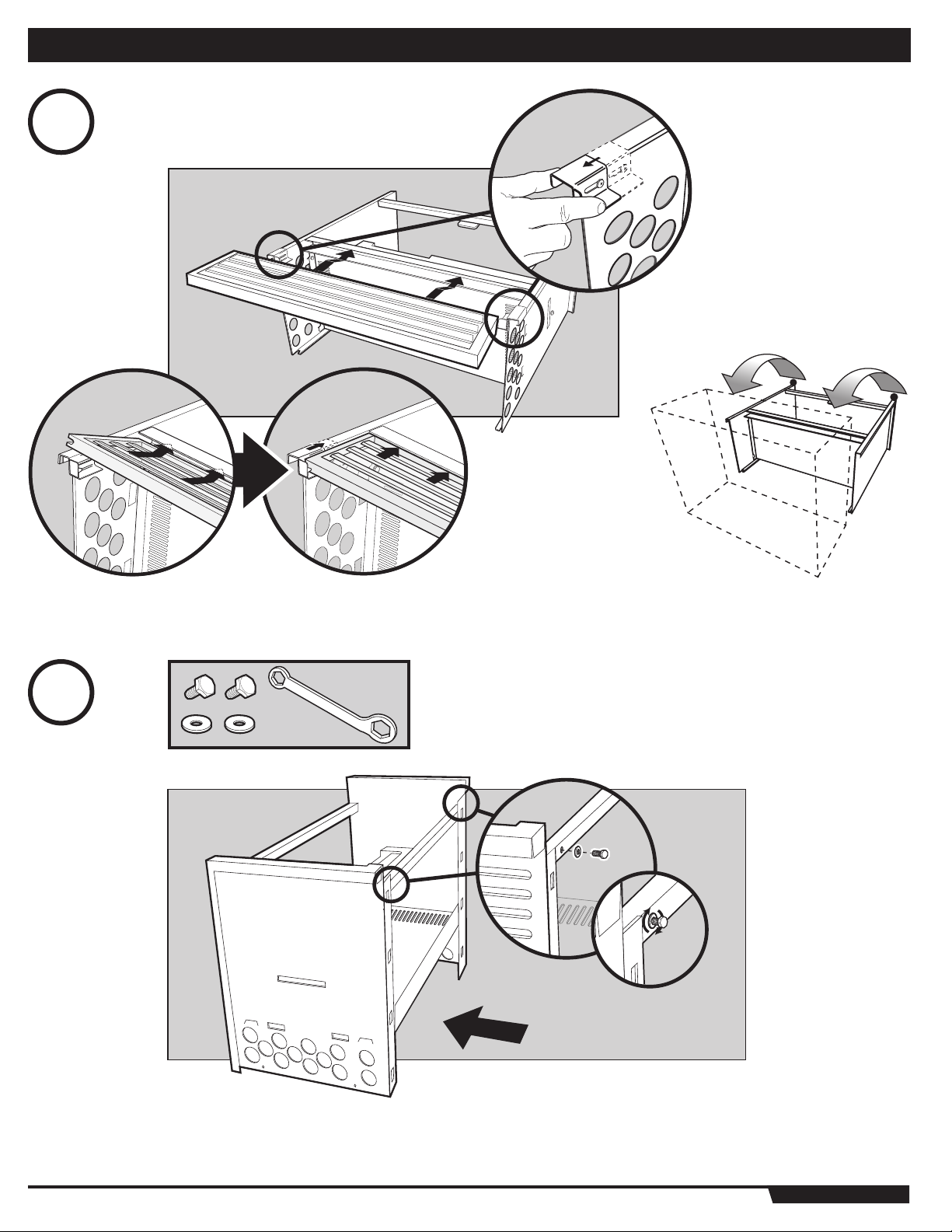

5

ASSEMBLY

6

Back

WWW.WEBER.COM

®

Page 9

7

ASSEMBLY

9

9

WWW.WEBER.COM

®

Page 10

10

8

ASSEMBLY

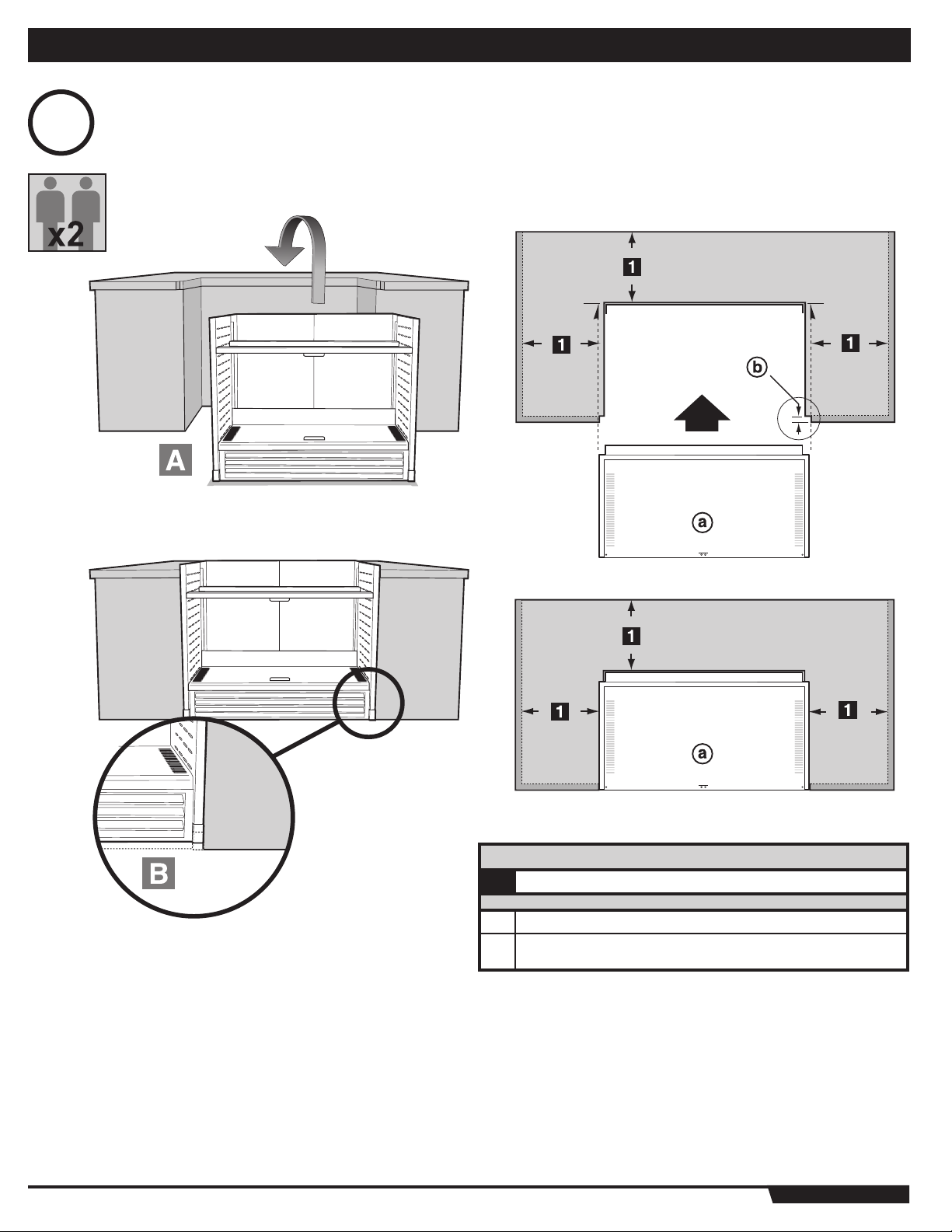

CAUTION: Use two people to lift and install the Summit® Built-In frame assembly.

A) Lift the frame assembly into the “island” structure opening. Make sure the frame is resting level on the finished surface of the structure.

B) Adjust the Front Vent to rest squarely on ground.

CLEARANCES

24" (610 mm) Any Surface

1

Grill Frame

a

Note: For a countertop treatment: Recommended 19.1 mm (3/4˝

b

inch) overhang. Notch front edge for frame to fully slide in.

WWW.WEBER.COM

®

Page 11

9

ASSEMBLY

11

11

1/4" (6.35 mm)

Drill Bit

10

S-460™

A

ATTENTION! Before applying

any silicone sealant make

sure the cookbox is flush with

the front of the grill frame.

A) Apply a bead of silicone sealant (1) around

the perimeter and front edges of the grill that

are in contact with the “island” structure. This

will prevent moisture seepage. The sealant

you use must have a temperature rating

above 120°F (48.8° C).

