Page 1

Built-In LP Side Burner

BUILT-IN LP SIDE BURNER INSTALLATION/OWNER'S GUIDE

Installation/Owner’s Guide

GUÍA DEL PROPIETARIO DEL ASADOR DE GAS LICUADO DE PROPANO - PG 21

GUIDE DE L’UTILISATEUR DU GRILL À GAZ PL - PG 38

#56069

THIS APPLIANCE MAY BE PURCHASED SEPERATELY FOR YOUR WEBER BUILT-IN BARBECUE GRILL.

YOU MUST READ THIS OWNER’S GUIDE

BEFORE OPERATING YOUR SIDE BURNER

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

Leaking gas may cause a fire or explosion

which can cause serious bodily injury or

death, or damage to property.

WARNING:

1. Do not store or use gasoline or other

flammable liquids or vapors in the vicinity

of this or any other appliance.

2. An LP cylinder not connected for use shall

not be stored in the vicinity of this or any

other appliance.

WARNING: Follow all leak-check

procedures carefully in this manual prior

to operation. Do this even if the appliances

were dealer-assembled.

NOTICE TO INSTALLER: These instructions

must be left with the owner and the owner

should keep them for future use.

THIS GAS APPLIANCE IS DESIGNED FOR

OUTDOOR USE ONLY.

WARNING: Do not try to light this appliance

without reading the “Lighting Instructions”

section of this manual.

56069 US 04/01/09

LP

US ENGLISH

Page 2

2

DANGERS & WARNINGS

DANGER

Failure to follow the Dangers, Warnings and Cautions contained in this Owner’s Manual may result in serious bodily injury or

death, or in a fire or an explosion causing damage to property.

WARNINGS

Do not store a spare or disconnected liquid propane cylinder under or near the barbecue and Side Burner.

Improper assembly may be dangerous. Please follow the assembly instructions carefully.

After a period of storage, and/or nonuse, the Weber® gas barbecue and Side Burner should be checked for gas leaks and

burner obstructions before use. See instructions in this manual for correct procedures.

Do not operate either the Weber

Do not use a flame to check for gas leaks.

Combustible materials should never be within 24 inches (61 cm) of the back or sides of your Weber

®

gas barbecue or Side Burner if there is a gas leak present.

®

gas appliances.

Do not put a cover or anything flammable on, or in the storage area under the appliances.

Your Weber® gas appliances should never be used by children. Accessible parts of the appliances may be very hot. Keep

young children away while it is in use.

You should exercise reasonable care when operating your Weber® gas appliances. It will be hot during cooking or cleaning and

should never be left unattended, or moved while in operation.

Should the burners go out while in operation, turn all gas valves off. Open the lid and wait five minutes before attempting to

relight, using the lighting instructions.

Do not use charcoal or lava rock in your Weber

®

gas appliances.

Never lean over open appliance or place hands or fingers on the front edge of the cooking area.

Should a grease fire occur, turn off all burners and leave lid closed until fire is out.

Do not enlarge valve orifices or burner ports when cleaning the valves or burners.

The Weber

®

gas appliance should be thoroughly cleaned on a regular basis.

Liquid propane gas is not natural gas. The conversion or attempted use of natural gas in a liquid propane unit or liquid propane

gas in a natural gas unit is dangerous and will void your warranty.

Do not attempt to disconnect any gas fitting while your appliances are in operation.

Use heat-resistant barbecue mitts or gloves when operating appliances.

Keep any electrical supply cord and the fuel supply hose away from any heated surfaces.

Combustion byproducts produced when using this product contain chemicals known to the state of California to cause cancer,

birth defects, or other reproductive harm.

Do not use this appliance unless all parts are in place. The unit must be properly assembled according to the assembly

instructions.

Proposition 65 Warning: Handling the brass material on this product exposes you to lead, a chemical known to the state of

California to cause cancer, birth defects or other reproductive harm.

(Wash hands after handling this product.)

LIQUID PROPANE GAS UNITS ONLY:

Use the pressure regulator and hose assembly that is supplied with your Weber® gas barbecue.

Do not attempt to disconnect the gas regulator and hose assembly or any gas fitting while your appliances are in operation.

A dented or rusty liquid propane cylinder may be hazardous and should be checked by your liquid propane supplier. Do not

use a liquid propane cylinder with a damaged valve.

Although your liquid propane cylinder may appear to be empty, gas may still be present, and the cylinder should be

transported and stored accordingly.

If you see, smell or hear the hiss of escaping gas from the liquid propane cylinder:

1. Move away from liquid propane cylinder.

2. Do not attempt to correct the problem yourself.

3. Call your fire department.

WWW.WEBER.COM

®

Page 3

WARRANTY, GARANTÍA, GARANTIE

WARRANTY, GARANTÍA, GARANTIE

3

WARRANTY

Weber-Stephen Products Co. (Weber) hereby warrants to the ORIGINAL PURCHASER of this Weber®

gas appliance that it will be free of defects in material and workmanship from the date of purchase as

follows:

Stainless Steel Lid, 10 years

All Remaining Parts, 5 years

When assembled and operated in accordance with the printed instructions accompanying it.

Weber may require reasonable proof of your date of purchase. THEREFORE, YOU SHOULD RETAIN

YOUR SALES SLIP OR INVOICE.

This Limited Warranty shall be limited to the repair or replacement of parts that prove defective under

normal use and service and which on examination shall indicate, to Weber’s satisfaction, they are

defective. Before returning any parts, contact the Customer Service Representative in your area using

the contact information on our website. If Weber confirms the defect and approves the claim, Weber will

elect to replace such parts without charge. If you are required to return defective parts, transportation

charges must be prepaid. Weber will return parts to the purchaser, freight or postage prepaid.

This Limited Warranty does not cover any failures or operating difficulties due to accident, abuse,

misuse, alteration, misapplication, vandalism, improper installation or improper maintenance or service,

or failure to perform normal and routine maintenance, including but not limited to damage caused by

insects within the burner tubes, as set out in this owner’s manual.

Deterioration or damage due to severe weather conditions such as hail, hurricanes, earthquakes

or tornadoes, discoloration due to exposure to chemicals either directly or in the atmosphere, is not

covered by this Limited Warranty.

GARANTÍA

Weber-Stephen Products Co. (Weber) por este medio le garantiza al COMPRADOR ORIGINAL de esta

barbacoa de gas Weber® que la misma estará libre defectos en cuanto a materiales y fabricación a

partir de la fecha de compra según lo siguiente:

Tapa de acero inoxidable, 10 años

Todas las demás partes 5 años

Cuando se ensambla y opera de acuerdo a las instrucciones impresas que lo acompañan.

Weber pudiese requerir prueba razonable de la fecha de compra. POR LO TANTO, DEBERÁ

GUARDAR SU RECIBO O FACTURA DE VENTA.

Esta garantía limitada está limitada a la reparación o reemplazo de piezas que se resultasen

defectuosas bajo uso y servicio normal y las cuales al examinarse indiquen, a la plena satisfacción de

Weber, que son defectuosas. Antes de devolver cualquier parte, contacte al Representante de Atención

al Cliente en su área geográfica, cuya información de contacto la encontrará en nuestro sitio web. Si

Weber confirma el defecto y aprueba el reclamo, ésta elegirá reparar o reemplazar tal pieza sin cargo

alguno. Si usted tiene que retornarnos las partes defectuosas, los gastos de transporte deben ser

prepagados. Weber retornará las partes al comprador con transporte o franqueo prepagado.

Esta Garantía Limitada no cubre ninguna falla o problema de operación a causa de accidentes,

abuso, mal uso, alteración, uso en aplicaciones indebidas, vandalismo, instalación inapropiada o

mantenimiento o servicio inapropiados, o por no llevar a cabo el mantenimiento normal y rutinario,

entre los que se incluyen, pero sin limitación, los daños causados por insectos dentro de los tubos

quemadores, según se detalla en este manual del propietario.

Esta Garantía Limitada no cubre el deterioro o daños a causa de condiciones de tiempo inclementes

tales como granizo, huracanes, terremotos o tornados ni tampoco la decoloración por exposición a

sustancias químicas bien sea por contacto directo o por las mismas contenidas en la atmósfera.

There are no other express warrants except as set forth herein and any applicable implied warranties

of merchantability and fitness are limited in duration to the period of coverage of this express written

Limited Warranty. Some regions do not allow limitation on how long an implied warranty lasts, so this

limitation may not apply to you.

Weber is not liable for any special, indirect or consequential damages. Some regions do not allow the

exclusion or limitation of incidental or consequential damages, so this limitation or exclusion may not

apply to you.

Weber does not authorize any person or company to assume for it any other obligation or liability in

connection with the sale, installation, use, removal, return, or replacement of its equipment; and no

such representations are binding on Weber.

This Warranty applies only to products sold at retail.

WEBER-STEPHEN PRODUCTS CO.

Customer Service Center

1890 Roselle Road, Suite 308

Schaumburg, IL 60195

USA

For replacement parts call:

1-800-446-1071

www.weber.com

No existe ningunas otras garantías expresas que no sean las las acá indicadas y cualesquier

garantías implícitas de comerciabilidad y aptitud de uso están limitadas en duración al tiempo de

cobertura de esta expresa Garantía Limitada por escrito. Algunas regiones no permiten limitación

alguna en el tiempo que una garantía implícita pueda durar, por lo que esta limitación pudiera no

aplicarle a usted.

Weber no se hace responsable de ningún daño especial, indirecto o emergente. Algunas regiones no

permiten la exclusión o limitación de daños incidentales o emergentes, por lo que esta limitación o

exclusión pudieran no aplicarle a usted.

Weber no autoriza a persona o empresa alguna a asumir en su nombre ninguna obligación o

responsabilidad en relación con la venta, instalación, uso, retiro, devolución o reemplazo de sus

equipos, y ninguna tal representación será vinculante para Weber.

Esta Garantía aplica solo a aquellos productos vendidos al por menor.

WEBER-STEPHEN PRODUCTS CO.

Customer Service Center

1890 Roselle Road, Suite 308

Schaumburg, IL 60195

USA

Para partes de repuesto llame a:

1-800-446-1071

www.weber.com

®

Para compras hechas en México

WEBER-STEPHEN PRODUCTS S.A.

de C.V.

Marcella No. 338,

Colonia Americana

44160 México, C.P.

México

®

Para partes de repuesto llame a:

(52) (33) 3615-0736

www.weber.com

®

GARANTIE

Weber-Stephen Products Co. (Weber) garantit par le présent document à l’ACHETEUR D’ORIGINE de

ce grill à gaz Weber® que celui-ci ne comportera aucun défaut de pièce ni de main d’oeuvre à compter

de la date d’achat comme suit :

Couvercle en acier inoxydable, 10 ans

Toutes les autres pièces, 5 ans

Lorsque celui-ci est monté et utilisé conformément aux instructions imprimées qui l’accompagnent.

Weber peut exiger une preuve raisonnable de votre date d’achat. PAR CONSEQUENT, VOUS

DEVRIEZ CONSERVER VOTRE TICKET DE CAISSE OU VOTRE FACTURE.

La présente Garantie limitée couvre uniquement la réparation ou le remplacement des pièces qui

se révèlent défectueuses dans des conditions d’utilisation et d’entretien normales et dont l’examen

indique, à la satisfaction de Weber, qu’elles sont défectueuses. Avant de nous retourner toute pièce,

veuillez entrer en contact avec le Représentant du service clientèle de votre région grâce aux

coordonnées à votre disposition sur notre site Internet. Si Weber confirme le défaut et approuve la

demande, Weber décidera de remplacer ces pièces gratuitement. Si vous devez retourner les pièces

défectueuses, les frais de transport doivent être prépayés. Weber renverra les pièces à l’acheteur, frais

de transport ou de poste prépayés.

La présente Garantie limitée ne couvre pas toute panne ou difficulté d’utilisation résultant d’un

accident, d’une utilisation abusive, d’une mauvaise utilisation, d’une altération, d’une mauvaise

application, d’un acte de vandalisme, d’une utilisation, d’une maintenance ou de réparations

incorrectes, ou de l’absence de maintenance normale et régulière, y compris mais pas uniquement les

détériorations provoquées par des insectes à l’intérieur des tubes du brûleur, comme indiqué dans le

présent mode d’emploi.

WWW.WEBER.COM

®

Toute détérioration provoquée par des conditions météorologiques extrêmes telles que de la grêle, des

ouragans, des séismes ou des tornades, toute décoloration résultant d’une exposition à des agents

chimiques directement ou dans l’atmosphère, n’est pas couverte dans le cadre de la présente Garantie

limitée.

Il n’y a aucune autre garantie expresse sauf celle présentée ici et toute garantie de commercialisation

et d’adaptation à un usage particulier induite est limitée dans le temps à la période de couverture de la

présente Garantie limitée écrite expresse. Certaines régions ne permettent pas la limitation de la durée

d’une garantie induite, il est donc possible que cette limitation ne s’applique pas à vous.

Weber n’est responsable d’aucun dommage particulier, indirect ou induit. Certaines régions

n’autorisent pas l’exclusion ou la limitation des dommages secondaires, il est donc possible que cette

limitation ou exclusion ne s’applique pas à vous.

Weber n’autorise aucune personne ou société à assumer en son nom toute autre obligation ou

responsabilité en relation avec la vente, l’installation, l’utilisation, le retrait, le retour, ou le replacement

de ses équipements ; et aucune représentation de ce type ne lie Weber.

