Page 1

Operation/Installation Manual - WBCC Series - Page : 1

Operation/Installation Manual - WBCC Series - Page : 1

Edition dated 1st January 2004

D

I

G

I

T

A

L

C

O

N

T

R

O

L

P

A

N

E

L

F

U

N

C

T

I

O

N

I

N

G

P

R

I

N

C

I

P

L

E

S

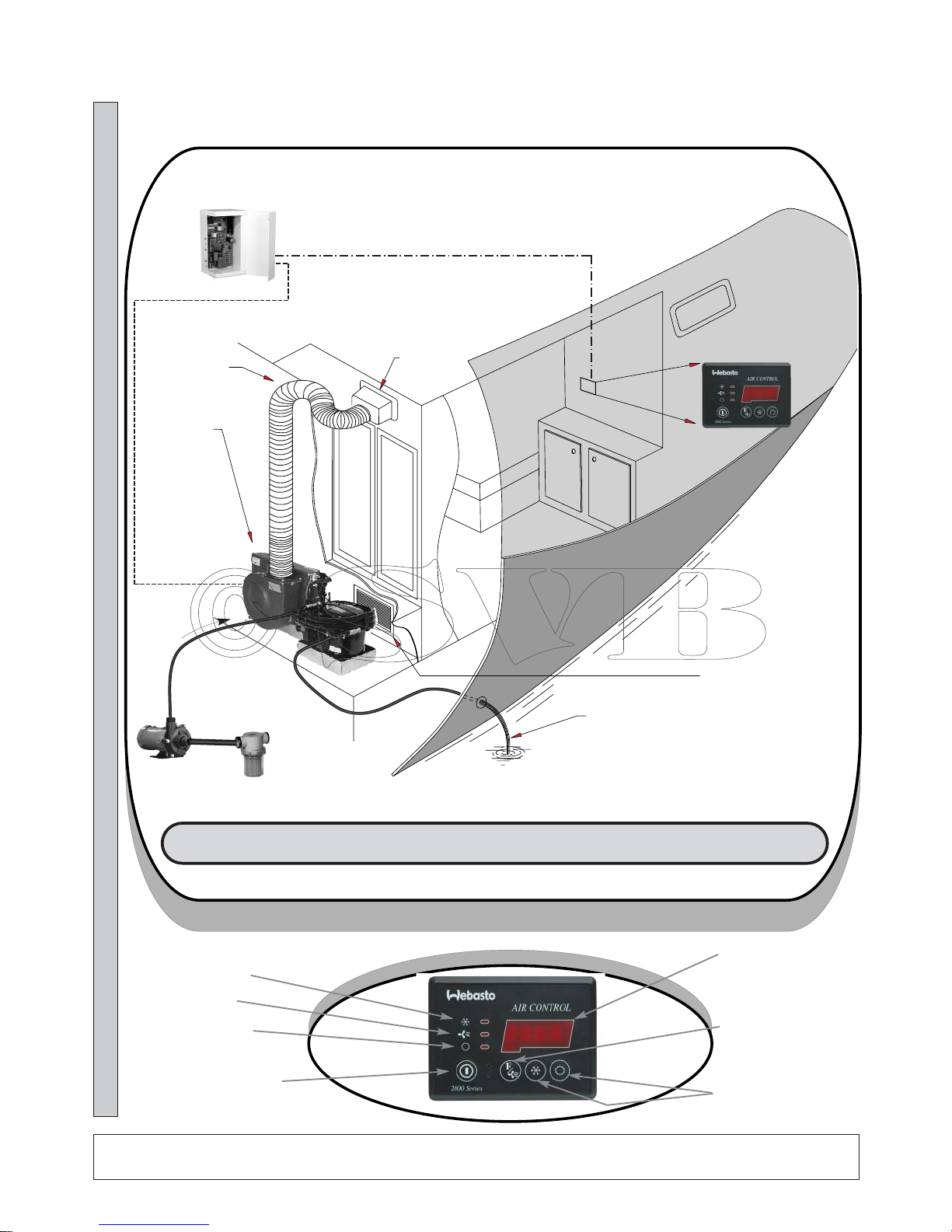

Webasto

- AIR CONDITIONING

SEA-WATER PUMP

ELETRICAL

CONTROL

BOX

SELF-CONTAINED CPAC

UNIT - 7000 TO 32000 BTU

- BLOWER EXIT TURNED

UPWARDS

FLEXIBLE AIR DUCT

TRANSITION BOX + SUPPLY

AIR-GRILLE

RETURN AIR-GRILLE

STRAINER

OVER-BOARD DISCHARGE

DIGITAL CONTROL

PANEL

DISPLAY CABLE

POWER CABLE

SELF-CONTAINED UNITS - WBCC SERIES

OPERATION AND INSTALLATION MANUAL

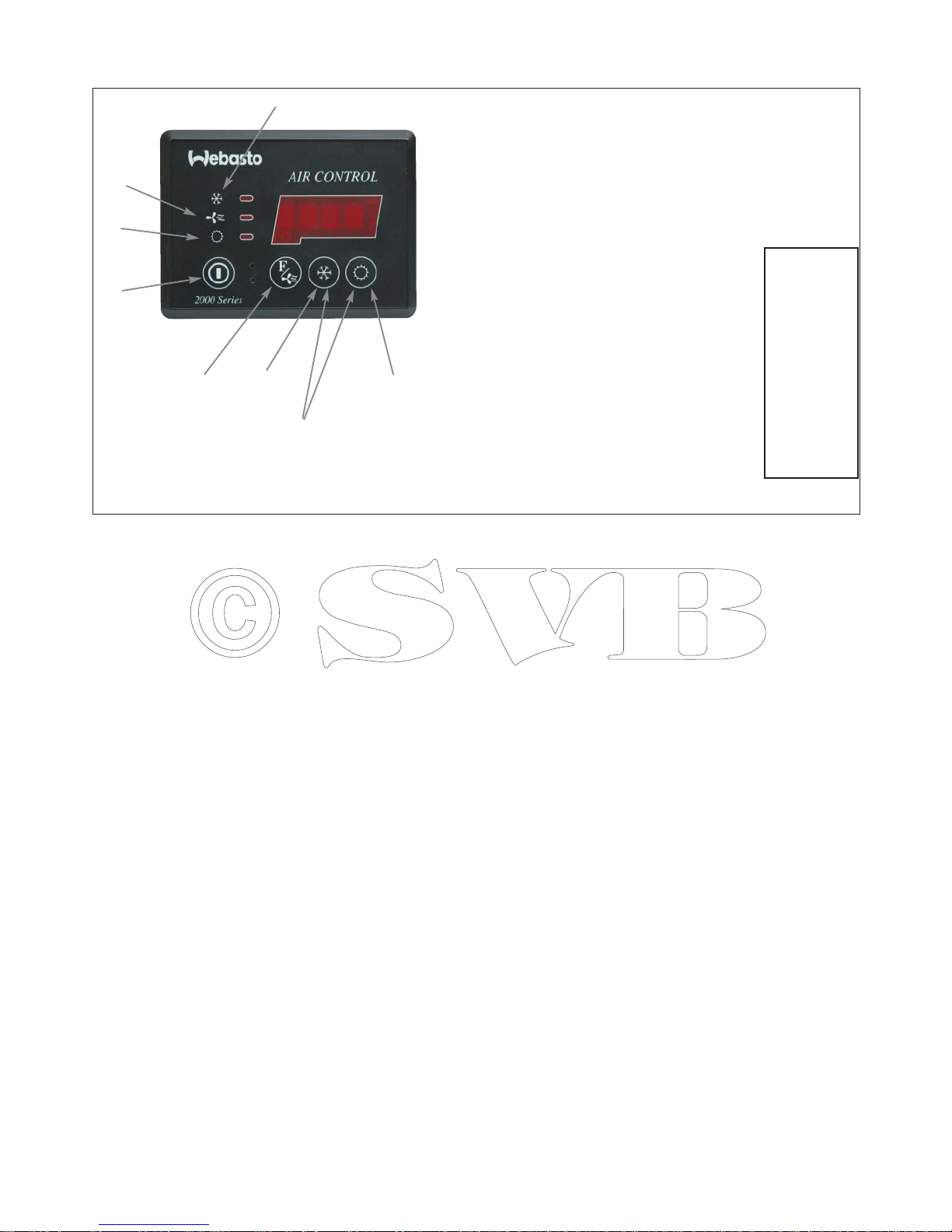

COOL CYCLE LED

BLOWER LED

ROOM TEMPERATURE OR

SET-POINT TEMPERATURE

OR SECONDARY FUNCTION

READ-OUT

SET-POINT MODIFICATION

KEYS

F/BLOWER KEY - GIVES

ACCESS TO BLOWER SPEED

CONTROL AND SECONDARY

FUNCTIONS

HEAT CYCLE LED

ON/OFF KEY

SELF CONTAINED UNITS

NNEEWW EELLEECCTTRROONNIICCSS -- 22000000 SSEERRIIEESS

19.4

Page 2

Operation/Installation Manual - WBCC Series - Page : 2

Operation/Installation Manual - WBCC Series - Page : 2

Edition dated 1st January 2004

SELF-CONTAINED AIR-CONDITIONING UNITS - WBCC SERIES

OPERATION AND INSTALLATION MANUAL

C O N T E N T S

Page

1) General Information ..................................................................................................

2) Digital Control - Operation Guidelines .....................................................................

2.1 - Digital Display <AIR CONTROL> - Basic Commands ...................................

3) Secondary Commandes by F/Blower key .................................................................

4) Visual Error Codes - Digital Display ........................................................................

5) Central Blower Control ...........................................................................................

6) Programmable Functions ...........................................................................................

6.1 - Digital Display <AIR CONTROL> - Programming access .............................

7) Pratical Installation Guide - Components (Pumps, accessories, etc) .......................

8) Routine Checks ........................................................................................................

8A) Trouble Shooting .....................................................................................................

9) Air-Ducting and V entilation .......................................................................................

10) Wirings Schematics .................................................................................................

10.1 - Wiring diagram - WBCC 5 to 16 - single phase - Rotary compressors ...........

10.2 - Wiring diagram - WBCC 24 and 30 - single phase - Rotary/Scroll compr. .....

10.3 - Wiring diagram - WBCC 5 to 16 - single phase - Piston Compr. (<2000) .....

10.3 - Wiring diagram - Wiring Running Capacitor - Blowers ...............................

3

4

4

5

5

5

7

7

8

9

9

10

11

11

12

13

13

Page 3

1. GENERAL INFORMATION

All WEBASTO air conditioning units are

controlled by a Digital Display <AIR

CONTROL> which gives access to all

