Page 1

OPERATING

Νο.

INSTRUCTION

2115

6

Archivkanie

table

combined

~

aktueller

STEAM

WEBECO-AUTOMAT

unit,

heated,

with

electrically

~

aliltioer

STERILIZER

water

jet

Stand

V

suction

or

pump,

steam

abweichend

on

site

(D.14)

BA.2115E

Page 2

TECHNICAL

DATA:

Manufacturer

User

Year

of

delivery

Fabric.-number

Designation

Nominal

size

Capacity

service

service

space

excess

pressure

Steril.temperature

Rated

voltage

WEBECO

W-2407

Haydom

GmbH,

Bad

Lutheran

Mbulu - Tanzania

1991

85

960 / 85

AUTOMAT V -

electrically

HxWxD

115

1

320 x 320 x 610

2.5 / -

:

120° C /

220/380

1.0

V

Můhlenstrasse

Schwartau

Hospital

961

table

or

steam

=3x3x6

mms

bar

vacuum

134°

C

38,

unit

heated

Type

of

Tated

Power

Protection

Any

and

freguency

input

changes

confirmation

current

class

of

the

and

three-phase-current

50

Hz

9.100

IP

steam

must

W

33

sterilizer

be

entered

require

in

the

the

manufacturer's

data

sheet,

i

approval

i

_

(D.14)BA2115E.1

ba

E

Page 3

GENERAL

The

familiarized

The

with

The

the

sterilization.

The

the

of

any

already

It

is

entered,

work.

If

the

the

drying

REMARKS

steam

responsibility

steam

operating

shift

person

unit

sterilizer

the

user.

sterilizer

change-over

taking

particularities,

taken.

necessary

for

sterilizer

must

out

with

personnel

example

be

of

seals,

must

the

for

must

turns

to

keep

batch

is

not

properly

jamming

not

operating

an

adequate

not

or

any

of

the

operating

has

properly

troubles,

an

equipment

documentation,

in

use

shut down

be

operated

instructions

training

be

used

third

defects

for a longer

and

of

pistons.

by

any

and

of

the

after a defect

party

taken

record

may

personnel

over

and

book

tests,

period

secured

endanger

the

the

against

person

trained

must

corresponding

where

checks,

unless

to

operating

has

ocurred

the

not

take

unit

and

the

maintenance

(for

example

damage,

he

has

use

the

personnel

through

successful

place

has

been

measures

daily

reports

approx. 8 weeks),

such

been

sterilizer.

lies

which

unless

informed

are

and

repair

as

corrosion,

Steam

their

It

used

instructions.

sterilizers

function

must

be

for

the

and

ensured,

respective

must

the

therefor,

be

operated

necessary

that

sterilizing

according

work

safety.

the

material

to

selectable

as

regulations

sterilizing

laid

down

in

programmes

in

these

order

to

secure

are

operating

(D.

14)

BA2115E.2

Page 4

TECHNICAL

I.

Installation

At

installation

For

an

angle

diameter

be

connected

For

of

2.5 - 3

For

3 - 3.5

II.

Description

DESCRIPTION

operation

valve

of

reliable

atm.

steam

supply

atm.

-

EQUIPMENT

of

unit

site,

of

the

the

water

following

jet

having a connection

1%" - 2"

to

operation

abs.

of

unit

for

the

angle

abs.

is

on

site a steam

has

to

the

valve

of

the

required.

be

SETUP

pump a water

of R 3/4"

waste

provided.

water

provided

water

pipe

must

be

provided

supply

and a drainage

of

same.

by

the

jet

pump, a constant

of

1/2"

with a pressure

by

NW

20

The

sterilizer

customer.

the

customer:

equipped

with

flow

with

a

must

pressure

of

AUTOMAT V provides

The

chamber

is

approved

subject

Authorities

by

the

chamber

in

single-walled

for a maximum

to a construction

(TUV).

remote

can

thermometer.

be

controlled

tele-thermometer.

The

red

drag

pointer

down

to

zero

before

pointer

if

Mains

The

phase-current.

section

The

temperature.

temperature

at

the

supp | y

rate

unit

121°

leaves

at

requisite

of

consumption

Each

of

2.5

mm*

has 2 pressure

One

at

134°

C.

a

capacity

The

temperature

at

the

each

sterilizing

the

highest reached

operating

of

phase

per

phase.

regulator

is

fixed

C,

the

space

of

construction

operating

and

water

pressure

pressure

prevailing

The

positive

at

the

vacuum

vacuum-manometer

cycle.

pressure

the

is

fused

unit

has

is

with

for

on

2.2

bar

and

other

one

is

32 x 32 x 61

made

of

of

2.5

test

in

and

negative

gauge,

the

has

After

pressure

been

and

reached.

