Page 1

8/2018

FEEL COOL FAST

MARINE AIR CONDITIONER

Installation & Operation Manual

Page 2

Table of Contents

INTRODUCTION ................................................................................................................................................. 5

PACKAGED COMPONENTS .............................................................................................................................. 6

OVERVIEW ......................................................................................................................................................... 6

INSTALLATION ................................................................................................................................................... 7

Unpacking and Inspection ....................................................................................................................................... 7

Safety Considerations ............................................................................................................................................. 7

Placement of System ............................................................................................................................................... 8

Blower Assembly ................................................................................................................................................... 10

Mounting Brackets ................................................................................................................................................. 10

Supply & Return Air Grilles and Transition Boxes.................................................................................................. 10

Ducting ................................................................................................................................................................... 11

Seawater Pump and Plumbing (Refer to page 31 for recommended flow rates and pump sizes) ......................... 11

Electrical Connections, Grounding and Bonding ................................................................................................... 13

Digital Display Installation ...................................................................................................................................... 14

Electric Box Installation.......................................................................................................................................... 14

Installation Checklist (Review Prior To Installation) ............................................................................................... 15

Wiring Diagrams .................................................................................................................................................... 16

OPERATION ...................................................................................................................................................... 21

Digital Display Operation ....................................................................................................................................... 21

Power ON/OFF.......................................................................................................................................................... 22

Sleep Mode of the digital display ............................................................................................................................... 22

FAN Control ............................................................................................................................................................... 22

Temperature Setting ................................................................................................................................................... 22

Mode Setting .............................................................................................................................................................. 22

Remote Control Operation – V1 ................................................................................................................................ 24

Remote Control Operation – V1 (continued) ............................................................................................................. 25

Remote Control Operation – V2 ................................................................................................................................ 27

ERROR CODES ................................................................................................................................................ 28

TROUBLESHOOTING ...................................................................................................................................... 28

MAINTENANCE ................................................................................................................................................ 30

Reversing Valves ................................................................................................................................................... 30

Seawater Strainer .................................................................................................................................................. 30

Condenser Coil Cleaning (Seawater Acid Flush) .................................................................................................. 30

Return Air Filters .................................................................................................................................................... 31

Winterization .......................................................................................................................................................... 31

UNIT DIMENSIONS & TECHNICAL SPECIFICATIONS ................................................................................... 31

LIMITED WARRANTY ....................................................................................................................................... 33

TECHNICAL ASSISTANCE ............................................................................................................................... 33

Page 3

Introduction

Thank you for your purchase. No matter which of the following features was the reason for your purchase, we are

sure it will meet your needs and give many years of efficient and trouble free use. These air conditioners are

designed for marine applications incorporating the following features:

• Compact design

• High efficiency rotary compressors (5-24K)

• Cupronickel condenser coil

• Raised lance fin designed evaporator coil

• Polyester coated 2” (50mm) deep drain pan with four condensate drain locations

• Anti-vibration base pan

• Pre-charged and pre-wired systems for easy connections

• 3-speed fan motor. This eliminates all harmonic sounds and rumbles.

• Rotatable blower assembly

The controller offers the most technologically advanced design specifically made for the unique requirements of

marine air conditioning. The controller has been designed with the following "user friendly" features:

• Non-volatile memory

• Low voltage display panel

• LED cabin temperature displayed in Fahrenheit or Celsius

• Multiple fan speed selections

• Compressor pressure fail safe protection

• Dehumidification Mode for humidity control

This manual is intended to provide the information necessary to ensure proper installati on, operation, and

maintenance of a FCF air conditioner. Improper installation can result in unsatisfactory performance and/or

premature failure. Before proceeding, please read this manual in its entirety. In the interest of product improvement,

specifications and design are subject to cha ng e without prior notice.

