46cm Self Propelled

Steel Deck Lawnmower

en - Original Instructions

ASSEMBLY REQUIRED

Minimum Two Persons

Sales & Support: 01793 333212

WER460SP

1938220001

Before use please read & understand this manual; paying particular attention to the safety instructions before use.

Whilst every eff ort has been made to ensure the accuracy of information contained in this manual, our policy of continuous improvement

Incorrect use of the product could put the operator or machine in danger.

determines the right to make modifi cations without prior warning.

Images are used for illustration purposes only.

INSTRUCTION MANUAL

CONTENTS

INTENDED USE

SAFETY INSTRUCTIONS

SPECIFICATIONS

KNOW YOUR MACHINE

ASSEMBLY

OPERATION

MAINTENANCE, CLEANING & STORAGE

TROUBLE SHOOTING

PARTS DIAGRAM & LIST

DECLARATION OF CONFORMITY

WARRANTY

INTENDED USE

This machine is to be used exclusively for cutting natural grass. Never use the mower for other purposes.

Any other use can endanger for your safety and can involve damage to the mower.

Persons under 16 years of age and persons who are not familiar with the user instructions must not use

the mower.

The user is responsible of the safety of other people in the working area. Keep children and domestic

animals at a safe distance while the mower is in use.

Before mowing, remove all foreign objects from the lawn which may be thrown by the machine, stay

alert for any foreign objects which may have been missed.

These operating instructions must be kept and referred to in order to ensure that the equipment is

properly used and maintained. The instructions contain valuable information on operating, maintenance

and servicing conditions.

WARNING

The equipment is to be used only for its prescribed purpose. Any other use is deemed to be a case of

misuse. The user/operator and not the manufacturer will be liable for any damage or injuries of any

kind caused as a result of this.

Please note that our equipment has not been designed for use in commercial, trade or industrial

applications. Our warranty will be 90 days from the original date of sale for commercial, trade or

industrial businesses or for equivalent purposes.

16 Sep 2019

Copyright Notice

Copyright © Handy Distribution

Permission is granted to reproduce this publication for personal & educational use only.

Commercial copying, redistribution, hiring or lending is prohibited.

No part of this publication may be stored in a retrieval system or transmitted in any other form or means without

written permission from Handy Distribution.

In all cases this copyright notice must remain intact.

CONTENTS

INTENDED USE

SAFETY INSTRUCTIONS

SPECIFICATIONS

KNOW YOUR MACHINE

ASSEMBLY

OPERATION

MAINTENANCE, CLEANING & STORAGE

TROUBLE SHOOTING

PARTS DIAGRAM & LIST

DECLARATION OF CONFORMITY

WARRANTY

INTENDED USE

This machine is to be used exclusively for cutting natural grass. Never use the mower for other purposes.

Any other use can endanger for your safety and can involve damage to the mower.

Persons under 16 years of age and persons who are not familiar with the user instructions must not use

the mower.

The user is responsible of the safety of other people in the working area. Keep children and domestic

animals at a safe distance while the mower is in use.

Before mowing, remove all foreign objects from the lawn which may be thrown by the machine, stay

alert for any foreign objects which may have been missed.

These operating instructions must be kept and referred to in order to ensure that the equipment is

properly used and maintained. The instructions contain valuable information on operating, maintenance

and servicing conditions.

WARNING

The equipment is to be used only for its prescribed purpose. Any other use is deemed to be a case of

misuse. The user/operator and not the manufacturer will be liable for any damage or injuries of any

kind caused as a result of this.

Please note that our equipment has not been designed for use in commercial, trade or industrial

applications. Our warranty will be 90 days from the original date of sale for commercial, trade or

industrial businesses or for equivalent purposes.

3

INSTRUCTION MANUAL

GENERAL SAFETY RULES

Before you put the machine into operation, you must read this instruction manual.

When using this machine, observe the following safety instructions to exclude the risk of personal injury or

material damage. Please also observe the special safety instructions in the respective chapters. Where

applicable, follow the legal directives or regulations for the prevention of accidents in relation to the use of

this machine.

WARNING

When using petrol tools, basic safety precautions, should always be followed to reduce the risk of serious

personal injury and/or damage to the unit.

TRAINING

The operator must receive proper training in the use, adjustment and operation of the machine, including

prohibited operations.

1. Read the instructions carefully. Be familiar with the controls & proper use of the equipment. Spend time

to familiarise yourself with your machine before each use.

2. Never allow children or people unfamiliar with these instructions to use the machine. Local regulations

can restrict the operator age.

3. This machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the machine by a person responsible for their safety.

4. Never work while people, especially children, or pets are nearby.

5. The operator or user is responsible for accidents or hazards occurring to other people or their property.

SAFETY INSTRUCTIONS FOR WORKING WITH TILLER

1. Do not leave engines running in enclosed spaces, where dangerous carbon monoxide could accumulate.

2. Operate in daylight or good artificial lighting. If possible, do not use on overly wet ground.

3. Ensure good stability on slopes. Always operate across the slope, never up and down.

4. Be particularly careful if changing direction of travel on the slope.

5. Do not operate on steep slopes.

6. Operate whilst walking, do not run.

7. Be particularly careful when you turn or when you pull the machine towards you.

8. Stop the engine and blade, if it is to travel across other areas or must be transferred to/from working area.

9. Never use the machine with damaged safety protection guards.

10. Do not change the engine regulation set up. (This should only be undertaken by a skilled technician).

11. Carefully start the engine. Keep your feet clear of the blade.

12. Never reach behind or under the rotating parts with hands or feet.

13. Never lift or carry the machine while the engine is on.

14. Switch the engine off and remove the spark plug cap out before unblocking or removing obstacles from

the blade or exit chute:

− Before releasing blockages, inspecting, cleaning or working on the machine.

− After hitting an obstruction. Search for damage on the machine & make repairs as necessary. If the

machine starts vibrating unusually, it should be inspected by an Approved Webb Service Dealer.

15. Switch the engine off:

− If you remove blockages from the machine.

− Before refueling.

Read & understand operator’s

future reference.

Fire Risk

or death.

Hot Surface.

on contact

Moving Parts

laceration can result

Keep guards in place and in

using it.

Safety alert symbol. Used to alert you

this symbol to avoid possible injury.

Indicates an imminently

injury

Indicates a potentially hazardous

injury.

Used without the safety alert symbol

result in property damage.

SAFETY INSTRUCTIONS

Read and understand the owner’s manual and labels affixed to the machine. Learn its application and

limitations as well as the specific potential hazards. Retain these instructions for future reference. The

operator is responsible for following the warnings & instructions in this manual and on the product.

4

DANGER

CAUTION

manual before using the machine.

Failure to follow instructions

could result in death or serious

injury.

Please keep in a safe place for

Keep all bystanders & animals

away from the machine during

operation. If approached, stop the

machine immediately.

Risk of Carbon Monoxide

Poisoning. Ensure working area is

correctly ventilated.

Fire and its vapors are extremely

flammable & explosive. Fire or

explosion can cause severe burns

Running engines produce heat.

Engine parts, especially the

exhaust, become extremely hot.

Severe thermal burns can occur

working order. Replace damaged,

missing or failed parts before

hazardous situation which, if not

avoided, will result in serious

situation which, if not avoided,

may result in minor or moderate

CE Marking - the product meets

demand and regulations set by

No smoking

the EU

WARNING

CAUTION

Always wear eye

Always wear gloves to protect your

Wear foot protection or sensible shoes

Do not use near a flame, or sparks

Rotating parts can contact or entangle

to potential personal injury hazards.

Obey all safety messages that follow

situation which, if not avoided, could

situation which, if not avoided, may

Noise Level - See label on machine

and ear protection

hands.

SHARP ROTATING BLADES

when using the machine

Do not expose to rain or damp

conditions.

hands, feet, hair, clothing or

accessories.

Traumatic amputation or severe

Indicates a potentially hazardous

result in serious injury

indicates a potentially hazardous

GENERAL SAFETY RULES

Before you put the machine into operation, you must read this instruction manual.

When using this machine, observe the following safety instructions to exclude the risk of personal injury or

material damage. Please also observe the special safety instructions in the respective chapters. Where

applicable, follow the legal directives or regulations for the prevention of accidents in relation to the use of

this machine.

WARNING

When using petrol tools, basic safety precautions, should always be followed to reduce the risk of serious

personal injury and/or damage to the unit.

TRAINING

The operator must receive proper training in the use, adjustment and operation of the machine, including

prohibited operations.

1. Read the instructions carefully. Be familiar with the controls & proper use of the equipment. Spend time

to familiarise yourself with your machine before each use.