9.000 W with

16

amperes

controlling

regulates

fixed

on

cms.

chrome-nickel-steel

atm. abs.

by

the

the

chamber

pressure

temperature

to

be

turned

sterilization

German

is

and

Technical

indicated

in

the

with

to

the

this

allows a supervision,

220/380 V three-

having a wire-cross-

the

sterilizing

the

sterilizing

1.1

bar

for

sterilization

is

a

left

(D.39)

グー と の

BA2115E.3

rt

Page 5

Technical

with

The

must

electrically

stam

in

the

lower

be

"feeding"

description

which

filled

in

is

section

with

the

for

immersion

needed

abt. 7 litres

front

of

for

the

of

operation

heating

sterilization

boiler.

the

unit.

Before

of

feeding

is

generated

each

water

by

sterilization

by

means

immersion

the

boiler

of

the

heaters

button

When

doing

mark!

If

there

is,

protection

The

re-engaging

side-casing

Attention!

A

second

This

for

The

is

an

power.

water

overheating

jet

sterilization

after

heating

the

sterilization.

up

this

open

by

some

switches

(switching-on

by

pressing

This

re-engaging

familirazed

additional

pump

sucks-off

takes

before

the

the

door

reason,

off the

the

heating

green

should

with

the

protection

protection

place

and

The

sterilization

to

compare

no

feeding

element

again)

is

button

only

unit.

is

under

and

switches-off

the

air

from

generates

sucking-off

starts.

if

the

water

and

only

at

the

be

made

the

the

the

post-vacuum

takes

water

in

the

the

possible

level

boiler,

controlling

by

overheating

by a technician

boiler.

the

heating

|

sterilizing

place

simultaneously

reaches

the

voltage.

dismounting

protection

who

from

goods

for

the

before

drying

the

filling

overheating

the

right

switch.

is

current

phase

with

the

(D.14)

