Page 1

Remo

RB-A35-1.DOC

08/98

archivkopie!

Gülüger

Stand

aktueler

abweichena

Page 2

Contents

Page:

1.

Preliminary

Designation

Intended

Technical

Device

Functional

Layout

Starting

7.1

7.2

Preparation

Material

Initial

Operation

Functional

Remarks

of

Use

Data

Description

Operation

of

Control

the

the

Device

Sterili

|

3

4

4

|

4

5 -

7

8 - 11

20 - 2]

10.

Care,

Maintenance

and

Periodic

Works

22

-26

Page 3

Preliminary

Remarks

These

training

is

device.

They

regulate

Operating

of

required

accompany

the

maintenance-,

performance

and

transport.

The

references

are

contained

e.g.

These

ions

marked

CAUTION

applies

be

dangerment

to

device.

(3/5)

Operating

which

by:

to

exactly

special

Instructions

the

operator

for

the

the

assembly,

service-

check

means:

have

"CAUTION",

working-

complied

of

dangers

and

to

illustration-

in

the

Illustration

Instructions

to be

persons.

and

handling

device

its

and

repair

text,

observed

"ATTENTION"

or

operating

with,

These

connected

form

provides

and

and

contain

initial

periodic

works

have

#3,

include

particularly.

in

order

also

with

the

basis

knowledge

maintenance

the

operation,

works,

as

well

and

item

been

put

Item

important

or

"NOTE".

methods

to

include

the

exclude

handling

for

of

description,

including

as

numbers

into

#5.

They

which

references

the

which

the

the

storage

which

brackets,

instruct-

are

have

any

of

to

en-

the

ATTENTION

refers

be

to

works

to

atmospheric

to

exactly

or

destruction

which

be

performed

NOTE.

applies

particularly

Improper

property

Preparatory

formed

staff.

by

working-

complied

are

influences

to

technical

observed

operation

damage.

measures

the

and

with,

of

the

to be

after

user/operator

carried

excessive

or

requirements

by

may

for

operating

in

order

device.

modes

the

user.

lead

to

application

or

methods

This

out

load

of

pe

by

to

avoid

also

regularly

or

with

operation.

which

specially

hay

may

which

any

applies

and

unusual

«to

È

njuries

only

instructed

have

be

to

damage

to

have

be

or

per-

Page 4

2.

Designation

of

the

Device

Article

Subject

Manufacturers

3.

The

and

rubber

is

intended

4.

Name

Number

Intended

WEBECO

serves

articles

Technical

Dimensions

Use

AUTOMAT

to

sterilize

and

for

the

Data

:

:

35

is a small-size

surgical

textiles

stationary

:

Small-Size

WEBECO

1

0107

1

0107

Webeco

23611

Bad

and

at

121

application.

440

x

500

Steam

AUTOMAT

1001

1003

GmbH,

Schwartau,

steam

dental

“C

or

x

Sterilizer

35

(Dental

MühlenstraBe

sterilizer,

instruments,

at

134

700

mm

(H x W x D)

Version)

Germany

С.

It

38

Installation

Useful-Space

Weight

Mains

Water

Supply

Supply

Area

Size

|

|

| |

:

:

:

500

x

550

250

x

380

55 kg

230 V /

Threaded

mm

(W x D)

mm

(Diameter

50

Hz / 16 A -

Connection

6

x

Depth)

min.10

3/4

A

Page 5

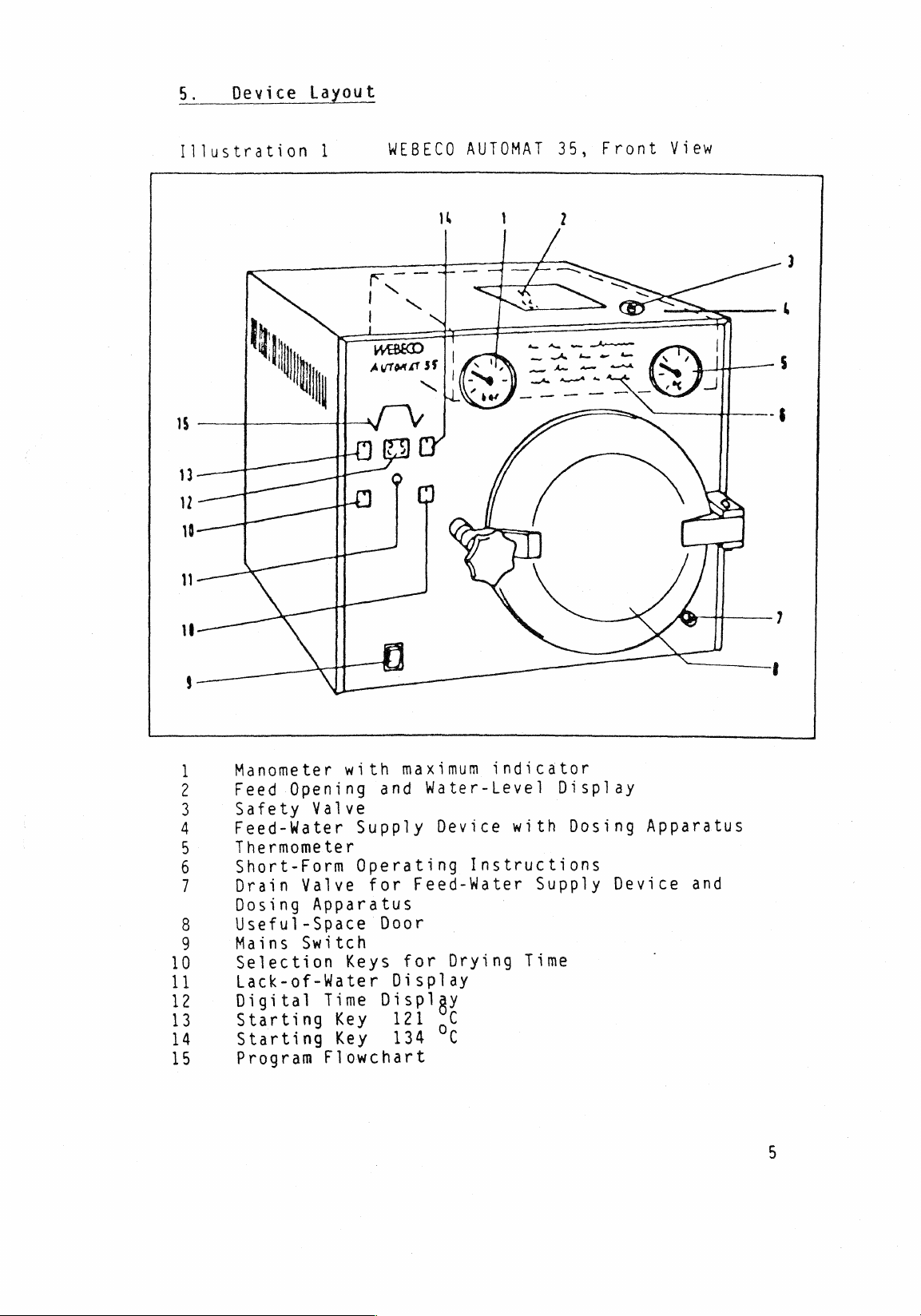

5.

Device

Layout

Illustration

15

i

12

TT

1

一

1

|

KN

i

‘ly

Front

35,

|

AUTOAAT

SV

40)

WEBECO

N

N

55

>

v

AUTOMAT

View

1!

