Page 1

Water Heaters Installation Instructions

BBW 46

DBW 46

Be sure to read these Operating Instructions

prior to putting the heater into operation.

9/1998

Page 2

BBW 46 / DBW 46

Table of Contents

Page

Installation Instructions 1

Legal Provisions 1

Installation Location 2

Installation Example

BBW 46 / DBW 46 3

Connection to the Cooling System 5

Re-Positioning of Circulating Pump 5

Fuel Circuit Connection 5

Combustion Air Supply 8

Exhaust Gas Pipe 8

Electrical Connections 8

Allocation of Telestart T60 9

Installation of Telestart Receiver 9

Circuit Diagrams 12

Initial Start-Up 13

Technical Data 14

Version 15

I

Page 3

Installation Instructions

Legal Provisions for Installation

For testing the heater in accordance with Section 19, 20 or

21 StVZO (German Regulations Authorising the Use of Vehicles for Road Traffic) the following regulations are primarily to be observed (Section 22 a StVZO):

NOTE:

These provisions are binding within the scope of the

StVZO and should also be observed in countries

where no special locally applicable regulations are in

effect!

Within the scope of the StVZO ”General Design Certifications” have been granted by the Federal Office for Motor

Traffic for the BBW 46 and DBW 46 water heaters with the

following design approval numbers:

~S 185 for heaters BBW 46 - petrol

~S 186 for heaters DBW 46 - diesel

The installation of the heaters must be performed in accordance with these Installation Instructions. The installation must be checked

a) upon the homologation of the vehicles

in accordance with Section 20 StVZO

b) upon any individual test

in accordance with Section 21 StVZO, or

c) upon any examination

in accordance with Section 19 StVZO by a

registered expert or examiner for motor traffic, an

expert for automotive vehicles, or any other

authorised official, in accordance with Paragraph

7.4 a of Appendix VIII to the StVZO,

and in the case of item c) the proper installation must be

certified on the approval certificate contained on the design certification stating the following:

- vehicle manufacturer

- vehicle type and

vehicle identification numb er.

The effectiveness of the design certification is dependent

on this certificate. The approval certification is to be kept in

the vehicle.

The year of initial operation must be durably marked by the

installer on the type plate of the heater by removing the

years that are not applicable.

Extracting the combustion air from the interior of the

vehicle is not permissible.

The discharge opening of the exhaust pipe should point upward, sideways, or in the case that the exhaust pipes are

routed on the underside of the bottom of the vehicle, it

must be positioned near the lateral or rear edge of the

driver’s cab or vehicle.

Exhaust pipes must be routed so that the possibility of exhaust fumes entering the interior of the vehicle is remote.

The functioning of any parts of the vehicle essential for its

operation must not be impaired.

The openings of the combustion air inlet and exhaust gas

outlet pipes must be so designed that a spherical object of

16 mm dia. cannot be introduced.

Electric lines, switchgear and controlgear of the heater

must be so arranged in the vehicle that their functioning

cannot be impaired under normal operating conditions.

For the routing of fuel lines and the installation of additional fuel tanks, Sections 45 and 46 StVZO are to be

adhered to. The most important excerpts therefrom are as

follows:

Fuel lines must be designed in such a way that they remain unaffected by torsional stresses in the vehicle, engine movement, and the like. They must be protected

against mechanical damage. All parts of the fuel system

must be protected against heat which would impair their

operation, and must be located such that dripping or evap-

BBW 46 / DBW 46

orating fuel can neither collect nor be ignited by hot components or electrical equipment.

The heater must not be installed in spaces occupied by

persons.

The operating state of the heate r at any given time – at

least an indication as to whether it is “on” or “off” - must be

easily recognisable.

The installation of components which are not of an approved type will lead to the revocation of the General Design Certification of the heater and thus the General Operating Permit of the entire vehicle. The same applies to improperly performed repairs or those where other than genuine replacement parts have been used.

Use of the Water Heater

The BBW 46 / DBW 46 water heaters, in conjunction with

the vehicle’s heating system, are used for

- heating the passenger compartment,

- defrosting the vehicle’s windows,

- preheating water-cooled engines.

The water heaters operate ind epen dent ly of the vehicle’s

engine and are connected to the cooling system, the fuel

system and the electrical system of the vehicl e.

1

Page 4

BBW 46 / DBW 46

Installation Location

Preferably, the heater should be installed in the engine

compartment in the splash-water protected area of the

front fenders or at the splash wall.