%

mæ

BA2115E.4

Page 6

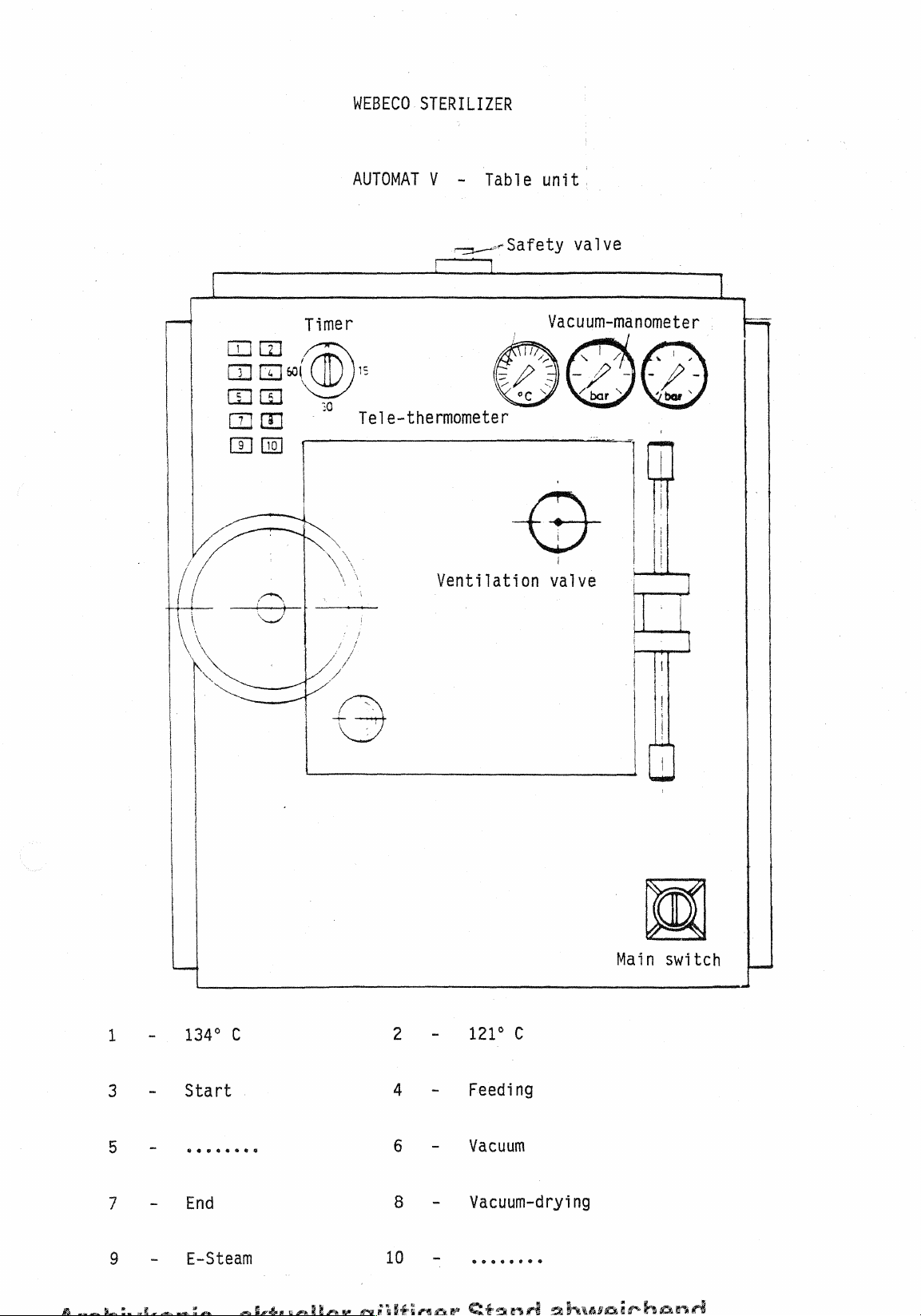

WEBECO

STERILIZER

|

eo

FN

/

/

/

Li

+

|

\

AS

ーー

OUT,

ama

2]

[3]

|

|

IN

TØ

|

Timer

X

р

ИХ

AUTOMAT V -

—

Safety

|

15

Tele-thermometer

À

|

|

/

Ventilation

|

=

Table

€23

unito

valve

Vacuum-manometer

|

KN

|

valve

7]

==

|

:

1

3

5

7

|

-

134°

-

Start

-

8605040685

-

End

C

Main

switch

上

2

-

121°C

.

4

6

8

-

Feeding

>

Vacuum

-

Vacuum-drying

9

-

E-Steam

E

qu

10

EEE

=

epa

o

00

c

Chess

6

ção

т.

Page 7

Control

Main

switch

-

and

indication

By

turning

switched

elements

from

on.

"0"

to

"I"

the

current

will

be

Button

Button

Button

Button

Button

Button

Button

1

2

3

4

6

7

8

"134°

-

for

134° C -

"121°

~

sterilization.

"Start"

-

After

(1

or

"Feeding"

~

Before

to

the

pressed

If

there

has

to

"Vacuum" - for

-

By

pressing

"End"

ー

Program-end

the

sterilizer

"Vacuum-drying"

ー

The

goods

Therefor

of

the

First

will

C" - Symbol

Sterilization.

C" - Symbol

closing

2)

will

(Sterilization

loading

water

be

chamber

the

be

level

constantly

is

no

filled

the

indication - after

will

a

solenoid

resistant

evacuated.

sterilizing

gloves,

the

door

be

started

the

feeding

in

faster

button

can

-

indication

be

dried

with

and

by

with

chamber

mark.

while

be

Therefor

filling

water

manually.

pre-vacuum

the

disloaded.

after

valve

the

water

water,

box,

program

choosing

pressing

E-steam)

the

chamber

connection

water

lighting

sterilization.

which

jet

then

connets

the

program

selection

the

this

has

this

button

process.

cycle

jet

pump

pump

is

humidity

selection

for

time,

button.

to be

on

site,

will

on

of

the

opened.

121° C -

the

has

be

the

lowest

in

the

program

filled

to be

the

water

started.

lamp

point

goods

up

Button

Timer

Tele-thermometer

Vacuum-manometer

Manometer

safety

9

valve

"E-Steam"

-

Button

By

be

sterilizing

The

This

For

(not

Indication

This

valve

Attention:

for

turning

chogsen.

timer

indication

must

instrument

shown

valve

it

should

changing

the

grip

The

time

temperature

be

fixed

indicates

of

pressure

in

the

drawing)

of

steam

is

regulated

be

Valve

could

from

steam

to

the

is

just

of

before

pressure,

at

lifted

be

pipe

right

started

134° C /

pressing

the

temperatur

in

the

generated

2.5

bar.

every 2 weeks

hot!

to

the

sterilizing

after

121°

chamber.