Page 4

ITEM

QUANTITY

Air Conditioning unit

1

Mounting Bracket

4

Packaged Components

Fuses (3.15 AL 250V) 2

Remote controller with batteries 1

Digital Display / Cable 1

Duct Ring / Hardware 1

Blower Insulation Foa m 1

Installation / Operat io n M anual 1

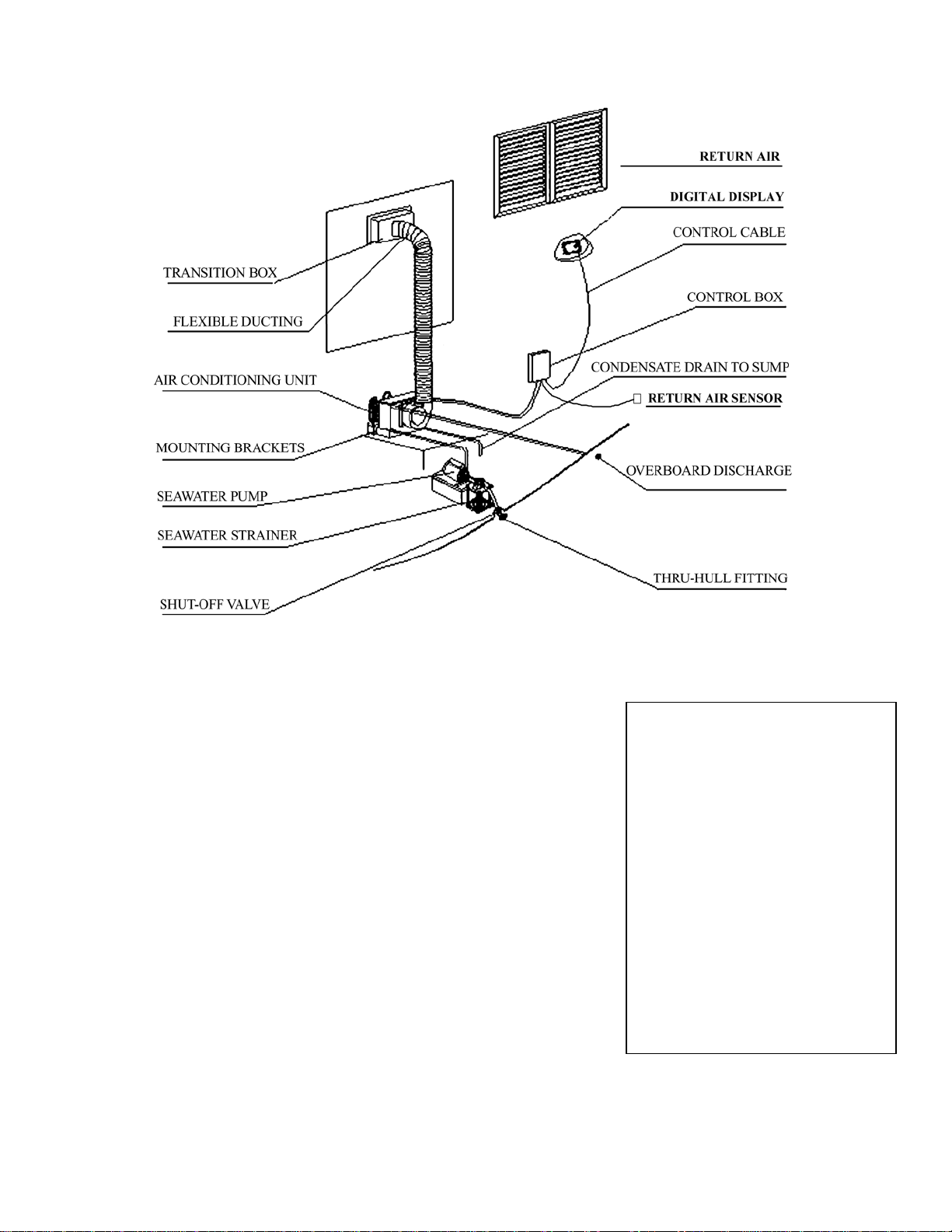

Overview

All units are manufactured without service ports

HOW IT WORKS

Your self-contained air conditioner consists of four main components and a refrigerant gas circulating through the

system. The BLOWER draws warm cabin air across the fins on the EVAPORATOR where the heat from the air is

transferred to the refrigerant in the evaporator coil. As the refrigerant evaporates from a liquid into a gas, it absorbs

the heat from the cabin air. The COMPRESSOR then compresses the refrigerant gas and pumps it through the

outer tube in the CONDENSER COIL. The seawater pump circulates cool seawater through the inner tube in the

condenser coil; this cools the refrigerant and condenses it into a liquid. The heat from the refrigerant is exchanged

to the seawater and discharged overboard. The liquid refrigerant is then passed through the EVAPORATOR COIL

and the cycle repeats; removing heat from the cabin air lowering its temperature. The cooled air is blown through

the ducting and out the supply air grille(s). For reverse cycle heating, the refrigerant flows in the opposite direction

through the reversing valve. Heat is transferred from the seawater in the condenser coil to the refrigerant and then

to the air blowing through the evaporator into the cabin. Seawater temperature will directly affect the air

conditioners efficiency. This air conditioner can effectively cool your boat in water temperatures up to 90°F and

heat in water temperatures as low as 40°F.

Page 5

Installation

Unpacking and Inspection

When the equipment is received, all items should be carefully checked according to the packaged components list

within this manual to ensure all components have been received. Examine components for shipping damage. If the

unit is damaged, the carrier should make the proper notation on the delivery receipt acknowledging the damage.

Safety Considerations

VERY IMPORTANT: Never install your air conditioner in the bilge or engine room areas. Ensure that the selected

location is sealed from direct access to bilge and/or engine room vapors. Do not terminate condensate drain line

within 3’ (914mm) of any outlet of engine, generator exhaust system, compartment housing an engine or generator ,

or in a bilge, unless the drain is connected properly to a sealed condensate or shower sump pump. Seal all cabin

penetrations around condensate hoses to eliminate harmful bilge fumes in the cabin living spaces.

Installation and servicing of this system can be hazardous due to system pressure and electrical components.

When working on this equipment, always observe precautions described in the literature, tags and labels attached

to the unit. Follow all safety precautions. Wear safety glasses and work gloves and place a fire extinguisher close

to the work area. The following is a summary of the labels on the unit:

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Special note. Make sure to read before proceeding.

Electrical shock hazard. Disconnect voltage at main panel or power source before

opening any cover. Failure to comply may result in injury or death.

This component does n ot meet feder al requirements for ignition protection. Do not install in

spaces containing gasoline engines, tanks, LPG/CPG cylinders, regulators, valves or fuel

line fittings. Failure to comply may result in injury or death.

Notice the 115V series and the 230V series are charged with Hydro fluorocarbon (HFC)

refrigerant R410A. Effective July 1, 1992, it shall be unlawful for any person to knowingly vent

or otherwise knowingly release any class 1 (CFC) or class 2 (H CFC) substance as a

refrigerant in a manner which permits such substance to enter the atmosphere per the clean

air act of 1990. Public law 101-549 title IV section 608-c. Failure to comply may result in

severe penalties, including f ines and impr is onment.

To minimize the hazard of electrical shock and personal injury, this component must be

effectively grounded. Refer to the installation guidelines for further information. Caution! High

compressor temperature is normal. Do not touch!

