Page 1

PLATINUM

™

SERIES II

LP Gas Barbecues

Step-By-Step Guide

THIS GAS APPLIANCE IS DESIGNED FOR

OUTDOOR USE ONLY.

NOTICE TO INSTALLER: These instructions

must be left with the owner and the owner

should keep them for future use.

FOR Y OUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, immediately call your

gas supplier or your fire department.

FOR Y OUR SAFETY

1. Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

2. An LP tank not connected for use shall

not be stored in the vicinity of this or

any other appliance.

WARNING: Follow all leak check

procedures carefully in this manual

prior to barbecue operation. Do this

even if barbecue was dealer assembled.

97460 12/96

Platinum Series II

2200 LP

Platinum Series II

3200 LP

Platinum Series II

3400 LP

R

A P P R O V E D

CANADIAN

GAS ASSOCIATION

®

National

Association

PROPANE

GAS

Page 2

2

TOOLS NEEDED

Phillips screwdriver

7/16 inch or adjustable wrench

SUPPLIES NEEDED

While we give much attention to our products, unfortunately an occasional error may occur. If a part is

missing, do not go back to the store. Call the Weber

Customer Service Center toll free 1-800-446-1071 to

receive immediate assistance. Have your owner’s

manual and serial number of the barbecue available

for reference.

You will need a soap and water solution to check for gas

leaks. (See section “Check for Gas Leaks.”)

Refer to exploded view in the Operating Guide if

replacement parts are needed.

Your LP tank is shipped empty for safety. After setting the

LP fuel scale you will need to fill it. (See section “Fill LP

Tank.”)

