Page 1

Workshop Manual

F

Transport Refrigeration

Frigo Top 10 - 43 | Pordoi 2000 - 4000

English

Page 2

Table of Contents

1 About this document 3

1.1 Purpose of the document 3

1.2 Using this document 3

1.3 Use of symbols and highlighting 3

1.4 Warranty and liability 3

2 Safety 3

2.1 General safety 3

2.2 Intended use 3

2.3 Versions 3

3 General description 4

3.1 Lock and unlock buttons 4

3.2 Cooling compartment temperature 4

3.3 Service levels 4

3.4 Service indicator 4

3.5 The programming tool or “hot key” 4

3.6 Hours of compressor operation 5

4 Parameter settings in 1st / 2nd level menus 6

4.1 Entering the 1st service level 6

4.2 Entering the 2nd service level 6

4.3 Change a parameter setting 6

4.4 Exit a service menu 6

5 Set and reset the service interval 7

5.1 Enter the service interval menu 7

5.2 Switch between reset interval and change interval 7

5.3 Reset the service interval 7

5.4 Change the service interval 8

6 The programming tool or “hot key” 8

6.1 General 8

6.2 Download parameters to the control element 8

6.3 Upload parameters to the hot key 9

7 Error messages 10

8 Technical support and customer service 10

9 Disposal 10

10 Annex 11

10.1 Technical data 11

10.2 (Typical) 12/24VDC wiring and connections 11

10.3 Parameter description 12

10.4 Standard parameter settings 16

Frigo Top 10 - 43 | Pordoi 2000 - 4000 2

Page 3

1 About this document

2 Safety

1.1 Purpose of the document

This workshop manual is used to support instructed personnel

when adjusting the parameters of the control element for transport refrigeration.

1.2 Using this document

X Read this document before changing parameters.

X Read the operating instructions.

1.3 Use of symbols and highlighting

Explanation

Action to be taken.

Requirements for the following necessary action.

Note on a special technical feature.

Separate information is available.

ATTENTION: Possibility on property damage.

WARNING: Possibility on minor or moderate injury.

DANGER: Possibility on a severe or mortal injury.

2.1 General safety

The repair and commissioning personnel must have the following

qualifications:

■

Successful completion of Webasto training.

■

Corresponding qualification for working on technical systems.

■

Certified to work on air conditioning systems.

The repair and installation of the unit may only be carried out in

accordance with the workshop manual and the installation instructions.

2.2 Intended use

The system is designed for cooling the load compartment of commercial vehicles while driving.

The performance values of your application are

closely related to ambient conditions, vehicle insulation, etc. The actual temperature may therefore deviate from the set value.

In the case of vehicles fitted with automatic startstop control, the function must be switched off

while operating the refrigeration system. For information on the control and function of the automatic start-stop control, please read the operating instructions for your vehicle.

1.4 Warranty and liability

Webasto shall not assume liability for defects or damage that are

the result that the installation, operating instructions and as well

as the instructions contained therein being disregarded.

This liability exclusion particularly applies for:

■

Improper use

■

Repairs not carried out by a Webasto service workshop

■

Use of non-genuine parts

■

Conversion of the unit without permission from Webasto

■

Mechanical damage to the equipment

■

Failure to comply with inspection and maintenance instructions

ATTENTION

Misuse as a result of failure to comply with the

workshop manual

Result: damage to the refrigeration system

X Follow the operating instructions and instructions

described in this document.

2.3 Versions

■

Fresh produce delivery system:

Cooling temperature can be selected between 0 – 40°C

(32 – 104°F).

■

Fresh produce delivery system with constant regulation of load

compartment temperature (optional feature):

Cooling temperature can be selected between 0 – 12°C

(32 – 54°F).

■

Deep frozen produce transport system:

Cooling temperature can be selected between -20 – 40°C

(-4 – 104°F).