functions necessary for the normal operation of the unit and attached accessories

(blowers, pumps, etc).

All WEBASTO air conditioning units are

sea-water cooled by means of an AC seawater pump.

In order to start the system you only need

to press the <POWER> key on the digital

display.

From there on the electronic control unit

takes care of the progressive starting up of

the air conditioning unit as well as it normal functioning.

The digital display will show the present

air temperature of the cabin in which the

digital display is situated or where the

main temperature sensor is located (in

case the optional secondary temperature

sensor is used).

After a delay of approx. 20 seconds the

display will indicate the cycle in which

operation will start i.e. <COOL> or

<HEAT>. The choice will depend upon

the set-point temperature and the air-temperature as measured by the display panel.

After a further delay of approx. 50 seconds the compressor(s) will start up and

the normal operation cycle will begin.

2000 SERIES DIGITAL DISPLAY

As from September 2000 all WEBASTO air

conditioning units are controlled by a Digital

Display <AIR CONTROL> 2000 SERIES

which gives access to all functions necessary

for the normal operation of the unit and

attached accessories (blowers, pumps, etc).

2000 Series Electronic Controls are easily

All air-conditioning units based on hermetic compressors function on the same

principle : a compressor compresses the

refrigerant gas which is then condensed to

liquid when passing through a sea-water

cooled condenser. Subsequently the liquid

refrigerant is injected through a small

nozzle and evaporates. This evaporation

process produces the refrigeration effect.

The evaporation takes place in a tubular

finned coil (also called : evaporator coil).

A blower forces the air through the evap-

orator coil.

While passing through the evaporator the

temperature of the air is lowered by

approximately 15 °C.

So far for the general principles.

HOW DOES IT WORK ?

COPPER TUBING OF

FINNED EVAPORATOR

FINNED TUBULAR

EVAPORATOR COIL

CONDENSER

EXIT

BLOWER EXIT

BLOWER

STAINLESS

STEEL DRAIN

PAN

CUPRO-NICKEL

CONDENSER

CONDENSER

ENTRY

REVERSED CYCLE VALVE

COOL/HEAT

HEAT CYCLE

It is quite possible to produce heat

with an air-conditioning unit. For

this purpose a 4-way reversed cycle

valve is added. During heat cycle

operation the sea-water condenser

effectively becomes the evaporator

and cools down the sea-water. The

finned evaporator becomes the condenser and produces heat to approx.

45/50° C.

Heat cycle becomes inefficient

when the outside water temperature

drops below 6° C approx.

STANDARD ELECTRICAL ACCESSORIES

ELECTRICAL CONTROL BOX

DIGITAL DISPLAY PANEL

MINIMUM STANDARD CONTROL ELEMENTS DELIVERED FOR ALL CPAC SELF-CONTAINED UNITS

Summary : 1 Alu control box + 1 display cable + 1 digital control panel (External air-sensor is optional)

104

DISPLAY CABLE

OPTIONAL EXTERNAL AIR SENSOR

76

Operation/Installation Manual - WBCC Series - Page : 3

Operation/Installation Manual - WBCC Series - Page : 3

Edition dated 1st January 2004

P

P = 132 mm

262

130

19.4

Page 4

recognized by the inscription <2000 Series>

at the bottom left hand corner of each digital

display.