3

l

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Manometer

Feed

Safety

Feed-Water

Thermometer

Short-Form

Drain

Dosing

Useful-Space

Mains

Selection

Lack-of-Water

Digital

Starting

Starting

Program

ae

Opening

Valve

Valve

Apparatus

Switch

Time

Key

Key

Flowchart

with

Keys

maximum

and

Supply

Operating

for

Door

for

Display

Display

121

134

indicator

Water-Level

Device

Instructions

Feed-Water

Drying

ος

С

with

Supply

Time

Display

Dosing

Device

Apparatus

and

Page 6

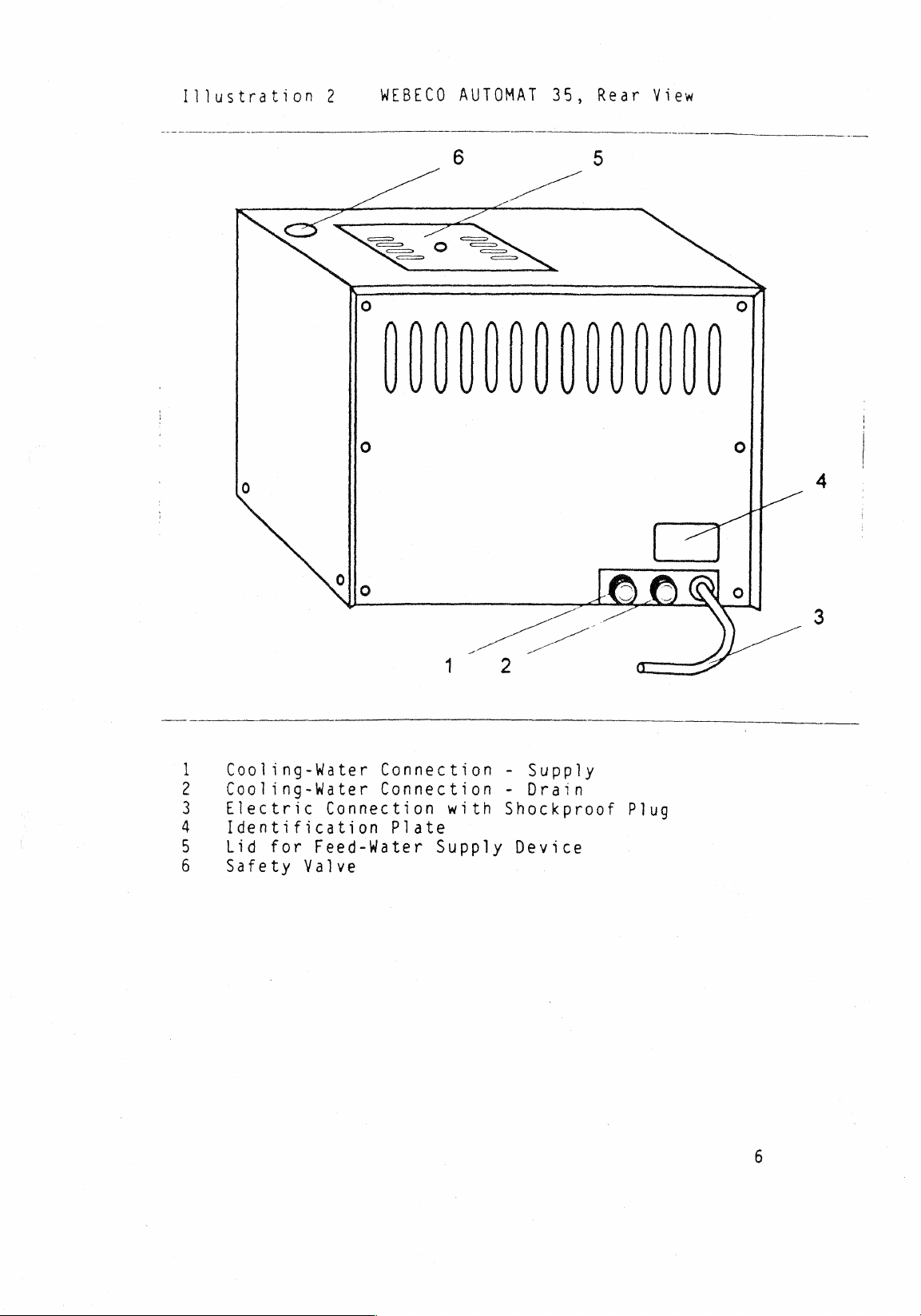

Illustration

2

WEBECO

AUTOMAT

35,

<>

Rear

View

Cooling-Water

„>

>

Cooling-Water

Electric

Co

BE

Identification

Lid

DUI

Safety

for

Connection

Feed-Water

Valve

Connection

Connection

with

Plate

Supply | Device

-

Supply

-

Drain

Shockproof

Plug

Page 7

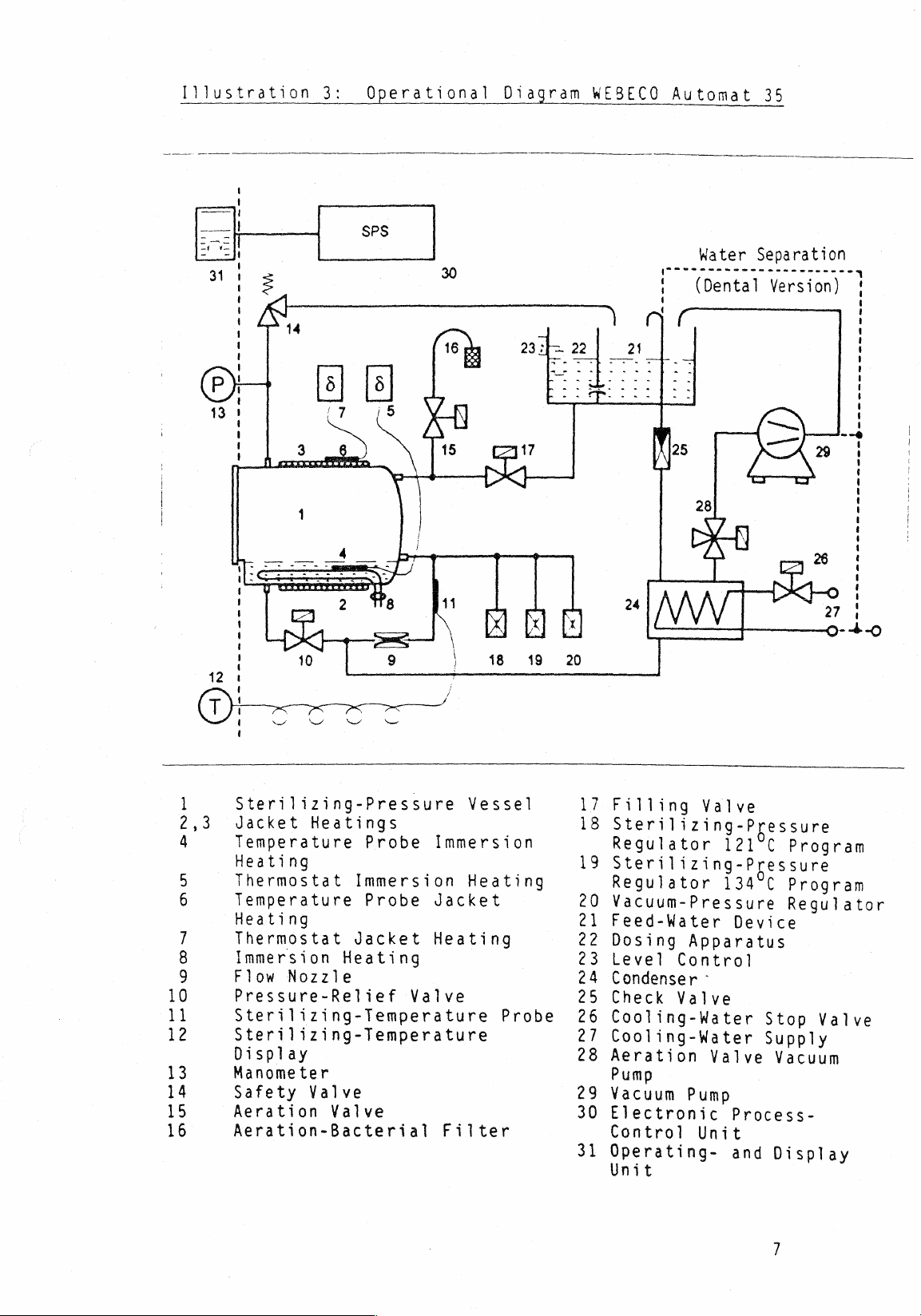

Illustration

3:

Operational

Diagram

МЕВЕСО

Automat

35

SPS

MR

Water

Om

Separation

OD

ἂν

ον

ee

oN em

ge

ae

ap

er

ae

ay

on

ee αν

MA

3

ó + ó

l

2

4

οι

Ον

CONI

19

10

11

12

13

14

15

16

Sterilizing-Pressure

,3

Jacket

Temperature

Heating

Thermostat

Temperature

Heating

Thermostat

Immersion

Flow

Pressure-Relief

Sterilizing-Temperature

Sterilizing-Temperature

Display

Manometer

Safety

Aeration

Aeration-Bacterial

Heatings

Heating

Nozzle

Valve

Valve

Probe

Immersion

Probe

Jacket

Valve

Vessel

Immersion

Heating

Jacket

Heating

Probe

Filter

Filling

Sterilizing-Pressure

Regulator

Sterilizing-Pressure

Regulator

Vacuum-Pressure

Feed-Water

Dosing

Level

Condenser

Check

Cooling-Water

Cooling-Water

Aeration

Pump

Vacuum

Electronic

Control

Operating-

Unit

Valve

121°C

134°C

Device

Apparatus

Control

:

Valve

Valve

Pump

Process-

Unit

and

Stop

Supply

Vacuum

Display

Program

Program

Regulator

Valve

Page 8

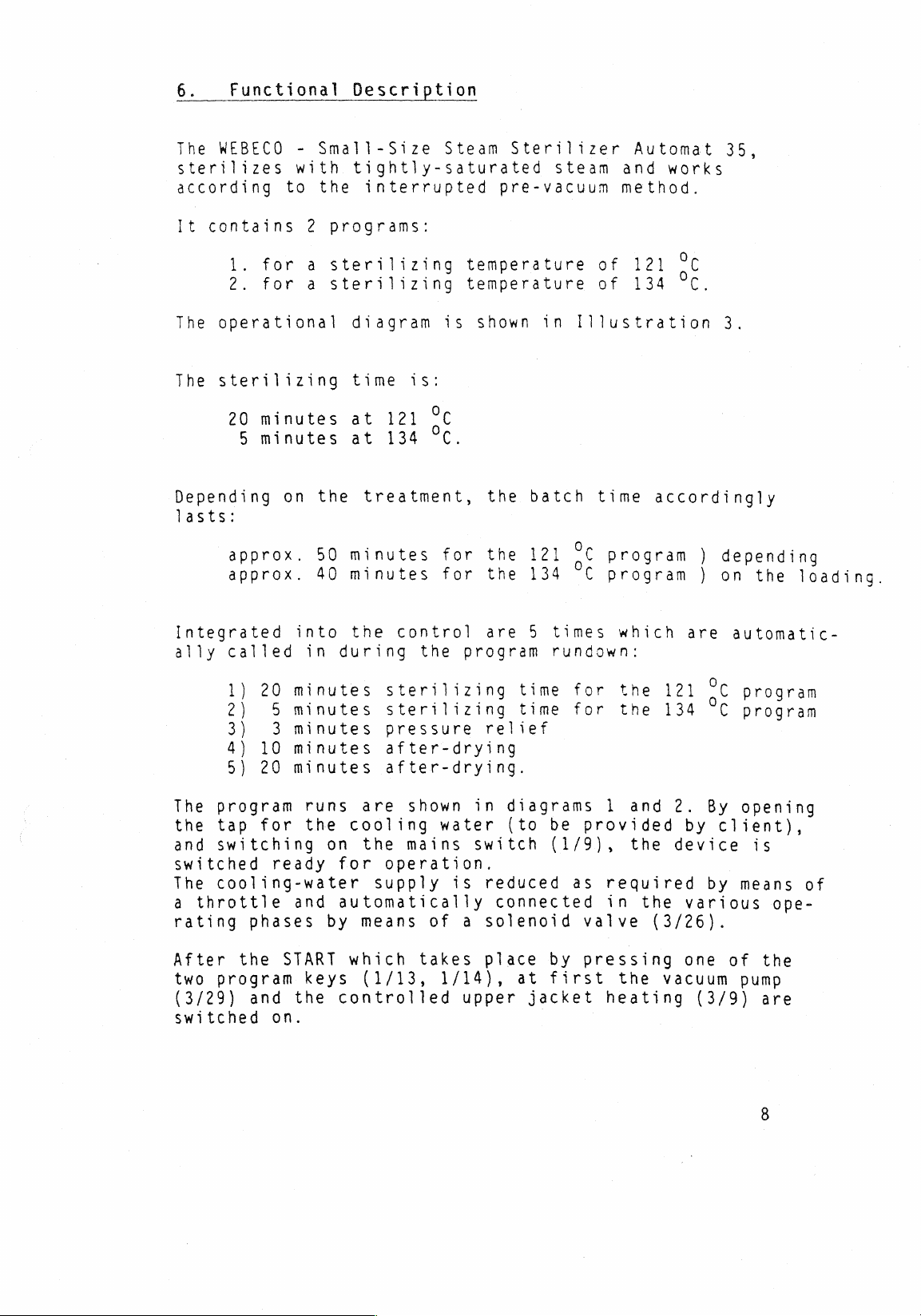

6.

The

sterilizes

according

It

Functional

MEBECO

contains

1.

2.

The

operational

The

sterilizing

20

5

-

Small-Size

with

to

the

2

programs:

for

a

sterilizing

for

a

sterilizing

minutes

minutes

Description

Steam

tightly-saturated

interrupted

temperature

temperature

diagram

time

at

121

at

134

is:

С

is

С.

shown

Sterilizer

steam

pre-vacuum

in

Automat

and

works

method.

of

121

of

134

Illustration

35,

°C

°С.

3.

Depending

lasts:

approx.

approx.

Integrated

ally

called

1)

2)

3)

4)

5)

The

program

the

tap

and

switching

Switched

The

cooling-water

a

throttle

rating

After

two

the

program

(3/29)

Switched

on

into

20

minutes

5

minutes

3

minutes

10

minutes

20

minutes

for

ready

and

phases

START

and

the

on.

the

treatment,

50

minutes

40

minutes

the

in

during

runs

the

keys

are

cooling

on

the

for

automatically

by

means

which

(1/13,

controlled

for

for

control

the

program

sterilizing

sterilizing

pressure

after-drying

after-drying.

shown

water

mains

operation.

supply

is

of a solenoid

takes place

1/14),

upper

the

the

the

are

time

time

relief

in

diagrams

(to

switch

reduced

connected

at

batch

121

ol

134

5

times

rundown:

for

for

be

(1/9),

as

by

first

jacket

|

time

program

“C

program

which

the

the

1

and

provided

the

required

in

valve

pressing

the

heating

accordingly

)

depending

)

on

are

121

°C

134

2.

by

“C

By

client),

device

by

the

various

(3/26).

one

vacuum

(3/9)

the

automatic-

program

program

opening

is

means

ope-

of

the

pump

are

loading.

of

Page 9

Thereby

point

-

0.8

vacuum

opens

the

Now

the

of

bar.

pump

the

evacuated

the

water

sterilizing

At

the

same

lower

of

As

jacket

pressure

soon

as

pressure,

to

remove

to

condensation

the

supply

As

soon

ed

the

switched

relief

ation

are

as

pressure

valve

phase

repeated.

chamber

the

vacuum

As

soon

stops,

connection

sterilizing

in

vessel.

time,

heating

thereby

the

boiler

a

flow

the

remaining

device.

the

pressure

off,

and

(3/10).

starts,

pressure

regulator

as

the

and

the

from

the

dosing

the

immersion

(3/2)

initiated.

pressure

starts

in

the

via

air.

condenser

correlating

the

steam

After

during

vacuum

feed-water

the

vessel.

are

in

the

approx.

which

is

reduced

(3/20)

regulator

dosing

apparatus

heaters

switched

exceeds

the

flow

The

escaping

(3/24),

sterilizing

with

is

121

discharged

the

which

filling

apparatus

can

the

nozzle

“C,

1

minute,

steps

to

the

lies

switches,

run

(3/8),

on,

and

atmospheric

(3/9),

steam

and

vessel

the

via

of

switching

at

valve

(3/22)

into

and

the

is

led

back

has

heating

the

pressure-

the

2nd

the

lst

approx.

the

(3/17)

to

the

the

increase

in

order

brought

to

reach-

is

evacu-

phase

As

soon

reached

sterilizing

and

the

By

connecting

(121

pressure

and

sterilizing

pressure

The

at

ing

device

or - in

cooling

During

denser

densate

minutes,

ces

20

°C)

thus

residual

this

vessel

(3/21)

the

from

the

minutes,

as

the

the

pressure

temperature,

immersion

or

or

the

regulator

the

temperature

time

relief.

water

point

of

via

by

the

dental

coil.

pressure

the

into

vessel

the

the

vacuum

depending

pressure

corresponding

heater

switching

immersion

(3/18

has

ended,

yet

time,

the

condenser

the

vessel

version

relief,

sterilizing

supply

pump

pressure.

in

the

switched

heater

or

regulation

existing

is

conveyed

device

is

The

on

the

the

sterilizing

sterilizing

off

the

3/19)

and

it

in

into

pressure

-

to

the

the

steam

vessel,

or

switched

post-vacuum

setected

with

off

lower

(134

takes

1s

the

back

the

into

vessel

the

respective

time

simultaneously.

jacket

ος),

so

switched

over

long,

the

the

until

sterilizing

from

the

feed-water

at

the

deepest

water

and

on

drain

flows

the

the

which

phase

drying

into

resulting

drain.

time.

is

started

heating

according

pressure-

over

steriliz-

supply

of

the

After

further

runs

has

the

to

vessel

point,

the

con-

10

now

con-

3

redu-

or

Afterwar

vessel

wa

a

ds,

erat

+

he

D

d

y

う

で

ー・

im

€

mo

pem

TÍ

W

sterile

at

witch 1 t

tn

4.

ct

f

e

1

off,

(>

ter

—

+,

an

(3/1

).