The heater should be installed at a level as low as possible

so as to ensure automatic venting of the heater and the circulating pump. . This is of special importance since the circulating pump is not of the self-priming type.

CAUTION:

The openings of the water connecting pipe sockets must

never, not any installation position, point downward.

CAUTION:

The heater must not be installed :

- in the immediate vicinity of or above hot vehicle parts

- in the direct splashwater area of the wheels

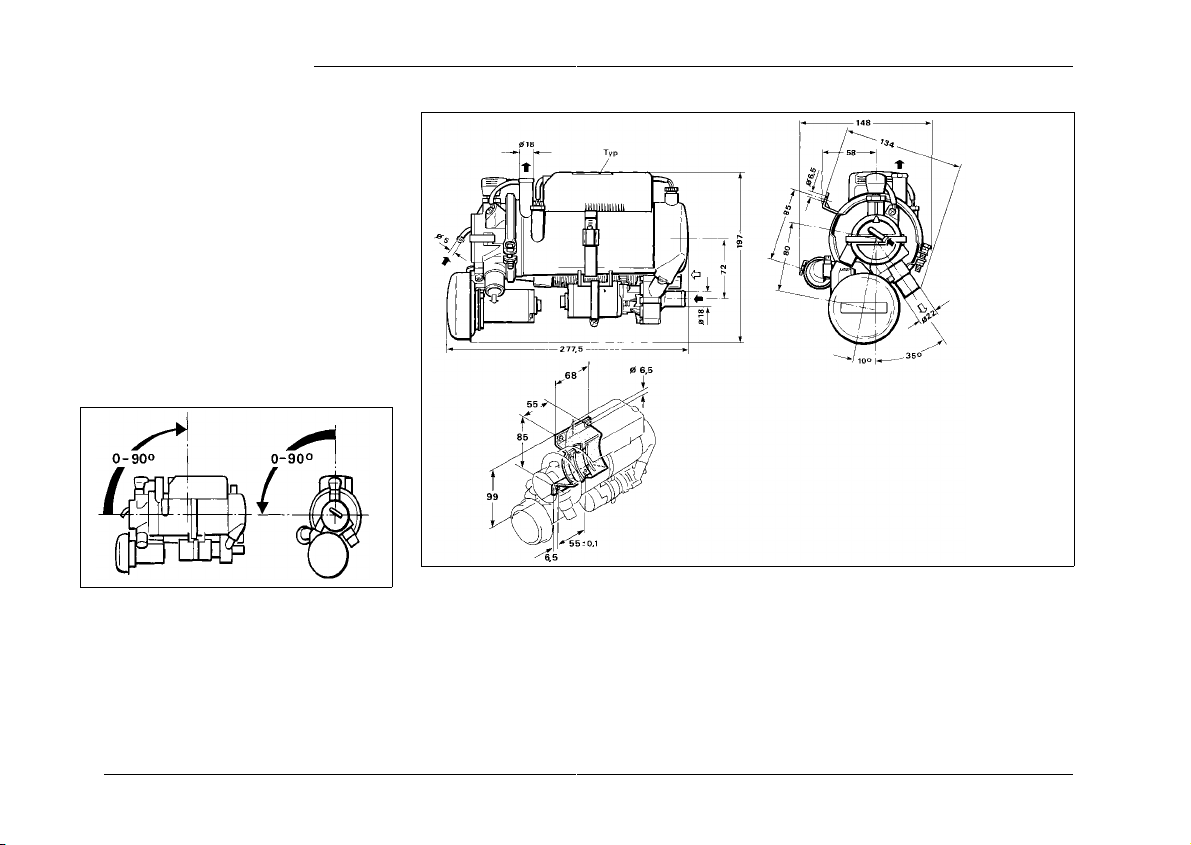

Fig 1: Installation Positions

Type Plate

The type plate must be located at a place where it is protected against damage and where it can be easily viewed

once the heater has been installed (or else, a type plate duplicate is to be used).

The years not applicable must be removed from the type

plate.

2

1

6

4

5

Fig 2: Installation Drawing BBW 46 / DBW 46

Mount

The heater mount must be fitted to the vehicle body or the

intermediate support by means of at least four M6 screws.

It is required that washers and lock washers be used.

2

3

1 Fuel inlet

2 Water outlet

3Water inlet

4 Exhaust gas outlet

5 Heater mount

6 Combustion air inlet

In the case of level body surfaces, the washers must have

a minimum diameter of 22 mm.

Do not use sheet metal screws for attaching the mount.