All WEBASTO air conditioning units are

sea-water cooled by means of an AC seawater pump.

In order to start the system you only need to

press the <POWER> key on the digital display.

From there on the electronic control unit

takes care of the progressive starting up of

the air conditioning components as well as it

normal functioning.

The digital display will show the present

room temperature of the cabin in which the

digital display is situated or where the main

temperature sensor is located (in case the

optional secondary temperature sensor is

used).

The WEBASTO <AIR CONTROL> digital

display allows gives access to information

and controls at three distinct levels :

Immediate Access - Level 1 :

1) Room temperature read-out in the main 4

LED display window

2) 3 small LED’s to the left indicating the

operating cycle presently active :

- Cool cycle only operation.

- Automatic cycle switching governed by

end-user entered set-point temperature.

- Heat cycle only operation.

3) 2 set-point keys give immediate access

to the thermostatic set-points for blowercontrol (“Sun” and “Snow” key).

These keys are also used to alter program-

ming values - see here-after chapter 6.

Secondary commands and info Level 2 :

4) The F/Blower key gives immediate access

to a number of secondary commands which

need to be accessed frequently for day to day

operation.

First access is to blower speed control, then

evaporator temperature read-out, etc.

See hereafter drawing 2.1 for complete list.

Programming Commands - Level 3 :

A number of programming commands that

do not need to be accessed for day to day

operation are hidden and require a special

procedure to enable access and modification.

An access code can be enforced to avoid

accidental modification of programming values.

See Chapter 6 - Page 7.

Start-up delay :

After pushing the on/off key the LED’s will

display <ON> while initializing the system.

Push again to stop operation - the display

will briefly show <off> before extinction.

The adequate LED to the left (heat, cool , etc)

will come on after approx. 20 seconds and

compressor operation will start after approx.

60 seconds.

The sea-water circulation pump will come on

approx. 9 seconds before compressor start.

Modification of set-point temperature :

The set-point temperature i.e. the temperature desired by the operator for blower operation directly connected to the TCC controller card, can be modified as following :

Press and hold one of the set-point selector

keys and wait until the new desired set-point

temperature is obtained. Release the setpoint key.

The display will return to normal room temperature read-out after approx. 5 seconds.

See drawing 2.1 - page 4 for visual operation

guide.

Non-volatile memory keeps last settings.

Special New Features - 2000 Series :

A) Automatic blank/sleep mode -

programmable time delay. Factory default : 15

minutes. While in blank/sleep mode the cycle

LED flashes discretely every 20 seconds. To

go back to normal operation push any key.

Operation/Installation Manual - WBCC Series - Page : 4

Operation/Installation Manual - WBCC Series - Page : 4

Edition dated 1st January 2004

2 - DIGITAL WBCC/BLOWER CONTROL - GENERAL PRINCIPLES

BASIC COMMANDS :

1 - Press to turn on - press again to turn off.

2 - Press to read set-point temperature - hold to raise

set-point temperature.

3 - Press to read set-point temperature - hold to lower

set-point temperature.

4 - Led indicating system working in cool mode

5 - Led indicating manual blower speed control is active

6 - Led indicating system working in heat mode

7 - Function/Blower Key - immediate access to :

- blower speed control .............................................

- evaporator temperature read-out ...........................

- manual cycle choice (cool, heat, auto-reverse) ....

- AC voltage read-out ..............................................

- selective on/off compressors 1 to 4 ......................

- starting priority compressors 1 to 4 .....................

- automatic dehumidifying cycle during absence

- display time secondary functions accessible by

F/Blower key

8 - Access to hidden programming functions - see

page 7.

1

3

8 -

Push Both Keys Simultaneously

after Display Extinction

DRAWING 2.1 - BASIC AND SECONDARY COMMANDS

4

5

6

7

2

*

bb AA

HH1133..22

*

FF 33

UU223300

11CC0011

etc

PP112233

etc

*

dd 00

*

tt 11

*Default Values

24.2

Page 5

B) Calibrate all blower speed settings

in real time mode.

It is now possible to calibrate all speed set-

tings (1 to 5) before actually putting the system into service.

To do so entrer programming mode with setpoint at 15° C.; proceed to following line i.e.

code <6> = speed 5 (max).

The blower will start to function as soon as

you access code <6>.

Alter value to the right of code <6> and

blower speed will immediately change in

real time. When satisfied go to follo wing line

<7> = speed 4 and do the same.

Proceed until lowest speed N° 1 and go back

again to speed N° 5 if not satisfied.

When all speeds are programmed according

to need, validate by pushing on/off key

(<memo> will be displayed briefly). See also

page 8 - programming access.

Attention : Never program speeds

so low that the blower is in danger

of stopping or will not re-start at

that setting.

This will inevitably entail motorwindings burn-out and will not be

covered by WEBASTO warranty.

C) Automatice De-Icing Control :

During intermediate seasons (spring,

autumn) when moderate temperature

conditions prevail, there is a definite risk

of icing the evaporator coil in cool mode

and pressure safety cut-outs in heat mode.

To allow maximum blower speed variation and still function within a normal

operating window, the TCC card is

equipped with a second temperature sensor which reads the exact evaporator coil

temperature.

Whenever coil temperature approaches

the danger zone, blower speed is

increased to half speed; if that is not sufficient the micro-processor will stop compressor operation for pre-determined

intervals and will resume normal operation when coil temperature has moved

back to within normal operating values.

This feature is completely transparent to

the end-user without an error code display; in short this feature belongs to the

normal operating procedures in the same

way as the temperature set-points.

D) Infra-Red Remote Control :

Infra-red remote control can be obtained as

an option. This remote control is based on the

standard protocols also used by TV and other

appliances. Although the WEBASTO controls have been chosen so as to avoid interference with most TV models, the end-user

should be aware that in certain cases interference may occur with TV sets or other appliances.

In general it is therefore advisable to avoid

locating a WEBAST O Air Control panel next

to other appliances using infra-red control

units whenever it is planned to use infra-red

control mode.

D) ACCESS CODE :

The end-user can deny access to all program

settings by introducing an access code (see

page 8 - code <b>). Blower speed and setpoints always remain accessible.

Once an access code is validated, the digital

panel will show <Code> if the end-user tries

to access other functions then blower speed

or set-point. To gain full access push the sun

key to reach the code number as programmed

and push the <F> key again to gain access to

full program settings.

3. SECONDARY COMMANDS :

The F/Blower key gives immediate access to

commands and display necessary for day to

day operation. When pushing the F key you

will see to the left a code which indicates the

type of display or command and to the right

the present value.

In order of appearance here-after an explanation of these commands/displays :

a) Blower speed control : < b A>

(0,1,2,3,4,5)

This command preceeded by the letter b

(blower) allows the following settings :

A = automatic blower speed adjusted to tem-

perature differential.