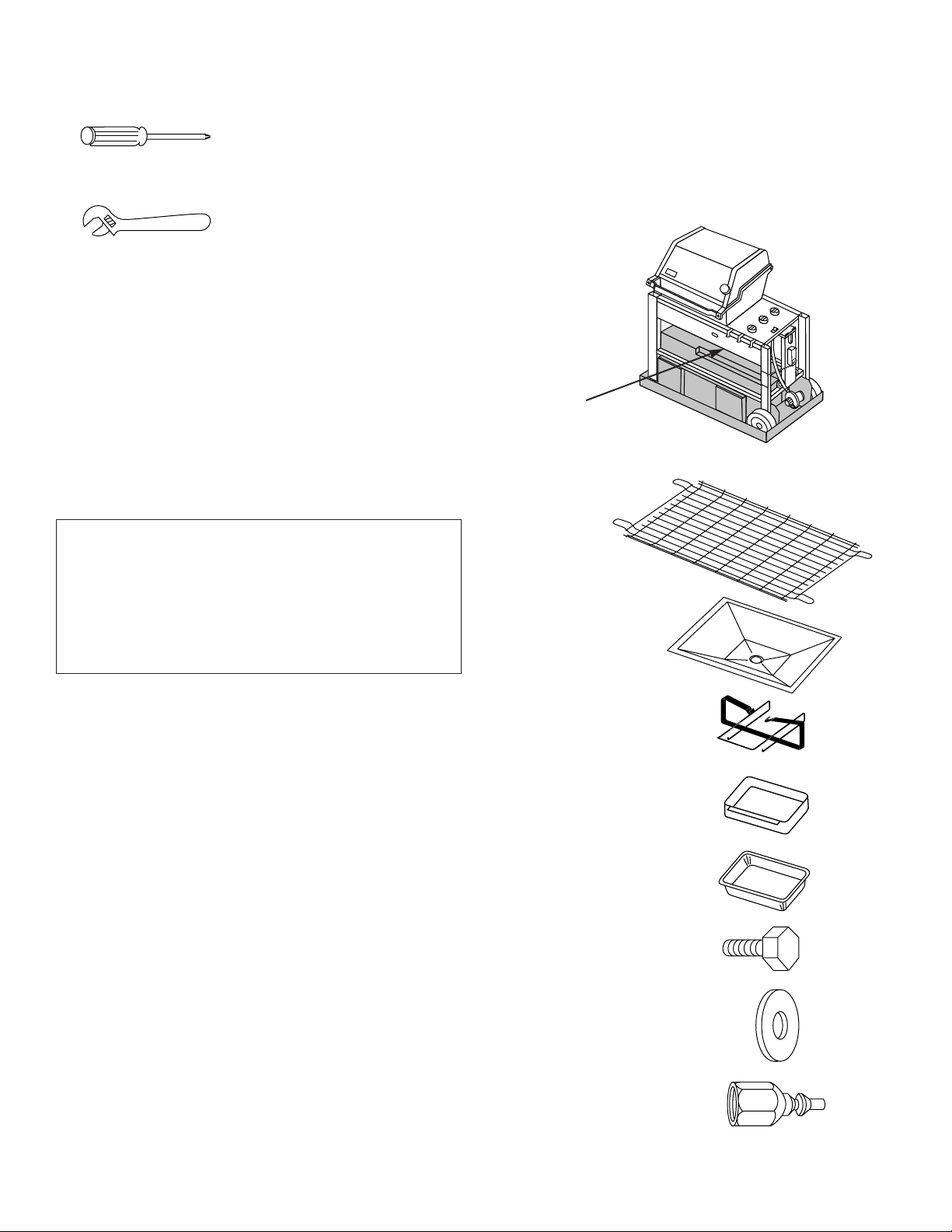

Bottom rack

Bottom tray

Catch pan holder

Catch pan

Drip pan

Four 1/4-20 x 1/2 inch bolts

Four nylon washers

Filler adapter

Bottom tray

Figure 1

REMOVE BOTTOM TRAY FROM GRILL

Remove all tape from packaging. Remove bottom rack

from top of packaging. Remove outer box. Pull out bottom

tray from cooking box. Remove packaging material from

bottom tray, catch pan holder, catch pan, and drip pan.

For the Platinum Series II 3400, remove the white plastic

from the stainless steel.

Page 3

3

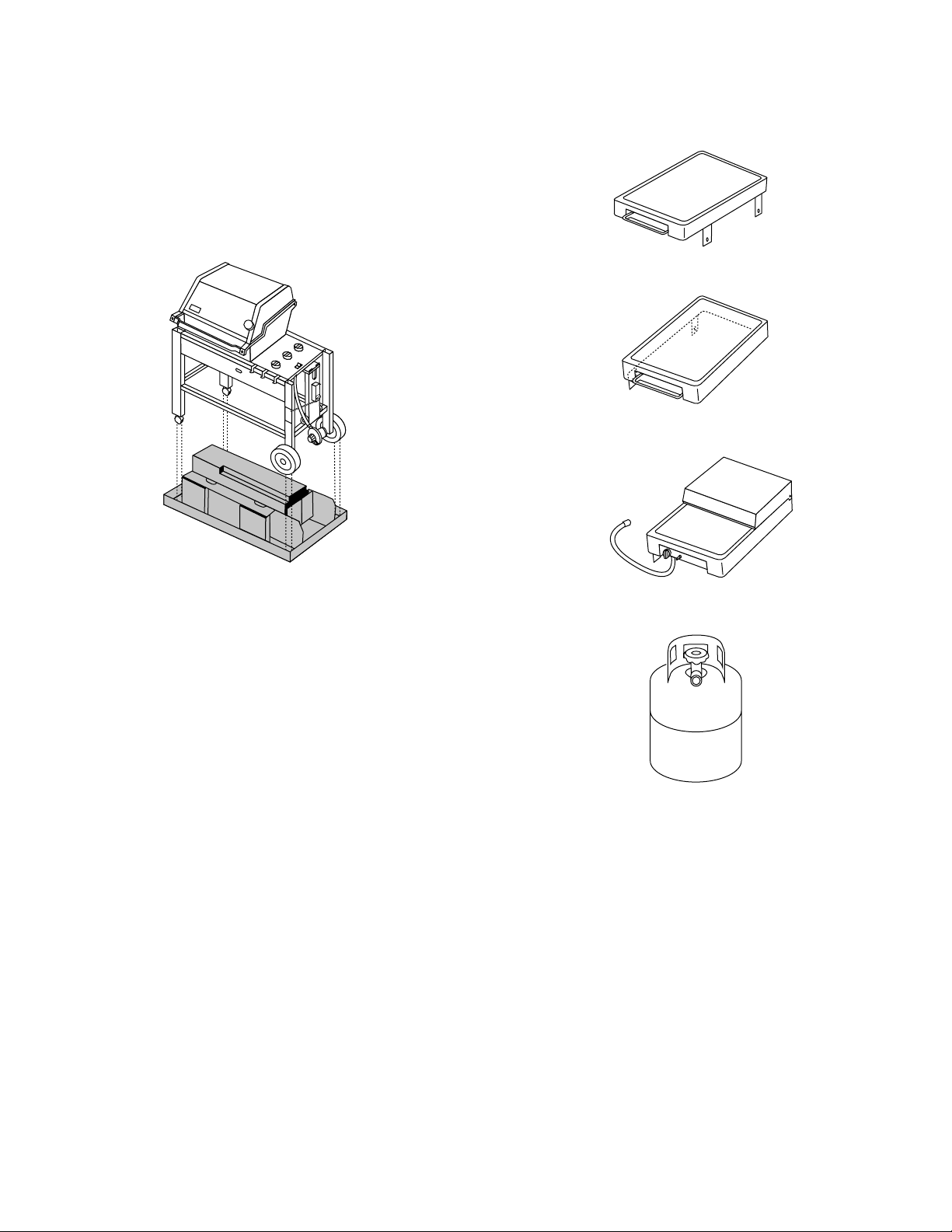

REMOVE GRILL FROM LOWER PACKAGING

WARNING: Lifting the barbecue from the lower

packaging requires at least two people.