La présente garantie s’applique uniquement aux produits vendus au détail.

WEBER-STEPHEN PRODUCTS CO.

Service clientèle

1890 Roselle Road, Suite 308

Schaumburg, IL 60195

USA

Pour des pièces de rechange, appelez le :

1-800-446-1071

www.weber.com

®

Page 4

4

1

2

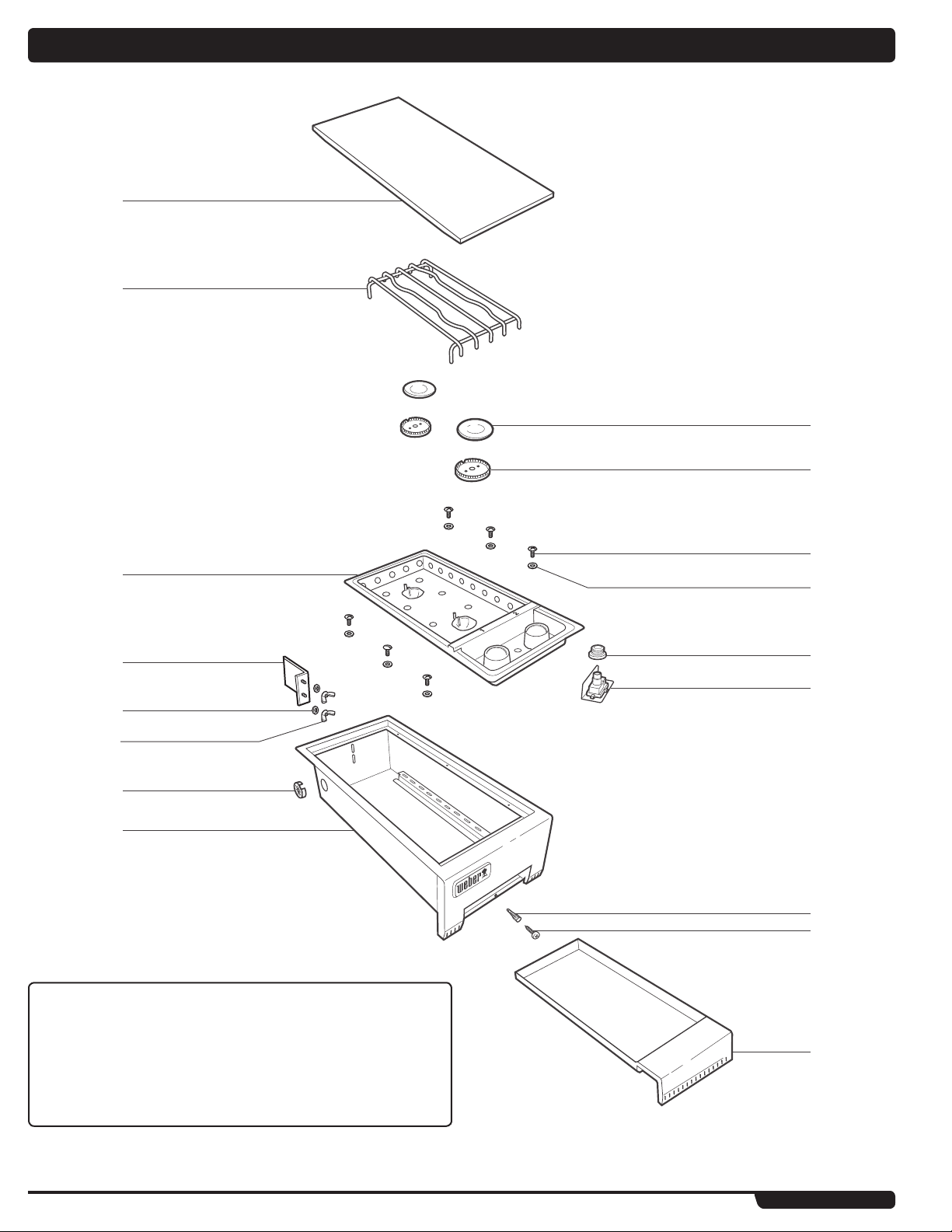

EXPLODED VIEW, DIAGRAMA DE DESPIECE, VISION ECLATEE

9

10

11

3

4

5

6

7

8

12

13

14

15

16

Before installing components, remove protective film from

the stainless steel part.

Antes de instalar el componentes, retire la película

protectora de la pieza de acero inoxidable.

Avant d’installer le composants, retirez la pellicule

protectrice de la pièce en acier inoxydable.

17

WWW.WEBER.COM

®

Page 5

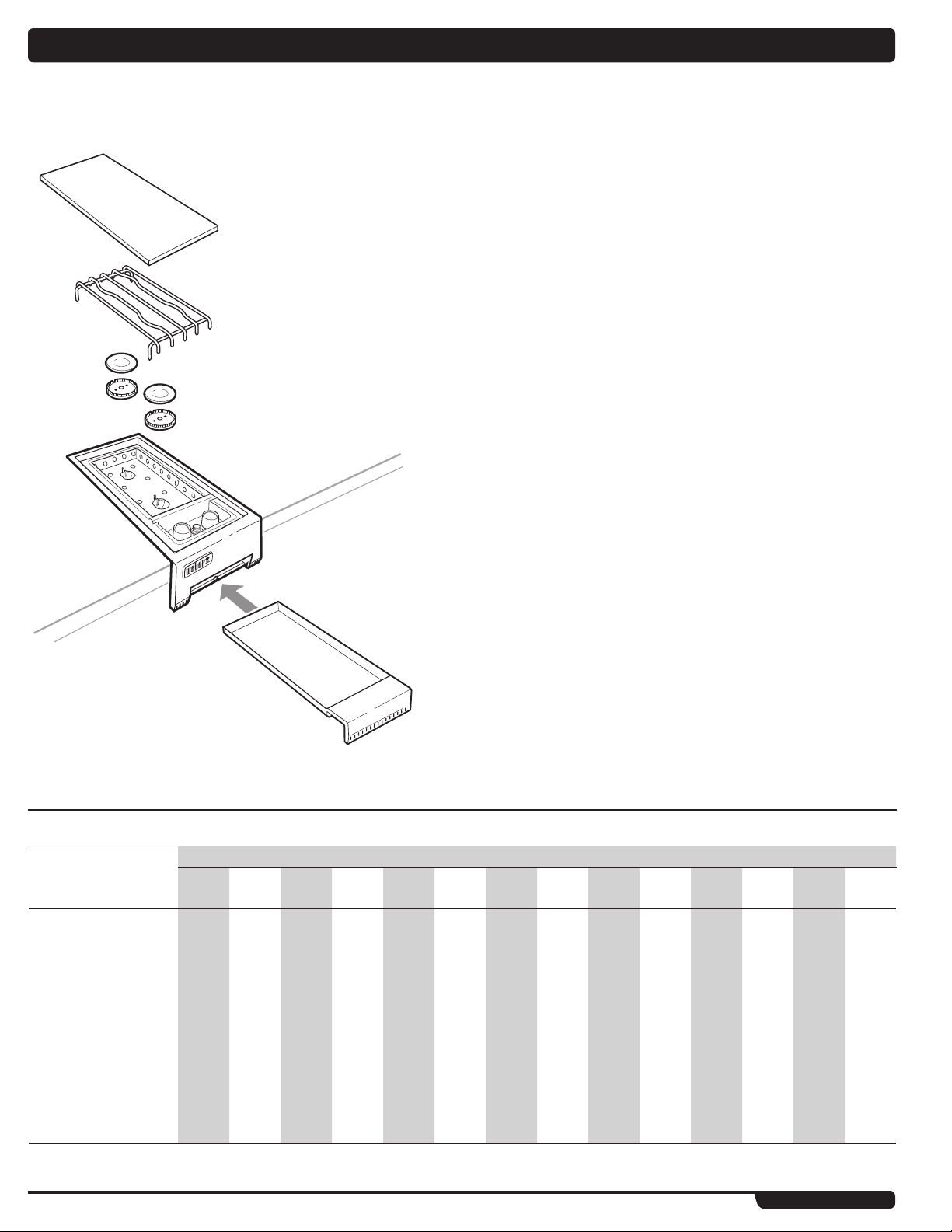

EXPLODED VIEW LIST, LISTA DEL DIAGRAMA DE DESPIECE, LISTE DE LA VISION ECLATEE

5

1. Lid

Tapa

Couvercle

2. Grate

Parrilla

Grille

3. Side Burner

Quemador lateral

Brûleur latéral

4. Mounting Bracket

Ménsula de montaje

Support de montage

5. Locking Washer

Arandela de seguridad

Rondelle de verrouillage

7. Bushing

Pasamuros

Douille

8. Side Burner Box

Caja del quemador lateral

Boîtier du brûleur latéral

9. Side Burner Cap

Tapa del quemador lateral

Cache du brûleur latéral

10. Side Burner Head

Hornilla del quemador lateral

Tête du brûleur latéral

11. Screw

Tornillo

Vis

13. Igniter Button

Botón encendedor

Bouton de l’allumeur

14. Igniter Module

Módulo encendedor

Module de l’allumeur

15. Screw Anchor

Ancla de tornillo

Douille à expansion

16. Non Corrosive Screw

Tornillo no corrosible

Vis non corrosive

17. Grease Tray

Bandeja de grasa

Plateau égouttoir

6. Wing Nut

Tuerca de mariposa

Ecrou à oreille

6 -

1 -

12. Washer

Arandela

Rondelle

HARDWARE LIST, LISTA DE LOS HERRAJES, LISTE DU MATERIEL

2 -

WWW.WEBER.COM

®

Page 6

6

INSTALLATION

OPERATING

Liquid Propane (LP) gas supply is easy to use and gives you more cooking control than

charcoal fuel.

• These instructions will give you the minimum requirements for assembling your

• Not for use by children.

• If there are local codes that apply to portable gas grills, you will have to conform to

• The pressure regulator supplied with the Weber® gas barbecue must be used.

• This Weber® gas Side Burner is designed for use with liquid propane (LP) gas

• Do not use with charcoal fuel.

• Check that the area under the appliance is free from debris that might obstruct the

• The areas around the LP cylinder must be free and clear from debris.

• Replacement pressure regulators and hose assemblies must be those specified

®

gas Side Burner. Please read the instructions carefully before using your

Weber

®

gas Side Burner. Improper assembly can be dangerous.

Weber

them. Installation must conform with local codes or, in the absence of local codes,

with either the National Fuel Gas Code, ANSI Z223.1/NFPA 54, Natural Gas and

Propane Installation Code, CSA B149.1, or Propane Storage and Handling Code,

B149.2 as applicable.

This regulator is set for 11 inches of water column (pressure).

only. Do not use with natural (piped in city) gas. The valves, orifices, hose and

regulator are for LP gas only.

flow of combustion or ventilation air.

by Weber-Stephen Products Co.

FOR INSTALLATION IN CANADA

These instructions, while generally acceptable, do not necessarily comply with the

Canadian Installation codes, particularly with piping above and below ground. In

Canada the installation of this appliance must comply with local codes and/or Standard

CSA-B149.2 (Propane Storage and Handling Code).

WARNING: Only use this appliance outdoors in a well-

ventilated area. Do not use in a garage, building, breezeway

or any other enclosed area.

WARNING: Your Summit® Built-In gas barbecue and Side

Burner shall not be used under an unprotected combustible

roof or overhang.

WARNING: Do not use the barbecue and Side Burner within

24 inches (610 mm) of combustible materials, top, bottom,

back or sides of the appliances.

WARNING: Appliance surfaces may get hot when in use. Do

not leave unattended.

WARNING: Keep any electrical supply cord and the fuel

supply hose away from any heated surface.

WARNING: Keep the cooking area clear of flammable vapors

and liquids such as gasoline, alcohol, etc., and combustible

materials.

WARNING: Never store an extra (spare) LP cylinder under or

near Weber® appliances.

WARNING: Keep the ventilation openings of the cylinder

enclosure free and clear of debris.

WARNING: Turn off the gas at the LP gas supply cylinder

when the outdoor cooking gas appliance is not in use.

WARNING: Never store an outdoor cooking gas appliance

indoors unless the LP cylinder is disconnected and removed

from the outdoor cooking gas appliance.

WARNING: LP cylinders must be stored outdoors out of

the reach of children and must not be stored in a building,

garage, or any other enclosed area.