1 to 5 = Manual Speed Control

Speed control is in real time mode i.e.

changes are effected immediately without

any validation procedure.

Attention : All following func-

tions need validation before a new

value is accepted.

Validation is obtained by pushing

the F key again and by going to the

next function line.

Then final validation will occur

automatically when the display

goes back to room temperature

read-out or final validation can be

forced by pushing the on/off key

briefly while still in F mode.

Validation is witnessed by the brief

display of the message <memo>.

b) Read out of evaporator coil temperature :

<E10.2> (10.2 ° C) - example.

c) Cycle mode choice : <F 3> (1 to 4)

The following cycle modes can be choosen

manually :

1 = cool cycle only

2 = heat cycle only

3 = automatic cycle switching with reversible

compressor

4 = automatic cycle switching without

reversible compressor

d) AC Voltage read-out : < U232>

(232 Volts) - example

e) Manual on/off Compressor 1 : <1C01>

<1C01> = Compressor 1 on

<1C00> = Compressor 1 off

f) Manual on/off Compressor 2 : <2C01>

<2C01> = on

<2C00> = off

Idem for compressors 3 and 4 - <3C01> and

<4C01>.

g) Starting Priority Compressors 1 to 4 :

<P123> = 1,2,3,4 ; <P341>=3,4,1,2

<P A> = automatic priority rotation; when

in this priotity mode, the starting

order will be changed every next

restart after thermostatic cut-out.

h) Starting delay between compressors :

<L 9> (9 seconds) - programmable

between 1 and 9 seconds.

i) Automatic dehumidification while absent.

factory default setting : <d 0>

0 = non active

1 = 1 cycle per 24H

2 = 2 cycles per 24H etc

k) display time of secondary functions (F/

Blower key) by periods of 20 seconds.

<t 1> (factory default setting) = display

time 20 seconds.

4. VISUAL ERROR CODES DIGITAL DISPLAY

The following malfunctions will be displayed directly on the digital display by a

Operation/Installation Manual - WBCC Series - Page : 5

Operation/Installation Manual - WBCC Series - Page : 5

Edition dated 1st January 2004

Page 6

Operation/Installation Manual - WBCC Series - Page : 6

Operation/Installation Manual - WBCC Series - Page : 6

Edition dated 1st January 2004

code and will be followed by a system halt.

Whenever any of these codes appear the system is stopped for approx. 60 seconds and

then a re-start is attempted.

If for more than 30 minutes the same malfunction occurs, the system will be stopped

completely and the error-code will become

steady.

No more re-starts will be attempted and the

user will have to re-set the system by pushing

the ON/OFF switch or by temporarily cutting

out the AC supply to the system.

List of error-codes and nature of malfunction :

Code <AAA> :

Persistent low voltage (voltage below 195V)

for more than 5 seconds - (see also hereafter

- Trouble-Shooting - Page 9).

Code A01 to A08 *) :

Pressure safety cut-out of compressors 1 to 4.

The HP and BP (if present) safety controls

are directly controlled by the micro-processor inclusive the time-delays for re-start, etc.

*) Standard TCC controller

cards

have only 1 outlet for 1 single com-

pressor. However the embedded microprocessor program can operate up to 4 CPAC

units from 1 single controller card. This special controller card can be obtained on special request but is not standard delivery.

Error codes displayed and probable nature of

anomaly.

<A01> : BP (low pressure) cut out - com-

pressor 1 - probable causes :

- insufficient refrigerant charging

level

- abnormal sea-water temperature

conditions in heat cycle (sea-water

temperatures under 6° C. approx.)

- first start-up in heat cycle with very

low chilled water circuit temperatures (below 8° C approx.).

ATTENTION:

models CPAC5 to 16 do

not have a low pressure safety switch (BP);

therefore if you see a A01 warning on such

model, it can only be an electrical connection

problem on the grey 3 pole HP/BP connector

on the TCC controller card. Check that the

connector is properly seated and that the BP

strap is properly tightened.

<A02> : HP (high pressure) cut out - com-

pressor 1 - probable causes :

- insufficient or non-existent sea-

water cooling - check sea-water

pump.

- too much refrigerant in system call specialist

- abnormal sea water temperature

conditions in heat cycle (sea-water

temperatures above 17° C approx.)

<A03> : BP cut out - compressor 2 - for

probable causes see <A01>

<A04> : HP cut out - compressor 2 - see

<A02>

<A05> to <A08> - same as above for compressors 3 and 4 (if present).

If any of these error codes appear too frequently and no appropriate action can be

taken with the available means on board, it is

necessary to call a specialist.

Do not insist with manual re-starts in such

case as this may cause major damage to the

principal components (compressors, pumps,

etc).

<A09> - absent or defective external or inter-

nal (Display Face) air sensor

<A10> - absent or defective evaporator

temperature coil sensor.

<CA11> - all compressor(s) have been disac-

tivated by soft - <F> procedure :

<1C00>, <2C00>, etc

To re-activate, reprogram as

follows : <1C01>, etc

<EA11> - compressor stopped by de-icing

control - automatic restart - this code does

not entail a complete system halt and will

only be visible when in reading out the evaporator temperature (F key - line E).

5. CENTRAL BLOWER CONTROL

The central <AIR CONTROL> digital display also directly controls the blower(s) of

the evaporator(s).

For all CPAC systems, there are two modes

of blower control and operation :

- thermostatic interruption of blower operation as soon as the desired set-point

temperature has been reached.

- un-interrupted blower operation regardless of thermostatic compressor control.

The choice between these two functioning

modes can be programmed directly by the

end user - see here-after Chapter 6 - programming procedures.

The digital control is initially programmed

by the manufacturer in second - i.e. un-interrupted blower operation.

Blower control can be manual with 5 different speed levels or automatic; in this case

blower speed will be governed by the temperature differential with the set-point temperature.

Page 7

Operation/Installation Manual - WBCC Series - Page : 7

Operation/Installation Manual - WBCC Series - Page : 7

Edition dated 1st January 2004

To gain access to the hidden programming

functions proceed as following :

Raise set-point to max. value i.e. 29° C (or

alternatively to lowest value i.e. 15° C) push Off key to extinguish digital display.

Press <snow> and <sun> key simultaneously

for approx. 3 seconds until you see to the left

of the display window a single number code

indicating the programming line presently

valid and to the right the programming value.

To go to the next programming line, push the

<F> key.

If you modify the programming value of any

line, you need to validate this new value by

pushing the <F> key again to move to the

next line. This step will validate and memorize the changes made.

1° Functions accessible by raising the setpoint to 29° C. :

Code <0> - factory setting : -1° Celsius -

lower set-point temperature of the ev aporator

coil temperature in cool cycle. Gives the

compressor cut-out point when the “deicing” procedure is activated..

Adjustment range : between -5° C. and +10°

C.

