Page 1

890IT-Series Wheel Clamp TIRE CHANGER

INSTRUCTION MANUAL

READ THIS ENTIRE MANUAL

BEFORE OPERATION BEGINS

Model 893-IT 20”turntable with internal clamping range 12"-23", external

clamping range 10"-20"

Model 898-IT 24”turntable internal clamping range 15"-28", external

clamping range 13"-24"

For servicing single piece automotive and most light truck tire/wheel assemblies

Safety Instructions

Operating Instructions

Installation Instructions

Maintenance Instructions

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for

easeof reference bysupervisorsand operators.

Page 2

RECORD THE FOLLOWING INFORMATION WHICH IS LOCATED ON THE

SERIAL NUMBER DATA PLATE.

Serial Number: _________ Model:

Factory Code:

Technical Standard Code Q/YGM001--2006

This product has passed the examination.

Operators Protective Gear and Equipment

Personal protective equipment helps make tire changing safer. However, equipment does not take the place of

safe operating practices. Always wear durable work clothing during tire service activity. Shop aprons or shop

coats may also be worn, however loose fitting clothing should be avoided. Tight fitting leather gloves are

recommended to protect operator’s hands when handling worn tires and wheels. Sturdyleather work shoeswith

steel toes and oil resistant soles should be used by tire service personnel to help prevent injury in typical shop

activities.Eyeprotectionis essential duringtire service activity. Safety glasses with side shields, goggles,or

faceshields areacceptable.Back belts provide supportduringliftingactivitiesand are also helpful in providing

operator protection. Considerationshould alsobegiven to the use of hearing protection if tire service activity

is performed inanenclosedarea, orifnoiselevels are high.

WARNING

Failure to follow danger, warning, and caution instructions may lead to serious personal

injury or death to operator or bystanderor damage toproperty. Donot operate this machine

untilyoureadand understandallthedangers,warnings and cautions in this manual.

For additionaltire,wheel, and/orinflationinformationcontact the following:

RUBBER MANUFACTURERSASSOCIATION

1400 K Street N.W.

Washington, DC 20005

(202)682-4800www.rma.com

TIRE GUIDES, INC.

The Tire Information Center 1101-6 South Rogers Circle Boca Raton, FL 33487-2795

(561) 997-9229

www.tireguides.com

Page 3

Owner’s Responsibility

Tomaintainmachineandusersafety,the responsibility of the owner is to readand follow these

instructions:

Follow all installation instructions.

Make sure installation conforms to all applicable Local, State, and Federal Codes,Rules,

and Regulations; such as StateandFederalOSHARegulationsandElectrical Codes.

Carefully check the unit for correct initial function.

Readandfollow the safetyinstructions.Keepthemreadilyavailableformachineoperators.

Make certain all operators are properly trained,know howto safely andcorrectly operate the

unit, and are properly supervised.

Allow unit operationonly with all parts in place and operating safely.

Carefully inspect the unit on a regular basis and perform all maintenance as required.

Serviceandmaintaintheunitonlywithauthorized or approved replacement parts.

Keepallinstructionspermanentlywiththeunit andalldecalsonthe unit clean andvisible.

This tire changer comes with a very detailed and easy to understand instruction manual. This

manual assumes that the customer has used a wheel clamp style tire changer previously, or has

operators that have operated a wheel clamp style tire changer. If this is your first tire changer

purchase and you have not operated a wheel clamp style tire changer, it is strongly

recommended to have a person/trainer who is familiar with this style of tire changer train you in

the operation. This tire changer is very similar to many other tire changers on the market. The

distributor that sold this unit will be glad to give you a training session at their location or guide

you to someone who can provide a service call to your location for training (a service charge

would apply). The distributor also offers telephone technical support and trouble-shooting

suggestions as needed. This does not take away from the responsibility you have to read and

understand this complete manual.

This responsibility is no different than when you purchase an automobile. The automobile dealer

assumes you know how to operate and drive a motor vehicle. Safe operation is your

responsibility and the dealer assumes you know how. Seek training as needed.

DANGER

EXPLOSION HAZARD – NEVER EXCEED40 PSI WHILE SEATING

BEADS

Explosion Hazard Never inflate tire above manufacturer’s

recommended pressure after bead is seated.

Page 4

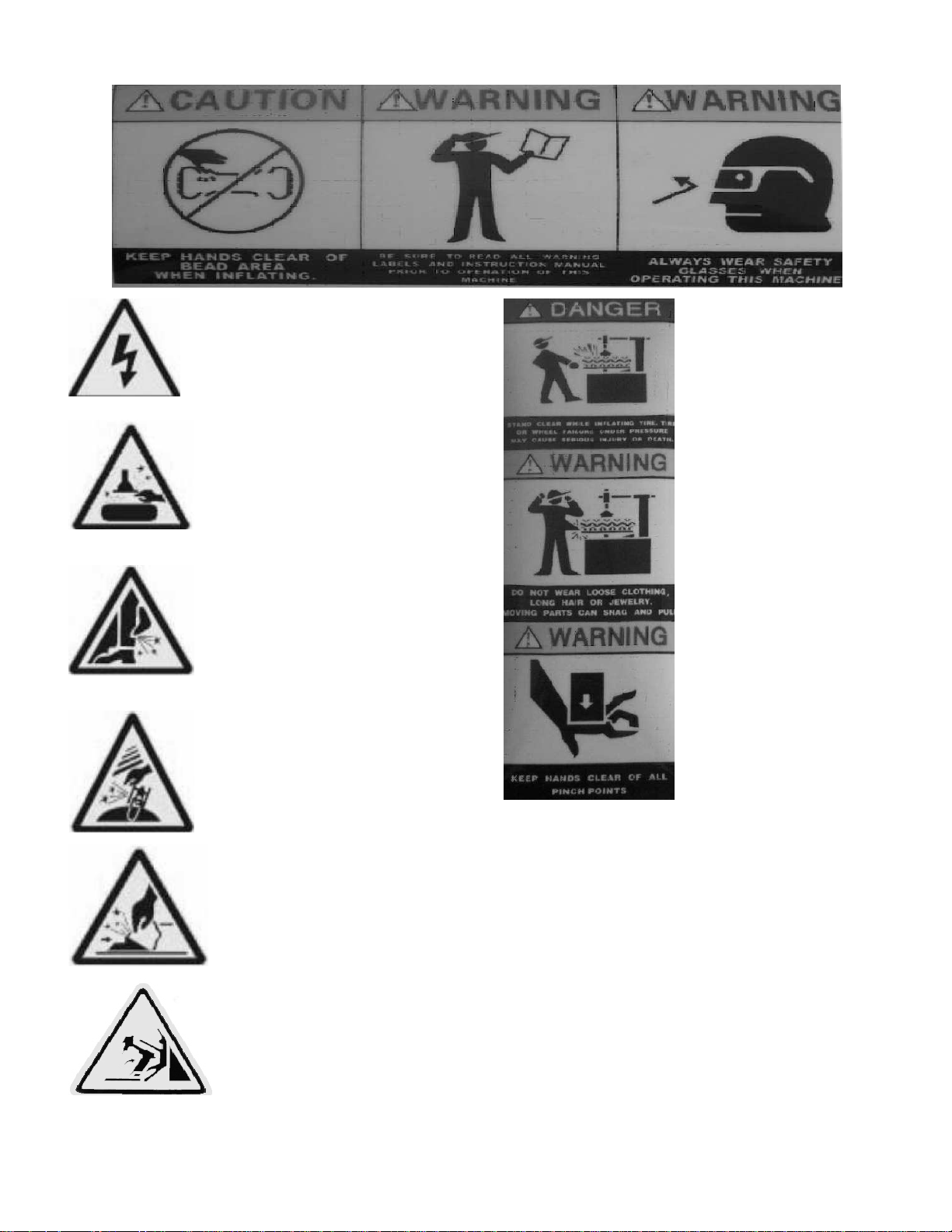

SAFTTY LABEL INSTRUCTION

.

Keep your hands far Carefully read operation When operation , wear

from tire when operation manual before operation the protective gear

electrical shock hazard!

Do not reach any part of your

body under the demount tool. When operating, do not

When rapid inflation,

ensure the wheel

clamped.

wear long hair, loose

clothing or jewelry

When breaking bead, the bead breaking

blade will quickly move leftwards. When operating, do not

SAFETY LABE Note: when pressing the tire, the

opened clamp cylinder may

injure the hand of the operator.

