Webasto Thermo Top C, Thermo Top E Repair Manual

Water Heaters Repair Shop Manual

Thermo Top Z

Supplementary Heater

Thermo Top E

Thermo Top C

Auxiliary Heater

Type Thermo Top E - B

Type Thermo Top Z/C - B

Fuel

Type Thermo Top E - D

Type Thermo Top Z/C - D

Diesel

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

List of Contents Thermo Top E and Z/C

II

List of Contents

1 Introduction

1.1 Scope and Purpose .............................................................................................................................. 101

1.2 Meaning of Warnings, Cautions, and Notes ......................................................................................... 101

1.3 Additional Documentation to be used................................................................................................... 101

1.4 Safety Information and Regulations...................................................................................................... 101

1.4.1 Legal Provisions for Installation.................................................................................................. 101

1.4.2 General Safety Notes ................................................................................................................. 102

2 General Description

2.1 Combustion Air Fan Assembly.............................................................................................................. 202

2.1.1 Combustion Air Fan.................................................................................................................... 202

2.2 Burner Housing..................................................................................................................................... 202

2.3 Burner Insert......................................................................................................................................... 202

2.4 Control Unit / Heat Exchanger.............................................................................................................. 203

2.4.1 Control Unit................................................................................................................................. 203

2.4.2 Temperature Sensor................................................................................................................... 203

2.4.3 Overheat Protection.................................................................................................................... 203

2.4.4 Heat Exchanger.......................................................................................................................... 203

2.5 Circulation Pump (Thermo Top E and C only)...................................................................................... 203

2.6 Dosing Pump ........................................................................................................................................ 203

3 Functional Description

3.1 Functional Description Thermo Top Z (Supplementary Heater)........................................................... 301

3.1.1 Switch On / Starting.................................................................................................................... 301

3.1.2 Heating Operation....................................................................................................................... 301

3.1.3 Switch Off / Deactivation............................................................................................................. 301

3.2 Functional Description Thermo Top E and C (Auxiliary Heater)........................................................... 302

3.2.1 Switch On ................................................................................................................................... 302

3.2.2 Heating Operation....................................................................................................................... 302

3.2.3 Switch Off ................................................................................................................................... 302

3.2.4 Auxiliary Heater in Supplementary Heater Function................................................................... 303

4 Technical Data

4.1 Thermo Top E....................................................................................................................................... 401

4.2 Thermo Top Z/C (Heating Flow 5.0 kW)............................................................................................... 402

4.3 Thermo Top Z/C (Heating Flow 5.2 kW)............................................................................................... 403

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Thermo Top E and Z/C List of Contents

III

5 Troubleshooting

5.1 General Fault Symptoms...................................................................................................................... 501

5.2 Error Messages during Functional Test with Diagnosis Tester Thermo Test....................................... 502

5.3 Malfunctions.......................................................................................................................................... 503

5.3.1 Error Lockout by Malfunction of Heater...................................................................................... 503

5.3.2 Error Lockout due to Low or High Voltage.................................................................................. 503

5.3.3 Error Lockout Reset.................................................................................................................... 503

6 Functional Checkouts

6.1 General................................................................................................................................................. 601

6.2 Functional Tests in the Vehicle............................................................................................................. 601

6.2.1 Heating Operational Test (Thermo Top E and C)....................................................................... 601

6.2.2 Timer Functional Test (Thermo Top E and C)............................................................................ 602

6.2.3 Telestart T60 Functional Test (Thermo Top C).......................................................................... 602

6.2.4 Telestart T70 Functional Test (Thermo Top C and E)................................................................ 602

6.2.5 Functional Test with Diagnosis Tester Thermo Test.................................................................. 603

6.2.6 CO2 Setting ................................................................................................................................ 604

6.3 Repair Shop Level Testing ................................................................................................................... 604

6.3.1 Components Testing .................................................................................................................. 604

7 Circuit Diagrams

7.1 General.................................................................................................................................................. 701

8 Servicing

8.1 General................................................................................................................................................. 801

8.2 Work on the Heater............................................................................................................................... 801

8.3 Work on the Vehicle.............................................................................................................................. 801

8.4 Heater Test Run ................................................................................................................................... 801

8.5 Servicing............................................................................................................................................... 801

8.6 Visual Inspections and Installation Regulations.................................................................................... 801

8.6.1 Connection to Vehicle Cooling System ...................................................................................... 801

8.6.2 Connection to Vehicle Fuel System............................................................................................ 803

8.6.3 Air Intake Muffler ........................................................................................................................ 805

8.6.4 Exhaust Line............................................................................................................................... 805

8.7 Removal and Installation ...................................................................................................................... 806

8.7.1 Heater, Removal and Installation ............................................................................................... 806