With two people lift straight up and over lower packaging

and cardboard support.

Note: For the Platinum Series II 3400, make sure the front

doors are securely closed before lifting.

Figure 2

REMOVE PACKAGED PARTS FROM LOWER CARTON

Left work surface

Right work surface

(Platinum Series II 2200 LP only)

Side burner

(Platinum Series II 3200 LP and 3400 LP only)

LP tank

Note: For the Platinum Series II 3200 and 3400, remove

the white plastic on the stainless steel of the side burner.

Page 4

4

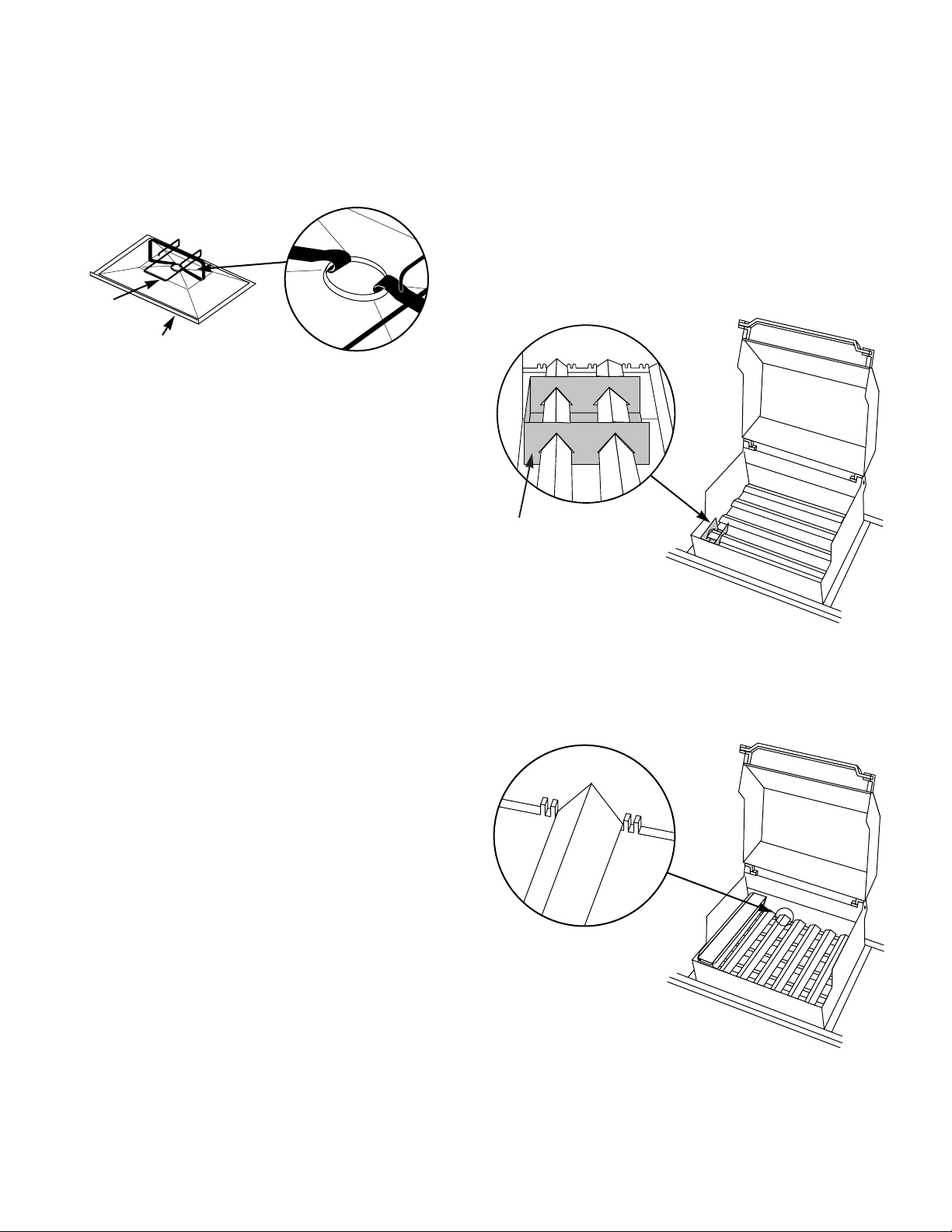

INSTALLATION OF CATCH PAN INTO BOTTOM TRAY

Slide the bottom tray onto the mounting rails under the

cooking box with finger grip toward you.

CAUTION: Do not line bottom tray with aluminum foil.

It can cause grease fires by trapping the grease and

not allowing grease to flow into the catch pan.

Put the foil drip pan into the catch pan.

Slide the catch pan into the catch pan holder with its

finger grip towards you.

Finger grip

Figure 3

Front of

catch pan

holder

Hook the ends of the catch pan holder into the hole in the

bottom tray. Figure 3. The front of the catch pan holder

must be on the same side as the finger grip of the

bottom tray.

