Page 1

Water heaters

Workshop manual

Thermo 90 S

Thermo 90 S-ADR

(Transport of hazardous goods)

Thermo 90 ST

Thermo 90 ST-ADR

(Transport of hazardous goods)

08/2004

Page 2

Thermo 90 S / Thermo 90 ST Table of contents

Table of contents

1 Introduction

1.1 Contents and purpose ........................................................................................................................... 101

1.2 Meaning of signal words ........................................................................................................................ 101

1.3 Additional documentation to be used..................................................................................................... 101

1.4 Safety instructions and regulations........................................................................................................ 101

1.4.1 General safety regulations........................................................................................................... 101

1.5 Statutory regulations governing installation ............................................................................................102

1.6 Suggestions for improvements and modifications ................................................................................. 102

2 General description

2.1 Combustion air fan................................................................................................................................. 202

2.2 Heat exchanger ..................................................................................................................................... 202

2.3 Temperature sensor .............................................................................................................................. 203

2.4 Temperature limiter................................................................................................................................ 203

2.5 Burner insert .......................................................................................................................................... 203

2.6 Glow plug............................................................................................................................................... 203

2.7 Flame monitor........................................................................................................................................ 203

2.8 Combustion pipe.................................................................................................................................... 203

2.9 Circulating pump.................................................................................................................................... 203

2.10 Control unit ............................................................................................................................................ 203

2.11 Metering pump....................................................................................................................................... 203

3 Function description

3.1 Switching on .......................................................................................................................................... 301

3.2 Heating mode ........................................................................................................................................ 301

3.3 Control mode ......................................................................................................................................... 301

3.4 Switching off .......................................................................................................................................... 302

3.5 Heater functions when installed in ADR vehicles .................................................................................. 302

3.6 Malfunctions........................................................................................................................................... 303

3.6.1 Fault lock-out ............................................................................................................................... 303

3.6.2 Diagnosis after fault lock-out, Thermo 90 S and Thermo 90 ST ................................................. 304

4 Technical data ................................................................................................................................................ 401

5 Troubleshooting

5.1 General .................................................................................................................................................. 501

5.2 General fault indications ........................................................................................................................ 501

5.3 Fault indications on fault lock-out .......................................................................................................... 502

5.4 Visual check for assessing the burner ................................................................................................... 503

5.4.1 Burner housing .............................................................................................................................503

5.4.2 Back wall with metal evaporator .................................................................................................. 504

5.4.3 Combustion chamber .................................................................................................................. 504

5.4.4 Complete burner.......................................................................................................................... 504

I

Page 3

Table of contents Thermo 90 S / Thermo 90 ST

6 Function tests

6.1 General ................................................................................................................................................. 601

6.2 Settings................................................................................................................................................. 601

6.2.1 Setting the CO

6.3 Testing individual components.............................................................................................................. 601

6.3.1 Resistance test of the temperature sensor ................................................................................. 601

6.3.2 Resistance test of the glow plug................................................................................................. 601

6.3.3 Resistance test of the flame monitor .......................................................................................... 601

6.3.4 Testing the combustion air fan.................................................................................................... 601

7 Circuit diagrams

7.1 General ................................................................................................................................................. 701

8 Service work

8.1 General ................................................................................................................................................. 801

8.2 Work on the heater ............................................................................................................................... 801

8.3 Work on the vehicle .............................................................................................................................. 801

8.4 Heater trial run ...................................................................................................................................... 802

8.5 Service work ......................................................................................................................................... 802

8.6 Visual inspections and installation instructions ..................................................................................... 804

8.6.1 Connection to the vehicle cooling system................................................................................... 804

8.6.2 Connection to the vehicle fuel system ........................................................................................ 804

8.6.3 Metering pump with damper ....................................................................................................... 807

8.6.4 Fuel filter..................................................................................................................................... 807

8.6.5 Combustion air supply ................................................................................................................ 807

8.6.6 Exhaust line ................................................................................................................................ 808

content.............................................................................................................. 601

2

8.7 Removal and installation....................................................................................................................... 808

8.7.1 Heater, removal and installation ................................................................................................. 808

8.7.2 Changing the circulating pump ................................................................................................... 809

8.7.3 Changing the temperature limiter ............................................................................................... 809

8.7.4 Changing the temperature sensor .............................................................................................. 809

8.7.5 Changing the combustion air fan................................................................................................ 809

8.8 Start-up ................................................................................................................................................. 809

II

Page 4

Thermo 90 S / Thermo 90 ST Table of contents

9Repair

9.1 General .................................................................................................................................................. 901

9.1.1 Work on stripped-down components ........................................................................................... 901

9.2 Dismantling and assembling.................................................................................................................. 902

9.2.1 Electrical connections (Thermo 90 S).......................................................................................... 902

9.2.2 Changing the circulating pump .................................................................................................... 903

9.2.3 Changing the temperature limiter ................................................................................................ 904

9.2.4 Changing the temperature sensor ............................................................................................... 904

9.2.5 Changing the combustion air fan................................................................................................. 906

9.2.6 Changing the burner, flame monitor and glow plug..................................................................... 907

9.2.7 Changing the burner head........................................................................................................... 909

9.2.8 Changing the heat exchanger ..................................................................................................... 910

10 Packing, storage and shipment

10.1 General ................................................................................................................................................ 1001

III

Page 5

List of illustrations Thermo 90 S / Thermo 90 ST

List of illustrations

301 Sequence of functions ............................................................................................................................... 302

501 General fault indications ............................................................................................................................ 501

502 Fault indications on fault lock-out .............................................................................................................. 502

503 Visual check, burner back wall................................................................................................................... 503

504 Visual check, pilot flame outlet opening ..................................................................................................... 504

505 Visual check, complete burner................................................................................................................... 504

701 System circuit for Thermo 90 S, 12 and 24 V, with standard clock............................................................ 702

702 System circuit for Thermo 90 S, 12 and 24 V, with standard clock and separate

circulating pump control ............................................................................................................................. 703

703 System circuit for Thermo 90 S-ADR, 24 V, with switch ............................................................................ 704

704 System circuit for Thermo 90 S-ADR, 24 V, with switch without power take-off ........................................ 705

705 System circuit for Thermo 90 ST, 12 and 24 V, with standard digital timer ............................................... 706

706 System circuit for Thermo 90 ST, 12 and 24 V, with standard digital timer and separate

circulating pump control ............................................................................................................................. 707

707 System circuit for Thermo 90 ST-ADR, 24 V, with switch .......................................................................... 708

708 System circuit for Thermo 90 ST-ADR, 24 V, with switch without power take-off...................................... 709

801 Specimen installations for heater in a truck ............................................................................................... 803

802 Fuel supply................................................................................................................................................. 804

803 Webasto fuel extractor............................................................................................................................... 805

804 Fuel extraction from the plastic tank (extraction through tank drain screw)............................................... 805

805 Fuel extraction from the plastic tank (extraction through tank fitting)......................................................... 805

806 Webasto fuel extractor............................................................................................................................... 806

807 Pipe/hose connection................................................................................................................................. 806

808 Metering pump, installation position and attachment ................................................................................ 807

809 Exhaust pipe opening, installation position................................................................................................ 808

901 Electrical connections (Thermo 90 S) ........................................................................................................ 902

902 Changing the circulating pump .................................................................................................................. 903

903 Changing the temperature limiter and temperature sensor ....................................................................... 905

904 Changing the combustion air fan ............................................................................................................... 906

905 Changing the burner, flame monitor and glow plug ................................................................................... 908

906 Changing the burner head ......................................................................................................................... 909

IV

Page 6

Thermo 90 S / Thermo 90 ST 1Introduction

1Introduction

1.1 Contents and purpose

This workshop manual is designed to assist trained

personnel with repairing both the petrol and the diesel

versions of the Thermo 90 S und Thermo 90 ST water

heaters.

The heater is only allowed to be operated with the

intended fuel (diesel or also with heating oil EL) and only

in the particular prescribed electrical connection type.

1.2 Meaning of signal words

Throughout this manual, the signal words WARNING,

CAUTION and NOTE have the following meanings:

WARNING

This heading is used to highlight operating instructions or

procedures which, if not or not correctly followed, may

result in personal injury or fatal accidents.

CAUTION

This heading is used to highlight operating instructions or

procedures which, if not or not correctly followed, may

result in damage to the equipment or its components.

1.4.1 General safety regulations

The year of first start-up must be indelibly identified

on the rating plate by removing the corresponding

year number.

The heaters are only licensed for heating the motor

vehicle engine and vehicle cabin, not however for heating

the hazardous material transport space.

The heater is only allowed to be installed in motor vehicles

or in independent heating systems with a minimum

coolant volume of 6 litres.

The heater is not allowed to be installed in the driver’s cab

or passenger compartment of vehicles. If the heater is

nevertheless installed in such a place, the installation box

must be tightly sealed against the vehicle interior. The

installation box must have sufficient external ventilation to

ensure that a maximum temperature of 40 °C is not

exceeded in the box. Malfunctions may occur if the

temperature exceeds this level.

WARNING

The heater must not be operated in enclosed areas,

such as garages or workshops without an exhaust

emissions extraction system, not even using the

timer or Telestart, because of the risk of asphyxiation

and poisoning.

NOTE

This heading is used to direct your attention to a special

feature deemed essential to highlight.

1.3 Additional documentation to be used

This workshop manual contains all necessary information

and instructions for repairing Thermo 90 S and Thermo 90 ST

water heaters.

Normally, there is no need to use additional

documentation.

If required, the installation instructions, the vehiclespecific installation instructions and the operating

instructions can be used as well.

1.4 Safety instructions and regulations

In principle, the general accident prevention regulations

and current works safety instructions are applicable.

The “General safety regulations” that go beyond the

scope of the above regulations are stated below.

Any special safety regulations relevant to this instruction

manual will be highlighted in the relevant sections or text

passages of the procedures.

The heater must be switched off at filling stations and

fuel tank farms because of the risk of explosion.

CAUTION

Wherever inflammable vapours or dust may form (for

example near fuel, coal, wood dust or cereal stores or

the like), the heater must be switched off because of

the risk of explosion.

A temperature of 85 °C (storage temperature) must not be

exceeded in the vicinity of the control unit (for example

when completing painting work on the vehicle).