2. Never allow children or people unfamiliar with these instructions to use the machine. Local regulations

can restrict the operator age.

3. This machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the machine by a person responsible for their safety.

4. Never work while people, especially children, or pets are nearby.

5. The operator or user is responsible for accidents or hazards occurring to other people or their property.

SAFETY INSTRUCTIONS FOR WORKING WITH TILLER

1. Do not leave engines running in enclosed spaces, where dangerous carbon monoxide could accumulate.

2. Operate in daylight or good artificial lighting. If possible, do not use on overly wet ground.

3. Ensure good stability on slopes. Always operate across the slope, never up and down.

4. Be particularly careful if changing direction of travel on the slope.

5. Do not operate on steep slopes.

6. Operate whilst walking, do not run.

7. Be particularly careful when you turn or when you pull the machine towards you.

8. Stop the engine and blade, if it is to travel across other areas or must be transferred to/from working area.

9. Never use the machine with damaged safety protection guards.

10. Do not change the engine regulation set up. (This should only be undertaken by a skilled technician).

11. Carefully start the engine. Keep your feet clear of the blade.

12. Never reach behind or under the rotating parts with hands or feet.

13. Never lift or carry the machine while the engine is on.

14. Switch the engine off and remove the spark plug cap out before unblocking or removing obstacles from

the blade or exit chute:

− Before releasing blockages, inspecting, cleaning or working on the machine.

− After hitting an obstruction. Search for damage on the machine & make repairs as necessary. If the

machine starts vibrating unusually, it should be inspected by an Approved Webb Service Dealer.

15. Switch the engine off:

− If you remove blockages from the machine.

− Before refueling.

5

INSTRUCTION MANUAL

condition that may affect the operation. If damaged, have the machine repaired by an Approved Webb

Service Dealer immediately. Many accidents are caused by poorly maintained machines.

12. Use the machine, accessories and tool bits etc., in accordance with these instructions and in the manner

intended for the particular type of petrol machine, taking into account the working conditions and the

work to be performed. Use of the machine for operations different from intended could result in a

hazardous situation.

PERSON PROTECTION

1. In case of any injury always proceed in accordance with the principles of first aid.

2. If someone is cut, cover the wound with a clean cloth & press hard to stop the flow of blood.

3. Do not let petrol or oil come in contact with your skin. Keep petrol and oil away from the eyes. If petrol or

oil come into contact with the eyes, wash them immediately with clean water. If irritation is still present,

see a doctor immediately.

4. Individuals with poor circulation who are exposed to excessive vibration may experience injury to blood

vessels or the nervous system. Vibration may cause the following symptoms to occur in the fingers, hands

or wrists: numbness, tingling, pain, stabbing sensation, alteration of skin colour or of the skin. If any of

these symptoms occur, see a doctor.

Put safety first in the case of fire:

5. If fire comes from the engine or smoke appears from anywhere other than the exhaust vent, at first

distance yourself from the product to ensure your physical safety.

6. Use a dry powder fire extinguisher on the fire to prevent it from spreading.

7. A panicked reaction could result in the fire and other damage becoming more extensive.

WORK AREA

1. Keep work area clean and well lit. Cluttered and dark areas invite accidents.

2. Check the landscape where the machine will be used and remove all objects such as stones, toys, sticks

and wires, which could be caught and thrown away from the work area. Damage of the machine or

operator’s injury could be caused.

3. Do not operate this machine in explosive atmospheres, in the presence of flammable liquids, gases or

dust. Machines create sparks which may ignite the dust or fumes.

4. Keep children & bystanders away while operating the machine. Distractions can cause you to lose control.

PERSONAL SAFETY

1. This machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the machine by a person responsible for their safety.

2. Children should be supervised to ensure that they do not use or play with the machine.

3. Stay alert, watch what you are doing and use common sense when operating this machine.

4. Do not use this machine while you are tired, ill or under the influence of drugs, alcohol, or medication. A

moment of inattention while operating this machine can cause you to lose control & may result in series

personal injury.

5. Do not overreach. Always keep proper footing and balance. This enables better control of the tool in

unexpected situations.

6. Remove any adjusting tools before turning the machine on. A tool that is left attached to a rotating part of

the machine may result in personal injury.

7. Use safety equipment. Always wear eye protection. Safety equipment such as a dust mask, non-skid safety

shoes, hard hat, or hearing protection used for appropriate condition will reduce personal injuries.

8. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing & gloves away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts. Wear foot protection or

sensible shoes when using the machine.

9. Prolonged use of the machine may lead to disorders of blood circulation in hands caused by vibration.

These effects can be worsened by low ambient temperatures and/or by gripping the handgrips excessively

tightly. Period of use you can extend with appropriate gloves or regular breaks. Take frequent work

breaks. Limit the amount of exposure per day.

PETROL TOOL USE AND CARE

1. Store petrol in containers specifically designed for this purpose.

2. Refuel outdoors only and do not smoke while refueling.

3. Add fuel before starting the engine. Never remove the cap of the tank or add petrol while the engine is

running or when the engine is hot.

4. If petrol is spilled, do not attempt to start the engine but move the machine away from the area of spillage

and avoid creating any source of ignition until petrol vapors have dissipated.

5. Replace fuel tank & container caps securely.

6. Do not operate the engine in a confined space where dangerous carbon monoxide can collect.

7. Do not force the machine. Use the correct machine for your application. The correct machine will do the

job better and safer at the rate for which it was designed.

8. Do not use the machine if the main OPC/Brake lever does not work to turn the machine off. Any machine

that cannot be controlled with the OPC/Brake lever is dangerous and must be repaired.

9. Turn machine off completely before making any adjustments, changing accessories, or storing. Such

preventive safety measures reduce the risks of starting the petrol tool accidentally.

10. Store idle machines out of the reach of children and do not allow persons unfamiliar with the machine or

these instructions to operate. Petrol machines are dangerous in the hands of untrained users.

11. Maintain your machine. Check for misalignment or binding of moving parts, breakage of parts & any other

Petrol is highly flammable and explosive.

WARNING!

6

condition that may affect the operation. If damaged, have the machine repaired by an Approved Webb

Service Dealer immediately. Many accidents are caused by poorly maintained machines.

12. Use the machine, accessories and tool bits etc., in accordance with these instructions and in the manner

intended for the particular type of petrol machine, taking into account the working conditions and the

work to be performed. Use of the machine for operations different from intended could result in a

hazardous situation.

PERSON PROTECTION

1. In case of any injury always proceed in accordance with the principles of first aid.

2. If someone is cut, cover the wound with a clean cloth & press hard to stop the flow of blood.

3. Do not let petrol or oil come in contact with your skin. Keep petrol and oil away from the eyes. If petrol or

oil come into contact with the eyes, wash them immediately with clean water. If irritation is still present,

see a doctor immediately.

4. Individuals with poor circulation who are exposed to excessive vibration may experience injury to blood

vessels or the nervous system. Vibration may cause the following symptoms to occur in the fingers, hands

or wrists: numbness, tingling, pain, stabbing sensation, alteration of skin colour or of the skin. If any of

these symptoms occur, see a doctor.

Put safety first in the case of fire:

5. If fire comes from the engine or smoke appears from anywhere other than the exhaust vent, at first

distance yourself from the product to ensure your physical safety.

6. Use a dry powder fire extinguisher on the fire to prevent it from spreading.

7. A panicked reaction could result in the fire and other damage becoming more extensive.

7

INSTRUCTION MANUAL

KNOW YOUR MACHINE

1. Self-Propelled Lever

2. Handle Soft Grip

3. Upper Handle

4. OPC/Brake Lever

5. Handle Fixing Knob & Bolt

6. Lower Handle

7. Grass Collector

8. Fuel Tank Cap

9. Engine Primer Bulb

10. Bumper (Not on WER460SP)

11. Single Height Adjuster Lever

12. Rear Wheel

13. Engine Oil Filler Cap & Dipstick

14. Side Discharge Cover

15. Side Discharge Chute

16. Cutting Deck

17. Spark Plug Cap

18. Recoil Starter Handle

19. Rear Discharge Cover

20. Front Wheel

SPECIFICATIONS

Model WER460SP

Product Number 1938220001

Guaranteed Noise Power Level LWA 96 dB(A)

Emission Sound Pressure Level LPA 83 dB(A)

The manufacturer reserves the right to change the product specification and livery according to continued

Working Width 460mm

Drive Type Self-Propelled

Cutting Heights 25-75mm - 7 levels

Collector Capacity 55L

Deck Steel

Front / Rear Wheel 7in / 8in

Engine Petrol, 4-Stroke Air Cooled

Engine Displacement 141cc

Rated Engine Power 2.5kw

Rated Engine Speed 2800rpm/min

Oil Tank Capacity 0.4L

Vibration ahv: 7.38 m/s2 - uncertainty K: 1.5 m/s

product improvements.