Figure 4

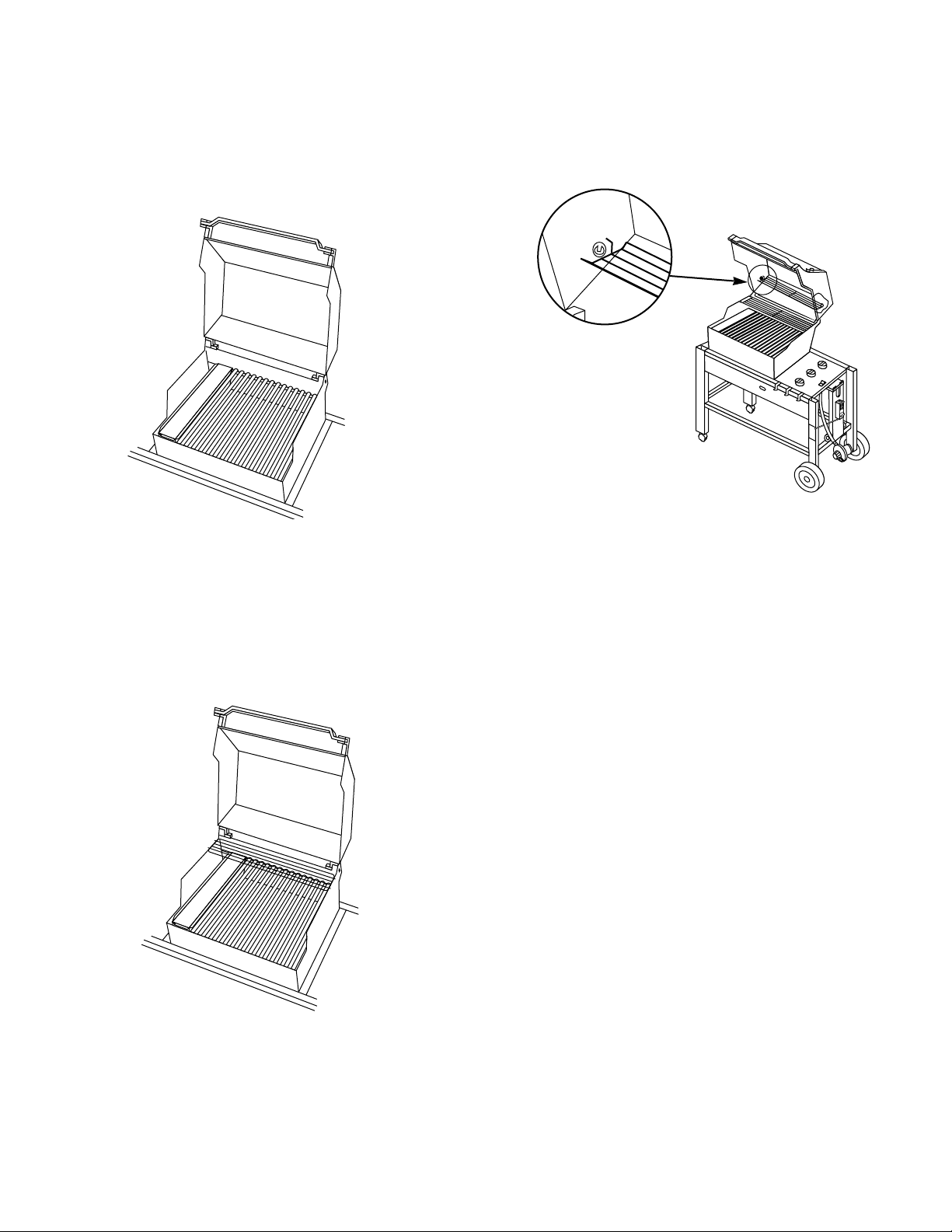

REINSTALLATION OF STAINLESS STEEL FLAVORIZER BARS

Set the short stainless steel Flavorizer bars front to back

in the upper position. Figure 5. Place Steam-N-Chips

Smoker so it opens towards Flavorizer bars.

Note: Remove any tape or packing material. Parts are

shipped in place. Use these steps to check that they are

in position. The Flavorizer bars are already in place.

This step is only for reinstallation.

Set the long stainless steel Flavorizer bars side to side in

the lower position of the cooking box. Insert the front two

Flavorizer bars through the Steam-N-Chips Smoker flue.

Figure 4.

Figure 5

Flue

Page 5

5

Note:The cooking grates are already in place.This

step is only for reinstallation.

Set the cooking grates onto the ledges in the cooking

box. The open "U" of the cooking grate goes down.

Figure 6.

Set the warming rack into the slots at the rear of the

cooking box. Figure 7.