If this temperature is exceeded, the electronic systems

may suffer permanent damage.

Follow the instructions supplied by the vehicle

manufacturer to check the cooling water level. The water

in the heating circuit of the heater must contain at least

10% branded anti-freeze.

Non-compliance with the installation instructions and the

warnings contained therein will lead to the exclusion of all

liability by Webasto. The same applies if repairs are

carried out incorrectly or with the use of parts other than

genuine spare parts. This will result in the revocation of

the type licence for the heater and therefore the general

operating licence for the vehicle.

101

Page 7

1Introduction Thermo 90 S / Thermo 90 ST

1.5 Statutory regulations governing

installation

Refer to the installation instructions for the statutory

regulations if necessary.

1.6 Suggestions for improvements and

modifications

Complaints, improvement suggestions or corrections

relating to this technical manual should be addressed to:

Webasto Thermosysteme International GmbH

Technical Documentation Dept.

D-82131 Stockdorf

Tel.: +49 (89) 8579 4542

Fax: +49 (89) 8579 4757

102

Page 8

Thermo 90 S / Thermo 90 ST 2 General description

2 General description

Thermo 90 S and Thermo 90 ST water heaters operate in

conjunction with the vehicle’s own heating system and

serve

– to heat the cab,

– to defrost the vehicle windows and

– to preheat water-cooled engines.

The water heater operates independently of the engine

and is connected to the cooling system, the fuel system

and the electrical system of the vehicle.

The concept of the heater is based on the evaporator

principle. It is controlled by the temperature sensor and

operates intermittently.

Depending on the deviation between the current coolant

temperature and the nominal value measured at the

temperature sensor, the burner power is regulated

between the limits of 1.8 to 7.6 kW in diesel heaters and

1.8 to 7.6 kW in petrol heaters. When the heating

requirement is particularly high (preheating), diesel

heaters provide a maximum power of 9.1 kW for up to

2 hours after the heater is switched on.

The Thermo 90 S and Thermo 90 ST heater is principally

composed of

– the combustion air fan

– the heat exchanger

– the burner insert with combustion pipe

– the circulating pump

To control and monitor it, the heater has

– a control unit (external)

– a flame monitor

– a glow plug

– a temperature sensor

– a temperature limiter

inside it.

In the case of the Thermo 90 S heater, the control unit can

also be flange-mounted on the combustion air fan.

The Thermo 90 ST heater is delivered with the control unit

already flange-mounted on the combustion air fan.

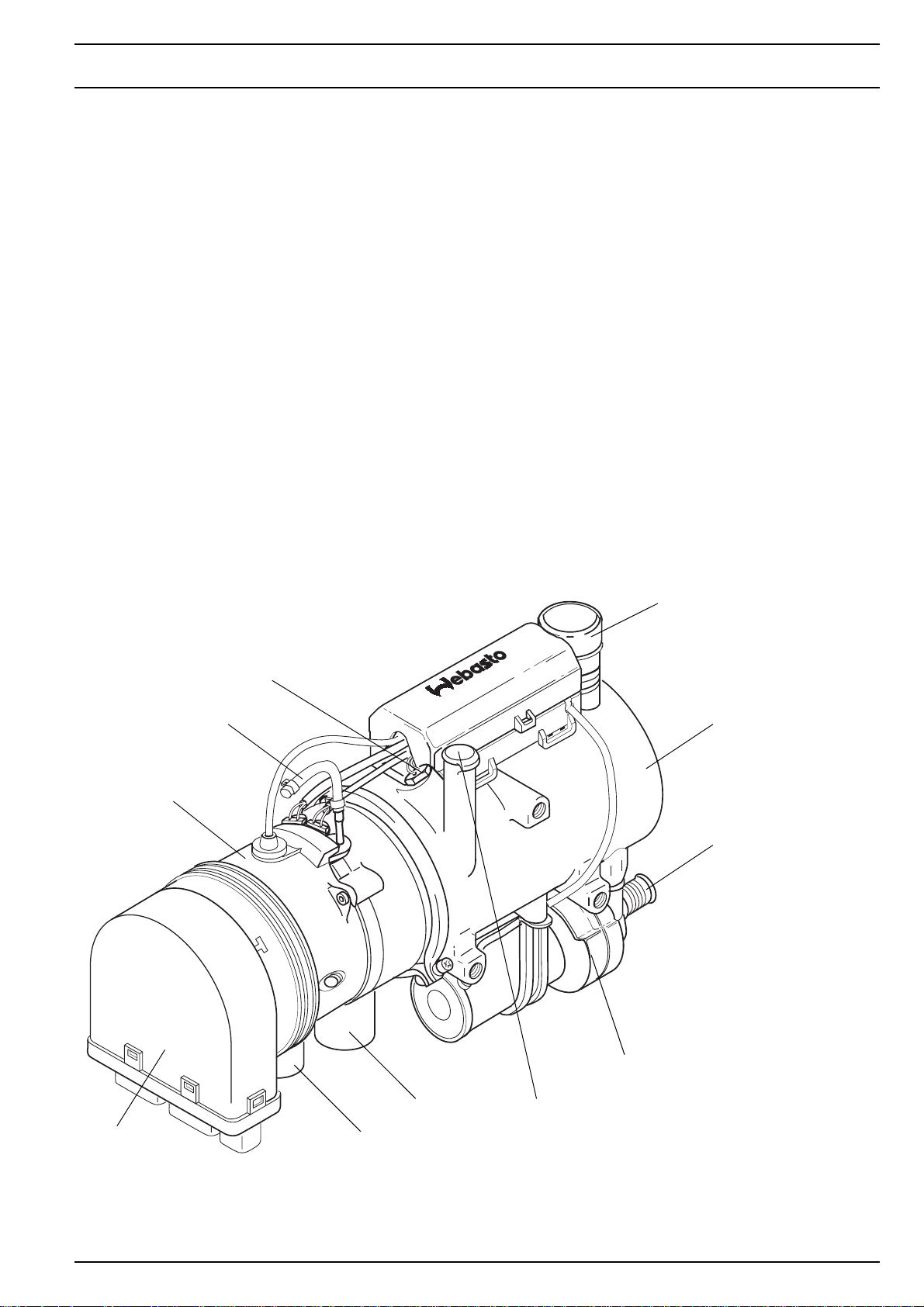

11

4

3

Thermo 90 S

2

1

7

10 Inlet, combustion air

11 Control unit (can also be

9

10

8

5

6

1 Combustion air fan

2 Fuel connection

3 Temperature sensor

4 Temperature limiter

5 Heat exchanger

6 Inlet, coolant

7 Circulating pump

8 Outlet, coolant

9 Outlet, exhaust gas

arranged externally in the

vehicle)

Thermo 90 S heater

201

Page 9

2 General description Thermo 90 S / Thermo 90 ST

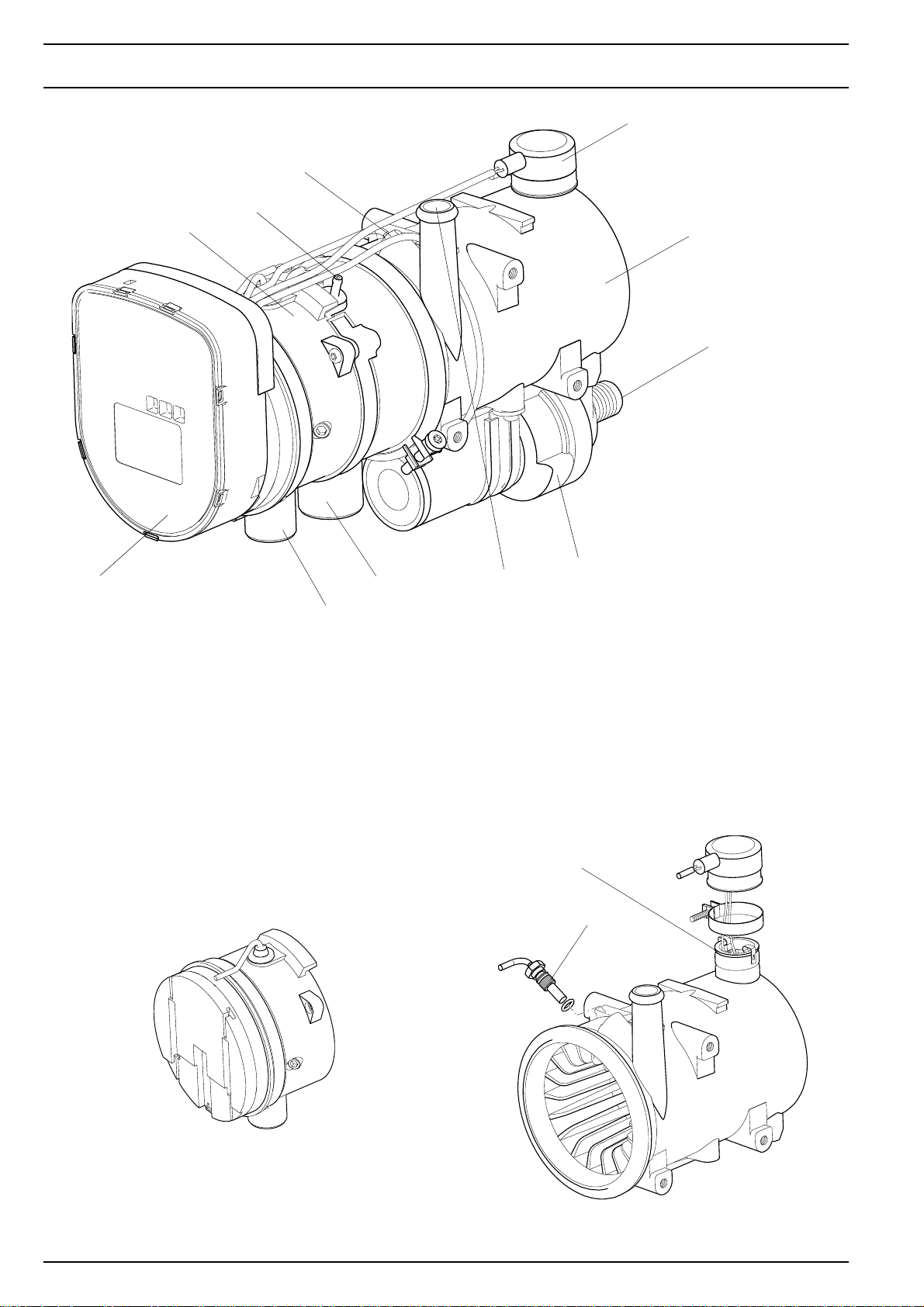

4

3

2

11

1

7

10

9

8

5

6

1 Combustion air fan

2 Fuel connection

3 Temperature sensor

4 Temperature limiter

5 Heat exchanger

6 Inlet, coolant

7 Circulating pump

8 Outlet, coolant

9 Outlet, exhaust gas

10 Inlet, combustion air

11 Control unit

Thermo 90 ST heater

2.1 Combustion air fan

The combustion air fan supplies the air required for the

combustion process from the combustion air inlet to the

burner insert.