Remember, do not touch the side

wall of the tire.

When clamping the rim, do not

Reach your hand or other parts

Of the body in between the clamp

& the rim.

reach your hand under the

falling objects.

Do not stand behind the column to

Avoid injuring the persons when swinging arm

Page 5

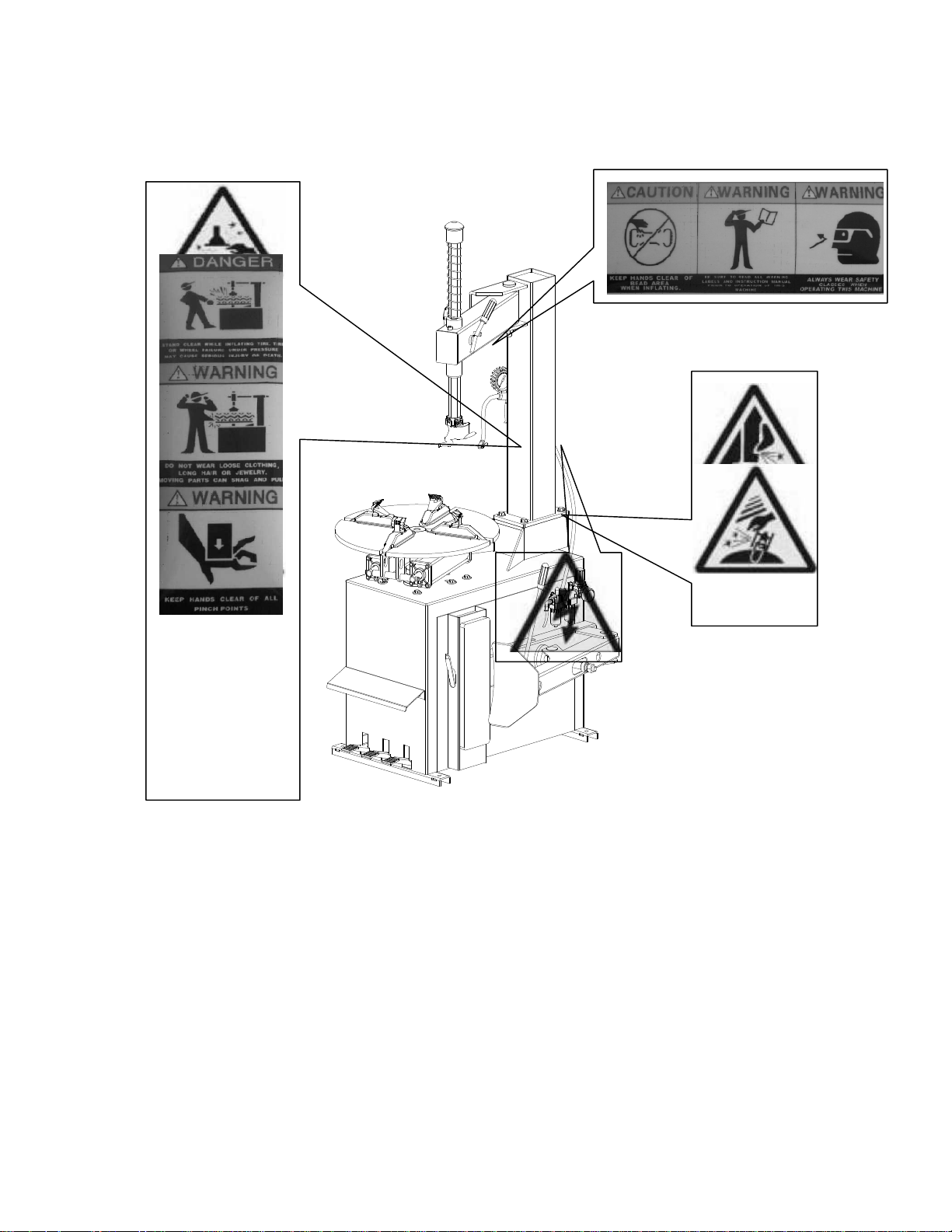

SAFETY LABEL POSITION DIAGRAM

Pay attention to keep the safety labels clean and readable at all times. Replace any label that is not clear, torn or

missing.

Operators review the safety labels clearly and understand the meaning of each label.

Page 6

CONTENT

CHAPTER Ⅰ BRIEF INTRODUCTION

1.1 BRIEF INTRODUCTION

1.2 EQUIPMENT OVERALL DIMENSION (EXCLUDING THE ASSSISTANT)

1.3 TECHNICAL PARAMETER

1.4 APPLICATION SCOPE

1.5 ENVIRONMENT REQUIREMENT

CHAPTER Ⅱ CONFIGERATION AND OPERATION

CHAPTER Ⅲ INSTALLATION AND CALIBRATION

3.1 OPEN PACKAGE CARTON

3.2 INSTALLATION OF THE COLUMN

3.3 AIR SOURCE INSTALLATION

CHAPTER Ⅳ DEMOUNT AND MOUNT TIRE

4.1 DEMOUNT TIRE

4.2 MOUNT TIRE

4.3 INFLATION

4.4 RAPID INFLATION

CHAPTER Ⅳ MAINTANENCE AND REPAIR

CHAPTERVI INSTALLATION & OPERATION OF THE ASSISTANT ARM

6.1 LEFT ASSISTANT INSTALLATION

6.2 RIGHT ASSISTANT INSTALLATION

CHAPTER ⅣTRANSPORTATION

CHAPTER Ⅳ ELECTCTRICAL AND PENUMATIC DRAWING

CHAPTER IX GENERAL TROUBLESHOOTING AND SOLUTION

Page 7

CHAPTER Ⅰ BRIEF INTRODUCTION

1.1 BRIEF INTRODUCTION

This series of equipment is the tire changer with fixed column and rocker arm tire changer. It is suitable to mount,

demount and inflate all types of automotive and most light truck tire/wheel assemblies. When used properly, the

operation is convenient, safe and reliable.

This series of machine can be divided into 4models. They are LC890, LC850, LC800(cylindrical column)and LC112

(square column)The corresponding models with the quick inflation function are:GT890,GT850,GT800(cylindrical

column). Among them LC890 and GT890 and be equipped with the assistant to adapt to demount and mount the low

profile and stiff tires.

1.2 EQUIPMENT OVERALL DIMENSION (EXCLUDING THE ASSSISTANT)

model

LC(GT) 890 2040 1135 870 223/233

LC(GT) 850 1820 985 780 200/210

LC(GT) 800 1858 975 895 210/220

LC112 1815 965 795 190

1.3 TECHNICAL PARAMETER

Operation pressure:8-10bar

motor:50Hz 380V 0.75Kw (standard) 50Hz/60Hz 220V/110V 1.1Kw(optional)

turntable speed:6rpm

noise:<70dB(A)

height(mm) length(mm) width(mm)

Net weight kg

1.4 APPLICATION SCOPE

model Max. wheel diameter Max. wheel width

LC890(GT)

LC850(GT)

LC800 960mm(37″) 305mm(12″)

GT800 960mm(37″) 305mm(12″)

LC112 960mm(37″) 305mm(12″)

(LC800 has adopted the enlargement of the movement base and clamp diameter for demount and mount the

motorcycle tire.

1.5 ENVIRONMENT REQUIREMENT

ambient temperature 0℃~45℃

relative humidity 30~95%

Sea level max.1000M

Without dust and flammable and explosive gas

The minimum operation space around the machine is indicated in FIG 1.

If installed outdoors, you must provide shelter to

protect from the weather. It is forbidden to use in the site

with the flammable gas!

