Page 1

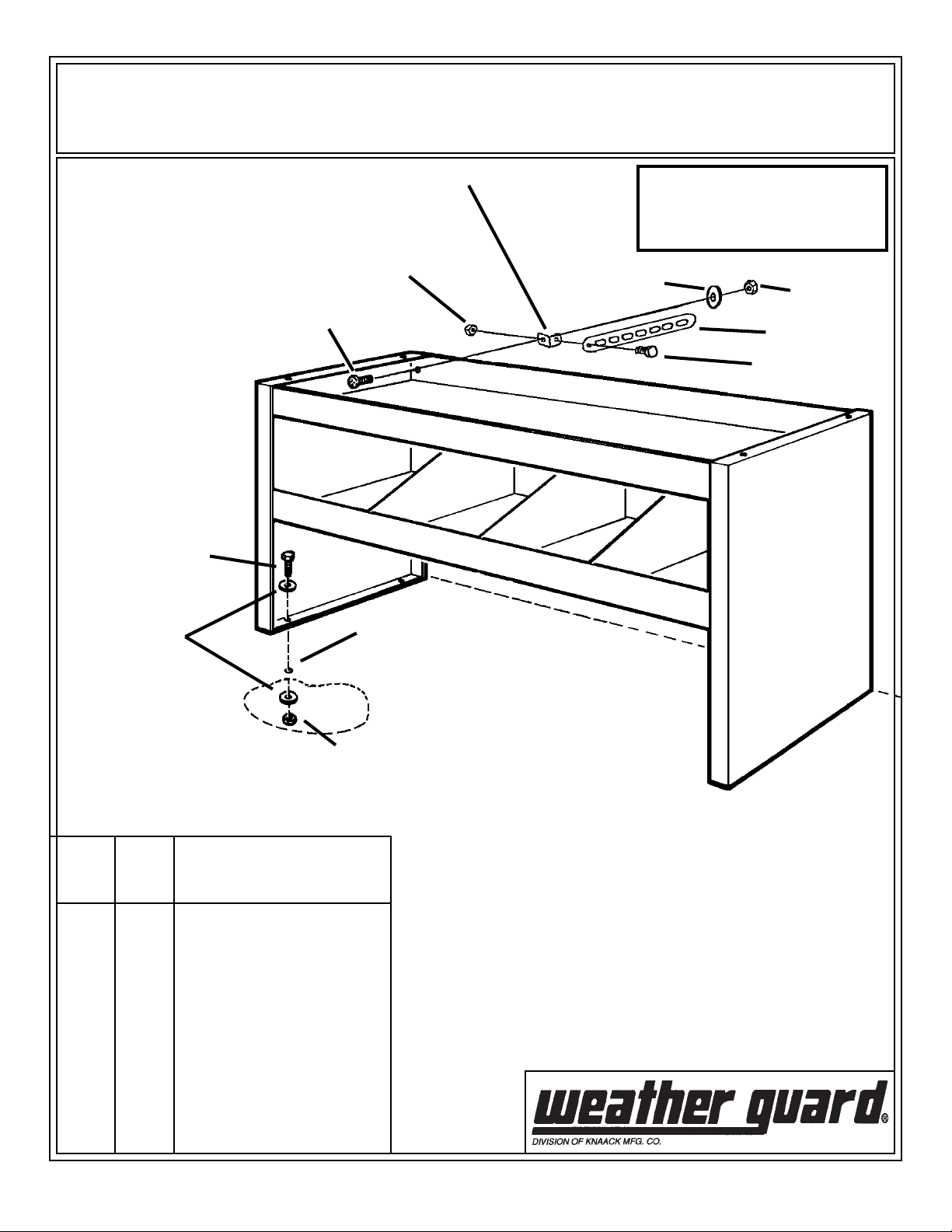

INSTALLATION INSTRUCTIONS

All-Welded Shelf Unit - Model 8234, 8230, 8222

IMPORTANT

BEFORE YOU BEGIN

Read these instructions and

warnings completely before

installation.