2.2 Heat exchanger

In the heat exchanger, the heat generated by combustion

is transferred to the coolant circuit.

Temperature limiter

Temperature sensor

202

Combustion air fan

Heat exchanger

Page 10

Thermo 90 S / Thermo 90 ST 2 General description

2.3 Temperature sensor

The temperature sensor records the coolant temperature

at the coolant outlet of the heater as an electrical

resistance. This signal is fed to the control unit where it is

processed.

2.4 Temperature limiter

The overheating guard circuit (bimetallic) protects the

heater against impermissibly high operating

temperatures. The overheating guard circuit trips if the

heat exchanger temperature exceeds 127 ±7 °C and

switches off the heater.

2.5 Burner insert

The fuel is distributed over the burner cross-section in the

combustion pipe in the burner insert.

2.6 Glow plug

The mixture of fuel and air is ignited by the glow plug when

the heater is started. The glow plug takes the form of an

electrical resistor and is positioned in the burner insert on

the side away from the flame.

2.8 Combustion pipe

The mixture of fuel and air burns in the combustion pipe,

thus causing the heat exchanger to become hot.

Combustion pipe

2.9 Circulating pump

The circulating pump ensures that coolant is pumped

through the vehicle and heater circuits. The pump is

switched on by the control unit and it runs throughout

operation of the heater (including in the control pause).

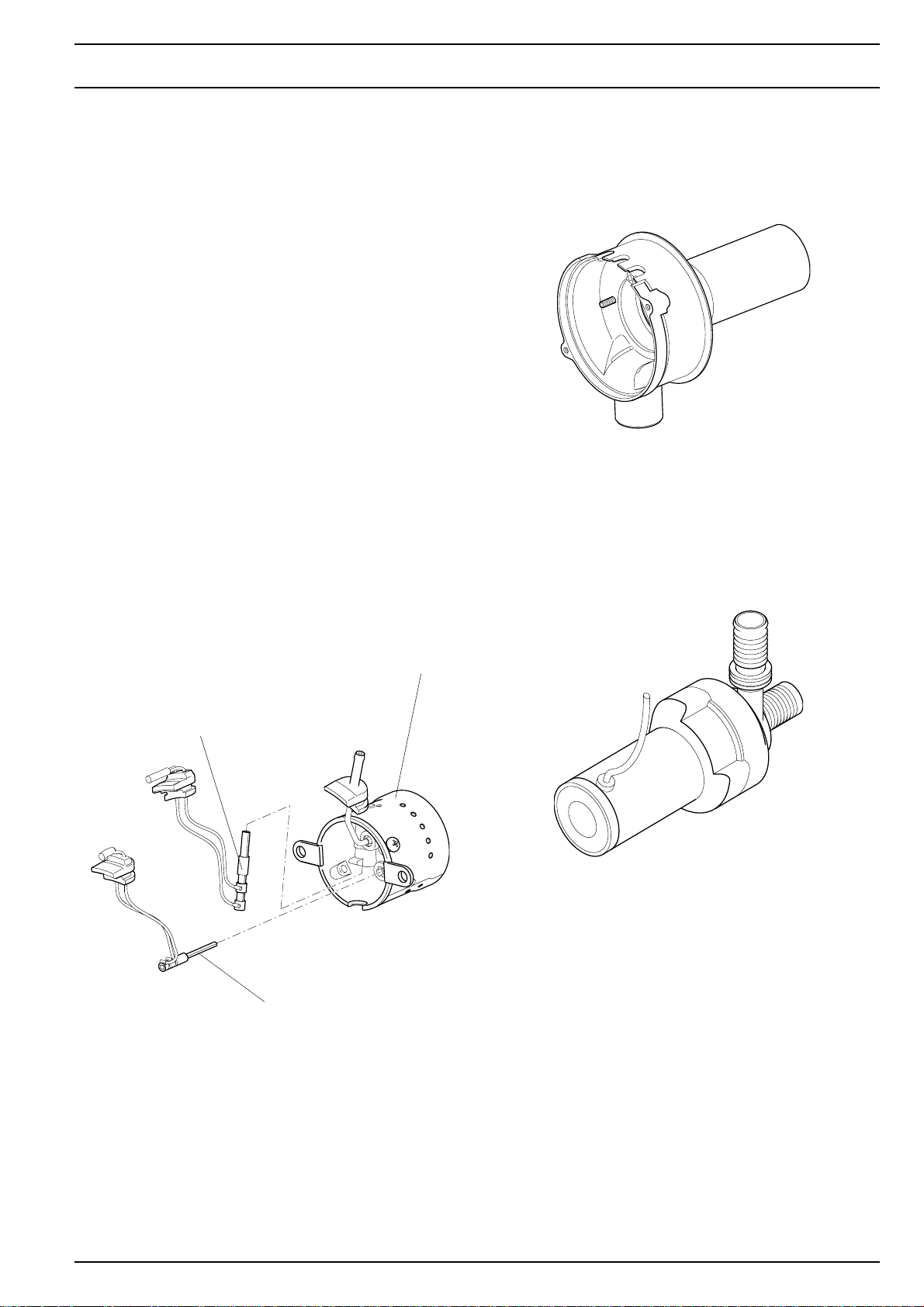

Burner insert

Glow plug

Flame monitor

2.7 Flame monitor

The flame monitor is a low-ohm PTC resistor, which

changes its resistance depending on the heat emitted by

the flame. The signals are fed to the control unit where

they are processed. The flame status is monitored by the

flame monitor whenever the heater is operating.

Circulating pump

2.10 Control unit

The control unit is the central component. It guarantees

the sequence of functions and monitoring of combustion

mode. It is flange-mounted on the combustion air fan,

although in the case of the Thermo 90 S it may be

installed externally in the vehicle.

2.11 Metering pump

The fuel supply and metering for the heater is assured by

an external metering pump. It addition, it serves as a shutoff element when the heater is switched off.

The solenoid coil of the metering pump receives its pulses

from the microprocessor in the control unit.