Page 6

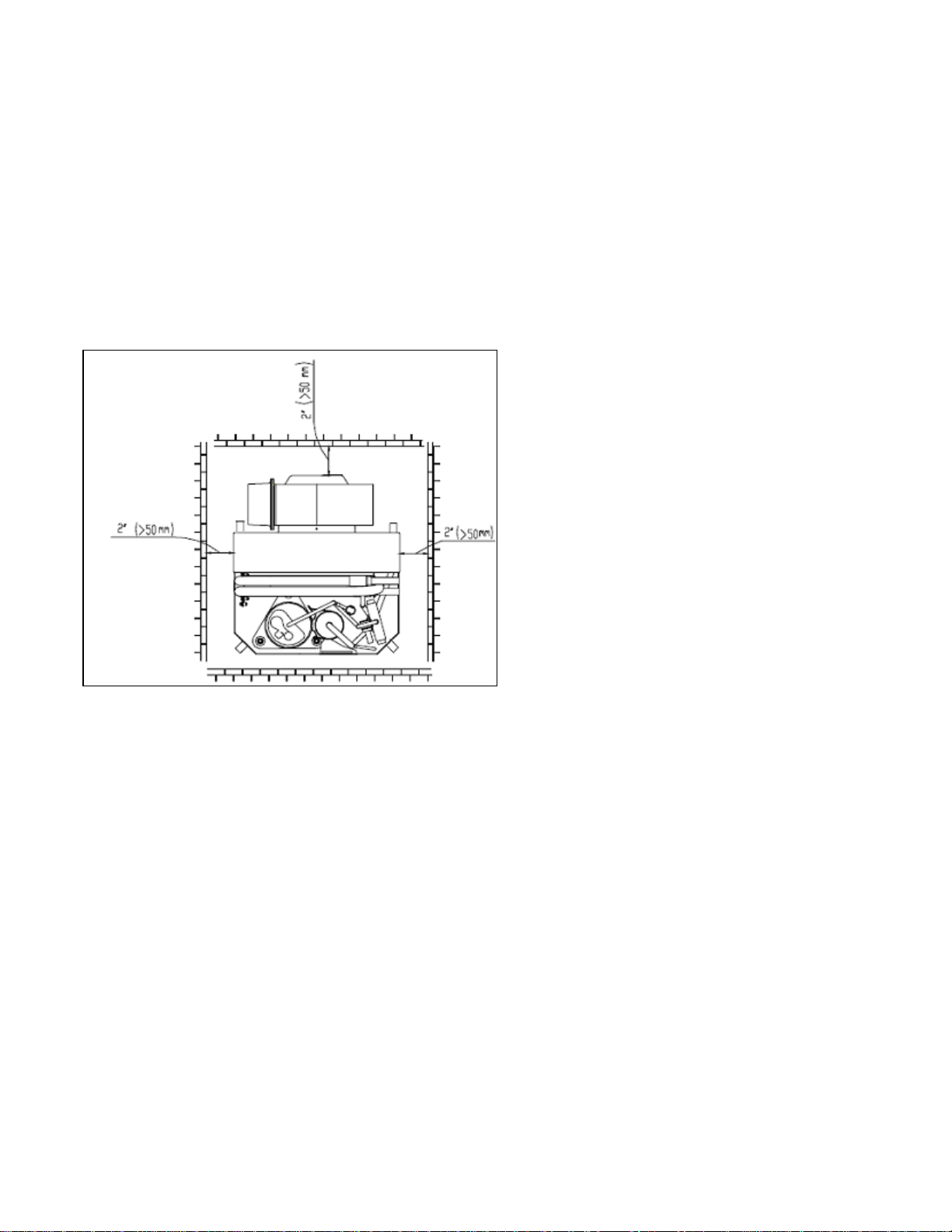

Placement of System

Selecting a good location for your air conditioner is the most important part of your preparation. Be sure to consider

the size of the area you are cooling, the air distribution needs, and the size of the unit you have chosen. Keeping in

mind that cool air has a tendency to fall; it is highly recommended that you locate the supply air grille as high as

possible in the cabin.

number of 90 degree bends

The ducting should be r un as straight, smooth and taut as possible minimizing the

. See diagram below.

Size of Sealed room

Ensure the area which the ai r conditioner is located is not t oo sm all otherwise it will affect proper operation.

See the diagram below.

Page 7

strainer, grilles & electrical box

The unit should be ins talled as low as pos s i ble, BUT NEVER IN T HE BILG E

OR ENGINE ROOM AREAS, ENSURE T HAT THE SELECTED LOCAT ION

IS SEALED FROM DIRECT ACCESS TO BILGE AND/OR ENGINE ROOM

VAPORS. Installing the unit as low as possible (such as under a V-berth,

dinette seat or bottom of a locker) and ducting the supply

air as high as possible, creates an ideal airflow condition. This type of

installation will prevent short or premature cycling.

The unit should be positioned on a firm, level, horizontal surface and the

condensate drain line should ru n downward f rom the unit to a suitabl e drain

location. Plan all Connections, which must be made including ducting,

condensate drain, and seawater in and out, electrical power connections,

location of control, and seawater pump placement, to assure easy access for

routing and servicing.

Tools required:

• Screws drivers

• Pliers

• Pipe wrench

• Wire cutters/crimpers

• Drill & bit set

• Jigsaw

• Duct tape

• Electrical tape

• Thread sealer

• Bedding compound t o seal thru

hull fittings

• Hardware to secure u nit, p um p,

Page 8

Condensate Drains

The condensate drain pan is 2” (50mm) deep with four drain locations. During conditions of high humidity,

condensate may be produced at a rate of approximately 1/2 gallon per hour (1.9 liters per hour). It is important to

route condensate drains downward to a sump pump. It is not recommended to route condensate drains to the bilge.

After the condensate drain installation is complete, test the installation by pouring water into the pan and checking

for good flow.

For installation of the condensate drain:

● Attach a 3/4” I.D. or 5/8” I.D. reinforced hose to the hose barb and secure with stainless steel hose

clamps.

● Install the condensate drain hose downhill from the unit and aft to a sump.

● Four drain fittings may be used and the hoses joined together with a tee fitting provided there is a

minimum 2" drop from the bottom of the base pan to the tee connection.

Do not terminate cond ensate drain line wit hin three 3’ (914mm) of any out let of engine, generator

exhaust systems , compartment housing an engin e or generator, nor in a bilge, unless the dr ain is

connected properly to a sealed condensate or shower sump pump. Seal all condensate hose

penetrations.

Blower Assembly

You can achieve multi-directional supply air discharge from a single unit by rotating the blower to the desired

position in 45° increments. It is ideal for tight installations as 360° of rotation is available with which to position the

blower. Its advanced design allows the blower to be easily removed for rotating or servicing by removing 4 screws.

Rotate the blower to allow the most direct flow of air to the supply air grille.

After the blower has been properly positioned, make sure to install the supplied

strip of insulation foam around the collar to prevent condensation build up.