1250mm(49″) 400mm(16″)

960mm(37″) 305mm(12″)

rim diameter(outer clamp) rim diameter(innerclamp)

10″~20″ 12″~23″

10″~18″ 12″~21″

8″~20″ 10″~22″

10″~20″ 12″~23″

10″~18″ 12″~21″

Fig 1

Page 8

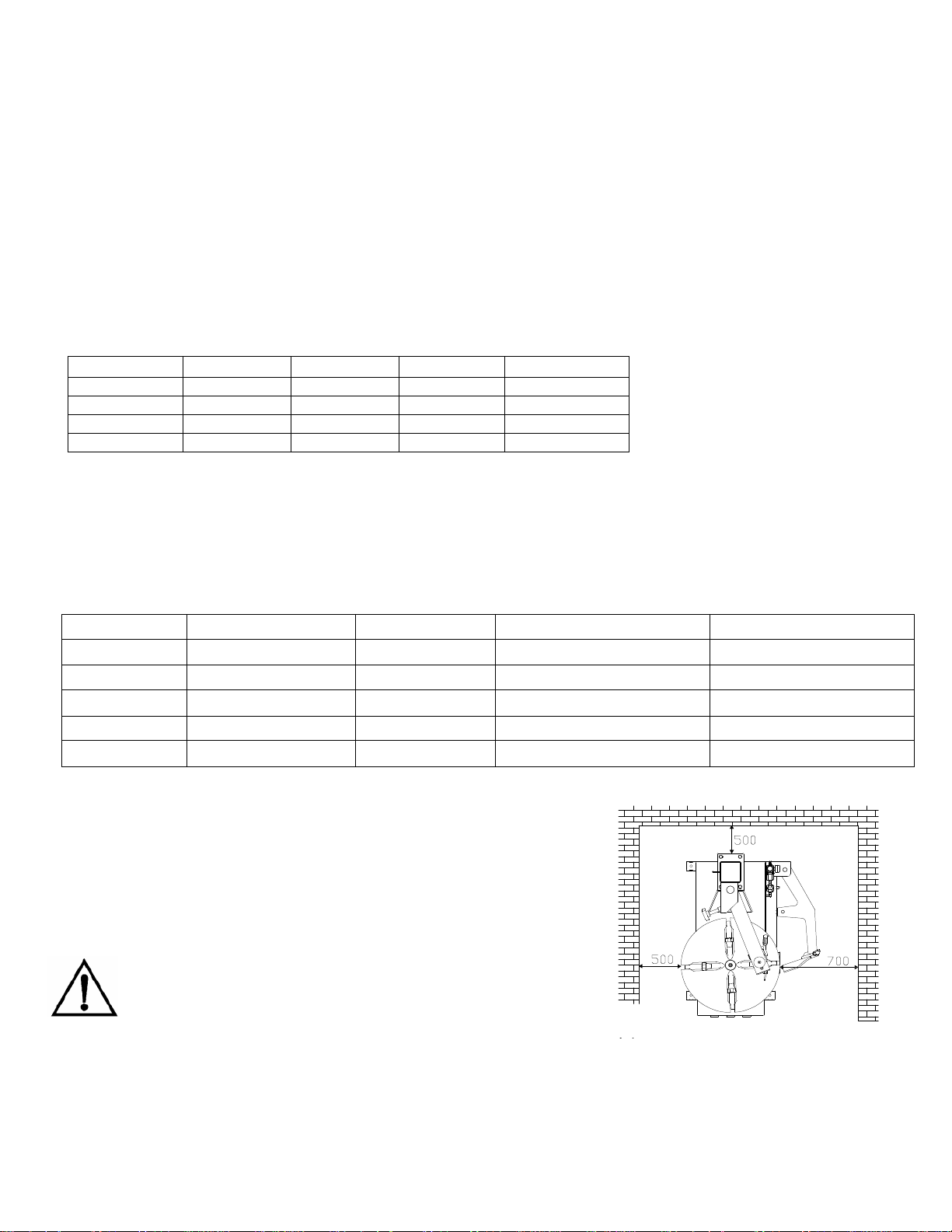

CHAPTER Ⅱ CONFIGERATION AND OPERATION

Know Your Unit - Compare thisillustration with the unit beforeplacing it into service. Maximum performance

and safety will be obtained only when allpersons using theunit arefully trained in its parts and operation. Each

usershouldlearn thefunctionandlocationofall controls.Prevent accidents and injuries by ensuring the unit is

properly installed, operated, and maintained.

图 2 图 3

FIG 2

1 vertical shaft spring 2 rocker valve 3 hexagon shaft 4 demount head

5 claw 6 turntable 7 operation label 8 turntable pedal

9 clamp pedal 10 tire press pedal 11 limit handle 12 lock handlel

13 column 14 inflation gun 15 clamp cylinder 16 blade handle

17 air source fitting 18 bead breaking cylinder 19 tire press arm 20 bead breaking blade

21 crowbar 22 air tank 23 inflation gauge box

CHAPTER Ⅲ INSTALLATION AND CALIBRATION

Before installation, carefully read this manual. The unauthorized change on the parts and spare parts of the machine

will cause damage to the machine. Installation personnel should have the specific electrical knowledge. Operators

must be trained and authorized. Before installation, carefully read the equipment list. If any question, please contact

our company.

To ensure the success of the installation, please prepare the following common tools: Two wrenches(10″), one

socket wrenches, one hexangular wrench, one tung and one screw driver. One hammer and one multi-purpose

meter.

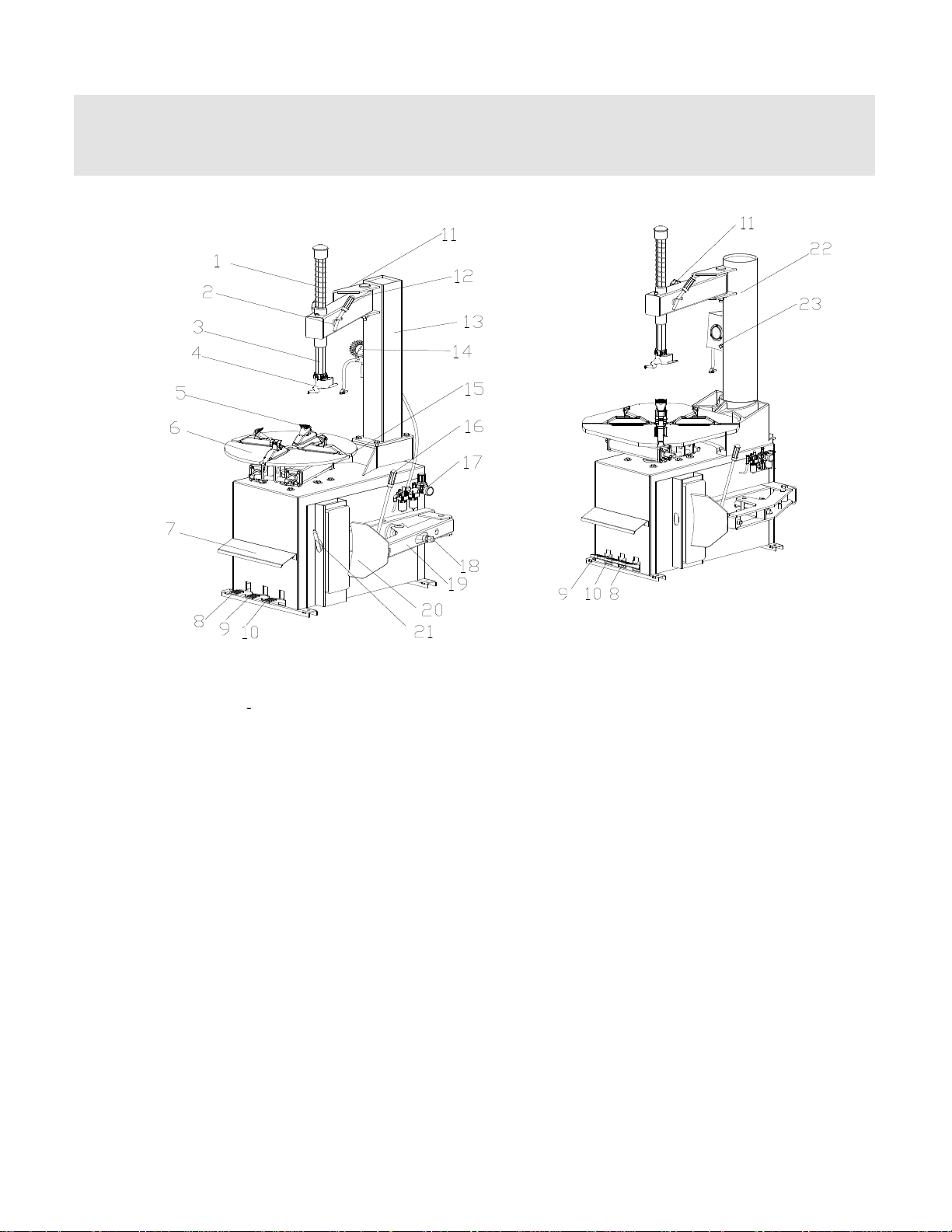

3.1 DEPACKAGE

3.1.1 According to the de-package instruction on the package box, detach the box and remove the package

material. Check to see if the machine has damage or not and if the spare parts are completed.