For

electrically

reaching

C.

the

button

in

the

on

site.

reliability

by

turning

heater.

time

can

the

"On".

chamber.

of

to

the

this

(D.14)BA2115E.5

left.

Page 8

INSTRUCTION

FOR

USE

WEBECO - AUTOMAT

electrically

Set

1.

Fill

2.

Press

on

the

at

the

Close

3.

Charge

Set

For

Press

For

If a drag

heated

"Main-switch"

in

destilled

push-button

ground

open

filling

the

timer:

the

sterilization

program-button

the

sterilization

pointer

V

from

water:

4

orifice

door

through

orifice

sterilizer

is

"0"

to

"Feeding"

at

the

the

(absolutely

and

shut

of

instruments

textile

rubber

(1)

or

of

instruments

rubber

built

into a manometer

"I".

as

buttom

filling

the

parts

(2):

parts

long

as

the

plate

orifice

necessary!)

door.

fabrics

and

textiles

or

=

=

=

water

fill

into

10min.

15

20

turn

has

in

the

min.

min.

it

attained

manually

chamber.

134°

C

121°

C

back

down

the

7

litres

to

mark

zero.

Press

the

Press"Vacuum"-button

Now

the

operation

The

air

from

decreases.

Then a second

evacuated

heater

At

the

lamp

If

automatically

The

out

After

If

10.

be

Open

11.

After

the

sterilization

whole

the

pressure

of

the

pushed

door

from

is

actived

steril.

"Vacuum-drying"

"Vacuum"-button

the

finishing

"Vacuum"-button

off

the

ventilation

pressure

can

"Start"-button

(6).

is

started.

the

chamber

Afterwards

pre-vacuum

chamber

of

and

in

the

chamber

for

porous

time.

lights

lamp

chamber

and

the

reaching

drying

now.

valve

increase

be

opened.

(3).

is

sucked

steam

cycle

and

out

loading

When

the

up.

(6)

has

lights

and

the

drying-cycle

time

at

the

textile-sterilization

at

up

to

off

power

follows.

of

the

the

choosen

as

time

been

up.

the

button

the

door.

"0"

bar,

switched-off

water

via

the

effects

In

abt.

goods.

textile

(fixed

After

steam-pressure.

at

jet

starts

"End"

indicated

flow

an

overpressure

15

fabrics,

the

it

pump

(abt.

(7)

lights

has

at

nozzle

min.

second

the

timer)

now

both

12

been

the

and

the

pressure

of

abt. 1 bar.

the

air

will

be

pre-vacuum

vacuum

is

will

be

press

min.

finished,

the

drying-time).

the

pump

switched-on

rest-water

up.

pushed,

vacuum-manometer

it

must

runs

the

|

(D.14)

BA2115E.6

Page 9

INSTRUCTION

FOR

USE

WEBECO - AUTOMAT

with

steam

1.

Set

2.

Charge

3.

Set

timer:

For

sterilization

4,

Press

5.

Turn

6.

Press

7.

Press

Now

At

first

water

out.

Again a second

on

site

"Main-switch"

the

program-button

back

the

"Vacuum"-button

the

operation

jet

The

V

from

sterilizer

of

red

drag

pointer

"Start"-button

is

the

pressure

pump.

following

This

pressure

vacuum

"0"

to

and

close

instruments

textile

rubber

(1)

or

(2).

at

(3).

(6).

started.

decreases,

vacuum

step

will

increase

will

"I".

the

door

steamtight.

:

fabrics

parts

vacuum-manometer

be

:

:

controlled

be

held

is

setted

started

10

min.

15

min.

20

min.

by

until

and

down

to

"O"

time,

the

at

holds 6 min.

effected

time

1.1

of 6 min.

bar.

bar.

by

the

goes

8.

9.

10.

11.