Code <1> - factory setting : +7° Celsius higher set-point temperature of de-icing procedure. This value gives the re-start point of

the compressor(s) after an interruption when

in de-icing mode.

Set-point temperature adjustable between

0°C. and +12° C.

Code <2> - factory setting : 40° C. higher

set-point temperature of the “de-icing” procedure in relation to the evap. coil temeprature when in heat cycle (to avoid HP cutouts). Gives the cut-out point of the compressor(s) when functioning in heat cycle.

Set-point temperature adjustable between

35° and 50° C.

Code <3> -factory setting : 35° C. - lower

set-point temperature of coil temperature cutin when in heat cycle. Gives the cut-in point

of the compressor(s) after an interruption

(“de-icing” procedure) when functioning in

heat cycle.

Set-point temperature adjustable between

30° and 50° C.

Code <4> - pre-programmed value : 0 - calibration of temperature display of the evaporator coil temperature read-out - correction

possible between -9° to +9° Celsius.

Code <5> - factory setting : 15 - time delay

in minutes before the digital display goes

into blank/sleep mode. Cycle LED flashes

discretely to indicate system is operational.

Code <6> - factory setting : 1 - time delay

first start up in seconds. To stage starting of

several CPAC units when switching on AC

supply after an interruption.

Code <7> - factory setting : 0 - calibration

of room temperature read-out. Possible

between +9 and -9° C.

Code <8> - pre-programmed value : 0.

Factory calibration of AC voltage 50 Hz as

displayed on the digital panel when accessing the secondary commands - F key.

Correction between -20 and +20 Volt.

Code <9> - pre-programmed value : 1 Time delay before re-start in minutes after a

compressor stop when in “de-icing” procedure. (both for cool and heat cycle).

Code <A> - pre-programmed value : N/A.

Factory calibration of AC voltage 60 Hz as

displayed on the digital panel when access-

ing the secondary commands by the F key.

Correction between -30 and +20 Volt

Code <b> - Program version

Re-intializing of factory default settings :

It is possible to force the program to re-initialize all program values to factory default

settings by the following procedure :

When reading the <b> line as above (through

the 29° set-point), push the <sun> key; continue to push; the program version will start

to flash. Keep the <sun> key pushed down

until the display shows <init>.

Leave programming mode by pushing

On/Off key - you are now back to the factory

default settings.

Attention :

this procedure should never be

attempted for any program version below a

value of 1.00 - i.e. for

<b0.12>

never

attempt to reinitialize the default settings :

your controller card will lock itself and cannot be unlocked.

On the contrary - example : program version

<b1.02>

or

<b2.03>

:OK to re-initialize.

2° Functions accessible when lowering

the set-point temperature to 15° C :

Code <0> - pre-programmed value : 195 low voltage cut-out value AC.

Time delay is 5 seconds approx. i.e. the low

voltage situation will have to persist during

more than 5 seconds before cut-out occurs.

After cut-out the electronic controller resets

and will start a new cycle. So a renewed

attempt to start the compressor will occur

after approx. 90 seconds.

PROGRAMMING MODE :

To enter programming mode : raise or lower set-point to 29 or 15° C.

Turn off system by pressing <Power> key - 14.

Press simultaneously keys <11>. The display will show to the left

<15>, the number code of the current programming line and to the right

<16> the present value.

To validate and memorize modified parameters press the <F> key (12)

and proceed to the following programming line.

6 - DIGITAL DISPLAY <AIR CONTROL> - PROGRAMMING ACCESS

00 44..66

11

12

14

15

16

Page 8

Operation/Installation Manual - WBCC Series - Page : 8

Operation/Installation Manual - WBCC Series - Page : 8

Edition dated 1st January 2004

During low-voltage cut-out the display panel

will show the 3 letters <AAA>.

Programming of a cut-out level below 195 V

is done at the entire risk of the operator. It

should be noted that almost all compressor

manufacturers decline all responsibility for

defects resulting from operating the compressors below 195V AC.

Code <1> - factory setting : 0 - infra-red

remote control :

0 = infra-red remote control disabled (in this

mode no interference is possible with other

infra-red commands)

1 = infra-red remote control active

Code <2> : Blower type : Centrifugal or

Cross-Flow. Factory default : 1

0 = centrifugal blowers only

1 = centrifugal + cross-flow

Code <3> - pre-programmed value : 1 basic choice of blower control :

0 - thermostatic control of blower operation

i.e. blower operation will be interrupted thermostatically when reaching the appropriate

set-point.

1 - un-interrupted blower operation regardless of the thermostatic control.

Code <4> - factory setting : 1 - Choice

between integrated air sensor and external air

sensor :

1 - air sensor integrated in digital display

0 - external air sensor

Code <5> - Celsius or Fahrenheit display -

factory setting : 1

0 = Celsius read-out

1 = Fahrenheit read-out

Code <6> : modification speed N° 5 (max)

Code <7> : idem speed N° 4

Code <8> : idem speed N° 3

Code <9> : idem speed N° 2

Code <A> : idem speed N° 1

Code <b> - factory setting : 0 - access code

for programming mode.

0 = no access code required

1 to 99 = access code/number activated

*) Factory access code : in case the system is

blocked and the access code cannot be found,

you can acces the programming line by using

the factory code number : 64

Code <c> - factory setting : 1 - duration in

minutes of heat cycle dehumidifying cycle.

Code <d> - factory setting : 1 - duration in

minutes of cool cycle dehumidifying cycle.

DIPSWITCHES :

The TCC controller card has a dipswitch

arrangement which should be set and maintained according to the following settings :

1) TCC controller for single compressor ,

without the secondary card for compressors 3

and 4 :

Attention :

if dipswitches are not set

according to the above configurations i.e.

according to the number of compressors

effectively on line, the TCC controller card

may behave in unpredictable manner :

- the initialisation <init> can not be completed - card remains locked on start-up.

- HP/BP alarms for non--existing compressors.

7. PRACTICAL INSTALLATION GUIDE

1) Sea-water cooling :

Install the pump/strainer assembly in such

a manner that a natural gentle upwards

slope exists from the sea-cock to the pump

itself. See also drawing hereabove ref. 6.1.

It is strongly recommended to install an

air-bleeder system both in the suction line

as well as immediately after the discharge

outlet of the pump. The advice is especially valid for pumps WEBASTO250/350/1000. The WEBASTO1500/2000 and Calpeda pumps 0.5HP

to 1 HP generally will not require a bleeder system to ensure proper operation.

For ALL boats it is strongly recommended to install a water-scoop at the entry of

the sea-cock and directed towards the bow

of the boat so that at speed positive pressure builds up in the supply line to the seawater pump.

2) Sea-water cooling exits :

Provide for a separate sea-water exit for

each air-conditioning unit installed even if

only one pump provides cooling for all

units.