Frigo Top 10 - 43 | Pordoi 2000 - 4000 3

Page 4

3 General description

F

SE

SE

SE

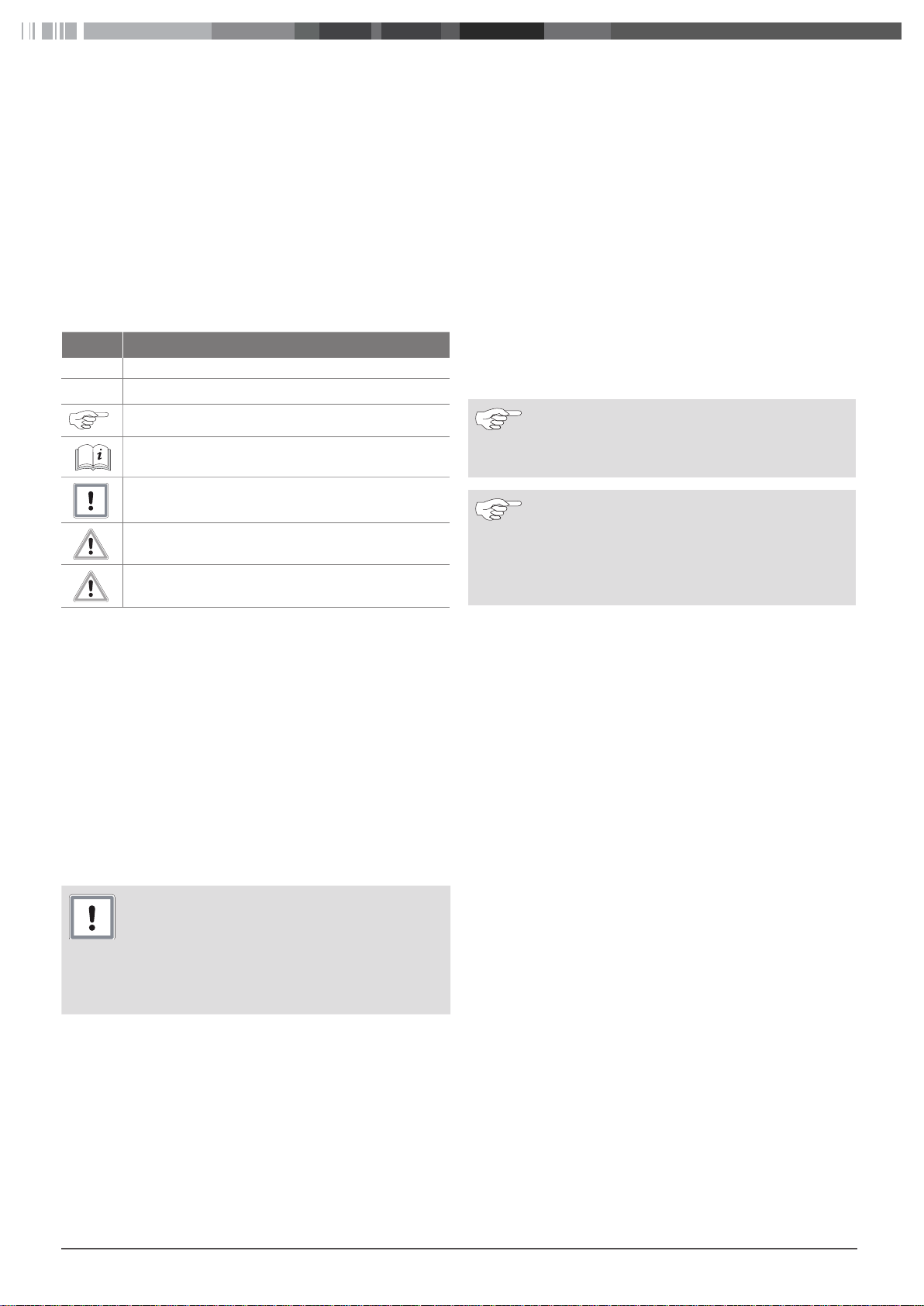

Fig. 01: Control element

The displays shown in this manual considers standard settings and programming of the control element.

3.1 Lock and unlock buttons

The keypad of the control element can be locked / unlocked with the following key combination:

Lock and unlock buttons

X Press the "Up" and "Down" button and hold for

several seconds:

–

The display shows "PoF", display is locked.

–

The display shows “Pon”, display is unlocked.

3.2 Cooling compartment temperature

3.3 Service levels

The control element has an extensive set of parameters to regulate and control the refrigeration process. The parameters are split

in 2 levels:

■

Level 1

■

Level 2

Access the Service Levels as follows:

st

Enter programming mode, 1

T

X Press the "SET" and "Down" button and hold for

3 seconds:

–

The menu shows “LS” (1

–

Symbol °C or °F starts blinking.

Enter programming mode, 2

T

X Press the “SET” and “Down” button and hold for

3 seconds, (1

X Release the keys.

X Press the “SET” and “Down” button again and

hold for 7 seconds:

–

The menu shows “PR2” (2

X Release the keys:

–

Displays shows the HY parameter.

–

Symbol °C or °F starts blinking.

Return to room temperature display

T

X Press the "SET" and "Up" button and hold for

several seconds.

st

level).

level

st

level).

nd

nd

level

level).

3.2.1 View cooling compartment set-point

X Press the “Set” button and release immediately.

SET

SET

X Press „Set“ again or the current value measured

in the cooling compartment is shown after 5 seconds.

3.2.2 Set the cooling compartment temperature

X Press the “Set” button and hold for 2 seconds.

SET

–

The current set-point is displayed

–

LED flashes

X Press "Up" and "Down" button to set the cooling

compartment set-point

SET

The display with the temperature set-point flashes for several seconds. Then it shows the temperature measured in the cooling

compartment.

X To save the cooling compartment set-point press

the "Set" button or wait for at least 15 seconds.

See chapter „4 Parameter settings in 1st / 2nd level menus“ for

more information.

3.4 Service indicator

The control element indicates when service is necessary. The service interval is based on the total operating hours of the refrigeration system. See chapter „5 Set and reset the service interval“ for

more information.

3.5 The programming tool or “hot key”

You can program the control element quickly or restore parameter

settings with help of a programming tool, called the “hot key. See

chapter „6 The programming tool or “hot key”“ for more information.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 4

Page 5

3.6 Hours of compressor operation

There is a counter (in hours) that saves the compressor operation

hour count. The resolution is 1 hour and the range goes from 0 to

50.000 hours. Saving interval: 5min.