203

Page 11

2 General description Thermo 90 S / Thermo 90 ST

Page for notes

204

Page 12

Thermo 90 S / Thermo 90 ST 3 Function description

3 Function description

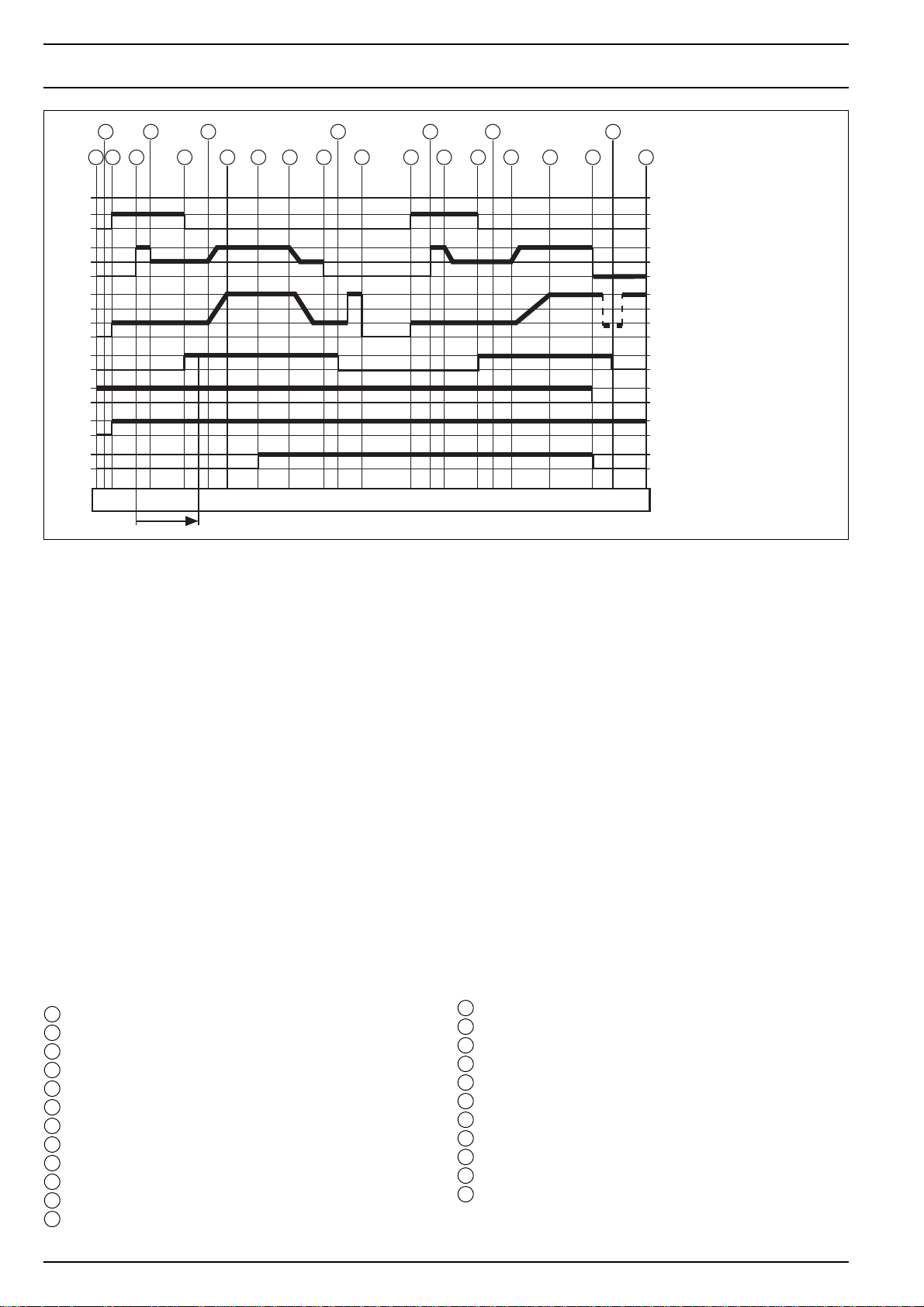

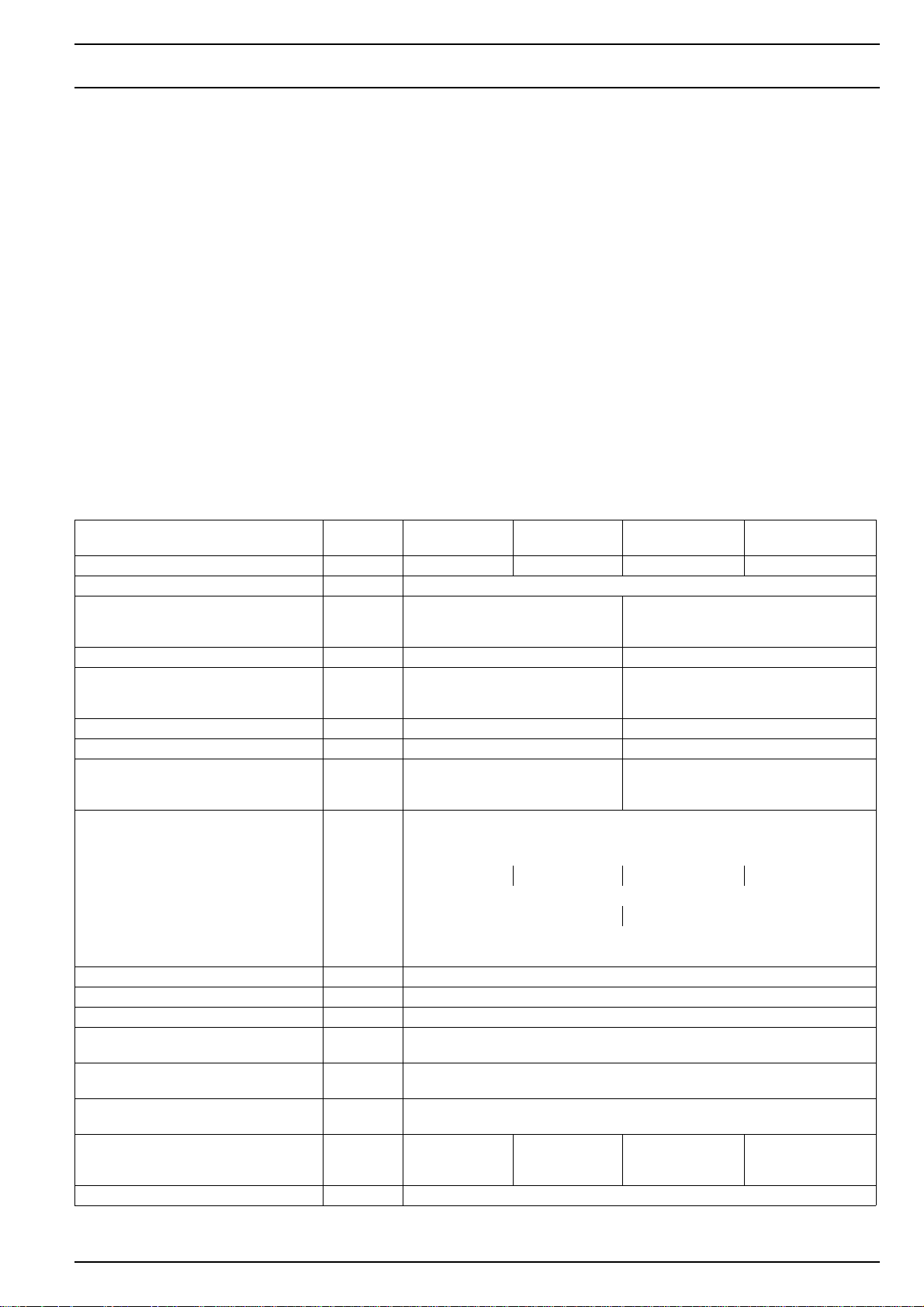

(Fig. 301)

3.1 Switching on

The “operating indicator” on the digital timer lights up

when the “immediate heating” button is pressed.

or

When switching on with the switch, the operating indicator

in the switch lights up.

The circulating pump, glow plug and combustion air fan

start operating.

3.2 Heating mode

Combustion starts after approx. 60 to 140 seconds.

Automatically controlled heating operation runs at full load

for a maximum of 2 hours.

The vehicle’s own heater fan does not switch on until the

heat carrier (coolant) has heated up sufficiently. Once the

preset nominal temperature has been reached (see table

of regulating temperatures) the heating power is reduced

to the lowest part load in small individual steps.

3.3 Control mode

The heater switches to the control pause if the

temperature of the coolant continues to rise to the

threshold of the control pause. The circulating pump, the

vehicle’s own heater fan and the operating indicator

continue to operate during the control pause.

The heater restarts when the coolant cools to the preset

temperature for switching back on.

Diesel heaters

If the water temperature in the heater is higher than the

nominal temperature but has not yet reached the

threshold for the control pause and if the temperature then

falls back to the nominal temperature within 10 minutes

(after reaching this temperature for the first time), the

heater switches back to the 9.0 kW heating stage.

When the nominal temperature is reached, the heater is

only switched back on again up to the 7.6 kW heating

stage.

Petrol heaters

The maximum heating power in petrol heaters is

always 7.6 kW.

301

Page 13

3 Function description Thermo 90 S / Thermo 90 ST

A

B

C

D

E

F

G

2 5 7

1

0

1

1

/4

0

1

1

/2

1

/4

0

1

0

1

0

1

0

1

0

*

Safety time

181512

986431

30 80 90 75 70 °C

22

212019171614131110

Fig. 301 Sequence of functions

23

* If no flame is formed, the

start is automatically

repeated (20 s pulse preglow, 90 s safety time).

o Possible regulating

❏

temperatures that can be

set, see table below

3.4 Switching off

The operating indicator on the digital timer/switch goes

out when the heater is switched off. The combustion

process will be ended and the run-on phase will start.

The circulating pump and the combustion air fan continue

to run, however, in order to cool down the heater (run-on)

and are switched off automatically after approx.

105 seconds. The heater may be switched on again

during the run-on time.

The temperature in the cabin can also be controlled using

the vehicle’s own heater fan with a cabin thermostat.

3.5 Heater functions

when installed in ADR vehicles

Sequence of functions for Thermo 90 S and ST

1

Switch on

2

Component interrogation

3

Pre-glow 40 s (pulsed)

4

Metering pump supply 5 – 7 s (1)

5

Metering pump / part load (1/4)

6

Flame monitor take-over

7

Stabilisation time

8

Full load

9

Vehicle fan “On”

10

Control range

11

Control pause

12

Flame monitor “Cold” (0)

The heater is started using the switch. An ADR case

(constrained shut-off) is triggered when

– the vehicle’s engine is switched off,

– a pumping device is started,

in which case the short run-on is terminated after

20 seconds (Thermo 90 S) and after 40 seconds

(Thermo 90 ST).

Following this, the control unit is left in the “fault lock-out”

status. The on/off switch must be moved to “Off” before it

can be restarted.

The disconnecting switch (emergency off switch) is only

allowed to be used in case of danger, because the heater

is switched off without any run-on (overheating possible).

13

Run-on ended

14

Pre-glow 15 – 20 s (pulsed)

15

Metering pump supply 5 – 7 s (1)

16

Metering pump / part load (1/4)

17

Flame monitor take-over

18

Stabilisation time

19

Coolant temperature reduced

20

Full load

21

Switch off (run-on)

22

Flame monitor “Cold” (0)

23

Run-on ended

302

Page 14

Thermo 90 S / Thermo 90 ST 3 Function description

A Glow plug

B Metering pump

C Combustion air fan

D Flame monitor

E Operation indicator light

F Circulating pump

G Vehicle fan

3.6 Malfunctions

3.6.1 Fault lock-out

Fuel is supplied for max. 240 seconds if the flame does

not start to burn.

Fuel is supplied for max. 240 seconds if the flame goes

out during operation.

The fuel supply is shut off if the system overheats

(temperature limiter is tripped). If the system overheats,

the button on the temperature limiter must be reset.

Once the cause of the fault has been eliminated, the fault

lock-out is cancelled by switching the heater off and on

again.

If the undervoltage guard switches off the system

Thermo 90 S and Thermo 90 ST

12 volts 10.5 V - 0.5 V

24 volts 21 V -1 V

for longer than 20 seconds, the fuel supply is interrupted.

CAUTION

A forced reset of the return spring when hot can result in

damage to the component.

303

Page 15

3 Function description Thermo 90 S / Thermo 90 ST

3.6.2 Diagnosis after fault lock-out

Thermo 90 S and Thermo 90 ST

Check the fuses and plug connectors.

3.6.2.1 Version with digital timer

If the system is equipped with a standard clock, a fault

message appears on the display of the digital timer after

a fault occurs:

F 01 No start (after 2 attempts to start)

F 02 Flame failure

F 03 Undervoltage or overvoltage

F 04 Premature flame recognition

F 05 Flame monitor interrupt or flame monitor short

circuit

F 06 Temperature sensor interrupt or temperature

sensor short circuit

F 07 Metering pump interrupt or metering pump short

circuit

F 08 Fan motor interrupt or fan motor short circuit or

fan motor incorrect speed

F 09 Glow plug interrupt or glow plug short circuit

F10 Overheating

F 11 Circulating pump interrupt or circulating pump

short circuit

3.6.2.2 Version with switch

If the system is operated with a switch, the nature of the

fault is indicated by a flashing code

indicator light during the run-on time of the heater.