(1)

S-660™

WWW.WEBER.COM

®

Page 12

12

ASSEMBLY

11

S-460™

F ))#

3 -

1

BATTERY HOUSING WIRING

1 BLACK WIRE

4

3

2 GREEN WIRE

3 RED WIRE

4 RED WIRE

WARNING: Make sure that all control knobs are turned to the OFF

2

position before connecting the gas supply and operating the grill.

D

WWW.WEBER.COM

®

Page 13

12

ASSEMBLY

Requires 3 “D” alkaline batteries (Included). Use alkaline

batteries only. Do not mix old and new batteries or different types

of batteries (standard, alkaline or rechargeable).

13

13

13

Note: Secure wire to side panel.

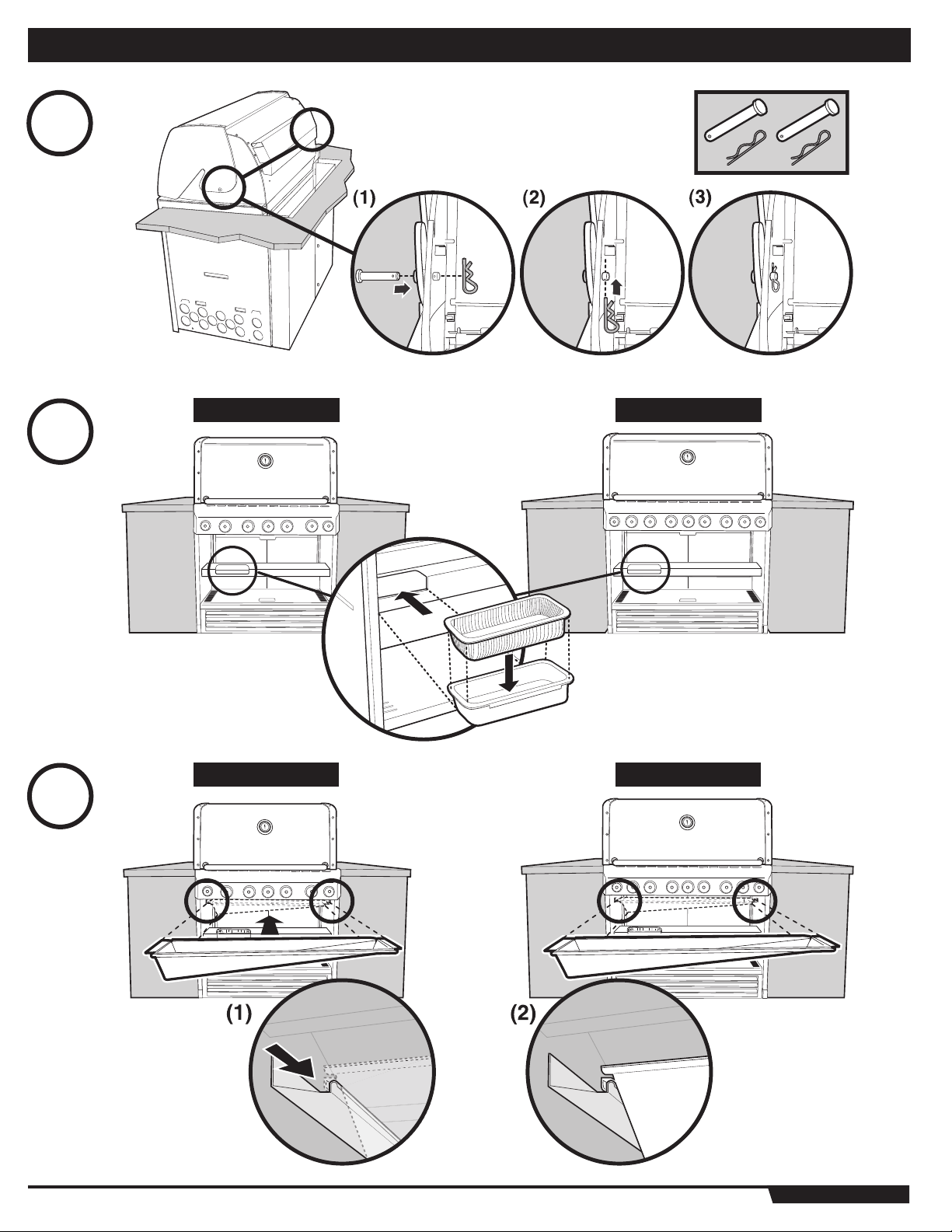

(1) (2) (3)

WWW.WEBER.COM

®

Page 14

14

14

15

ASSEMBLY

S-660™S-460™

16

S-660™S-460™

WWW.WEBER.COM

®

Page 15

ASSEMBLY

15

17

A

S-660™S-460™

15

WWW.WEBER.COM

B

Match Holder

C

®

Page 16

16

18

ATTENTION!