Example:

If the saved value is 1511 hours of operation, the first time the

button is pressed “001” (thousands) is displayed. The second time

the “Clock” button is pressed “-511” (units) is displayed.

X Press the “Clock” button:

–

The compressor operation count, in hours,

appears on the display. The first value displayed

indicates the thousands.

X Press the “CLOCK” button again:

–

The units of the compressor operation count

appears on the display; preceded by a minus

sign.

Fig. 02: ”Thousands” indication

Fig. 03: ”Units” indication

Repeatedly pressing the “Clock” button toggles between the two

values.

During display of the compressor operating hours only the “Clock”

LED remains on.

When no key is pressed for 3s, the instrument goes back to normal display.

The user cannot reset the saved value. Only Dixell

can reset it, using a special reset procedure.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 5

Page 6

4 Parameter settings in 1st / 2nd level menus

T

T

T

T

T

T

For more information and overviews:

■

Chapter „10.3 Parameter description“

■

Chapter „10.4 Standard parameter settings“

For sake of overview the parameters are grouped per function:

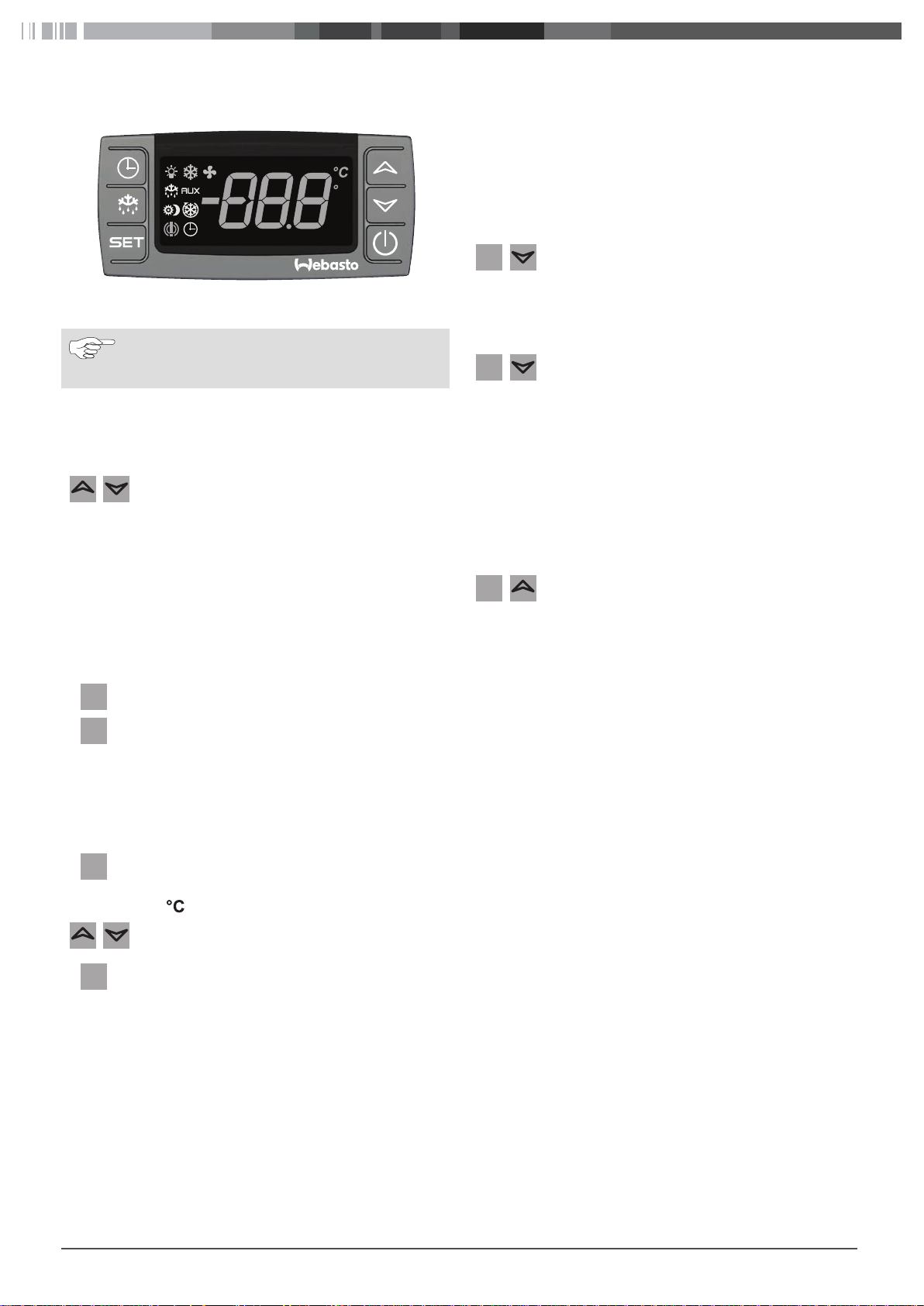

Fig. 04: Level 1 parameter in service

level 2

4.1 Entering the 1st service level

Fig. 05: First parameter of the 1st

level service menu

1. Regulation

2. Display

3. Defrost

4. Fans

In service level 2 the decimal point is on to show that the parameter

is a level 1 parameter.