DA

the

sterilizing

Page 10

U À AURA

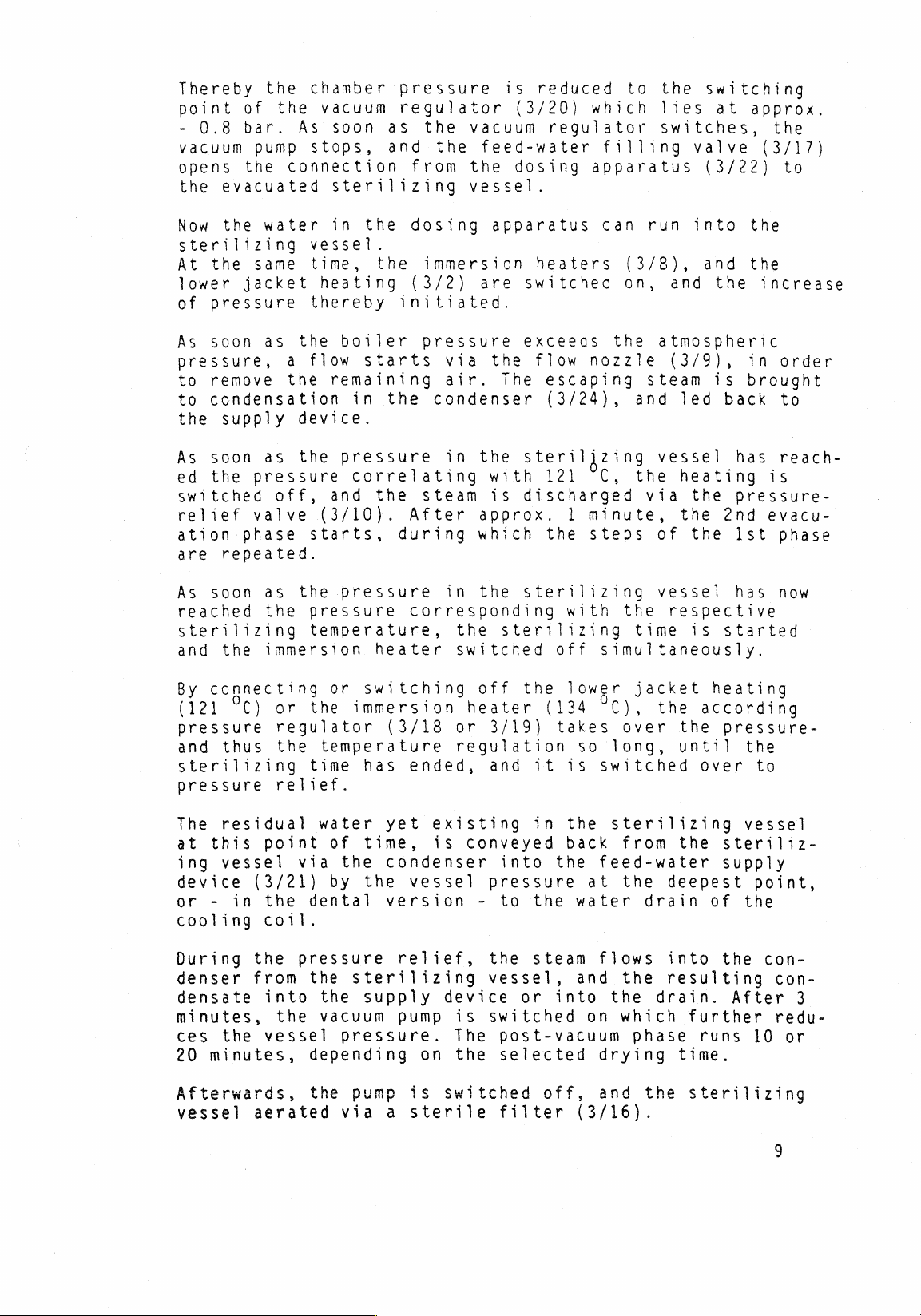

Program

dor

hs

Des

г

Le

ription

for a Sterilizing

Temperature

64140

of

121°

C

I9J9U

UNNIBA-OUBU

100p

pue

243

„0,

‘.,0N3,

je

TetiaJew

347

pue

pauado

UOTIEZIIIIAI?S

NO0T1dIHJS3d

MV890dd

uoT3Tsod

Λετάςτρ

UJTM

Lelszaqew

snoaod

pue

S33nUTU

OZ

:9an4grgdumg」

:・9rnsggrd

:auT

bu

buTzTTTIa39

BurTzTTTI93G

て

z

て

{Tra3S

u014e13e8(

pttos

Joy

:1етлазей

чотзе2т[т1э3<

:шопэел-5за

:шезбохта

"poAduwší

aq

eu

Sa3nutu

OZ

10

OL

:

gu

て

」

Butdag

3

|

uva

yet

+

12

Zt

+

bet

ο

—

01-

-

j

10

Page 11

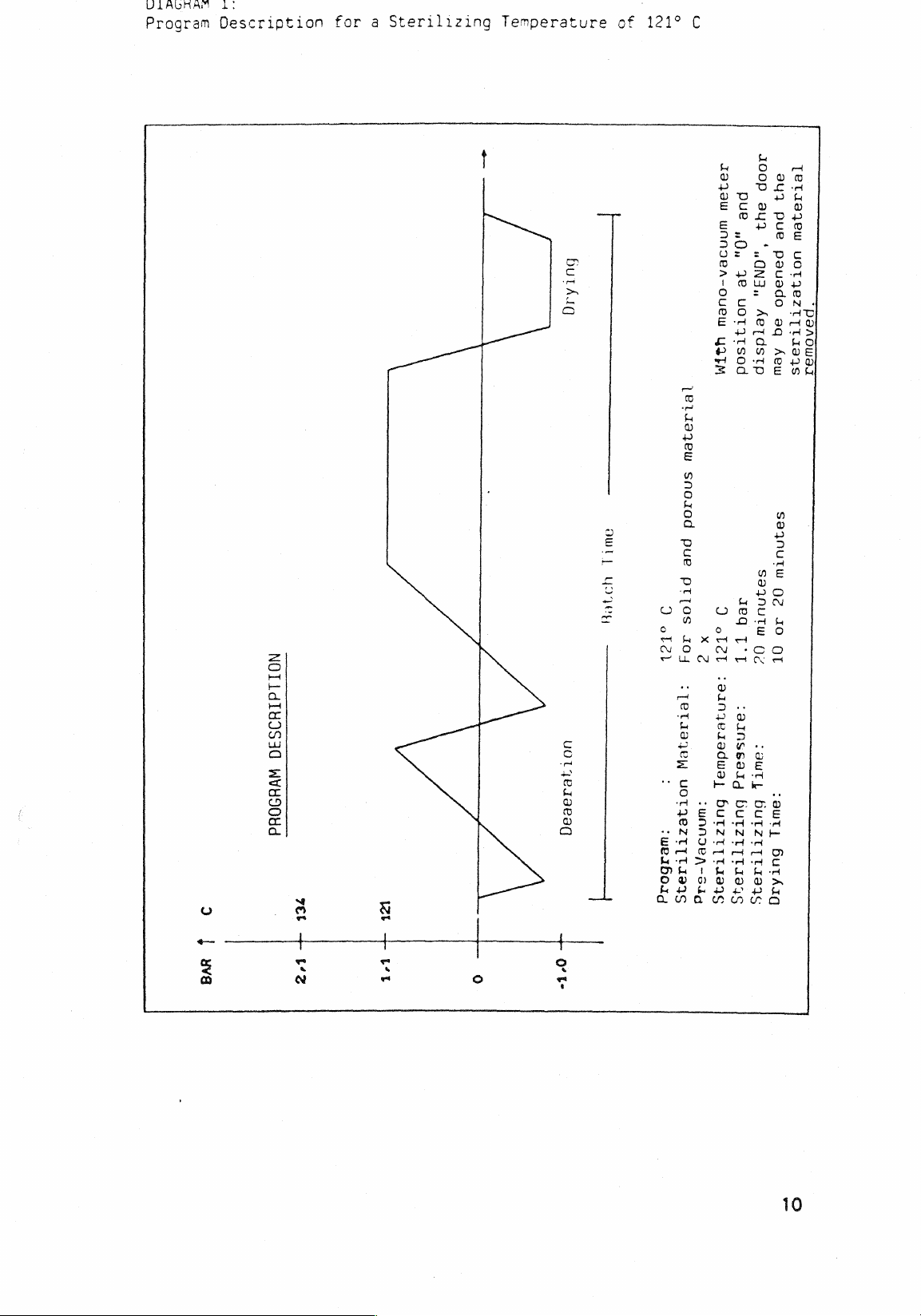

DIAGRAM

Program

2

Description

for

a

Sterilizing

Temperature

of

134°

C

auty

Butztriras3s

NOÏJ1dIH9S10

WyYH90Hd

©

|

BUTAIG

Теттазеш

5позод

эшт|

чозен

υΟΤΑ4ΘΙΘΒΘῃ

рие

рт|0$

J

obET

10]

Тетчэчен

mop

Taya

pue

wondea-ouew

QU.

12

UOTITSOO

UJTM

J

ovEl

хе

:aanJesadwaj

Тетлэзеш

344

341

pue

',,003,,

pausdo

UOTIEZI]

Åerdstp

aq

LI9IS

Aew

sa3nutw

02 10

sa3nutw

1eq

12

ϱἱ

G

:

gunssgrJd

*PBAOUBI

9

|}

uva

yet

+

1-2

gl

+

LL

0

-

ον

|

UOTIEZTITI3Y

Durzttrrg4S

ZUWNANDEA-

we

T

bolg

did.

:9WT」

:awti

butZT1tag35

DurZ

て

TTY335

butAig

11

Page 12

1.

Starting

7.1

1.

2.

3.

Initial

Тре

Biases

Connect

Please

the

min.

device

may

check

fuse

10

Operation

must

lead

the

power-supply

previously

protection!

A)

CAUTION:

The

plug

connection

protective-conductor

On

the

ion

possibilities

hoses

the

the

other

(Illustr.

water-tap

hose

connection

nection

free

end

rear

side

-

with

two

(Illustr.

is

to

be

be

installed

to

interferences.

(230

must

connection

of

the

for

the

2).

At

device

thread-ends

(2/2)

2/2).

applied.

on

lead

the

be

device

with

type

V / 50

provided

accompanying

one

of

these

connection

is

serves

For

the

this,

a

flat

the

mains.

of

mains

Hz

/

16 A -

with a leading

(shock-proof

there

are

connections

is

made.

to

be

device

the

hose

connection

applied.

surface.

and

two

For

-

drain

with

socket).

connect-

(2/3),

this,

The

con-

the

4,

Fill

or

approx.

the

feed-water

demineralized

6

litres.

NOTE:

If

the

filling

(1/11)

Due

sate

Therefore,

illuminates.

to

the

takes

sufficient

of-water

after

next

needs

To

facilitate

a

cartridge-demineralizer

Parts,

distilled

supply

switch

display

the

2nd

sterilizing

to

be

Accessories),

water

is

automatically

(3/23).

is

water

place

the

available

for

one

evacuation

refilled

the

and

supply

water

too

separation,

in

which

batch

low,

The

the

full

up

device

dental

sterilizing

illuminates

the

again.

work,

by

the

we

which

refilling

controlled

device

to

the

the

lack-of-water

cannot

no

version

feed-water

phase,

feed-water

recommend

unit

(see

the

(1/4)

mark.

be

return

amount

cycle.

during

indicates

supply

the

Item

generation

of

the

by

means

with

Necessary

distilled

display

started.

of

the

of

the

is

The

the

that

device

connection

10.6

of

feed-water

of

amount:

conden-

device.

only

lack-

filling

for

Spare

the

the

12

the

of

float

Page 13

Operation

.2

„2

Preparation

.

1.

Check,

Check,

Check,

connected.

Measures

.2.

Switch

cooling-water

Loading

The

Space

porous

Suitable

The

liquefied

Insert

accumulating

for

whether

whether

whether

for

Operation

on

the

the

device:

sterilization

in

cassettes

material

packing

sterilization

by

heat

objects

in

the

enough

the

the

mains

tap.

can

for

with

these

Operation

distilled

device

plug

cooling-water

switch

material

or

on

perforated

be

sterilized

sterilization

of

liquids

is

not

permissible!

cavities

spaces

is

(1/9),

is

loaded

or of

so

can

water

in

hoses

slightly

trays.

unpacked

material.

substances

that

drain

is in

the

are

into

the

off.

the

socket.

properly

open

the

useful

Solid

or

in

being

condensate

tank.

the

and

ATTENTION:

Handpieces

if

they

to

sterilization

urers'

If

the

the

water occurs.

and

instrument

sterilization

of

sterilization

of

the

To

avoid

enter

material,

tal

bear

specifications

manufacturers

sterilization,

exchanged

circulation

that

the

dosing

a

version

and

bends

an

The

regularly.

oils

material.

the

water

(see

and

according

by

the

recommend

an

water

may

be

paper

water.

oil

apparatus

separation

Illustr.

turbines

sign

manufacturers.

have

oiling-up

must

to

therefore

Only

applied

The

application

clearly

and

other

from

takes

3).

can

be

or

have

be

obeyed.

the

oil

of

the

emulsifying

for

the

reduces

volatile

the

sterilization

place

sterilized,

been

The

care

circulation

be

admitted

manufact-

prior

controlled

special-

care

the

of

of

bags made

oiling-up

substances

in

the

to

the

den-

13

Page 14

Lock

Upon

turn

the

audible

on

tightly.

door

by

tightly.

clicking

approx.

of

3

rotations,

the

door-contact

until

the

switch,

door sits

7. 2 .3.