Before drilling

any holes for the

rear vent make

sure the cookbox

is flush with the

front of the grill

frame.

ASSEMBLY

1/4" (6.35 mm)

Drill Bit

WWW.WEBER.COM

®

Page 17

ASSEMBLY

17

19

S-660™S-460™

17

20

S-460

™

S-660

™

WWW.WEBER.COM

®

Page 18

18

21

ASSEMBLY

22

S-460

™

S-660

™

S-660™S-460™

WWW.WEBER.COM

®

Page 19

ASSEMBLY

19

23

S-660™S-460™

19

WWW.WEBER.COM

®

Page 20

20

24

S-460

S-660

ASSEMBLY

™

™

WWW.WEBER.COM

®

Page 21

+

+

+

25

AAA

AAA

AAA

S-460

S-660

ASSEMBLY

™

- 1

™

- 2

The Weber Grill Out™ Handle Light has a “Tilt Sensor”: Lid up - ON / Lid Closed - OFF. The power

button (a) activates or deactivates the “Tilt Sensor.” For daytime use, deactivate the sensor by

pressing power button (a).

Requires 3 “AAA” alkaline batteries

(not included)

21

S-460

S-660

21

™

- 2

™

- 4

WWW.WEBER.COM

™

S-660

®

Page 22

22

GAS SUPPLY

BUILT-IN GAS LINE LOCATIONS

Note: Leave an access in the “island” structure for gas supply and regulator service

that is not inside the grill structure. Note: Area should be kept clear of sharp, jagged, or

extremely abrasive surfaces to avoid possible damage to gas supply lines. Exercise

caution when pulling gas lines through built-in structure.

1

(120.65 mm)

2

DIMENSIONS

3

a

b

c

BUILT-IN GAS LINE LOCATIONS

460 660 TOLERANCES

4 3/4˝

6 1/4˝

(158.8 mm)

2 1/2˝

(63.5 mm)

4 3/4˝

(120.65 mm)

6 1/4˝

(158.8 mm)

2 1/2˝

(63.5 mm)

Plan View Left

Side View

Gas Inlet

+1/8˝(

- 1/8˝(

+1/8˝(

- 1/8˝(

+1/8˝(

- 1/8˝(

3.8

3.8

3.8

3.8

3.8

3.8

mm)

mm)

mm)

mm)

mm)

mm)

TYPICAL BULK PROPANE GAS SUPPLY INSTALLATION

We recommend that this installation be done by a LICENSED professional.

GENERAL SPECIFICATIONS FOR PIPING

Note - Contact your local municipality for building codes regulating outdoor gas grill

installations. In absence of Local Codes, you must conform to the latest edition of the

National Fuel Gas Code ANSI Z223.1/NFPA 54, Natural Gas and Propane Installation

Code, CSA B149.1, or Propane Storage and Handling Code, B149.2, or the Standard for

Recreational Vehicles, ANSI A 119.2/NFPA 1192, and CSA Z240 RV Series, Recreational

Vehicle Code, as applicable.

• This grill is designed to operate at 11 inches of water column pressure. An LP in line

regulator may be necessary for this pressure.

CAUTION: If young children are in the area, a locking valve

should be considered.

• Pipe compound should be used which is resistant to the action of liquid propane

gas when gas connections are made.

• The gas connections must be firmly attached to rigid, permanent construction.

Note: The information provided in this manual is general for typical installations. We

cannot cover all possible installation ideas. We recommend, prior to installation, that you

contact your municipality for local building codes and your local fire department for

installation verification.

If you have any questions, contact Customer Service at 1-800-446-1071.