1

23

4

OPEN

ATT. DIPSWITCH SETTINGS

BLACK = PUSHED DOWN

TO OVER-BOARD OUTLET APPROX. 10 CMS ABOVE WATER-LINE

INSTALLATION OF BLEEDER ADVISABLE

MEMBRANE PUMP CLD125 L7 12/24V

SITUATED JUST BELOW WATER-LINE

SEA-WATER STRAINER

SUCTION GENTLY UPWARDS TO

FACILITATE PRIMING

CLAM-SHELL TYPE THRU-HULL FITTING

WITH SLOTS DIRECTED TOWARDS BOW TO OBTAIN POSITIVE PRESSURE IN SUCTION LINE

NB - ALL PIPING AS SHORT AS POSSIBLE WITHOUT

KINKS NOR SYPHONS

WATER-LINE

7.1 - INSTALLATION AND POSITIONING OF SEAWATER PUMP AND ACCESSORIES

Page 9

Introduce shut-off valves for each unit if 1

pump provides cooling for more than 1

air-conditioning unit.

This will allow easy priming of the circuit

and also calibration of the sea-water flow

for each air-conditioning unit in case of

imbalance in the water tubing lengths.

3) Evaporator coils :

The finned coils of the evaporators and/or

air-handlers are fragile. When during

installation the fins of these coils are damaged, take care to re-align the fins in

order not to impair proper air-flow.

4) Air-ducts :

Flexible air-ducts need to be of good quality with sufficiently strong steel or plastic

re-inforcement. Do not restrict air-flow by

bending the air-ducts too tightly or by

accidental local deformation.

Do not install air-ducts of excessive

lengths (+ 2.5 ml); the pressure loss and

consequent reduction of air-flow will seriously diminish the efficiency of the installation.

8. ROUTINE CHECKS

When starting up an air conditioning unit

it is advisable to carry out a certain number of routine checks to ensure proper

functioning of the unit.

- always check (especially after a long

absence) the functioning of the sea water

cooling system. Immediately stop the system if no sea-water comes out of the pump

exit after compressor starts up.

- periodically check the air filter in the

return air grilles. Clean if necessay.

- check condensation drain from the evaporator drain pan.

- take care not to damage the air-ducts. A

damaged air-duct may stop air flow

through the evaporator, freeze up the

evaporator and subsequently damage the

compressor.

- when preparing for winter lay-up take

care to rince all sea-water circuits with a

fresh-water/glycol solution (25% or more

depending on local winter conditions).

8A. TROUBLE SHOOTING

1) No sign of live : check main electrical

supply, fuses, etc.

2) The digital display shows 3 lettres

<AAA>. This means a persistent state of

low voltage (less than 195 V AC). The

system will re-start as soon as the voltage

level climbs above cut-out level and the

system will then re-start after a timedelay of 1 minute approx.

3) The compressor will start but no seawater circulation can be observed :

- check sea-cock to sea-water pump.

- check sea-water strainer

- check if pump turns

- if the pump does not turn with the compressor working, check power-supply

from the main control unit box to the

pump.

4) Compressor and pump work but no correct operation in either cool or heat cycle :

- check proper air ventilation - blowers. If

air flow completely stops with the compressor working, the evaporator coils may

freeze up completely,obstruing all air circulation.

- during the heat cycle with too slow a seawater circulation you may actually freeze

up the sea-water in the cupro-nickel condenser and completely block the system.

- check voltage level. Do not operate a

system with a persistent voltage level

below 195 V AC.

- check freon charge if operation is still

not satisfactory, after having checked all

the above points.

5) The compressor works but is subject to

intermittent stops without having attained

the desired set-point temperature.

- the HP and BP (if present) pressure safety switches stop the compressor because

of abnormal working pressures either on

the high or on the low side. Check proper

functioning of the cooling circuit. Check

ventilator/blower system for obstructions.

- incorrect freon charge (over-charge or

insufficient charge level).

See also here-above : Error codes/interrupted system operation.

6) The heat cycle takes very long to get

started.

- normal if the sea-water temperature is

very low. If sea-water temperature drops

below approx. 8° C. the heat cycle

becomes much less effective and takes

long to get properly started.

* * *

Operation/Installation Manual - WBCC Series - Page : 9

Operation/Installation Manual - WBCC Series - Page : 9

Edition dated 1st January 2004

Page 10

Operation/Installation Manual - WBCC Series - Page : 10

Operation/Installation Manual - WBCC Series - Page : 10

Edition dated 1st January 2004

9 - AIR DUCTING - VENTILATION

1) MINIMUM AIR-GRILLE SECTIONS

In order to obtain an acceptable noise level at

max. blower speed certain requirements as

regards grille and ducts sections should be

observed.

Also the size of the transition boxe behind

the supply air-grille is important.

See table here-under to choose correct grille

sections according to BTU rating.

2) DUCT TYPE

Flexible air-ducts should be of high quality

with sufficiently strong steel spiral reinforcement to avoid accidental crushing.

Spiral type ducts should be extended to their

maximum possible length to obtain max.

interior smoothness.

For very long duct sections preference should

be given to rigid ducts (in PVC for example)

which offer a far greater smoothness than

flexible spiral type ducting and therefore will

greatly reduce internal friction.

For very short lengths non-insulated ducts

may possibly be used. Over greater lengths it

is advisable to use insulted type ducts to

avoid condensation on the outside of the airducts.

AIR/HANDLER-CPAC SUPPLY AIR GRILLE RETURN AIR GRILLE DUCT DIAM. DUCT DIAM.

MODEL MODEL/ SECTION cm² MODEL/SECTION cm² <1.8 M DUCT LEN. >1.8 M DUCT LEN.

4000/4500 BTU

6000 BTU

9000 BTU

12000 BTU

16000 BTU or

16000 BTU

24000 BTU

32000 BTU

1 x 8x4” 150 cm²

1 x 10x4” 190 cm²

1 x 12x4” 235 cm²

1 x 10x5” 250 cm²

1 x 12x6” 390 cm²

2 x 10x4” 380 cm²

2 x 10x5” 500 cm²

2 x 12x5” 650 cm²

1 x 12x5” 325 cm²

1 x 11x8” 490 cm²

1 x 11x8” 490 cm²

1 x 14x7” 550 cm² or

1 x 14x10” 800 cm2

1 x 14x12” 1000 cm²

2 x 14x10” 1600 cm²

80 mm

100 mm

100 mm

125 mm

125 mm

125 mm

2 x 125 mm

2 x 125 mm

100 mm

125 mm

125 mm

150 mm

150 mm

150 mm

2 x 150 mm

2 x 150 mm

3) BLOWER OUTLETS

90° turns with flexible ducts directly from

blower outlets should be avoided at all costs

as they introduce severe restrictions in the

air-flow.

All WEBASTO blowers (except on 24000

BTU models) can be rotated through 45°

steps so as to obtain a straight-line outlet

from the blower. This facility should be used

whenever possible.

See also drawing to the right.

