Page 1

WEBECO

Installation & Operation

Vertical

Model

Manual

of

Steam

B-C-H

for

Sterilizer

Page 2

1610e

No.

VERTICAL

Description

Mains

First

mains

Model B -

Model C -

Model H -.7.5 fused

ater

Water

Supply

of

all

voltage

2,7

4,5

Connection

Operated

AUTOCLAVES

of

Apparatus

INSTALLATION

check

(if

rating

necessary,

fused

fused

for

Units

Exhaust

Steam

and

Instructions

AND

ELECTRIC

plate

reaf from

220/380

3x

3 x 10

3 x 15

with

Condenser

MODEL

CONNECTION

of

apparatus

meter).

V

SA

À

A

Water

Jet

B-C-H

for

with

220

16

25

40

Pump

Use

Y

or

your

with

A

cold

the

Model

Model C +

The

hose

For a proper

pressure

pump

Water

The

condenser

The

of 19

C

and H respectively.

jet

water

water,

water

installation

B R

connection

or

pipe.

is

running.

Drain

waste water

drain

mms,

pump

of

connection

H в

takes

operation

of 3 atm.abs.

must

hose

or

the

be

or

for

autoclave B and

exhaust

drain

site.

1/2"

3/4".

from

led

drain

with stop

place

of

(minimum)

the

water

to a gully

pipe

The

steam

in

order

valve

by

means

the

water

is

jet

of 1 1/2"

must

hose

concenser

to

have a minimum

of

24

or

pipe

avoid

must

of a pressure-resistant

jet

pump, a water

necessary,

pump

or

mms,

fastend

must

re-sucking

be

when

exhaust

to

2"

for

autoclaves

to

not dip

laid

of

to

the

steam

width,

clearance

tho

water

into

the

waste

Page 3

Filling

Before

valve

(12).

deposits

sterilized,

The

through

bottom

water

level

(18)

Loading

Load

clamps

the

press

by

means

If

the

ner and

gins

(13)

downwards

mometer

the

passes

The

de-aeration

ately.

of

distilled

Distilled

operation,

(18), Now

Use

and

distilled

the

and

cut-off

mark

completely.

and

the

unit,

(7)

lid,

majority

thermometer

Bring

push-button

of

autoclave

adjust

to

boil

into

(17)

the

Otherwise a loss

FUNCTION

Water

shut

pour

distilled

harm

water

perforated

covers

(22).

at

the

Heating-up

close

and

shut

heating

the

it

and

the

capacity

into

the

and

of

thermometer

phase,

water would

water

the

poured

the

Pour

gauge

off the

(25),

pilot

is

gas

to a big

the

exhaust

the

the

air has

reading

Shut

OF

AUTOCLAVE

off

drain

distilled

only;

apparatus

inner

heating

in

(10).

the lid (4),

switch

Working

lamp

or

steam

space.

opened

which

of

off

of

occur,

water

ordinary

and the

into

(26).

kerosene

flame,

streams

steam

100

steam

the

bottom

elements

distilled

Now

aeration

(24)

of

The

de-aeration

escaped,

then

°C

de-aeration

valve

open

tighten

Gradually

heavy

piping

indicates

means

and

(11) and

into

inner

(15)

valve

into

the

heated,

through

practically

consequently a loss

the

water

materials

jacket

into

(21) and the low

water

de-aeration

the

(6)

position

heating

the

cold

(20)

valve

the

valve

de-aeration

inner

would

the

up

to

locking

arranged

is

light

the

water

bore-holes

air

passing

(18),

100

°C.

end

of

(18)

jacket

cause

to

be

flows

boiler

the

water

valve

on

III

and

indicated

the

bur-

be-

is

pushed

ther-

When

pure

steam

the

immedi-

Attention!

de-aeration

valve

Only

valve

Pressure

3.

After

longer

which

ion

sate

(16)

only

must

after

according

having

is

valve

and

and

slowly.