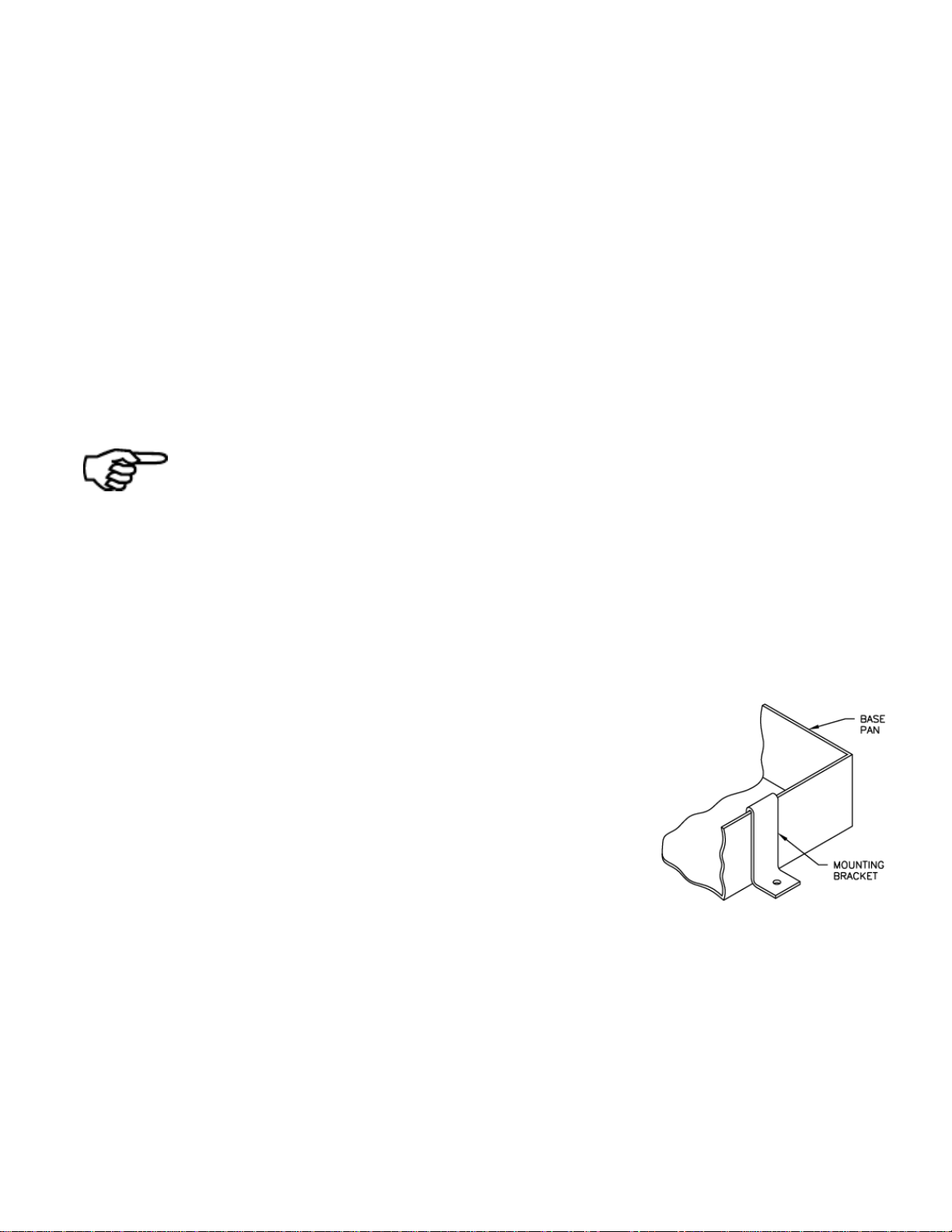

Mounting Brackets

The air conditioning unit is supplied with a base pan that also serves as a

condensate pan. Mounting clip brackets (4) are provided to secure the base pan to

a flat, horizontal surface. Hardware for the mounting clips must be provided by the

installer as needed.

Supply & Return Air Grilles and Transition Boxes

Install the supply air grille as high as possible in a location that will provide uniform air distribution throughout the

cabin. Grille louvers should be directed properly for best air flow. The return air grille should be installed as low and

close to the air conditioner as possible to insure direct uninterrupted airflow to the evaporator. The return air grille

should have a minimum four inches (4') of clearance in front of it, free from any furniture or other obstructions. In no

instance should a supply air discharge be directed towards a return air grille, as this will cause the system to short

cycle. Allow for adequate clearance behind the supply air grille(s) for the transition box and ducting connection.

See the Maintenance section of this manual for return air filter cleaning instructions.

Page 9

Ducting

Good airflow is critical for the performance of the entire system. It is highly dependent on the quality of the ducting

installation. The ducting should be run as straight, smooth and taut as possible minimizing the number of 90

degree bends (two tight 90° bends can reduce airflow by 25%). If a transition box is used, the total area of supply

air ducts going out of the box should at least equal the area of the supply duct feeding the box. To calculate the

square inch area of a round duct, multiply the radius by itself (r

2

) and multiply that number by 3.1416(π). The

following is a summary of proper ducting connections:

1. Pull back the fiberglass insulation exposing the inner Mylar duct hose.

2. Slide the Mylar duct hose around the mount ring until it bottoms out.

3. Screw 3 or 4 stainless steel sheet metal screws through the duct hose into the transition ring. Make

sure to catch the wire in the duct hose with the heads of the screws. Use finish washers with the screws

if necessary. Do not use band clamps, as the hose will slide off.

4. Wrap duct tape around the ducting and ring joint to prevent any air leaks.

5. Pull the insulation back up over the Mylar to the ring and tape this joint.

6. Remove excess ducting and use the same connection method at the supply air grille.

All ducting should:

● Be insulated and appropriately sized for each application.

● Run as smoothly and taut as possible.

● Have as few bends or loops as possible.

● Be securely fastened to prevent sagging or chafing during vessel operation.

● Have all excess ducting lengths trimmed off.

● Not be flattened or kinked.

● Be properly protected against potential damage when routed through open areas or bulkheads.