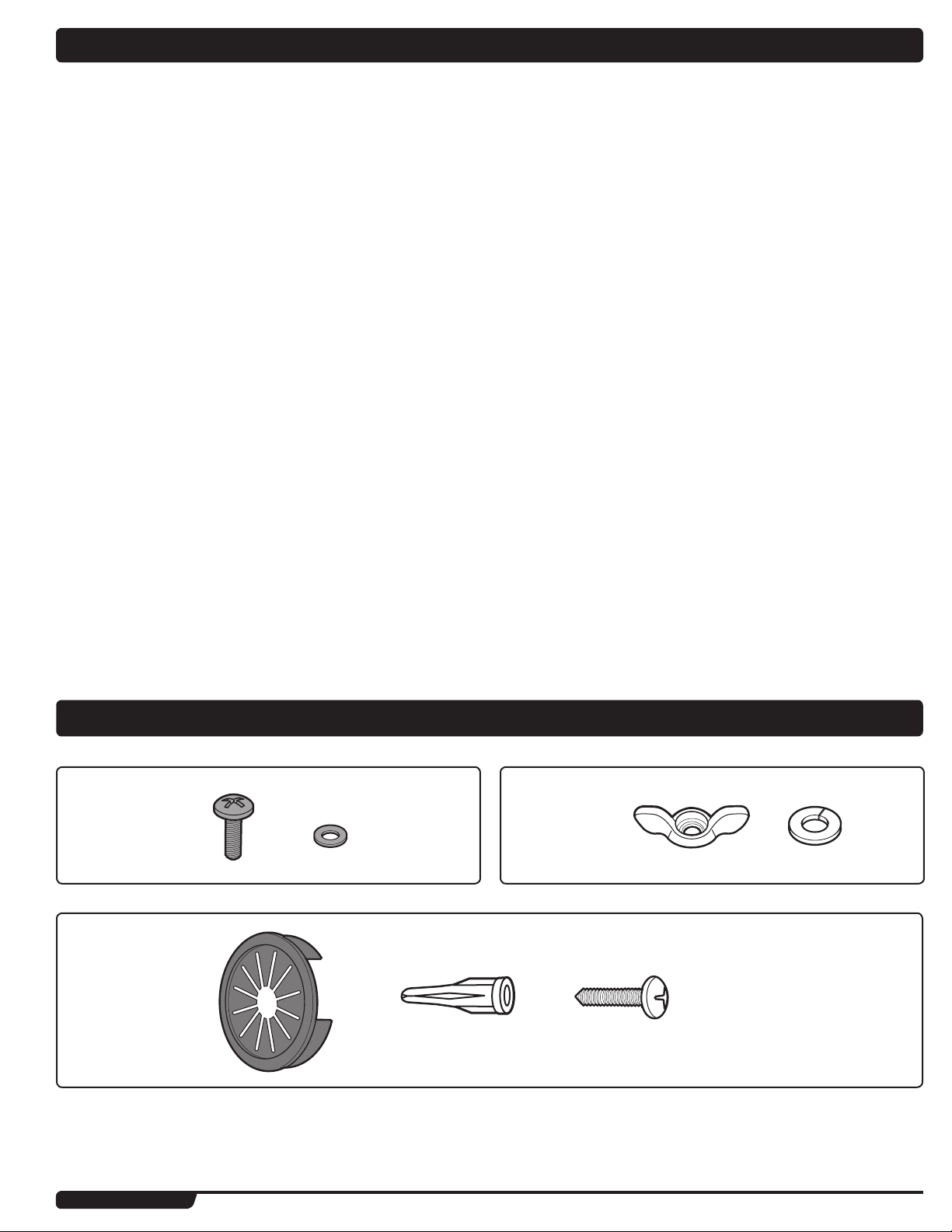

“ISLAND” STRUCTURE CONFIGURATION OPTIONS

There are many available options for locating the major components of your Island

structure.Your major components are:

1) The Built in Grill

2) Gas supply enclosure

3) Optional Side burner accessory

The 3 common options (A, B, C) are illustrated in the “Island Structure Configuration

Options” table.

2

A

3

1

B

1

2

3

C

3

1

2

“ISLAND” STRUCTURE CONFIGURATION OPTIONS

1 Summit® 4-burner/6-burner grill

2 Gas supply

3 Optional sideburner accessory

NOTE: GAS LINE LIMITATION

The gas supply hose from grill manifold to gas supply bulkhead must not exceed 58"

(147cm). The 3/8 (9.52mm) Side Burner accessory hose (not included) must not exceed

58 (147cm).

WWW.WEBER.COM

®

Page 7

INSTALLATION

LOCATING YOUR BUILT-IN SIDE BURNER APPLIANCE

When determining a suitable location for your Built-In Side Burner installation, give

attention to concerns such as exposure to wind, proximity to traffic paths, and keeping

any gas supply lines as short as possible. Never locate the Summit® Built-In Side Burner

in a garage, breezeway, shed, under overhang, or other enclosed area. Locate the Side

Burner and structure so there is enough room to safely evacuate the area in case of a

fire.

CLEARANCE FROM COMBUSTIBLE SURFACES OR STRUCTURES

WARNING: Clearance from the outside walls of the sides

and back of the Built-In Side Burner must be a minimum

of 24 inches (61 cm) from any combustible surface. Refer

to “Installation/Gas Instructions” section before starting

installation.

DANGER

The structure, “island” counter tops and adjacent work areas

for the Built-In Side Burner installation must be built from

noncombustible materials only. Incorrect installation may

result in a fire, which can cause serious bodily injury or

death, and cause damage to property.

B

A A

B

C

B

1

SIDE BURNER LOCATION

A Any Surface

7

NOTE: If you have questions on what materials are considered noncombustible, contact

you local building supplier or fire department.

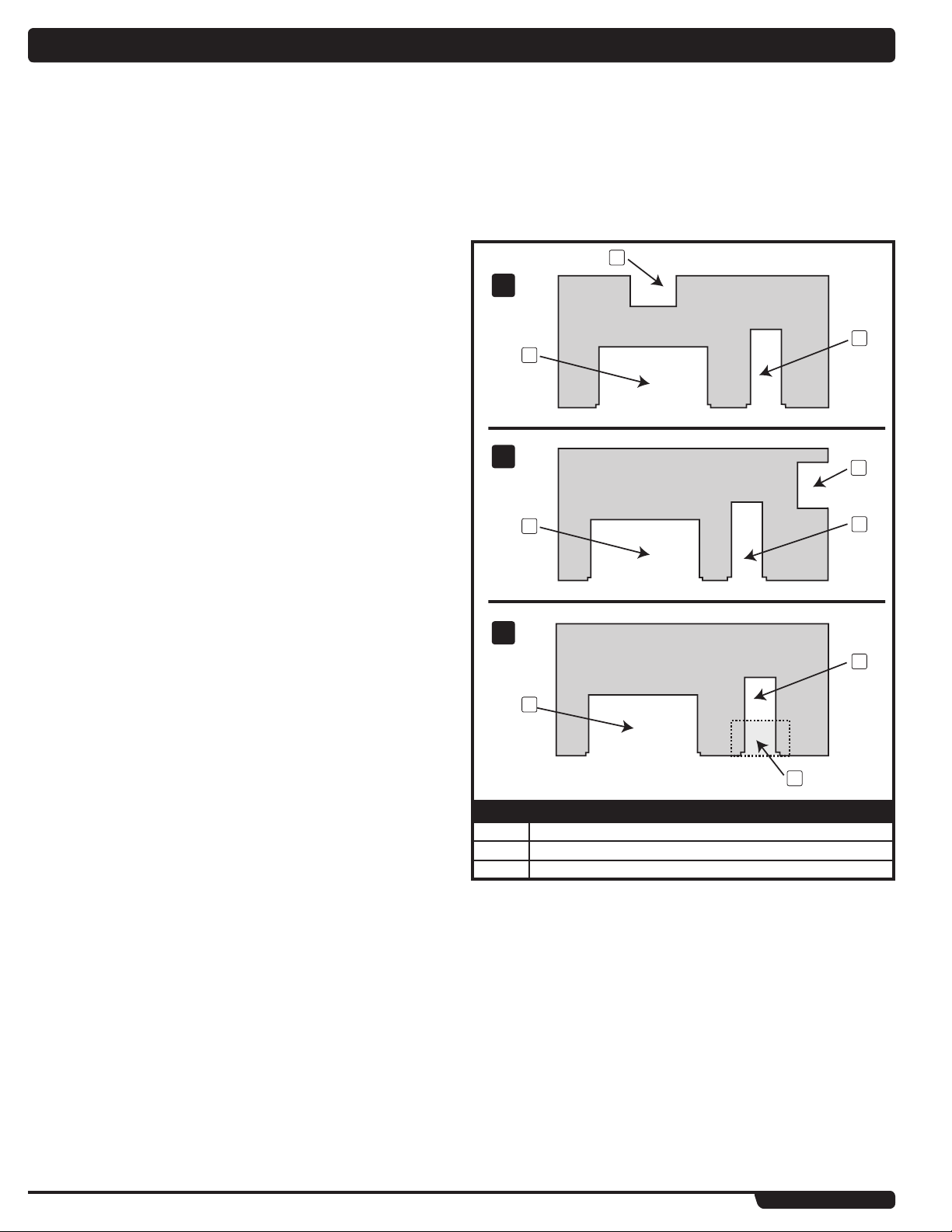

BUILT-IN STRUCTURE CUTOUT DIMENSIONS

All dimensions are to finished surfaces.

C

B

A

B 24" (61 cm) From Any Combustible Surface

C Side Burner

Note: For a countertop treatment: Recommended 3/4" (19 mm) overhang.

1

Notch front edge for frame to fully slide in.

SIDE BURNER

Cut out Dimensions Tolerances

A 12 3/8" (31.4 cm) + 1/8" - 1/8" (3.18mm)

B 7 7/8" (20 cm) -

C 27" (68.6 cm) + 1/8" - 1/8" (3.18mm)

WARNING: All counter top finished surfaces must be

constructed of a noncombustible material.

WWW.WEBER.COM

®

Page 8

8

a

b

c

INSTALLATION

BUILT-IN GAS LINE LOCATIONS

GENERAL CONSTRUCTION DETAILS

• Summit® Built-In Side Burner unit should be on site before construction begins.

• Provide access for a corrugated gas line depending on the location of the side

burner in relation to your main gas supply and regulator position.

• Area should be kept clear of sharp, jagged, or extremely abrasive surfaces to

avoid possible damage to gas supply lines. Exercise caution when pulling gas lines

through built-in structure.

• A 3/8 inch (9.52 mm) stainless steel corrugated gas line (NOT INCLUDED) should

be used to connect the side burner to the bulkhead accessory coupling.

CAUTION: 3/8 inch (9.52 mm) stainless steel corrugated gas

line must not exceed 58 inches (147 cm) in length. A longer

hose could cause an improper pressure drop.

WARNING: Do not use a rubber gas hose.