8.7.2 Timer, Removal and Installation................................................................................................. 806

8.8 Initial Operation..................................................................................................................................... 806

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

List of Contents Thermo Top E and Z/C

IV

9 Repair

9.1 General................................................................................................................................................. 901

9.1.1 Work on Components after Disassembly ................................................................................... 901

9.2 Disassembly and Assembly.................................................................................................................. 902

9.2.1 Circulation Pump, Replacement (Thermo Top E and C)............................................................ 902

9.2.2 Combustion Air Fan, Replacement............................................................................................. 903

9.2.3 Burner Insert with Glow Plug / Flame Sensor, Replacement...................................................... 905

9.2.4 Control Unit / Heat Exchanger with Burner Housing, Replacement ........................................... 905

10 Packaging, Storage and Shipping

10.1 General............................................................................................................................................... 1001

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Thermo Top E and Z/C List of Figures

V

List of Figures

501 Fault Symptoms......................................................................................................................................... 501

502 Error Messages ......................................................................................................................................... 502

701 Control Unit Connector Pin Assignment (Thermo Top E and C) ............................................................... 701

702 Automatic Switching Circuit for Thermo Top E and Z/C, 12 V Timer and Telestart T60............................ 702

703 Automatic Switching Circuit for Thermo Top E and Z/C, 12 V Timer......................................................... 703

704 Automatic Switching Circuit for Thermo Top Z, 12 V................................................................................. 704

801 "Inline Integration" in the Engine Water Cooling Circuit............................................................................. 801

802 Example for Heater Installation in Passenger Vehicle............................................................................... 802

803 Fuel Supply................................................................................................................................................ 802

804 Webasto Fuel Tap ..................................................................................................................................... 803

805 Pipe/Hose Connection............................................................................................................................... 804

806 Dosing Pump, Installation Position ............................................................................................................ 804

807 Air Intake Muffler, Installation Position....................................................................................................... 805

808 Exhaust Pipe Outlet, Installation Position.................................................................................................. 805

809 Timer, Removal and Installation ................................................................................................................ 806

901 Replacement of Circulation Pump (Thermo Top E and C) ........................................................................ 902

902 Heater Disassembly................................................................................................................................... 904

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

List of Figures Thermo E and Top Z/C

VI

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Thermo Top E and Z/C 1 Introduction

101

1 Introduction

1.1 Scope and Purpose

This repair shop manual is intended to support

familiarised personnel in the repair of the water heaters

Thermo Top E, Thermo Top Z and Thermo Top C of the

fuel and Diesel types.

As their appearance is identical or similar, the heaters are

marked by type on their identification plate with "Benzin"

(fuel) or "Diesel". The heaters may only be operated with

the specified type of Diesel (or with fuel oil EL) and the

appropriate type of electrical installation.

Heaters which have Diesel or fuel specified on their

identification plate must not be operated with PME

(vegetable methyl ester).

Thermo Top E and C are variants of Thermo Top Z with a

circulation pump.

1.2 Meaning of Warnings, Cautions,

and Notes

WARNINGS, CAUTIONS, and NOTES in this manual

have the following meaning:

WARNING

This heading is used to highlight that non-compliance with

instructions or procedures may cause injuries or lethal

accidents to personnel.

CAUTION

This heading is used to highlight that non-compliance with

instructions or procedures may cause damage to

equipment.

NOTE

This heading is used to highlight and draw specific

attention to information.

1.3 Additional Documentation to be

used

This workshop manual contains all information and

procedures necessary for the repair of water heaters

Thermo Top E, Thermo Top Z and Thermo Top C.

The use of additional documentation is normally not

necessary.

Operating instructions/installation instructions and the

vehicle specific installation proposal may be used as

complementary information as necessary.

1.4 Safety Information and Regulations

The general safety regulations for the prevention of

accidents and the relevant operating safety instructions

have to be observed at all times.

"General Safety Regulations" beyond the scope of these

regulations are detailed in the following.

The specific safety regulations applicable to this manual

are highlighted in the individual chapters by Warnings,

Cautions, and Notes.

1.4.1 Legal Provisions for Installation

Within the scope of the StVZO (Road Licensing

Regulations of the Federal Republic of Germany) "Design

General Approvals" laid down by the Federal Office for

Motor Traffic exist for the Water Heaters Thermo Top with

the following official marks of conformity:

~ S316 for Heater Thermo Top E-B (fuel type)

~ S317 for Heater Thermo Top E-D (Diesel type)

~ S292 for Heater Thermo Top Z/C-B (fuel type)

and

~ S289 for Heater Thermo Top Z/C-D (Diesel type).