4) TRANSITION BOXES

Transition boxes behind supply air-grilles

essentially serve the following purpose :

Serve as an expansion volume for the airflow to be reduced in velocity and therefore

reduce air noise when crossing the outlet

louvres.

It follows therefore that the depth of the transition box is an important factor to allow dispersion of the air-flow

The table to the right gives the necessary

information as to the minimum dimensions

advisable for such transition boxes.

5) RETURN GRILLE OFFSET

It is best to avoid placing a return air grille

directly opposite the finned coil surface of an

air-handler. This will inevitably allow propagation of direct blower-motor noise through

the grille.

Always try to offset the grille so as to chi-

cane the return air to the coil inlet.

This will lower direct noise propagation in a

significant manner.

AIR FLOW

AIR FLOW

BLOWER ROTATED TO

MINIMZE FRICTON LOSSES

H

H

DUCT DIAM. MINIMUM VALUE OF “H”

80 mm 100 mm

100 mm 120 mm

125 mm 140 mm

150 mm 165 mm

TRANSITION BOX INFORMATION

Deflection curve for longitudinal

entry transition boxes

NB : For duct lengths over 1.80 ml, it may be possible to use the nominal duct diameter (for example 100 mm - 6000 BTU

model), if instead of spiral type flexible ducts, rigid perfectly smooth interior ducts are used.

ROTATABLE BLOWER OUTLETS

Page 11

Operation/Installation Manual - WBCC Series - Page : 11

Operation/Installation Manual - WBCC Series - Page : 11

Edition dated 1st January 2004

10 - W I R I N G D I A G R A M S

DIPSWITCH SELECTOR

DISPLAY CABLE CONNECTOR

EXTERNAL AIR TEMP. SENSOR

EVAP. COIL TEMP. SENSOR

SEAWATER

PUMP 230V

SUPPLY

GND

BLOWER

REVER. CYCLE

VALVE

HP SAFETY

SWITCH

C

R

S

RUN

CAPAC.

TERMINAL

STRIP

230V AC

230V

HP

BP

COMP1

VALVE

FAN

COMP1

FAN

VALVE

PUMP1

GND

PUMP1

HARD

START

CAP.

10.1 - Wiring diagram WBCC 5000 T O 16000 BTU (Rotary Comp.) - single phase

1

23

4

OPEN

ATT. DIPSWITCH SETTINGS

BLACK = PUSHED DOWN

Page 12

Operation/Installation Manual - WBCC Series - Page : 12

Operation/Installation Manual - WBCC Series - Page : 12

Edition dated 1st January 2004

RUN

CAPAC.

BLOWER

REVER. CYCLE

VALVE

HP BP

C

R

S

SEAWATER

PUMP

230V

SUPPLY

GND

GND

DIPSWITCH SELECTOR

DISPLAY CABLE CONNECTOR

EXTERNAL AIR TEMP. SENSOR

EVAP. COIL TEMP. SENSOR

BP

HP

230V AC

230V

COMP1

VALVE

FAN

COMP1

PUMP1

FAN

VALVE

PUMP1

TERMINAL

STRIP

HARD

START

CAP.

10.2 - ELECTRICAL WIRING - WBCC 24 TO 30 - SINGLE-PHASE

1

23

4

OPEN

ATT. DIPSWITCH SETTINGS

BLACK = PUSHED DOWN

Page 13

DIPSWITCH SELECTOR

RUN

CAPACIT.

START

CAPAC.

START RELAY

5

2

1

R

C

S

BLOWER

REVER. CYCLE

VALVE

HP SAFETY

SWITCH

SEA-WATER PUMP

TERMINAL STRIP

230 V AC

SUPPLY

PUMP1

VALVE

FAN

COMP1

230V AC

230V

FAN

COMP1

HP

BP

PUMP1

VALVE

GND

DISPLAY CABLE CONNECTOR

EXTERNAL AIR TEMP. SENSOR

EVAPORATOR COIL TEMP. SENSOR

Operation/Installation Manual - WBCC Series - Page : 13

Operation/Installation Manual - WBCC Series - Page : 13

Edition dated 1st January 2004

10.3 - ELECTRICAL WIRING - WBCC 7 TO 16 - 1 PHASE - PISTON COMPR.

1

23

4

OPEN

ATT. DIPSWITCH SETTINGS

BLACK = PUSHED DOWN

10.4 - WIRING SCHEMATICS - RUNNING

CAPACITORS FOR BLOWER MOTERS -

ECOFIT/EBM

PHASE

NEUTRAL

BROWN

WIRE

CONNECTION

BLACK

BLACK

GND WIRE

CABLE FROM

BLOWER MOTER

BLUE

230V SUPPLY

RUNNING

CAPACITOR

Page 14

WEBASTO-REPRESENTATIVES - WEBASTO-VERTRETUNGEN

Germany -Deutschland

Bayern, Webasto AG

Baden-Würtemberg, Business Unit SPM

Hessen (teilweise), Niederlassung Süd

Saarland, Kraillinger Strasse 5, D-82131 Stockdorf

Rheinland Pfalz Tel. +49 89 85794-789, Fax +49 89 85794-702

Australia- Australien

AUS-2229 NSW Caringbah Webasto Product Australia Pty. Ltd.

4/65 Captain Cook Drive

Tel. +61 295 404811, Fax +61 295 404316

www.webasto.com.au

Austria - Österreich

A-1230-Wien Webasto Fahrzeugtechnik G.m.b.H.

Jochen Rindt Strasse 19

Tel. +43 1 6043780, Fax +43 1 6043786

www.webasto.at

Baltic Republics - Baltikum

EE-11214 Tallinn AS KG Knutsson

Saeveski 12

Tel. +372 651 9309, Fax +372 651 9303

www.kgk.ee

Belarus - Weißrussland

BY-220004 Minsk Falkat GmbH

8, Per. Obuwnoj

Tel. +37 50172201894, Fax +37 50172201894

Belgium - Belgien

B-1070-Bruxelles S.A. Webasto Product Belgium N.V.

Allée Hof Ter Vleestdreef 1

Tel. +32 2 5580660, Fax +32 2 5214004

www.webasto.be

Bosnia-Herzegovina - Bosnien-Herzegovina

SLO-1000 Ljubljana via Slovenia - Webasto d.o.o. Slovenia

Bulgaria - Bulgarien

BG-1839 Sofia Rhea MP GmbH

Boris-Iliev-Strasse 17

Tel. +359 2 9420-555, Fax +359 2 9420-566

www.rheagroup.com

Canada - Kanada

USA-48430 Fenton via USA - Webasto Product North America, I

China

RC-Hong Kong Webasto Product China Ltd.

Connaught Road West Room 907-910, Yat Chau Int'l. Plaza, 118

Tel. +852 28 118230, Fax +852 28 563063

www.webastochina.com

Croatia - Kroatien

SLO-1001 Ljubljana via Slovenia - Webasto d.o.o. Slovenia

Czech Republic - Tschechien

CZ-140 00 Praha 4 Webasto Thermo s.r.o.