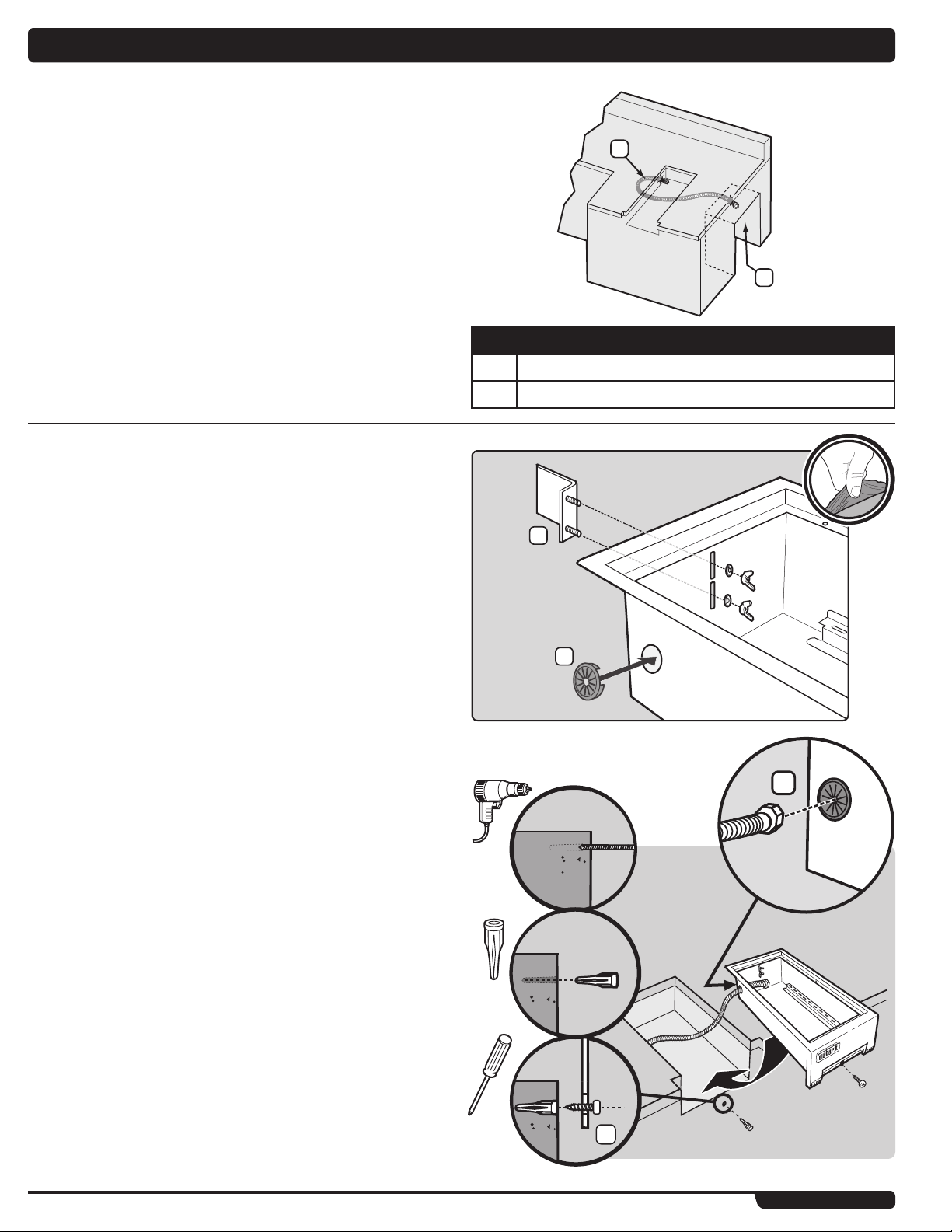

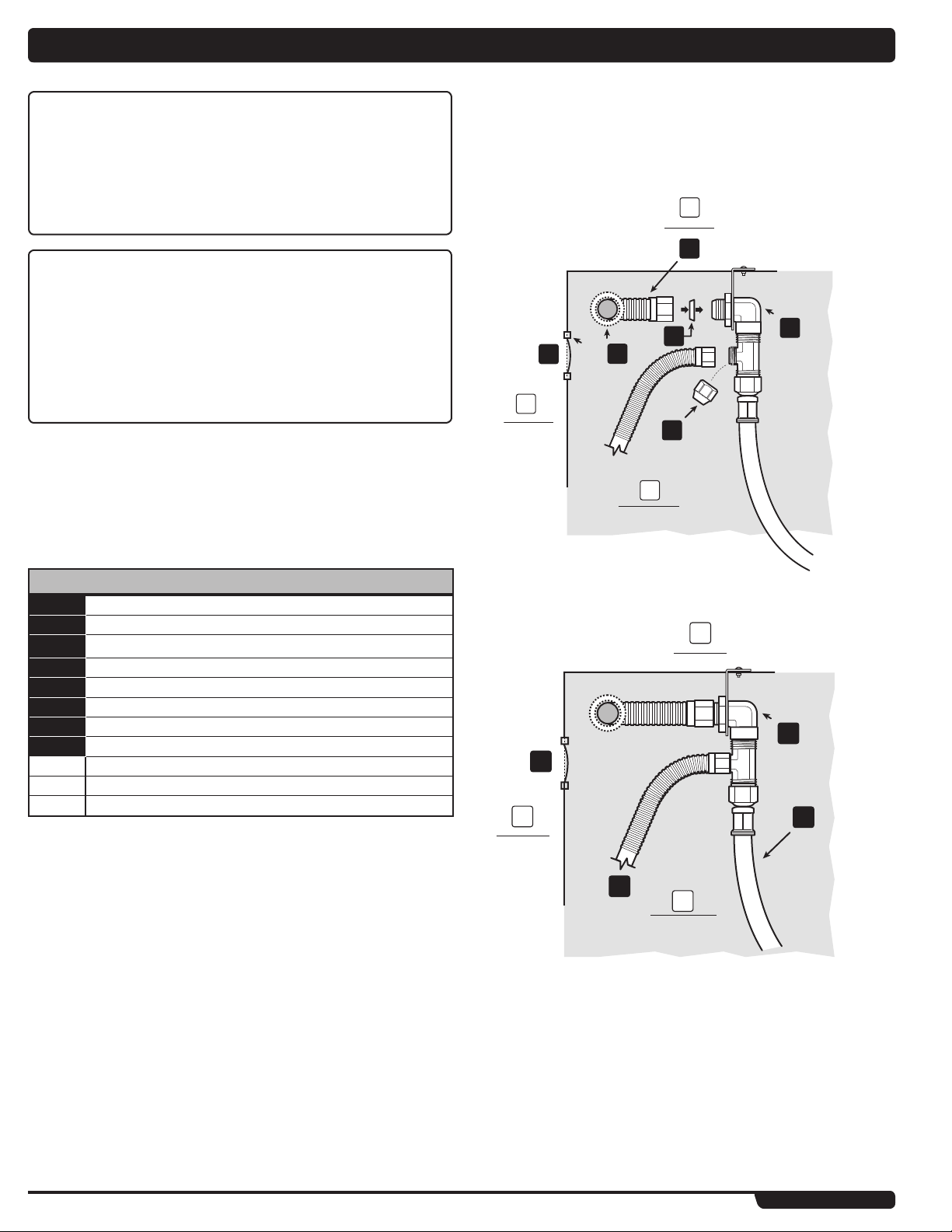

MOUNTING THE SIDE BURNER

1) Attach the mounting bracket(a) to the outside rear of the Side Burner box. Secure

with locking washers and wing nuts. Hand-tighten only.

2) Insert bushing(b) into hole at rear/left side of Side Burner box until it snaps into

place.

3) Route the 3/8 inch (9.52 mm) stainless steel corrugated gas line through the hole

in the left side of the Side Burner box(c). Pass the supply end of the hose to the

gas supply enclosure (see “CONNECT GAS SUPPLY” section).

CAUTION: Before installing component, remove protective

film from the stainless steel part.

1

2

GAS LINE LOCATIONS

1 3/8" (9.52 cm) Stainless Corrugated Gas Line (58" Max. Length)

2 Gas Supply Enclosure Location

4) Lower the Side Burner box into the Side Burner cut out.

5) Secure the Side Burner box with a non corrosive screw(d) anchored into the

finished surface of the “island structure”.

d

WWW.WEBER.COM

®

Page 9

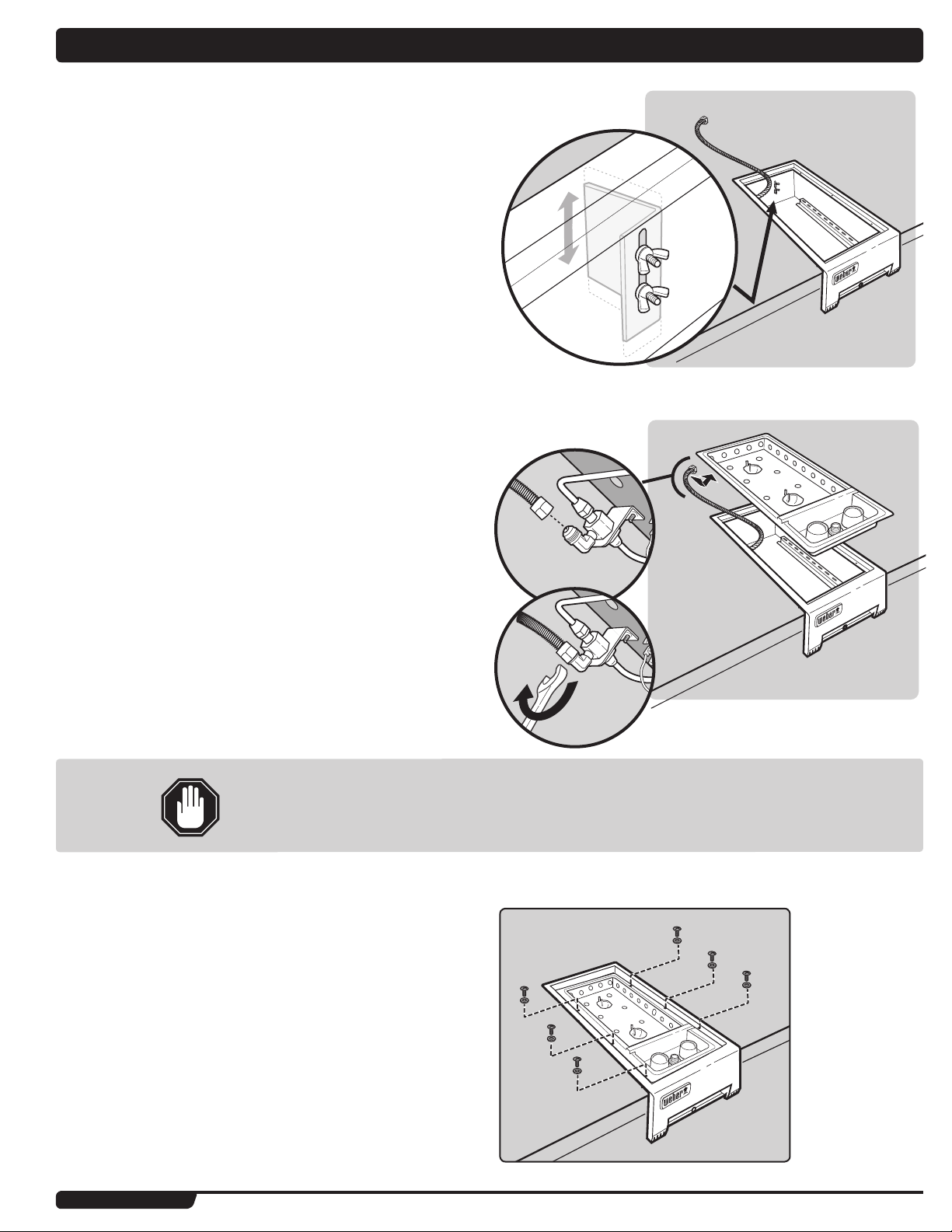

INSTALLATION

6) Secure the rear of the Side Burner box to counter top by adjusting bracket at back

of Side Burner box. Tighten wing nuts.

7) Connect the 3/8 inch (9.52 mm) stainless steel corrugated gas line to the Side

Burner valve located underneath the Side Burner.

9

CAUTION: Before continuing installation- you must connect the Side Burner gas

line to the main gas supply, then test all Side Burner gas connections for leaks.

See “CONNECTING GAS SUPPLY” section and “GAS LEAK TESTING” section.

8) Lower the Side Burner into the Side Burner box. Use the 6 included screws and

washers to secure Side Burner to Side Burner box.

WWW.WEBER.COM

®

Page 10

10

INSTALLATION/GAS INSTRUCTIONS

9) Install remaining components.

TYPICAL BULK PROPANE GAS SUPPLY INSTALLATION

We recommend that this installation be done by a LICENSED professional.

General Specifications for Piping

Note - Contact your local municipality for building codes regulating outdoor

gas grill installations. In absence of Local Codes, you must conform to the latest

edition of the National Fuel Gas Code ANSI Z223.1/NFPA 54.

• This appliance is designed to operate at 11 inches of water column pressure. An

LP in line regulator may be necessary for this pressure.

CAUTION: If young children are in the area, a locking valve

should be considered.

• Pipe compound should be used which is resistant to the action of liquid propane

gas when gas connections are made.

• The gas connections must be firmly attached to rigid, permanent construction.

Note: The information provided in this manual is general for typical installations. We

cannot cover all possible installation ideas. We recommend, prior to installation, that you

contact your municipality for local building codes and your local fire department for

installation verification.

If you have any questions, contact Customer Service at 1-800-446-1071.

GAS LINE PIPING

• Refer to piping chart.

• The corrugated gas line from the manifold is 58 inches (1,473.2 mm) long. Do not

extend the gas line.

• We have provided the means to make an SAE 45° flare connection. Do not use

pipe sealant on this connection.

• If the length of line required does not exceed 50 feet, use a 5/8" O.D. tube. One

size larger should be used for lengths greater than 50 feet. Refer to piping chart.

• Gas piping may be copper tubing, type K or L; polyethylene plastic tube, with a

minimum wall thickness of .062 inch (1.57 mm); or standard weight (schedule 40)

steel or wrought iron pipe.

• Copper tubing must be tin-lined if the gas contains more than 0.3 grams of

hydrogen sulfide per 100 cubic feet of gas.

• Plastic tubing is suitable only for outdoor, underground use.

• Gas piping in contact with earth, or any other material which may corrode the

piping, must be protected against corrosion in an approved manner.

• Underground piping must have a minimum of 18" cover.

Tab le

6.2(a)

Nominal

Iron Pipe

Size

(Inches)

Actual

ID:

(Inches)

Maximum Capacity of Metallic Pipe in Cubic Feet of Gas per Hour for Gas Pressures of 2 psi or Less and

a Pressure Drop of 0.3 Inch Water Column. (Based on a 0.60 Specific Gravity Gas)

Length of Pipe (Feet)

10 20 30 40 50 60 70 80 90 100 125 150 175 200

1/4 .364 32 22 18 15 14 12 11 11 10 98876

3/8 .493 72 49 40 34 30 27 25 23 22 21 18 17 15 14

1/2 .622 132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4 .824 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1 1.049 520 350 285 245 215 195 180 170 160 150 130 120 110 100

1 1/4 1.380 1050 730 590 500 440 400 370 350 320 305 275 250 225 210

1/12 1.160 1600 1100 890 760 670 610 560 530 490 460 410 380 350 320

2 2.067 3050 2100 1650 1450 1270 1150 1050 990 930 870 780 710 650 610

2 1/2 2.469 4800 3300 2700 2300 2000 1850 1700 1600 1500 1400 1250 1130 1050 980

3 3.068 8500 5900 4700 4100 3600 3250 3000 2800 2600 2500 2200 2000 1850 1700

4 4.026 17500 12000 9700 8300 7400 6800 6200 5800 5400 5100 4500 4100 3800 3500

© 2009 National Fire Protection Association, Inc. and International Approval Services - U.S., Inc. All Rights Reserved.

WWW.WEBER.COM

®

Page 11

GAS INSTRUCTIONS

11

TEST CONNECTIONS

All connections and joints must be thoroughly tested for leaks in accordance with local

codes and all listed procedures in the latest edition of the National Fuel Gas Code ANSI

Z223.1/NFPA 54, Natural Gas and Propane Installation Code, CSA B149.1, or Propane

Storage and Handling Code, B149.2, or the Standard for Recreational Vehicles, ANSI A

119.2/NFPA 1192, and CSA Z240 RV Series, Recreational Vehicle Code, as applicable.

DANGER

Do not use an open flame to check for gas leaks. Be sure

there are no sparks or open flames in the area while you

check for gas leaks. This will result in a fire or explosion

which can cause serious bodily injury or death, and damage

to property.