Installation of the heater is to be performed in accordance

with the installation instructions and must be checked in

case of

a) the vehicle type inspection in accordance with

§ 20 StVZO

b) the individual inspection in accordance with

§ 21 StVZO or

c) the examination in accordance with § 19 StVZO

performed by an officially authorised expert or

examiner for road traffic, a vehicle inspector or a

public servant as per section 4 of Annex VIIIb to the

StVZO.

In the event of c) the installation must be certified on the

acceptance certificate included in the copy of the “General

Operating License” giving details about

– manufacturer

– type of vehicle and

– vehicle identification number.

This validates the “Design General Approval”. The

acceptance certificate must be kept with the vehicle.

The obligation to apply for a new "Operating License"

(with expertise) after heater installation does not

exist, if the installation meets entirely the

requirements of an installation instruction, for which

a special supplement exists for the "Design General

Approval". The "Design General Approval" and the

"Operating License" documentation are to be kept

with the vehicle.

The heaters are cleared for heating the vehicle engine

and the vehicle cabin. When using the heaters in vehicles

not subject to the Road Licensing Regulations (StVZO)

(e.g. ships), the applicable partially regional regulations

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

1 Introduction Thermo Top E and Z/C

102

must be observed. The use of the heater in "vehicles for

the transportation of dangerous goods" (ADR) is not

permitted.

The examination is performed by presentation of the

manufacturer’s operating/installation instructions.

The year of first operation must be durably marked by

the installer on the heater identification label by removing

the numerals of the years not applicable.

The heater must not be installed in the passenger or driver

compartments of vehicles.

The heater may only be installed in vehicles or

independent heating systems with a minimum coolant

capacity of 4 litres.

When checking the cooling water level proceed in

accordance with the vehicle manufacturer's instructions.

The water in the heating circuit of the heater must contain

at least 10 % of a quality brand anti-freeze.

Extracting combustion air from the vehicle interior is

prohibited.

The exhaust line outlet is to point downwards or to the

side, or in case of exhaust venting below the vehicle floor,

to be located at the nearest possible location of the

vehicle's or cockpit side or rear end.

Exhaust lines must be routed so that exhaust fumes are

unlikely to penetrate into the vehicle's interior. The

function of any part of the vehicle essential for operation

must not be impaired. Accumulations of condensate in the

exhaust line must be directly drained. A drain hole may be

provided as required.

The openings of the combustion air inlet and the exhaust

outlet must not allow a ball of 16 mm in diameter to be

inserted.

Electrical lines and switching gear of the heater must be

located in the vehicle so that their proper function cannot

be impaired under normal operating conditions.

For the routing of fuel lines and the installation of

additional fuel tanks §§ 45 and 46 of the StVZO are to be

adhered to. The most important regulations are:

• fuel lines are to be designed in such a way that they

remain unaffected by torsional stresses in the vehicle,

engine movement, and the like. They must be

protected against mechanical damage. Fuel-carrying

parts are to be protected against excessive heat and

are to be arranged so that any dripping or evaporating

fuel can neither accumulate nor be ignited by hot

components or electrical equipment.

• the heater must not be located in rooms

accommodating persons.

• the heater mode of operation – at least "on" or "off" –

must be clearly visible.

1.4.2 General Safety Notes

At filling stations and fuel depots the heater must be

switched off as there is a potential danger of explosion.

Due to the danger of poisoning and suffocation the heater

must not be operated, not even with timer or under remote

radio control (Telestart), in enclosed areas such as

garages or workshops not equipped with an exhaust

venting facility.

In the vicinity of the heater a temperature of 120° C

(storage temperature) must not be exceeded under any

circumstances (e.g. during body paint work). Excessive

temperatures may cause permanent damage to the

electronics.

All fuel lines must have leak-proof connections, must

show no damage and must be checked in regular intervals

(at least to the same schedule as the vehicle itself).

Should damage or leakage be detected, it is not permitted

to continue heater operation until the damage has been

rectified by an authorized Webasto repair shop.

NOTE

Make heater inoperative by removing fuse. The fuel lines

(Mecanyl hoses) must not come into direct contact with

exhaust pipe and must be thermally insulated to prevent

fires.

Non-compliance with the installation instructions will void

the Webasto warranty. The same applies for unskilled

repairs or repairs not using original spare parts. This will

also void the general marks of conformity of the heater

and thus the vehicle’s permit of operation.

Before first operation make sure to read the heater

operating instructions.

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Thermo Top E and Z/C 2 General Description

201

2 General Description

The water heater Thermo Top Z (supplementary heater)

is intended to compensate for the shortage in heat

generated by engines optimised for low fuel consumption.

The water heater Thermo Top E and C (auxiliary heater)

is used to:

• heat the vehicle cabin,

• defrost the vehicle windscreens,

• preheat water-cooled vehicle engines.

The heater Thermo Top Z may be converted into an

auxiliary heater using a retrofit kit.