4

2

Page 5

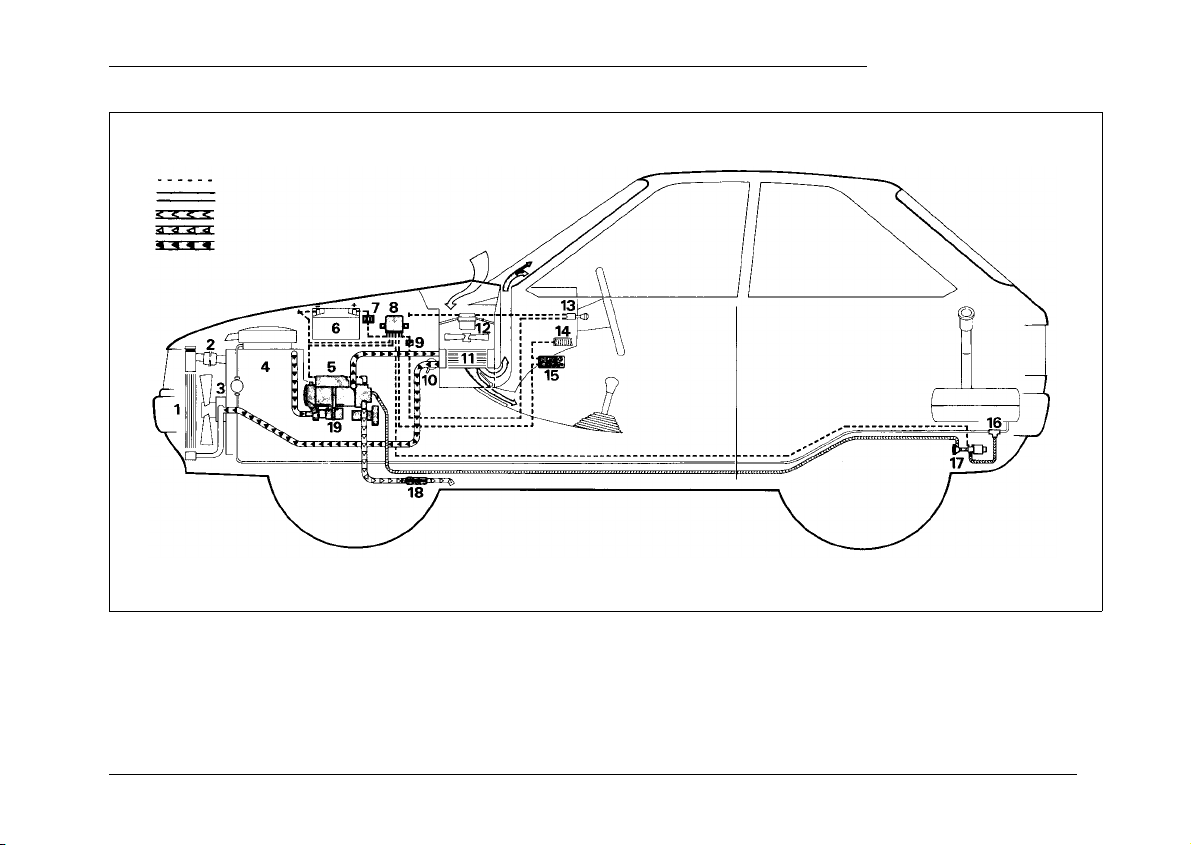

Cable harness

Fuel line

Heater fuel line

Exhaust gas line

Water circuit

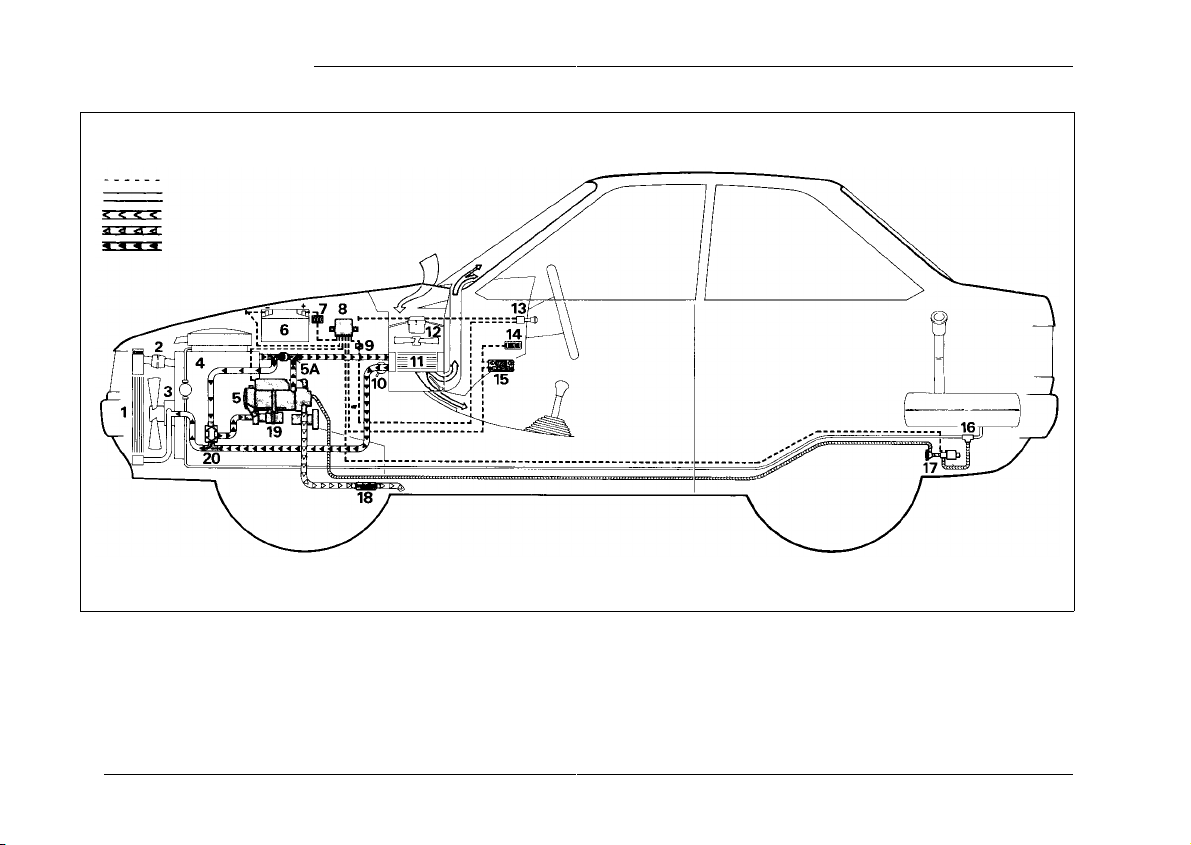

Fig 3: Installa tion example of BBW 46 / DBW 46 heating device in a passenger car (inline integration)

1 Radiator

2 Cooling water thermostat

3 Water pump (of vehicle engine)

4 Vehicle engine with standard equipment

5 Water heater

6 Battery

7 Fuse holder

8 Control unit

9 Relay (for vehicle fan)

10 Regulating valve of vehicle heating

11 Heat exchanger of vehicle heating

12 Vehicle heating fan

13 Switch for vehicle heating fan

14 Fuse bank in vehicle

BBW 46 / DBW 46

15 Digital timer

16 Fuel extractor

17 Fuel metering pump

18 Exhaust silencer

19 Circulating pump

3

Page 6

BBW 46 / DBW 46

Cable harness

Fuel line

Heater fuel line

Exhaust gas line

Water circuit

Fig 4: Installation example of BBW 46 / DBW 46 heating device in a passenger car (thermostat integration)

1 Radiator

2 Cooling water thermostat

3 Water pump(of vehicle engine)

4 Vehicle engine with standard equipment

5 Water heater