WWW.WEBER.COM

®

Page 23

GAS SUPPLY

23

Tab le

6.2(a)

Nominal

Iron Pipe

Size

(Inches)

1/2 .622 131 90 72 62 55 50 46 42 40 38 33 30 28 26

3/4 .824 273 188 151 129 114 104 95 89 83 79 70 63 58 54

1 1.049 514 353 284 243 215 195 179 167 157 148 131 119 109 102

1 1/4 1.380 1,060 726 583 499 442 400 368 343 322 304 269 244 224 209

1/12 1.610 1,580 1,090 873 747 662 600 552 514 482 455 403 366 336 313

2 2.067 3,050 2,090 1,680 1,440 1,280 1,160 1,060 989 928 877 777 704 648 602

2 1/2 2.469 4,860 3,340 2,680 2,290 2,030 1,840 1,690 1,580 1,480 1,400 1,240 1,120 1,030 960

3 3.068 8,580 5,900 4,740 4,050 3,590 3,260 3,000 2,790 2,610 2,470 2,190 1,980 1,820 1,70 0

4 4.026 17,500 12,000 9,660 8,270 7,330 6,640 6,110 5,680 5,330 5,040 4,460 4,050 3,720 3,460

TEST CONNECTIONS

All connections and joints must be thoroughly tested for leaks in accordance with local

codes and all listed procedures in the latest edition of the National Fuel Gas Code ANSI

Z223.1/NFPA 54, Natural Gas and Propane Installation Code, CSA B149.1, or Propane

Storage and Handling Code, B149.2, or the Standard for Recreational Vehicles, ANSI A

119.2/NFPA 1192, and CSA Z240 RV Series, Recreational Vehicle Code, as applicable.

Actual

ID:

(Inches)

© 2008 National Fire Protection Association, Inc. and International Approval Services - U.S., Inc. All Rights Reserved.

Maximum Capacity of Metallic Pipe in Cubic Feet of Gas per Hour for Gas Pressures of 2 psi or Less and

a Pressure Drop of 0.3 Inch Water Column. (Based on a 0.60 Specific Gravity Gas)

Length of Pipe (Feet)

10 20 30 40 50 60 70 80 90 100 125 150 175 200

DANGER

Do not use an open flame to check for gas leaks. Be sure

there are no sparks or open flames in the area while you

check for gas leaks. This will result in a fire or explosion

which can cause serious bodily injury or death, and damage

to property.

23

WWW.WEBER.COM

®

Page 24

24

GAS SUPPLY

TYPICAL 20 LP PROPANE GAS SUPPLY INSTALLATION

The remote tank enclosure kit provide with you grill shall be used for installations using a

20 lb LP cylinder, mounted in an “island” structure.

The remote tank enclosure shall house the included hose and regulator assembly and

gas connections, the tank bracket and the fuel scale for connecting a remote mounted

LP cylinder to the Summit

part of the CSA listed Summit® Built-In gas grill.

A properly installed tank enclosure meets the requirements for venting, tank retention

and separation of the LP cylinder from a heat source as outlined in the ANSI Standard for

Outdoor Cooking Gas Appliances, Z21.58/CSA 1.6 for LP enclosures.

You need to hire a licensed contractor or licensed plumber and they need to follow the

requirements described in the ANSI Standard for Outdoor Cooking Gas Appliances,

Z21.58/CSA 1.6 for LP enclosures.

The requirements described in the Standard for Outdoor Cooking Gas Appliances,

Z21.58/CSA 1.6. are as follows;

A remote enclosure for an LP gas cylinder shall be ventilated by openings at both the

upper and lower levels of the cylinder. This shall be accomplished by one of the following:

A) One side of the remote LP cylinder enclosure shall be completely open; or

B) If the remote LP cylinder enclosure is designed to have four sides, a top and a bottom,

ventilation is required for the remote LP cylinder enclosure;

1) There should be at least two ventilation openings, (a hole or group of

holes, for the purpose of ventilation) in the sidewalls of the island structure.

The openings should be located within 5 inches (127mm) of the top of the

enclosure. The ventilation openings should be equally sized and spaced at a

minimum of 90 degrees, and be unobstructed. The openings shall have a total

free open area of not less than 20 square inches. (This relates to 1 square

inch of ventilation area, per pound of stored fuel capacity).

2) Ventilation openings (a hole or group of holes, for the purpose of ventilation)

should be provided at floor level. The ventilation openings should have a total

free area of not less than 10 square inches. (This relates to 1/2 square inch of

ventilation area, per pound of stored fuel capacity). There should be at least

two ventilation openings if the ventilation openings at floor level are in the

sidewall. The ventilation openings should be within 5 inches (127mm) of the

floor. The ventilation openings should be of equal size and be spaced at a

minimum of 90 degrees, and should be unobstructed.

3) The minimum size of the ventilation hole (s) should not be less than 1/4 inch.

