Page 1

JUMBO VAN SHELVING

INSTALLATION MANUAL

ATTENTION: PLEASE READ AND UNDERSTAND ALL INSTRUCTIONS AND WARNINGS BEFORE ASSEMBLING, INSTALLING OR USING THIS PRODUCT.

DANGER

Danger of explosion. Do not use this product for storing or

transporting flammables, explosives, hazardous materials, or

hazardous waste, such as containers of gasoline, solvents, gun

powder, dynamite, propane tanks, acetylene tanks and cutting

torches. This product is only intended and safe for use in storing

and transporting small tools, equipment and other similar materials.

Any modifications made to, or unintended use of this product,

could create a hazardous condition that can cause death, serious

personal injury or property damage.

Approximate Assembly and Installation Time:

60-80 min. (1 to 1.3 hours) depending on number of shelf

units and van equipment installation experience.

TOOLS REQUIRED

• Electric Drill

• Drill Bits: 13/32", 5/16", 1/8"

• Open End Wrenches: (2) 7/16", 9/16"

• 1" Hole Saw

E

WARNING

These instructions are to be followed using the parts and fasteners

supplied for proper installation. Any modifications or improper

installation of this product will create a hazardous condition that

can cause property damage, serious personal injury or death.

– NOTICE –

Any modification or unintended use of this product shall immediately

void all manufacturers warranties. Manufacturer disclaims all liability

for injuries to persons or property resulting from any modification

to, or unintended use of this product.