Figure 6

Figure 7

REINSTALLATION OF COOKING GRATES

INSTALLATION OF WARMING RACK

INSTALL WARM-UP BASKET

Insert one end of the Warm-Up Basket into the hole in the

right end of the lid and the other end into the slot in the

left end of the lid. Figure 8.

Figure 8

Page 6

6

SET LP FUEL SCALE

You will need: LP tank (empty).

Note - For accuracy, the fuel scale must be set with an

empty tank.

We utilize various LP tank manufacturers. Some of the

tanks we receive have differing top collar assemblies.

(The top collar is the metal protective ring around the

valve.) One series of tanks mounts with the valve facing

front. The other tanks mount with the valve facing away

from the fuel scale. These types of tanks are illustrated in

Figure 9.

Loosen the tank lock wing nut. Tighten so the lock is held

up out of the way. Figure 9 (a). Lift and hook the tank onto

the fuel scale. With an empty LP tank, adjust the fuel scale

setting to E with scale setting (top) wing nut. Figure 9 (b).

CAUTION: Do not remove adjustment wing nut from

tank scale.

After adjusting tank scale, push tank down a couple of

times to check that the tank scale is set on “E”.

F

E

(a)

Scale setting

wing nut

Figure 9

F

E

(b)

FILL LP TANK

To fill, take the LP tank and filler adapter to an RV center,

or look up gas-propane in the phone book for other

sources of LP gas.

WARNING: We recommend that your LP tank be filled

at an authorized LP gas dealer by a qualified

attendant, who fills the tank by weight.

IMPROPER FILLING IS DANGEROUS.

Tell your LP dealer that this is a new LP tank. The air

must be removed from a new LP tank before the initial

filling. Your LP tank dealer is equipped to do this.

CAUTION: If you exchange your LP tank, make sure

you get a similar tank in return.Your LP tank is

equipped with a Type II, CGA #810 quick-disconnect

valve. Other LP tanks are not compatible with your

barbecue connection.

The LP tank must be installed, transported and stored in

an upright position. LP tank should not be dropped or

handled roughly.

Never store or transport the LP tank where temperatures

can reach 125° Fahrenheit (too hot to hold by hand – for

example: do not leave the LP tank in a car on a hot day).

For full instructions on safe handling of LP tanks, see

Section "General Tank Information”.

Page 7

7

GENERAL TANK INFORMATION

LP Tank Manufacturer

The LP tank manufacturer is responsible for the materials,

workmanship and performance of the tank. If the tank has

a defect, malfunctions, or you have a question regarding

the tank, call the tank manufacturer's customer service

center. The phone number is on the warning decal which is

permanently attached to the tank. If the tank manufacturer

has not resolved the issue to your satisfaction, then call

Weber-Stephen Products Co., Customer Service Center.

For Y our Safety

Your LP tank is shipped empty for safety. After setting the

LP fuel scale you will need to fill it. Refer to Filling your

LP tank.

Safe handling tips for LP Gas

■ Liquid Propane (LP) gas is a petroleum product as are

gasoline and natural gas. LP gas is a gas at regular

temperatures and pressures. Under moderate pressure,

inside a cylinder, LPgas is a liquid. As the pressure is

released the liquid readily vaporizes and becomes gas.

■ LP gas has an odor similar to natural gas. You should

know this odor.

■ LP gas is heavier than air. Leaking LP gas may

collect in low areas that prevent dispersion.

■ The LP tank must be installed, transported and stored

in an upright position. LP tanks should not be

dropped or handled roughly.

■ Never store or transport the LP tank where

temperatures can reach 125° F (too hot to hold by

hand - for example: do not leave the LP tank in a car

on a hot day).

■ The LP cylinder supply must be arranged for vapor

withdrawal.

Note - A refill will last about 20 hours of cooking time at

normal use.The fuel scale will indicate the propane

supply so you can refill before running out.You do not

have to run out before you refill.

■ Treat "empty" LP tanks with the same care as when

full. Even when the LP tank is empty of liquid there

still may be gas pressure in the cylinder. Always

close the tank valve before disconnecting.

■ Do not use a damaged LP tank. Dented or rusty LP

tanks or LP tanks with a damaged valve may be

hazardous and should be replaced with a new one

immediately.

■ The joint where the hose connects to the LP tank

must be leak tested each time the LP tank is

reconnected. For example, test each time the LP tank

is refilled.

■ Be sure the regulator is mounted with the small vent

hole pointed downward so it will not collect water.

This vent should be free of dirt, grease, bugs etc.

■ The LP tank and connections supplied with your

Weber Gas Barbecue have been designed and tested

to meet government, American Gas Association and

Underwriters Laboratories requirements.

■ Replacement LP tanks supplied by Weber satisfy the

requirements. Check to be sure the tank has a D.O.T.

certification, and has been tested within five years.

Your LP gas supplier can do this for you. Figure 10.

If you have questions about spare LP tanks, please

call Weber-Stephen Customer Service.