Afterwards

set

at

the

When

on

The

water

drying-time)

After

must

Open

After

the

the

If

the

"Vacuum"-button

automatically

pressure

out

finishing

If

the

"Vacuum"-button

be

the

pressure

door

time

pushed-off

ventilation

can

the

timer.

in

of

the

be

sterilizing

is

finished,

and

lamp

the

chamber

chamber

drying

now.

valve

increase

opened.

cycle

the

(6)

has

lights

and

and

time

at

the

textile-sterilization

at

up

to

been

the

the

"0"

is

started

lamp

"Vacuum-drying"

switched-off,

up.

the

water

drying

button

door.

bar,

and

jet

pump

cycle

"End"

indicated

starts.

(7)

controlled

lights

it

now

both

(abt.

lights

has

been

at

the

(D.14)

by

the

time

up.

will

press

be

the

12

switched-

rest-

min.

up.

pushed,

vacuum-

it

manometer

BA2115E.7

f

有

Page 10

Maintenance

1.

For

and

the

the

means

rinsed.

water

of

Afterwards

jet

pump.

maintenance

the

and

care

cleaning

the

water

unit

must

has

be

to

be

sucked

thoroughly

off

by

means

cleaned

of

Main

Set

Press

Then

After

lights

Open

manometer.

Attention

2.

regular

piping

In

the

the

the

loosening

From

Use

switch

timer

button

turn back

approx.

up.

the

intervals.

of

the

case

door

hinge

axle

time

grease

"I".

for

abt. 5 min.

"E-Steam"

timer

12

min.

ventilation

must

be

paid

the

water

of

leakages

must

axle

caps.

and

to

free

be

re-tightened

must

With a new

to

the

time

all

from

to

(sucking

valve

These

jet

be

right

threaded

acid.

and

"Start".

zero.

and

that

both "Dirt

dirt

pump

caused

removed.

door

for

off

water)

open door

traps

and

of

are

in

the

by

reduced

the

packing

For

this

packing,

re-tightening.

parts

and

the

at

indication

traps"

arranged

vacuum

elasticity

purpose,

turn

the

signal

of

the

in

the

suction

replaced.

loosen

the

axle

hinge

axle

lamp

"0"

unit

water

piping.

of

the

When

nut

must

"End"

at

are

the

to

(7)

vacuum-

cleaned

supply

packing,

re-tightening,

screws

the

left

be

greased.

at

either

of

for

‘Malfunctions:

If

the

unit

“Start"-button

a)

Electrical

b)

Water

requisite

c)

Is

d)

If

handling,

Or

jet

the

door

the

sterilizing

if

steam-on

will

not

proof

installation

pump

working?

water

flow

closed

proof

at

site

operate

the

after

following:

(fuses

pressure

at

steamtight?

pressure

E-steam-operation

is

used

will

if

setting

a.s.0.)?

least

not

be

if

the

house-steam

the

timer

2.5

bar!

reached,

enough

and

although

water

pressure

pressing

has

been

is

the

right

filled

o.k.

(D.14)BA2115E.8

in.

Page 11

DEE

SET

さっ

2°718

HOVN'dS43N3LS

|

0

+

L/027S

о

和

a

1023

UOD

l

;

|

|

2/7124

€

\6/007%-

6

3

ε

ES

2?

엇

9

6/0073-

\-+6/3008

7

6

f£/007%-

411/007%-,0

ve

UOTAPUTGUOJ

1OJ

«

N

9

>

co

o

DI

S/20€H

|

6/007x-

L

6116

re

oi

113

L/3974

N

了

4

wee

UDITMS

js-¥

"L'IVHISHN

ty

THE

sat]

ice

8

L

9

G

가히

eta

ANVUYHIS

=

$760

OZTL

Vus

HAM

|

uy

09393

T

00110^456

608

DE7N

1

|

|

ren

|

|

|

Su

lo

|

|

vz

SITR

>

0

©

|

|

|

Î

|

alva)

crepi

\-\-\

-k

7º

LZOLEX

一

|

;

|

|

に

|

CLS

に

TÃO

に

fra

MAIN

ooo

|

|

!

|

looo

|

|

|

:

|

Lit

LEZN

|

|

|

139

|

\-\-\++

ooze

7HISILTAV+

NOZZ/MOOOEXE

Aa

(ОО

호러

|

|

|

|

[

|

|

|

|

|

(11

|

|

-=

!

!