Parameters can be moved from one level to the other,

but it is better to keep the parameters in their original

level.

XPress “Set” and “Up” to move a 2nd level parameter

to service level 1 and visa versa.

+ XPress “Set” + “Down” and hold for 3 seconds.

SE

–

The menu shows “LS”, the first parameter of the 1

service level.

–

The degree symbol starts blinking.

5. Alarms

6. Condenser temperature alarm

7. Digital input

8. Others

st

4.2 Entering the 2nd service level

Fig. 06: 2nd level service menu

Fig. 07: First parameter of the 2nd

level service menu

4.3 Change a parameter setting

Fig. 08: 2nd level service menu

Fig. 09: First parameter of the 2nd

level service menu

+ XPress “Set” + “Down” and hold for 3 seconds.

SE

–

The menu shows “LS” (First parameter of the 1

service level).

–

The degree symbol starts blinking.

+

SE

XPress “Set” + “Down” again and hold for 7 seconds.

–

The menu shows “Pr2” (2nd service level).

XRelease the keys.

–

The menus shows “HY”, the first parameter of the

2nd service level.

XEnter the desired service menu.

XSelect the required parameter with the “Up” or

“Down” key.

SE

XPress “Set”.

XSelect the required value with the “Up” or “Down”

key.

SE

XPress “Set” to store the selected value.

st

4.4 Exit a service menu

+ XPress “Set” + “Up” and hold for several seconds.

SE

or

XWait 15s without pressing a key

A set value is stored even when you exit the service

menu by means of waiting 15s without pressing a key.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 6

Page 7

5 Set and reset the service interval

T

T

T

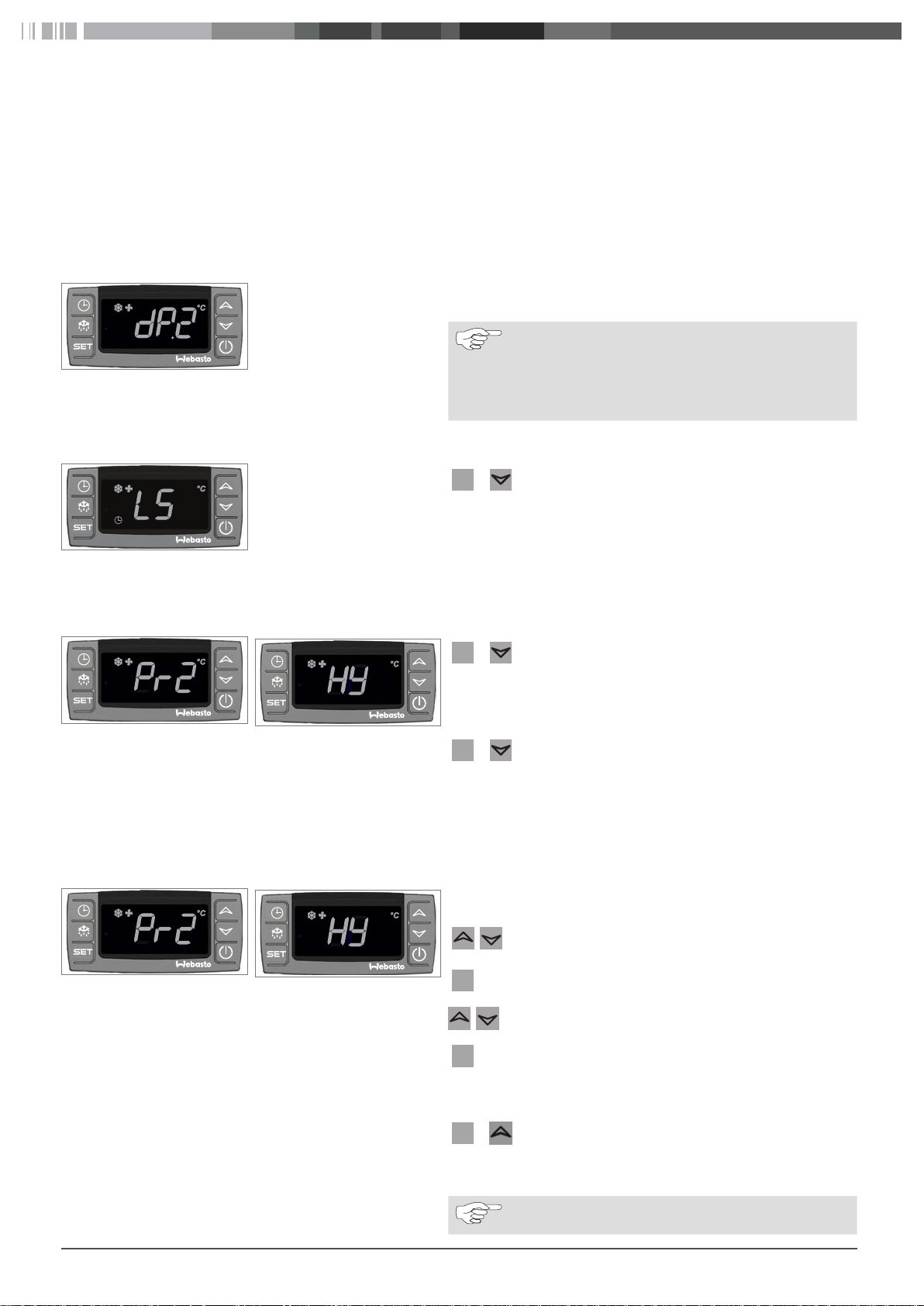

5.1 Enter the service interval menu

The instructions below describe how to change the settings via the

control element.