DOT 4BA240

2/96

Date Tested

20 lb LP tank

D.O.T. Certification (example)

■ All LP tank supply systems must include a collar to

protect the tank valve.

■ The LP tank must be constructed and marked in

accordance with the specifications for LP gas

cylinders of the U.S. Department of Transportation

(D.O.T.).

Figure 10

Page 8

8

INSTALL WORK

SURFACES

FOR THE PLATINUM SERIES II 2200

You will need...left work surface, right work surface, four

1/4-20 x 1/2 inch bolts, four nylon washers and a 7/16

inch or adjustable wrench.

Insert the left work surface tabs in the slots to the left of

the cooking box. Figure 11 (a). Slip washers on the bolts

and insert the bolts as shown. Tighten. Figure 11 (b).

Insert the right work surface tabs in the slots to the right of

the cooking box. Figure 11 (c). Slip washers on the bolts

and insert the bolts as shown. Tighten. Figure 11 (d).

Platinum Series II 2200

Figure 11

(a)

(b)

(c)

(d)

View from

left side

View from left

underside

View from

right side

View from right

underside

Tabs

Tabs

Tabs

If you have the Platinum Series II 2200,

continue to step “Install Work

Surfaces” on this page.

If you have the Platinum Series II 3200,

go to step “Install Work Surface and

Side Burner” on page 9.

If you have the Platinum Series II 3400,

go to step “Install Work Surface and

Side Burner” on page 11.

After this assembly, proceed to step “Install Bottom

Rack” on page 13.

Page 9

9

INSTALL WORK SURFACE

AND SIDE BURNER

FOR THE PLATINUM SERIES II 3200

You will need... left work surface, side burner assembly,

four 1/4-20 x 1/2 inch bolts, four nylon washers and a

7/16 inch or adjustable wrench.

Insert the left work surface tabs in the slots to the left of

the cooking box. Figure 12 (a). Slip washers on the bolts

and insert the bolts as shown. Tighten. Figure 12 (b).

Note: Remove protective covers from tabs of

side burners.

Insert the side burner assembly tabs in the slots to the right

of the cooking box. Figure 12 (c). Slip washers on the bolts

and insert the bolts as shown. Tighten. Figure 12 (d).

Side burner can only be installed on right side

of barbecue.

Platinum Series II 3200

Figure 12

Route the side burner hose so it will not interfere with the

scale indicator rod.