After five short signals, count the long flashes:

1x No start (after 2 attempts to start)

2x Flame failure

3x Undervoltage or overvoltage

4x Premature flame recognition

5x Flame monitor interrupt or flame monitor short

circuit

6x Temperature sensor interrupt or temperature

sensor short circuit

7x Metering pump interrupt or metering pump short

circuit

8x Fan motor interrupt or fan motor short circuit or fan

motor incorrect speed

9x Glow plug interrupt or glow plug short circuit

10x Overheating

11x Circulating pump interrupt or circulating pump short

circuit

on an operating

304

Page 16

Thermo 90 S / Thermo 90 ST 3 Function description

Page for notes

305

Page 17

Thermo 90 S / Thermo 90 ST 4 Technical data

4 Technical data

Except where limit values are specified, the technical data

below refer to the usual heater tolerances of ±10% at an

ambient temperature of +20 °C and at the rated voltage.

Fuel for Thermo 90 S / Thermo 90 ST and Thermo 90

S-ADR / Thermo 90 ST-ADR (diesel):

The diesel fuel specified by the manufacturer must be

used.

Electrical components

The control unit, motors for combustion air fan and

circulating pump, glow plug, switch and digital timer (no

timer for ADR mode) are designed for either 12 volts or

24 volts.

The temperature limiter, temperature sensor and flame

We know of no negative influences due to additives. If fuel

is extracted from the vehicle’s tank, follow the additive

instructions issued by the vehicle manufacturer.

If you change to low-temperature fuel, the heater must be

operated for approx. 15 minutes so that the fuel line and

fuel pump are filled with the new fuel.

monitor are identical on 12 V and 24 V heaters.

Fuel for Thermo 90 S / Thermo 90 ST petrol:

The fuel specified by the manufacturer must be used.

Both leaded and unleaded fuel may be used.

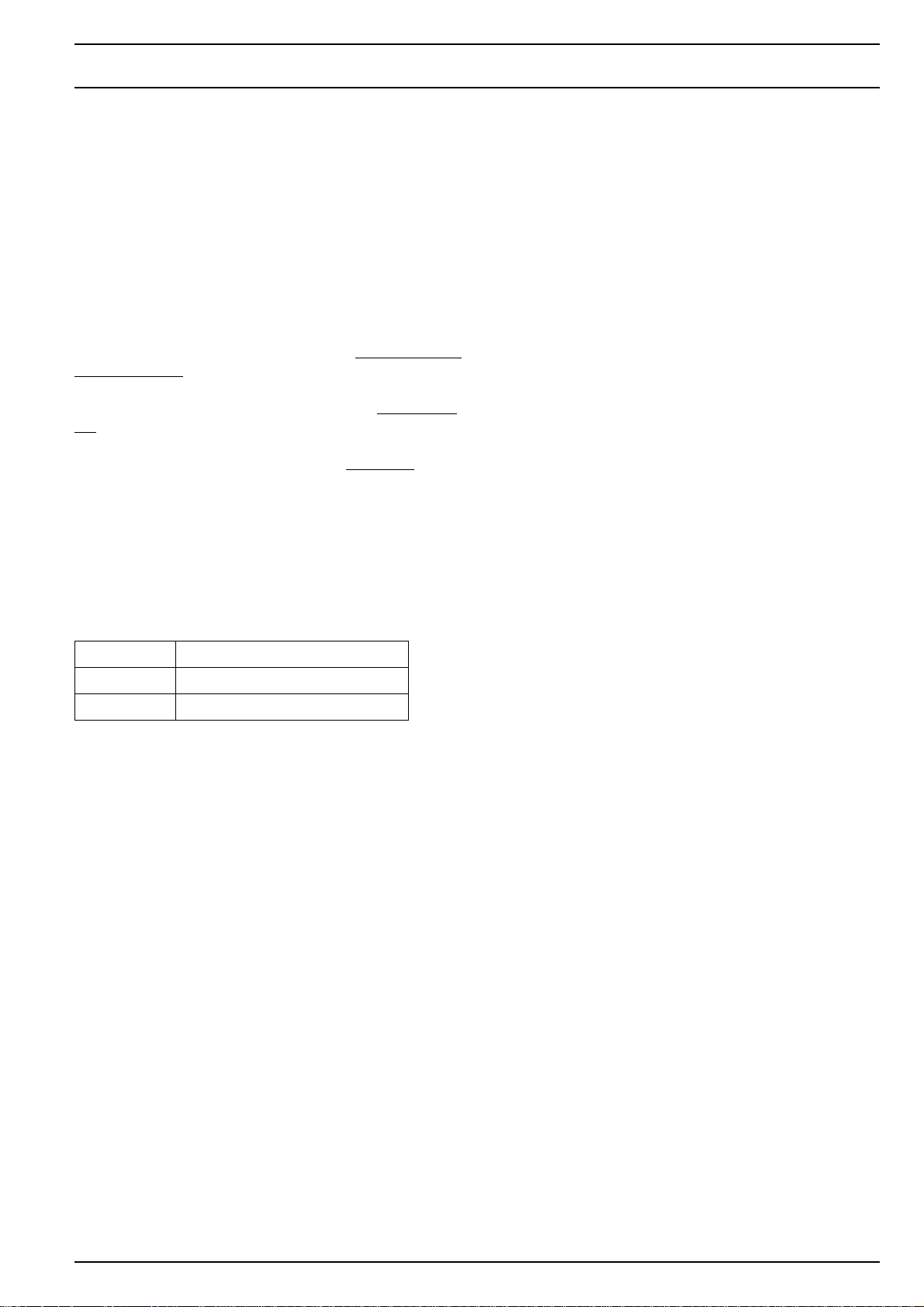

Heater Operation Thermo 90 S

Petrol

EC licensing symbol ~S299 ~S298

Model Water heater with Ferro-Tec technology

Heat output Max.

regulating

range

Fuel Petrol Diesel

Fuel consumption Max.

Rated voltage 12 volts 12 or 24 volts

Operating voltage range 10 ... 15 volts 10 ... 15 or 20 ... 30 volts

Nominal power consumption with circulating

pump

(without vehicle fan)

Max. ambient temperature:

Heater: - Operation -40 ... +110 °C (90 °C with control unit installed on heater)

- Storage -40 ... +110 °C (90 °C with control unit installed on heater)

Control unit: - Operation -40 ... +75 °C -40 ... +85 °C -40 ... +75 °C -40 ... +85 °C

- Storage -40 ... +85 °C

Metering pump: - Operation -40 ... +20 °C -40 ... +40 °C

- Storage -40 ... +85 °C

Permitted operating pressure (heat carrier) Max. 2.0 bar

Capacity of the heat exchanger 0.15 l

Max. combustion air intake temperature +40 °C

Minimum capacity of the circuit 6.00 l

Delivery rate of the circulating pump

against 0.15 bar

in exhaust fumes (permitted function

CO

2

range)

adjustment values at approx. +20 °C

CO

2

and geographic altitude above sea level

Heater dimensions (tolerance ± 3 mm)

* Control unit installed on the heater

Weight 4.8 kg

regulating

range

Max.

regulating

range

Max. 10 ... 12.0% by volume

Max. 0 m 500 m 1000 m

L 310 (355*) mm

2.0 kW – 7.6 kW

0.25 l/h – 1.0 l/h

37 W – 83 W

W 131 mm

H 232 mm

Thermo 90 ST

Petrol

10% 10.6% 11.3%

L 307 (352*) mm

W 131 mm

H 232 mm

Thermo 90 S diesel

Thermo 90 S-ADR

1.8 kW – 7.6 kW

0.19 l/h – 0.9 l/h

1650 l/h

L 310 (355*) mm

W 131 mm

H 232 mm

Thermo 90 ST diesel

Thermo 90 ST-ADR

9.1 kW

1.1 l/h

90 W

37 W – 83 W

L 307 (352*) mm

W 131 mm

H 232 mm

401

Page 18

4 Technical data Thermo 90 S / Thermo 90 ST

Page for notes

402

Page 19

Thermo 90 S / Thermo 90 ST 5 Troubleshooting

5 Troubleshooting

5.1 General

This section describes how to identify and remedy faults

on the Thermo 90 S und Thermo 90 ST heater.

CAUTION

Troubleshooting work demands precise knowledge of the

structure and theory of operation of the various

components and must be carried out by trained personnel

only.

If in doubt, refer to sections 2 and 3 for a description of

how the functions interact.

CAUTION

As a rule, fault detection is restricted to the localisation of

defective components.

The following potential sources of malfunctions are not

taken into account and should always be checked so that

they can then be excluded as the cause of the particular

fault:

• Corroded plugs

• Loose plug contacts

• Poor crimp contacts on plugs

• Corroded cables and fuses

• Corroded battery terminals

• Impermissibly high ambient temperature

Conduct a function test in the vehicle after rectifying each

fault; switch the heater off and back on again first.

5.2 General fault indications

The following table (Fig. 501) lists the possible general

fault indications.

Fault indication Possible cause Remedy

Heater switches off

automatically

No combustion after start and

restart

Flame extinguishes during

operation

Heater overheats due to lack/

loss of coolant

Voltage failure

longer than 20 seconds

Switch off by temperature limiter After the unit has cooled down,

No flame recognition on start Check flame monitor and connections

Fig. 501 General fault indications

Control unit enters fault lock-out status.

Switch the heater off and back on again.

Contact a Webasto service centre if heater

operation does not start again

Top up coolant.

After the unit has cooled down, press the

button of the temperature limiter before

switching on or fit a new temperature limiter

Check fuses, plug connectors and charge

condition of the battery

press the button of the temperature limiter

before switching on or fit a new temperature

limiter

NOTE

In many cases, the burner may be one possible cause.

Perform a visual check in accordance with 5.4.

501

Page 20

5 Troubleshooting Thermo 90 S / Thermo 90 ST

5.3 Fault indications on fault lock-out

NOTE

If the system is operated with a switch, the nature of the

fault is indicated by a flashing code on an indicator light

during the run-on time of the heater.

Fault indication Possible cause Remedy

No function Electrical cabling,

fuses

Control unit defective Replace control unit

1 Flashing pulse

(start did not occur)

2 Flashing pulses

(flame failure during burner

operation)

Fuel system Check fuel level

Combustion air/exhaust line Check combustion air/exhaust line for

Burner Clean burner and change if necessary

Fuel supply Check fuel level

After five short signals, count the long flashes.