Fig. 10: 1st level Fig. 11: Service menu

+

SE

+

XPress “Set” + “Down” and hold for 3 seconds.

XPress “Up” + “Down” and hold for 7 seconds.

5.2 Switch between reset interval and change interval

/ XPress “Up” or “Down” to switch between:

Fig. 12: SEr: Change interval Fig. 13: rSt: Reset interval

5.3 Reset the service interval

Make sure that the screen shows “rSt”

3

ATTENTION

Do not reset the service interval without servicing

the refrigeration system.

Fig. 14: Reset interval, No Fig. 15: Reset interval, Yes

Result: System failure could occur due to insufficient

maintenance.

XReset of the service interval is only allowed after ser-

vice has been carried out.

–

The menu shows “LS” (1

–

The degree symbol starts blinking.

–

The menu shows “SEr” (Service menu).

–

“SEr” change interval

–

“rSt” reset interval

st

service level).

More information about service is available in “Service

handbook and system data” supplied with the system.

SE

SE

XPress “Set”.

–

The screen shows “n”.

XPress “Up” to switch to “y”.

XPress “Set” to reset the service interval.

–

“rSt” starts blinking.

–

The clock symbol disappears.

–

Screen shows “SEr”.

–

After approx. 10 s the display turns back to the

operating menu.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 7

Page 8

5.4 Change the service interval

T

SE

Make sure that the screen shows “SEr”

3

The standard service interval is 2.000 hr.

XPress “Set”

SE

Fig. 16: Interval setting at 2.000 hr

/

T

–

The screen shows the actual service interval

XPress “Up” or “Down” to increase or decrease the

service interval value:

0=Service indicator is disabled

100=1.000hr;

150=1.500hr;

200=2.000hr;

XPress “Set” to confirm a service interval.

–

“SEr” starts blinking.

–

Screen shows “SEr”.

–

After approx. 10 s the display turns back to the

operating menu.

250=2.500hr;

300=3.000hr.

6 The programming tool or “hot key”

You can program the control element quickly or restore parameter with help of a programming tool, called the “hot key. The hot key

has 2 functions:

■

Download parameters from the hot key into the control element.

■

Upload parameters from the control element into the hot key.

Uploading parameters from the control element into the hot key provides a back up for eventual restoring parameter settings or to program other control elements with the same set of parameters quickly.

6.1 General

Provide access to the backside of the control element or remove

3

the control element from its mounting panel.

XYou insert a hot key in the slot at the back of the control element.

Fig. 17: Slot hot key

Fig. 18: Upload / download error in-

dication

6.2 Download parameters to the control element

Mind the right position of the hot key!

The control element shows “Err” in case the download

or upload failed.

■

Switch the control element off and on again to

restart the download or upload.

or

■

Remove the hot key to stop operation.

XSwitch off the control element.

XInsert a hot key in the slot at the back of the control

element.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 8

Page 9

Fig. 19: Download indication Fig. 20: End of download cycle

6.3 Upload parameters to the hot key

Fig. 21: Upload indication Fig. 22: End of upload cycle

XSwitch on the control element:

–

Download starts and the parameters of the hot key

are loaded into the control element.

–

The display of the control element shows “doL”

during the download.

–

At the end of the download cycle the display shows

“End”.

–

After 10s the control element restarts, and uses the

new parameters.

XRemove the hot key.

Program the control element as desired with the keys on the front.

3

Leave the control element on.

3

XInsert a hot key in the slot at the back of the control element.

X Press the “Up” key.

–

Upload starts.

–

Control element shows “upL”.

–

At the end of the upload cycle the display shows

“End”.

XPress “SET” to finish the upload cycle.

XSwitch off the control element.

XRemove the hot key.

XSwitch the system on again.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 9

Page 10

7 Error messages

Error messages on the display indicate malfunctions in the refrigeration system. A message is displayed until the cause is rectified.

Code Possible cause Measure

P1 Fault on the room temperature sensor Depending on parameter setting in the control unit the refrigeration

system keeps operating or switches off.

XCheck the connections before replacing the sensor.

XContact a Webasto service partner.

P2 Fault on the evaporator sensor The refrigeration system keeps operating but the error will continue

to be displayed.

XCheck the connections before replacing the sensor.

XContact a Webasto service partner.

HA Maximum temperature alarm Temperature in cooling compartment is too high.

LA Minimum temperature alarm Temperature in cooling compartment is too low.

POF Not an error.

The keyboard is locked

CA Alarm pressure switch.