If

the

and

always

sterilization

Rise

shut

escape,

indicated

(18)

residual

at

thus

and

thermometer

temperature

to

sterilizer

be

opened.

item

off

at

safety

air

6.

de-aeration

causing a pressure

the

are

(17)

is

equipped

control

of

solutions

pressure

valve

gathered

so

(19)

that

valve

with

device,

lock

rise

gauge

are

in

the

temperature

the

de-aeration

(18),

in

(5),

shut-off,

de-aeration

an

automatic

de-aeration

steam

the

As

can

boiler

de-aerat-

conden-

pipe

increase

no

Page 4

At

the

moment

safety

control.

condensate

and

Now

sterilization

(hen

attained,

II.

safety

With

a

little

valve

The

safety

the

thermometer

the

temperature

Thus

valve.

gas

not

or

bit.

when

(19)

steam

and

residual

valve

the

kerosene

(19)

temperature

heating

too

much

the

pressure

is

attained,

in

excess

air

into

reading

needed

switch

steam

heated

set

by

the

the

safety

is

released

gathered

the

exhaust

increases

corresponding

for

sterilization

may

wiîl

autoclave,

at

very

be

brought

be

released

thermometer

steam

to

throttle

weight

valve

and

pushes

piping

quickly

the

has

into

through

of

the

begins

pressure.

been

position

the

to

out

(17)

(20).

to

the

the

flame

Sterilization

When

attained,

The

ions,

and

where,

Therefore,

rubber

lid

rubber gloves

zontally

Avoid

through

equally

At

minated

If

flame.

Drying

Jf

water

lization,

valve

steam

indicates

period

(29)

compensated

In

indicates

lid

TE

open

through

gauge

valve

use

the

of

the

temperature

the

relevant

During

the

sterilization

gloves,

and

bottom

in

too

tight

the

and

the end

and the

the

autoclave

Goods

of

autoclave

the

valve

so

(29),

sucked

are

the

required

then

and

seat

its

"zero"

(4).

autoclave

the

de-aeration

the

indicates

(5)

and

(6)

heat

the

residual

wood

of

duration

this

for

the

drum

pushes

of

(31)

that

so

by

filter

exhaust

in

water

finger's

Phase

needed

actual

sterilization

etc.

perforation.

have

drums,

packing,

sterilization

heating

to

that

negative

for

water

opening

loosen

the

sterilization

is

phase,

temperature

use

to

be

from

is

is

has

out

loosen

is

valve

top

out

any

gas

Sterilized

be

equipped

to

pump

the

first

of

pressure.

drying,

valve

the

incorporated.

is

not

(18),

steam

"zero",

the

boiler

opening

by

breadth

for

stated

the

only

Textile

placed

so

that

to

residual

phase,

has

to

or

keronsene

opened

be

begins

any

boiler.

the

shut

(31).

pressure

locking

the

equipped

piping

open

locking

for

sterilization

phase

in

the

steam

of

drums

bottom

with

residual

Now

valve

between

penetrates

has

textile

in

fabrics

vertically

the

penetrates

air

sterilization

switched

(except

water

a

completely

to

The

the

At

off

Vacuum

equalizing

When

clamps

with

steam

(20).

the

clamps

drying

(11)

lid

starts,

operating

been

good

steam

heated,

suck.

first

a

pressure

the

achieved

fabrics,

condition

and

and

streaming

through

of

immediately.

turn

solutions)

jet

after

Now

water

pressure

end

in

water

pressure

When

(7),

and

and

of

vacuum

the

pressure

(7)

the

material,

and

boiler

has

been

instruct-

the

material

every-

dressings,

with

especially

not

hori-

the

material

the

bottom,

is

ter-

off

the

pump

boiler

jet

equelizing

In

put

(27-33),

steri-

open

the

valve

and

vacuum

then

gauge

sucking

valve

is

(6).

gaugo

open

pump

escapes

pressure

order

drain

piece

©

rim.

the

to

(5)

(5)

Page 5

små

mm

6.