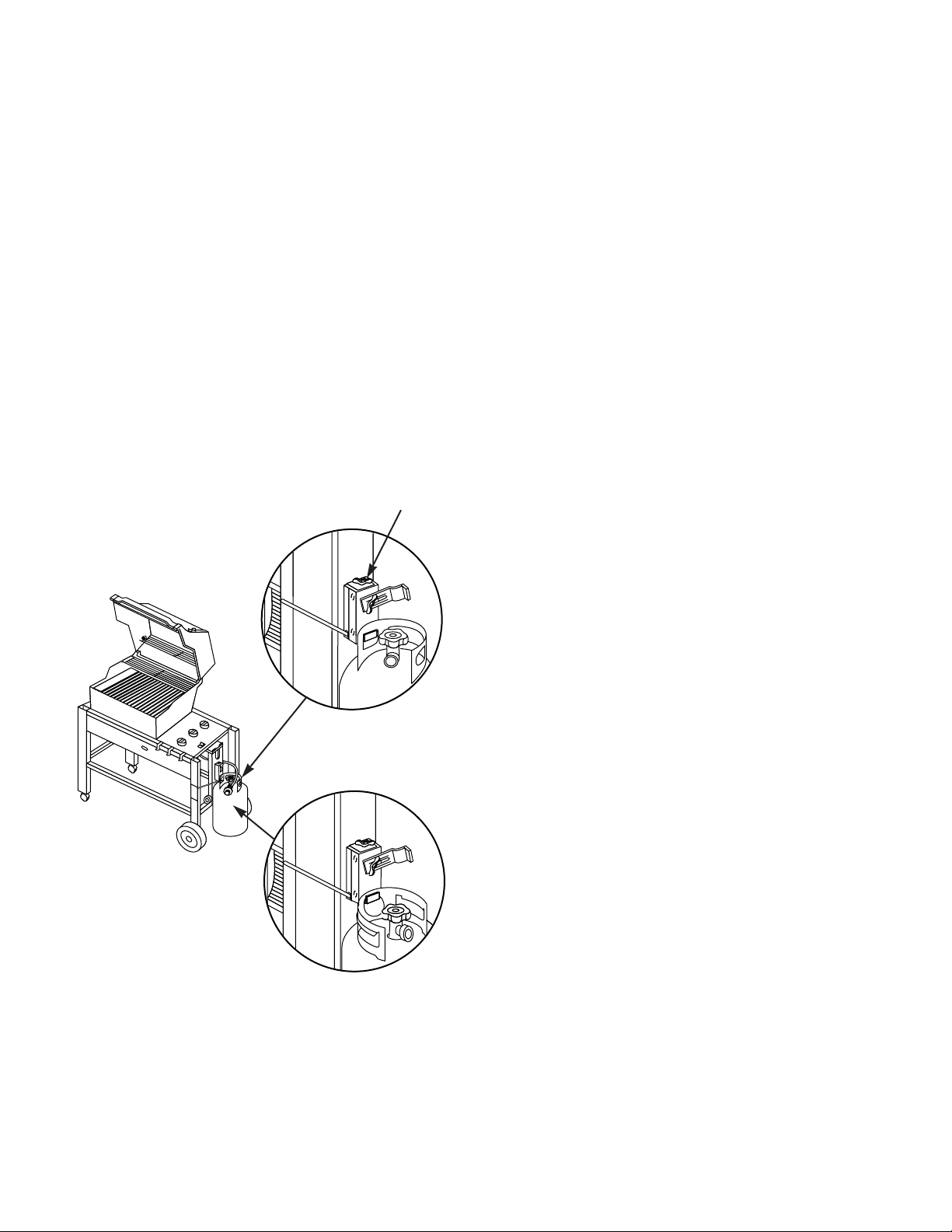

The side burner hose is connected in the following

manner:

Slide back the collar of the quick disconnect on the

manifold. Push the male fitting of the side burner hose

into the quick disconnect, and maintain pressure. Slide

the collar closed. Figure 13. Figure 14 shows the quick

disconnect engaged.

View from

left side

View from left

underside

View from

right side

View from right

underside

Manifold side view

Manifold side view

Figure 14

Figure 13

Male fitting

Quick disconnect

engaged

Side burner hose

Tabs

Tabs

Tabs

(d)

(b)

(c)

(a)

View from right

underside

To LP tank

To side burner

connection

Figure 15

Page 10

10

Check that the side burner is properly assembled.

Figure 16

Burner cap

Burner ring

Burner head

Burner base

Windshield

Grate

(a)

(c)

(b)

Burner orifice

WARNING: Set the burner ring onto the burner head.

Rotate the burner ring until the four lugs on the

burner ring are seated in the four slots on the burner

head. Figure 16 (b).

Note: The burner head has a hole in it that fits over the

igniter electrode.

INSTALL WORK SURFACE

AND SIDE BURNER

FOR THE PLATINUM SERIES II 3200

(CONTINUED)

Slots

Lugs

Igniter

electrode

After this assembly, proceed to step “Install Bottom

Rack” on page 13.

Page 11

11

INSTALL WORK SURFACE

AND SIDE BURNER

FOR THE PLATINUM SERIES II 3400

Figure 17

Platinum Series II 3400

View from

left side

View from left side

View from

right side

View from right

underside

Tabs

Tabs

Tabs

(d)

(b)

(c)

(a)

You will need... left work surface, side burner assembly,

four 1/4-20 x 1/2 inch bolts, four nylon washers and a

7/16 inch or adjustable wrench.

Insert the left work surface tabs in the slots to the left of

the cooking box. Figure 17 (a). Slip washers on the bolts

and insert the bolts as shown. Tighten. Figure 17 (b).

To install side burner

Note: Remove protective covers from tabs of

side burners.

Insert the side burner assembly tabs in the slots to the right

of the cooking box. Figure 17 (c). Slip washers on the bolts

and insert the bolts as shown. Tighten. Figure 17 (d).

Side burner can only be installed on right side

of barbecue.

Left panel

Page 12

12

Route the side burner hose around the tank panel so it

will not interfere with scale indicator rod.

The side burner hose is connected in the following

manner:

Slide back the collar of the quick disconnect on the

manifold. Push the male fitting of the side burner hose

into the quick disconnect, and maintain pressure. Slide

the collar closed. Figure 18. Figure 19 shows the quick

disconnect engaged.

Manifold side view

Manifold side view

Figure 19

Figure 18

Male fitting

Quick disconnect

engaged

Side burner hose

View from right

underside

To LP tank

To side burner

connection

Figure 20

Check that the side burner is properly assembled.

Figure 21

Burner cap

Burner ring

Burner head

Burner base

Windshield

Grate

(a)

(c)

(b)

Burner orifice

INSTALL WORK SURFACE

AND SIDE BURNER

FOR THE PLATINUM SERIES II 3400

(CONTINUED)

WARNING: Set the burner ring onto the burner head

with the slots facing up. Rotate the burner ring until

the four lugs on the burner ring are seated in the four

slots on the burner head. Figure 21 (b).

Note: The burner head has a hole in it that fits over the

igniter electrode.

Lugs

Slots

Igniter

electrode

After this assembly, proceed to step “Install Bottom

Rack” on page 13.

Page 13

13

INSTALL BOTTOM RACK

Figure 22

Place the bottom rack between the frame supports.

Figure 22.