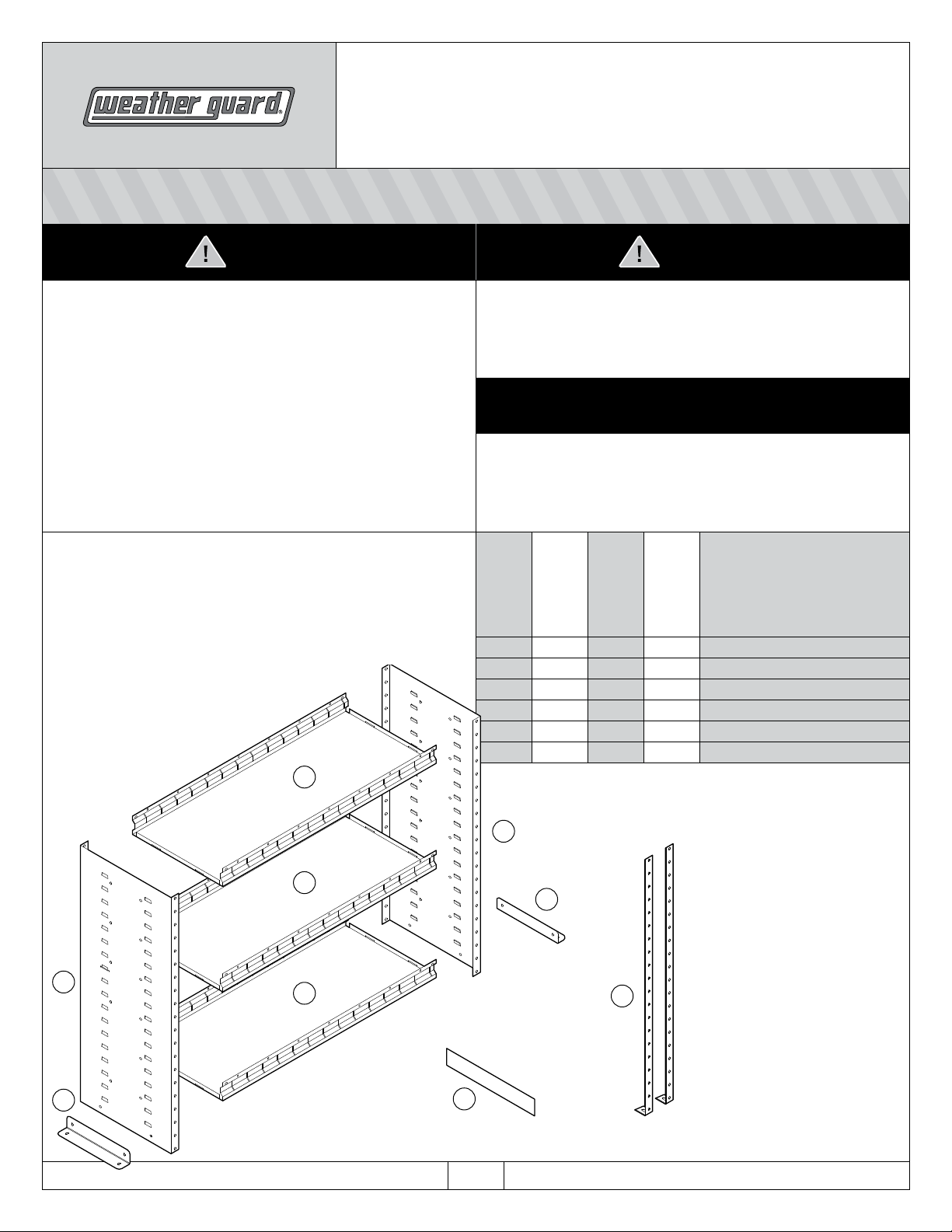

8380

8320

8332

8342

8352

#32-0162 #32-0162 #32-0163 #32-0183

8381

8383

8384

8390

8393

2 2 2 2 A Floor Mounting Brackets

0 0 2 0 B Center Supports

8 12 12 0 C Shelf Dividers

2 2 2 2 D End Panels

2 3 3 0 E Shelves

8385

8391

8394

8395

8345

8957

8958

8959

Parts List

Bolt Kit

D

E

A

D

A

E

C

PAGE 1IF YOU HAVE ANY QUESTI ONS, PLEASE CONTACT U S TOLL-FREE AT 1.800.4 56.7865 24-0245 R EV. A 07/06

B

Page 2

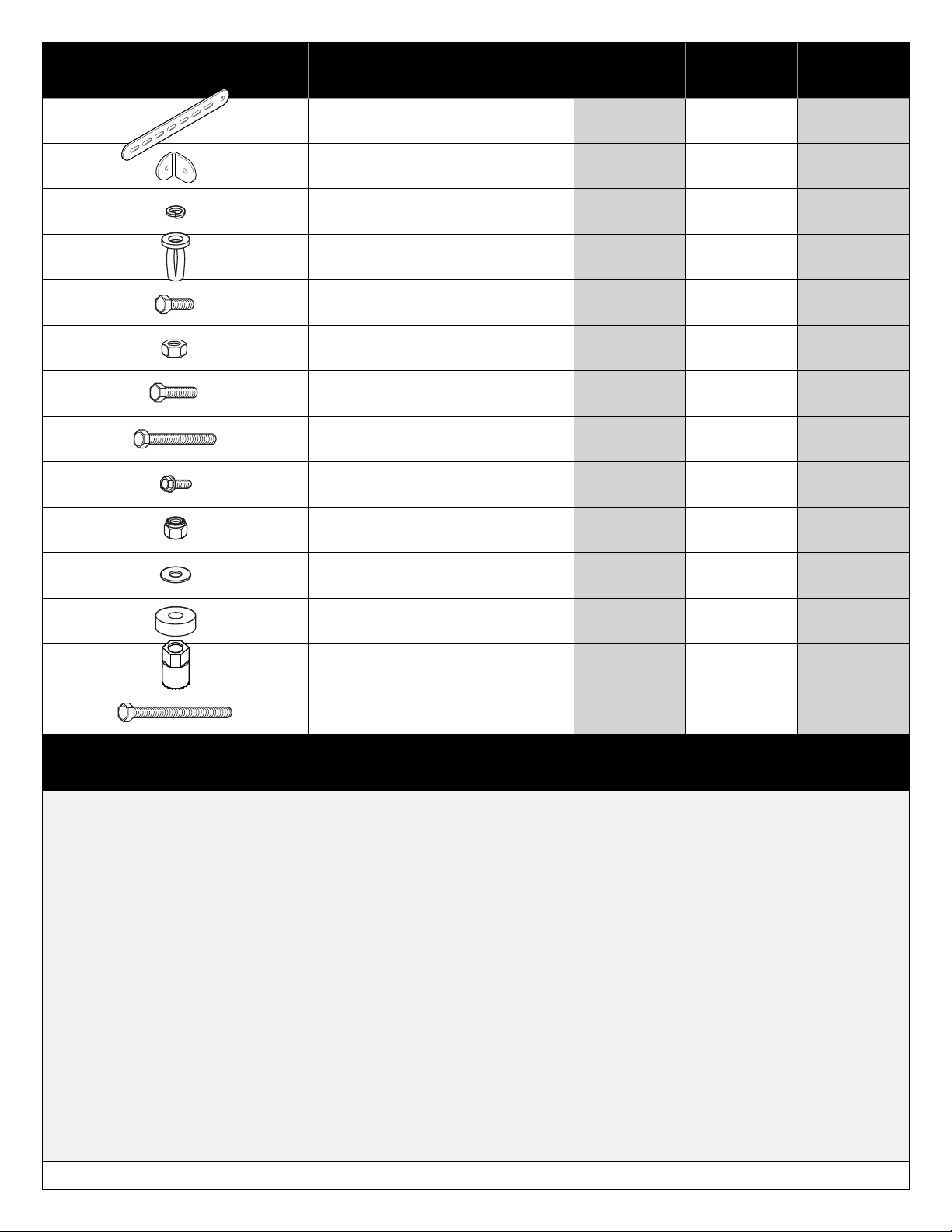

NOTE: Depending on your application you may end up

with extra hardware after installation is complete.

DESCRIPTION

Mounting Straps 3 3 3

Mounting Strap Angles 3 3 3

1/4" Lock Washers 4 4 4

1/4-20 Blind Fasteners 4 4 4

1/4-20 x 5/8" Hex Head Bolts 10 10 10

1/4-20 Serrated Nuts 12 12 0

1/4-20 x 3/4" Hex Head Bolts 7 13 7

1/4-20 x 1-1/4" Hex Head Bolts 4 6 4

1/4-20 x 1/2" Hex Head Screws 12 12 0

BOLT KIT #32-0162

QTY.

BOLT KIT #32-0163

QTY.

BOLT KIT #32-0183

QTY.

1/4-20 Nylon Lock Nuts 18 26 18

1/4" Flat Washers 18 22 18

Floor Mounting Spacers 4 6 4

Blind Fastener Installation Tool 1 1 1

1/4-20 x 2-1/4" Hex Head Black Bolt 1 1 1

KNAACK MANUFACTURING COMPANY LIMITED WARRANTY

This LIMITED WARRANTY is made by Knaack Manufacturing Company, 420 E. Terra Cotta Ave., Crystal Lake, Illinois to the original retail purchaser

of KNAACK® Products.

KNAACK MANUFACTURING COMPANY WARRANTS THAT KNAACK PRODUCTS WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP

FOR A PERIOD OF THREE (3) YEARS FROM DATE OF PURCHASE BY THE ORIGINAL RETAIL PURCHASER.

If, before the expiration of the Warranty period, purchaser discovers that the KNAACK Product fails to fulfill the Warranty, purchaser shall contact Knaack

Manufacturing Company to make arrangements for an inspection of the product. If Knaack Mfg. Co. determines a defect exists, Knaack Mfg. Co. shall,

at its option and expense, repair or replace any defective part. All Warranty repairs shall be made by an authorized KNAACK Product dealer or Knaack

Mfg. Co. approved service company.

This Warranty shall not apply if the KNAACK Product has been subjected to misuse, abnormal service or handling, improper maintenance, or alterations

made by anyone other than a KNAACK Product dealer or a Knaack Mfg. Co. approved service company.

THE WARRANTY PRINTED ABOVE IS THE ONLY WARRANTY APPLICABLE TO THIS PURCHASE. ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED.