2

8

KNOW YOUR MACHINE

1. Self-Propelled Lever

2. Handle Soft Grip

3. Upper Handle

4. OPC/Brake Lever

5. Handle Fixing Knob & Bolt

6. Lower Handle

7. Grass Collector

8. Fuel Tank Cap

9. Engine Primer Bulb

10. Bumper (Not on WER460SP)

11. Single Height Adjuster Lever

12. Rear Wheel

13. Engine Oil Filler Cap & Dipstick

14. Side Discharge Cover

15. Side Discharge Chute

16. Cutting Deck

17. Spark Plug Cap

18. Recoil Starter Handle

19. Rear Discharge Cover

20. Front Wheel

9

INSTRUCTION MANUAL

5. To attach the upper handlebar, first remove the two handlebar knobs and washers. Please note that these

have a two-phase thread, to stop the knobs was coming off the bolt accidently and being damaged.

NOTE: The Recoil rope guide attached to the upper handle, should be on your right side.

6. Position the handlebar over the lower handles just below the lower handlebar, aligning the holes in the

upper handle with those in the lower handles. Insert the two locking knob bolts through the lower handle,

then through the upper handle holes.

7. Then attach the handlebar knobs on the outer side of the upper handle and secure until tight.

CABLE TIDY

1. Place the cable tidy over the handle assebly and house the cables into the tidy.

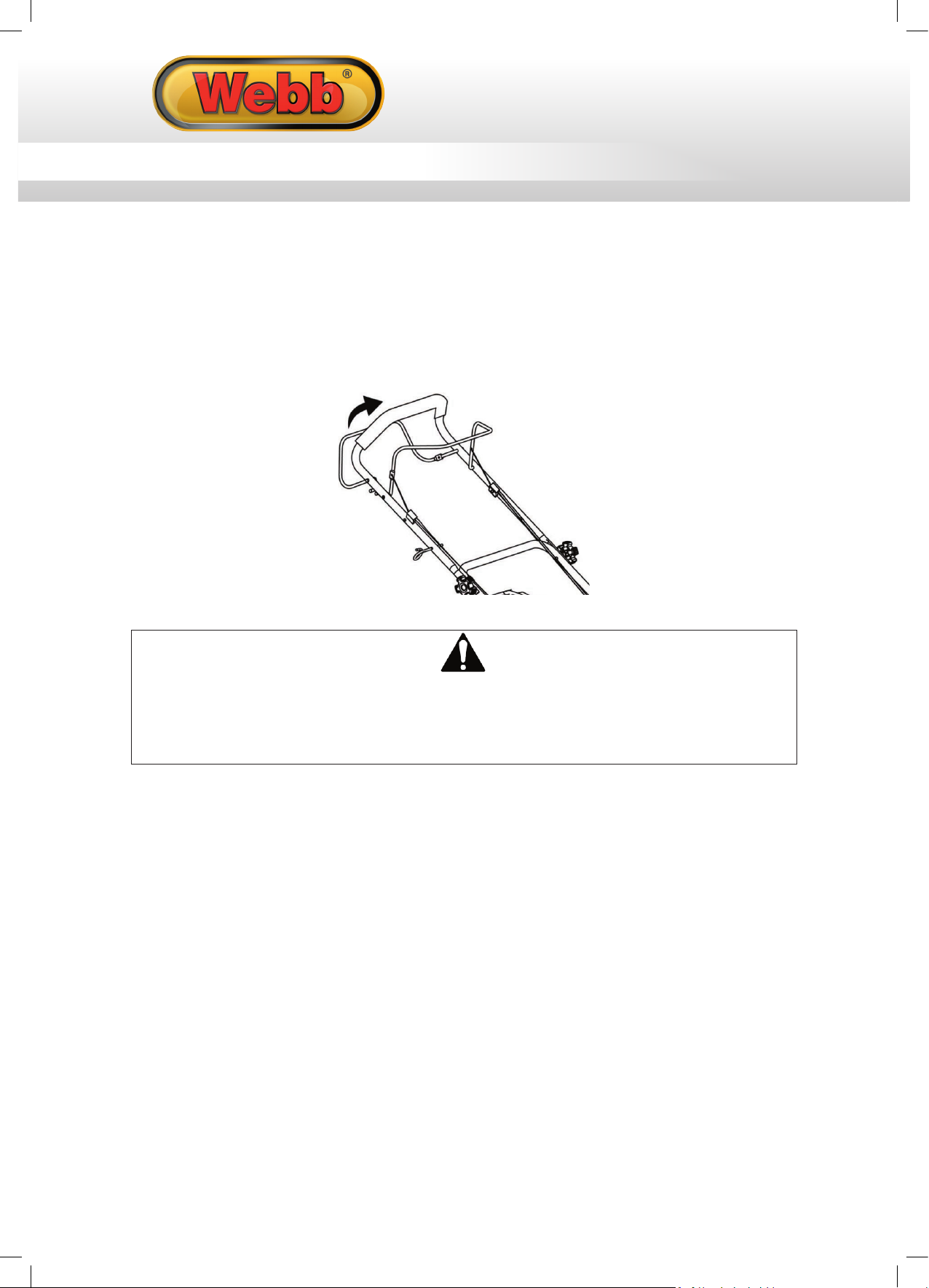

ASSEMBLY

Remove the machine and contents from the carton. Be sure the carton is empty before discarding.

If you require any assistance with regards to the contents of the machine, contact us:

Tel: 01793 333212 - Mon – Fri 8.00am – 5.30pm (excl. Bank Holidays)

Email: customerservice@webbgardenpower.co.uk

IMPORTANT INFORMATION

NOTE: This product is a 4-stroke engine powered machine.

The engine MUST be filled with recommended 4-stroke SAE30 or 10W/30 air cooled lawnmower engine oil

BEFORE starting. Fresh unleaded petrol must be used in this unit. DO NOT use Ethanol based fuels. DO NOT

mix oil with fuel.

WARNING

Stop the engine and unplug the spark plug before any repairs or maintenance operations.

DO NOT attempt to start this machine without it first being FULLY assembled.

DO NOT attempt to start this mower without first adding 4-stroke SAE30 or 10W/30 air cooled lawnmower

engine oil to the engine.

HANDLES

1. To attach the lower handle, first remove the two lower handlebar knobs and washers. Please note that the

bolts have a two-phase thread, to stop the knobs was coming off the bolt accidently and being damaged.

2. Place the lower handle in position by aligning the lower handle with the outer side of the metal mounting

plates located at the back of the mower deck.

3. Once in position, insert the bolt on each side through the mounting plate and then through the lower

handle.

4. Once the bolts are loosely in position, attach the washer and lower handlebar locking knobs onto the

outer side of the lower handles and secure until tight.

10

5. To attach the upper handlebar, first remove the two handlebar knobs and washers. Please note that these

have a two-phase thread, to stop the knobs was coming off the bolt accidently and being damaged.

NOTE: The Recoil rope guide attached to the upper handle, should be on your right side.

6. Position the handlebar over the lower handles just below the lower handlebar, aligning the holes in the

upper handle with those in the lower handles. Insert the two locking knob bolts through the lower handle,

then through the upper handle holes.

7. Then attach the handlebar knobs on the outer side of the upper handle and secure until tight.

CABLE TIDY

1. Place the cable tidy over the handle assebly and house the cables into the tidy.

11

INSTRUCTION MANUAL

HEIGHT OF CUT

To adjust the height of cut, the machine has been supplied with a single lever, located at the right rear wheel.

Adjusting the height of cut should only be undertaken when the engine is off, and the blade has come to a

complete standstill.

To adjust the height of cut, grab the height of cut lever and push it away from the gauge (1) and then lift or

lower the lever to the required height of cut (2).

Moving the lever forward will lower the height of cut (Min. 25mm). Moving the lever back, will raise the height

of cut (Max. 75mm)

SIDE DISCHARGE CHUTE

NOTE : When using the side discharge function. Remove the grass collector and plug the mulch plug into the

rear of the machine.

1. Unlock the side discharge cover and lift. Hook in the side discharge chute.

2. Allow the side discharge cover to secure onto the side discharge chute into position.

MULCH PLUG

NOTE: Mulching stops collection of grass into the rear collector.