Cooling

of

Solutions

after

Sterilization

After

do

not

decreases

apparatus,

the

clamps

be

left

7.

Setting

Pressure

trolled

valve,

valve

On

request,

The

are

safety

Attention!

Tf

the

device

thermometer

sterilization

boil

pressure

(7).

As

weight

requisite

automatically

valve

sterilizer

the

over

gradually

When

in

the

the

and

by

means

standard

weights

weights

requisite

pressure

equalizing

To

cool

opened

Sterilization

thus

for

there

sterilization

weights.

(37).

and

of

a

shut

corresponding

down

the

the

supply,

working

are

for

for

kept

is

off

all

bottles

valve

autoclave

temperature

weight

available:

1.0

0,5

constant

equipped

temperature

cannot

gauge

completely,

Pressure

the

pressure

atm.abs. = 120

atm,abs, = 110

temperatures

valves

to

(5)

indicates

(6)

and

for

for

in

the

autoclave

by

using

with a temperature

must

sc

that

burst,

the

loosen

the

some

sterilization

body

of

be

Now

cooling-down

solutions

time.

of

is

2.1

atm.abs.

°C

°C.

(refer

the

set

solutions

the

"zero",

the

the

equipped

to

corresponding

at

the

locking

control

pressure

of

the

open

should

are

con-

safety

with

=

134%,

table)