In the Thermo 90 S heater with a standard clock, the fault

is output on the clock display (see 3.6.3). The following

table can be used accordingly.

Check fuses

Check battery connections:

+ on 12 / – on 9 / + on 3, plug X12

(Thermo 90 S)

+ on 12 / – on 9 / + on 3, plug X8

(Thermo 90 ST)

Check fuel filter

Bleed fuel system

foreign bodies and clean if necessary

Check fuel filter

Bleed fuel system

3 Flashing pulses

(undervoltage)

4 Flashing pulses

(flame monitor continuously

hot)

5 Flashing pulses

(flame monitor defective)

6 Flashing pulses

(temperature sensor

defective)

7 Flashing pulses

(metering pump defective/

(overheating guard circuit

defective)

Burner Clean burner and change if necessary

Electrical power supply Check battery

Check electrical connections

Flame monitor defective Replace flame monitor

Cabling Check cabling for damage, discontinuity and

short-circuit

Flame monitor defective Replace flame monitor

Cabling Check cabling for damage, discontinuity and

short-circuit

Temperature sensor defective Replace temperature sensor

Coolant circuit Check coolant level

Bleed coolant circuit

Reset temperature limiter

Cabling Check cabling for damage, discontinuity and

short-circuit

8 Flashing pulses

(combustion air fan

defective)

502

Metering pump defective Replace metering pump

Cabling Check cabling for damage, discontinuity and

short-circuit

Combustion air fan defective Replace combustion air fan

Fig. 502 Fault indications on fault lock-out (page 1 of 2)

Page 21

Thermo 90 S / Thermo 90 ST 5 Troubleshooting

Fault indication Possible cause Remedy

9 Flashing pulses

(glow plug defective)

10 Flashing pulses

(overheating)

11 Flashing pulses

(circulating pump defective)

Cabling Check cabling for damage, discontinuity and

Flow plug defective Replace glow plug

Heater overheats Check coolant and top up if necessary.

Cabling Check cabling for damage, discontinuity and

Circulating pump defective Replace circulating pump

Fig. 502 Fault indications on fault lock-out (page 2 of 2)

5.4 Visual check for assessing

the burner

The burner and the evaporator in the heater display

specific characteristics when they must be replaced or do

not have any fault source.

The criteria of a correct check are listed below.

short-circuit

After the unit has cooled down, press the

button of the temperature limiter before

switching on or fit a new temperature limiter

short-circuit

5.4.1 Burner housing

• The start air hole (Fig. 503) must be clear otherwise

no start will occur.

Remedy

Carefully remove impurities from the start air hole

(e.g. using a 1.5 mm diameter wire). Remove the glow

plug first.

1

9

8

4

7

6

5

2

1 Fuel pipe

2 Round seal

3Flame monitor

4 Insulation

5 Glow plug

6Housing

7Screw

3

8Bar

9 Start air hole

Fig. 503 Visual check, burner back wall

503

Page 22

5 Troubleshooting Thermo 90 S / Thermo 90 ST

5.4.2 Back wall with metal evaporator

• The pilot flame outlet opening (Fig. 504) must be clear

otherwise no start will occur.

Remedy

Replace burner

• Cracks, flaking as well as black or other discoloration

of the evaporator do not lead to burner failure and are

not significant.

• Coke deposits on the evaporator surface (except for

the pilot flame outlet opening) are normal; as a rule,

the burner cleans itself due to the load changes from

full load to part load and part load to full load.

Pilot flame outlet opening

5.4.3 Combustion chamber

• The combustion chamber (Fig. 505) should not be

damaged (e.g. dented). A dented combustion

chamber can lead to poor combustion or carbon buildup in the heater.

Remedy

Replace burner

• The air holes (Fig. 505) in the combustion chamber

must not be blocked up by carbon deposits. If the air

holes are blocked up by carbon deposits, this may

result in failure of combustion to start or to run

effectively.

Remedy

Carefully scratch clear the air holes

5.4.4 Complete burner

• The cables of the glow plug and flame monitor must

be routed as shown in Fig. 503.

• The screw connection of the housing and combustion

chamber (Fig. 505) must be tight.

Metal evaporator, petrol

Pilot flame outlet opening

• The housing and the combustion chamber (Fig. 505)

must be firmly connected together and there must not

be any play (check by moving the fuel pipe slightly).

• The round sealing ring (Fig. 503) must evenly

surround the fuel pipe and must not leak.

• The distance (gap) between the edge of the housing

and the top edge of the combustion chamber

(Fig. 505) does not have to be even all the way

around.

• The insulation (Fig. 503) must not be missing.

Combustion chamber

Swirl orifice

Metal evaporator, diesel

Fig. 504 Visual check, pilot flame outlet opening

504

Air holes

Gap between housing

and combustion chamber

Fig. 505 Visual check, complete burner

Page 23

Thermo 90 S / Thermo 90 ST 6 Function tests

6 Function tests

6.1 General

This section describes the tests conducted on the heater

and its settings when it is installed and not installed to

verify that it is in working order.

WARNING

The heater must not be operated in enclosed areas such

as garages and workshops without an emissions

extraction system.

6.2 Settings

6.2.1 Setting the CO2 content

It is permitted for the factory-set combustion air quantity to

be modified. This is achieved by turning the air regulating

screw.

Setting procedure

Turning clockwise: CO

run for about 5 minutes before measuring).

Rough setting: Screw the adjusting screw fully in

clockwise and then one turn back.

value is reduced (let the heater

2

6.3.3 Resistance test on the flame monitor

If you conduct this electrical test with a digital multimeter,

the flame monitor should have the following values:

Cold test:

Resistance at 25 °C: 3.0 ±0.4 Ω

Test current: < 5 mA

Hot test:

Resistance at 800 ±20 °C: 8 ±1.0 Ω

(ceramic rod at red heat over length of approx. 20 mm)

Test current: < 5 mA

6.3.4 Testing the combustion air fan

The motor speed test must be performed with the heater

assembled and in the operating voltage range. Listen out

for grinding noises.

NOTE

The cover must be removed from the fan in order to check

the motor speed. Fit a new seal before re-installing.

CAUTION

Make sure the detent lugs do not break off.

Fit a new cover and a new seal if the detent lugs have

broken off.

Speed in control range min. 1800 rpm (±9%)

Speed in control range max. 5600 rpm (±9%)

6.3 Testing individual components

6.3.1 Resistance test of the temperature sensor

If you conduct this electrical test with a digital multimeter,

the temperature sensor should have the following values

at room temperature:

Resistance at 25 °C: 990 ... 1010 Ω

Test current: < 1 mA

6.3.2 Resistance test of the glow plug

If you conduct this electrical test with a digital multimeter,

the glow plug should have the following values:

Glow plug: 12 volts (red) 24 volts

(green)

Resistance at 25 °C: 0.3 ... 0.6 Ω 1.3 ... 1.44 Ω

Test current: < 5 mA < 5 mA

Fit a new combustion air fan if the speeds are outside

tolerance (see 9.2.5).