You will find the mulch plug loose in the carton or fitted to the machine. If the mulch plug is not located in the

carton, lift the grass collector flap at the rear of the machine and remove the mulch plug.

GRASS COLLECTOR

1. Left the grass collector flap up, so that it opens past the handle assembly. Hold in position and place the

grass collector hooks over the springs and place into position.

2. Lower the grass collector flap to sit onto the grass collector.

RECOIL STARTER HANDLE

1. To ease starting of the machine, the recoil starter handle can be housed on the handle assembly.

2. To house it correctly, pull the OPC/Brake lever towards the main handle. Do not let go.

3. Now grab the recoil starter handle and slowly lift it towards the housing. There will be some resistance

and do not pull too hard. Wrap the Starter rope through the housing and seat the recoil starter housing.

4. You can now release the OPC/Brake lever.

12

HEIGHT OF CUT

To adjust the height of cut, the machine has been supplied with a single lever, located at the right rear wheel.

Adjusting the height of cut should only be undertaken when the engine is off, and the blade has come to a

complete standstill.

To adjust the height of cut, grab the height of cut lever and push it away from the gauge (1) and then lift or

lower the lever to the required height of cut (2).

Moving the lever forward will lower the height of cut (Min. 25mm). Moving the lever back, will raise the height

of cut (Max. 75mm)

SIDE DISCHARGE CHUTE

NOTE : When using the side discharge function. Remove the grass collector and plug the mulch plug into the

rear of the machine.

1. Unlock the side discharge cover and lift. Hook in the side discharge chute.

2. Allow the side discharge cover to secure onto the side discharge chute into position.

13

INSTRUCTION MANUAL

ENGINE OIL

1. Remove the oil filler cap with built in dipstick.

2. Fill the engine with 4-stroke SAE30 or 10W/30 air cooled lawnmower engine oil. DO NOT USE automotive

or marine oil. The use of a funnel will aid the filling. The engine capacity is 0.40L.

3. We recommend the dipstick on the oil filler cap is wiped with a clean cloth and dipped (without screwing

into the filler neck) to ensure the oil level remains between the minimum and maximum marks on the

dipstick.

4. Replace and tighten the oil filler cap with built in dipstick.

NOTE: Below 40F° (4°C) the use of SAE 30 will result in hard starting.

Above 80F° (27°C) the use of 10W-30 may cause increased oil consumption. Check oil level more frequently.

ENGINE STARTING & STOPPING PROCEDURE

(NOTE: STARTING AN ENGINE WITHOUT ENGINE OIL OR FUEL CAN SERIOUSLY DAMAGE THE MACHINE)

STARTING THE ENGINE (COLD)

1. Push the red engine primer bulb a maximum of 3 times.

FUELING THE MACHINE

OPERATION - ENGINE

FUEL & OIL

Operating the engine with insufficient oil, can have catastrophic consequences. Any failure caused by

YOUR MACHINE IS SUPPLIED WITHOUT ENGINE OIL OR PETROL

insufficient oil, will not be covered by the manufacturer’s warranty.

READ INSTRUCTIONS CAREFULLY.

WARNING

Fuel & its vapors are very flammable. Do not use or fuel the machine near a flame, sparks or while smoking.

running. Fuel the engine at least 15 metres away from your work area. Always fuel your machine outdoors.

IMPORTANT:

Fuel which is older than 30 days old can become stale and cause acid

essential carburettor components. This could result in starting issues which would not be covered by your

manufacturer’s warranty.

Ensure that any stored petrol is clearly marked in a separate appropriate canister for a maximum of 30 days,

if not mixed with a fuel additive. If the machine is not going to be used for a long period, drain the fuel tank,

start the engine and drain the carburetor of any remaining fuel.

To keep fuel fresh, we recommend you use SURE-START FUEL ADDITIVE (HP-199) from Handy Parts. A fuel

additive added to your fuel at the time of purchase, will help make your machine easier to start, extend the

shelf life of your fuel mixture for up to two years, keeps the carburettor & engine clean, plus reduces emissions

and increases fuel economy. A 250ml bottle of SURE-START FUEL ADDITIVE will treat 25 litres of fuel. Only use

4-stroke SAE30 or 10W/30 air cooled lawnmower engine oil. DO NOT USE automotive or marine oil.

Allow the engine to cool for more than 3 minutes, before re-fueling. Never fuel the machine with engine

& gum deposits in the fuel system or

Place the machine onto a solid flat surface, ensuring the engine is

not running. Let the engine rest for a minimum of two minutes. Fill

the fuel tank outdoors or in well-ventilated areas.

Unscrew the fuel cap slowly and fill the fuel tank with clean, less

than 30 days old unleaded petrol with an Octane rating of 87 (91

RON) or higher. Fill to a maximum of 80% capacity. This will allow

the fuel tank to expand. Fasten the fuel cap tightly, being careful not

to cross-thread. This will also prevent loosening through vibration

during use. Wipe away any spillage, with an appropriate material. If

the machine has continued leaks, the product should not be started.

Never use the machine with damaged ignition cable or spark plug

cap, as there is a risk of sparks.

WARNING

Fuel and its vapors are extremely flammable and explosive. Fire or

explosion can cause severe burns or death.

14

ENGINE OIL

1. Remove the oil filler cap with built in dipstick.

2. Fill the engine with 4-stroke SAE30 or 10W/30 air cooled lawnmower engine oil. DO NOT USE automotive

or marine oil. The use of a funnel will aid the filling. The engine capacity is 0.40L.

3. We recommend the dipstick on the oil filler cap is wiped with a clean cloth and dipped (without screwing

into the filler neck) to ensure the oil level remains between the minimum and maximum marks on the

dipstick.

4. Replace and tighten the oil filler cap with built in dipstick.

NOTE: Below 40F° (4°C) the use of SAE 30 will result in hard starting.

Above 80F° (27°C) the use of 10W-30 may cause increased oil consumption. Check oil level more frequently.

ENGINE STARTING & STOPPING PROCEDURE

(NOTE: STARTING AN ENGINE WITHOUT ENGINE OIL OR FUEL CAN SERIOUSLY DAMAGE THE MACHINE)

STARTING THE ENGINE (COLD)

1. Push the red engine primer bulb a maximum of 3 times.

15

INSTRUCTION MANUAL

2. Grab the recoil starter handle and pull lightly until resistance is felt, then pull rapidly.

3. The engine should start.

4. Rehouse the recoil starter handle. Do not let it go until housed to prevent damage.

5. If the engine does not start, run through from step 1 again, but press the primer bulb once only.

NOTE: if the engine won’t start after you have operated the starter several times, the engine may be

flooded with excess fuel. Use following procedure to clear and start a flooded engine.

1. Release the OPC/Brake lever.

2. Remove the spark plug, dry it, and then reinstall it.

NOTE: Install the spark plug carefully by hand, to avoid cross-threading. After the plug is seated tighten

1/8 to 1/4 turn with socket spanner of spark plug to compress the washer.

3. Pull the OPC/Brake lever towards the upper handle.

4. Operate the starter as described above.

STOPPING THE ENGINE

• Release the OPC/Brake lever. The engine will come to a stop and a couple of seconds later, the blade will

stop rotating.

2. Pull the OPC/Brake lever towards the main handle. Do not let go.

3. Grab the recoil starter handle and pull lightly until resistance is felt, then pull rapidly.

4. The engine should start.

5. Rehouse the recoil starter handle. Do not let it go until housed to prevent damage.

6. If the engine does not start, run through from step 2 again.

NOTE: If the engine won’t start after you have operated the starter several times, the engine may be flooded

with excess fuel. Use the following procedure to clear and start a flooded engine.

1. Release the OPC/Brake lever.

2. Remove the spark plug, dry it, and then reinstall it.

NOTE: Install the spark plug carefully by hand, to avoid cross-threading. After the plug is seated tighten 1/8

to 1/4 turn with socket spanner of spark plug to compress the washer.

3. Pull the OPC/Brake lever towards the upper handle.

4. Operate the starter as described above.

STARTING THE ENGINE (WARM/HOT)

1. Pull the OPC/Brake lever towards the main handle. Do not let go.

16

2. Grab the recoil starter handle and pull lightly until resistance is felt, then pull rapidly.

3. The engine should start.

4. Rehouse the recoil starter handle. Do not let it go until housed to prevent damage.

5. If the engine does not start, run through from step 1 again, but press the primer bulb once only.

NOTE: if the engine won’t start after you have operated the starter several times, the engine may be

flooded with excess fuel. Use following procedure to clear and start a flooded engine.