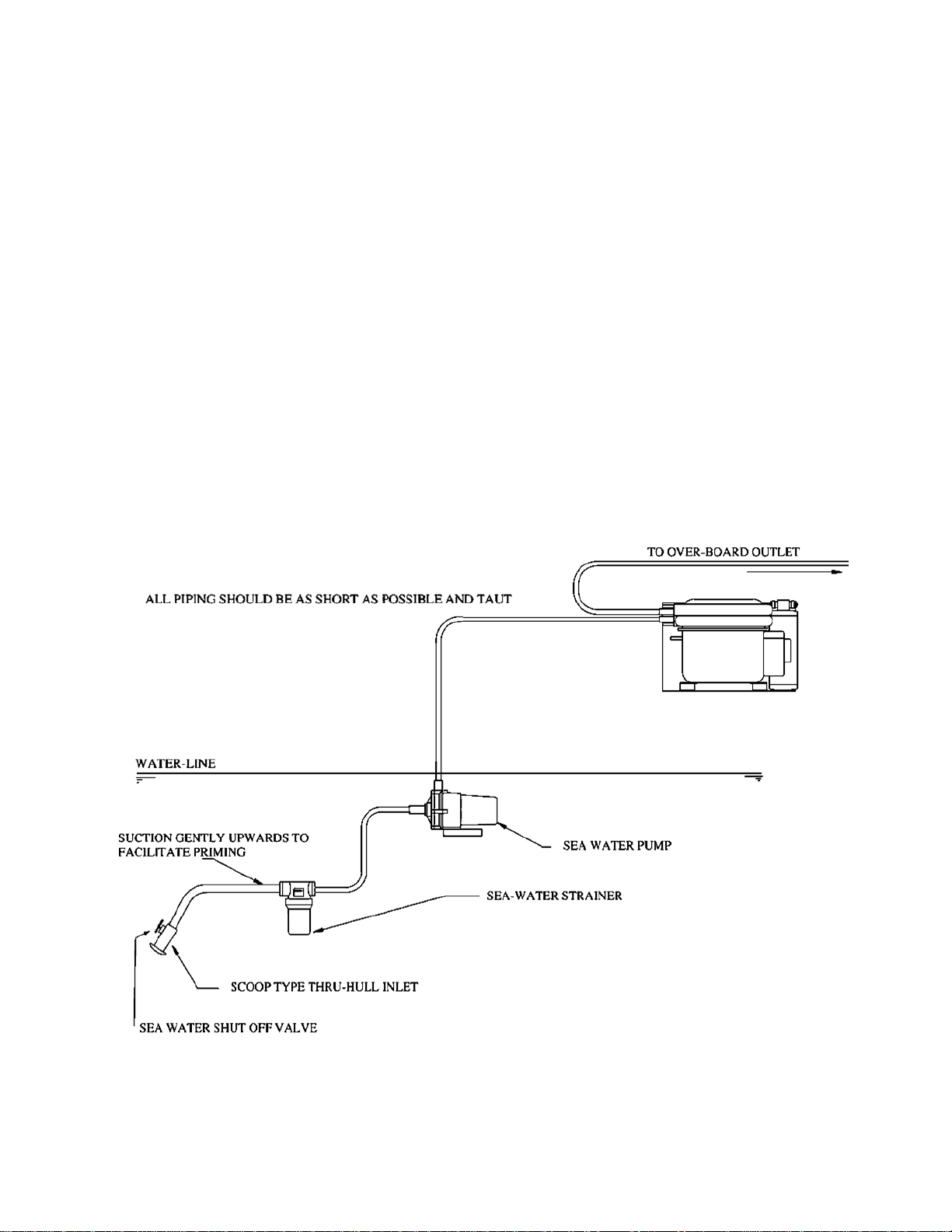

Seawater Pump and Plumbing (Refer to page 31 for recommended flow rates and pump sizes)

Several guidelines should be followed during the installation of the seawater system. If the circulation pump is

centrifugal and not self-priming, it must be mounted so that it is always at least 1’ (305mm) below the water line

regardless of which tack the vessel is on. Pump must always be mounted per manufacturers recommendations,

however, the discharge must always be above the inlet. Pump head should be rotated toward the direction of water

flow. Install the seawater speed scoop intake as far below the water line and as close to the keel as

possible in any application, but espe cially on a sailboat, to keep the intake in the water when the boat

heels over so that air does not get into the system. The speed scoop intake must face forward and not be

shared with any other pump. A seawater strainer is mandatory between the shut off valve (seacock) and the pump

to protect the pump from any foreign matter. Failure to install a seawater strainer will void the pump warranty. The

seawater system should be installed with an upward incline from the speed scoop & seacock, through the strainer,

to the inlet of the pump, next to the inlet of the air conditioning unit's condenser coil. The discharge from the air

conditioning unit should run to the seawater outlet thru-hull fitting that should be located where it can be visually

inspected for water flow as close to the waterline to reduce noise. All hose connections should be secured using

double/reversed stainless steel hose clamps. Use thread sealer on all threaded connections.

Page 10

Summary of the seawater system installation:

1. Install the speed scoop thru-hull inlet as close to the keel and as far below the water line as possible,

facing forward. Bed the scoop with a marine sealant designed for underwater use.

2. Install a bronze, full flow seacock on the speed scoop thru-hull inlet.

3. Install a seawater strainer below the level of the pump with access to filter.

4. Mount the pump above the strainer and at least 1’ (305mm) below the waterline.

5. Connect the seacock and strainer with an uphill run of 3/4" reinforced marine grade hose.

6. Connect the discharge from the pump uphill to the bottom inlet of the air conditioning unit's condenser coil

with 3/4" or 5/8” hose as required. Connect the discharge from the condenser coil to the overboard

discharge thru-hull fitting with 3/4" or 5/8” hose as required.

7. Avoid loops, high spots or the use of 90° elbows with seawater hose (each 90° elbow is equivalent to 2.5'

(762mm) of hose and a 90° elbow on the pump outlet is equivalent to 20' (6.1m) of hose).

8. Double clamp all hose connections with stainless steel clamps, reversing the clamps.

9. Use thread sealer on all threaded connections.

10. Connect all metallic parts in c on tact with seawater to the vessel's bonding system including the

speed scoop inlet, strainer, pump and the air conditioner. Failure to do so will void warranty.

Page 11

Electrical Connections, Grounding and Bonding

Turn off air conditioner power supply circuit breaker before opening electric box.

All air conditioner units have a terminal strip mounted inside the electric box. The terminal strip is labeled for proper

connections of the electrical supply, ground wires and pump circuits. A wiring diagram is provided in the electrical

box and later in this manual. The wiring diagram in the electrical box supersedes any found in this manual and

ABYC standards. The correct size circuit breaker should be used to protect the system as specified within the

technical specifications section. A minimum of 12 AWG boat cable should be used to supply power to the air

conditioning unit and the seawater pump. All connections should be made with ring or captive fork terminals.

Each air conditioner installed requires its own dedicated circuit breaker. If there is only one air conditioner installed,

the seawater pump does not require a circuit breaker; the wiring from the seawater pump is connected to the

terminal strip in the electric box. If two or more air conditioners use the same seawater pump, the pump wires will

be connected to a pump relay, Please refer to the wiring diagram. Electrical connections in the bilge and/or below

the waterline should use heat shrink type butt splices. Field wiring must comply with ABYC electrical codes. Power

to the unit must be within the operating voltage range indicated on the data plate. Properly sized marine grade

circuit breakers must be installed for circuit protection. All units must be effectively grounded to minimize the

hazard of electrical shock and personal injury. Make sure to connect the green grounding wire to the GRND stud

within the electrical box per ABYC standard E-8, or equivalent.