4) The ventilation openings in the sidewalls should not allow venting into

the empty or “hollow” area of the “island”. If a gas leak should occur or

the LP cylinder should vent in the LP cylinder enclosure, the gas should

not be allowed to vent or migrate into the empty or “hollow” area of the

“island”. Ventilation openings in the sidewalls of the enclosure should only

communicate with the outside of the “island” structure, so that the gas can

dissipate outside of the “island” structure.

C) If the remote LP cylinder enclosure has four sides, a top and a bottom, and is intended

for installation in a built-in “island” enclosure;

1) At least one ventilation opening (a hole or group of holes, for the purpose

of ventilation) needs to be on one side of the enclosure that communicates

with the outside of the “island” structure. If a gas leak should occur or the

LP cylinder should vent in the LP cylinder enclosure, the gas should not

be allowed to vent or migrate into the empty or “hollow” area of the “island”.

Ventilation openings should only communicate with the outside of the “island”

structure, so that the gas can dissipate outside of the “island” structure. The

ventilation opening should be located within 5 inches (127mm) of the top of

the enclosure, and should have a total free area of 20 square inches. (This

relates to 1 square inch of ventilation area, per pound of stored fuel).

2) At least one ventilation opening (a hole or group of holes, for the purpose of

ventilation) needs to be on one side of the enclosure that communicates with

the outside of the “island” structure, at the bottom. If a gas leak should occur

or the LP cylinder should vent in the LP cylinder enclosure, the gas should

not be allowed to vent or migrate into the empty or “hollow” area of the “island”.

Ventilation openings should only communicate with the outside of the “island”

structure, so that the gas can dissipate outside of the “island” structure. The

ventilation opening should be located within 5 inches (127mm) of the bottom

of the enclosure, and should have a total free area of 10 square inches. (This

relates to 1/4 square inch of ventilation area, per pound of stored fuel).

3) The minimum size of the ventilation hole (s) should not be less than 1/4 inch

(6.35mm).

®

Built-In gas grill. The hose and regulator is listed as a required

D) The remote LP cylinder enclosure should be constructed with non-combustible

materials. The remote LP cylinder enclosure should isolate the LP cylinder from the

burner compartment, so that it provides shielding from radiation, be a flame barrier

and provide protection from foreign material such as hot drippings.

E) There should be a minimum of 2 inches (50.8mm) between the ground and the floor of

the remote LP cylinder enclosure.

F) The LP cylinder valve should be readily accessible for hand operation. A door on the

remote LP cylinder enclosure to gain access to the LP cylinder valve is acceptable,

provided it is non-locking and can be opened without the use of tools.

DANGER

Use of any other hose and regulator assembly could be

dangerous, and may not provide adequate gas supply to

the Summit® Built-In gas grill, and could result in a fire or an

explosion causing serious bodily injury or death, and damage

to property.

DANGER

Failure to build a remote LP cylinder enclosure for a 20 lb

cylinder following the requirements for ventilation, cylinder

retention and separation of the LP cylinder from a heat

source, listed in the ANSI Standard for Outdoor Cooking Gas

Appliances, ANSI Z21.58 CSA 1.6, could be dangerous, and

could result in a fire or an explosion causing serious bodily

injury or death and damage to property.

If you do not follow the DANGER statements exactly, the Warranty on the Summit® Built-In

gas grill will be voided.

WWW.WEBER.COM

®

Page 25

BUILT-IN TANK ENCLOSURE INSTRUCTIONS

25

25

OPERATING

WARNING: Only use the Weber® Tank Enclosure Kit outdoors

in a well-ventilated area. Do not use in a garage, building,

breezeway or any other enclosed area.

WARNING: Your Weber® Tank Enclosure Kit shall not be used

under an unprotected combustible roof or overhang.

WARNING: Your Weber® Tank Enclosure Kit is not intended to

be installed in or on recreational vehicles and/or boats.

WARNING: Keep any electrical supply cord and the fuel

supply hose away from any heated surface.

WARNING: Never store an extra (spare) LP cylinder under or

near the Weber® gas barbecue.

WARNING: Keep the ventilation openings of the cylinder

enclosure free and clear of debris.

WARNING: Turn off the gas at the LP gas supply cylinder

when the outdoor cooking gas appliance is not in use.

WARNING: Never store an outdoor cooking gas appliance

indoors unless the LP cylinder is disconnected and removed

from the outdoor cooking gas appliance.

WARNING: LP Cylinders must be stored outdoors out of

the reach of children and must not be stored in a building,

garage, or any other enclosed area.