1. Release the OPC/Brake lever.

2. Remove the spark plug, dry it, and then reinstall it.

NOTE: Install the spark plug carefully by hand, to avoid cross-threading. After the plug is seated tighten

1/8 to 1/4 turn with socket spanner of spark plug to compress the washer.

3. Pull the OPC/Brake lever towards the upper handle.

4. Operate the starter as described above.

STOPPING THE ENGINE

• Release the OPC/Brake lever. The engine will come to a stop and a couple of seconds later, the blade will

stop rotating.

17

INSTRUCTION MANUAL

SIDE DISCHARGE CHUTE

NOTE : When using the side discharge function. Remove the grass collector and plug the mulch plug into

the rear of the machine.

1. Unlock the side discharge cover and lift. Hook in the side discharge chute.

2. Allow the side discharge cover to secure onto the side discharge chute into position.

3. Remove the grass collector. Place the grass collector in a safe place.

4. Insert the mulch plug into the rear of the machine.

5. Start the machine and mow. Grass will be discharged from the side discharge chute back to the floor.

NOTE: If any grass residue is caught in the side discharge chute, clean it using a brush. Do not remove

grass debris in the mower deck or on the blade by hand or with your feet. Instead use suitable tools such

as a brush or broom.

MULCH PLUG

NOTE: Mulching stops collection of grass into the rear collect o r.

1. Lift the rear cover and remove the grass collector.

2. Insert the mulch plug into the rear of the machine

3. Allow the rear collector to sit on the rear of the deck.

1. Start the machine and mow. The grass will be discharged back to the floor, under the deck in finely cut

particals providing nutriants to the ground.

MOWING INSTRUCTIONS

1. Walk, never run with the mower, be very careful when mowing un even or rough ground.

2. Be careful when changing the direction of the mower on a slope. Mow across the face of slopes, never

down or up.

3. Do not mow excessively steep slopes.

4. Best results will be achieved if the grass is dry. Wet grass will clog the blade & grass collection system.

5. Grass grows at different rates at different times of the year. Never use the lowest cutting height for the

first cut of the season or in drought conditions.

6. Do not remove grass debris in the mower deck or on the blade by hand or with your feet. Instead use

suitable tools such as a brush or broom.

7. Check that all nuts, bolts and screws are well tightened.

8. Before mowing, place the grass collector in its position.

9. Before mowing make sure that the blade and the blade fixing screw are securely fastened. When blade

cutting edges require re-sharpening, this must be done evenly on both sides, so as to prevent any

imbalance. If you are unsure how to sharpen the blade, please visit your local Approved Service Dealer.

If the blade is damaged, it must be replaced.

10. When mowing, always wear a long trousers and strong footwear.

11. Do not run the engine in an enclosed and/or poorly ventilated area, where gas of the engine contains

carbon monoxide, which are dangerous for your health.

12. Work only when there is enough light.

13. Turn off the engine if you must leave the lawnmower unattended.

14. Never lift the rear of the mower while starting the engine and never place your hands and feet

underneath the deck or into the rear discharge chute while the engine is running.

15. Never change in any way the rated speed of the engine.

16. On self-propelled mowers, disconnect the self-propelled system before starting the engine.

17. Never lift or carry the mower while the engine is running.

18. Stop the engine and remove the spark plug cover in these cases:

- Before any operation under the deck or the rear discharge chute.

- Before any maintenance, repairing or checking operations.

- Before carrying, lifting or removing the mower.

- If you leave the mower unattended or changing the cutting height.

- To remove and emptying the grass catcher.

- After hitting a foreign object, stop the engine and check thoroughly the mower in order to see if it

SELF-PROPELLED

To se l f-propel your lawnmower,

1. Start the engine as stated above.

2. Push the drive lever up to the main handle. The lawnmower will start to move with the engine running

18

and blade rotating. It is easier to manually push the machine a couple of steps and then engage the selfpropelled motion to ensure the grass is not damaged and the machine does not take off, away from the

user suddenly.

3. To stop the lawnmower moving, just simply release the drive lever in good time.

4. The self-propel speed has been set at the factory and cannot be adjusted.

MOWING WITH COLLECTOR

Always observe the strictest safety procedures when using the lawnmower. Carefully read the safety

instructions of this manual before using the lawnmower.

Never open the rear flap when the grass bag has been detached (to be emptied) and the engine is still

1. Select your required height of cut setting.

2. Start the engine and allow it to run and warm up. See Starting the Engine section of the manual.

3. Keep a firm grip on the upper handle with OPC/Brake lever always engaged when attempting to cut.

4. Pull the Drive lever up to the handle when you wish to self-propel.

EMPTYING THE GRASS BAG

As soon as grass clippings start to trail the lawnmower, it is time to empty the grass bag.

NOTE: Before taking off the grass collector, switch off the engine and wait until the blade has come to a

stop.

1. To take off the grass collector, use one hand to lift up the rear cover and the other to grab onto the grass

collector carry handle. The rear cover automatically falls down after removing the grass collector and

closes off the rear chute opening.

2. Empty the grass debris from the grass collector and refit.

NOTE: If any grass residue is caught in the discharge chute, clean it using a brush. Do not remove grass

debris in the mower deck or on the blade by hand or with your feet. Instead use suitable tools such as a

brush or broom. To ensure that the cut grass can be collected into the grass collector, the discharge

opening and inside the mower deck must be cleared of any blockage.

running. The rotating blade can cause serious injuries!

WARNING

SIDE DISCHARGE CHUTE

NOTE : When using the side discharge function. Remove the grass collector and plug the mulch plug into

the rear of the machine.

1. Unlock the side discharge cover and lift. Hook in the side discharge chute.

2. Allow the side discharge cover to secure onto the side discharge chute into position.

3. Remove the grass collector. Place the grass collector in a safe place.

4. Insert the mulch plug into the rear of the machine.

5. Start the machine and mow. Grass will be discharged from the side discharge chute back to the floor.

NOTE: If any grass residue is caught in the side discharge chute, clean it using a brush. Do not remove

grass debris in the mower deck or on the blade by hand or with your feet. Instead use suitable tools such

as a brush or broom.

MULCH PLUG

NOTE: Mulching stops collection of grass into the rear collect o r.

1. Lift the rear cover and remove the grass collector.

2. Insert the mulch plug into the rear of the machine

3. Allow the rear collector to sit on the rear of the deck.

1. Start the machine and mow. The grass will be discharged back to the floor, under the deck in finely cut

particals providing nutriants to the ground.

MOWING INSTRUCTIONS

1. Walk, never run with the mower, be very careful when mowing uneven or rough ground.

2. Be careful when changing the direction of the mower on a slope. Mow across the face of slopes, never

down or up.

3. Do not mow excessively steep slopes.

4. Best results will be achieved if the grass is dry. Wet grass will clog the blade & grass collection system.

5. Grass grows at different rates at different times of the year. Never use the lowest cutting height for the

first cut of the season or in drought conditions.

6. Do not remove grass debris in the mower deck or on the blade by hand or with your feet. Instead use

suitable tools such as a brush or broom.

7. Check that all nuts, bolts and screws are well tightened.

8. Before mowing, place the grass collector in its position.

9. Before mowing make sure that the blade and the blade fixing screw are securely fastened. When blade

cutting edges require re-sharpening, this must be done evenly on both sides, so as to prevent any

imbalance. If you are unsure how to sharpen the blade, please visit your local Approved Service Dealer.

If the blade is damaged, it must be replaced.

10. When mowing, always wear a long trousers and strong footwear.

11. Do not run the engine in an enclosed and/or poorly ventilated area, where gas of the engine contains

carbon monoxide, which are dangerous for your health.

12. Work only when there is enough light.

13. Turn off the engine if you must leave the lawnmower unattended.

14. Never lift the rear of the mower while starting the engine and never place your hands and feet

underneath the deck or into the rear discharge chute while the engine is running.

15. Never change in any way the rated speed of the engine.

16. On self-propelled mowers, disconnect the self-propelled system before starting the engine.

17. Never lift or carry the mower while the engine is running.

18. Stop the engine and remove the spark plug cover in these cases:

- Before any operation under the deck or the rear discharge chute.

- Before any maintenance, repairing or checking operations.

- Before carrying, lifting or removing the mower.

- If you leave the mower unattended or changing the cutting height.

- To remove and emptying the grass catcher.

- After hitting a foreign object, stop the engine and check thoroughly the mower in order to see if it

19

INSTRUCTION MANUAL

REMOVE ENGINE OIL

CAUTION

Used oil is a hazardous waste product and must be disposed of properly. Do not discard with household

waste. Check with your local authorities, service center, or dealer for safe disposal/recycling facilities.