5A Non-return valve

6 Battery

7 Fuse holder

8 Control unit

9 Relay (for vehicle fan)

10 Regulating valve for vehicle heating

11 Heat exchanger, vehicle heat ing

12 Vehicle heating fan

13 Switch for vehicle heating fan

14 Fuse bank in vehicle

15 Digital timer

16 Fuel pick-up

17 Fuel metering pump

18 Exhaust silencer

19 Circulating pump

20 Thermostat

4

Page 7

BBW 46 / DBW 46

Connection to the Vehicle’s Cooling System

The heater is to be connected to the vehicle’s cooling system in accordance with Figs 3, 4, 5 and 6. A minimum of 4

litres of coolant must be maintained in the cooling circuit.

2

1

7

Fig 5: Integration into Engine/Water

Circuit “Inline Integration”

1

7

Fig 6: Integration into Engine/Water

Circuit “Thermostat Integration”

Legend of Figs. 5 and 6:

1 Expansion tank

2 Thermostat

3 Vehicle engine

4 Circulating pump

5 Heating device

6 Heat exchanger of heater

7 Radiator

8 Thermostat

9 Non-return valve

3

2

3

4

5

6

9

4

5

8

6

The integration of the heater into the cooling circuit is to be

performed in the flow line of the vehicle’s heat exchanger.