KNAACK MANUFACTURING COMPANY SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

ANY BREACH OF THIS WARRANTY. NOR SHALL THE DAMAGES EXCEED THE RETURN AMOUNT OF THE PURCHASE PRICE PAID BY THE

ORIGINAL PURCHASER.

This Warranty is in lieu of all Warranties express or implied. The terms of this Warranty shall not be modified by any party, their successors or assigns.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

PAGE 2IF YOU HAVE ANY QUESTI ONS, PLEASE CONTACT U S TOLL-FREE A T 1.800.456.7865 24-0245 R EV. A 07/ 06

Page 3

CAUTION WARNING

Prior to drilling, so as not to cut or puncture fuel tanks, fuel lines,

brake lines, electric wires, etc., check behind or underneath drilling

and mounting locations.

To keep debris out of your eyes when checking the underside of

the vehicle, or when drilling, always wear protective eyewear.

1 After determining shelf spacing, assemble

each Shelf to the End Panels by pushing the

Shelf down, with the End Panel tab entering

the pierced opening on the Shelf edge.

Fasten the Shelves to the End Panels using

four (4) 1/4-20 x 1/2" Hex Head Bolts and

1/4-20 Serrated Nuts.

All floor mounting bolts near the fuel tank area should be installed

from the underside of the vehicle, to guard against the fuel tank

being punctured in the event of a collision. This would mean not

using Blind Fasteners in this area. Holes in this area should be 5/16".

Ensure ample space in roof ribs and sidewall ribs for mounting

screws so as not to puncture exterior roof or wall.

2 Attach the Floor Mounting Brackets to both

ends of the unit using four (4) 1/4-20 x 3/4"

Hex Head Bolts, 1/4" Flat Washers and

1/4-20 Nylon Lock Nuts.

NOTE: Floor Mounting Brackets can be

installed on the outside or inside ends of the

units. When installing two units side by side

or connecting to a Bulkhead, only one Floor

Mounting Bracket is required and should be

installed inside.

If installing more than one shelf unit, holes

in the end panels are provided for throughbolting into the next unit for greater rigidity.

PAGE 3IF YOU HAVE ANY QUESTI ONS, PLEASE CONTACT U S TOLL-FREE A T 1.800.456.7865 24-0245 R EV. A 07/ 06

Page 4

3 Place the unit into your selected position

in the van, as close to the wall as possible.

Mark the four floor mounting holes where

the Floor Mounting Bracket comes in

contact with the floor ribs.

NOTE: 60" & 69" SHELF UNITS: Center

Support Legs have been added to these

units to strengthen these shelves because

of their length. (Go to step 6). If Center

Supports are needed, then mark their floor

mounting holes also. The Center Support

can face towards the unit or away from the

unit and should also contact the floor rib.

Remove the unit and pre-drill the floor

mounting locations with an 1/8" drill bit, then

re-drill the hole with a 5/16" drill bit. If there

is a floor mat, then Floor Mounting Spacers

are required. Cut the floor mat around the

5/16" holes with the 1" hole saw, allowing

Floor Mounting Spacers to rest against the

metal floor. DO NOT DRILL THROUGH

THE VAN FLOOR WITH THE HOLE SAW.

4 Move the unit back into position. Fasten unit

to van floor using four (4) 1/4-20 x 1-1/4"

Hex Head Bolts, 1/4" Flat Washers, Floor

Mounting Spacers (if applicable), second set

of 1/4" Flat Washers and 1/4-20 Nylon Lock

Nuts. (See example bolting solutions below).

NOTE: One (1) Blind Fastener and Lock

Washer have been provided in case throughbolting is impossible due to heat shields, floor

channels, fuel lines, etc. If Blind Fastener

installation is necessary, redrill the 5/16"

mounting holes with 13/32" drill bit. See

INSTALLATION INSTRUCTIONS FOR BLIND

FASTENERS on page 6.

NOTE: The floor bolting

solution could be a variation

on any of these three examples

with or without the floor mat.