TYPICAL 20 LP PROPANE GAS SUPPLY INSTALLATION

The remote tank enclosure kit provided with your Weber Built-In grill shall be used for

installations using a 20 lb LP cylinder, mounted in an “island” structure.

The remote tank enclosure shall house the included hose and regulator assembly and

gas connections, the tank bracket and the fuel scale for connecting a remote mounted

LP cylinder to the Summit® Built-In gas grill. The hose and regulator is listed as a

required part of the CSA listed Summit® Built-In gas grill.

A properly installed tank enclosure meets the requirements for venting, tank retention

and separation of the LP cylinder from a heat source as outlined in the ANSI Standard

for Outdoor Cooking Gas Appliances, Z21.58/CSA 1.6 for LP enclosures.

You need to hire a licensed contractor or licensed plumber and they need to follow the

requirements described in the ANSI Standard for Outdoor Cooking Gas Appliances,

Z21.58/CSA 1.6 for LP enclosures.

The requirements described in the Standard for Outdoor Cooking Gas Appliances,

Z21.58/CSA 1.6. are as follows;

A remote enclosure for an LP gas cylinder shall be ventilated by openings at both

the upper and lower levels of the cylinder. This shall be accomplished by one of the

following:

A) One side of the remote LP cylinder enclosure shall be completely open; or

B) If the remote LP cylinder enclosure is designed to have four sides, a top and a

bottom, ventilation is required for the remote LP cylinder enclosure;

1) There should be at least two ventilation openings, (a hole or group of

holes, for the purpose of ventilation) in the sidewalls of the island structure.

The openings should be located within 5 inches (127mm) of the top of the

enclosure. The ventilation openings should be equally sized and spaced at

a minimum of 90 degrees, and be unobstructed. The openings shall have

a total free open area of not less than 20 square inches. (This relates to 1

square inch of ventilation area, per pound of stored fuel capacity).

2) Ventilation openings (a hole or group of holes, for the purpose of ventilation)

should be provided at floor level. The ventilation openings should have a total

free area of not less than 10 square inches. (This relates to 1/2 square inch

of ventilation area, per pound of stored fuel capacity). There should be at

least two ventilation openings if the ventilation openings at floor level are in

the sidewall. The ventilation openings should be within 5 inches (127mm) of

the floor. The ventilation openings should be of equal size and be spaced at

a minimum of 90 degrees, and should be unobstructed.

3) The minimum size of the ventilation hole (s) should not be less than 1/4 inch.

4) The ventilation openings in the sidewalls should not allow venting into

the empty or “hollow” area of the “island”. If a gas leak should occur or

the LP cylinder should vent in the LP cylinder enclosure, the gas should

not be allowed to vent or migrate into the empty or “hollow” area of the

“island”. Ventilation openings in the sidewalls of the enclosure should only

communicate with the outside of the “island” structure, so that the gas can

dissipate outside of the “island” structure.

C) If the remote LP cylinder enclosure has four sides, a top and a bottom, and is

intended for installation in a built-in “island” enclosure;

1) At least one ventilation opening (a hole or group of holes, for the purpose

of ventilation) needs to be on one side of the enclosure that communicates

with the outside of the “island” structure. If a gas leak should occur or the

LP cylinder should vent in the LP cylinder enclosure, the gas should not

be allowed to vent or migrate into the empty or “hollow” area of the “island”.

Ventilation openings should only communicate with the outside of the “island”

structure, so that the gas can dissipate outside of the “island” structure. The

ventilation opening should be located within 5 inches (127mm) of the top of

the enclosure, and should have a total free area of 20 square inches. (This

relates to 1 square inch of ventilation area, per pound of stored fuel).

2) At least one ventilation opening (a hole or group of holes, for the purpose

of ventilation) needs to be on one side of the enclosure that communicates

with the outside of the “island” structure, at the bottom. If a gas leak should

occur or the LP cylinder should vent in the LP cylinder enclosure, the gas

should not be allowed to vent or migrate into the empty or “hollow” area of

the “island”. Ventilation openings should only communicate with the outside

of the “island” structure, so that the gas can dissipate outside of the “island”

structure. The ventilation opening should be located within 5 inches (127mm)

of the bottom of the enclosure, and should have a total free area of 10 square

inches. (This relates to 1/4 square inch of ventilation area, per pound of

stored fuel).

3) The minimum size of the ventilation hole (s) should not be less than 1/4 inch

(6.35mm).

D) The remote LP cylinder enclosure should be constructed with non-combustible

materials. The remote LP cylinder enclosure should isolate the LP cylinder from the

burner compartment, so that it provides shielding from radiation, be a flame barrier

and provide protection from foreign material such as hot drippings.

E) There should be a minimum of 2 inches (50.8mm) between the ground and the floor

of the remote LP cylinder enclosure.

F) The LP cylinder valve should be readily accessible for hand operation. A door on the

remote LP cylinder enclosure to gain access to the LP cylinder valve is acceptable,

provided it is non-locking and can be opened without the use of tools.

WWW.WEBER.COM

®

Page 12

12

CONNECTING GAS SUPPLY

DANGER

Use of any hose and regulator assembly other than that

provided or recommended by Weber-Stephen Products Inc.

could be dangerous, and may not provide adequate gas

supply to the Summit

®

Built-In gas grill, and could result in a

fire or an explosion causing serious bodily injury or death,

and damage to property.

DANGER

Failure to build a remote LP cylinder enclosure for a

single 20 lb cylinder only, following the requirements for

ventilation, cylinder retention and separation of the LP

cylinder from a heat source, listed in the ANSI Standard

for Outdoor Cooking Gas Appliances, ANSI Z21.58 CSA

1.6, could be dangerous, and could result in a fire or an

explosion causing serious bodily injury or death and

damage to property.

If you do not follow the DANGER statements exactly, the Warranty on the Summit

gas grill will be voided.

®

Built-In

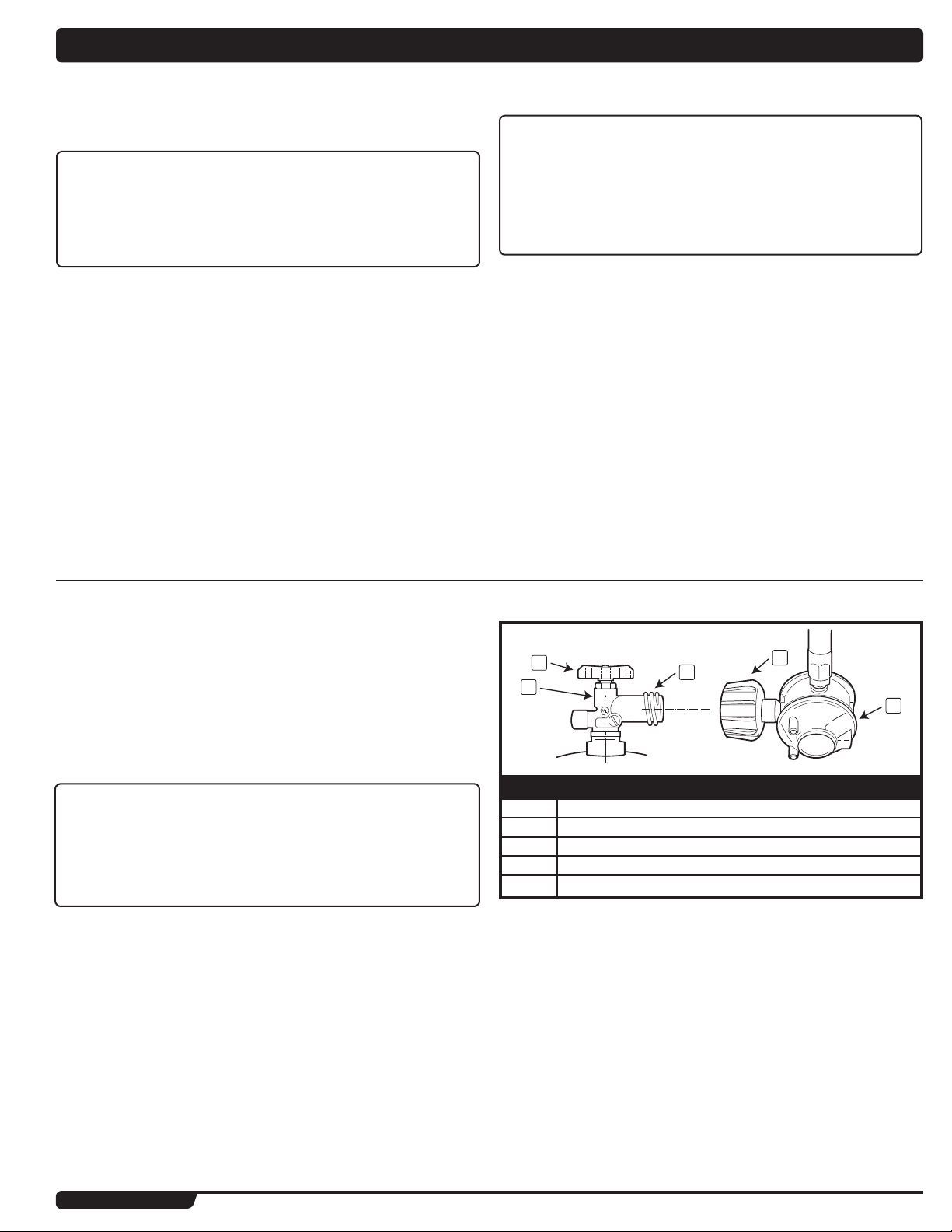

CONNECT GAS SUPPLY

1) Uncap the flare fitting from the optional side burner connection located inside the

2) Connect the corrugated gas line to the side burner Connection.

®

Summit

Built-In Tank Cabinet (#21280).

a

1

4

2

3

5

b

6

c

SIDE BURNER LP SUPPLY CONNECTIONS

1

2

3

4

5

6

7

8

a

b

c

Top of Box

Back of Box

Side View

Corrugated Gas Line to Manifold

Plug unused hole with supplied plug

Use bushing for gas line hole

1/2" (12.7mm) Flared Gasket

90° Fitting

Cap (Optional Side Burner)

To Side Burner

Connection to LP Tank

a

5

2

b

8

7

c

WWW.WEBER.COM

®

Page 13

CONNECTING GAS SUPPLY

13

TEST CONNECTIONS

All connections and joints must be thoroughly tested for leaks in accordance with local

codes and all listed procedures in the latest edition of ANSI Z223.1/NFPA 54.

DANGER

Do not use an open flame to check for gas leaks. Be sure

there are no sparks or open flames in the area while you

check for gas leaks. This will result in a fire or explosion

which can cause serious bodily injury or death, and damage

to property.

FILL LIQUID PROPANE CYLINDER

To fill, take the liquid propane cylinder and filler adapter to an RV center or look up gaspropane in the phone book for other sources of liquid propane gas.

WARNING: We recommend that your liquid propane cylinder

be filled at an authorized liquid propane gas dealer by a

qualified attendant, who fills the tank by weight.

IMPROPER FILLING IS DANGEROUS.

The liquid propane cylinder must be installed, transported and stored in an upright

position, and should not be dropped or handled roughly.

Never store or transport the liquid propane cylinder where temperatures can reach

125°F / 51°C (too hot to hold by hand – for example: do not leave the liquid propane

cylinder in a car on a hot day).

For full instructions on safe handling of liquid propane cylinders, see Section “Operating

Instructions”.

IMPORTANT LP CYLINDER INFORMATION

DANGER

NEVER store a spare LP Cylinder under or near Weber

®

gas appliances.

NEVER fill the tank beyond 80% full.

Failure to follow these statements exactly may result in a

fire causing death or serious injury.

Weber® gas appliances are equipped for a cylinder supply system designed for vapor

withdrawal.

WARNING: Only use Weber® gas appliances outdoors in

a well-ventilated area. Do not use in a garage, building,

breezeway or any other enclosed area.

The proper filling methods for the filling of your cylinder are by weight or volume, as

described in NFPA 58. Please make sure your filling station fills your LP cylinder by

weight or volume. Ask your filling station to read purging and filling instructions on the

LP cylinder before attempting to fill.

LEAK CHECK PREPARATION

CHECK THAT ALL BURNER VALVES ARE OFF

Valves are shipped in the “OFF” position, but you should check to be sure that they are

turned off. Check by pushing down and turning clockwise. If they do not turn, they are

off. Proceed to the next step. If they do turn continue turning them clockwise until they

stop, then they are off. Proceed to the next step.