The heater designed to the evaporator principle operates

intermittently controlled by the temperature sensor.

In order to minimise the battery's workload the heater

switches from full-load operation to part-load operation

after reaching a water temperature of 72° C.

In this mode of operation the heater operates with

extremely low noise and particularly low power and fuel

consumption.

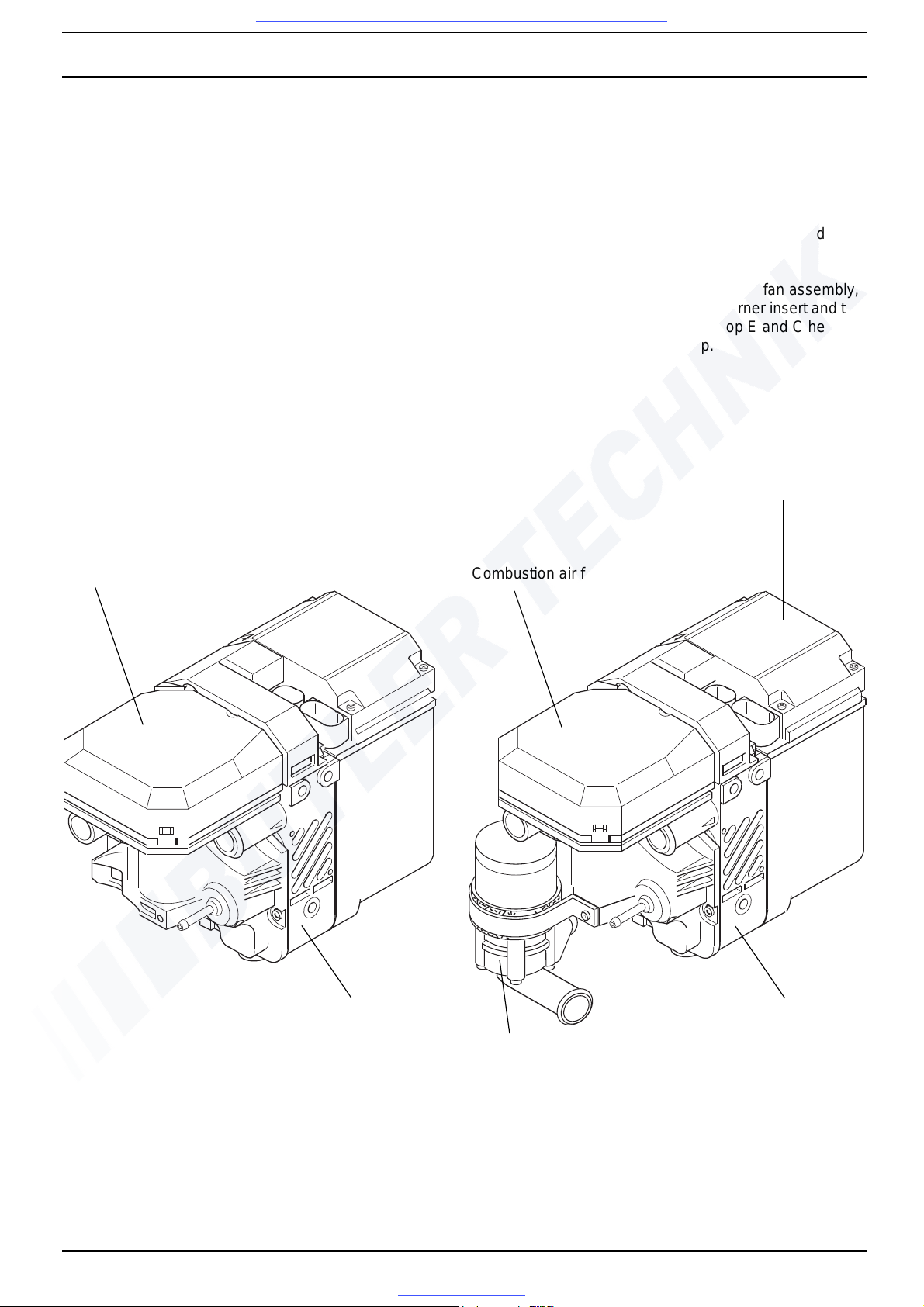

The heater consists of the combustion air fan assembly,

the control unit/heat exchanger, the burner insert and the

combustion chamber. The Thermo Top E and C heater

has an additional circulation pump.

Combustion air fan assembly

Combustion chamber

Control unit/

Thermo Top Z

heat exchanger

Control unit/

heat exchanger

Combustion air fan assembly

Combustion chamber

Circulation pump

Thermo Top E and C

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

2 General Description Thermo Top E and Z/C

202

2.1 Combustion Air Fan Assembly

The combustion air fan assembly includes the

combustion air fan

combustion air line inlet

fuel supply inlet.