Na Stri 1373/35

Tel. +420 2 41045450-7, Fax +420 2 41045458-9

www.webasto.cz

Denmark - Dänemark

DK-2610 Rødovre Webasto Product Danmark ApS

Islevdalvej 182

Tel. +45 44 522000, Fax +45 44 522019

www.webasto.dk

Finland - Finnland

FIN-01740 Vantaa Oy Kaha AB

Ansatie 2

Tel. +358 9 61568379, Fax +358 9 61568305

www.webasto.fi

France - Frankreich

F-91250 Tigery Webasto Product France S.A.S.

1, rue de la Haye, Z.A. Paris Sud II

Tel. +33 1 69138383, Fax +33 1 69130606

www.webasto.fr

Greece - Griechenland

GR-10442 Athen Ikaros S.A.

19, Dimitras Str.

Tel. +3010 5150235-6, Fax +3010 5151480

www.ikaros.gr

Hungary - Ungarn

H-1135 Budapest Webasto-Hungaria Kft.

Szent Lázló út 73

Tel. +36 1 3502337, Fax +36 1 3502339

www.webasto.hu

Iceland - Island

IS-210 Gardabaer Bilasmidurinn HF.

Hörgslundi 19

Tel. +354 5672330, Fax +354 5673844

www.webasto.com

India - Indien

IND-201301 Noida (U.P.) Webasto Motherson Sunroofs Ltd.

A 6, sector 2. Distt.Gautam Budh Nagar

Tel. +91 120 2551851, Fax +91 120 2521866

www.motherson.com

Italy - Italien

I-20080 Zibido San Giacomo Webasto Product Italy S.p.A. (I)

Via Longarone, 35

Tel. +39 02 90005011, Fax +39 02 90005189

www.webasto.it

Japan

J-739-0038 Higashi- Webasto Japan Co., Ltd.

Hiroshima-City 5-10 Taguchi Research Complex

Tel. +81 824 253111, Fax +81 824 253152

www.webasto.co.jp

Kazakhstan - Kasachstan

KZ-480019 Almaty Kazachstan Truck Service Ltd.

M-on Atyrau-2, Geb. 111

Tel. +7 3272 312650, Fax +7 3272 312545

Korea (Republic of)

ROK680-160 Nam-Gu Ulsan Webasto DongHee Co.,Ltd (WDH)

579-9 Younyun-Don

Tel. +82 52 2578190, Fax +82 52 2570171

www.donghee.co.kr

Luxembourg - Luxemburg

B-1070 Bruxelles via Belgium - S.A. Webasto Product Belgium N.V.

Macedonia - Mazedonien

SLO-1001 Ljubljana via Slovenia - Webasto d.o.o. Slovenia

Mongolia - Mongolei

Ulaanbaatar Mongolia Thermosystems Ltd.

P.P. Box 49/491

Tel. +976 11 312 081, Fax +976 11 312 079

Netherlands - Niederlande

NL-8263 BC Kampen Webasto Product Nederland B.V.

Constructieweg 47

Tel. + 31 38 3371137, Fax + 31 38 3325181

www.webasto.nl

New Zealand - Neuseeland

AUS-2229 NSW Caringbah via Australia - Webasto Product Australia Pty. Ltd.

Norway - Norwegen

N-1386 Asker Kolberg, Caspary Maskin A/S

Røykenveien 70

Tel. +47 66 760900, Fax +47 66 760908

www.webasto.no

Poland - Polen

PL-05-092 Lomianki Webasto Petemar SP. z.o.o.

ul. Warszawska 205/219

Tel. +48 22 7517787, Fax +48 22 7517788

www.webasto.pl

Portugal

E-08620 Sant Vicenç via Spain - Webasto Product Ibérica, S.L.

dels Horts (Barcelona)

Romania - Rumänien

H-1135 Budapest via Hungary - Webasto-Hungary Kft.

Russia - Russland

RU-107 065 Moscow Webasto Rus OOO

Altayskaya ulitsa 19-1a

Tel. +7 095 7770245, Fax +7 095 7770246

www.webasto.ru

Serbia and Montenegro - Serbien und Montenegro

SLO-1000 Ljubljana via Slovenia - Webasto d.o.o. Slovenia

Slovakia - Slowakische Republik

SK-04012 Koice Webasto Thermo SK s.r.o.

Pri Karásnej 1

Tel. +421 55 6747792, Fax +421 55 6747792

www.webasto.sk

Slovenia - Slowenien

SLO-1000 Ljubljana Webasto d.o.o.

Cesta v. Gorice 34

Tel. +386 1 2008710, Fax +386 1 2008726

www.webasto.si

South Africa - Südafrika

ZA-7780 Wetton, Cape Down Webasto South Africa (Pty) Ltd.

7 Venus Way Hillstar Industria

Tel. +27 21 7619971, Fax +27 21 7619980

www.webasto.co.za

Spain - Spanien

08620 Sant Vicenç Webasto Product Ibérica, S.L.

dels Horts (Barcelona) Poligono Industrial La Barruana,

Avenida de Torrelles 12 y 14

Tel. +34 93 6724515, Fax +34 93 6724520

www.webasto.es

Sweden - Schweden

S-19181 Sollentuna/ KG Knutsson AB

Stockholm Hammarbacken 8

Tel. +46 8 923000, Fax +46 8 923307

www.webasto.se

Switzerland - Schweiz

CH-4123 Allschwil/BL Webasto (Schweiz) AG

Hagmattstrasse 4

Tel. +41 61 4869580, fax +41 61 4869589

www.webasto.ch

Turkey- Türkei

TR-34510 Esenyurt - Istanbul Webasto Termo Sistemleri A.?.

Evren Oto Sanayi Sitesi

Tel. +90 212 6721590, Fax +90 212 6721604

www.webasto.net

Ukraine

UA-290069 Lviv Webasto Elektron GmbH

Schewtschenko Str. 315

Tel. +38 0322 911564, Fax +38 0322 913753

www.webasto.com

United Kingdom - Großbritannien

GB-DN4 5JH South Yorkshire Webasto Product UK Ltd.

Webasto House, White Rose Way,

Doncaster Carrington

Tel. +44 1302 322232, Fax +44 1302 322231

www.webasto.co.uk

USA

USA-48430 Fenton Webasto Product North America, Inc

15083 North Road

Tel. +1 810 593-6000, Fax +1 810 593-6001

www.webasto.us

Hamburg, Bremen Webasto AG

Niedersachsen Business Unit SPM

Schleswig Holstein Niederlassung Nord

Nordrhein Westfalen Speicherstraße 3, D-17033 Neubrandenburg

Sachsen, Sachsen-Anhalt Tel. +49 3 95 55 92-290, Fax +49 3 95 5 59 2-325, 369

Mecklenburg-Vorpommern

Brandenburg, Berlin

Hessen (teilweise)

Thüringen

Loading...

Loading...