For the Platinum Series II 3400, place the bottom rack

under the cart between the frame supports. Lift up one

end of the rack so it clears the crosspiece. Continue to lift

until the opposite end clears the opposite crosspiece. Set

the rack in place on both crosspieces.

Valves are shipped in the OFF position, but you should

check to be sure. Put the knob on each valve. Check by

pushing down and turning clockwise. If they do not turn,

they are off. Proceed to the next step. Figure 23.

Figure 23

For models 3200 & 3400, check that the side burner

valve is in the OFF position. Push in and turn to OFF.

Figure 24.

Figure 24

CHECK THAT ALL BURNER VALVES ARE OFF

Page 14

14

CONNECT FILLED LP TANK

WARNING: Make sure that the LP tank valve is

closed. Close by turning clockwise.

Hook the LP tank onto the fuel scale. Loosen the tank

lock wing nut. Swing the tank lock down. Tighten the wing

nut. Figure 25.

Figure 25

Tank lock wing

nut

Remove the tape and packaging from the hose and regulator.

Route the hose so it will not interfere with the scale

indicator rod.

The hose and regulator are connected in the following manner:

Slide back the collar of the quick disconnect on the tank

valve. Push the male fitting of the regulator into the quick

disconnect, and maintain pressure. Slide the collar closed.

Figure 26 (a). Figure 26 (b) shows the quick disconnect

engaged and various components of the tank and

regulator. Regulator vent hole should be at 3, 6, or 9

o'clock. It should not be pointed up. Figure 26 (c).

Figure 26

Turn so regulator vent

does not collect water

Hose

Quick disconnect

engaged

Valve handwheel

close clockwise

Tank valve

Collar

Male

fitting

Pressure

relief valve

Tank

Regulator

Regulator

vent

(a)

(b)

(c)

Page 15

15

CHECK FOR GAS LEAKS

WARNING

The gas connections of your Weber Gas

Barbecue have been factory tested. We do

however recommend that you leak check all

gas connections before operating your

Weber Gas Barbecue.

Remove the knobs from the control panel. Figure 27.

Figure 28

Figure 27

Use a Phillips screwdriver to remove the screws from the

underside of the control panel. Figure 28.

Stand at the right end of the barbecue. Lift the control

panel off. The side burner or work surface remains

in place.

View from right

underside

WARNING: You should check for gas leaks every time

you disconnect and reconnect a gas fitting.

You will need: a soap and water solution and a rag or

brush to apply it.

Note - Since some leaks test solutions, including soap

and water, may be slightly corrosive, all connections

should be rinsed with water after checking for leaks.

DANGER

Do not use an open flame to check for

gas leaks. Be sure there are no sparks or

open flames in the area while you check for

leaks. This will result in a fire or explosion

which can cause serious bodily injury or

death and damage to property.

Figure 29

To perform leak checks: open tank valve by turning the

tank valve handwheel counterclockwise. Figure 29.

WARNING

Make sure all burner control knobs are in

the OFF position, including the side burner,

if the barbecue has a side burner.

Page 16

16

CHECK FOR GAS LEAKS

WARNING: Do not ignite burners while checking

for leaks.

Check for leaks by wetting the connections with the soap

and water solution and watching for bubbles. If bubbles

form or if a bubble grows there is a leak.

Check:

a) Hose to manifold connection. Figure 30 (a).

WARNING: If there is a leak at connection a, retighten

the fitting with a wrench and recheck for leaks with

soap and water solution.

If a leak persists after retightening the fitting, turn

OFF the gas. DO NOT OPERATE THE BARBECUE.

Contact Weber-Stephen Customer Service.

b) Regulator to tank connection. Figure 30 (b).

c) Manifold to side burner hose connection.

Figure 30 (c).

d) Valves to manifold connections. Figure 30 (d).

e) Side burner hose to side burner valve, and side

burner supply line to side burner valve. Figure 30 (e).

f) Side burner supply line to side burner orifice

connection. Figure 30 (f).

g) Hose to regulator connection. Figure 30 (g).

WARNING: If there is a leak at connections

b, c, d, e, f or g, turn OFF the gas. DO NOT OPERATE

THE BARBECUE. Contact W eber-Stephen

Customer Service.

When leak checks are complete, turn gas supply OFF at

the source and rinse connections with water.

Figure 30

(a) (b)

(c)

(g)

(e)

(d)

views from

below

(f)

Page 17

17

REINSTALL THE CONTROL PANEL

Set the control panel in place over both frame braces.

(Hold the Crossover Ignition button up while setting the

control panel in place.) Slip washers on Phillips screws,

insert into holes as shown, and tighten. Figure 31 (a).

Push on the burner control knobs. Figure 31 (b).

Figure 31

REFER TO OPERATING

GUIDE BEFORE LIGHTING

BARBECUE

Underside view

of right work

surface or side

burner

Page 18

18

Page 19

Page 20

Loading...

Loading...