The heater Thermo Top E and Z has the circulation pump

mounted on the combustion air fan assembly.

2.1.1 Combustion Air Fan

The combustion air fan delivers the air required for

combustion from the combustion air inlet to the burner

insert.

Combustion Air Fan Assembly

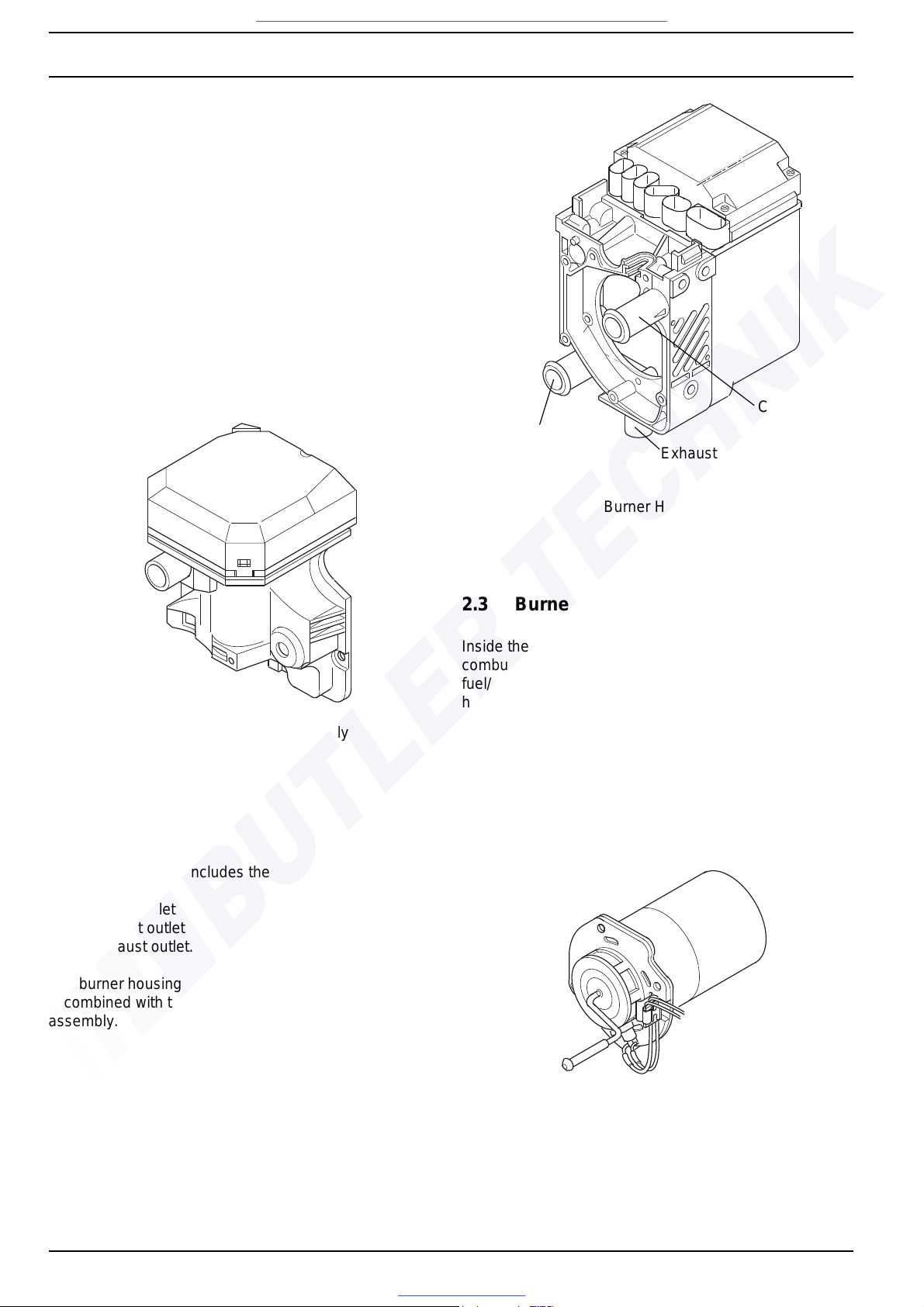

2.2 Burner Housing

The burner housing includes the

coolant inlet

coolant outlet

exhaust outlet.

The burner housing accommodates the burner insert and

is combined with the control unit / heat exchanger to an

assembly.

Burner Housing

2.3 Burner Insert

Inside the burner insert fuel is distributed across the

combustion pipe fuel cross section. Combustion of the

fuel/air mixture takes place within the combustion pipe to

heat the heat exchanger.