contact

a

The

requisite

meter,

The

ture,

Timer

temperature,

rilization

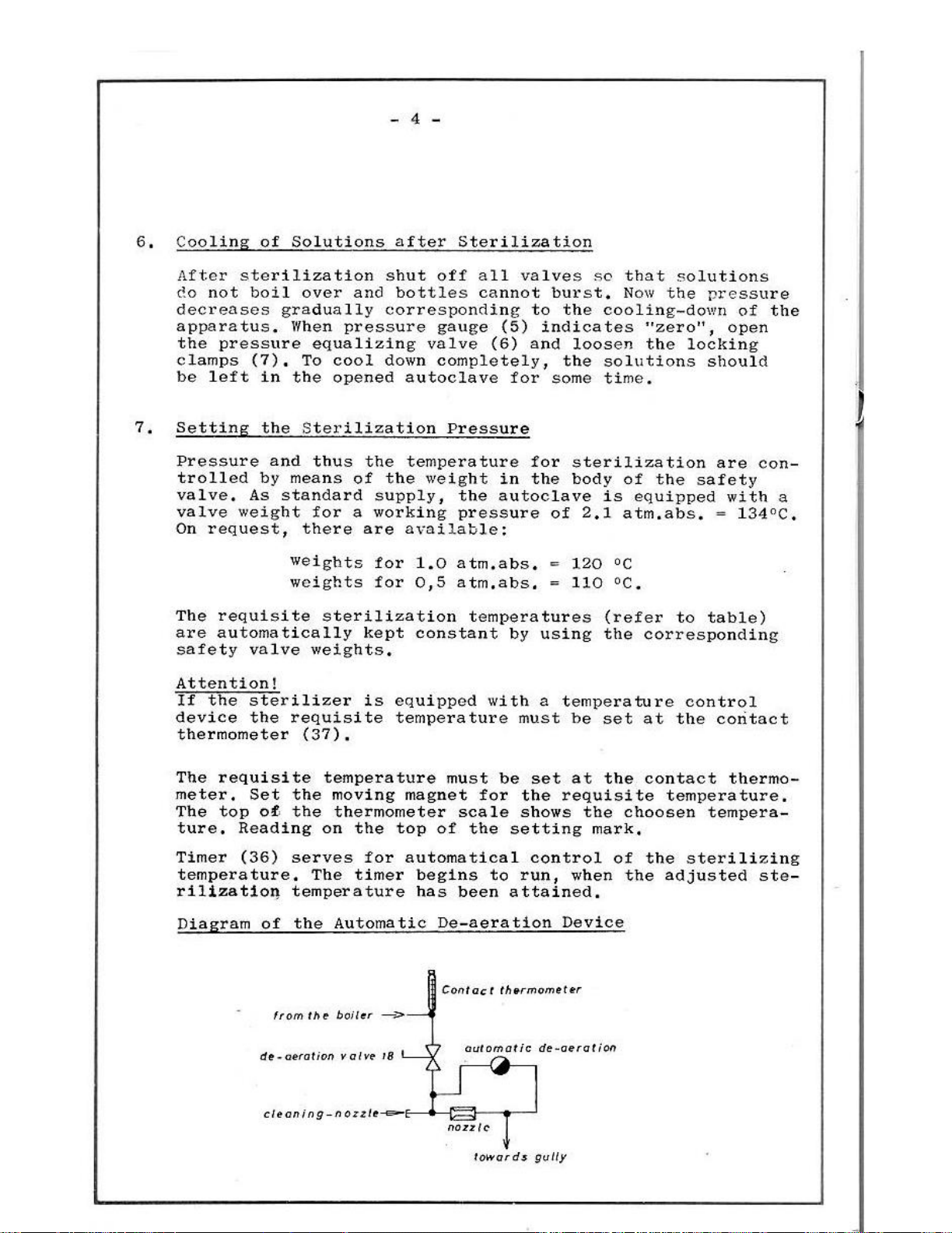

Diagram

Set the

top

of

Reading

(36)

of

from

de-aeration

creaning-nozzle-

temperature

moving magnet

the

thermometer

on

the

serves

The

temperature

the

the boiler

for

timer

Automatic

valve

must

scale shows

top

of

the

automatical

begins

has

been

De-aeration

Contact

>

18

automatic

a

nozzle

towards

be

set

for the

setting

to

attained.

thermometer

requisite

control

run,

Device

de-aeration

gully

at

the

the

mark,

when

contact

temperature,

choosen

of

the

the

adjusted

thermo-

tempera-

sterilizing

ste-

Page 6

If

during

at

the

(see

screwed,

with a cannula

zle

After

inserted

nozzle.

diagram)

can

the

contact

this

also

having

and

operating

thermometer,

has

to

nozzle

or a corresponding

be

unscrewed

been

tightened,

cleansed

period,

then

be

cleansed.

of

1.0

mms.

with a screwdriver,

thoroughly,

The

unit

the

temperature

the

flow

After

in Y should

wire,

does

the

If

the

not

nozzle

operate

is

not

of

the

plug

necessary,

nozzle

be

pushed

has

been

the

must

without

reached

device

un-

through

noz-

be

re-

this

LA

(8

N

(a

TEMPERATURE

CONTACT

AUTOMATIC

Temperature

contact

thermometer

DIAGRAM

or

CONTROL

WITH

THERMOMETER

AND

DE-AERATION

contml

by

DEVICE

DEVICE

means

x

iw’

of

The

de-aeration

ways

sidual

and

When

aerator

via the

When

attained,

(37)

The

and

ATTENTION!

aeration

solutions

opened

air

in

the

flow

temperature

(38)

flow

the

set

the

regulates

steam

must

escapes

be

By

valve

do

valve

until

nozzle

shut

nozzle

temperature

drained

not

the end

the

capacity

(39),

of

abt.

off

(39).

timer

the

the

(18)

(36)

heating

via the

by

sterilization

at

boil

(18)

automatically

over,

must

of

space

100

at

runs

of

nozzle

means

once

never

the

sterilization

escapes

°C

has

contact

down

the

unit

(39)

of a hose

of

after

steriliaztion,

been

and the

thermometer

and

solutions

be

shut,

via the

attained,

the

automatically.

into

or

piping.

it

phase,

de-aerator

steam

(37)

contact

the

water

shut-off

so

remains

escapes

ál-

The re-

(38)

the

de-

only

has

been

thermometer

jet

pump

de-

that

the

Page 7

MAINTENANCE

Maintenance

If

after

pressure

can

hardly

water

of

opening

posits,

solutions

after

Lid

A

lid

load

of

lid

after a longer

by

front,

ible

is

be

must

sterilization

unloading

threaded

hinge.