Select

Press

The

drying

Starting

diode

program

The

curve

illuminate

ning

down.

down.

The

display

Upon

been

ed.

After

reset,

for

Interrupting

If

(e.g.

ruption

voltage

basic-level

illumination

reached,

opening

so

operation

the

already

due

on

has

started.

sections

according

This

remaining

(1/12)

that

to

occurs

loss),

state.

time,

Key

(1/13,

the

key

on

makes

in

minutes.

of

and

the

the

door,

the

device

upon

and

faulty

reloading.

Resetting

started

by a defect

the

device

10

or

20

1/14)

illuminates

the

program

to

the

it

possible

time

loading),

the

device

the

program

is

entire

is

the

in

is to

minutes.

of

(GREEN).

flowchart

program

to

indicated

curve,

can

be

program

immediately

Program

has

or

if a program

the

supply

be

the

desired

section

follow

on

the

opened

is

automatically

to

be

reset

program.

Thereby

(1/15)

just

the

the

digital

“END"

and

ready

interrupted

dis-

(e.g.

to a defined

the

run-

run-

has

unload-

again

mains-

Switching

thereafter

keys

interrupts

short

Thereafter,

ing

for

reset-program

cycle

off

the

simultaneously

the

drying

the

~

Opening

for

-

Evacuating

1

minute;

-

Pressure

valve.

the

started.

mains

current

approx.

device

switch

pressing

time

with:

a

(1/10)

operating

drainage-

1

minute;

the

useful

compensation

can

be

and

for

mode,

and

opened

on

again,

both

at

least

and

deaeration

space

via

an

and

and

selection

5

starts

for

approx.

aeration

a

new

sec.,

a

valve

operat-

14

Page 15

7

.

2

.

4.

Temporary

Placing

Out

of

Operation

7

.2

.5

.

After

-

-

the

disrupt

the

water

Switch

Placing

Transport

-

Withdraw

-

Dismantle

and

-

Open

the

-

Wipe

-

Clean

and

extraction

useful

last

the

tap

off

Out

of

mains

supply

remove

drain

feed-water

dry

the

and

dry

space;

sterilization

cooling-water

(to

be

the

mains

Operation

plug;

hoses

any

remaining

valve

(1/7)

supply

useful

insertion

grips

provided

switch

during

|

for

by

device;

space;

rack,

if

necessary,

of

the

supply

(1/9).

Standstill

the

water;

turning,

day:

by

turning

by

client);

cooling

and

instrument

and

and

system

fully

trays

store

off

for

empty

in

-

-

Lock

Pack

the

useful-space

device

and

supply

door

hoses.

without

pressing

15

it

on;

Page 16

7.

2.

Placing

6.

Period

2

corrosion

-

-

-

-

-

-

If

it

tion

weeks),

the

Prior

Item

Open

Screw

(Art.No

to

Switch

Operate

-

Switch

the

for

Out

of

Time

is

intended

for

a

we

evacuation

damage.

to

7.2.5.:

the

in

1

an

audible

on

starting

the

vacuum

off

mains

actuating

of

Operation

to

longer

recommend

period

system,

performing

door

the

1120

when

too]

2877,

clicking

the

mains

pump

the

device

switch

the

place

the

the

for

switch

key

starts

(1/9),

door

and

Storage

the

of

time

to

perform

in

order

measures

device

actuating

obtainable

sound;

(1/9);

(1/13)

after

switch;

of

running;

approx.

and

turn

device

(more

a

to

is

the

as

the

for

a

out

than

drying

prevent

according

ready

for

door

accessory)

121

ὃς

20

minutes

out

again

longer

of

opera-

approx.

run

possible

to

operation;

switch

program

the

for

up

on

tool

-

Continue

according

to

Item

7.2.5.

16

Page 17

Preparation

of

the

Sterilization

Material

Disinfection

Due

to

the

instruments,

and

contaminate

water.

Therefore

and

add

to

detergent.

Rinse

with

and

and

hot

the

rinsing

Packing:

Only

perforations

If

trays

ing

layers.

instrument

instruments

or

to

use

of

heat

Syringes

clean

the

dry

water,

in

in

cassettes,

sheets

the

during

the

material,

the

cleaning

intensely

so

that

water

trays

the

lid

are

sterilized

of

Material

the

sterilization,

and

accessories

instruments

water

after

also

are

eliminated.

and

cassettes

and

the

it

is

crepe-

or

prior

the

boiler

thoroughly

a

proven,

the

cleaning,

residues

bottom

unpacked

practical

filter

are

bactericidal

of

of

aluminium

may

on

for

paper

to

Sterilization:

residues

burned

and

the

after

if

the

detergent

be

used.

perforated

better

as

on

in,

supply

usage,

possible

with

dry-

bottom

Gauze-

For

ization

of

according

or

pulp

single

transparent-sterilization

packing

paper

to

according

DIN

ATTENTION:

Foil-bags

packing,

used

The

dependent

subsequently

suitability

mined

here,

Part

*)

5.

DIN = German

for

in

or

-tubes

and

should

on

the

the

Fractionated

excerpts

sheets

and

58

953

are not

in

as

storage

of

the

sterilization

in

Table

Industrial

are

sterile

to

*),

any

various

unsuitable

stockage,

DIN

58

packing

Part

suited

case

be

packing

types

material,

Vacuum

1

according

Standard

953

4,

are

as

avoided

Method

tt!

bags

*)

Part

(paper

to

and

be

sterilization

or

!!!

of

packing,

is

predeter-

(FRVM)

to

DIN

of

steril-

3,

or

foil)

applied.

only

being

used

58

946

17

,

)

Page 18

Table

1:

Applicability

in

dependence

of

standardized

on

Sterilization

Steam-Sterilization

Material

and

Type

Methods

of

Packing.

Solid

and

porous

Sterili-

zation

Material

and

aie

(pursuant

the

|

es

Type

Sterilization

Textiles

cases

the

(acc.

Textiles

cases

lid

packed | (acc,

Textiles

cases

(acc.

perforated

Instruments

cases

(acc.

perforated

Textiles

cases

(acc.

perforated

Textiles

cases

(acc.

perforated

Instruments

cases

bottom

(acc.

lid

to

and

Packing

in

with

and

lid

DIN

to

.

in

AM

(StB-V

to

DIN

in

with

to

DIN

with

DIN

to

in

with

to

DIN

in

with

to

DIN

with

(StB-F)

to

DIN

not

perforated

lid

lid

filter

lid

filter

bottom

filter

DIN

58

946,

of

Material

sterilizing

valves

bottom

the

at

952,

58

~

sterilizing

952

952

and

in

bottom

valve

58

sterilizing

filter

58

Part

Symbolic

|Notation

Packing

Position

$

DNŮ

on

===>»!

|

に

===>

HAT

==

(1)

the

(1) | [EEE

ina

(1)

in

sterilizing

filter

58

and

sterilizing | fn

58

sterilizing

58

in

sterilizing

58

(StB-F)

(1),

952

bottom]

(StB-F)

952

(1),

(StB-F)

952

(1),

in

952

(1)

the

Е

Es

0000000

5)

AA

ーー

1000

fama

LITTA

|!

croco

一

一

Gravi

+

ravitational

Method

GRAV

È

|

|

,

|

}

|

|

|

Steam

-

-

+

9

+

- -

0

-

+

Sterilization

acc.

to

.

DIN

Pre-

Vacuum

Method

PRVM

0

-

+

+

+

+

+

+

Method

58

946,

Part

1

|

|Fractionat

Vacuum

|

Method

FRYM

,

+

+

+

+

+

+

+

+

18

Page 19

Table 1 (Cont'd)

Type

the

Sterilization

:

Packing

and

ization

of

M

Material

Symbolic

+:

Packing:

position

Steam

acc.

ーー

*

[Gravitational | Pre-

Method

Sterilization

to

58

DIN

Vacuum

Method

Method

Part

946,

{Fractionated

Vacuum

Method

1

Solid

and

porous

Sterili-

zation

Material

and

Rubber

Articles

packed

Liquid

Sterili-

zation

Material

+

applicable

non-perforated

receptacles

Sterilization

DIN

to

lacc.

Part

5,

|Sterilization

acc.

Part

Transparent-steriliz-

ation

acc.

Transparent-steriliz-

ation

acc.

Polyamide

PA

Part

Sterilization-material-

single

Polyamide

PA

Part

Sterilization-material-

double

Glass

|plastic

not

2)

|

single-packed

DIN

to

5,

double-packed

packing,

DIN

to

packing,

DIN

to

66),

acc.

0.05

1,

packing,

66),

acc.