TOP DOWN INSTALLATION THROUGH

FLOOR MAT AND VAN FLOOR

BOTTOM UP INSTALLATION THROUGH

FLOOR MAT AND VAN FLOOR

PAGE 4IF YOU HAVE ANY QUESTI ONS, PLEASE CONTACT U S TOLL-FREE A T 1.800.456.7865 24-0245 R EV. A 07/ 06

BLIND FASTENER INSTALLATION THROUGH

FLOOR MAT AND VAN FLOOR (SEE PAGE 5)

Page 5

5 Three (3) Mounting Straps and Mounting

Strap Angles are provided. The Mounting

Straps can be bent to any shape and/or

used with the Mounting Angles. The

Mounting Straps should be attached to the

upper portion of the shelf unit in a manner

that would minimize movement of the unit

both front to rear and side to side. Attach

the Mounting Straps to the shelf unit through

existing holes (or drill new holes using a

5/16" drill bit) and fasten with three (3) 1/420 x 5/8" Hex Head Bolts and 1/4-20 Nylon

Lock Nuts.

Fasten the other end of the Mounting

Straps by installing two to three (2-3) Blind

Fasteners in the wall or wall ribs at the

Mounting Strap locations by pre-drilling

1/8" holes and then re-drill the holes with

a 13/32" drill bit. Set the Blind Fasteners

in the holes per the INSTALLATION

INSTRUCTIONS FOR BLIND FASTENERS

on page 6.

Realign the Mounting Straps/Mounting Strap

Angles on top of the Blind Fasteners and

secure them to the wall or wall rib using two

to three (2-3) 1/4-20 x 3/4" Hex Head Bolts

and 1/4" Lock Washers.

INSTALLATION IS COMPLETE.

6 60" & 69" SHELF UNITS: Fasten the

Support Leg(s) in the center of the Shelf

using three (3) 1/4-20 x 3/4" Hex Head

Bolts, and 1/4-20 Nylon Lock Nuts.

Return to step 3.

NOTE: If installing doors on these units,

the Support Leg will need to be installed

off-center on the shelf. Positioning of the

Support Leg can easily be found by holding

the door in position on the shelf. The

notched out area of the hinge is where

to locate the Support Leg.

A second leg can also be fastened to the

back of the unit.

NOTE: The Center Support Leg may need

to be trimmed depending on application. If

the Support Leg is cut, remove burrs and

apply paint.

PAGE 5IF YOU HAVE ANY QUESTI ONS, PLEASE CONTACT U S TOLL-FREE A T 1.800.456.7865 24-0245 R EV. A 07/ 06

Page 6

7 Insert the Shelf Dividers into the shelf slots.

NOTE: The side panels of the units have

pre-punched holes conveniently located for

installation of accessory items or to fasten

to other shelf units for additional strength.

Extra 1/4-20 x 5/8" bolts and lock nuts have

been provided in the bolt kit for this purpose.

WARNING

Prior to drilling, so as not to cut or puncture fuel tanks, fuel lines,

brake lines, electric wires, etc., check behind or underneath

drilling and mounting locations.

CAUTION

To keep debris out of your eyes when checking the underside of

the vehicle, or when drilling, always wear protective eyewear.

Place a drop of oil on the black oxide bolt before assembling as

shown on right. Place the Blind Fastener in the hole and use a

7/16" wrench to tighten black hex bolt until the Blind Fastener is

fully seated. When setting black hex bolt, it will start out hard.

As the Blind Fastener “bulbs” out it will get easier, until it bottoms

out or sets. Make sure the Blind Fastener and Installation Tool

do not turn during installation.

INSTALLATION INSTRUCTIONS FOR BLIND FASTENERS

7/16” Wrench

(Or 7/16” Socket)

Black Oxide Bolt

Flat Washer

9/16” Wrench

Installation Tool

Blind Fastener

WEATHER GUARD® products are protected by one or more of the following trademarks: U.S. 842268, 1661625, 1663369, 2228051, 2362167; Canada - 282725; U.K. - 1400720; N.Z. - 296049; Aus.- 761964

PAGE 6IF YOU HAVE ANY QUESTI ONS, PLEASE CONTACT U S TOLL-FREE A T 1.800.456.7865 24-0245 R EV. A 07/ 06

Loading...

Loading...