WARNING

Before draining any oil, ensure the fuel tank is empty. Fuel can leak out and result in a fire or explosion. To

empty the fuel tank, run the engine until it stops from lack of fuel.

• Draining the oil can only be undertaken from the oil filler neck.

• Turn off the engine.

• Remove the spark plug cap and keep away from the spark plug.

• Drain while the engine is still warm to assure rapid and complete drainage.

• Remove the oil filler cap with dipstick.

• Place an approved container below the machine.

• Ensure you keep the spark plug end of the engine up.

• Install Oil drain plug and wrench tighten.

• Refill with the recommended oil and check its level as required, following instructions within this manual.

Oil capacity: See Specification section of this manual.

Wash your hands with soap and water after touching used oil.

NOTE: Please dispose of used motor oil in a manner that is compatible with the environment. We suggest

you put it in a sealed container to your local service for reclamation. Do not throw it away into the refuge

collection or pour it on the ground or in drains.

AIR FILTER

A dirty air filter will block air flow into the carburettor. To prevent carburettor malfunction, service the air filter

regularly. Service more frequently when operating the engine in extremely dusty areas.

1. Remove the air filter cover. Remove the filter. Carefully check both for holes and tears and replace it if

damaged.

2. Foam element: clean in warm soapy water, rinse and allow to dry thoroughly or clean in high flash-point

solvent and allow to dry. Dip the element in clean engine oil and squeeze out all the excess. The engine

will smoke during initial start-up if too much oil is left in the foam.

WARNING

Never use gasoline or low flash point solvents to clean the air cleaner element. A fire or explosion

could occur.

CAUTION

Never run the engine without air filter or rapid engine wear will be the result.

is damaged. Take the machine to a local Approved Service Dealer for inspection if necessary.

MAINTENANCE, CLEANING & STORAGE

Improper maintenance & storage of the machine may void your warranty. Keep the machine clean for better

Turn off the engine before performing any maintenance. If the engine must be run, make sure the area is

MAINTENANCE

Use only original equipment replacement parts. Other parts may not perform as well, may damage the unit

and may result in injury. In addition, use of other parts may invalidate your warranty.

• Before each use, check all nuts & bolts to be sure they are sufficiently tightened.

• We recommend only manufacturer original parts are used when maintaining this machine. Failure to do so

• The engine must be switched off, with the spark plug cap removed, before the machine is unassembled,

LUBRICATION

• WHEELS - Lubricate the ball bearings in each wheel at least once a season with a light oil.

20

Repairs of this nature are not covered under the Manufacturer’s warranty.

- If the mower vibrates in an abnormal way, find the reasons why, and take your mower to a local

Approved Service Dealer.

After the engine has stopped, the blade will still rotate a couple of seconds.

Allowing anyone to operate this machine without proper instruction may result in injury.

Wear sturdy, full coverage footwear. Operating this machine with bare feet, or with open toe shoes or

Be sure to transport the machine from one place to another with the engine off.

Be sure to wear heavy gloves when cleaning underside of the deck or handling the blade.

To prevent damage, check the machine for any signs of damage or other faults when operated.

could invalidate your manufacturer’s warranty.

cleaned, serviced or maintained.

Operating on gradients could cause the machine to tip over.

sandals increases your risk of injury.

Do not use the machine at night or in poor light.

and safer performance.

well ventilated. The exhaust emits dangerous carbon monoxide gases.

WARNING

CAUTION

WARNING

REMOVE ENGINE OIL

CAUTION

Used oil is a hazardous waste product and must be disposed of properly. Do not discard with household

waste. Check with your local authorities, service center, or dealer for safe disposal/recycling facilities.

WARNING

Before draining any oil, ensure the fuel tank is empty. Fuel can leak out and result in a fire or explosion. To

empty the fuel tank, run the engine until it stops from lack of fuel.

• Draining the oil can only be undertaken from the oil filler neck.

• Turn off the engine.

• Remove the spark plug cap and keep away from the spark plug.

• Drain while the engine is still warm to assure rapid and complete drainage.

• Remove the oil filler cap with dipstick.

• Place an approved container below the machine.

• Ensure you keep the spark plug end of the engine up.

• Install Oil drain plug and wrench tighten.

• Refill with the recommended oil and check its level as required, following instructions within this manual.

Oil capacity: See Specification section of this manual.

Wash your hands with soap and water after touching used oil.

NOTE: Please dispose of used motor oil in a manner that is compatible with the environment. We suggest

you put it in a sealed container to your local service for reclamation. Do not throw it away into the refuge

collection or pour it on the ground or in drains.

AIR FILTER

A dirty air filter will block air flow into the carburettor. To prevent carburettor malfunction, service the air filter

regularly. Service more frequently when operating the engine in extremely dusty areas.

1. Remove the air filter cover. Remove the filter. Carefully check both for holes and tears and replace it if

damaged.

2. Foam element: clean in warm soapy water, rinse and allow to dry thoroughly or clean in high flash-point

solvent and allow to dry. Dip the element in clean engine oil and squeeze out all the excess. The engine

will smoke during initial start-up if too much oil is left in the foam.

WARNING

Never use gasoline or low flash point solvents to clean the air cleaner element. A fire or explosion

could occur.

CAUTION

Never run the engine without air filter or rapid engine wear will be the result.

21

INSTRUCTION MANUAL

STORAGE & TRANSPORT

The following steps should be taken to prepare your machine for storage.

STORING THE LAWNMOWER FOR SHORT PERIODS

The lawnmower can be stored for short periods of time (less than 15 days) without performing any storage

maintenance.Before placing the lawnmower into storage always carry out the following:

1. Allow the engine to fully cool.

2. Ensure the grass collector is empty.

3. Clean all debris from under the mower deck.

4. Store the lawnmower on a flat and level surface with the mower upright.

5. Store in a safe place which is not accessible by children or people who are not familiar with operation.

STORING THE LAWNMOWER FOR EXTENDED PERIODS

If the lawnmower is to be place into storage for more than 15 days, storage maintenance must be performed

on the lawnmower. If the following steps are not carried out, when you next operate the lawnmower it may

not start correctly and may need to be serviced.

CAUTION

Do not empty the petrol tank in enclosed areas, near fire or when smoking. Petrol fumes can cause

explosions and fire

1. Empty the petrol tank with a petrol suction pump if available.

2. Alternatively, start the engine and let it run until any remaining petrol has been used up.

3. Change the oil at the end of every season. See removing oil within this manual.

4. Clean the cooling fins of the cylinder and the housing

5. Be sure to clean the entire machine to protect the paint.

6. Store the machine in a well-ventilated place.

7. Remove the spark plug. Use an oil can to fill approx. 20 ml oil into the combustion chamber. Operate the

starter to evenly distribute the oil in the combustion chamber. Replace the spark plug.

2. Store in a dry, clean and frost-protected place, out of reach of unauthorised persons.

CAUTION

The engine must have completely cooled down before storing.

NOTE:

When storing any type of power equipment in an unventilated or material storage shed,

− Care should be taken to rust-proof the equipment. Using a light oil or silicone, coat the equipment,

especially cables and all moving parts.

− Be careful not to bend or kink cables.

− If the starter rope becomes disconnected from rope guide on handle, disconnect and ground the spark

plug wire. Depress the blade control handle and pull the starter rope out from engine slowly. Slip the

starter rope into the rope guide bolt on handle.

DO NOT STORE fuel for longer than 30 days. Fuel can become stale and cause damage to the engine

carburetor, which is not covered by the machines manufacturer’s warranty.

SPARK PLUG

To ensure proper engine operation, the spark plug must be properly gapped and free of deposits.

1. Do not attempt to remove the plug from a hot engine in order to avoid possible damage to the threads.

2. Remove the spark plug cap.

If the engine has been running, the exhaust (muffler) will be very hot. Be careful not to touch the exhaust

3. Visually inspect the spark plug. Discard it if the insulator is cracked or chipped.

4. Measure the plug gap with a feeler gauge. The gap should be 0.7-0.8mm (0.028-0.031 in), correct as

22

necessary by bending the side electrode.

5. Attach the plug washer, thread the plug in by hand to prevent cross-threading.

6. When mounting a new spark plug, you should screw 1/2 more thread with the wrench after the washer is

compressed. If you are mounting an old one, you should only screw 1/8-1/4 more thread.

The spark plug must be securely tightened. An improperly tightened plug can become very hot and possibly

CLEANING

Do not use a water hose or pressure washer to clean the engine. Water can damage the engine or

• Keep your machine clean. Thoroughly clean the machine at the end of each use, paying attention to

stones or mud in and around the tines.