The glow plug/flame sensor located in the burner insert

ignites the fuel/air mixture during start of the heater. After

start the glow plug / flame sensor operates in the flame

sensor function. The glow plug / flame sensor designed as

an electrical resistor is located in the burner insert

opposite the flame side.

Burner Insert

Coolant

Coolant

outlet

inlet

Exhaust outlet

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Thermo Top E and Z/C 2 General Description

203

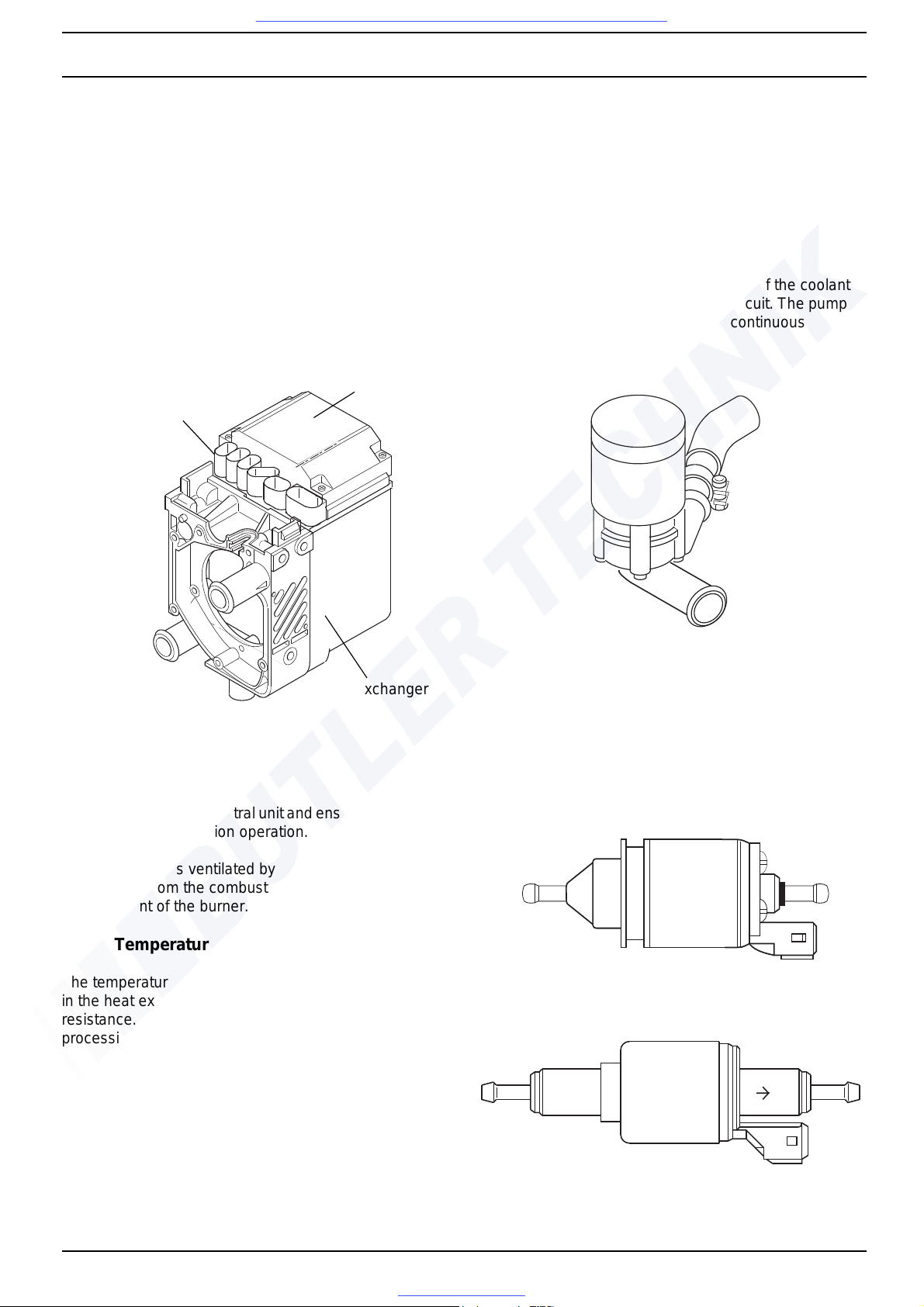

2.4 Control Unit / Heat Exchanger

The control unit / heat exchanger includes the

control unit

temperature sensor

overheat protection

heat exchanger

connector terminal.

CAUTION

The control unit / heat exchanger and the burner housing

represent an assembly and must not be disassembled.

2.4.1 Control Unit

The control unit is the central unit and ensures control and

monitoring of combustion operation.

The control unit is ventilated by means of a ventilation

hose routed from the combustion air collector

compartment of the burner.