As a rule, the water hoses supplied by Webasto with the

heater should be used. If this is not the case, the hoses

must comply with DIN 73411 requirements as a minimum.

The hoses are to be routed without any kinks and – to

ensure proper venting – in an upward pitch, if

possible. Hose connections must be secured against

slipping off by means of hose clamps.

NOTE:

When securing the hose clamps to the heater, be sure to

fit them between the bead (thicker part) of the hose and

the heater.

The hose clamps must be tightened to a torque of 2.0 +

0.5 Nm.

Before the heater is started up for the first time, or after the

coolant has been replaced, it must be ensured that the

cooling system is properly bled. Heater and piping should

be installed in such a way that static bleeding of the system is ensured.

During heating operation, inadequate bleeding may lead to

a malfunction due to overheating.

Re-Positioning of Circulating Pump

The circulating pump may be integrated into the water circuit either by installation at the location provided on the

heater or at a heater-remote location.

It is important that the correct direction of flow through the

heater be observed (water outlet at top / water inlet at

bottom) as otherwise malfunctions will occur!

Connection to the Fuel System

Fuel system integration without non-return valve

in the tank

The heater’s fuel supply circuit must be integrated in the return line as shown in Fig. 3.

Fuel system integration with non-return valve in the

tank or fuel system integration in the case of singleline fuel supply

Tank extractor with 90°-elbow is to be installed in the tank

fitting (Fig. 7)

5

8,5

Bild 7: Tankarmatur 90°

Lochbild

Bild 8: Webasto-Tankentnehmer

500

Mindestabstand 25 mm

5

Page 8

BBW 46 / DBW 46

l2

l

1

l2

l

1

l1 + l2 ≤ 13 m

l1 ≤ 3 m

l2 ≤ 10 m

Fig 9: Fuel Supply

Fuel Supply

Details on the permissible pressure at the fuel extraction

point are contained in the table below.

Permissible

fuel feed height H (m)

0.00 1.5

1.25 1.4

2.50 1.3

3.75 1.2

5.00 1.1

6.25 1.0

7.50 0.9

8.75 0.8

10.0 0 0.7

Permissible fuel suction

height S (m)

0.00 -0.15 -0.15

0.50 -0.11 -0.11

1.00 – -0.07

NOTE

A fuel flow line can usually be identified by the in-line fuel

filter.

NOTE:

If the vehicle’s fuel system is equipped with a vapour separator, fuel extraction is to take place upstream of same.

For fuel extraction from flow or return lines it is imperative

that the special Webasto fuel pick-up (see Fig. 10) be

used.

at max. permissible

overpressure (bar ) in fuel

line

at max. permissible

underpressure (bar) in fuel

tank

petrol diesel

to engine

from tank

to metering pump

Fig 10: Webasto Fuel Pick-Up

The fuel pick-up is to be mounted so that any air or gas

bubbles that may form are automatically discharged toward the tank (see Fig. 10).

Air or gas bubbles in the fuel line of the vehicle can form if

there is a leak in the vehicle’s carburettor or fuel pump, or

if the ambient temperature exceeds the evaporating temperature of the fuel.

Fuel should not be extracted in the vicinity of the engine

since here gas bubbles are likely to form in the lines owing

to the heat radiating from the engine, which may result in

malfunctions of the combustion operation.

6

Page 9

BBW 46 / DBW 46

If the heater is installed in vehicles with petrol injection systems it must therefore be determined whether whether the

fuel pump is mounted inside or outside the tank.

Where the fuel pump is located inside the tank, the fuel

can only be drawn from the return pipe in which case it

must be ensured that the return pipe extends almost to the

bottom of the tank. If this is not the case, it is possible to

extend the return pipe.

Where the fuel pump is mounted outside the tank, the connection to the fuel system can be accomplished between

the fuel tank and the fuel pump.

Fuel Lines

NOTE:

The hose clamps are to be tightened to a torque of 1.0 +

0.4 Nm.

Any fuel that may have leaked is to be removed from the

engine or heater prior to starting up the heater or engine.

Only steel, copper and plastic pipes made of plasticised, light-resistant and temperature-stabilised PA 11

or PA 12 (e.g. Mecanyl RWTL) in accordance with DIN

73378 may be used as fuel lines.