1/4-20 x 5/8"

Hex Head Bolt

1/4-20 x 1-1/4"

Hex Head Bolt

1/4" Flat

Washer

Mounting Angle

1/4-20 Nylon

Lock Nut

5/16" Hole

1/4" Flat Washer

Approximate Installation Time:

18 min. per unit (0.3hrs.)

depending on van equipment

installation experience.

1/4-20 Nylon

Lock Nut

Mounting Strap

1/4-20 x 5/8"

Hex Head Bolt

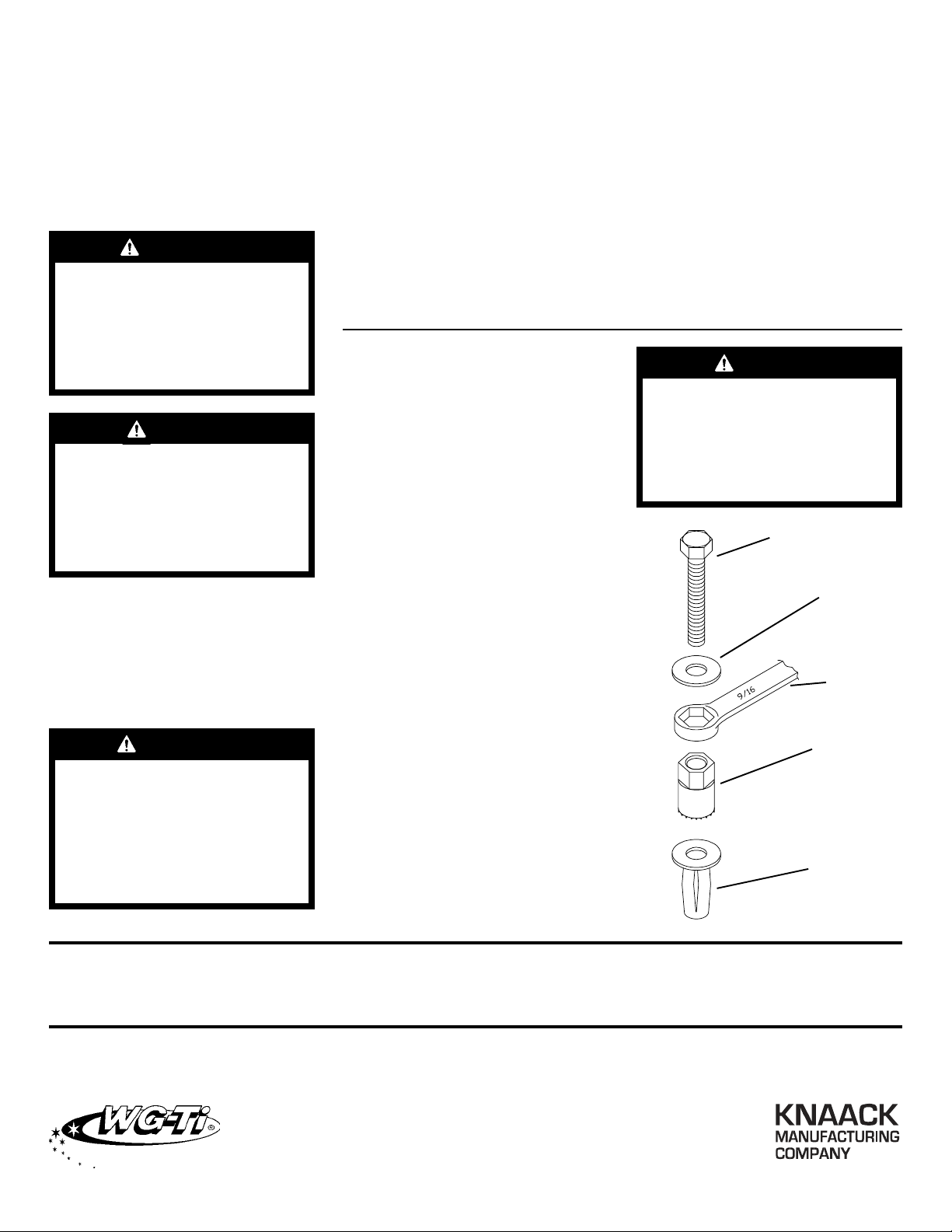

BOLT KIT

The following Bolt Kit is provided

with each unit. Check this bolt kit to

be sure the following parts are included:

8222

8230 8234 Description

32-8233 32-0153

2 0 1-1/4" x 12" Mounting Strap

4 0 1/4-20 x 5/8" Hex Hd. Bolt

8 4 1/4-20 Nylon Lock Nut

4 4 1/4-20 x 1-1/4" Hex Hd. Bolt

2 0 12-14 x 3/4" Tek Screw

12 0 1/4" Flat Washer

1 0 Installation Tool

1 0 1/4-20 Blind Fastener

1 0 1/4" Lock Washer

1 0 1/4-20 x 2-1/4" Blk. Ox. Bolt

2 0 Mounting Angle

1/4-20 Nut

PARTS LIST

• 1- Welded Shelf Unit

TOOLS REQUIRED

• 7/16" Open or Box End Wrench [2]

• Electric Drill with 5/16" Drill Bit

• 5/16" Nut Driver

• 9/16" Open or Box End Wrench

Rev. C 1/01 Part No. 24-0119

Page 2

INSTALLATION INSTRUCTIONS

1. Place Shelf Unit in position in ve-

hicle. Mark through mounting holes in

side panel bottom flange.

2. Remove shelf unit. Drill holes. Replace unit and secure.

3. Two wall Mounting Straps and two

Mounting Angles are provided. The

Mounting Straps can be bent to any

shape and/or used with the Mounting

Angles.The Mounting Straps should

be attached to the upper portion of the

unit in a manner that would minimize

movement of the unit both front to

rear and side to side.

CAUTION

To keep debris out of your

eyes when checking the

underside of the vehicle, or

when drilling, always wear

protective eyewear.

CAUTION

Prior to drilling, so as not to

cut or puncture fuel tanks, fuel

lines, brake lines, electric

wires, etc., check under

vehicle for locations.

NOTE: A Blind Fastener and 1/4"

Lock Washer have been provided for

use in areas where standard

fasteners can't be used, such as heat

shields and support channels. See

Blind Fastener installation

instructions.

4. Fasten the other end of the strap to

the vehicle wall (brace member).

Repeat on the other end of the

cabinet.

INSTALLATION PROCEDURE

USING BLIND FASTENERS

Place a drop of oil on the black oxide

bolt before assembling as shown below. Place the Blind Fastener in the

hole and use a 1/2” or 7/16” wrench to

tighten black hex bolt until the blind

fastener is fully seated. When setting

black hex bolt, it will start out hard.

As the Blind Fastener “bulbs” out it

will get easier, until it bottoms out or

sets. Make sure the Blind Fastener

and Installation Tool do not turn during

installation.

CAUTION

Prior to drilling, so as not to

cut or puncture fuel tanks,

fuel lines, brake lines, electric

wires, etc., check under vehicle for locations.

Black

Oxide

Bolt

Flat

Washer

9/16”

Wrench

WARNING

All floor mounting bolts near

the gas tank should be installed from the underside of

the vehicle, to guard against

the gas tank being punctured

in the event of a collision.

Installation

Tool

Blind

Fastener

-NOTICE-

Any modification or unintended use of this product shall immediately void all manufacturers warranties.

Manufacturer disclaims all liability for injuries to persons or property resulting from any modification to, or

unintended use of this product.

If you have any questions, please give us a call. Call Toll Free 1-800-456-7865

WEATHER GUARD® products are protected by one or more of the following trademarks:

U.S. - 842268, 1661625, 1663369, 2228051, 2362167; Canada - 282725; U.K. - 1400720; N.Z. - 296049; Aus. - 761964;

KNAACK MANUFACTURING COMPANY

420 E. TERRA COTTA AVENUE - CRYSTAL LAKE, ILLINOIS, USA 60014

815-459-6020

©2001 Knaack Manufacturing Company

Loading...

Loading...