Battery alarm, low voltage

Only valid for Rolle and Frigo Top 10 I-ES

XPress and simultaneously and hold for several seconds to

unlock the keyboard.

XSwitch off system.

XContact a Webasto service partner.

8 Technical support and customer service

Do you have any technical questions or problem with the device?

National phone numbers of our representatives are provided on the following website: www.webasto.com.

9 Disposal

When you eventually decommission the system, please dispose of the individual components properly at a recycling centre.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 10

Page 11

10 Annex

10.1 Technical data

Description Data Description Data

Power supply 12/24VDC Operating temperature 0 – 60°C (32 – 140°F)

Power consumption 3VA Storage temperature -30-85 °C (-22 – 185°F)

Protection IP20 Relative humidity 20 – 80%, non-condensing

Frontal protection IP65 Measuring and regulating

range:

Digital input Potential free contact NTC probe -40 – 110°C (-40 – 230°F)

Relay outputs: PTC probe -50 – 150°C (-58 – 302°F)

Compressor 8(3)A, 16(6)A, or 20(8)A,

250VAC

Defrost 8(3)A, 250VAC

Fan 8(3), 250VAC

60

32

F

74

29

Fig. 23:

Control element dimensions

71

10.2 (Typical) 12/24VDC wiring and connections

9

10 11 12

Max.

16 A

1 2 3 4 5 7 8

13

Legenda:

1. Line

2. Defrost

3. Not connected

4. Fan

5. Compressor

6. -

7. Supply 12/24V

8. Supply 12/24V

9. Digital input

10. Evaporator temperature sensor

11. Common

12. Room temperature sensor

13. Hot key plug

Fig. 24: Wiring connections

Frigo Top 10 - 43 | Pordoi 2000 - 4000 11

Page 12

10.3 Parameter description

10.3.1 Regulation

Label Description Range

HY Intervention differential for set point:

Compressor Cut IN is Set Point Plus Differential (HY).

Compressor Cut OUT is when the temperature reaches the set point.

LS Minimum set point:

Sets the minimum acceptable value for the set point.

US Maximum set point:

Sets the maximum acceptable value for set point.

ot Thermostat probe calibration: allows to adjust the possible offset of the

thermostat probe.

P2P Evaporator probe presence:

n = not present: time stops the defrost cycle;

y = present: temperature stops the defrost cycle.

oE Evaporator probe calibration:

Allows to adjust possible offset of the evaporator probe.

odS Outputs activation delay at start up:

This function is enabled at the initial start up of the instrument and inhibits

any output activation for the period of time set in the parameter.

db Dead band (= neutral zone); allows the system to control the cell tempera-

ture to higher or lower temeratures compared to the set temperature. To

be used in case of heating kit.

n = neutral zone disabled; cooling only

y = neutral zone enabled; heating kit installed

AC Anti-short cycle delay: minimum interval between the compressor stop and

the following restart.

CCt Compressor ON time during continuous cycle:

Allows to set the length of the continuous cycle: compressor stays on without interruption for the CCt time. Can be used, for instance, when the room

is filled with new products.

CCS Set point for continuous cycle: it sets the set point used during the continu-

ous cycle.

Con Compressor ON time with faulty probe: time during which the compressor

is active in case of faulty thermostat probe.

With Con = 0 the compressor is always OFF.

CoF Compressor OFF time with faulty probe: time during which the compressor

is OFF in case of faulty thermostat probe.

With COF = 0 the compressor is always active.

0.1 – 25.5 °C (1 – 255 °F) 2

- 50 °C – SET (-58 °F – SET) 1

SET – 110 °C (SET – 230 °F) 1

-12 – 12 °C (-120 – 120 °F) 2

-12 – 12 °C (-120 – 120 °F). 2

0 – 255min 2

0 – 50min 2

0.0 – 24.0h; res. 10min 2

-50 – 150 °C (-58 – 302 °F) 2

0 – 255min 2

0 – 255min 2

Program level

1 2

1

2

10.3.2 Display

Label Description Range

CF Temperature measurement unit:

°C = Celsius; °F = Fahrenheit.

ATTENTION

When the measurement unit is changed the SET point and the

values of the parameters HY, LS, US, Ot, ALU and ALL have to

be checked and modified if necessary).

rES Display resolution (for °C only):

in = 1 °C;

dE = 0.1 °C; allows decimal point display.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 12

Program level

1 2

2

2

Page 13

Label Description Range

Lod Instrument display : selects which probe is displayed by the instrument:

P1 = Thermostat probe;

P2 = Evaporator probe.

10.3.3 Defrost

Program level

1 2

2

Label Description Range

tdF Defrost type:

EL = electrical heater;

in = hot gas

dtE Defrost termination temperature: (Enabled only when EdF=Pb).

Sets the temperature measured by the evaporator probe, which causes the

end of defrost.

idF Interval between defrost cycles:

Determines the time interval between the beginning of two defrost cycles.

MdF (Maximum) length for defrost:

When P2P = n, (no evaporator probe: timed defrost) it sets the defrost duration,

when P2P = y, (defrost end based on temperature) it sets the maximum

length for defrost.

dSd Start defrost delay:

This is useful when different defrost start times are necessary to avoid overloading the plant.

dFd Temperature displayed during defrost:

rt = real temperature;

it = temperature at defrost start;

SEt = set point;

dEF = “dEF” label

dAd MAX display delay after defrost:

Sets the maximum time between the end of defrost and the restarting of

the real room temperature display.