of

about 3 mm

and

right

pressure,

accessible

replaced

of

sterilization

according

be

formed

not

the

drain

If

during

will

holt with

This

the

lid,

remains

packing

turn

The

so

fuse

after

in

AND

OPERATION

the

Boiler

the

residual

to

the

operating

at

the

boiler

be

drained

of

liquids,

valve

the

burst, a thorough

of

the

bolt

The

ring.

working

that

valve,

is

inside

screwing

case

of

under

(11)

sterilizing

material

square

serves

tension

in

the

If

the

period,

the lid

which

the

leakage.

pressure,

then

in

order

cleansing

is

head

for the

of

the lid

front

packing

the

lifts

blows

lid

off

water

instructions,

bottom.

it

should

cycle

indispensable.

and

slit

adjustment

between

ring

bolt

to a gap

off

below

the

is

If

e.g.

to

flush

an

ampoule

of

stands

is

relaxes

has

in

case

the

inner

drained

the

in

be

drained

out

the

of

right,

loose

to

be

of 3 mm

of

hinge.

lid

and has

under

deposits

residual

the

case

by

any

de-

with

boiler

out

of

the

the

pre-

if a gap

laying

somewhat

tightened

inadmiss-

The

on

in

the

valve

to

Cleansing

Untighten

move

perforated

and

the

can

of

the

the

srew

inner

bottom

be

thoroughly

Boiler - Removal

jacket,

plate,

at

the

bottom

With

Now

rinsed

of

Boiler

of

the

inner

single-walled

the

boiler

and

cleansed,

bottom

Scale

jacket

units

Deposits

and

remove

is

accessible

re-

the

Page 8

ama

STERILIZATION

Insert

table).

Shut

de-aeration

If

device,

Pour

the

Load

pressure

Start

and

Open

It

til the

of

When

to

is

opened),

sure

the

Set

off

drain valve

the

sterilizer

the

distilled

water

autoclave

autoclave

autoclave

drums

equalizing

the

by

pressing

de-aeration

remains

water

the

boiler,

the

thermometer

boil,

equipped

shut

Now

gauge

valve

contact

valve

valve

gauge,

with

apparatus

open

with a temperature

(5).

weight

(18)

is

remains

water

Requisite

model B (290

model C (400

model H (500 mms.

goods

the

valve

until

begins

off

de-aeration

the

pressure increase

The

for

thermometer

(11)

equipped

into

valve

by

push-button

to

indicates

temperature

arranged

beneath

open,

the

water

mms,

mms.

to be

(6).

bringing

(18)

the

thermometer

boil,

the

requisite

(37)

thermometer

with a temperature

boiler

in 9)

in G)

in の )

sterilized

switch

(25),

arranged

so

100°C

valve

control

increases

and

beneath

up

quantity

beneath

that

or

(18),(If

is

temperature

timer

water

to

the red

for:

approx,

approx.

approx,

and

shut

(24)

Glow

indicates

the

device,

indicated

into

lamp

air can

when

slowly.

(see

(36).

gauge

control

3,5

litres

5

litres

16

litres

lid

position

lights

thermometer

100°C

escape

the

water

the

sterilizer

valve

at

and

mark

and

up.

or

begins

(18)

the

pres-

at

(17)

un-

out

III

|

is

When

rature

valve

perature

zation

table.

(31)

At

ratus

set

the

After

the

(29),

pump. A vacuum

After

vacuum

to

In

be

the set

are

(19)

phase

In

of

the

the

end

at

the

heating

values

the

water

First

having

valve

this

order

steaming

sequence,

opened

values

controlled

or

the

is

reached

starts,

order

of

once,

set,

apparatus

jet

open

to

first.

in,

to

water

the

If

switch

Otherwise

pump

the

residual

of

sucked

(29)

the

have been

automatically

contact

at

the

the

duration

condense

jet

pump

Sterilization

the

working

to

has

been

(30)

about

and

This

completely,

water

0,8

for

about 8 minutes,

then

lid,

valve

attained,

thermometer

thermometer,

any

or

of

pressure

position

too

much

switched

then

atm.abs.