601

Page 24

6 Function tests Thermo 90 S / Thermo 90 ST

Page for notes

602

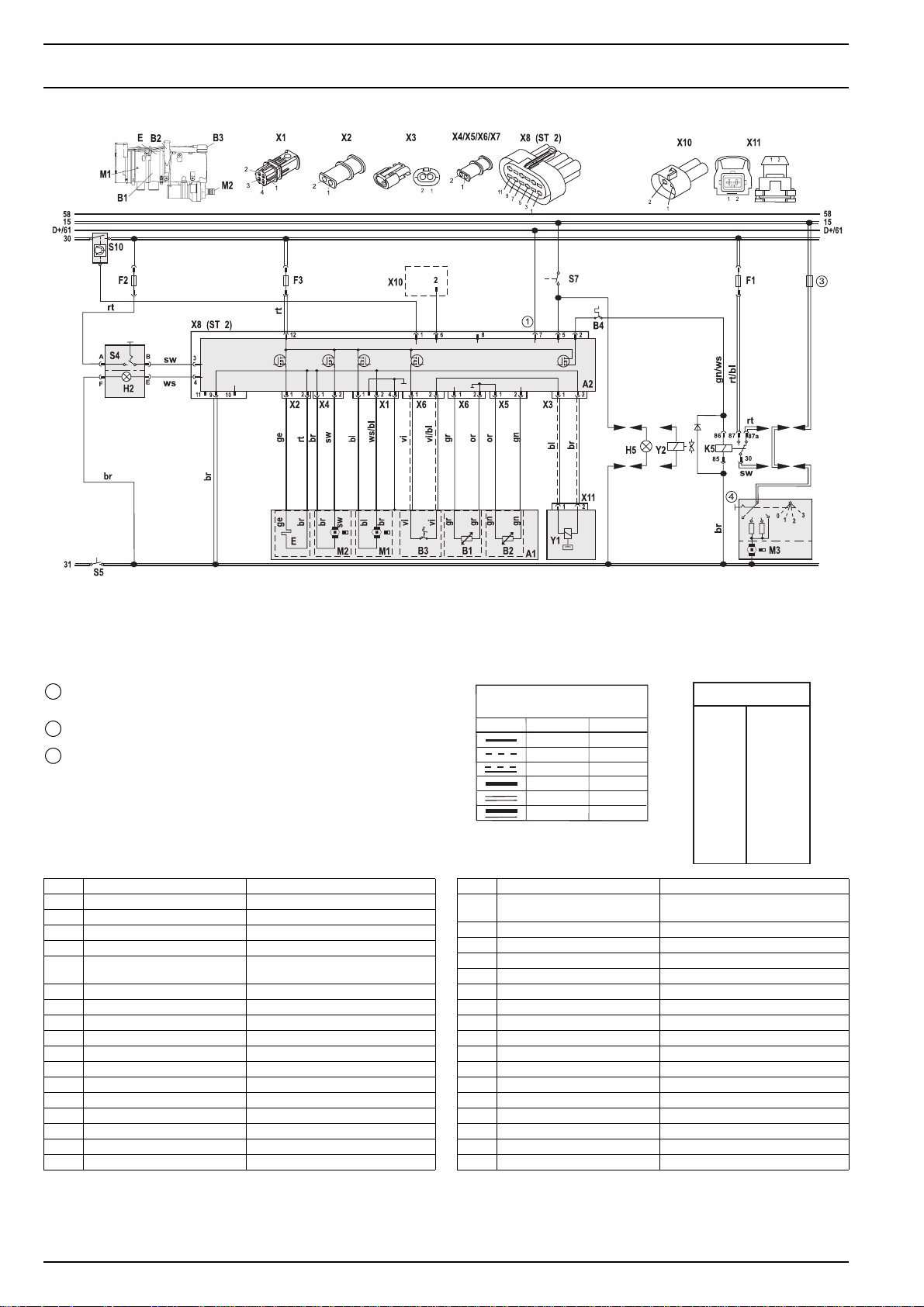

Page 25

Thermo 90 S / Thermo 90 ST 7 Circuit diagrams

7 Circuit diagrams

7.1 General

The circuit diagrams (Figs. 701 to 704) show the possible

circuits for the Thermo 90 S heater with

– Standard clock

– Standard clock and separate circulating pump

control

– ADR and switch

– ADR and switch, without power take-off

The circuit diagrams (Figs. 705 to 708) show the possible

circuits for the Thermo 90 ST heater with

– Standard clock

– Standard clock and separate circulating pump

control

– ADR and switch

– ADR and switch, without power take-off

701

Page 26

7 Circuit diagrams Thermo 90 S / Thermo 90 ST

58

15

30

M1

P2

31

H3

B1

E

B2

2

101

H1

12

4

7

S8

br

B3

X1

M2

X1

11221131049586

X3

3

6

7

9

12

F2 F3

H6

rt

11

2

8

sw

ws

X12 (ST 2)

3

4

11

9

10

X3

X11

(ST 1)

rt

1458

ge

br

112

ge

E

X5

21

122

X6

9

12

rt

br

bl

br

sw

8657

br

ws/bl

br

bl

sw

M

M

M2M3M1

X6

2

1

12

32

11 6

X11 (ST 1) X12 (ST 2)

11

9

7

5

3

1

710

(ST 3)

vi

239

gr

vi/bl

11 10 4

vi

vi

B3

gr

B1 B2

or

or

gn

X1

gr

ϑϑ

gn

gn

A1

1

71568

X13

Y1

X13 (ST 3)

11

9

7

5

3

1

F1

B4

212

gn/ws

A2

2

1

rt/bl

1

58

15

30

3

rt

86 87

br

bl

K5

87a

3085

sw

4

X5

2

1

br

M

3

0

1

2

31

Temperature coding (temperature at water outlet):

1

See table on page 302

Digital timer P2:

2

with positive at connection 10 = Continuous operation with immediate

heating

Connection 10 open = Variable heating duration can be

programmed = (10 min to 120 min);

= Default setting 120 min

Vehicle fuse

3

Vehicle fan switch

4

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H1 “Heating” symbol in the display Operating indicator (in item P2)

H3 Symbol light Light (in item P2)

H6 Red LED Light in immediate heat button, ready

indicator, switch-on indicator

(in item P2)

K5 Relay For vehicle fan

M1 Motor Combustion air fan

Cable colours

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

2

2

2

2

2

2

Cable colours

bl

bl

br

br

ge

ge

gn

gn

gr

gr

or

or

rt

rt

sw

sw

vi

vi

ws

ws

Blue

Blue

Brown

Brown

Yellow

Yellow

Green

Green

Grey

Grey

Orange

Orange

Red

Red

Black

Black

Violet

Violet

White

White

Item Designation Comment

M2 Motor Circulating pump

M3 Motor Vehicle fan

P2 Standard clock For programmed operation

S8 Momentary-contact switch Immediate heat button remote

control

X1 12-pin plug connector To item A1

X3 12-pin plug connector To item P2

X5 12-pin plug connector To Y1

X6 12-pin plug connector Diagnosis

X11 12-pin plug connector To item A2 (ST 1)

X12 12-pin plug connector To item A2 (ST 2)

X13 12-pin plug connector To item A2 (ST 3)

Y1 Metering pump Fuel pump for heater

702

Fig. 701 System circuit for Thermo 90 S, 12 and 24 V, with standard clock

Page 27

Thermo 90 S / Thermo 90 ST 7 Circuit diagrams

58

15

30

M1

P2

31

H3

B1

E

B2

2

101

H1

12

4

7

S8

br

B3

X1

M2

X1

11221131049586

X3

3

6

7

9

12

F2 F3

rt

11

2

sw

8

ws

S9

X12 (ST 2)

3

4

H6

X3

rt

rt

11

9

10

br

X11

(ST 1)

1458

ge

sw

112

ge

E

X5

21

122

X6

9

12

sw

br

rt

8657

br

br

ws/bl

br

bl

sw

M

M

M2M3M1

X6

2

1

12

32

11 6

X11 (ST 1) X12 (ST 2)

11

9

7

5

3

1

710

(ST 3)

viblvi/bl

11 10 4

239

vi

B3

gr

vi

gr

B1 B2

or

gn

or

X1

gn

gn

gr

ϑϑ

A1

1

71568

X13

Y1

X13 (ST 3)

11

9

7

5

3

1

F1

B4

212

gn/ws

A2

2

1

rt/bl

1

58

15

30

3

rt

8686 8787

bl

br

K5K3

87a87a

3030 8585

sw

4

X5

2

1

br

M

3

0

1

2

31

Temperature coding (temperature at water outlet):

1

See table on page 302

Digital timer P2:

2

with positive at connection 10 = Continuous operation with immediate

heating

Connection 10 open = Variable heating duration can be

programmed = (10 min to 120 min);

= Default setting 120 min

Vehicle fuse

3

4

Vehicle fan switch

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H1 “Heating” symbol in the display Operating indicator (in item P2)

H3 Symbol light Light (in item P2)

H6 Red LED Light in immediate heat button, ready

indicator, switch-on indicator (in item

P2)

K3 Relay For circulating pump remote control

K5 Relay For vehicle fan

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

2

2

2

2

2

2

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Blue

Brown

Yellow

Green

Grey

Orange

Red

Black

Violet

White

Item Designation Comment

M1 Motor Combustion air fan

M2 Motor Circulating pump

M3 Motor Vehicle fan

P2 Standard clock For programmed operation

S8 Momentary-contact switch Immediate heat button remote

control

S9 Switch Heating/circulating pump remote

control

X1 12-pin plug connector To item A1

X3 12-pin plug connector To item P2

X5 12-pin plug connector To Y1

X6 12-pin plug connector Diagnosis

X11 12-pin plug connector To item A2 (ST 1)

X12 12-pin plug connector To item A2 (ST 2)

X13 12-pin plug connector To item A2 (ST 3)

Y1 Metering pump Fuel pump for heater

Fig. 702 System circuit for Thermo 90 S, 12 and 24 V, with standard clock and separate circulating pump control

703

Page 28

7 Circuit diagrams Thermo 90 S / Thermo 90 ST

58

15

D+/61

X11 (ST 1) X12 (ST 2)

11

9

7

5

3

1

S7

1

71568212

A2

2

1

X13

(ST 3)

gn

X1

gn

br

bl

X5

2

1

Y1

A1

11

9

7

5

H5 Y2

X13 (ST 3)

3

1

gn/ws

rt/bl

1

58

15

D+/61

F1

3

rt

86 87

87a

K5

30

85

sw

4

3

0

1

br

2

M

122

X5

21

X6

2

12

X6

1

X1

B3

M2

M1

E

B2

B1

30

S5

X1

11221131049586

7

F2 F3

rt

rt

X12 (ST 2)

A

F

31

S5

B

S4

E

H2

br

ws

sw

3

4

11

10

9

X11

(ST 1)

1458

rt

ge

11 6

9

12

bl

br

sw

ws/bl

32

710

vi

gr

or

vi/bl

or

br

11 10 4

8657

112

br

br

ge

E

sw

M

M2M3M1

239

gr

vi

br

bl

M

vi

B3B4B1 B2

gr

gn

ϑϑ

Temperature coding (temperature at water outlet):

1

See table on page 302

Vehicle fuse

3

4

Vehicle fan switch

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H2 Light max. 2 W Operating indicator (in item S4)

H5 Lamp min. 1.2 W Switch-on indicator pumping device

K5 Relay For vehicle fan

M1 Motor Combustion air fan

M2 Motor Circulating pump

M3 Motor Vehicle fan

S4 Switch ON/OFF

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

2

2

2

2

2

2

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Item Designation Comment

S5 1 or 2-pin disconnecting switch Emergency off switch

S7 Pumping device switch To positive

X1 12-pin plug connector To item A1

X5 12-pin plug connector To Y1

X6 12-pin plug connector Diagnosis

X11 12-pin plug connector To item A2 (ST 1)

X12 12-pin plug connector To item A2 (ST 2)

X13 12-pin plug connector To item A2 (ST 3)

Y1 Metering pump Fuel pump for heater

Y2 Solenoid valve For pumping device

electrical or pneumatic

Blue

Brown

Yellow

Green

Grey

Orange

Red

Black

Violet

White

704

Fig. 703 System circuit for Thermo 90 S-ADR, 24 V, with switch

Page 29

Thermo 90 S / Thermo 90 ST 7 Circuit diagrams

D+/61

X11 (ST 1) X12 (ST 2)

11

9

7

5

3

1

1

gn

gn

71568212

X13

(ST 3)

X1

B4

A2

2

1

br

bl

X5

2

1

Y1

A1

X13 (ST 3)

11

9

7

5

3

1

gn/ws

rt/bl

1

58

15

D+/61

F1

3

rt

86 87

87a

K5

30

85

sw

4

3

0

1

br

2

M

122

X5

21

X6

2

12

X6

1

X1

B3

M2

M1

E

B2

B1

58

15

30

S5

X1

11221131049586

7

F2 F3

rt

rt

X12 (ST 2)

B

A

S4

E

F

H2

br

31

S5

sw

ws

3

4

11

10

9

X11

(ST 1)

1458

rt

br

ge

sw

11 6

9

12

bl

ws/bl

32

710

vi

gr

or

vi/bl

or

br

11 10 4

8657

112

br

br

ge

E

sw

M

M2M3M1

239

br

bl

M

gr

vi

vi

B3

gr

gn

ϑϑ

B1 B2

Temperature coding (temperature at water outlet):