• Clean the engine regularly with a cloth or brush. Keep the cooling system (blower housing area) clean to

permit proper air circulation which is essential to engine performance and life. Be certain to remove all

dust, dirt and combustible debris from exhaust area.

damage the engine. Never use a spark plug with an improper heat range.

contaminate the fuel system.

WARNING

(muffler).

CAUTION

CAUTION

STORAGE & TRANSPORT

The following steps should be taken to prepare your machine for storage.

STORING THE LAWNMOWER FOR SHORT PERIODS

The lawnmower can be stored for short periods of time (less than 15 days) without performing any storage

maintenance.Before placing the lawnmower into storage always carry out the following:

1. Allow the engine to fully cool.

2. Ensure the grass collector is empty.

3. Clean all debris from under the mower deck.

4. Store the lawnmower on a flat and level surface with the mower upright.

5. Store in a safe place which is not accessible by children or people who are not familiar with operation.

STORING THE LAWNMOWER FOR EXTENDED PERIODS

If the lawnmower is to be place into storage for more than 15 days, storage maintenance must be performed

on the lawnmower. If the following steps are not carried out, when you next operate the lawnmower it may

not start correctly and may need to be serviced.

CAUTION

Do not empty the petrol tank in enclosed areas, near fire or when smoking. Petrol fumes can cause

explosions and fire

1. Empty the petrol tank with a petrol suction pump if available.

2. Alternatively, start the engine and let it run until any remaining petrol has been used up.

3. Change the oil at the end of every season. See removing oil within this manual.

4. Clean the cooling fins of the cylinder and the housing

5. Be sure to clean the entire machine to protect the paint.

6. Store the machine in a well-ventilated place.

7. Remove the spark plug. Use an oil can to fill approx. 20 ml oil into the combustion chamber. Operate the

starter to evenly distribute the oil in the combustion chamber. Replace the spark plug.

2. Store in a dry, clean and frost-protected place, out of reach of unauthorised persons.

CAUTION

The engine must have completely cooled down before storing.

NOTE:

When storing any type of power equipment in an unventilated or material storage shed,

− Care should be taken to rust-proof the equipment. Using a light oil or silicone, coat the equipment,

especially cables and all moving parts.

− Be careful not to bend or kink cables.

− If the starter rope becomes disconnected from rope guide on handle, disconnect and ground the spark

plug wire. Depress the blade control handle and pull the starter rope out from engine slowly. Slip the

starter rope into the rope guide bolt on handle.

DO NOT STORE fuel for longer than 30 days. Fuel can become stale and cause damage to the engine

carburetor, which is not covered by the machines manufacturer’s warranty.

23

INSTRUCTION MANUAL

PROBLEM

POSSIBLE CAUSES

REMEDIAL ACTION

Fill tank with fuel: refer to ENGINE

OWNERS MANUAL.

Spark plug loose.

Tighten spark plug.

Spark plug wire loose or

disconnected from plug.

Install spark plug wire on spark

plug.

Set correct gap between

electrodes.

Spark plug is defective.

Install new, correctly gapped plug.

Remove air cleaner element and

install air cleaner element.

Fuel becomes stale after 30 days

Dealer.

Clean air filter: refer to relevant

section in manual

REPLACEMENT PARTS

Please find on the following pages, parts lists and drawings for your machine. Should you require a replacement

part, please call our Spares Team on 01793 333212, option 1 for assistance.

Webb recommends the use of Handy Parts oils, fuel additives, nylon lines pre-packed parts for all of items

machines.

TRANSPORT

• Empty the petrol tank

• Always let the engine run until it has used up the remainder of petrol in the tank.

• Empty the engine oil from the warm engine.

• Remove the spark plug boot from the spark plug.

• Clean the cooling fins of the cylinder and the housing.

• Use the original packaging to ship whenever possible.

TROUBLE SHOOTING

Fuel tank is empty.

Spark plug gap is incorrect

Engine does not start

Carburettor is flooded with fuel.

Old Fuel

Motor speed drops off Air filter clogged

pull starter rope continuously

until carburetor clears itself and

and causes residues to build and

‘gunk up’ the carburettor. Change

fuel with fresh. If problem persists

consult local Approved Service

24

REPLACEMENT PARTS

Please find on the following pages, parts lists and drawings for your machine. Should you require a replacement

part, please call our Spares Team on 01793 333212, option 1 for assistance.

Webb recommends the use of Handy Parts oils, fuel additives, nylon lines pre-packed parts for all of items

machines.

25

INSTRUCTION MANUAL

PARTS LIST - DVO140 - PT 1

Item No

Webb Part No.

Webb Description

Qty

1

WE151-91365

M6x12 Bolt

7

2

WE151-311101

Cylinder Head Cover

1

3

WE151-96161

Cylinder Gasket

1

4

WE151-312101

Rocker Arm

2

5

WE151-312201

Push Rod Guide Plate

1

6

WE151-311802

Valve Spring Seat

2

7

WE151-316001

Valve Spring

2

8

WE151-311801

Intake Valve Returner

2

9

WE151-311701

Intake Valve

1

10

WE151-315901

Exhaust Valve

1

11

WE151-97109

Spark Plug

1

12

WE151-316302

Recoil Housing

1

13

WE151-91369

M6x25 Bolt

1

14

WE151-313701

Muffler Assembly

1

15

WE151-314302

Governor Plate

1

16

WE151-311901

Push Rod

2

17

WE151-316101

Valve Lifter

2

18

WE155-312003

Camshaft Assembly

1

19

WE151-311602

Piston Ring Set

1

20

WE155-311202

Piston

1

21

WE155-315502

Piston Pin

1

22

WE151-291301

Piston Clip

2

23

WE151-311501

Connecting Rod Assembly

1

24

WE151-310202

Cylinder

1

25

WE155-93517

Oil Seal

1

26

WE155-90030

M6 Flange Nut

3

27

WE151-91829

Rocker Arm Adjuster

2

28

WE151-310505

Deflector

1

29

WE155-315201

Brake Assembly

1

30

WE151-300605

Circular Plate

1

31

WE151-310606

Breather Valve Spring

1

32

WE151-91038

Stud Bolt

2

33

WE151-293601-055

Fuel Cap Assembly

1

34

WE151-293206-055

Fuel Tank

1

35

WE151-300505

Deflector

1

36

WE151-92007

M4x8 Screw

1

37

WE151-91370

M6x16 Bolt

3

38

WE151-299901

Fuel Filter

1

39

WE151-94403

Fuel Pipe Clamp Ф7.5

1

40

WE151-95457

Fuel Pipe

1

41

WE151-313901

Governor Arm Shaft

1

42

WE151-96808

Governor Arm Shaft Washer

1

43

WE151-93520

Governor Arm Shaft Seal

1

44

WE151-243902

Lock Pin

1

45

WE151-314001

Governor Arm

1

PARTS DIAGRAM - DVO140

26

Item No

Webb Part No.