0.05

1,

packing,

receptacles

receptacles,

or

tightly

0

paper

953,

58

paper

953,

58

single,

953,

58

double,

953,

58

foil

foil

*)

to

DIN

thick,

mm

sealed

3)

to

DIN

thick,

mm

sealed

sealed

conditionally

the

operating

(4)

(4)

(PA

6|or

16

773,

EI,

>)

(PA

6

16

and

applicable

instructions

(further

of

GRAV

i

+

0

0

0

-

-

-

details

the

manufacturers)

PRYM

”

+

+

+

0

-

-

-

are

contained

FRYM

0

+

+

+

+

0

-

-

in

-

not

applicable

2)

Small-size

the

safety

3)

An

Note:

Maximum

Maximum

identification

loading

loading

sterilizers

devices

of

with

required

of

the

cassettes

instruments:

the

according

for.the

foil

has

with

to

this

standard

sterilization

to

be

performed

textiles:

are

of

by

1,200

1,100

not

equipped

liquids.

the

manufacturers.

g

g

with

19

Page 20

Functional

General

The

Automat

the

sterilization

-

Biological

and

-

Chemo-Process

The

tests

the

DIN

58

Control

35

Indicators

are

946,

has

Indicators

based

Part

to

be

procedures

pursuant

on

8:

-

-

-

tested

by

.

for

Steam

Small-Size

Efficacy

for

the

to

DIN

steam

Sterilizers

sterilizers.

Sterilizers

Test

efficacy

58

946,

of

Part

4,

Tests

-

-

-

-

The

Performance

Each

tested.

g

Part

lization

the

are

to be

Initial-operation

or

when

Periodical

device

Unscheduled

replacement

izing

taking

being

performance;

Unscheduled

performance

tests

and

sterilizing

The

ica]

4.

For

packing

respective

performed

over

test

in

test

of

at

use;

parts

test

is

suspected

the

results

program

test

indicators

the

is

test,

have

purpose

test

prior

the

intervals

following

which

when

an

of

to

be

sterilization

to

be

of

to

the

device;

of

6

repairs

might

insufficient

are

to

be

the

sterilizer

performed

pursuant

used

the

which

sterilizing

first

months

or

after

affect

sterilizing

documented.

with

material

correspond

application

with

the

has

b i o ] o

to

the

the

steril-

to

DIN

and

be

58

steri-

with

program.

-

946,

20

Page 21

‘Instruments’

the

biological

or

sealed

vidually,

Program

indicators

into

together

transparent-sterilization

with

are

the

instruments.

packed

into

paper

packing

bags

indi-

distribute

loaded

Maximum

‘Laundry’

-

For

the

New

cloths

Remove

Sterilizing

cloths.

Fold

into

Alternatively,

which

being

Distribute

according

the

the

instrument

loading

Program

test,

must

the

cloths

sterilizing

the

cloths

wrapped

5

to

the

indicators

for

smooth

be

insertion

cassettes

so

also

can

into

biological

lllustr.

thus

trays.

instruments:

and

folded

washed

rack

prior

from

have

that

they

cassette

wire

sterilization

be

placed

indicators

4.

baskets

to

be

can

(approx.

packed

1,100

cloths

to

application.

the

useful

used

be

could

in

the

paper.

in

onto

g

have

for

packed

180

be

form

the

the

four

to

be

used.

space.

packing

vertically

x

150

applied,

of a package

laundry

the

mm).

package

into

Maximum

Illustration

Laundry

loading

4

Package

for

in

Sterilizing

textiles:

1,200

Cassette

g

21

Page 22

10.

10.

Care,

General

l

In

order

the

necessary.

user

Maintenance

to

device,

or

by

maintain

regular

They

the

and

the

care-

are

to

instructed

Periodic

readiness

&

be

performed

device

Works

of

maintenance

attendant.

application

works

by

the

of

are

operator/

Repairs

manufacturers

WEBECO

We

further

company

on

GmbH!

pursuant

(Recurrent

the

device

or a service

refer

to

to

Tests)

are

the

obligations

DIN

58

and A 5

only

to be

department

946,

(Tests

Part

in

performed

authorized

of

the

5,

Annex

Special

by

by

operating

A

4

Cases).

the

22

Page 23

10.2

Serial

No

1

2

3

4

Periodic

|

Test

¡Description

Chamber

Insertion

Instrument

Feed-Water

Supply

Threaded

on

the

lock

Aeration

Schedule

Location

Floor

Rack

Trays]

Device

bolt

turning

Filter | exchange

Test

Activity

Cleaning

user/device

attendant

Replace

distilled

water

user

grease

by

device’

attendant

by

urers

authorized

service

/

by

user

manufact-|

or

Reference

by | according

|

to

Chapter

10.3

according

to

Chapter | sterili-

10.4

acc.to

/

dept.

Chapter

10.4

acc.

Chapter

by | 10.5

to

Term

the

work

weekly

after

zations

or

weekly

weekly

yearly

of

30

5

6

7

8

Useful-Space

Door

Supply

Entire

Entire

Device

Device

Device

exchange

seal

by

user

device

attendant

clean

by

user

device

attendant

Test

ning

regulations

by

manufacturers

or

authorized

service

Major

by

manufacturers

or

authorized

service

/

/

concer-|

safety

dept.

Overhaul

dept.

acc.

Chapter

10.5

acc.

Chapter

10.4

acc.

|

Chapter

|10.1

to

to

to as

+

as

required

as

required

required

every

5

years

23

Page 24

10.3

Care

Works

Wipe

rack

useful

and

subsequently

10.4

1.

Maintenance

Replace

Empty

drain

to

(approx.

If

ply

to

Depending

a

fat-dissolving

eliminated

CAUTION:

Make

works.

space

instrument

rinse

distilled

the

fresh-water

valve

the

mark

6

it

is

found

device,

refilling.

on

the

device

out

moistly

trays

with

Works

(Illustr.

with

litres).

that

then

the

again

currentless

with

clear

water:

supply

1/7).

distilled

there

a

cleaning

type

agent

by

of

has

intensive

and

rub

wetting-agent

water

and

device

Thereafter

or

demineralized

are

impurities

has

to

the

residues,

to

be

rinsing.

prior

dry.

rub

be

applied

to

Clean

solution,

dry.

by

turning

fill

performed

a

which

any

cleaning

inserted

up

water

in

the

detergent

can

and

the

again

sup-

prior

or

be

Grease

Remove

and

point

the

old

then

grease.

threaded

grease

rub

in

residues

the

bolt

on

threaded

the

from

bolt

turn

the

with

lock.

threaded

high

bolt,

melting-

24

Page 25

10.

5

Repair

Work

Exchange

CAUTION:

-

Withdraw

-

Loosen

-

Remove

casing,

-

Pull

-

Fasten

NOTE:

The

device,

off

filter

Exchange

Remove

of

Carefully

the

door

door.

ATTENTION:

It

has

to

the

door

groove)

aeration

mains

the

the

and

the

casing

is

hanging

door

sealing

remove

be

and

are

not

plug

rear

fixing

wall.

lift

filter

and

located

on a hose,

sealing

any

paid

the

attention

support

damaged.

filter

prior

screws

up

the

and

rear

on

from

larger

to

on

casing.

replace

wall

the

the

adhesive

that

of

the

starting

both

again.

right

groove

door

it

the

sides

by

in

the

on

the

residues.

inner

sealing

the

of

a

work.

the

new

back

inner

side

one,

of

side

of

(lining

the

Spread

thinly

of

Fit

the

the

silicone

and

the

door

new

door

adhesive

ATTENTION:

Slip

adhesives

evenly

in

door

slightly

adhesive

the

sealing

to

bind.

may

onto

base

by

not

the

into

aid

be

(e.g.

support

of

the

the

of

applied.

Wacker,

groove.

support,

the

on

locking

Elastosil

the

inner

and

press

bolt.

E

side

on

Allow

25

41)

Page 26

10.6

Spare

The

ble

department:

Parts,

following

via

Accessories

the

manufacturers

spare

parts

and

or

an

accessories

authorized

are

service

availa-

Article:

Aeration

Door

Tool

Inserted

Instrument

Tray

Tray

Sealing

for

Cassette,

Bowl,

Sterilizing

Sterilizing

Sterilizing

stainless

Sterilizing

stainless

Filter

operating

Rack,

double

Tray,

Alu

Alu

Cassette,

Cassette,

Basket,

Basket,

Alu

the

Door

and

Alu

Alu

|

Switch

quadruple

35x18x

28x19x

28x19x

35x18x18

35x18x

35x18x

35x18x18

3

4

3

5

8

cm

cm

cm

cm

cm

cm

cm

Article

5

2021

5

5405

1

1120

1

1113

1

0901

1

5928

1

5901

1

0935

1

0935

1

5904

1

5904

No:

6001

3502

2877

8480

3518

1904

2819

1818

1805

3501

3502

Cartridge

Demineralizer

"Formula

2000“

5

5302

2000

26

Page 27

(Short-Form

on

the

Load

front

Chamber,

Operating

of

the

Lock

Door

Instructions

Device):

Tightly,

Switch

On

Mains

Switch.

Program

Program

Program

Program

meter

In

When

When

place

position

case

display

the

orderly.

Selection:

I:

II:

runs

down

is

of

emergency

"A"

curve

line

Press

Select

120

and

134

instruments

automatically,

-0-

blinks:

is

the

°C

textiles

*C

switch

"Lack

Fill

fully

drying

(Pressure a =

(Pressure a =

off

appurtenant

time B or

and

textiles

Open

door

mains

of

up

with

illuminated,

switch.