2.4.2 Temperature Sensor

The temperature sensor senses the coolant temperature

in the heat exchanger of the heater as an electrical

resistance. This signal is routed to the control unit for

processing.

2.4.3 Overheat Protection

Overheat protection, controlled by a temperature resistor,

protects the heater against undue operating temperatures.

Overheat protection responds at a water temperature in

excess of 105° C and switches the heater off.

2.4.4 Heat Exchanger

The heat exchanger transfers the heat generated by

combustion to the coolant circuit.

2.5 Circulation Pump

(Thermo Top E and C only)

The circulation pump ensures circulation of the coolant

within the vehicle and heater coolant circuit. The pump is

activated by the control unit and is in continuous

operation.

Circulation Pump

2.6 Dosing Pump

The dosing pump is a combined delivery, dosing and

shut-off system for the fuel supply of the heater out of the

vehicle fuel tank.

Dosing Pump DP 2 for Fuel operated Heaters

Dosing Pump DP 30.2 for Diesel operated Heaters

Connector Terminal

Control Unit

Heat Exchanger

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

2 General Description Thermo Top E and Z/C

204

Page free for notes

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Thermo Top E and Z/C 3 Functional Description

301

3 Functional Description

3.1 Functional Description Thermo Top Z

(Supplementary Heater)

3.1.1 Switch On / Starting

Fuel

When starting the vehicle engine the heater goes in

standby. With a water circuit temperature below 60° C and

an outside temperature below 5° C (option with outside

temperature sensor) the starting sequence commences.

The glow plug and the combustion air fan are activated.

After 30 seconds the fuel dosing pump starts operation

and combustion air fan operation is suspended for

3 seconds. Subsequently the combustion air fan speed is

increased in a ramp within 57 seconds to nearly full load

operation.

After reaching full load fuel delivery within this period the

glow plug is deactivated and the combustion air fan

operation increased to full load.

During the subsequent 45 seconds as well as in normal

operation the glow plug functions as flame sensor to

monitor the flame condition.

After all these events the automatically controlled heating

operation starts. In case of a no flame condition or a

flameout, a restart is automatically initiated. If the no flame

condition persists, fuel delivery is stopped and the heaters

enters an error lockout with a run-down of the combustion

air fan.

Diesel

When starting the vehicle engine the heater goes in

standby. With a water circuit temperature below 60° C and

an outside temperature below 5° C (option with outside

temperature sensor) the starting sequence commences.

The glow plug and the combustion air fan are activated.

After 30 seconds the fuel dosing pump starts operation

and combustion air fan operation is suspended for

3 seconds. Subsequently the combustion air fan speed is

increased in two ramps within 56 seconds to nearly full

load operation. After a stabilisation phase (constant

speed) of 15 seconds the combustion air fan speed is

again increased in a ramp within 50 seconds to nearly full

load.

After reaching full load fuel delivery the glow plug is

deactivated and the combustion air fan operation

increased to full load.

During the subsequent 45 seconds as well as in normal

operation the glow plug functions as flame sensor to

monitor the flame condition.

After all these events the automatically controlled heating

operation starts. In case of a no flame condition or a

flameout, a restart is automatically initiated. If the no flame

condition persists, fuel delivery is stopped and the heater

enters an error lockout with a run-down of the combustion

air fan.

A flameout during normal combustion operation causes

an automatic restart.

3.1.2 Heating Operation

Fuel

When the temperature rises to reach 72° C the heater

switches to the energy saving part load operation. A rise

in temperature up to 76.5° C causes the heater to enter a

control idle period. This also happens when exceeding a

total heating operating time of 76 minutes.

After cool-down of the coolant to 71° C the heater

resumes part load operation. Another rise in temperature

to 76.5° C causes the heater to enter again the control idle

period. A drop in the coolant temperature during part load

operation due to an increased demand in heat will cause

the heater to switch to full load operation at 56° C.

Diesel

Heating operation for the Diesel type heater is identical in

the sequence of events. Should the coolant temperature

drop during the control idle period to but not below 71° C

within 900 seconds, a subsequent drop in the coolant

temperature below 71° C causes the heater to perform a

regular starting sequence into full load operation.

A drop in the coolant temperature during part load

operation due to an increased demand in heat will cause

the heater to switch to full load operation at 65° C.

3.1.3 Switch Off / Deactivation

When turning the engine off the heater is deactivated.

Combustion stops and run-down commences. The

combustion air fan first continues operation to cool the

heater down (run-down) to be automatically switched off

afterwards.

NOTE

The run-down time and the combustion air fan speed

depend on the heater operating condition at the time of

deactivation.

Run-down time is for:

Fuel

168 seconds when deactivated in full load operation and

157 seconds when deactivated in part load operation.

Diesel

175 seconds when deactivated in full load operation and

100 seconds when deactivated in part load operation.