1

See table on page 302

Vehicle fuse

3

4

Vehicle fan switch

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H2 Light max. 2 W Operating indicator (in item S4)

K5 Relay For vehicle fan

M1 Motor Combustion air fan

M2 Motor Circulating pump

M3 Motor Vehicle fan

S4 Switch ON/OFF

S5 1 or 2-pin disconnecting switch Emergency off switch

electrical or pneumatic

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

2

2

2

2

2

2

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Item Designation Comment

S7 Pumping device switch To positive

X1 12-pin plug connector To item A1

X5 12-pin plug connector To Y1

X6 12-pin plug connector Diagnosis

X11 12-pin plug connector To item A2 (ST 1)

X12 12-pin plug connector To item A2 (ST 2)

X13 12-pin plug connector To item A2 (ST 3)

Y1 Metering pump Fuel pump for heater

Blue

Brown

Yellow

Green

Grey

Orange

Red

Black

Violet

White

Fig. 704 System circuit for Thermo 90 S-ADR, 24 V, with switch without power take-off

705

Page 30

7 Circuit diagrams Thermo 90 S / Thermo 90 ST

Temperature coding (temperature at water outlet):

1

See table on page 302

Digital timer P2:

2

with positive at connection 10 = Continuous operation with immediate

heating

Connection 10 open = Variable heating duration can be

programmed = (10 min to 120 min);

Vehicle fuse

3

4

Vehicle fan switch

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H1 “Heating” symbol in the display Operating indicator (in item P2)

H3 Symbol light Light (in item P2)

H6 Red LED Light in immediate heat button, ready

K5 Relay For vehicle fan

M1 Motor Combustion air fan

M2 Motor Circulating pump

M3 Motor Vehicle fan

= Default setting 120 min

indicator, switch-on indicator

(in item P2)

ϑϑ

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

2

control

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

Item Designation Comment

P2 Standard clock For programmed operation

S8 Momentary-contact switch Immediate heat button remote

X1 4-pin plug connector To item A2

X2 2-pin plug connector To item A2

X3 2-pin plug connector To item A2

X4 2-pin plug connector To item A2

X5 12-pin plug connector To item A2

X6 12-pin plug connector Diagnosis

X8 12-pin plug connector To item A2 (ST 2)

X9 12-pin plug connector To item P2

X10 2-pin plug connector W-bus diagnosis

X11 12-pin plug connector To Y1

Y1 Metering pump Fuel pump for heater

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Blue

Brown

Yellow

Green

Grey

Orange

Red

Black

Violet

White

706

Fig. 705 System circuit for Thermo 90 ST, 12 and 24 V, with standard clock

Page 31

Thermo 90 S / Thermo 90 ST 7 Circuit diagrams

Temperature coding (temperature at water outlet):

1

See table on page 302

Digital timer P2:

2

with positive at connection 10 = Continuous operation with immediate

heating

Connection 10 open = Variable heating duration can be

programmed = (10 min to 120 min);

Vehicle fuse

3

4

Vehicle fan switch

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H1 “Heating” symbol in the display Operating indicator (in item P2)

H3 Symbol light Light (in item P2)

H6 Red LED Light in immediate heat button, ready

K3 Relay For circulating pump remote control

K5 Relay For vehicle fan

= Default setting 120 min

indicator, switch-on indicator

(in item P2)

ϑϑ

control

control

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Blue

Brown

Yellow

Green

Grey

Orange

Red

Black

Violet

White

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

2

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

Item Designation Comment

M1 Motor Combustion air fan

M2 Motor Circulating pump

M3 Motor Vehicle fan

P2 Standard clock For programmed operation

S8 Momentary-contact switch Immediate heat button remote

S9 Switch Heating/circulating pump remote

X1 4-pin plug connector To item A2

X2 2-pin plug connector To item A2

X3 2-pin plug connector To item A2

X4 2-pin plug connector To item A2

X5 12-pin plug connector To item A2

X6 12-pin plug connector Diagnosis

X8 12-pin plug connector To item A2 (ST 2)

X9 12-pin plug connector To item P2

X10 2-pin plug connector W-bus diagnosis

X11 12-pin plug connector To Y1

Y1 Metering pump Fuel pump for heater

Fig. 706 System circuit for Thermo 90 ST, 12 and 24 V, with standard clock and separate circulating pump control

707

Page 32

7 Circuit diagrams Thermo 90 S / Thermo 90 ST

Temperature coding (temperature at water outlet):

1

See table on page 302

Vehicle fuse

3

4

Vehicle fan switch

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H2 Light max. 2 W Operating indicator (in item S4)

H5 Lamp min. 1.2 W Switch-on indicator pumping device

K5 Relay For vehicle fan

M1 Motor Combustion air fan

M2 Motor Circulating pump

M3 Motor Vehicle fan

S4 Switch ON/OFF

ϑϑ

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

2

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

Item Designation Comment

S5 1 or 2-pin disconnecting switch Emergency off switch

S7 Pumping device switch To positive

S10 Switch Battery switch in positive

X1 4-pin plug connector To item A2

X2 2-pin plug connector To item A2

X3 2-pin plug connector To item A2

X4 2-pin plug connector To item A2

X5 12-pin plug connector To item A2

X6 12-pin plug connector Diagnosis

X8 12-pin plug connector To item A2 (ST 2)

X10 2-pin plug connector W-bus diagnosis

X11 12-pin plug connector To Y1

Y1 Metering pump Fuel pump for heater

Y2 Solenoid valve For pumping device

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

electrical or pneumatic

Blue

Brown

Yellow

Green

Grey

Orange

Red

Black

Violet

White

708

Fig. 707 System circuit for Thermo 90 ST-ADR, 24 V, with switch

Page 33

Thermo 90 S / Thermo 90 ST 7 Circuit diagrams

Temperature coding (temperature at water outlet):

1

See table on page 302

Vehicle fuse

3

4

Vehicle fan switch

Item Designation Comment

A1 Heater

A2 Control unit

B1 Flame monitor

B2 Temperature sensor

B3 Temperature limiter/

overheating guard circuit

B4 Cabin thermostat

E Glow plug

F1 20 A fuse Blade-type fuse SAE J 1284

F2 5 A fuse Blade-type fuse SAE J 1284

F3 20 A fuse Blade-type fuse SAE J 1284

H2 Light max. 2 W Operating indicator (in item S4)

K5 Relay For vehicle fan

M1 Motor Combustion air fan

M2 Motor Circulating pump

M3 Motor Vehicle fan

S4 Switch ON/OFF

S5 1 or 2-pin disconnecting switch Emergency off switch

electrical or pneumatic

ϑϑ

Cable cross-sections

mm

2

2

2

2

2

2

7.5 - 15 m

1.0 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

2

2

2

2

2

2

< 7.5 m

0.75

0.75 mm

1.0 mm

1.5 mm

2.5 mm

4.0 mm

Item Designation Comment

S10 Switch Battery switch in positive

X1 4-pin plug connector To item A2

X2 2-pin plug connector To item A2

X3 2-pin plug connector To item A2

X4 2-pin plug connector To item A2

X5 12-pin plug connector To item A2

X6 12-pin plug connector Diagnosis

X8 12-pin plug connector To item A2 (ST 2)

X10 2-pin plug connector W-bus diagnosis

X11 12-pin plug connector To Y1

Y1 Metering pump Fuel pump for heater

Cable colours

bl

br

ge

gn

gr

or

rt

sw

vi

ws

Blue

Brown

Yellow

Green

Grey

Orange

Red

Black

Violet

White

Fig. 708 System circuit for Thermo 90 ST-ADR, 24 V, with switch without power take-off

709

Page 34

7 Circuit diagrams Thermo 90 S / Thermo 90 ST

Page for notes

710

Page 35

Thermo 90 S / Thermo 90 ST 8 Service work

8 Service work

8.1 General

This section describes the service work that can be

carried out on the heater when it is installed.

8.2 Work on the heater

Disconnect the main power cable from the vehicle’s

battery before carrying out any work on the heater. The

main battery power must not be disconnected whilst the

heater is operating or running on as a result of the risk of

the heater overheating and the overheating guard circuit

thus being tripped.

If you wish to carry out extensive repair work on the

heater, it may be a good idea to remove it completely.

After working on the heating circuit, top up with a coolant

mixture of water and antifreeze according to the

manufacturer’s instructions and carefully bleed the

heating circuit.

Refer to the relevant installation instructions and the

installation proposal for the heater for the specific vehicle

for repairs that necessitate the installation position being

changed.

8.3 Work on the vehicle

CAUTION

A temperature of 90 °C must not be exceeded in the

vicinity of the heater in any circumstances (for example

when completing painting work on the vehicle). See

section 4.

801

Page 36

8 Service work Thermo 90 S / Thermo 90 ST

8.4 Heater trial run

The heater must not be operated in enclosed areas such

as garages and workshops without an emissions

extraction system, even if you use the timer.

8.5 Service work

The following service work is to be carried out after or

before each heating period to maintain the functional

reliability of the heater:

• Clean the exterior of the heater (avoid the ingress of

water).

• Check the electrical connections for contact corrosion

and to ensure that they are secure.

• Check the exhaust and combustion air lines for signs

of damage and to ensure that they are clear.

• Check the fuel line and filter for leaks.

• Check the coolant circuit and circulating pump for

leaks.

• Inspect hoses for cracks.

• Replace the fuel filter if there is one.

802

Page 37

Thermo 90 S / Thermo 90 ST 8 Service work

NOTE

The Thermo 90 S and Thermo 90 ST

heater is supplied with the control

unit mounted on the combustion air

fan.

Wiring harness

Fuel line

Exhaust line

Coolant circuit

With non-return valve and thermostat

Without non-return valve

1 Heat exchanger

vehicle heating

2 Switch for fan

of the vehicle heating

3 Relay for vehicle fan

4 Digital timer

5 Fuse strip in the car

6 Non-return valve with

leakage hole

7T-piece

8 Vehicle engine

9 Heater

10 Circulating pump

11 Water pump

12 Radiator

13 Regulating valve

14 Exhaust muffler

15 Metering pump