water

pressure

has

pressure

by

means

(37),

the

of

which

escaping

the

exhaus

phase,

valve

a

switch

is 1 or

II

after

steam would

off,

Then

the

steam

is

produced,

(31),

equalizing

filter

of

After

actual

is

stated

steam,

steam

off

0,5

having

be

open

open

shut

purify

to

vacuum

escape

off

Pay

valve

and

tempe-

the

safety

the

tem-

sterili-

in

the

open

valve

valve

condenser,

the

appa-

atm.abs.,

reached

wasted.

(31)

valve

via

first

attention

must

(6)

air

the

of

the

Page 9

10.

11,

Material

glassware,

textile

rubber gloves

solutions

If

no

vacuum

cording

ion,

Attention!

Sterilization

After

must

Daily

drained

A

been

in

pre-sterilized

having

be

after

promptly

boilt

STERILIZATION

to

instruments

fabrics,

free

to

closed,

out

be

drying

items 5 and 6 of

of

finished

last

of

the

drainage

over

sterilized

dressings

from

spores

receptacles

is

needed,

solutions:

sterilization,

sterilization,

boiler

is

also

or

bursted.

TABLE

for

please

the

detailed

the

via the

requisite,

autoclaves

ec

134

120

drain-valve

134

120

operate

technical descript-

de-aeration

residual

when

model

atm.abs.

2.1

24

1

1

the

water

(11),

solutions

B,

unit

valve

must

C,

H

minutes

10

25

30

20 - 30

ac-

(18)

be

have

solutions

receptacles

solutions

(all

gelatine

(open

completey)

Overheating

In

protection

The

Switch

is

protection

The

in

glucose

case

pilot

without

overheating

front

in

sensitive

de-aeration

protect:

of

lack

automatically

lamp

off

the

pressure.

EMF

the

of

not

pre-sterilized

to

heat

solutions)

valve

of

distilled

extinguishes.

unit

and

Re-set

544

before.

protection

autoclave,

water

switches

fill

up

distilled

the

green

is

placed

in

the

the

off

button

behind

120

110

100

chamber,

unit.

water

of

the

the

when

the

overheating

electric covering

1

0.5

o

overheating

the

apparatus

50 - 60

60

60

Page 10

Nomber-index

Standard

outer

boiler

cover

«RM

lid

ER

mano-vacuummeter

go

aeration-valve

locking

っ o

lid

gasket

drain

oo

water

10

drain

inner

12

bore

13

filling

14

perforated

15

de-aeration

16

thermometer

17

de-aeration

18

19

safety

20

exhaust

21

heating

22

water

23

threaded

24

switch

25

push

26

pilot

Unit

jacket

hinge

clamps

pipe

gauge

valve

jacket

holes

pipe

valve

steam

element

protection

bolt

button

lamp

glass

inner

pipe

valve

line

for

schematic

bottom

diagram

Unit

27

28

29

30

31

32

33

Unit

densing device;

31

32

33

34

35

Unit with

device

fevice

36

37

38

39

with

suction

non

vacuum

water

water valve

non

dirt

with

water

non

dirt

water

exhaust

devise

timer

contact

automatic

flow

water

line

return

jet

return

trap

exhaust

valve

return

trap

supply

temperature

and

ana

contact

nozzle

valve

valve

pump

valve

valve

steam

contact

thermometer

de-aerator

jet

pum

(air)

(water)

steam

line

condensing

thermometer:

tncrmoncter:

con-

一

(water)

control

Page 11

=

WEBECO

drainage

Webeco

Schematic

vertical

diagram

steam

sterilizer

Model

B-C-H

steam

exhaust

Page 12

=

WEBECO

Model

with

Water

jet

B-C-H

pump

==

wastewaterline

by

customer

exhaust

steam

Model

with

exhaust

steam

device

B-C-H

condensation

Page 13

u

el2O

L30-

N

0601

1

..