FIG 3

3.1.2 Keep the package material far away from the working site and remove it properly.

Page 9

3.2 INSTALLATION

3.2.1 After un-packaging the package carton, take out accessory boxes(FIG 4-1),bead breaking arm(FIG 4-5)

and column assembly(FIG 4-2). Position the body according to the FIG1.4. Remove the bolt(FIG 4-4), elastic washer

and plate washer on the body.

FIG 4 FIG 5

3.2.2 Place the column on the body. The direction of the warning label is forwards. Make the holes on the column

base plate align to thread holes on the body. Once again assemble the removed the bolt(3.2.1), elastic washer

and plate washer and plate washer removed in 3.2.1 The torque is 70 N·M(FIG5)Use torsion wrench to tight.

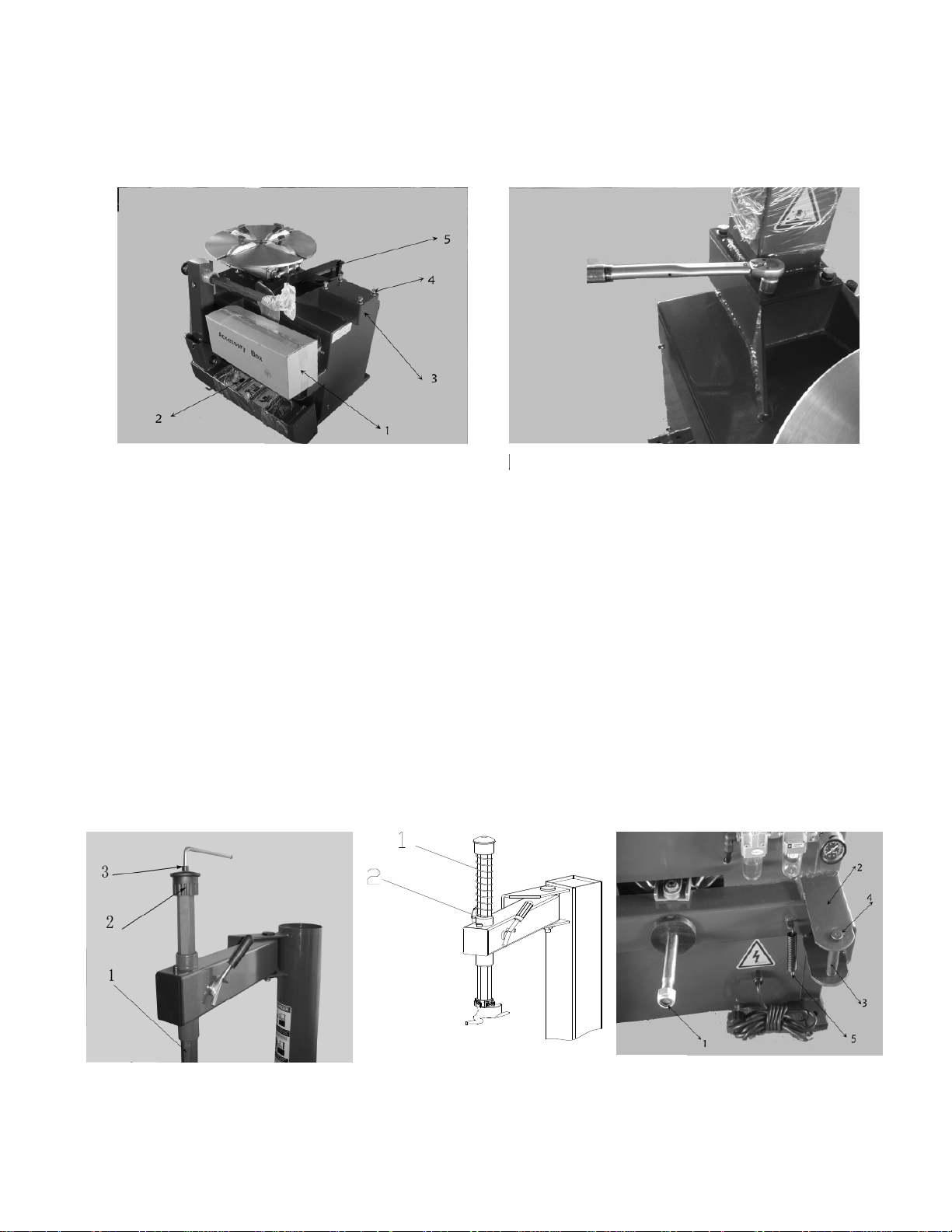

3.2.3 Use the wrench to remove the screw(FIG 6-3)hexangular shaft(FIG6-1)and take off the vertical shaft cap

(FIG 6-2). When removing the screw on the vertical shaft cap, you need to use the lock handle to lock the

hexangular shaft to avoid sliding off to avoid damage to the machine or injury to personnel!

Install the vertical shaft spring(FIG7-1)on the vertical shaft. Mount the vertical shaft cap and mount the removed

screw and assemble the hand wheel into the nut bushing of the rocker arm(FIG 7-2)。

3.2.4 Remove the lock nut at the front end of the bead breaking cylinder piston rod(FIG 8-1)and use the wrench to

remove the nut on the bead breaking arm bolt(FIG8-4) Removethe bolt(FIG8-3)and hang the spring(FIG8-2)

FIG 6

FIG 7 FIG 8

Page 10

3.2.5 Position the bead breaking arm shaft bushing into the bead breaking support plate on the body(FIG 9-1)to

align the hole and install the bead breaking bolt(FIG 9-2)and assemble the nut to lock(FIG 8-4). Insert the piston

rod(FIG10-2)through the hole of the bead breaking slide bushing(FIG10-1). The surface of the slide bushing should

be outwards(FIG 10). Assemble the removed nut(FIG 8-1)into the front end of the piston rod. The nut will be

assembled. The distance from the edge of the bead breaking blade to the bead breaking rubber is 30~40mm

(FIG11). Hang the spring.(FIG9-3)。

FIG 9 FIG 10

Note:If the machine is the one with the quick inflation, please open the side panel and insert 2 pieces of Ø12pu hose

at the inlet of the quick deflation valve into the 2 Ø12nozzle and then install the side panel.