1. Connections between the vessel's AC system grounding conductor (green wire) and the vessel’s DC

(Direct Current) negative or bonding system should be made as part of the vessel's wiring, per ABYC

standard E-9, or equivalent.

• When servicing or replacing existing equipment that contains a chassis-mounted ground stud, the

installer must check the vessel's wiring for the existence of the connection required in item 1

above.

The air conditioner unit must be connected to the ship's bonding system to prevent

corrosion due to stray electrical current or voltage. All pum ps, metallic valves and fittings

in the seawater circuit that are isolated from the air conditioning unit by PVC or rubber

hoses must be individually bonded to the vessels bonding system. This will help eliminate

any possibility of corrosion due to stray current or voltage.

Page 12

Digital Display Installation

DO NOT turn the unit off and immediately turn it back on. Wait at least 30 seconds for

refrigerant pressures to stabilize.

Before mounting the digital displ ay, consider the location. The digita l dis pla y

should never be mounted in direct sunlight or exposed to excessive

moisture.

NOTE: The display cable must be grounded at the electrical box.

Electric Box Installation

Mount the electric box using four M5 screws.

Mount the electric box in a cool dry location leaving plenty of room for access.

Page 13

Installation Checklist (Review Prior To Installation)

Seawater cooling system:

Speed scoop located as far below the water line and as close to the keel as possible

Shut off valve (sea cock) and speed scoop properly sealed and tightened

Seawater pump is at least 1’ (305mm) below water line and securely mounted

Strainer mounted below pump with access to filter

Double/reversed stainless steel hose clamps on all hose connections

Thread sealer on all threaded connections

Hose runs uphill from speed scoop and sea cock to strainer, pump and air conditioning unit, then downhill

(if possible) from air conditioner unit to overboard discharge

Water flowing freely from overboard discharge while pump is running

Pump relay panel, if used, must have its own circuit breaker sized for the pump (20 amp max)

All metal fittings should be bonded

Mounting

Not in engine room or bilge area, must be sealed away from exhaust or fumes

Proper spacing allowed around unit

Attached to solid level platform with hold down brackets provided

Condensate drain routed aft and down hill to a sealed sump (not bilge)

All penetrations to bilge area sealed

Blower rotated toward supply air grille

Electrical

All butt connections on pumps are tightly crimped and covered with heat shrink

AC power source installed and grounded/bonded in accordance with ABYC standards

Control wires connected to terminal strip with captive fork or ring terminals

Circuit breakers sized accor ding to technical specifications section.

Pump Relay Panel (if used) has a dedicated circuit breaker sized for the pump but not to exceed 20 amps

maximum.

Grilles and Ducting

Supply air grille mounted as high as possible

Return air grille mounted as low and as close to the air conditioner as possible

Return air grille mounted away from bilge vapors or exhaust fumes

Ducting is pulled taut, straight, smooth and properly connected with no excess

Quick Start Operations Checklist

Ensure seawater intake ball valve (sea cock) is open.

Turn on the air conditioners circuit breaker. If the seawater pump has its own circuit breaker, make sure to

turn it on.

Turn the system on. Set the desired cabin temperature (set point).

Check for a steady solid stream of water from the overboard discharge.

Verify that there is steady airflow out of the supply air grille

If the unit does not appear to be operating properly, refer to troubleshooting guidelines. Note: Do not turn

the unit off and immediately back on. Allow at least 30 seconds for refrigerant pressure equalization.

Page 14

115V ~ 60Hz Line In

115V ~ 60Hz Neutral

Cooling Pump Line In

Cooling Pump Neutral

Power 208V / 230V ~ 60Hz

60Hz Line In

208V / 230V ~ 60Hz Neutral

Cooling Pump Line In

Cooling Pump Neutral

Wiring Diagrams

Power 115V ~ 60Hz

L

N

1

2

208V / 230V ~

L

N

1

2

Page 15

Fuse = 3.15 AL 250V

Page 16

Fuse = 3.15 AL 250V

WIRING SCHEMATIC FCF 12,000 (115V & 230V) FCF 16,000 (115V & 230V)

Page 17

Fuse = 3.15 AL 250V

Page 18

Fuse = 3.15 AL 250V

Page 19

Operation

Digital Display Operation

• Don't install the digital display in a location where it can get wet.

• Don’t knock, throw or open the digital display.

1. Remote receiver 6. Fan control button

2. Display 7. Temp. Setting button (Increasing)

3. Fan speed display (HIGH-MID-LOW and AUTO speed) 8. Temp. Setting button (Decreasing)

4. Display of mode operation (COOL-DEHUMIDIFY-HEAT and AUTO) 9. ON/OFF button

5. Mode button

The digital display has a built in memory function that’s will retain the last modes settings. Settings include

operation mode, set temperature, operation fan speed, and the temperature display format.

In cooling / heating / dehumidify mode, the p um p starts before the compressor starts, stops

after a 5 second delay of the compressor.

Page 20

Power ON/OFF

• Press ON/OFF button to turn the unit display on. Press the ON/OFF button a second time to select

mode and start operation.

• While the display is active press the ON/OFF button once to turn the unit OFF. Press the ON/OFF

button a second time if the display has already entered sleep mode to turn the unit OFF.

Sleep Mode of the digital display

The ambient temperature display will automatically enter a sleep status within 5 minutes of inactivity. Press any

button on the display or the remote controller to wake the display.

Note: Normal unit operation will continue while in sleep mode, it’s only the digital display that turns off.

FAN Control

• Press the FAN button, the fan speed will change in the following order:

→ HIGH →MID → LOW → AUTO →

• In “DEHUMIDIFY” mode, the fan will work at low speed automatically

Temperature Setting

• Press temperature setting key

o

▲To increase in 1

▼ To decrease in 1

increments

o

increments

• The setting range of temperature in each mode:

COOL 61°F 86°F or 16°C 30°C

DEHUMIDIFY 61°F 86°F or 16°C 30°C

HEAT 61°F 86°F or 16°C 30°C

FAN In this mode, temperature cannot be changed.

AUTO In this mode, temperature cannot be changed.

Mode Setting

• Press this key to change the operation mode in order of

→ COOL → DEHUMIDIFY → FAN → HEAT → AUTO →

COOL Mode Operation

• In “COOL” mode, the LED next to the

display.

● If room temperature is higher than set temperature, the unit runs in COOL mode.