As in the majority of cases it is not possible to route the

lines in a continuous upward pitch, the inside diameter

must not exceed a given dimension. If the inside diameter

is larger than 4 mm, air or gas bubbles accumulate which

result in malfunctions if the lines sag or are routed in a

downward pitch. If the diameters shown in Fig. 9 are used

you can be sure that no unwanted bubbles will form.

The lines leading from the metering pump to the heater

should not be routed in a downward pitch.

To prevent the fuel lines from sagging, freely suspended

lines must be secured. Mounting should be performed in

such a manner that the lines are protected against flying

stones and thermal influence (exhaust pipe).

Connecting Two Pipes Using a Hose

The proper connection of fuel lines using a hose is shown

in Fig. 11.

Check for leaks!

correct

clamp

wrong

bubble

Fig 11: Pipe/Hose Connection

Metering Pump

The metering pump is a combined fuel delivery, metering

and shutoff system and is subject to certain installation

criteria (see Figs. 8 and 11).

bubble

Fig 12: Metering Pump without Diaphragm Damper

Installation position and mounting

Installation Location

Prior to installing the metering pump make sure that the

maximum pressure prevailing at the fuel extraction point is

lower than the max. permissible value indicated in the

table on page 6.

It is recommended that the metering pump be installed in a

location which sufficiently cool. On no account must the

permissible ambient temperature at any given operating

state be in excess of + 20°C.

Metering pump and fuel lines must not be mounted within

the radiation range of hot vehicle parts. If necessary, a radiation protection is to be provided.

The preferred installation location is near the tank.

Installation and Mounting

The metering pump is to be attached by vibration-damping

suspension. The installation position is restricted as shown

in Fig. 12 in order to ensure proper self-ventilation of the

system.

7

Page 10

BBW 46 / DBW 46

Combustion Air Supply

The combustion air required must be drawn in from the outside of the vehicle.

The combustion air should be drawn in at a splash-water

protected location.

The combustion air intake opening must be so located that

the possibility of clogging due to contamination is remote.

It must not point in the direction of travel.

The combustion air line can be so routed that it features sev-

eral bends (total of 270°, smallest bending radius 50 mm).

The combustion air line can have a length of max. 1000 mm.

On no account should the combustion air be extracted

from areas occupied by persons. If the heater is located in

an enclosed installation casing, a ventilation opening of at

least 3 cm2 is required.

Where the heater is installed in the vicinity of the vehicle tank

in a common installation space, combustion air must be

drawn in from the outside of the vehicle and the exhaust gas

be discharged to the atmosphere. The lead-through openings

must be splash-proof.

Exhaust Pipe

The exhaust pipe (inside diameter 22 mm) may have a

length of up to 5m and may feature several bends (in total

720°, smallest bending radius 50 mm).

The exhaust silencer is preferably to be mounted in the vicinity of the heater.

It must not be installed near the combustion air intake

opening.

Operation of the BBW 46 / DBW 46 heater is also permissible without silencer.

The discharge opening of the exhaust pipe must not point

in the direction of travel (see Fig. 14).

Fig 13: Exhaust silencer

Direction of flow (optional)

direction of discharge approximately vertical 90° ± 10°

Fig 14: Exhaust Pipe Discharge Opening

Installation Position

Rigid pipes made of unalloyed steel with a minimum wall

thickness of 1.0 mm or flexible tubes of alloyed steel

should be used as exhaust pipes.

NOTE:

Any condensation water that may have collected in the exhaust pipe must be drained immediately. If necessary, it is

permitted to drill a condensation water drain hole.

Electrical Connections

Control Unit/Heater Connection

The electrical connection of the heaters is to be performed

in accordance with Fig. 16.

The connection of the digital timer should be carried out in

accordance with the circuit diagram shown in Fig. 15.

Vehicle Fan

The activation of the vehicle fan is controlled by the vehicle

fan relay, see circuit diagram shown in Fig. 16.

Connection of Telestart Receiver T60

The connection of Telestart receiver T60 is to be carried

out as shown in Fig. 16.

8

Page 11

BBW 46 / DBW 46

Tuning of Teles ta rt T6 0 Han dhe ld Tr ansm it ter a nd Receiv er

NOTE:

Each receiver can be allocated 2 handheld transmitters.

- Place batteries in battery compartment.

- Pull antenna out of transmitter approx. 5 cm.

25

15

A

1

A

A

Wait 10 seconds

-

Interrupt voltage supply for at least 10 seconds by removing the 15A flat fuse (blue).

NOTE:

If the Telestart receiver is retrofitted, fuse F2, 1A (black)

has to be removed.