3.2.6 If being equipped with the tool box, you must fix firmly and the column completely installed.

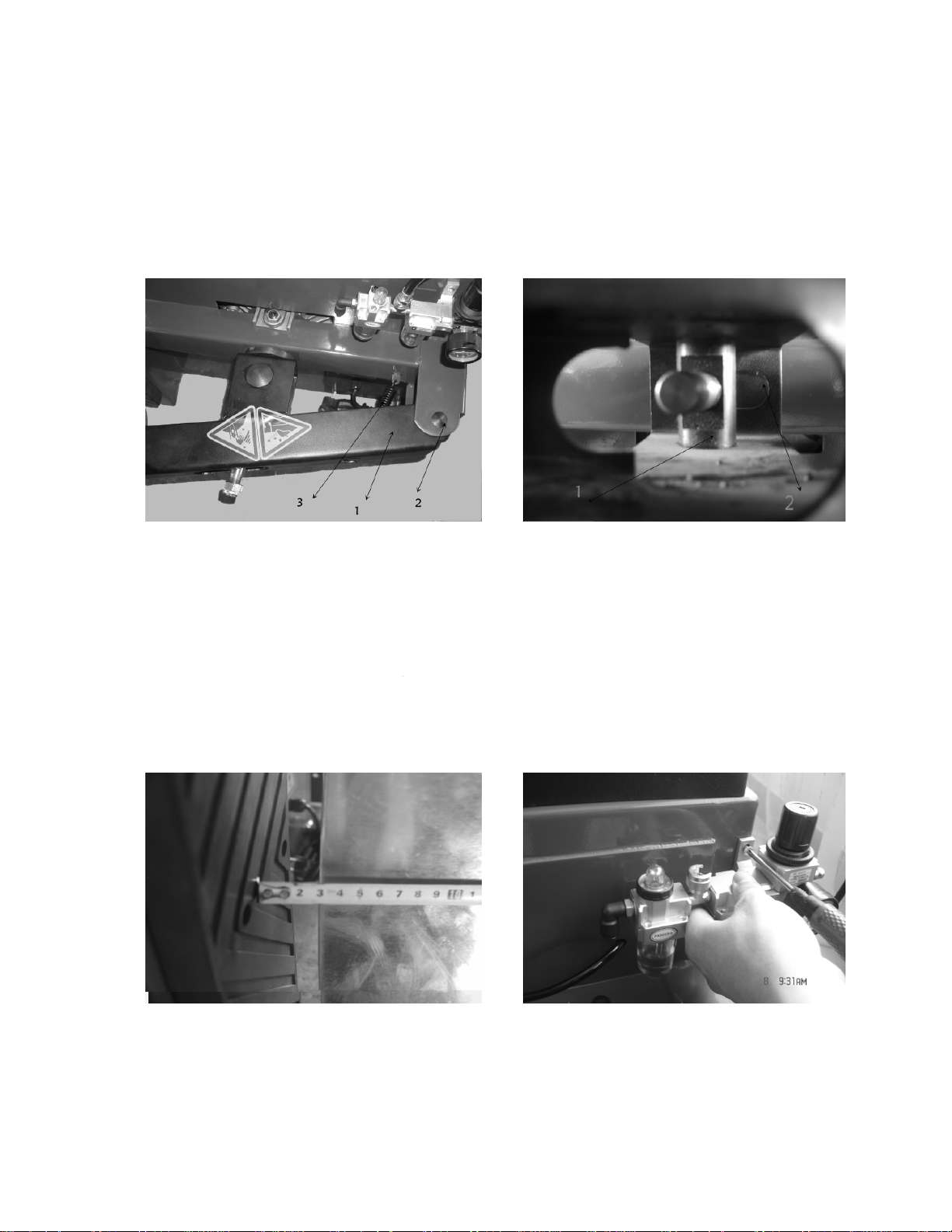

3.3 AIR SOURCE FITTING INSTALLATION:

When the machine leaves the factory, the air source fitting has been detached and placed in the accessory box.

3.3.1 Take out the air source fitting from the accessory box and the screw and remove the oil and dust. Use the

screw to fix it on the right side of the body(fig12)。

FIG 11 FIG 12

Page 11

3.3.2 Connect the air hose. Detach the adapter on the ø8 PU hose on the side wall of the body and insert it into the

elbow. See the fig13/14. The adapter is to keep the hose from sliding into the body.

FIG 13 FIG 14

3.3.3 Connect the inflation gun or inflation gauge box: Inlay the adapter of the inflation gun or inflation gauge box

into the groove (fig15) on the open nut on the air source fitting. Tighten the open nut and then connect the air source.

3.3.4 Air source has been adjusted before ex-factory. If it needs change, adjust again:Pressure: Lift up the pressure

adjustable button( FIG16-1)and twist clockwise and the air pressure will increase. Meanwhile, if counterclockwise,

the air pressure will decrease. Oil Feed:Use screw driver to twist the screw(FIG16-2). If clockwise, the oil dropping

speed will slow. If counterclockwise, it will become faster.

FIG 15

FIG 16

Page 12

CHAPTER Ⅳ BEAD LOOSENING, DEMOUNT AND MOUNT TIRE

OPERATING INSTRUCTIONS

The unit must be properly operated and properly maintained to help avoid accidents that could damage

the unit and injure the operator or bystanders. This section of the Operating Instructions

manual reviews the basic operations and use of controls. These instructions should be reviewed with all

employees before they are allowed to work with the machine. Keep these instructions near the machine for

easy reference.

CAUTION - This machine may operate differently from machines you have previously operated.

Practice with a regular steel wheel and tire combination to familiarize you with the machine’s operation

and function.

4.1 BEAD LOOSENING, and DEMOUNT TIRE

4.1.1 Deflate the air in the tire completely and pull out the core. Use the special tool to detach any wheel weights on

the rim (FIG17). NOTE: Loosening the beads on a partially or fully inflated tire is unsafe and causes excessive

wear on pivots with friction against the bumper pads. Deflate the tire completely to prolong the life of your machine.

FIG 16

FIG 17

4.1.2 Place the tire between the bead breaking blade and tire pressing runner clog. (Fig18) Then step down the tire

press pedal to detach the rim from the tire(fig2-10 or 3-10). WARNING – Watch your fingers and legs! Repeat the

same operation on the other parts of the tire to make the tire completely detached from the rim. Place the wheel with

the tire detached from the rim on the turntable and step the clamp pedal(fig2-9; 3-9) to clamp the rim. Place the

wheel WITH DROP CENTER UP on the turntable, and clamp in position. Press the wheel down while clamping. You

can select the outer clamp and inner clamp to clamp the wheel according to the rim type. To detach the lip smoothly,

you can use the brush to spread the lubricant or thick soap

liquid between the lip and rim.

WARNING - TO MINIMIZE THE RISK OF SCRATCHING

ALLOY and PAINTED RIMS, THESE SHOULD BE

CLAMPED FROM THE OUTSIDE.

FIG 18

WARNING! - ON CHEVROLET CORVETTE WHEELS WITH

THE OPTIONAL LOW PRESSURE SENSOR INSTALLED,

BREAK THE BEAD AT 90 DEGREES OFFSET FROM THE

VALVE STEM. DAMAGE TO THE WHEEL WILL RESULT

IF THE BEAD IS BROKEN AT ANY OTHER POINT ON THE

RIM.

Page 13

4.1.3 Position the hexangular shaft (FIG 2-3) to the working position to make the demount tool close to the rim of the

wheel. And use the hand wheel (FIG 7-2) to push against the rocker arm and then use the lock handle( FIG 2-12) to

lock. Position the mount/demount head in contact with the rim edge and lock it into place: the tool automatically

moves away from the rim edge vertically. Turn the adjustment knob until the mount/demount head clears from the

rim flange about 2 mm (1/16"): this is necessary to avoid rim damage (FIG19).

The angle of the demount tool has been calibrated according to the standard rim. Adjust as necessary for different

size rims.

FIG 19

4.1.4 Use the bead lifting crowbar to detach until the lip to the hump of the demount tool (FIG20). Press down the

turntable rotation pedal(FIG2-8)to rotate the turntable clockwise until the entire lip completely detached. Depress

the tabletop pedal to rotate the wheel clockwise. The demount head will guide the upper bead up and over the edge

of the wheel. Push down on the tire across from the demount head during table top rotation to utilize the drop center

area of the wheel. This reduces the tensional force on the top or first bead during demount. If desired, the bead lifting

tool can be removed after lifting the bead onto the finger.

Lift and hold the tire at an angle so that the lower bead is resting in the drop center directly across from the demount

head, and is loose below the demount head. Insert the smooth curved end of the bead lifting tool down over the

forward end of the mount/demount tool and below the lower bead. Lift the bead up and over the knob on the demount

head. Depress the table top pedal to rotate the wheel. The demount head will guide the bead up and

over the edge of the wheel. Continue rotation until lower bead is demounted.

FIG 20

CAUTION

At times during the mounting and demounting procedure, the bead lifting tool may encounter resistance or

come under load. Keep one hand firmly on the tool to avoid possible tool disconnect. Use the reversing feature to back

out of jam ups.

Normal table top rotation for demounting is clockwise. Depress the table top pedal to rotate this direction. To rotate

the table top counterclockwise, lift the pedal up with your toe.

Page 14

In the process of demounting tire, you should keep your hands and the other parts of your body as well as clothing

from the movable parts to prevent injury.

4.1.5 If handling the tube tire, to avoid the damage on the tube, you should keep the valve stem of the tire 10cm from

the right side of the demount tool when demounting. When handling the tube tire, take out the tube and then move

the lower lip upwards to the upper edge of the rim and then repeat the above steps to detach the other lip.

4.2 MOUNT TIRE:

This information must be read and followed carefully to prevent accidents and injuries during mounting.

Check tire and wheel carefully before mounting. Make sure the tire bead diameter and wheel diameter match exactly.

Consult the Rubber Manufacturer's Association for approved rim widths for tire sizes. Attempts to force a bead seat on

mismatched tires and wheels can cause the tire to violently explode, causing serious

personal injury or death to operator and/or bystanders.

Never mount a tire and wheel handed to you by anyone without checking both tire and wheel for damage and

compatibility. Be extra cautious of persons without knowledge of tire service. Keep bystanders out of service area.