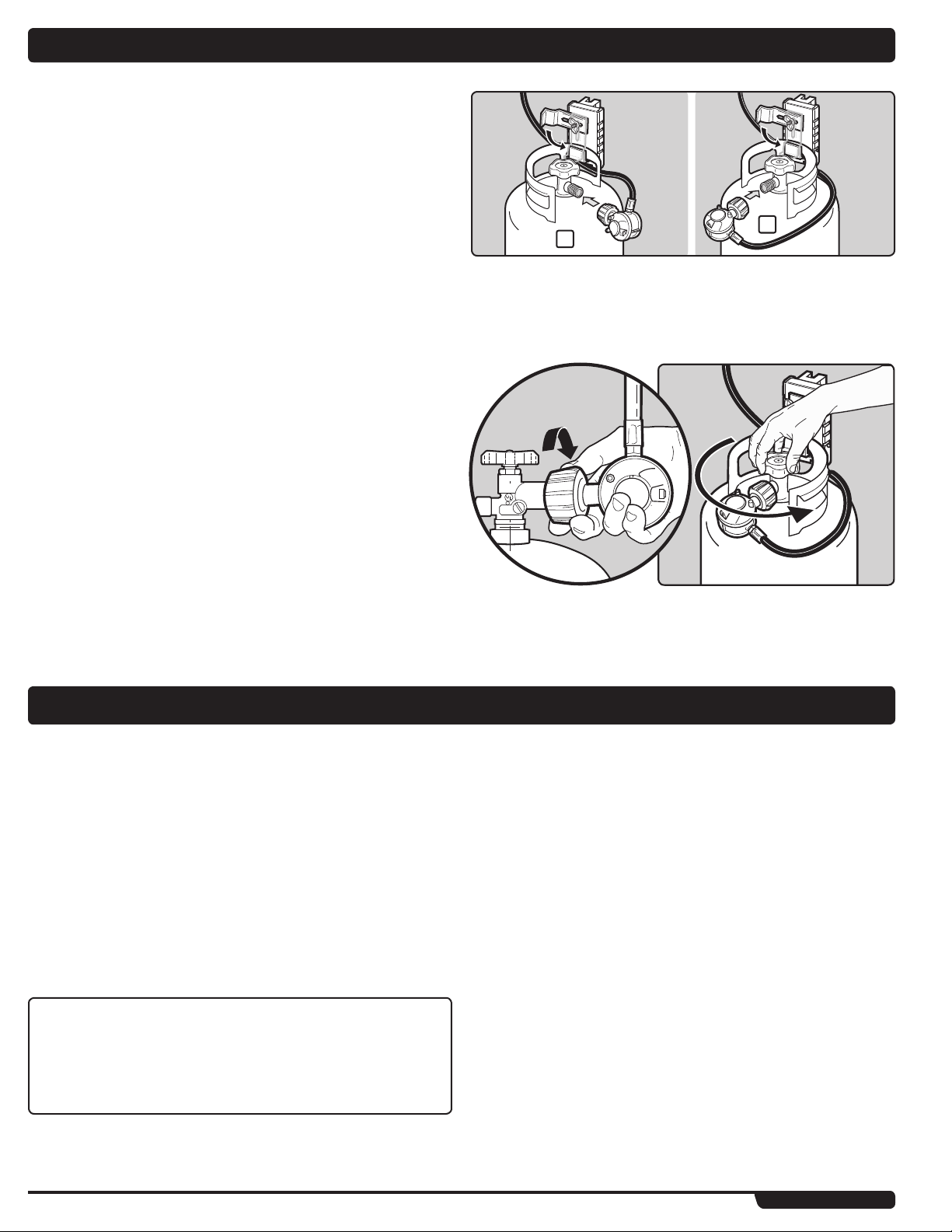

CONNECTING THE LIQUID PROPANE CYLINDER

All Weber® liquid propane gas grill regulators are equipped with a UL-Listed tank

connection as per the latest edition of ANSI Z21.58. This will require a liquid propane

tank that is similarly equipped with a Type 1 connection in the tank valve. This Type 1

coupling allows you to make a fast and totally safe hookup between your gas grill and

your liquid propane tank. It eliminates the chance of leaks due to a POL fitting that is

not properly tightened. Gas will not flow from the tank unless the Type 1 coupling is fully

engaged into the coupling.

WARNING: Make sure that the LP cylinder valve is closed.

Close by turning valve clockwise.

DANGER

Do not use an open flame to check for gas leaks. Be sure

there are no sparks or open flames in the area while you

check for leaks. Sparks or flames will result in a fire or

explosion which can cause serious bodily injury or death,

and damage to property.

2

3

4

1

TYPE 1 CONNECTIVE COUPLING

1 Type 1 Valve

2 Hand Wheel

3 External Thread

4 Thermally Sensitive Nut

5 Propane Regulator

5

WWW.WEBER.COM

®

Page 14

14

b

a

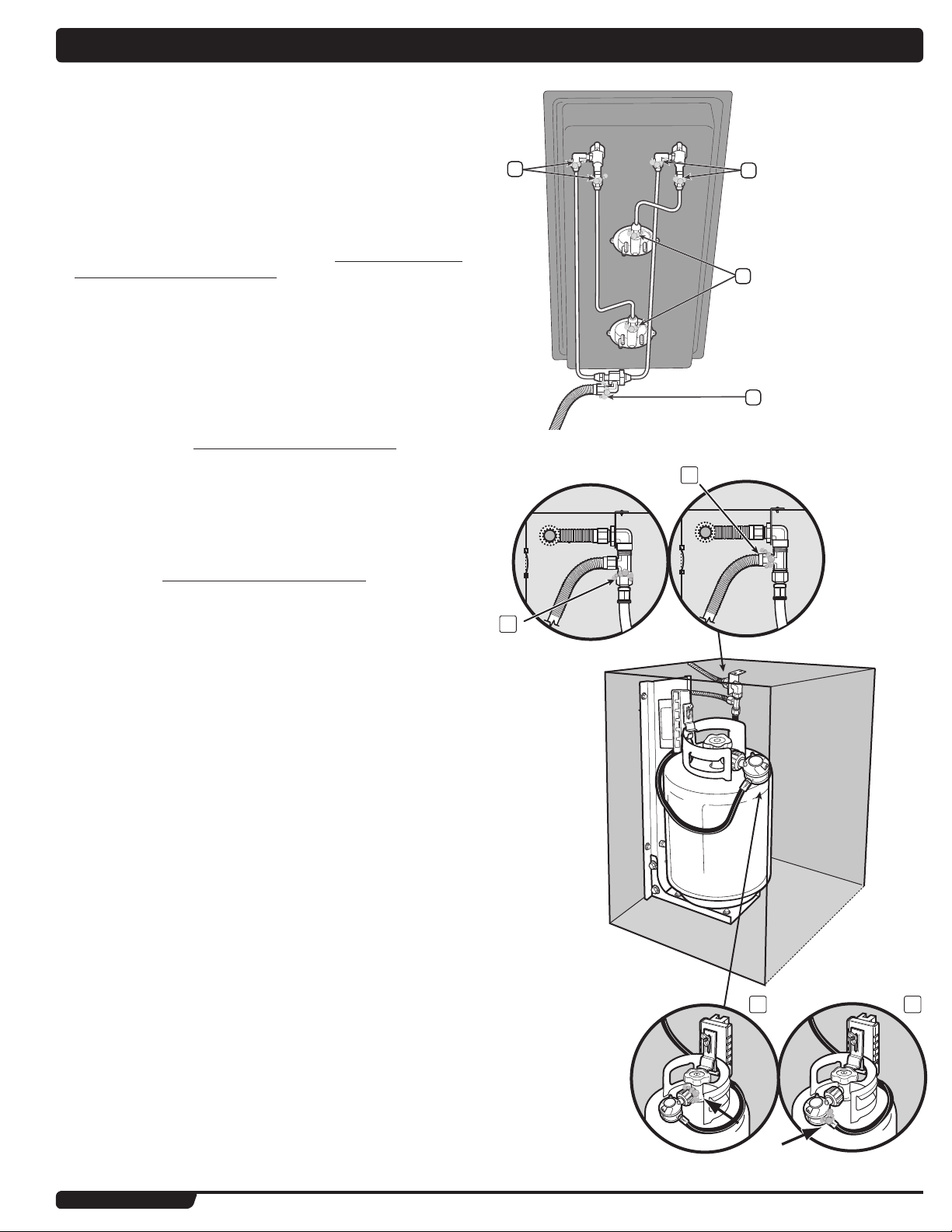

Some LP tanks have differing top collar assembles. (The top collar is the metal

protective ring around the valve.) One series of tanks mount with the valve facing front

(a). The other tanks mount with the valve facing away from the fuel scale (b). Weber

recommends the use of cylinder manufacturer’s Manchester and Worthington, with a

47.6 lb water capacity. Other cylinders may be acceptable for use with the appliance

provided they are compatible with the appliance retention means (see illustrations).

The LP cylinder is installed inside the tank enclosure or tank cabinet, on the tank scale.

1) Turn the LP cylinder so the opening of the valve is either to the front, side or rear

of the Weber

2) Lift tank up into position on the tank scale.

3) Loosen the cylinder lock wing nut. Swing the cylinder lock down. Tighten the wing

nut.

®

gas barbecue. Lift and hook the cylinder onto the fuel gauge.

CONNECTING GAS SUPPLY

TO CONNECT THE HOSE TO THE CYLINDER:

4) Remove the plastic dust cover from the valve.

5) Screw the regulator coupling onto the tank valve, clockwise, or to the right. Handtighten only.

Note: This connection tightens clockwise and will not allow gas to flow unless the

connection is tight. The connection requires tightening by hand only.

WARNING: Do not use a wrench to tighten the connection.

Using a wrench could damage the regulator coupling and

could cause a leak.

6) Check for gas leaks.

GAS LEAK TESTING

CHECK FOR GAS LEAKS

After a period of nonuse, we recommend that you perform the following maintenance

procedures for your safety.

WARNING: Check the hose before each use of the grill for

nicks, cracking, abrasions or cuts. If the hose is found to

be damaged in any way, do not use the grill. Replace using

only Summit® authorized replacement hose. Contact the

Customer Service Representative in your area using the

contact information on our web site.

Log onto www.weber.com®.

• Inspect the burner for correct flame pattern. Clean if necessary, following the

procedures outlined in the “General Maintenance” section of this manual.

• Check all gas fittings for leaks.

All connections and joints must be thoroughly tested for leaks in accordance with local

codes and all listed procedures in the latest edition of ANSI Z223.1/NFPA 54.

DANGER

Do not use an open flame to check for gas leaks. Be sure

there are no sparks or open flames in the area while you

check for leaks. Sparks or open flames will result in a fire or

explosion, which can cause serious bodily injury or death

and damage to property.

WARNING: You should check for gas leaks every time you

disconnect and reconnect a gas fitting.

Note - All factory-made connections have been thoroughly checked for gas leaks. The

burners have been flame-tested. As a safety precaution however, you should recheck

all fittings for leaks before using your Weber® appliances. Shipping and handling may

loosen or damage a gas fitting.

WARNING: Perform these leak checks even if your appliance

was dealer or store assembled.

You will need: a soap and water solution, and a rag or brush to apply it.

Note - Since some leak test solutions, including soap and water, may be slightly

corrosive, all connections should be rinsed with water after checking for leaks.

Make sure side burner is OFF.

To perform leak checks: open cylinder valve by turning the cylinder valve hand-wheel

counterclockwise.

WARNING: Do not ignite burners when leak checking.

WWW.WEBER.COM

®

Page 15

GAS LEAK TESTING

Check for leaks by wetting the connections with the soap and water solution and

watching for bubbles. If bubbles form or if a bubble grows, there is a leak.

CHECK SIDE BURNER COMPONENT

Check:

1) Side burner lines to valve connections.

2) Side burner line to side burner orifice.

3) Side burner hose to side burner bulkhead.

WARNING: If there is a leak at connection (1, 2 or 3),

retighten the fitting with a wrench and recheck for leaks

with soap and water solution. If a leak persists after retightening the fitting, turn OFF the gas. DO NOT OPERATE

THE GRILL OR SIDE BURNER. Contact the Customer Service

Representative in your area using the contact information on

our web site. Log onto www.weber.com®.

CHECK GAS SUPPLY CONNECTIONS

Check:

4) Corrugated gas line-to-Accessory “T” Connection.

5) Regulator hose to bulkhead.

WARNING: If there is a leak at connection (4 or 5), retighten

the fitting with a wrench and recheck for leaks with soap and

water solution. If a leak persists after re-tightening the fitting,

turn OFF the gas. DO NOT OPERATE THE GRILL. Contact

the Customer Service Representative in your area using the

contact information on our web site.

Log onto www.weber.com®.

Check:

6) Regulator to cylinder.

7) The hose-to-Regulator connection.

WARNING: If there is a leak at connections (6 or 7), turn

OFF the gas. DO NOT OPERATE THE GRILL. Contact the

Customer Service Representative in your area using the

contact information on our web site.

Log onto www.weber.com®.

When leak checks are complete, turn gas supply OFF at the source and rinse

connections with water.

15

1

4

5

1

2

3

WWW.WEBER.COM

6 7

®

Page 16

16

GAS INSTRUCTIONS

SAFE HANDLING TIPS FOR LIQUID PROPANE GAS

CYLINDERS

• Liquid Propane (LP) gas is a petroleum product as are gasoline and natural gas.

LP gas is a gas at regular temperatures and pressures. Under moderate pressure,

inside a cylinder, LP gas is a liquid. As the pressure is released, the liquid readily

vaporizes and becomes gas.

• LP gas has an odor similar to natural gas. You should be aware of this odor.

• LP gas is heavier than air. Leaking LP gas may collect in low areas and prevent

dispersion.

• To fill, take the LP cylinder to a gas propane dealer, or look up “gas-propane” in

the phone book for other sources of LP gas.

WARNING: We recommend that your LP cylinder be filled

at an authorized LP gas dealer, by a qualified attendant,

who fills the tank by weight. IMPROPER FILLING IS

DANGEROUS.

• Air must be removed from a new LP cylinder before the initial filling. Your LP

dealer is equipped to do this.

• The LP cylinder must be installed, transported and stored in an upright position.

LP cylinders should not be dropped or handled roughly.

• Never store or transport the LP cylinder where temperatures can reach 125° F

(too hot to hold by hand - for example: do not leave the LP cylinder in a car on a

hot day).