NO

PECA

ai

E

ni

|

R

NASA

>

Ke

e)

leal

ει

"3 x 900 W -

3x1500W

3x

2800W

-3X

20004

7

lol

2209.

-

220v

“220

2204

a.

ki

1

+

|

ti

|

Wi

slo

»

;

으으

4

i

τς

iş

01

54

K4

K

1

K

2

N

3

N

2

N

1

H

1

1-3

K

3

wiring

with

diagram

contact

three-stage

button

heating

control

control

control

contact

overheating

control

heating

el.

timer

for

thermometer

switch

START

contactor

contactor

contactor

relay

thermometer

protection

lamp

elements

autoclaves

LEGEND

2700

and

Model

timer

W,

4500

B-C-H

W,

Art.Nr.:

No.

No.

No.

No.

No.

No.

No.

No.

No.

7500

No.

No.

15055-0-1/7-4

W,

6

6

6

6

6

6

6

6

6

220

6

5403

5801

6102

6101

6101

5904

6302

6205

7104

V

5204

1614

1012

0463

4261

4261

0101

2202

1544

2200

0263

Page 14

220/3804

229v~

РЕ

123

u

n

L30-

N

0

i

мо

0+

5

6

7

8

8

ο

at

É

HR

A

nan

Hi

N

"3x900W-220V

で

"H"3x2500W-220V

Heizung

"3x1500W-220V

ue

85

sz

sd

=

6

7

8]

01

S

1

Η

1

K

1

N

1

1-3

wiring

three-stage

button

control

heating

overheating

heating

diagram

START

lamp

contactor

element

for

autoclares

in

standard

LEGEND

switch

protection

B

2700

C

4500

H

7500

B-C-H

design

W

W

W

No.

6

5403

No.

6

5801

No.

6

7104

No.

6

6102

No.

6

6205

No.

6

0205

No.

6

0206

No.

6

0208

No.

15054-0-1/7-4

1614

0102

2200

0561

1544

3090

3150

3250

Page 15

060E

OSTE

ТОРТ

SOz0

0066

9020

9

$

9

0906

8000

9

TON

prepueas

yyST

6006

9087

9009

9

9

6960

7191

2010

0019

6079

1089

9

9

9

SrO

0022

6064

Sop

9

9

5920

7908

TOTO

5069

7029

1019

9

9

9

2022 2059

9

Н-9-8 Тэрои

09383М

10$

53400

84006

0073919550

02X02

0076

H

"STXST

Ὁ

'ΤΤΧΟΤ

8

39598

ρττ

679

40

£TS/2TG

303

1409

40142090.70

2

sseTb

-

0169

“zagawoureya

6uT3eadxenAo

0

409800464

OT

X

8

M

‘М

X

O0STXE

006ХЕ

DT

UOSTITS

3

@

PT

‘quewera

Ø

SSETÒ

'03Tp

Burgeay

TOAST

107

78806

sagem

395

PI

ezts

ZH

M

1973

OS/A

00S2XE

xnTal

O22

H

300/707)

4095605

s683S-3adU3

4042063402

9916

z0T'z0S09"T

23044

Jeq

20/100'20101'1

9120

SATOA

I4VH

00/1

02Z

"39o0S

798

‘013

403300

96040

eaten

dueT

duet

Aqazes

AoTB

mori

~_——"zawt

H-9-8

TapoW

|

/deqewowsayg

xoA

s1rad

axedS

Teuof3Tppy

A

3960000

022

0T

4974

ny9

fetos

0ST-0

A

zz

0zz

Ad

тезешошлеца

00-5

460

750

09-0

roqoe3uoo

3083403

40055

ay

“sog

T

"T

T

e

T

jE

T

y

2

т

‘9

“9

て

ye

T

8

E

‘6

т

т

“11

‘or

т

1

“er

τετ

T

T

“pt

“ST

1

τ

“at

“ar

Loading...

Loading...