0"

|

&

6

δὸχ-

Битзеэн

ONNZIH

ZHOG/A08E

Atddns

ΘΝΩΦΙ345ΝΙ

sutew

3

7

€

G

L

=

112

[014

E

-

H38

:

“SHOX

T

:

"dLSM+1/SV

te

Jo

pusu

Ade

oy

TB"G0

1335

ЕР

RIST

Галуа

TINTO

4

CE

re

16

bun

606

repay

И

Page 12

7:98

fim

NOA

a

N

8

L

211918

之

A

760

OSLL

2?

29

L

ga”

AL/007%-

ΟΥ

9

\L/007%-

27

6

G

\L/007%-

oy

g

7

\-+€/z0es

。

LL

L

\z/007x-

7

:

€

7

\-42/20€S

71

©

A)

ae

9

ef

41/0074

245

„jee

/007%-

007

9/2974-

[в/=37ч-

>

uf

a?

cL?

79

e

Т/ЗОЕН

Ito

by

ELLA

©

7/80€H

gi

Ly

BOLA

£/20€H

2/007M-

2

Ol:

Brig

A

1.9

ta

PILL

rte

ИППУЛ

AW

43SSVA

AN

tt

118

Ay

элтел

рточэто5

unnoeA

9

dund

элтел

G

390

DTOUSTOS

лэзем

7

949

021

т

*4N

740197

Η

4

5)

09338

1ΝΜ

xy

8

{0

4

:

NB

PIWAYSG

pog

—

p

273

.

.

37533]

€

È

一

29

„9

LI

L

._\1/007%-

€

も

|--“L/Z0ES

Я

|-17/20€8

ot

7

L

7

о

一

一

一

一

一

人

0

z)

8/007

メ

ー

A)

LE

/007%-

de/007x

路

-

ϱ/2921-

>

119

)

еее

É

2/20CH|

τν

1/0074

LV

8/007λ

1/2084

En

LZLA

.

€

7

06:19

HG

τος

o

01:19

With

나

TE

rtf

も

118

SS

iL8

49

Ν35

[3845

NY

AW

049

YEL

の

элтел

了

рточэто5

BuTpss]

66065

AH

pito

ST

N

+0

puswworfg

ТБ

"СО

"СТ

|

unyeg

.

16

"70

"Ed

“¿desp

EKEN

MSNISWON

01001

Le

bun¿spuy

‘So

"SI

*

4807

Page 13

%

7"08

HDYN

dé

y

NE

007%-

ай

|

ot

è

6

+

一

一

BL

一

„h

Y

eby

2/007A-

BL

cire

_N8/007A-

>

yet

/00SH-

22

9

©

ς

8

|-19/20€S

ez

72$

L

/B0EX-

ZL

gle:

\L/007%-

8LON

Å.

LAVES

E

AE]

BLON

es?

À

la]

LON

2

vais

p+

2

113

uvas

d+

LS

€

p

7

5

1/009%=,

gi?

\£/007%-

HAVEL”

L+

78

0

GuTue31JS

자

一

一

一

一

一

一

一

a

ar

LSLA

9/007%-

met

ーーーーーーーー

サ

ーーーーーーー

ーーーーーーー

ema

es

eo

reto

o

e

-g-

—

—

——

L

e

ce

cine

cem

사세

vene

somo

too

ae

comem

δεις

enorme

sro

denza

Gusta

seno

ss

cen

ms

E

me

gear

人

全

Sl

διις

人

人

一

一

gu

一

一

一

e

人

一

22

Ò

S

ars

41/806%

τν

9

G

3

6

6

ΟΣ

Jar

/0071-

——9

LZ

92

σαι

zy

„1

o

1/0062-

d9/007%-sr

p)

3

01V007X\S/007%=\9/007%-\7/007XE/007%-

se

gilt

cls

cl?

af

al:

\7/007k-

Dé

[4/297ч-

"σα

EV

ТУ

LZ]

oy

VW

ut?

L7

гу

by

“ST

DI

\6/007%-Q,

9+

O

L/80E%-

45/004-

[た

EZ

SY

LY

V/OLEX-|

BY

LY

A

LILA

CZ]

Ev

Lv

5/007%-

CZ)

27

фу

7/007%-

LZ]

LY

LY

|

E/007%-

|

©

9/Z0EH

[7]

SY

ιν

LL/007»-

E

07:19

&

+)

110

g

一

м

一

ge

TA

_

TITTI

1

ーー

Fi

レー

0:19

—

00169

ーー

ТОРЕЗ

ASI

ΘΔΤΘΔ

ΡΤΟΙΘΤΟΘ

cotti

+1

27

TS

Sis

~

VIT

atte

HAL

A

U

AZ

dund

gel

N3N3OYLS

iegzem

AH

,

27

A?