● If set temperature is higher than room temperature then only the fan will run.

icon will illuminate when mode is selected on the digital

Page 21

DEHUMIDIFY Mode Operation

• In “DEHUMIDIFY” mode, the LED next to the

display.

• In DEHUMIDIFY mode, if the indoor temperature is higher than temperature setting, the unit will run in

cooling mode and the fan will run on low speed.

FAN Mode Operation Procedure

• In “FAN” mode, the room temperature will be displayed and the temperature cannot be set.

• Temperature cannot be set in this operation mode.

icon will illuminate when mode is selected on the digital

HEAT Mode Operation

• In “HEAT” mode, the LED next to the

• If room temperature is lower than set temperature, the unit runs in HEAT mode

• If set temperature is lower than room temperature, then only the fan will run

AUTO Mode Operation

• In “AUTO” mode, the LED marked AUTO will appear on the digital display. The temperature cannot be set;

the system will run automatically in the appropriate mode according to the difference between room

temperature and set temperature.

Display Fahrenheit or Centigrade

• Pressing the ▲ and ▼ key simultaneously, will switch between Fahrenheit and Centigrade modes.

Key Lock

• Press ▼and FAN key simultaneously, all keys are locked. Press ▼and FAN key simultaneously again, to

unlock the keys.

• When keys are locked, the controller is locked out of system operation. “EE” will be displayed.

icon will illuminate when mode is selected on the digital display.

Page 22

Remote Control Operation – V1

Wakes up Digital Display

Page 23

Remote Control Operation – V1 (continued)

Liquid Crystal Display. Opening

cover while unit is on will not

affect unit operation.

NOTE: This is a universal

remote; the sleep and timer

ON/OFF buttons are not used

with this application.

Page 24

Battery Replacement - Remote Control – V1

Remote controller battery requirements: Two AAA alkaline cells.

1. Slide the cell cover downward to take out the

2. Close the cell cover.

3. The LCD will show all the functional figures and

4. The life span of batteries is approximately 1 year.

5. If the remote controller doesn’t work after the

worn cells. Replace the worn cells. (Note to the

correct polarity).

letter codes after the batteries are installed. Wait

approximately 10 seconds for normal use.

(Depending on usage)

batteries have been replaced, remove the back

cover and press the “ACL” button to reset the

controller.

Page 25

Remote Control Operation – V2

Version 2 (V2) remote controls are used on FCF models equipped with digital displays from version 30 and newer. If

replacing a lost remote control, look on the data tag on the rear of the control panel. For version 29 and older, order

version 1 (FCF Classic), for version 30 and newer, order version 2 (FCF Platinum).

To switch between F and C modes both the remote control and the FCF unit must be

turned OFF.

* - These buttons do not have a function on the FCF air conditioning unit. Disregard

the information related to these buttons on rear panel of the remote controls.

Page 26

Error Codes

When there are faults within the system, an error code will be displayed on the display controller: Power off the unit

and contact professional service.

Error code Description

E1 Compressor high pressure protection – check sea water flow

E2 Evaporator freezing protection – check air flow and outlets

E3 Compressor low pressure protection

E6 Communication error

F0 Ambient temperature sensor error

F1 Evaporator temperature sensor error

Troubleshooting

FAULT POSSIBLE REASON CORRECTION

Will not start Air conditioning circuit breaker is off Turn circuit breaker on at ship's panel,

See control operation section in this manual.

Display control is not turned on. Check wiring Diagram and correct if necessary.

Fuse is broken Replaced with a new fuse. (3.15 AL 250V)

Incorrect wiring at terminal strip.

Push-on butt connectors pulled apart during

installation.

Input line voltage is insufficient, Check wiring and terminals for proper sizes and

Fan not running. Check your specific control Troubleshooting

section

No cooling or

heating

Temperature set point is above (in cooling) or

below (in heating) ambient temperature

Obstructed seawater flow. Clean seawater strainer. Check for obstructions at speed

Seawater pump maybe air-locked,

Refrigerant gas leaked. Check air conditioning unit for r efrigerant oil leakage, call

Disconnect power supply and open electric box, check

wiring diagram, correct if necessary,

Check power source (shore/generator) for proper

voltage.

connections.

Lower or raise set point.

scoop thru-hull inlet. Check for a good steady flow from

the overboard discharge.

Remove hose from pump dis charge t o purg e air fr om line

service technician.

Page 27

No cooling or

heating

(continued)

Seawater temperature too high for cooling or too

low for heating.

Seawater temperature will directly affect the air

conditioning unit’s efficiency. This air conditioning unit

can effectively cool your boat in water temperature up to

0

90

F and heat (if revers e cycle option is installed) in

water as low as 40

o

F.

Coil is iced (in cooling) See below

Fan is not running. See below

Pressure switch or thermal overload opened. Check your specific control troubleshooting sec tion.

No Heating Reversing valve may be stuck. Tap reversing valve lightly with rubber mallet while unit is

in heat mode, call for service if the problem cannot be

solved.

Low air flow

Air flow is blocked

Remove any obstructions i n return air stream, Clean

return air filter and grille. Check for crushed or restricted

ducting, ducting must be as straight, smooth and taut as

possible.

Coil is iced See below.

Coil is iced

System runs

continuously.

Thermostat set point is too low Raise set point.

Improper air flow Remove any obstructions i n return air stream. Clean

return air filter and grille. Check for crushed or restricted

ducting, ducting must be as straight, smooth and taut as

possible.

Supply air is short-cycling, Redirect supply air so that is not blowing into the return

air stream. Seal any air leaks on duct.

Seawater temperature is below 40oF Shut down s ystem to prevent damage to condenser.

Allow coil to defrost (see below).

Humidity level too high.

Close hatches and doors.

When all else fails. Switch air conditioner to heat until ice melts or use hair

dryer

Check your specific control troubleshooting

Set point temperature is improperly set: too low

Raise or lower set point.

for cooling or too high for heating.

Porthole or hatches open. Close all port holes and hatches,

Seawater temperature too high for cooling or too

low for heating.

Seawater temperature will directly affect the air

conditioning unit's effi ciency . T his air condit i onin g unit

can effectively cool your boat i n w ater temperat ures up t o

90°F and heat (if reverse cycle option is installed) in

Page 28

water as low as 400F.

Improper air sensor location. Check your specific control troubleshooting section,

Digital display is

not lit.

4-pin display cable plugs are not making contact

(unplugged, dirty, bent, or broken pins).