Fdt Drip time: time interval between reaching defrost termination temperature

and the restoring of the control’s normal operation. This time allows the

evaporator to eliminate water drops that might have formed due to defrost.

dPo First defrost after start-up:

y = immediately;

n = after the IdF time

dAF Defrost delay after continuous cycle: time interval between the end of the

fast freezing cycle and the following defrost related to it.

-50 – 50 °C (-58 – 122 °F) 1

0 – 120h 1

0 – 255min 1

0 – 99min 2

0 – 255min 2

0 – 120min 1

0 – 23.5h 2

Program level

1 2

2

2

2

10.3.4 Fans

Label Description Range

FnC Fans operating mode:

C-n= runs with the compressor, OFF during defrost;

o-n = continuous mode, OFF during defrost;

C-Y = runs with the compressor, ON during defrost;

o-Y = continuous mode, ON during defrost;

Fnd Fans delay after defrost: Time interval between end of defrost and evapora-

tor fans start.

Frigo Top 10 - 43 | Pordoi 2000 - 4000 13

0 – 255min 2

Programm level

1 2

1

Page 14

Label Description Range

FSt Fans stop temperature: setting of temperature, detected by evaporator

probe, above which fans are always OFF.

Fon Fans on time: with FnC = C_n or C_y, (fan activated in parallel with the

compressor). It sets the evaporator fan ON cycling time when the compressor is off. With Fon = 0 and FOF ≠ 0, the fans are always off. With Fon = 0

and FOF = 0 the fans are always off.

FOF Fan off time: with FnC = C_n or C_y, (fan activated in parallel with the com-

pressor). It sets the evaporator fan OFF cycling time when the compressor

is off. With Fon = 0 and FOF ≠ 0, the fans are always off. With Fon = 0 and

FOF = 0 the fans are always off.

-50 – 50 °C (122 °F) 1

0 – 15min 2

0 – 15min 2

10.3.5 Alarms

Programm level

1 2

Label Description Range

ALC Temperature alarms configuration:

Ab = absolute temperature: alarm temperature is given by the ALL or ALU

values.

rE = temperature alarms are referred to the set point.

Temperature alarm is enabled when the temperature exceeds the “SET+ALU” or “SET-ALL” values.

ALU Maximum temperature alarm: when this temperature is reached the alarm

is enabled, after the “ALd” delay time.

ALL Minimum temperature alarm: when this temperature is reached the alarm

is enabled, after the “ALd” delay time.

ALd Temperature alarm delay: time interval between the detection of an alarm

condition and alarm signalling.

dAo Exclusion of temperature alarm at startup: time interval between the detec-

tion of the temperature alarm condition after instrument power on and

alarm signalling.

SE Regular service has to be performed (x10 hours). 2

SET – 110 °C (SET – 230 °F) 2

-50.0 – SET °C (-58 – 230 °F) 2

0 – 255min 2

0.0 min to 23.5h 2

Program level

1 2

10.3.6 Digital input

Label Description Range

i1P Digital input polarity:

oP: the digital input is activated by opening the contact;

CL: the digital input is activated by closing the contact.

i1F Digital input configuration:

EAL = external alarm: “EA” message is displayed;

bAL = serious alarm “CA” message is displayed.

PAL = pressure switch alarm, “CA” message is displayed;

dor = door switch function;

dEF = activation of a defrost cycle;

LHt = not enabled;

Htr = kind of action inversion (cooling – heating)

AUS = not enabled;

FAn = not set it

ES = energy saving.

Program level

1 2

2

2

2

Frigo Top 10 - 43 | Pordoi 2000 - 4000 14

Page 15

Label Description Range

did Digital input alarm delay: with i1F = EAL or i1F = bAL digital input alarm de-

lay: delay between the detection of the external alarm condition and its signalling.

With i1F = dor: door open signalling delay

With i1F = PAL: time for pressure switch function: time interval to calculate

the number of the pressure switch activation.

nPS Pressure switch number: Number of activation of the pressure switch, dur-

ing the “did” interval, before signalling the alarm event (I2F = PAL).

If the nPS activation in the did time is reached, switch off and on the instrument to restart normal regulation.

OdC Compressor and fan status when door open:

no = normal;

Fan = Fan OFF;

CPr = Compressor OFF;

F_C = Compressor and fan OFF.

0 – 255min 2

0 – 15 2

10.3.7 Other

Program level

1 2

2

Label Description

PbC Type of probe: it allows to set the kind of probe used by the instrument:

PbC = PBC probe,

ntC = NTC probe.

OnF On/Off key enabling:

no = disabled.

OFF = enabled.

ES = not set it.

dP1 First probe display. 1

dP2 Second probe display. 1

rEL Software release for internal use. 2

Ptb Parameter table code: read only. 2

Program level

1 2

2

2

Frigo Top 10 - 43 | Pordoi 2000 - 4000 15

Page 16

10.4 Standard parameter settings

The standard parameter settings differ depending on the refrigerant. The tables below show the standard settings for refrigerant:

■

R134a

■

R134a and system with defrost

■

R404A

Making changes to these settings affects the functional safety of the system. Only make changes to the settings if you are familiar with

the outcome!