118

A

unnoeA-91d

4132

WONAVAXS

43897

x

“SITINILS

7

9ΝΠΖΙ3Η

2

7

|

AddHVO

AN

L'E

yo

zii

tě

A?

내

zi

ATE

Al

1

ι8

Cgi

LUVLS

te

A?

LB

8931448

"reta

THISTL-AY

8

NES

Е

«76ο

30400

OZTT

L

158355\

T

.AN

ANT

42}

2Z

9

Hquo

no

30410-3"9080

G

6

ΠΣΠΕΡΗ

y

ΡΑΤΕΑ

proustos

€

2

3123S

UOTIPI9dO

【

Όλος

0J383A

pog

7HOSILTAV+

ーー

24

P_$13

afo,

d

.

Η38

=

"8Ο

42313

.

"dLSM+41/SV

1670

Lo

пориво

+

¿den

M

vě

ЕТО

"G0

"SL

|

376%

ta

“nwg

ол

JON

das

SON

EME)

Le

bun¿apuy

‘S0

"el

δη

Lo

&

PETER

Le

UD

ンク

ee

Page 14

8

91TS

unnDca-sid

L

r

9760

061

A

iye

>

μή

7

|

cs

6/007%-

8693

4

NOA

}

-3

1/00GM-

SET

929

c

Seo

rat

vas

/

LOEN-

ナーーーーーーーーーー

Lv]

SLON

LI

„ss

\6/007%-

ЕЕ

ds/007X-

EET

val“

0+

gl!

ς

151

/007ΧἈ-

LL

LISE

19/007λ-

LLPY

49/007

-

oj

0L/007%-

LET

11)

01/0074-

£

1

>-1/89E7%-

8

>

rt

8

BETA

a

b-1/LOEN-

UHS

г

人

3

5

LE

dE

66

8/8974-

|

fo

σν

ty

(0

ov

τν

UR

2

Ly

3

a

è?

KA

ὄν

τν

XA

m

ZN

EV

O

ay

pv

UR

evil

Wis

31/007M-

|

01/007%-|

L/L0E%-

z

УТРА

OSLA

2/908H

L/OO7A-

L/8E74-

ーー

cl

+

mene

4

aman

2

ema

e

à

mans

+

tesine

è

santone

pome

+

fans

à

mm

©

shines

4

.-

和

2

maze

è

mcm

©

-全

一

:一

一

一

一

年

一

SE

/

一

一

VE

ge

Grua

Hi

би

AA

E

5%

o

frio

AI

6

E

一

一

ЗИ

Sgi

나

εί

119

gh

AN

wa

BL

LTL

320119

k

uo

eos

UTI

Je

아

ΜΠΠΣΝΛΝΟΛ

4dNYU-H

4

|

내

NN

1137

ヨ

A

DITS

πο

элтел

PTOUSTOS

Wi

БитАлр

unnoea

wees

AdHYO-H

NANJOULS

bUTUESIIS

ddNYO-

uP33S-A

AW

ヨ

JON3

pus

fr

NINXIO

WANAVA

“WSL

AL

Υ

L

“aN

yoy

a7

7

9

Hua

noyabmyıg

ODAGAN

peg

G

|

7HOSTLTAV#

143

presa

[014

7

|

ο

"H38"8K0X"dLSK+1/SV

è

E

.

と

の

了

+0

puduwoy

TE

COCE

|

uno

16

"70

EC

‘Adsan

rie

ss

“sda

JON

SU

DAŞ

«nrg

LR

Ounsapuy

*

SR

9

SE

δη

a.

x.

δν,

Ki

®

Page 15

64006

2910

8206

4.06!

MA

|

70922

A

2007)

5.

Il

71

a

)

Ато

nz

|

|

\

эшом

|

60;

B

お

©

円

りり

フタ

カリ

ο

Mi

BUDA

Boj

Bunzapuy

SUBA

501

Cone

16

|

9315

By

JdwopsnoH

UO

wes

4s

^

o!

|

1

|

DS

LUZ

|

i

/

DI

9

|

==

>

9!

y

/

/

|

L

一

i

4917

81

|

SI

bat

Я

2

=

Pai

EA

9

=

EU

01

.