WARNING: The LP pressure regulator and hose assembly

supplied with the Weber

Replacement LP pressure regulators and hoses must be

obtained from Weber-Stephen Product Co.

®

Tank Enclosure Kit must be used.

WWW.WEBER.COM

®

Page 26

26

BUILT-IN TANK ENCLOSURE INSTRUCTIONS

DANGER

Use of any other hose and regulator assembly could be

dangerous, and may not provide adequate gas supply to

the Summit

®

Built-In gas grill, and could result in a fire or an

explosion causing serious bodily injury or death and damage

to property.

DANGER

Failure to build a LP cylinder enclosure for a 20 lb cylinder

following the requirements for ventilation, cylinder retention

and separation of the LP cylinder from a heat source, listed in

the ANSI Standard for Outdoor Cooking Gas Appliances, ANSI

Z21.58 CSA 1.6, could be dangerous, and could result in a fire

or an explosion causing serious bodily injury or death and

damage to property.

If you do not follow the DANGER statements exactly, the Warranty on the Summit®

Built-In gas grill will be voided.

LOCATING YOUR LP TANK ENCLOSURE KIT

When determining a suitable location for your LP Tank Enclosure Kit installation, give

attention to concerns such as proximity to traffic paths, and keeping any gas supply

lines as short as possible. Never locate the Summit® LP Tank Enclosure Kit in a garage,

breezeway, shed, under an unprotected overhang, or other enclosed area. Locate the LP

Tank Enclosure Kit and structure so there is enough room to safely evacuate the area in

case of a fire.

c

1

b

1 1

b

a

ENCLOSURE CHART

24˝ inches (610 mm) Any Surface

1

LP Tank Enclosure

a

Any Surface

b

Non-Combustible Surface

c

CLEARANCE FROM COMBUSTIBLE SURFACES OR

STRUCTURES

WARNING: Clearance from the outside walls of the sides

and back of the LP Tank Enclosure must be a minimum of

24" (60.96cm) any surface. Refer to “Typical Gas Supply

Installation” before starting installation.

WARNING: The structure, “island” counter tops and adjacent

work areas for the LP Tank Enclosure must be built from

noncombustible materials only.

NOTE: If you have questions on what materials are considered noncombustible, contact

you local building supplier or fire department.

WWW.WEBER.COM

®

Page 27

PARTS LIST / ASSEMBLY

27

PARTS LIST

Hose and regulator - 1

Tank stand - 1

1

4

8

4

27

Tank stand base - 1

Tank Scale - 1

1/4-20 nut - 6

Nylon washer - 12

1/4-20 x 1/2” bolt - 6

Cylinder glide - 2

2

2

4

WWW.WEBER.COM

1/2” Flare Gasket - 2

2

3/8” Flare Gasket - 2

®

2

Page 28

28

MOUNTING THE LP TANK BRACKET

Mount the LP tank bracket to the right hand side of the enclosure opening using non corrosive hardware. Mounting holes are provided on the sides and bottom of your LP tank bracket.

Be sure to mount the bracket securley to the enclosure before use.

MOUNTING HARDWARE NOT INCLUDED.

MOUNTING THE LP HOSE AND REGULATOR

Securley mount the hose and regulator bracket to the top of the built-in tank enclosure using non corrosive hardware.

ASSEMBLY

3

MOUNTING HARDWARE NOT INCLUDED.

LP TANK ENCLOSURE GAS LINE LOCATIONS

Area should be kept clear of sharp, jagged, or extremely abrasive surfaces to avoid possible damage to gas supply lines. Exercise caution when pulling gas lines through built-in

structure.

4

WWW.WEBER.COM

®

Page 29

GAS SUPPLY

29

CONNECT GAS SUPPLY

A 58 inch (147.32 cm) corrugated gas line is supplied with the grill. This line needs to pass

through the gas inlet opening to the main gas supply.

1) Connect the corrugated gas line to the manifold located on the right hand side of grill

under the control panel. Use the 1/2” flared gasket (1) to ensure proper seal.

Note: 1/2” flared gaskets are included in the Summit

with your grill.

The corrugated line passes through the “Island Structure” cavity to the hose and regulator

connection inside the tank enclosure. (Shown in illustration)

2) Uncap one flare fitting from the 90º Connection on the regulator hose located inside

the tank enclosure.

3) Use the 1/2 (12.7 mm) inch flared gasket to ensure proper seal.

NOTE: Only use the 3/8 inch (9.53 mm) flared gasket if you are installing the optional side

burner.