10.4.1 Regulation

Label Description

HY Differential 2 2 2 2

LS Minimum set point 0 0 -20 1

US Maximum set point 30 30 30 1

ot Thermostat probe calibration 0 0 0 2

P2P Evaporator probe presence y y y 1

oE Evaporator probe calibration 0 0 0 2

OdS Outputs delay at start up 0 0 0 2

db Dead band (neutral zone) n n n

AC Anti-short cycle delay 1 1 1 2

CCt Continuous cycle duration 0 0 0 2

CCS Set point for continuous cycle 0 0 0 2

COn Compressor ON time with faulty probe 15 15 15 2

CoF Compressor OFF time with faulty probe 30 30 30 2

R134a R134a with defrost R404A 1 2

Refrigerant Program level

2

y in case of

heating kit

10.4.2 Display

Label Description

CF Temperature measurement unit °C °C °C 2

rES Resolution dE dE dE 2

Lod Probe displayed P1 P1 P1 2

R134 R134a with defrost R404A 1 2

Refrigerant Program level

10.4.3 Defrost

Label Description

tdF Defrost type EL in in 2

dtE Defrost termination temperature 2 5 5 1

idF Interval between defrost cycles 1 3 3 1

MdF (Maximum) length for defrost 8 5 5 1

dSd Start defrost delay 0 0 0 2

dFd Displaying during defrost dEF dEF dEF 2

dAd MAX display delay after defrost 1 1 1 2

Fdt Draining time 1 1 1 1

dPo First defrost after start-up n n n 2

dAF Defrost delay after fast freezing 0 0 0 2

R134 R134a with defrost R404A 1 2

Refrigerant Program level

Frigo Top 10 - 43 | Pordoi 2000 - 4000 16

Page 17

10.4.4 Fans

Label Description

FnC Fan operating mode C-y C-y C-n 1

Fnd Fan delay after defrost 0 0 2 2

FSt Fan stop temperature 50 50 50 1

Fon Fan on time with compressor off 0 0 0 2

FOF Fan off time with compressor off 0 0 0 2

R134 R134a with defrost R404A 1 2

Refrigerant Program level

10.4.5 Alarms

Label Description

ALC Temperature alarms configuration Ab Ab Ab 2

ALU Maximum temperature alarm 110 110 110 2

ALL Minimum temperature alarm -50 -50 -50 2

ALd Temperature alarm delay 15 15 15 2

dAo Delay of temperature alarm at start up 1.3 1.3 1.3 2

SE Regular service has to be performed (x10 hours) 200 200 200 2

R134 R134a with defrost R404A 1 2

Refrigerant Program level

10.4.6 Digital input

Label Description

i1P Digital input polarity cL cL cL 2

i1F Digital input configuration dor dor PAL 2

did Digital input alarm delay 15 15 10 2

nPS Number of activation of pressure switch 15 15 5 2

odc Compress and fan status with open door no no no 2

R134 R134a with defrost R404A 1 2

Refrigerant Program level

10.4.7 Other

Label Description

PbC Kind of probe ntC ntC ntC 2

OnF on/off key enabling oFF oFF oFF 2

dP1 Room probe display / / / 1

dP2 Evaporator probe display / / / 1

rEL Software release … … … 2

Ptb Map code / / / 2

R134 R134a with defrost R404A 1 2

Refrigerant Program level

Frigo Top 10 - 43 | Pordoi 2000 - 4000 17

Page 18

In multilingual versions the English language is binding.

The telephone number of the respective country can be obtained from the Webasto service point flyer or the homepage of your respective Webasto

country representative.

Im Fall einer mehrsprachigen Version ist Englisch verbindlich.

Die Telefonnummer des jeweiligen Landes entnehmen Sie bitte dem Webasto Servicestellenfaltblatt oder der Webseite Ihrer jeweiligen Webasto

Landesvertretung.

Dans le cas d’une version rédigée en plusieurs langues, l’anglais est alors la langue qui fait foi.

Pour trouver le numéro de téléphone du pays concerné, veuillez consulter le dépliant des points-service Webasto ou la page web de la représentation

Webasto de votre pays.

Nelle versioni multilingue la lingua inglese è vincolante.

I recapiti telefonici dei diversi Paesi sono riportati nel pieghevole relativo ai centri di assistenza Webasto oppure nel sito web del proprio rappresentante

di riferimento Webasto.

En documentos multilingües, se considera vinculante el texto en inglés.

Puede encontrar el número de teléfono del país correspondiente en el folleto de centros de servicio de Webasto o en la página web del representante de

Webasto en su país.

Ident No. • 6243665A • 05/18 •Errors and omissions excepted •© Webasto Thermo & Comfort SE 2018

Webasto Thermo & Comfort SE

Postfach 1410

82199 Gilching

Germany

Company address:

Friedrichshafener Str. 9

82205 Gilching

Germany

www.webasto.com

Loading...

Loading...