891

1

|

tee

LA

Gi;

|

|

|

δις

i

ド

D

о“

è

o

É

in

Á

13

unz

=

o

15

5

E

2

р

İS

E

«|

bo

©

in

-SBunuy3jdz

ing

jm

MYIS

DDG

Hatun

DDB00M

İYYİŞ

Zİ

cesso

7260

|

O!

/

/

YS!

4219489

|

A

149

у

1U1QUIOH

UD)

YO

000

|

20884254

44115038)

>

W

zí

—

=)

Page 16

iping

P

Eat

diagram

neto

menti

noso

como

орт

чать

ført

art

mg

ner

thes

의

e

Sout

ri

oe

μας

sane

ae

AN

i

x

son

ser

кие

4

0

mes

deseo

que

ESS

DE

4 po

EE:

né

st

í

3,

SERA

deny once

pute

Gone

ORE

SOK

Ses

EME

ARNO

AULE

SIA

evan

eRe

fie

brah

AG

hey

ABER

1

Dee

et

j

hipp

pump

le

k

Te

sasa в с

cane

st

the

sm

dirt

trap

were

ee

water

double

яя

a

Page 17

Page 18

se

diagram

Pe

PAs URE

double

syny

ts

BARR

PERE

Ap

Ceci

art

vaa

zn

fis

raso

ep

sockets

dade

Page 19

ste

Be

ae

ating

tre

nné a geme

element

per

ve

tazione

*

Mere

Ain

Rue

US

tr

ng

regulator

Bent

σέλα

Εφ

pars

sedi

great

time

på

sst

aut göm

relay

ο.

bean

eg

Page 20

“o

:

P

.

.

:

5

i.

|

Lei

“o

т.

é

:

é

É

Ем

Di

a

i

i

|

1

É

:

i

i

:

:

È

È

:

Ë

:

=

È

ω

Čs

ivo

e

È

E

:

i

Ê

È

Leo

ο...

の

Ro

ti

に

i

i

i

ii

ii

u

Е

ii

si

ii

fi

di

S

i

m

i

È

3

i

È

fom

É

È

き

E

그

o

ats

why

Bor,

çar

Lt

a

È

uns

a

ASI

et

È

i

i

Е

é

1

os

{i

HOR

a

si

:

E

Al

#

E

é

5

a

È

=

i

s

i

i

z

E

=

E

E

È

:

но

i

則

È

:

sui

oz

ZA

ET

-

ты

1

E

=

i

Е

i

È

gS

z

E

Kaye

en

SI

ue

q

=

K;

ue

em

Е

;

>

5

È

i

È

3

È

É

E

E

Pu

alo

、

E

À

È

3

Eo

て

È

Е

poa

E

È

$

E

А

Es

:

E

*

E

wes

IPE

E

È

san

ii

3

을

ghe

È

z

da

:

ii

‘wl

È

É

So

E

EOS

ii

fi

È

i

i

i

y

i

:

i

ii

|

E

E

i

x

i

를

Ho:

8

i:

Е

i

E

i

Е

i

:

i

E

i

和

E

3

E

i

|

a

adi

i

Ko

;

=

р

i:

:

©

ce

s

i

E

per

i

pus

、

„OB

5

ᾷ

È

È

ξ

>

:

:

È

È È

i

i

E

E

pui

È

EA

ao

8

i

È

E

i

É

E

z

ЕЁ

È

3

E

E

E

i

ic

È

ë

:

;

É

>

È

É

3

È

E

E

i

:

$

i

E

À

È

È

Ë

i

:

i

8

{

Е

È

i

š

$

E

E

E

ni

È

È

b

을

be“

i

:

i

È

è

É

i

É

È

E

È

8

È

È

È

4

き

È

-=

E

i

A

È

å

É

f

È

ş

£

3

i

ge

2M

b

:

È

:

に

:

ven

m

起

ğ

S

;

ἡ

¿

x

x

:

È

å

E

Е

E

s

i

i

£

:

:

»

F

È

4

i

a

С

È

À

3

ê

È

;

È

E

i

È

È

i

È

i

È

:

:

a

$

É

i

:

:

È

i

;

:

i

:

È

È

:

È

:

:

É

:

은

도

:

È

|

:

i

;

i

i

:

s

i

E

和

:

i

i

:

ER

i

:

:

—

:

Бы

:

:

i

Loading...

Loading...