Never mount a damaged tire. Never mount a tire on a rusty or damaged wheel. Damaged tires and/or wheels may

explode. If you damage the tire bead during mounting, STOP! Remove the tire and mark it as damaged. Do not mount a

damaged tire.

WARNING - LIBERAL LUBRICATION OF THE TIRE AND RIM IS NECESSARY TO MOUNT TIRE CENTERING

CORRECTLY AND GET A PROPER ON THE RIM. BE SURE YOU ARE USING APPROVED LUBRICANT ONLY.

WARNING - OBSERVE THE ROTATION DIRECTION OF THE TIRE, IF REQUIRED. SOME TIRES HAVE A

COLOR DOT THAT MUST BE KEPT ON THE OUTSIDE OF THE WHEEL.

4.2.1 Clean the dirt and rust on the rim and lock it on the chuck. Lock the rim on the turntable.

4.2.2 Spread the lubrication liquid or soap liquid around the tire beads. Tilt the tire against the rim and keep the front

end upwards. Press down the hexangular shaft to move the demount arm to contact with the rim and lock. The left lip

above the tail of the demount tool and the right lip will be positioned under the front end of the demount tool (FIG 21).

Depress table top pedal and rotate the wheel to mount the lower bead. Use the drop center of the wheel to reduce

the tensional force on the bead by pressing down on the tire directly across from the mount head. Rotate table top

until lower bead is fully mounted.

FIG 21

For top bead, rotate the table top until the valve stem is at the 5 o'clock position. Lift the upper bead up and over the

rear of the mount head. Press down on the tire between the mount head and the valve stem to hold the tire in the

drop center. Depress table top pedal and rotate tire until the bead is mounted. Continue to press down on tire during

the remaining mounting process.

If table top rotation stalls, reverse the table top momentarily until the tire bead is again loose on the wheel. Reposition

the tire on the mount head; make sure the bead is correctly positioned in the drop center of the wheel, then attempt

mounting again.

4.2.3If there is tube, place it in the tire and plug the core. And assemble the lip according to the above mentioned

Page 15

step (FIG22). In the process of clamping the rim, do not reach your hands in between the rim and the claw to avoid

the damage to the personnel.

FIG 23FIG 22

4.2 INFLATION:

CAUTION, WARNING, DANGER

Check for proper inflation gauge operation. Accurate pressure readings are important to safe tire inflation. Refer to the

Operating Maintenance section of this manual for instructions.

If the rim has been clamped from the outside for tire mounting, release the clamps, lift the tire, and move the clamps to

the center of the table top. THE RIM MUST BE UNCLAMPED WHEN INFLATING BUT ONLY AFTER BEADS

HAVE BEEN SEATED.

If the wheel/tire has a diameter larger than 14 inches and is difficult to bead seal, the clamps should be moved to the

center of the table top for the bead seal operation.

Tire failure under pressure is hazardous. This tire changer is not intended to be a safety device to contain exploding

tires, tubes, wheels, or bead sealing equipment. Inspect tire and wheel carefully for

match, wear, or defects before mounting. Always use approved tire bead lubricant during mounting and inflation.

The inflation pedal, located at the rear of the left side of the machine, controls the flow of air through the inflation

hose.

NOTE: The clip-on chuck on the end of the hose should always be an open style with all parts in proper working order.

ATTENTION! WHEN OPERATING THE BEAD SEATER IT IS MANDATORY TO WEAR SAFETY GLASSES TO

PROTECT EYES.

The Inflation pedal operates in 3 positions as described below.

Page 16

Position 1 (All the way up at rest) - Tire Pressure – With the inflation hose attached to the tire valve and the pedal in

this position, the air gauge will register the air pressure in the tire. Whenever your foot is removed from the pedal, it

will return to this position.

Position 2 (Pushed down to the mid level) - Tire Inflation – This is the first activated position. With the inflation hose

attached to the tire valve and the pedal in this position, line pressure is allowed to flow through the valve and

into the tire for inflation. Tire pressure is not indicated on the gauge in this position. The pedal must be released to

read pressure.

Position 3 (Pushed down all the way to lowest level) - Bead Sealing – This is the second and last activated position.

With the inflation hose attached to the tire valve and the pedal in this position, line pressure is allowed to flow through

the valve and to the inflate bead seal jets on the table top for bead sealing.

Use Position 3 for bead sealing only. Do not use this position without a tire and wheel positioned on the table top. Dirt

and debris could be blown into the air with enough force to injure the operator or bystanders. Do not use this position to

inflate a tire.

When the inflation pedal is held in position 2, the pressure should be checked every few seconds to prevent over

inflation. This cycling helps to prevent over inflation of the tire. Tires can still be over inflated and explode with the

use of this technique and if all of the instructions in this manual are not followed completely. It is the operator's

responsibility to follow all instructions and to control inflation pressure as specified in these instructions. Tires

requiring inflation beyond 60 PSI should be inflated in a safety cage.

Tire inflation is performed in three steps: Bead Seal, Bead Seat, and Inflation.

Bead Sealing

1. Position valve stem in front of operator and connect the inflation hose. Hold tire up against upper edge of the

wheel. Be sure tire’s top bead is over the bottom of the valve stem.

2. Depress inflation pedal to position 2 and hold about 1 second to begin air flow through tire valve, then depress

pedal to position 3 and hold briefly – less than 1 full second. The blast of air from the jets will expand tire and seal the

beads.

3. Release the inflation pedal and allow it to return to position 1. Verify that both beads are completely sealed to the

wheel. Repeat these steps if beads have not sealed. It may be necessary to wait a few seconds for the air storage

tank to recover before attempting again.

Note: If tire and wheel are properly lubricated and operator cannot achieve bead seal after 3 or 4 attempts, the valve

core may be removed from the valve stem to allow more air flow into the tire to assist with bead seal. After bead seal

is achieved, remove the chuck and reinstall the valve core.

Bead Seating

Operator should keep hands, arms, and entire body away from the tire during the remaining bead seat and inflation

procedures. Do not stand over tire, as personal injury could result.

NEVER increase air pressure to exceed 40 PSI when attempting Bead Seat. If operator is unable to obtain Bead Seat,

something is wrong. Deflate tire completely, inspect tire and wheel, and correct any problems

found, relubricate both tire beads, and reattempt Bead Seal and Seat procedures. Follow all safety instructions in this

manual and on machine.

1. Once tire pressure is indicated on the air gauge (inflation pedal in position 1; foot removed from pedal), continue to

inject air into the tire in short intervals. Check the pressure frequently. Stand back during bead seat. Keep hands,

arms, and entire body away from tire during this procedure. Tire beads should move outward and "pop" into their

bead seat position as pressure inside the tire increases. If this does not happen, a problem exists. Investigate

carefully.

Check tire pressure frequently. Never exceed 40 PSI while seating beads. Once seated, never exceed tire

manufacturer's recommended air pressure. Tires can explode, especially if they are inflated beyond their limits. At all

pressure levels when inflating through the valve stem, keep hands, arms, and entire body away from inflating tire.

An exploding tire, wheel, or bead sealing equipment may propel upward and outward with sufficient force to cause

serious injury or death to operator or bystander.

Inflation

NEVER exceed tire manufacturer's recommended air pressure. Tires can explode, especially if inflated

Page 17

beyond these limits. Keep hands, arms, and entire body back from inflating tire. Avoid distraction during inflation.

Do not stand over tire

Inflation

wider

range.

seal on top side

Check tire pressure frequently to avoid over inflation. Excessive pressure can cause tires to explode, causing serious

injury or death to operator or bystander. THE RIM MUST BE UNCLAMPED WHEN INFLATING BUT ONLY AFTER

BEADS HAVE BEEN SEATED.

This machine is equipped with an inflation gauge for monitoring the inflation of the tire and the inflation pressure(FIG

22).

1. Connect the inflation hose with the tire air core. See

FIG23. Make sure both beads are seated. When both

beads are seated, the tire is ready for inflation.

2. Replace the valve core if it was removed.

3. Depress the inflation pedal to position 2 to inflate the

tire. Release air pressure from tire by pressing the

manual release valve button (inflation hose must be

attached to the valve stem).

STAGES OF INFLATION

Review these descriptions and diagrams carefully.

Refer to them as necessary during bead sealing,

bead seating, and inflation to verify that you are

proceeding properly and safely.