25

15

A

1

A

A

Wait 5 seconds

- Briefly press the ”Start” button.

Start

Operation indicator on transmitter is flashing.

Wait 15 seconds

- Briefly press the ”Off” button.

Off

Operation indicator on transmitter no longer flashes.

- Tuning is finished.

If any specified time period is exceeded or fallen short of,

tuning will not be successful and the procedure is to be repeated from the beginning.

Proceed in the same way for tuning and thus allocating a

second transmitter.

Off

Retrofitting the T60 Telestart Receiver

NOTE:

The BBW 46 / DBW 46 water heaters can be retrofitted

with the T60 Telestart remote control.

The retrofit kit T60 consists of the following parts:

- Transmitter T60 with 2 alkaline LR1 1.5V batteries

- Standard antenna T6

- Receiver T6

- Mounting hardware (bag) comprising

2 sheet metal screws

1 receptacle housing

1 tab connector housing

3 push-on receptacles

The installation may only be performed by authorised Webasto service centres.

CAUTION:

The receiver must be installed in the interior of the vehicle.

It is not permitted to extend the cable harness (approx . 70

cm long) provided on the receiver.

- Determine suitable installation location for receiver T6 in

the interior of the vehicle, in the vicinity of the digital

timer.

- Mount receiver using the sheet-metal screws (containe d

in the kit).

- Immediately after reinstalling the flat fuse press the ”Off”

button.

9

Page 12

BBW 46 / DBW 46

Installation of Antenna

NOTE:

Preferably, the antenna should be installed in the interior

of the vehicle, at the top in the centre of the windshield or

rear window. If installed at different location s, the range is

likely to be diminished.

For an optimal reception, a distance of 2 ± 0.5 cm from the

windshield edge is to be maintained (Fig. 15). The cable

should be routed upward, beneath the panelling in the vehicle roof and then directed to the right or left to the

chassis member.

NOTE:

In the case of lack of space, the antenna may be installed

up to 15 cm off-centre.

- Clean windshield or rear window using grease-dissolving cleaner (e.g. methylated spirit s).

- Peel off protective film from antenna and glue antenna

in place.

Antenna

2 ± 0.5 cm

Fig 15: Installation of Antenna

NOTE:

Do neither shorten nor sharply bend antenna cable.

- Route antenna cable to receiver.

- Establish plug connection at receiver and tighten connector hand-tight.

- Secure antenna cable using cable ties.

10

Page 13

BBW 46 / DBW 46

B1B2EX1F3

R1

AB C D

M1

M2

(75) 15

30

61

X1Y1

K7

X2Y2

87

1

7

8

9

87a87b

22

bl/ge

gr

33

44

vi

55

br

66

rt

7

sw

8

ge

P

rt

30

E1

sw

A4

31

Fig 16: Automatic control circuit BBW 46 / DBW 46, 12V digital timer and Telestart T6 (legend see page 12)

E2

31

br

5

6

4

3

2

1

F4 F2 F1

W1

B3

rt/bl

87

87a

86

K6

85

30

sw

S1

br

M3

S2

2

2

1

1

W1

rt

W1

34

sw/rt

rt

gn/ws

57

68

1

2

A

3

4

1

5

2

6

S3

W1

ws/sw

br

br

br

br

bl

M

X1

bl

A1

2

341

6 8 10 12

57911

br ge

X1 X1

A2

221111

bl

br

16

5

24V

Y

4

M1

rt

rtrtvi vi

R1

B1 B2

312312

sw sw

br

br

bl ge/rt

M

ϑ

F3

M

M2

R2

10

ws ws

or or

gn gn

gn

ϑ

X2

12V

2

ge

197887645

2

br

ge ge

E

11

Page 14

BBW 46 / DBW 46

Wire Cross-Sections

< 7.5 m 7.5 - 15 m

2

0.5 mm

2

0.75 mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

0.75 mm

1.5 mm

2.5 mm

4.0 mm

6.0 mm

Wire Colours

bl

blue

br

2

2

2

2

2

brown

ge

yellow

gn

green

gr

grey

or

orange

rt

red

sw

black

vi

violet

ws

white

Pos. Designation Remarks

A1 Heater BBW 46 / DBW 46

A2 Electroni c control uni t SG 1560

A4 Telestart receiver T 6

B1 Flame detector

B2 Temperatur e sensor

B3 Room thermostat for vehicle fan on/off

E Glow plug

F1 Fuse 16A motor vehicle fuse DIN 72581

F2 Fuse 8A motor vehicle fuse DIN 72581

F3 Temperature fuse

F4 Fuse 16A motor vehicle fuse DIN 72581

K6 Relay for vehicle fan

K7 Relay for Telestart receiver

M1 Motor combustion air fan

M2 Motor circulating pump

M3 Motor vehicle fan

P Timer, digital for presetting operating time

R1 Resistor for part-load operation

R2 Resistor only required for 12-volt glow plugs in a 24-volt heater

S1 Switch for vehicle fan S1 or S2 depending on vehicle

S2 Switch for vehicle fan S1 or S2 depending on vehicle

S3 Switch for circulati ng pump for separate activation

V3 Diode (in pos. A2)