Water"

water.

program

C,

1.1

bar)

2.2

bar)

only

the

rundown

key.

as

required.

for

for

when

rubber

syringes,

the

mano-

has

taken

Page 28

B

Za

ČO

oto

MD

>>> $ TUE

C

EL

I 8 1 E <<<

Pos-F

letzte

001-0 1 1120

00

003-0 1 1120

00

004-0 1 1120

00

005-0 1 1111

00

006-0 1 1111

00

Tellenr/AG

- 1 1120

Ânder

:18.03.93

|

Ko

1666

1658

1664

1602

5471

2470

007-0 5 1740 0031

00

008-0 5 1816

3143

00

Menge/V E MA

-00

-00

-00

-00

-00

-00

-00

1,000

SRK

1,000

1,000

1,000

1,000

1,000

1,000

STK

-00

1,000

STK

Benennung/Werkstoff

ROHRPLAN

Piping

KONDENSGEFASS

STK

KOHLER

STK

ABLASSVENTIL

STK

A35

Plan

KPL.

KPL

A

KPL.

A35

A35

RUCKSCHLAGVENTIL

STK

SCHLIESSBOLZEN

BELUFTUNGSFILTER

STK

VAK-PUMPE-PJ-5673-726

230V/50HZ

IP20

VAKUUMMANOMETER

DM63:ROT2,5:

GRÜN

35

ーー

ニー

ニー

A35

KPL

F/L

KPL.

M.DECKEL

-1/+3

BAR

2,1-2,3

ュ

compare

Feed

ed-water

a

condenser

|

drain

check

Bacterial

for

aeration

Vacuum

nano-

Side

7 > No.

deyi

device

valve

valve

filter

pump

vacuumeter

21

24

25

16

29

13

009-0 5 1922

00

010-0 1 1120

00

011-0 5 0131

00

012-0 5 0120

00

013-0 5 0131

00

014-0 5 0141

00

015-0 5 0141

00

016-0 6 6408

00

017-0 6 6408

00

7165

1867

0631

4131

0631

3163

2163

0003

0111

-00

-00

-00

-00

-00

-00

-00

-00

ーー

-00

1,000

STK

1,000

STK

1,000

STK

1,000

STK

1,000

STK

1,000

'

STK

1,000

STK

2,000

STK

1,000

STK

FERNTHERMOMET.

0-160'C

BNR.82001835

ROHRLEITUNGEN

MAGNETVENTIL

G1/4-230/50

MV

I129-D1-1/4"3-2224-230

50

2/2

WEGE

MAGNETVENTIL

8201-21-60

435

256-A-6-F-

140C

D.DUTRAL | zorotion

256-А-6-Р-

G1/4-230/50

MAGNETVENTIL

3-WEGE

CV-25-HT196

MAGNETVENTIL

2-WEGE

DV-25-HT196-230/50

DRUCKSCHALTER

46380

VAKUUMSCHALTER

46715

_

TYP

TYP

FEMA

VCM

3163

230/50

2163

DCM

111

i

tele-thermometer

pipin

ping

solen

cooling.

solenoid

tion

solenoid

feeding

3

pressure

1.1

vacuum

solenoid

press.decrease

Solenoid

and

uum

valve

valve

_.

valve

in

valve

chamber

regulator

2.2

requlator

m

bar

12

19

15

26

28

17

18

19

20

019-0 5 0525

00

021-0 2 0120

00

P

en 개 아그 고 오오 고 오고

STL-NR.:

1

1120

1525

3114

으으

1666

-00

-00

SD

SH OH

Ww

ER

-00

dE

QU

1,000

1,000

AB n cb

SICHERHEITS-VENTIL

STK

6105.1-G1/2-2,5

DOPPELNIPPEL

STK

ui

an

ca

DATUM:

MS58

ча m <5

6KT

<p

<p

E

10.03.94

19X28

A

DŮSE

1/4X1/4

A

Bearb:

DIL

A A ap e ep

HE)

safety

double

for

nozzle

valve

nipple

19

Page 29

WEBECO

GMBH

>>>

y ~ +

STUECKLISTE

~

1% Sa

+

mon

ca

ーー

<<<

Pos-F

WE

ISMS

letzte

Teilenr/AG

MA

MÉ

BASS

SST

-

1

1120

Ander.:18.03.93

022-0 5 2211

00

025-0 5 4314

00

026-0 5 4313

00

028-0 5 3630

00

037-0 4 0431

00

041-0 2 0120

00

042-0 5 4312

00

SS

RASS

1666

0500

0665

0664

1001

7010

3035

1686

Ko

Menge/V E MA

MSS

KASS

SSS

-00

-00

-00

-00

-00

-00

-00

-00

SST

Se

1,000

STK

1,000

STK

2,000

STK

1,000

STK

2,000

STK

1,000

STK

1,000

STK

3,000

STK

Benennung/Werkstoff

KK

SSS VSS

ROHRPLAN

SSIS

A35

MSR

KPL

SSS

MECO-DUESE-GR--50-NR-4652

SCHWENKVERSCHRAUBUNG

MS

1521-6/4-1/4

EINSCHRAUBVERSCHRAUBUNG

MS

1511-6/4-1/4

T-VERSCHRAUBUNG

MS

1210-4

ROHRMUTTER

6KT

22X6

ANSCHLUSS

MS58

6KT

VERSCHRAUBUNG

MS

1463-8/6-1/4

DIN431

F.

27X50

MS

DRUCKR.

IG

SS

oe

G1/4

D/L

nozzle

streaming

screwing

screwing

screwing

nut

plug

for

printer

screwing

043-0 4 0431

00

044-0 2 0111

00

046-0 5 3630

00

048-0 5 3630

00

049-0 5 3632

00

051-0 5 3630

00

067-0 5 3630

00

068-0 2 0120

00

069-0 5 3630

00

7030

6270

1303

0105

0013

1403

0405

2385

0006

-00

-00

-00

-00

-00

-00

-00

-00

-00

4,000

STK

1,000

STK

10,000

STK

11,000

STK

1,000

STK

10,000

STK

3,000

STK

1,000

STK

1,000

STK

ROHRMUTTER

6KT

27X8

DIN431

MS

REDUZIERNIPPEL

MS58

6KT

27X32

1/4-1/2

ÚBERWURFMUTTER

MS

1303

8-1/4

EINSCHRAUBVERSCHRAUBUNG

MS

1051

8-1/4

WINKEL

MS

VN

2020-1/4

IA

A=KONISCH

KLEMMRING

MS

1310-8

WINKELVERSCHRAUBUNG

MS

1093

8-1/4

DOPPELNIPPEL

MS58

6KT

27x50

IK3/4-3/8)

EINSCHRAUBVERSCHRAUBUNG

MS

1050

8-3/8

G1/2

IG

Ρ/]

D/L

I

nut

reducing

nipple

nut

screwing

angle

ring

screwing

double

screwing

nipple

070-0 5 3632

00

071-0 5 3491

00

~

te o ap

am | EE

XX 4 4 & A

STL-NR.:

1

0083

7010

1120

Gis

cm

1666

-00

-00

1,000

STK

1,000

T-VERSCHRAUBUNG

MS

2003

-G

3/8

STOPFEN

RG

G3/8

3290

screwing

cap

STK

Gp

Ti:

ci

OY

GD

GD

GH

we

Cr

Gi

Gue dip © Hib

Mo

GP

OD

EE

RE

RR

-00

DATUM:

neem

10.03.94

Bearb:

in

do

aH

HE

Page 30

WEBECO

GMBH

>>>

STUECRLISTE

<<<

Pos-F

人

Tellenr/AG

- 1 1120

letzte

Ander.:18.03.93

072-0 4 0431

00

073-0 5 3171

00

074-0 5 3630

00

075-0 2 0109

00

076-0 2 0120

00

077-0 5 3630

00

078-0 5 3630

00

1666

7021

0060

0604

9321

1154

1401

1301

Ko

Menge/V E MA

-00

-00

-00

-00

-00

-00

-00

-00

1,000

STK

1,000

STK

1,000

STK

1,000

STK

1,000

STK

1,000

STK

1,000

STK

1,000

STK

Benennung/Werkstoff

ROHRPLAN

ROHRMUTTER

6KT

WINKEL

27X7

RG

A35

DIN431

90’

KPL

I/I

T-VERSCHRAUBUNG

MS

1010

8-1/8

ÜBERWURFMUTTER

CUZN35NIF50

6KT

HULSE

1.4305

RD.11X13

KLEMMRING

MS

1310-4

ÚBERWURFMUTTER

MS

1303

4-1/8

3090

G1/4

19X13

MS

Gl/4

G3/8

D/L

D/L

nut

angle

screwing

nut

socket

ring

nut

080-0 5 3630

00

081-0 5 3630

00

082-0 5 0141

00

083-0 1 1120

00

084-0 4 0431

00

085-0 5 3630

00

088-0 5 5904

00

089-0

D0934R6

00

090-0

D0125R6,4

00

Gir

Ge

Se a ep

en

qe

1003

0201

9051

2127

7010

0101

0010

CG

GY > my

Pe

GE

-00

-00

-00

-00

-00

-00

-00

-00

-00

OY OH a me

1,000

1,000

3,000

1,000

2,000

3,000

4,000

4,000

4,000

av

au

αν

he GY

T-VERSCHRAUBUNG

STK

MS

1210-8

VERSCHRAUBUNG

STK

MS

1063

4-1/8

REDUZIERNIPPEL

STK G 1/4 - 1/8

DOPPELNIPPEL

STK

ROHRMUTTER

STK

6KT

22X6

EINSCHRAUBVERSCHRAUBUNG

STK

MS

1051

4-1/8

METALASTIK

STK

GEKURZT

MUTTER

1MAL

DIN

STK

SCHEIBE

DIN

STK

GD

ae

we + a

©

pm a e

my

A/I

M.

DIN431

11MN60

M6X10

934

125

GS

co

©

IG

2531

DŮSE

A2

A2

АЗ:

MS

G1/«

521809.