Bead Sealing

A140 PSIair blastfrom thetable top jetscreates an

air curtain to aid in bead sealing. Never exceed

10 PSI in the tire during bead sealing. The tire

will contain about 1/2 to 2 PSI when bead seal

is obtained.

Bead Seating

Bead seating usually occurs on the long tapered

side of the wheel first and the shorter side last. Bead

seating will usually require at least 7 PSI in the tire.

40 PSI is the maximum safe pressure at this stage

regardless of tire operating pressure.

Most European import cars and many aftermarket

alloy wheels are very tight and can be difficult to

bead seat. Also note that asymmetrical hump and

run-flat tires are extremely difficult to bead seat.

Follow tire manufacturer's recommended procedure

for bead seating.

Requires rubber lubricant on

bothupperand lower beads

Table topjets

Requires visual confirmation of bead seat

Air flow through valve requires

about 140 PSI air pressure drop to

insure sufficient flow on difficult

tires.

Lift tire up to assist

Usually last to "pop" is top side

during inflation.

After the beads are seated, the tire is inflated.

Do not inflate the tire above the manufacturer's

recommended pressure as stamped on the tire

sidewall. The typical inflation pressure for

automobile tiresis between24 and45 PSI. Light

truck inflation pressure typically covers a

Do not stand over

tire during inflation.

Page 18

DANGER!

17.5, etc.

MISMATCHED TIRES AND WHEELS

Never attempt to mount and inflate mismatched

tires and wheels.

Mismatched tire and wheel combinations

explode, causing personal

injury or death to operator and bystanders.

For safety, do not attempt to mount and inflate

mismatched tires and wheels.

Half Size Tires

14.5, 15.5, 16.5,

Even Size Wheels

14.0, 15.0, 16.0,

17.0, etc.

Even Size Tires

14.0, 15.0, 16.0,

17.0, etc.

Note the gap

in this area

Note 15°

Bead Seat

Bead will not

seat properly

HalfSize Wheels

14.5, 15.5, 16.5,

17.5, etc.

Page 19

READ…

Mounting and inflating the wrong size tire can get you hurt. Read the size on the tire and make sure it matches the

rim. Be especially careful about putting a smaller tire on a larger rim, such as a 16-inch tire on a 16.5-inch rim.

Inflation of a mismatched tire and rim can cause an explosion.

INSPECT…

Before you put any tire on a rim, inspect the rim for rust, tough spots, bent edges, or cracks that could prevent the

tire from seating right. If you spot any of these problems, don’t mount the tire until the rim has been checked by your

shop foreman. Inspect the tire for bead damage.

MOUNT…

Once you’ve made sure the tire is OK and the right size and the rim is OK, mount the tire safely. NEVER, ever lean

over the tire when you’re inflating it. If a tire does explode, it will go straight up. You don’t want to be over the tire if

that happens. Also, never over-inflate the tire, even if the bead doesn’t seat. Never inflate over 40 PSI. If the tire

wasn’t seated, something is wrong. Deflate the tire and check it and the rim again. If it doesn’t work the second time,

try another tire.

FAILURE TO READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS IN THIS MANUAL CAN LEAD TO

SERIOUS PERSONAL INJURY OR DEATH TO OPERATOR OR BYSTANDER.

THE OWNER IS RESPONSIBLE FOR MAINTAINING THE OPERATION INSTRUCTIONS AND

DECALS FOR THIS MACHINE AS WELL AS PROVIDING THEM TO ALL OPERATORS.

TIRE FAILURE UNDER PRESSURE IS HAZARDOUS!

This tire changer Will Not Restrain Exploding Tires, rims or other related equipment.

TIRES CAN EXPLODE, ESPECIALLY IF INFLATED BEYOND SPECIFIED LIMITS. DO NOT EXCEED

TIRE MANUFACTURERS RECOMMENDED AIR PRESSURE. AN EXPLODING TIRE, RIM, OR BEAD SEATING

EQUIPMENT MAY PROPEL UPWARD AND OUTWARD WITH SUFFICIENT ENERGY TO CAUSE SERIOUS

INJURY OR DEATH TO OPERATOR AND/OR BYSTANDERS

19

Page 20

Chapter V MAINTANENCE & REPAIR

NOTE:

Only the qualified professional personnel can execute the maintenance. Before

any maintenance, Cut off the power .And ensure the maintenance personnel

can take charge of the power plug. Meanwhile, cut off the air supply and push the

air supply switch to the off position and completely deflate the residual air in the

machine. To correctly use the tire changer and prolong its working life, it is

necessary to periodically maintenance and repair according to the instruction

manual. Or the running and reliability of the machine will be affected and the

personnel near the machine or the operator will be injured.

The following position should be monthly maintenance:

Keep the machine and working area clean.

Use the diesel oil to clean the hexangular shaft (FIG24),Use the machine oil to lubricate.

Use the diesel oil to clean the turntable claw and its guide and use the lithium base oil to lubricate (FIG25),

20

Page 21

Periodically check the lubrication oil level in the oil fog device. If the oil level lower than the oil scale, please feed in

FIG 25

FIG 24

FIG26FIG 27

FIG 26

FIG 28

the SAE30 lubrication oil in time(FIG 26)

Periodically drain out the water and impurity in the oil water separator.

Periodically check and adjust the tension of the drive belt. Properly adjust the adjust nut in A and B to realize the

proper tension.(FIG27).

Check all the connect parts and tight the loosen bolt.

HEXANGULAR SHAFT & LOCK PLATE LOCK GAP ADJUSTMENT

When press downward the hexangular lock handle, the hexangular shaft

will vertically slide under the effect of the weight of the hexangular shaft

and return spring. When the lock handle rotate clockwise for about 100

degree, the cam connected to the handle will push up the lock plate to

lock the hexangular shaft. If you can not realize this situation, you can

reach the target to lock the hexangular shaft through adjusting the position

of the screws and nuts.(FIG 28)

LOCK

PLATE

CAM

LOCK

HANDLE

ADJUST

NUT

HEX

SHAFT

21

Page 22

CHAPTER VI INSTALLATION & OPERATION OF THE ASSISTANT ARM

6.1 INSTALLTHE LEFT ASSISTANT

6.1.1 PL330 left assistant can be equipped on the tire changer which can handle the tire with the diameter of 20″ to

help complete the demount on the stiff and low profile tire. We can use it to handle the work which if difficult and

impossible to do only by the operators.

Before installation, the power and air source must be cut off!

6.1.1 The left and right side of the base plate of body of the tire changer which can handle the tire with the diameter

of more than 20″ all have the installation hole for the left assistant prepared. Before installation, you can remove the

side panel and take off the installation rubber plug. If there being the tool box, you should detach the tool box.

6.1.2 Detach the package of the PL330assistant. Check the accessory according to the pack list. After confirmation,

takeout the base assembly(fig29) and install the screw and washer on it.

FIG 29 FIG 30

6.1.3 Push the platform of the base plate of the base assembly into the body through base plate on the left-back side

of the body. Align the thread hole to the reinforce hole and use the bolt and washer to fix.(fig30).

6.1.4 Install the body bracket(fig31-1)on the seat assembly. Align. Use the screw removed before to fix and not

tighten

6.1.5 Use the fix supporting bracket(fig32)to connect the body bracket and the body and insert the screw to fix.

6.1.6 Connect the air source hose(fig33-2)and use Y Tee to connect the outlet hose and the other end connect with

the inlet of the assistant pressure adjusting valve.

22

FIG 32FIG 31

Page 23

6.1.7 Connect the air source, insert the press cone roller connect rod(fig34-1)into the rotation shaft hole(fig 34-2)

FIG 36

FIG 38

of the rotation arm. Handle manual direction change valve to make the tip of the press cone roller coincide to the

center of the turntable(fig35). If not coincide, use the screw to adjust the position of the base to realize the proper

fit. After adjustment, fix the bolt.

FIG 34FIG 33

6.1.8 According to the fig36, fix the fix bracket on the body and fixes the tool box on the fix bracket and then use the

lock nut to tight.

FIG 35

6.1.9 As fig37, fix the cone support on the body bracket and install the press cone on the bracket.

6.1.10Loose the nut below the base and turn the screw clockwise until it against the ground and tight(fig38) and

install The side panel and tool box removed in the 6.1.1. At this moment, the installation of the left assistant

completed.