4) Connect the corrugated gas line to the 90º Connection.

®

Built-In tank Enclosure Kit included

29

A

CONNECTION CHART

Top View

A

Typical tank cabinet or tank enclosure location

B

Side View

C

Top of Box

D

Back of Box

E

Corrugated Gas Line to Manifold

i

90° fitting

ii

1/2” (12.7 mm) Flared Gasket

iv

Cap (Optional Side Burner)

v

B

i

E

iv

v

C

D

ii

WWW.WEBER.COM

®

Page 30

30

GAS SUPPLY

VENTILATION

WARNING: Ventillation holes must be provided in the

structure at the top and bottom to provide ventilation in the

event of a gas leak.

Ventilation holes can be located in a low visibility area and should be protected by

screening material to prevent rodents and insects from entering the structure. Air holes

will also help dry moisture.

Note: These drawings are only a reference.

• Cross ventilation must be incorporated in the supporting structure. We recommend

a minimum of 100 square inches (254 square cm )of venting per side.

• Vents should be on two sides of the structure.

• The above drawings are for reference only.

• Location of the vents should be from the center, outward.

• Locate the vents at both the bottom of the structure and at the top of the structure.

• The bottom vents should be as close to ground level as possible. Make sure the

vent area is not blocked by interior supports of the structure.

• We recommend vents with screens.

• Access doors to the structure are not considered vents.

• Clean the vents periodically.

DANGER: Failure to follow recommended minimum venting

instructions can cause gas to collect in the structure in the

event of a gas leak. This may result in a fire or an explosion

which can cause serious bodily injury or death, and damage

to property.

WWW.WEBER.COM

®

Page 31

NOTES

31

31

Page 32

ATTENTION: This product has been safety tested and is only certified for use in a specific country. Refer to country designation

located on outer carton.

These parts may be gas carrying or gas burning components. Please contact Weber-Stephen Products Co., Customer Service Department for genuine Weber-Stephen

Products Co. replacement part(s) information.

WARNING: Do not attempt to make any repair to gas carrying, gas burning, igniter components or structural components

without contacting Weber-Stephen Products Co., Customer Service Department. Your actions, if you fail to follow this Product

Warning, may cause a fire, an explosion, or structural failure resulting in serious personal injury or death as well as damage to

property.

WEBER-STEPHEN PRODUCTS CO.

www.weber.com

©2009 The following trademarks are registered in the name of Weber-Stephen Products Co., an Illinois corporation, located at 200 East Daniels Road, Palatine, Illinois 60067 U.S.A.

Australia; Smokey Joe, Weber, Kettle Silhouette

tion, Botswana; Weber, Canada; Smokey Joe, Genesis, China; Kettle Silhouette

Smokey Joe, Weber, One-Touch, Germany; Smokey Joe, Weber, One-Touch, Greece; Smokey Joe, Ireland; Kettle Silhouette

Joe, Weber, Korea; Smokey Joe, Weber, New Zealand; Weber, Smokey Joe, Nigeria; Weber, Norway; Smokey Joe, Weber, Portugal; Weber, South Africa: Smokey Joe, Weber, Kettle

Configuration, Spain; Smokey Joe, Weber, Sweden; Kettle Silhouette

One-Touch, U.S.A..; Kettle Configuration, Kettle Silhouette

Crossover, Flamgo, Performer, Rapidfire, Tuck ‘N Carry, Jumbo Joe, Bar-B-Kettle, Master-Touch, Spirit, Grill Out, Summit, Platinum, 1-800-Grill-Out, Ranch, Matchless Flame, Zimbabwe;

Weber, Kettle Configuration, Kettle Silhouette

, Genesis, Austria; Kettle Silhouette , Smokey Joe, Weber, Benelux; Kettle Silhouette , Smokey Joe, Weber, Compact Grill Configura-

, Smokey Joe, Switzerland; Kettle Silhouette , Smokey Joe, Weber, United Kingdom; Smokey Joe, Weber, Weber

, Smokey Joe, Weber, One-Touch, Firespice, Go-Anywhere, U.S.A.;Kettle Configuration, Kettle Silhouette, Genesis, Flavorizer,

.

, Denmark; Kettle Silhouette , Smokey Joe, Weber, Finland; Smokey Joe, France; Kettle Silhouette ,

®

, Smokey Joe, Italy; Smokey Joe, Weber, Japan; Smokey

Loading...

Loading...