LIQUID PROPANE (LP) CYLINDER(S)

• The joint where the hose connects to the LP cylinder must be leak tested each

time the LP cylinder is reconnected. For example, test each time the LP cylinder is

refilled.

• Be sure the regulator is mounted with the small vent hole pointed downward so

that it will not collect water. This vent should be free of dirt, grease, bugs etc.

• The gas connections supplied with your Weber® gas appliance have been

designed and tested to meet 100% CSA and ANSI requirements.

WARNING: Replacement LP tanks must match the regulator

connection supplied with this Weber® gas appliance.

LIQUID PROPANE CYLINDER REQUIREMENTS

• Check to be sure cylinders have a D.O.T. certification (1), and date tested (2) is

within five years. Your LP gas supplier can do this for you.

• All LP tank supply systems must include a collar to protect the cylinder valve.

• The LP cylinder must be a 20-lb. size approximately (18¼ inches high, 12¼

inches in diameter).

• The cylinder must be constructed and marked in accordance with the

Specifications for LP - Gas Cylinders of the U.S. Department of Transportation

(D.O.T.) or the National Standard of Canada, CAN/CSA-B339, Cylinders,

Spheres and Tubes or Transportation of Dangerous Goods; and Commission, as

applicable.

IN CANADA

LIQUID PROPANE CYLINDER REQUIREMENTS

Note: Your retailer can help you match a replacement tank to your barbecue.

• The LP cylinder must be constructed and marked in accordance with the

specifications for LP gas cylinders, T.C.

Note: A refill will last about 18-20 hours of cooking time at normal use. The fuel scale

will indicate the propane supply so you can refill before running out. You do not have

to run out before you refill.

• Treat “empty” LP cylinders with the same care as when full. Even when the LP

tank is empty of liquid there still may be gas pressure in the cylinder. Always close

the cylinder valve before disconnecting.

CAUTION: Place dust cap on cylinder valve outlet whenever

the cylinder is not in use. Only install the type of dust cap

on the cylinder valve outlet that is provided with the cylinder

valve. Other types of caps or plugs may result in leakage of

propane.

• Do not use a damaged LP cylinder. Dented or rusty LP cylinders or LP cylinders

with a damaged valve may be hazardous and should be replaced with a new one

immediately.

1

DOT 4BA240

00/09

2

WWW.WEBER.COM

®

Page 17

2

1

2 4

5

OPERATING INSTRUCTIONS

SIDE BURNER LIGHTING INSTRUCTIONS

Summary lighting instructions are inside the left hand cabinet door.

DANGER

Failure to remove the lid while igniting the side burner, or not

waiting 5 minutes to allow the gas to clear if the side burner

does not light, may result in an explosive flame-up which can

cause serious bodily injury or death.

1) Remove the Side Burner lid by pushing down slightly on one end while lifting from

the other end. Store the Side Burner id in your grill cabinet.

CAUTION: Do not use lid as a cooking surface or a cutting

surface.

2) Check that the side burner valves are turned OFF. (Push knobs in and turn

clockwise to ensure that they are in the off position.)

WARNING:

The burner control knobs must be in the OFF position before

turning on the liquid propane cylinder valve. If they are not

in the OFF position, when you turn on the LP cylinder valve,

the “excess gas flow control” feature will activate, limiting

the flow of gas from the LP cylinder. If this should occur, turn

OFF the LP tank valve and burner control knobs. Then start

over.

17

3) Turn the LP tank valve on (turn counter-clockwise).

4) Push in and turn the side burner control knob (

front) to START/HI.

- rear) or control knob (2 -

1

CAUTION: Do not turn gas on to both burners at the same

time.

5) Push igniter button and hold until burner ignites. You will hear the igniter sparking.

CAUTION: Side burner flame may be difficult to see on a

bright sunny day.

WARNING: If the side burner does not light:

1) Turn OFF the side burner control valve.

2) Wait 5 minutes to let the gas clear before you try again

or try to light with a match.

TO EXTINGUISH

Push down and turn each burner control knob clockwise to the OFF position. Turn gas

supply OFF at the source.

WWW.WEBER.COM

®

Page 18

18

2

1

2

4

5

6

OPERATING INSTRUCTIONS

MANUALLY LIGHTING THE SIDE BURNER

DANGER

Failure to open the lid while igniting the side burner, or not

waiting 5 minutes to allow the gas to clear if the side burner

does not light, may result in an explosive flame-up which can

cause serious bodily injury or death.

1) Remove the Side Burner lid by pushing down slightly on either end.

2) Check that the side burner valves are turned OFF. (Push knobs in and turn

clockwise to ensure that they are in the off position.)

WARNING:

The burner control knobs must be in the OFF position before

turning on the liquid propane cylinder valve. If they are not

in the OFF position, when you turn on the LP cylinder valve,

the “excess gas flow control” feature will activate, limiting

the flow of gas from the LP cylinder. If this should occur, turn

OFF the LP tank valve and burner control knobs. Then start

over.

3) Turn the LP tank valve on (turn counter-clockwise).

4) Put match in a match holder and strike match.

5) Push in and turn the side burner control knob (

front) to START/HI.

6) Hold match holder and lit match by right side of side burner.

- rear) or control knob (2 -

1

CAUTION: Side burner flame may be difficult to see on a

bright sunny day.

WARNING: If the side burner does not light:

1) Turn OFF the side burner control valve.

2) Wait 5 minutes to let the gas clear before you try again

or try to light with a match.

WWW.WEBER.COM

®

Page 19

SIDE BURNER TROUBLESHOOTING

1

1

2

3

PROBLEM CHECK CURE

Side Burner does not light. Is gas supply off?

The excess flow safety device, which is part

of the barbecue to cylinder connection, may

have activated.

Flame is low in “HI” position. Is the fuel hose bent or kinked? Straighten hose.

Push button ignition does not work. Does burner light with a match? If match lights burner, check igniter (see Sideburner Maintenance).

Turn supply on.

To reset the excess flow safety device turn all burner control knobs and the cylinder

valve off. Disconnect the regulator from the cylinder. Turn burner control knobs to

START/HI. Wait at least 1 minute. Turn burner control knobs to “OFF”. Reconnect

the regulator to the cylinder. Turn cylinder valve on slowly. Refer to “Lighting

Instructions”.

19

If problems cannot be corrected by using these methods, please contact the Customer Service Representative in your area using the contact information on our

web site. Log onto www.weber.com

®

.

IGNITER

If the Ignition system fails to ignite the side burner, light the burner with a match.

• Check that both ignition wires are attached properly.

• You should hear the igniter sparking.

REPLACE BATTERY IF NECESSARY

AAA alkaline battery only. See illustration:

If the Electronic Ignition System still fails to light, contact the Customer Service

Representative in your area using the contact information on our web site.

Log onto www.weber.com

®

.

GENERAL MAINTENANCE

SIDE BURNER MAINTENANCE

WARNING: All gas controls and supply valves should be in

the “OFF” position.

Make sure ignition wires(1) are connected between the igniter and electrodes.

Make sure grounding wire(2) is connected between the igniter and grounding clips on

the burner cups.

Spark should be a white/blue color, not yellow.

1) Igniter Wires

2) Ground wire

3) Burner

WWW.WEBER.COM

®

Page 20

20

GENERAL MAINTENANCE

BURNER FLAME PATTERN

The Weber® gas side burner is manufactured to perform with the proper air and gas

mixture. The correct flame pattern is shown.

1) Burner cap

2) Tips occasionally flicker yellow

3) Light blue

4) Dark blue

If the flames do not appear to be uniform throughout the burner Head, follow the burner

cleaning procedures.

• Remove Side Burner Cap(a) and wash with a soft cloth and a soap and water

solution.

• Brush debris from Burner Head(b) using a non-metallic brush. Wash with a soft

cloth and a soap and water solution. Dry Burner Head thoroughly.

1

4

3

2

a

b

CLEANING

WARNING: Turn your Weber® Gas Side Burner off and wait

for it to cool before cleaning.

Inside surfaces - Use a warm soapy water solution to clean, then rinse with water.

CAUTION: Do not use oven cleaner, abrasive cleansers

(kitchen cleansers), cleaners that contain citrus products, or

abrasive cleaning pads on the appliance.

Grease tray - Pull grease tray out of Side Burner Box. Remove excess grease and

moisture, wash with warm soapy water, then rinse.

Stainless steel surfaces - Wash with a soft cloth and a soap and water solution. Be

careful to scrub with the grain direction of the stainless steel.

Do not use cleaners that contain acid, mineral spirits or xylene. Rinse well after

cleaning.

Preserve Your Stainless Steel - Your Side Burner, lid, control panel and grease tray are

made from stainless steel. To keep the stainless steel looking its best is a simple matter.

Clean it with soap and water, rinse with clear water and wipe dry. For stubborn particles,

the use of a non-metallic brush can be used.

IMPORTANT: Do not use a wire brush or abrasive cleaners

on the stainless steel surfaces of your Side Burner as this

will cause scratches.

IMPORTANT: When cleaning surfaces be sure to rub/wipe

in the direction of the grain to preserve the look of your

stainless steel.

WWW.WEBER.COM

®

Page 21

Instalación/Guía del propietario del Quemador

BUILT-IN LP SIDE BURNER INSTALLATION/OWNER'S GUIDE

Lateral Empotrado de gas propano licuado

HERRAJES - PG 4

#

42376

#56069

ESTE ARTEFACTO PUEDE SER ADQUIRIDO POR SEPARADO PARA SU BARBACOA EMPOTRADA WEBER

DEBE LEER ESTA GUÍA DEL PROPIETARIO

ANTES DE PONER A FUNCIONAR EL

QUEMADOR LATERAL

PELIGRO

Si huele a gas:

1. Cierre el suministro de gas al artefacto.

2. Apague todas las flamas cerrando la

valvula general de paso.

3. Abra la tapa.

4. Llame inmediatamente a la central de

fugas o a su proveedor de gas.

Una fuga de gas puede provocar un incendio

o explosión que puede resultar en lesiones

corporales serias o la muerte, o daños a la

propiedad.

PARA SU SEGURIDAD

1. No almacene gasolina u otros fluidos

flamables en la cercanía de su aparato.

2. Ningún cilindro de propano licuado que

no esté conectado para su uso deberá

almacenarse cerca de éste o cualquier

otro artefacto doméstico.

NOTA IMPORTANTE: Antes de poner a

funcionar la asador, siga cuidadosamente

todos los procedimientos en este manual

para verificar que no existan fugas. Haga

esto aun y cuando la asador haya sido

ensamblada por el distribuidor.

AVISO AL INSTALADOR:

Estas instrucciones deben permanecer con el

propietario, quien las deberá guardar para un

futuro uso.

ESTE ARTEFACTO A GAS ESTÁ DISEÑADO

PARA USARSE SOLAMENTE AL AIRE LIBRE.

NOTA IMPORTANTE: No trate de encender

este artefacto sin antes leer la sección

“Instrucciones para encender la asador”

de este manual.

56069 ESNA

LP

SPANISH

Page 22

22

PELIGROS Y ADVERTENCIAS

PELIGRO

El hacer caso omiso de los avisos de peligros, advertencias y precauciones contenidos en este Manual del Propietario pudiera

resultar en lesiones corporales serias o la muerte, o en un fuego o explosión que cause daños a la propiedad.

ADVERTENCIAS

No almacene un tanque de propano licuado desconectado o de repuesto debajo o cerca de la barbacoa y el Quemador Lateral.

El ensamblaje incorrecto puede ser peligroso. Por favor siga cuidadosamente las instrucciones de ensamblaje.

Tras haber estado guardados o sin uso por algún tiempo, antes de usar la barbacoa de gas y el Quemador Lateral Weber® revise

ambos para verificar que no existan fugas de gas o obstrucciones en los quemadores. Vea en este manual las instrucciones

para los procedimientos correctos.

No opere la barbacoa de gas o el Quemador Lateral Weber®si existe una fuga de gas.

No utilice una llama abierta para comprobar la existencia de fugas de gas.

Nunca debe haber materiales combustibles a una distancia menor de 24 pulgadas (60 cm) de la parte superior, inferior, trasera

o lateral de su asador de gas Weber®.

No coloque una funda para barbacoas ni cualquier otra artículo inflamable sobre o dentro del área de almacenaje ubicada

debajo del asador.

Nunca permita que los niños usen la barbacoa de gas Weber®. Algunas partes accesibles de la barbacoa pudieran estar muy

calientes. Mantenga alejados a los niños pequeños mientras ésta se esté usando.

Usted debe proceder con razonable cuidado al usar su barbacoa de gas Weber®. Ésta estará caliente al cocinarse en ella o al

limpiarla, y nunca deberá dejarse desatendida o moverse mientras esté funcionando.

Si llegasen a apagarse los quemadores, cierre todas las válvulas de gas. Abra la tapa y espere cinco minutos antes de tratar de

volver a encender la barbacoa, usando las instrucciones de encendido en este manual.

No use carbón o piedra pómez en su barbacoa de gas Weber®.

No se incline sobre la barbacoa abierta o coloque las manos o dedos en el borde delantero de la caja de cocción.

Si la grasa llegase a agarrar fuego, apague todos los quemadores y mantenga la tapa cerrada hasta que se haya apagado el

fuego.

Al limpiar las válvulas o los quemadores, no ensanche los orificios de las válvulas o las aberturas de los quemadores.

La barbacoa de gas Weber® deberá limpiarse a fondo regularmente.