M6

6,4

kk k «ςδ

screwing

screwing

reducing

nipple

double

nozzle

nut

screwing

rubber

for

vacuum

nut

disc

nipple

for

to

metal

with

cooling

eleme

pump

wa

чо

καν

an © Me

STL-NR.:

ve

ap

ee

Ge

1

Gis 2 <p

do

GF

GE

ED

GR

1120 1666

TD

Qu GO а че

ов а ча о чо

-00

вр a @ o 0

DATUM:

GND

GPO

Gh

GR

10.03.94

«ον

GE

Gh aH

GD

ED

EP

Gm a Me

EP 4 aw

am M Em ae

oD

Bearb:

HE

Page 31

+

Ati

1

|

LET

tx-

wzaljermizs-

<

ò

sia

0-3

i

da

OT

e

Ja

Nİ

nin.

z

ix-

ESEN

_

|

I

}

il

|

|

ry

M

|

|

I

ㅣ

|

|

i

|

|

|

|

——

PI

i

1

}

I

ーー

|

|

!

:

Jaztytyeys

A

эбезтол

72

8

L

94183151

118915

|

9

A

sl

eyl

se

9860

ОСТ

|

Г.

ΑΝ

ο}

90

Haus

N01

101436

099g

poyg

gn

|

'0Nwissev

~

iyefosg

B

1

ο

μμ.

vot

ᾖσ,τισ:-

VL

и

/7таз-

LT

jd

O——

O

1

|

O

9690

|

|

|

;

|

|

:

|

I

|

T

TIT

TT

I

=

——

TYL

|

|

ーーーーーーーーー

III

i

i

inni

AVS

om

TO

310004

na)

G

7

^_^

no)

Mo

(2340

>

No

一

+

一

I

оо

i

GYVONVLS

Lead

TESTE

L

て

wl

-A2/662x

sl

>

|

(Jeu

N

III

TT

|

i

I

|

イーーーーーーーー

å

}

ONNZ

L

3H

29400

[32e

3LNN

11393439

nose

€

SEV

rà

66

"2060

|

99190

10

jpudwwo

TSV

rep

den

AO

T

oj

이

|

-A1

sj“

도

/662M

N

?

(rs

ух

-

i

|

TT

TT

ч-------

|

1

nana]

TUTTI

UOTSIAWUT

BuTr3PaH

LEBUBTS

"

ONNZ

HINV

I

IL

IH

80021

boo

ㅣ

i

3

1

441)

E

SON

|

I

|

ㅣ

i

i

1

eli

72

|

0020

|

|

SUTByj

|

I

}

i

|

I

i

|

i

I

|

|

I

|

|

|

i

|

i

—

3343

INNS

#HOS/

3LSONNHIS

I

3dSNI

AOZZ

3

VOL

=

|

|

789x

站

y

Ý

N

|

i

|

ㅣ

ㅣ

1

i

Y

|

|

A0022

L

=

d

AS

A

ACA

A

IMA

Page 32

A

medi

44

ον

a

ONS

配

呆

一

一

一

一

:一

一

一

:一

8

L

ーー

σας

Coty

z

9560

OS

오길

し

ーー

<

-

o

Lo

|

о

o

o

Ge

4467

yeğ

şe

оч

A

+

wd

en

=

‘

mm

…

13534

(01s

い

<7ors

/

19]

ita)

i

{a

\

1005

고

계

보

호

=

—odr

“у

ra

k

ο-

O

O

OH

9

S

7

€

г

INdN1

i

0

3

(00

-

000

I

DNVINI3

(-)

WO?

1/8290

rrr

ee

DUM

“OND

一

:一

:一

:一

:一

:一

-一

:一

:一

:一

:一

一

:一

一

:一

一

:一

一

:一

:一

:一

-一

:一

:一

:一

:一

:一

-一

-一

:一

:一

-一

-一

:一

:一

:一

-一

:一

.

1393H

YISSVA

DNNY

Guypeey

Je

31500

XING

20180

WON

пБат

AV

A

ga

MIL

On

qUOTOT

HASSVA-

TIONVH

Jap

3A

CR

TRS

*ssaıd

WE

4371934

LL

ve

331938

*ssaid

zzZ

8604

431934

002

1984105

LMVINOM

oop

νι

9

S

7

Ja

2M

‘ивр

€

IDILINDAI

amenna

с

L

【

|

L

ㆍ

INT

YI)

OF

H9

ω

noyionv2G

9

03383M

pog

=

LTONVISSEV

yeefory

2040

CUVONVIS

Je

tb

SEV

20

Bi

9

$

U

«de.

Durs

©

Ao

res

tratos

a

TT

ge

971280]

60

07

1

Page 33

[9

+

(1

+

«0

5

РА

78

ca

L

9

9

9

1/

テ

7【A

[Tree

N

IND

|

|

т

t

=

-

aoTAap

NA

INA

34Y0

38

8

NÝM

t

|

ST

©

pere

çi

Elas

18

trés

BOT

I

Butqeay

on

123433439

9E60

021

L

MN

19

643

3 3

5

5

S

?

?

EV

2ν

ιν

ァ

V

εν

and3n0

σον

tv

28

18

28

cg

LOZ

V

-

002

v

INVISAY

28

19

1/6290

【

0

る

7

Е

G

{1]

s90n

€

tx-

OOLW

7LLA

SELA

SELA

N

CELA

N

L/662™

|

NY

NPUO

.

eu

N

N

+

|

+

+

|

ОИ

+

I

ー

イ

|

ーーーーーーーーーーー

peş

+

|

ㅣ

|

|

—t

14

şi

+

ONS

d

И

ИО

e)

n

comes

+

ce

à

on

«nue

©

een

—

e

nine

Sr

n

n

nn

一

一

一

一

本

eu

gii

14

burpaa3

Vigo

nach

as

Toddn

"ssaud

LOTIBIDE

JEQUEUD

зотлар

【

gere

4380

t3esy

aseaJDap

nveav

32080

UnnoeA

WON

AVA

N34

430138

94531500

a

Inv

x

UOT

INNZ

HINVI

1

31

”

WYDYe

WAMAVA

αλ

LNYLSNOX

ONNZ

ROS!

I

3H

Lya]

9

日

dw9

09393M

S

LTONVISSEV

НАЯ

7

OYVONV

DOTT

€

v

o

Bureau

=

Pí

&

ar

dund

L

56-020

|

noyrenang

ва

TT

Y

ra

иена

вика

τν

Page 34

cOS-r

TELIENT/AU

AU

Menges

£

MA

DENENNUNQ}

HET

RSCOII

ENEL

UNİ

DO

VA

A

11120

letzte

Ander.:20.10.93

002-0 2 0120

3326

2929

00

007-0 6 4252

0390

00

008-0 6 4252

9590

00

040-0 6 4250

0001

00

041-0 6 4250

0002

00

042-0 6 4250

0003

00

043-0 6 4250

1102

00

-00

-00

-00

-00

-00

-00

-00

-00

1,000

1,000

7,000

2,000

1,000

1,000

1,000

1,000

E-MONTAGEPLAME

STK

STANDARD

E-MONTAGEPLATTE

STK

AL99.5

SCHNAPPSCHILD-PESO-6/15

STK

2039.0

SCHRAUBE

STK

2959.0

KLEMMENBEZEICHNUNG

STK

GW

KLEMMENBEZEICHNUNG

STK

GW

KLEMMENBEZEICHNUNG

STK

GW

KLEMMENBEZEICHNUNG

STK

GW

1

HH

BL.3X303X480

FKSC

5226.6

5226.6

5226.6

5227.6

ASS

A3S

MSX8

3

NS

1

2

и

OBAEFN

0EAEFB

UT

OEAFBB

TTT

OEAFBB

TS

0EAFBB

OEAFBB

TT

0EAFBB

OEAFBB

ーー

3

3

|

|

|

0

ーー

0

0

0

044-0 6 4250

1101

00

050-0 6 4105

0075

00

051-0 6 4105

0050

00

055-0 6 4108

2140

50

057-0 6 4111

3735

00

058-0 6 4104

2790

00

061-0 6 4105

7007

00

063-0 6 4251

9150

00

110-0 1 1114

3490

00

mo em

mm e a

DI

A

214-0 6 4252

00

4892

A A An

-00

-00

-00

-00

-00

-00

-00

-00

-00

UD

ee Eu

AD A A e o

-00

|

1,000

50,000

20,000

4.000

10,000

10,000

15,000

1,000

1,000

KLEMMENBEZEICHNUNG

STK

GW

ADERENDHÚLSEN

STK

WEISS

ADERENDHULSEN

STK

ORANGE

RINGKABELSCHOR

STK

NR.5500665

WINKEL-STECKHÚLSE

STK

MS

ISOL.HULSE

STK

2790

ADERENDHULSE

STK

VPE-1000

QUERVERBINDERQL3

STK

1915.0

ERDUNGSSCHRAUBE

STK

We

ee

Qu

3,000

WEIDM-KLEMME-SAK

STK

2489.2

5372.6

VZ

BNR.

F.WINKELSTUCK

BNR.

5590100

55002020

PE...

0,75

ISOLL.

0,5

ISOLI.

RA

3735

5590100

0,75

KPL.

5 3

=

=

§

8

01

=~

TS

ee

OEAFBB

OEAFBB

TT

OEAFBB

DEAFBB

TS

OEAFBB

OEAFBB

=~

OEAFBB

0BAFBB

OTAEFB

—

an ee

ОЕА

РВ

ch

В

TT

ea

am > >

0

0

9

0

0

0

0

0

4

0

в

0

239-0 6 4254

3846

00

ce

ue

our

aN

es

cu

cap

Ge

зо вю

cep

TO

STL-NR.:

1

1120

em

So

dp

dn

cm

emo

3326

-00

fn

EP

A

-00

4,000

STK

GH a au

ste a an

DATUM:

KLEMMEDK4Q

5900.6

oe

am

ae

ie a Oh