Webb Description

Qty

1

WE151-91365

M6x12 Bolt

7

2

WE151-311101

Cylinder Head Cover

1

3

WE151-96161

Cylinder Gasket

1

4

WE151-312101

Rocker Arm

2

5

WE151-312201

Push Rod Guide Plate

1

6

WE151-311802

Valve Spring Seat

2

7

WE151-316001

Valve Spring

2

8

WE151-311801

Intake Valve Returner

2

9

WE151-311701

Intake Valve

1

10

WE151-315901

Exhaust Valve

1

11

WE151-97109

Spark Plug

1

12

WE151-316302

Recoil Housing

1

13

WE151-91369

M6x25 Bolt

1

14

WE151-313701

Muffler Assembly

1

15

WE151-314302

Governor Plate

1

16

WE151-311901

Push Rod

2

17

WE151-316101

Valve Lifter

2

18

WE155-312003

Camshaft Assembly

1

19

WE151-311602

Piston Ring Set

1

20

WE155-311202

Piston

1

21

WE155-315502

Piston Pin

1

22

WE151-291301

Piston Clip

2

23

WE151-311501

Connecting Rod Assembly

1

24

WE151-310202

Cylinder

1

25

WE155-93517

Oil Seal

1

26

WE155-90030

M6 Flange Nut

3

27

WE151-91829

Rocker Arm Adjuster

2

28

WE151-310505

Deflector

1

29

WE155-315201

Brake Assembly

1

30

WE151-300605

Circular Plate

1

31

WE151-310606

Breather Valve Spring

1

32

WE151-91038

Stud Bolt

2

33

WE151-293601-055

Fuel Cap Assembly

1

34

WE151-293206-055

Fuel Tank

1

35

WE151-300505

Deflector

1

36

WE151-92007

M4x8 Screw

1

37

WE151-91370

M6x16 Bolt

3

38

WE151-299901

Fuel Filter

1

39

WE151-94403

Fuel Pipe Clamp Ф7.5

1

40

WE151-95457

Fuel Pipe

1

41

WE151-313901

Governor Arm Shaft

1

42

WE151-96808

Governor Arm Shaft Washer

1

43

WE151-93520

Governor Arm Shaft Seal

1

44

WE151-243902

Lock Pin

1

45

WE151-314001

Governor Arm

1

PARTS LIST - DVO140 - PT 2

Item

No

46

WE151-91066

Recoil Stud Bolt 2

1

47

WE155-90016

M6 Nut

2

48

WE155-312701

Governor Rod

1

49

WE155-314201

Throttle Return Spring

1

50

WE155-314102

Governor Spring

1

51

WE151-90036

Nut

2

52

WE155-314401

Upper Shroud Assembly

1

53

WE151-95626

Breather Tube

1

54

WE155-210801

Q-Type Line Card

1

55

WE155-310305

Crankshaft

1

56

WE151-90037

Nut

2

57

WE151-94225

Crankshaft Washer

1

58

WE151-314303

Governor Assembly

1

59

WE151-96162

Breather Chamber Gasket

1

60

WE151-310602

Breather Chamber Cap

1

61

WE151-310901

Dowel Pin

2

62

WE151-310102

Crankcase Cover Assembly

1

63

WE151-93523

Oil Seal

1

64

WE151-91366

M6x18 Bolt

6

65

WE151-91367

M6x45 Bolt

2

66

WE155-95904

Tube

1

67

WE151-94415

Fuel Pipe Clip

3

68

WE151-315601-138

Dipstick

1

69

WE151-90038

M6 Nut

2

70

WE151-310608

Breather Filter

1

71

WE155-97566

Ignition Coil Assembly

1

72

WE151-91064

Ignition Coil Stud Bolt

1

73

WE151-91065

Recoil Stud Bolt 1

1

74

WE155-310403

Flywheel Assembly

1

75

WE151-304602

Recoil Starter Fan

1

76

WE151-304501

Starter Pulley

1

77

WE151-90003

Nut

1

78

WE155-292506

Muffler Shield

1

79

WE152-96130

Air Filter Gasket

1

80

WE155-312901

Air Filter Assembly

1

81

WE151-91039

Stud Bolt

2

82

WE151-96128

Intake Gasket

1

83

WE151-312301

Carburettor Insulator

1

84

WE151-96129

Carburettor Gasket

1

85

WE155-312802

Carburettor Assembly

1

86

WE155-96168

Exhaust Gasket

1

87

WE151-294909-053

Engine Cover

1

88

WE155-294802-053

Recoil Assembly

1

89

WE151-91816

Drain Bolt

1

90

WE151-94007

Drain Bolt Washer

1

Webb Part No. Webb Description Qty

27

INSTRUCTION MANUAL

PARTS LIST - WER460SP (1938220001) - PT 1

Item

No

Webb Part No.

Webb Description

Qty

1

WE153-91221

Bolt 3/8-24UNFX38

1

2

WE153-94042

Flat Washer

1

3

WE153-602001

Blade Washer

1

4

WE158-602002

Blade (460mm)

1

5

WE153-602003

Blade Adapter

1

6

WE158-602004

Blade Adapter Bush

1

7

WE153-296510

Key

1 8 WE154-91304

Bolt M6x16

2

9

WE158-606109

Belt Cover

1

10

WE153-90060

Nut M6

14

11

WE154-606011

Pulley

1

12

WE154-91405

Bolt M6x8

1

13

WE158-606088

Belt VZ762

1

14

WE154-92139

Screw KAL50x12

11

15

WE154-296501

Key

1

16

WE158-601168-333

Cutting Deck

1

17

WE154-606003

Front Wheel Shaft Retaining Plate

2

18

WE154-92111

Bolt M6x14

8

19

WE158-91347

Bolt M8x30

3

20

WE149-94040

Spring Washer

3

21

WE149-94041

Washer 8.4x24x2

4

22 Engine DVO140

1

23

WE153-94036

Circlip Φ5

3

24

WE153-604016

Left Torsional Spring

1

25

WE158-604039

Rear Cover Axle

1

26

WE158-604090

Rear Cover

1

27

WE153-604045

Right Torsional Spring

1

28

WE154-606160

Nylon Collar

2

29

WE154-606009

Rear Wheel Shaft Retaining Plate

2

30

WE154-601005

Cable Bush

1

PARTS LIST - WER460SP (1938220001) - PT 3

Item No

Webb Part No.

Webb Description

Qty

61

WE154-606006

Wheel (8")

2

62

WE154-606008

Inner Wheel Cover (8")

2

63

WE158-604008

Side Discharge Chute

1

64

WE158-604001

Side Discharge Spring

1

65

WE158-604012

Side Discharge Bracket

1

66

WE158-604010

Side Discharge Axle

1

67

WE158-91406

Bolt M6x14

2

68

WE158-604009

Side Discharge Cover

1

69

WE149-90057

Nut M10x1.5

4

70

WE153-605006

Stem

2

71

WE153-94046

Flat Washer

4

72

WE158-606005

Front Axle

1

73

WE154-606004

Front Axle Hoop

2

74

WE153-606001-198

Wheel Cover ("7)

2

75

WE153-606002

Wheel (7")

2

76

WE154-94049

Circlip

4

77

WE154-606013

Right Drive Cog

1

78

WE153-603002

Height Adjuster Plate

1

79

WE153-603003-198

Height Adjuster Handle

1

PARTS DIAGRAM - WER460SP (1938220001)

28

Item

No

Webb Part No. Webb Description Qty

1

WE153-91221

Bolt 3/8-24UNFX38

1

3

4

WE158-602002

Blade (460mm)

1

5

WE153-602003

Blade Adapter

1

6

WE158-602004

Blade Adapter Bush

1

8

WE154-91304

Bolt M6x16

2

10

11

Pulley

1

12

WE154-91405

Bolt M6x8

1

13

WE158-606088

Belt VZ762

1

15

16

WE158-601168-333

Cutting Deck

1

17

WE154-606003

Front Wheel Shaft Retaining Plate

2

18

WE154-92111

Bolt M6x14

8

20

WE149-94040

Spring Washer

3

22

23

WE153-94036

Circlip Φ5

3

24

WE153-604016

Left Torsional Spring

1

25

WE158-604039

Rear Cover Axle

1

27

28

WE154-606160

Nylon Collar

2

29

WE154-606009

Rear Wheel Shaft Retaining Plate

2

30

WE154-601005

Cable Bush

1

PARTS LIST - WER460SP (1938220001) - PT 2

Item No

Webb Part No.

Webb Description

Qty

31

WE158-604004

Deck Rear Panel

1

32

34

WE153-91868

Bolt M8x45

4

35

WE154-599601

Wire Harness Clip

1

37

WE158-601098

Left Handle Support

1

39

WE158-605005

Lower Handle

1

40

WE153-605221

Cable Clip

2

42

43

WE153-91870

Bolt M6x35

1

44

WE153-605010-136

OPC/Brake Lever

1

45

WE153-605007-053

Soft Grip (Come's with 42)

1

47

48

WE153-90016

Nut M6

1

49

WE149-94057

Washer Φ8.4*20*2

3

50

WE153-90061

Nut M6

2

52

53

WE154-606016

Return Spring

1

54

WE158-601099

Right Handle Support

1

55

WE153-91404

Bolt M6x14

4

57

58

WE158-604046-010

Collection Bag Frame

1

59

WE153-605002-198

Large Handle Knob

2

60

WE153-606007-198

Wheel Cover (8")

2

Item No

Webb Part No.

Webb Description

Qty

61

WE154-606006

Wheel (8")

2

62

WE154-606008

Inner Wheel Cover (8")

2

63

WE158-604008

Side Discharge Chute

1

64

WE158-604001

Side Discharge Spring

1

71

WE153-94046

Flat Washer

4

72

WE158-606005

Front Axle

1

73

WE154-606004

Front Axle Hoop

2

74

WE153-606001-198

Wheel Cover ("7)

2

75

WE153-606002

Wheel (7")

2

76

WE154-94049

Circlip

4

PARTS LIST - WER460SP (1938220001) - PT 3

Item No

Webb Part No.

Webb Description

Qty

61

WE154-606006

Wheel (8")

2

62

WE154-606008

Inner Wheel Cover (8")

2

63

WE158-604008