El propano licuado no es gas natural. El uso de gas natural en una unidad de propano licuado o viceversa, propano licuado en

una de gas natural, es peligroso y anulará su garantía.

Mientras opere la barbacoa, utilice guantes resistentes al calor.

Mantenga alejados de todas las superficie calientes a todo cordón eléctrico y a la manguera de suministro de combustible.

Los subproductos de la combustión producidos al usar este producto contienen sustancias químicas que son conocidas por

el Estado de la California como causantes de cáncer, defectos de nacimiento, u otros daños reproductivos.

No use esta barbacoa a menos que todas sus partes estén colocadas en su sitio. La unidad debe ensamblarse correctamente

de acuerdo con las instrucciones de ensamblaje.

Propuesta 65 Advertencia: El manipular los materiales de latón en este producto lo exponen al plomo, una sustancia quimica

conocida por el estado de California como causante de cáncer, de defectos de nacimiento o de otros daños reproductivos.

(Lávese las manos después de manipular este producto.)

ÚNICAMENTE UNIDADES DE GAS PROPANO LICUADO

Use el regulador que se suministra con la barbacoa de gas Weber®.

No trate de desconectar el regulador de gas o ninguna conexión de gas mientras esté funcionando la barbacoa.

Un cilindro de propano licuado abollado u oxidado pudiera ser peligroso y deberá ser revisado por su suplidor de propano

licuado. No utilice ningún cilindro de propano licuado con una válvula dañada.

Aunque el cilindro de propano licuado pudiera aparentar estar vacío, algo de gas pudiera aún estar presente, por lo que el

cilindro deberá transportarse y almacenarse tomando esta posibilidad en consideración.

Si usted ve, huele o escucha el silbido de un escape de gas del cilindro de propano licuado:

1. Apártese del cilindro de propano licuado.

2. No trate de corregir el problema usted mismo.

3. Llame al cuerpo de bomberos local.

WWW.WEBER.COM

®

Page 23

INSTALACIÓN

23

OPERACIÓN

El suministro de gas propano licuado es fácil de usar y le da más control al cocinar que

el carbón vegetal.

• Estas instrucciones le indicarán los requisitos mínimos para ensamblar su

Quemador Lateral de gas Weber

antes de utilizar su Quemador Lateral Weber® de gas. Un ensamblaje incorrecto

puede ser peligroso.

• No debe ser usado por niños.

• Si existiesen códigos locales que aplicasen para barbacoas de gas portátiles,

usted deberá acatarlos. La instalación debe acatar los códigos locales o, en la

ausencia de estos, bien sea el código nacional de gases combustibles “ National

Fuel Gas Code, ANSI Z223.1/NFPA 54”, el código para las instalaciones de gas

natural y propano “Natural Gas and Propane Installation Code, CSA B149.1” o

el código de manejo y almacenaje de propano “Propane Storage and Handling

Code, B149.2”, según apliquen.

• Debe usarse el regulador de presión suministrado con la barbacoa de gas Weber®

Este regulador está ajustado para una presión de 11 pulgadas de columna de

agua.

• Este Quemador Lateral Weber

exclusivamente con gas propano licuado (LP). No lo use con gas natural

(suministrado a través de tuberías en las ciudades). Las válvulas, los orificios, la

manguera y el regulador son solamente para gas propano licuado.

• No la use con carbón vegetal.

• Asegúrese de que el área debajo del artefacto no tenga desechos que pudiesen

obstruir el flujo de aire de combustión o de ventilación.

• Las áreas alrededor del cilindro de gas de propano licuado deben estar libres y

sin acumulación de desperdicios.

• Los reguladores de presión y los ensambles de manguera de reemplazo deberán

ser los especificados por Weber-Stephen Products Co.

®

. Por favor lea cuidadosamente las instrucciones

®

de gas está diseñado para ser usado

PARA LA INSTALACIÓN EN CANADÁ

Esta instrucciones, aunque de manera general son aceptables, no necesariamente

cumplen con los códigos de instalación canadienses, en particular en lo que respecta

a tuberías bajo y sobre tierra. En Canadá la instalación de este artefacto debe cumplir

con los códigos locales y/o la Norma CSA-B149.2 (Código de instalación de artefactos

y equipos que queman propano).

ADVERTENCIA: Use este artefacto sólo al aire libre en

un área bien ventilada. No lo use en un garaje, edificio,

pasadizo techado o en cualquier otra área cerrada.

ADVERTENCIA: La barbacoa empotrada de gas Summit® y el

Quemador Lateral no deberán usarse debajo de un techo o

saliente combustible desprotegido.

ADVERTENCIA: No utilice ni la barbacoa ni el Quemador

Lateral con la parte superior, inferior, posterior, o lateral de

los mismos a menos de 24 pulgadas (610 mm) de distancia

de materiales combustibles.

ADVERTENCIA: Las superficies del artefacto pueden

calentarse al usarse. No lo deje desatendido.

ADVERTENCIA: Mantenga cualquier cordón eléctrico y la

manguera de suministro de gas alejados de toda superficie

caliente.

ADVERTENCIA: Mantenga la zona donde se cocina libre de

vapores y líquidos inflamables tales como gasolina, alcohol,

etc. y de materiales combustibles.

ADVERTENCIA: Nunca almacene cilindros de propano

licuado extra (de repuesto) debajo o cerca de los artefactos

Weber®.

ADVERTENCIA: Mantenga limpios los orificios de

ventilación de la caja del cilindro.

ADVERTENCIA: Cierre el suministro de gas en el cilindro de

propano licuado cuando el artefacto para cocinar al aire libre

no esté en uso.

ADVERTENCIA: Nunca guarde dentro de la casa un

artefacto de gas para cocinar al aire libre sin haber antes

desconectado y sacado del artefacto el cilindro de propano

licuado.

ADVERTENCIA: Los tanques de propano licuado deben

almacenarse al aire libre fuera del alcance de los niños y no

deben almacenarse en edificaciones, garajes o cualquier

otra área cerrada.

OPCIONES DE CONFIGURACIÓN DE LAS ESTRUCTURAS TIPO

“ISLA”

Existen muchas opciones disponibles de cómo ubicar los componentes principales en

su estructura tipo isla. Los componentes principales son:

1) La Barbacoa Empotrada

2) La caja del suministro de gas

3) El quemador accesorio lateral opcional

Las 3 opciones comunes (A, B, C) se ilustran en la tabla “Opciones de configuración de

las estructuras tipo isla.”

2

A

3

1

B

1

2

3

C

3

1

2

OPCIONES DE CONFIGURACIÓN DE LAS

ESTRUCTURAS TIPO “ISLA”

1 Barbacoa Summit® de 4 y de 6 quemadores

2 Suministro de gas

3 Quemador lateral accesorio opcional

NOTA: LIMITACIÓN DE LA LÍNEA DE GAS

La manguera de suministro de gas del múltiple de gas al tabique de suministro de gas

no debe exceder de 58 pulgadas (147 cm). La manguera accesoria de 3/8 pulg. (9.52

mm) (no incluida) del Quemador Lateral no debe exceder de 58 pulg. (147 cm).

WWW.WEBER.COM

®

Page 24

24

INSTALACIÓN

UBICACIÓN DEL QUEMADOR LATERAL EMPOTRADO

Al seleccionar una ubicación adecuada para la instalación de su Quemador Lateral

Empotrado, preste atención a tales asuntos como la exposición al viento, la proximidad

al paso de la gente y en mantener cualquier línea de suministro de gas lo más corta

posible. Nunca coloque el Quemador Lateral Empotrado Summit

pasadizo techado, cobertizo, bajo un voladizo desprotegido o cualquier área encerrada.

Coloque el Quemador Lateral y la estructura en un sitio donde exista suficiente espacio

para evacuar la zona de manera segura en caso de un incendio.

SEPARACIÓN DE LAS SUPERFICIES O ESTRUCTURAS

COMBUSTIBLES

®

en un garaje,

ADVERTENCIA: La separación desde las paredes exteriores

de los lados y la parte posterior del Quemador Lateral

Empotrado a cualquier superficie combustible debe ser

de por lo menos 24 pulgadas (61 cm). Antes de iniciar la

instalación, consulte la “Instalación/Instrucciones para el

gas”.

PELIGRO

La estructura, las encimeras de la “isla” y las áreas de

trabajo adyacentes a la instalación del Quemador Lateral

Empotrado deben construirse exclusivamente de materiales

no combustibles. La instalación incorrecta puede resultar

en un fuego o explosión, que pueden causar serias lesiones

corporales o la muerte, y daños a la propiedad.

NOTA: Si tuviese cualquier pregunta sobre que materiales son considerados

no combustibles, póngase en contacto con su proveedor local de materiales de

construcción o con el cuerpo de bomberos.

B

A A

B

C

B

1

UBICACIÓN DEL QUEMADOR LATERAL

A Cualquier superficie

B 24” (61 cm) de cualquier superficie

C Quemador lateral

Nota: Para conformar la encimera: Se recomienda una saliente de 3/4”

(19 mm). Haga una muesca en el borde frontal para que el bastidor puede

1

deslizarse completamente hacia adentro.

DIMENSIONES DE LA CAVIDAD PRECORTADA DE LA

ESTRUCTURA EMPOTRADA

Todas las dimensiones son con respecto a las superficies acabadas.

C

B

A

ADVERTENCIA: Todas las superficies de acabado de

las encimeras deben construirse con materiales no

combustibles.

QUEMADOR LATERAL

Dimensiones seccionales Tolerancias

A 12 3/8" (31.4 cm) + 1/8" - 1/8" (3.18mm)

B 7 7/8" (20 cm) -

C 27" (68.6 cm) + 1/8" - 1/8" (3.18mm)

WWW.WEBER.COM

®

Page 25

INSTALACIÓN

a

b

c

UBICACIONES DE LAS LÍNEAS DE GAS EMPOTRADAS

DETALLES GENERALES DE CONSTRUCCIÓN

• El Quemador Lateral Empotrado Summit® deberá estar en el lugar antes de

comenzar la construcción.

• Proporcione acceso para una línea de gas corrugada de acuerdo a la ubicación

del quemador lateral en relación a la posición del suministro de gas principal y del

regulador.

• La zona no deberá tener superficies afiladas, dentadas o muy abrasivas a fin de

evitar posibles daños a las líneas de suministro de gas. Tenga cuidado al halar las

líneas de gas a través de la estructura empotrada.

• Deberá utilizarse una línea de gas corrugada de acero inoxidable de 3/8 pulgada

(9.52 mm) (NO INCLUIDA) para conectar el quemador lateral al acople accesorio

en el tabique.

PRECAUCIÓN: La línea de gas corrugada de acero

inoxidable de 3/8 pulgada (9.52 mm) no debe exceder de 58

pulgadas (147 cm) de longitud. Una manguera más larga

podría causar una caída de presión indebida.

ADVERTENCIA: No utilice una manguera de gas hecha de

hule.

MONTAJE DEL QUEMADOR LATERAL

1) Fije la ménsula de montaje(a) a la parte posterior de la caja del Quemador Lateral.

Asegúrela con las arandelas de seguridad y las tuercas de mariposa. Sólo apriete

a mano.

2) Inserte el pasamuros(b) en el orificio en el lado posterior izquierdo de la caja del

Quemador Lateral hasta que encaje en su sitio.

3) Pase la línea corrugada de 3/8 pulgada (9.52 mm) de acero inoxidable del gas a

través del orificio en el lado izquierdo de la caja del Quemador Lateral (c) Pase el

extremo de la alimentación de la manguera a la caja de suministro de gas (vea la

sección “CONEXIÓN DEL SUMINISTRO DE GAS”).

PRECAUCIÓN: Antes de instalar el componente, retire la

película protectora de la pieza de acero inoxidable.

25

1

2

UBICACIONES DE LA LÍNEA DE GAS

1 3/8” (9.52 cm) Linea de gas corrugada de acero inoxidable SAE

2 Ubicación típica del gabinete para tanques

4) Baje la caja del quemador alterar dentro de la abertura precortada para el mismo.

5) Fije la caja del Quemador Lateral a su sitio con un tornillo no corrosivo(d) anclado

a la superficie terminada de la “estructura tipo isla”.

WWW.WEBER.COM

®

d

Page 26

26

6) Fije la parte posterior de la caja del Quemador Lateral a la encimera ajustando la

ménsula en la parte posterior de la caja del Quemador Lateral. Apriete las tuercas

de mariposa.

7) Conecte la línea corrugada de 3/8 pulgada (9.52 mm) de acero inoxidable del gas

a la válvula del Quemador Lateral ubicada debajo de este último.

INSTALACIÓN

PRECAUCIÓN: Antes de continuar con la instalación, debe conectar la línea de gas del

Quemador Lateral a la línea de suministro de gas, y luego probar todas las conexiones de gas

al Quemador Lateral para asegurarse de que no hayan fugas. Vea la sección “CONEXIÓN DEL

SUMINISTRO DE GAS” y la sección “PRUEBAS DE DETECCIÓN DE FUGAS DE GAS”.

8) Baje el Quemador Lateral dentro de la caja del mismo. Utilice los 6 tornillos

incluidos para fijar el Quemador Lateral a su caja.

WWW.WEBER.COM

®

Page 27

INSTALACIÓN/INSTRUCCIONES PARA EL GAS

27

9) Instale los componentes remanentes.

INSTALACIÓN TÍPICA DE SUMINISTRO DE GAS PROPANO A

GRANEL