23

Page 24

6.2INSTALLTHE RIGHT ASSISTANT

6.2.1After detach the tire from the rim according to the instruction of the chapter IV, we can execute the following

operations.

6.2.2 First, position the claw according to the dimension of the tire and then clamp the rim by the claw and position

the tire press cone roller at the center of the rim(fig39). Push down the manual valve to press down the rim until the

external rim of the rim is lower than the surface of the claw.At this moment, you can immediately lock the rim. Lift up

the support arm and place it at the working position and take off the press cone roller and place it on the support.

6.2.3 Use the press(fig40-1)to press down the tire section by section rim detached from the mouth and use the

brush to spread the lubricant on edge of the lip. Position the demount tool(fig40-2)in the demount position. Place the

press beside of the demount tool to press down the lip and insert the crowbar below the demount tool in between the

rim and lip(fig41),Lift up the press and move it to the position opposite to the demount tool and press the lip into the

tire detach groove and then rotate the crowbar to lift the lip onto the demount tool(fig42). Rotate the turntable to

detach the upper lip.

FIG 42

6.2.4 DETACH THE LOWER LIP: Use the disk to lift up the bottom of the tire from the bottom of the mouth(fig48)

and detach the lower lip (fig43) according to the step(4.1.5).

FIG 44FIG 43

24

Page 25

6.2.5 MOUNT TIRE

First, according to the step(4.2.1)~(4.2.3), install the lower lip and use the press to press the lower lip as shown

In the fig45. Rotate the turntable by about 90°. And then clamp the press in the demount tool(fig46)andcontinually

rotate the turntable until the completion of the operation.6.2.5

FIG 45 FIG 46

CHAPTER ⅣTRANSPORTATION

When transport the machine must apply the original package and place

According to the mark on the package. The machine must be transported

by the forklift with the corresponding tonnage(FIG69)and the stacked

layer will not exceed 3layers.

CHAPTER Ⅳ ELECTCTRICAL AND PENUMATIC DRAWING

8.1.220V ELECTRICAL PRINCIPLE DRAWING

8.2.380V ELECTRICAL PRINCIPLE DRAWING

8.3.110V/220V ELECTRICAL PRINCIPLE DRAWING

8.4. PNEUMATIC PRINCIPLE DRAWING

FIG 47

25

Page 26

8.1. 220V ELECTRICAL PRINCIPLE DRAWING

PHASE MOTOR(220V) WIRING

MOTOR SWITH

PE

N L

SA

9 5 7 11 1 3

6

10

8 12

2

4

FU20A

BY CUSTOMER

由用户完成的安装

POWER CABLE 3X1.5mm2

电源线3X1.5mm2

QC

1

电机转向开关

LW5D-16

16A/500V

拆胎机

INTERNAL

内部连线

WIRING

0

2

U1

Z2 U2 V1

M

1ph

220V 1.1KW 1400rpm

TIRE CHANGER 1-

拆胎机单相电机220V接线原理图(通用)

DRAWING (UNIVERSAL)

26

Page 27

8.2. 380V ELECTRICAL PRINCIPLE DRAWING

BY CUSTOMER

由 用户 完 成 的 安装

POWER CABLE 4X1.5mm2

电 源线 4X 1 . 5mm

INTERNAL WIRING

MOTOR SWITH

电 机 转 向 开 关

拆 胎机

内 部连 线

TIRE CHANGER 3-PHASE MOTOR(380V) WIRING DRAWING (UNIVERSAL)

拆 胎 机 三 相 电 机 接 线 原 理 图 通 用 )

27

Page 28

8.3.110V/220V ELECTRICAL PRINCIPLE DRAWING

TIRE CHANGER DUAL VOLTAGE MOTOR ( II)

LINE BAN

K

MOTOR SWITH

VOTAGE SWITH

B

lue

R

ed

G

reen

220V

兰

110V

黄

电压转换开关

2W30A

PE

AC

L1

110V/220V

FU1

5

9

绿

10

6

红

11

7

12

8

1

2

L2

BY CUSTOMER

用户配置

FU2

FU1

3

4

FU2 40A

0

1

2

电机转向开关

LW5-40

40A/500V

Yellow

兰

4

黄

绿

2

U1 U2 U3 U4 Z1 Z2

U1

PE

红

6

U3

U2

U4

Z1

M

1

~

Z2

扒胎机双压电机连线图之二

115

接线排

TB-2506L

600V/25A

1.1KW 4P

110/220V 50 60HZ

28

Page 29

8.4. PNEUMATIC PRINCIPLE DRAWING

SEMI AUTOMATIC PNEUMATIC

SEMI AUTOMATIC PNEUMATIC

半自动气动原理图

φ70/20X262

φ70/20X310

φ70/20X262

φ186/20X150

φ70/20X310

φ186/20X150

半自动代快充型气动原理图

(IT)

29

Page 30

φ80/20X80

1 2 3 4 5 6

φ70/20X310

φ70/20X310

φ186/20X150

φ66/66.5X16

4

φ66/66.5X16

30

Page 31

CHAPTER Ⅳ TROUBLESHOOTING ANALYZE AND SOLUTION

CHAPTER REASON TROUBLESHOOTING

Turntable rotate in one direction. Universal switch contact burned Change Universal switch

Turntable does not rotate. Belt damage

Belt too loose

Motor or power source have problems

Universal switch contact damage

Turntable can not clamp the rim as

normal

Quadric and hexangular shaft

cannot lock

Chassis pedal not return. Pedal return spring damage Chang torsion spring

Motor not rotate or the output

torque not enough

Cylinder output force not enough Air leakage

Claw worn

Clamp cylinder air leakage

Lock plate not in position

Drive system jam

Capacitor broken down

Voltage not enough

Short-circuit

Mechanic fault

Air pressure not enough

Air Leakage air hose broken

Change belt

Adjust the tension of the belt

Check motor, power source and

power source cable

Change motor if motor burned

Change Universal switch

Change claws

Change the air leakage sealing parts

Refer to the chapter V

Remove the jam

Change capacitor

Wait for the restore of the voltage

Remove

Change sealing parts

Remove the fault

Adjust the air pressure to meet the

requirement

Change broken parts

pipe fitting broken

sealing head broken

loss of the sealing glue

Refill the sealing glue

31

Page 32

LC SERIES MACHINE OIL SAFETY DATA SHEET

MOBIL XHP 222

ITEM QUALITY STANDARD

Penetration rate25℃ mm/10 280

dropping point ℃ 280

anticorrosion passed

Basic oil viscosity 220

oxidize stability 100h pressure-drop kpa 35

water lose percentage79% 5

copper corrosion 1A

SAE30# LUBRICATION OIL

ITEM QUALITY STANDARD

density 15℃ 0.893

Flash point 224

Pour point ℃ -18

viscosity 40℃ 100

viscosity 100℃ 11.2

Viscosity index 97

2# LITHIUM BASE GREASE

ITEM QUALITY STANDARD

Penetration rate mm/10 278

dropping point ℃ 187

copper corrosion 100℃ 24h No change

oxidize stability(99℃ 100h) 0.2

anticorrosion(52℃ 48h) 1 level

similarity viscosity(-15℃、 10S¯¹)/(Pa·S) 800

water lose(35℃ 1h) % 8

CKC460 INDUSTRIAL GEAR OIL

ITEM QUALITY STANDARD

Viscosity 40℃ 461

Viscosity index 92

Flash point ℃ 212

Freezing point ℃ -26

copper corrosion100℃ 3h 1A

mechanical impurity 0.007

Pour point -10

32

Page 33

WEARABLE (OPTIONAL) PARTS LIST FOR 890IT SERIES

Item No Description Specification Quantity Parts Codes

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Seal-Y Ring 5010202

O-Ring 5010097

Valve-A 6000227

Valve-B 6000222

Switch 5010055

Cam 6000211

Fork spring plate 6000204

Valve connecting rod 6000210

torsion spring 6000220

Hinge Tee 6000010

Hinge elbow 6000009

Front cover 6000004

Rear cover 6000003

Circlip 5010024

Rigid PU hose

PU hose

Ф6

Ф8

5509032

5509033

17 Crowbar Protector QT-20 5309016

18 Demounting Head

BT-4 5509015

Protector

19 Demounting Tail

BT-4 5509014

Protection Washer

20 Bead Breaker Blade

CT-A 5509018

Protector

21 Clamp Protection Cover KT-4 5509019

33

Loading...

Loading...