With POWER OFF at the circuit breaker, remove

connector and inspect. If damaged, replace connector or

entire display cable.

Maintenance

Reversing Valves

Reverse cycle units have a reversing valve; the valve must be energized periodically to keep the internal parts

moving freely. To do this, switch the air conditioning unit into heat mode 2-3 cycles per month.

Seawater Strainer

Ensure that your pump receives adequate seawater flow by regularly (daily in extreme cases) cleaning the strainer

basket. Periodically check the overboard discharge for a steady stream of water. Check seawater intake speed

scoop for obstructions. Make sure hoses are not looped, kinked or crushed. Check and clean strainer as needed

weekly - minimum once per month.

Condenser Coil Cleaning (Seawater Acid Flush)

1. With the system turned off at the circuit breaker on the ship's panel, disconnect the inlet and outlet

connections of the condenser coil.

2. Use chemical resistant hoses (PVC 3/4" I.D. or 5/8” I.D. as required, etc.) to connect the inlet of the

condenser coil to the outlet of a chemical resistant, submersible pump and let the hose connected to the

Coil outlet flow freely into the container mentioned below.

3. Place a strainer or piece of screen over the inlet of the pump and submerse the pump into a container filled

with a 5% solution of muriatic or hydrochloric acid and fresh water or use a premixed over-the-counter

solution. Use a large container as possible to hold the solution (5-25 gallons). CAUTION: avoid spilling or

splashing the solution. Remember to wear all necessary protective gear, i.e. approved safety goggles and

chemical resistant gloves. Follow all warnings and recommendations given by the manufacturer of any

acids or premixed solutions.

4. Power the pump and circulate the solution through the condenser coil for 15-45 minutes depending upon

the size of the coils and the extent of the contamination. Visual inspection of the solution in the container

should indicate when the contamination has been removed.

5. Circulate fresh water through the coil to flush any residual acid from the system.

6. Restart the system and check operational parameters to ensure thorough cleaning has taken place.

Additional cleaning ma y be necessary with extreme contamination.

7. Minimum once per year or as needed.

For the purpose of protecting the environment, dispose of any contaminated acid solutions in

accordance with federal, state and/or local regulations.

Page 29

Return Air Filters

Check the return air filter about once a month and clean as necessary. To clean the filter, remove it from the unit,

rinse with water, air dry and reinstall. (Do not used compressed air)

Winterization

There are several methods of winterization, some of which work better than others. There are various methods

employed using a 50/50 non-polluting biodegradable anti-freeze/water solution. Any method that causes the

anti-freeze solution to flow downward is the method of choice. By this, the anti-freeze solution will displace any

water trapped and eliminate the possibility of freezing in hidden areas. In addition, since the seawater pump utilizes

a magnetically driven impeller, the impeller should be removed from the wet end assembly, Wiped with a solution,

and stored in a warm, dry area until commissioning takes place.

Collect all discharged liquids and recycle or dispose of in a proper manner.

Unit Dimensions & Technical Specifications

Page 30

** Slow Delay

Unit Dimensions & Technical Specifications

BTU Capacity 5000 9000 12000 16000 24000

Capacity in kW 1.5 2.6 3.5 4.6 7.5

Voltage (V) 115 230 230 115 230 230 115 230 230 115 230 230 115 Soft 230 230

Frequency (Hz) 60 50 60 60 50 60 60 50 60 60 50 60 60 50 60

Running Current (A) 5.8 3.8 2.5 8.3 4.9 4.6 11 4.6 5.6 12.4 6.2 8.4 20.4 8.6 12.5

Starting surge (A) 23.5 15.5 13.5 36.5 16.5 18 45 29 25 54.5 25.5 26.5 39 41 46

Starting Time (ms) 150 160 200 125 115 165 150 125 340 140 190 320 250 350

Refrigerant R410A R410A R410A R410A R410A

Net Weight (kg) 24 27 33 34 60

Shipping weight (kg) 28 32 38 39.5 68

Blower Output (m3/h) 300 450 550 750 1100

Dia. Cupro (mm) 16 16 16 16 16

H (mm) 295 310 330 330 382

H1 (mm) 260 260 290 290 326

H2 (mm) 54 54 54 54 56

P (mm) 285 380 380 450 595

D (mm) 100 100 125 125 127

L (mm) 408 408 438 454 529

L1 (mm) 280 280 280 295 382

L2 (mm) 380 395 410 440 519

**Suggest Breaker (A) 15 10 10 15 10 10 20 15 15 **25 20 20

Internal Fuse 3.15 AL 250V 3.15 AL 250V 3.15 AL 250V 3.15 AL 250V

19l / min.

1140l / hr.

5.016gal / min.

25l / min.

1,500l / hr.

6.600gal / min.

Iwaki WB 1000

Pan World 100PX

Minimum Flow Rate

Recommended Flow Rate

Recommended Pump

6l / min.

360l / hr.

1.584gal / min.

10l / min.

600l / hr.

2.640gal / min.

Iwaki WB 350

Pan World 30PX

11 l / min.

660l / hr.

2.904gal / min.

15l / min.

900l / hr.

3.960gal / min.

Iwaki WB 500

Pan World 50PX

15l / min.

900l / hr.

3.960gal / min.

20l / min.

1,200l / hr.

5.280gal / min.

Iwaki WB 1000

Pan World 100PX

30 25 25

3.15 AL 250V

28l / min.

1680l / hr.

7.392gal / min.

32l / min.

1920l / hr.

8.448gal / min.

Iwaki WB 2000

Pan World 250 PS

Page 31

This data is subject to change without notice; please refer to the data on the nameplate.

Limited Warranty

This product comes with a 24 month limited warranty from the date of purchase. For warranty policy details, visit

http://www.techwebasto.com

860-7866 or e-mail at: info-us@webasto.com.

. To obtain warranty service, contact a customer service representative at: (800)

T echn ical A ssistance

If you require help, check our technical assistance website at http://www.techwebasto.com or call the technical

support hotline at (800) 860-7866.

For quick service, please have the following information available:

● Full Name

● Phone number including the area code

● Unit Model Information and serial number

● The type of assistance you are requesting

● Document any error codes

Page 32

Original 7/2006 | Rev. L | Date: 8/2018

Webasto Thermo & Comfort N.A., Inc.

T echnical Assistance Hotline

Phone: (800) 860-7866

Outside U.S. (810) 593-6000

www.webasto.us

www.techwebasto.com

Loading...

Loading...