Dependent on the software variant implemented in the

control unit there might be deviations from those run-down

periods.

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

3 Functional Description Thermo Top E and Z/C

302

3.2 Functional Description

Thermo Top E and C (Auxiliary Heater)

3.2.1 Switch On

Fuel

When operating the "instant heat" switch button the timer

display shows or when operating the switch on the

Telestart transmitter the operating indicator light on the

transmitter flashes. This puts the heater in standly.

The glow plug, the combustion air fan and the circulation

pump are activated. After 30 seconds the fuel dosing

pump starts operation and combustion air fan operation is

suspended for 3 seconds.

Subsequently the combustion air fan speed is increased

in a ramp within 57 seconds to nearly full load operation.

After reaching full load fuel delivery within this period the

glow plug is deactivated and the combustion air fan

operation increased to full load.

During the subsequent 45 seconds as well as in normal

operation the glow plug functions as flame sensor to

monitor the flame condition.

After all these events the automatically controlled heating

operation starts. In case of a no flame condition or a

flameout, a restart is automatically initiated. If the no flame

condition persists, fuel delivery is stopped and the heater

enters an error lockout with a run-down of the combustion

air fan.

Diesel

When operating the "instant heat" switch button the timer

display shows or when operating the switch on the

Telestart transmitter the operating indicator light on the

transmitter flashes. This puts the heater in standby.

The glow plug, the combustion air fan and the circulation

pump are activated. After 30 seconds the fuel dosing

pump starts operation and combustion air fan operation is

suspended for 3 seconds.

Subsequently the combustion air fan speed is increased

in two ramps within 56 seconds to nearly full load

operation. After a stabilisation phase (constant speed) of

15 seconds the combustion air fan speed is again

increased in a ramp within 50 seconds to nearly full load.

After reaching full load fuel delivery the glow plug is

deactivated and the combustion air fan operation

increased to full load.

During the subsequent 45 seconds as well as in normal

operation the glow plug functions as flame sensor to

monitor the flame condition.

After all these events the automatically controlled heating

operation starts. In case of a no flame condition or a

flameout, a restart is automatically initiated. If the no flame

condition persists, fuel delivery is stopped and the heater

enters an error lockout with a run-down of the combustion

air fan.

A flameout during normal combustion operation causes

an automatic restart.

3.2.2 Heating Operation

Fuel

When the temperature rises to reach 72° C the heater

switches to the energy saving part load operation. A rise

in temperature up to 76.5° C causes the heater to enter a

control idle period. This also happens when exceeding a

total heating operating time of 76 minutes.

The circulation pump, the vehicle's own heating air fan,

and the operation indicator light remain on during control

idle.

After cool-down of the coolant to 71° C the heater

resumes part load operation. Another rise in temperature

to 76.5° C causes the heater to enter again the control idle

period. A drop in the coolant temperature during part load

operation due to an increased demand in heat will cause

the heater to switch to full load operation at 56° C.

Diesel

Heating operation for the Diesel type heater is identical in

the sequence of events. Should the coolant temperature

however not drop within 900 seconds during the control

idle period to below 71° C, a subsequent drop in the

coolant temperature below 71° C causes the heater to

perform a regular starting sequence into full load

operation.

3.2.3 Switch Off

When turning the heater off by pushing the "instant heat"

switch button ( in indicator panel extinguishes) or

when operating the switch on the Telestart (flashing

indicator on hand-held transmitter extinguishes) the

vehicle heating air fan stops.

Combustion terminates and run-down commences. The

circulation pump and the combustion air fan first continue

operation to cool the heater down (run-down) to be

automatically switched off afterwards.

NOTE

The run-down time and the combustion air fan speed

depend on the heater operating condition at the time of

deactivation.

Run-down time is for:

Fuel

168 seconds when deactivated in full load operation and

157 seconds when deactivated in part load operation.

Diesel

175 seconds when deactivated in full load operation and

100 seconds when deactivated in part load operation.

Dependent on the software variant implemented in the

control unit there might be deviations from those run-down

periods.

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Thermo Top E and Z/C 3 Functional Description

303

3.2.4 Auxiliary Heater in Supplementary Heater

Function

3.2.4.1 Switch On

When starting the engine the heater goes in standby

(see 3.1.1).

With the temperature of the water circuit below 60° C and

the outside temperature below 5° C (option with external

temperature sensor) the starting procedure is initiated.

NOTE

When operating in the supplementary heater function

there will be no automatic trigger of the circulation pump

and the vehicle's heating air fan.

3.2.4.2 Switch Off

Turning the engine off deactivates the heater.

Combustion is terminated and run-down commences.

The combustion air fan however continues operation to

cool the heater down (run-down) to be automatically

switched off afterwards (see 3.1.3).

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Loading...

Loading...