V108 Transistor (in pos. A2)

W1 Cab le harnes s

X1 Connector 12-pole

X2 Connector 2-pole

X4 Connector 1-pole

Y Metering pump

12

Page 15

BBW 46 / DBW 46

Initial Operation

NOTE:

The safety information contained in the Operating Instructions have to be adhered to!

After the heater has been installed, the water circuit and

the fuel supply system are to be thoroughly bled. Follow

the directions of the vehicle manufacturer.

Perform a test run of the heater thereby checking all water

and fuel connections for leakage and security. Should the

heater fail during operation, troubleshooting activities are

to be carried out.

Malfunctions

Fault Lock-Out Due to Malfunctions of the Heater

If no flame forms fuel is delivered for max. 180 seconds.

If the flame is extinguished during operation, fuel is delivered for max. 90 seconds.

In the event of overheating fuel supply is immediately

stopped.

CAUTION:

No visual indication occurs in the case of overheating.

Fault Lock-Out Due to Undervoltage

In the case of an undervoltage of 9.5 ± 0. V (in the case of

12-volt heaters) or 19 ± 1 V (in the case of 24-volt

heaters), measured at the input of the control unit, occurring over a period of 20 seconds, the heater will shut down

in its fault lock-out mode and an after-run period will follow.

Interlock Deactivation

- Eliminate cause of malfunction

- Resetting is performed by switching the heater off and

back on again (the ’off’ period has to last for at least

1 sec).

- In the case of overheating, the temperature fuse has to

be replaced or the temperature limiter to be reset.

13

Page 16

BBW 46 / DBW 46

Technical Data

Unless tolerances are shown within the technical data

table, a tolerance of ± 10% applies at an ambient tempera-

ture of +20°C and at the rated voltage.

Fuel for BBW 46 (Petrol):

The type of fuel specified by the vehicle manufacturer is

suitable as fuel for the heater.

Fuel for DBW 46 (Diesel):

The diesel fuel specified by the vehicle manufacturer is

suitable as fuel for the heater. When changi ng to cold-resistant fuels, the heater must be operated for about 15

minutes to ensure that the fuel line and fuel pump are also

filled with the new fuel.

Any negative effect caused by additives is not known.

Heater Operating

Mark of approval

Type water heater with vaporising burner

Heat output full load

Fuel petrol diesel

Fuel consumption full load

Rated voltage 12 or 24 volts

Operating voltage range 10 ... 14 volts or 20 ... 28 volts

Rated power consumption without

circulating pump (without vehicle fan)

Max. permissible ambient temperature:

Heater: - operation

Control unit: - operation

Metering pump: - operation

Max. allowable working pressure (heat carrier) 0.4 ... 2.0 bar

Filling capacity of heat exchanger 0.25 l

Min. amount to be maintained in the circuit 4.00 l

Volume flow of circulating pump against 0.1 bar 950 l/h

CO2 content in exhaust gas (perm. funct. range) 10 ... 10.5 % by vol.

Dimensions of heater length 277 mm

Weight incl. control unit and circulating pump 3.9 kg

- storage

- storage

- storage

Mode

part load

part load

full load

part load

BBW 46 DBW 46

S 185

~

0.63 l/h

0.23 l/h

4.6 kW

2.3 kW

44 W

33 W

-40° ... + 80°C

-40° ... +100°C

-40° ... + 75°C

-40° ... + 85°C

-40° ... + 20°C

-40° ... + 85°C

width 148 mm

height 197 mm

S 186

~

0.58 l/h

0.29 l/h

14

Page 17

BBW 46 / DBW 46

Version

Type

DBW 46 Supplementary Heater

Water heater for ”diesel” fuel

Type

BBW 46 Supplementary Heater

Water heater for ”petrol” fuel

The BBW 46 / DBW 46 water

heaters are designed for 12-volt or

24-volt operation.

15

Page 18

Loading...

Loading...