Page 1

INSTALLATION INSTRUCTIONS

Hi-Side and Super Side Boxes - Models 246 through 297

IMPORTANT

BEFORE YOU BEGIN

Read these instructions and

warnings completely before

installation.

BOLT KIT

Bolt Kit #32-0027 is provided with

Models 246 thru 265. Check this

bolt kit to be sure the following

parts are included:

Quan. Description

8 5/16" Lock Washer

1 4 5/16" Flat Washer

4 5/16-18 Blind Fastener

1 Installation Tool

1 5/16-18 x 2-1/4" Bolt,

black oxide

1 1-3/4" Round Cap Plug

4 5/16-18 x 1-1/4" Hex Bolt

4 5/16-18 x 1" Hex Bolt

1 0 5/16-18 Nylon Lock Nut

2 "J" Bolt

2 Plastic Retaining Washer

2 Fender Washer

Bolt Kit #32-0028 is provided with

Models 272 thru 297. Check this

bolt kit to be sure the following

parts are included:

Quan. Description

8 5/16" Lock Washer

1 4 5/16" Flat Washer

4 5/16-18 Blind Fastener

1 Installation Tool

1 5/16-18 x 2-1/4" Bolt,

black oxide

1 1-3/4" Round Cap Plug

4 5/16-18 x 1-1/4" Hex Bolt

4 5/16-18 x 1" Hex Bolt

1 2 5/16-18 Nylon Lock Nut

4 "J" Bolt

4 Plastic Retaining Washer

4 Fender Washer

Rev. H 1/01 Part No. 24-0029

Approximate Installation Time:

42 min. per unit (0.7 hrs.) Depending on truck equipment installation experience

Figure 1. Typical Installation

D ANGER

Danger of explosion. Do not use this product for storing or transporting flammables, explosives, hazardous materials, or hazardous

waste, such as containers of gasoline, solvents, gun powder,

dynamite, propane tanks, acetylene tanks and cutting torches.

This product is only intended and safe for use in storing and transporting small tools, equipment and other similar materials. Any

modifications made to, or unintended use of this product, could

create a hazardous condition that can cause death, serious

personal injury or property damage.

WARNING

This product can reduce the driver's ability to clearly see roadways, vehicular or pedestrian traffic and other objects through the

rear and side windows of the vehicle, which may cause an accident. Extra precautions should be taken when driving a vehicle

with this product. Make all adjustments necessary to ensure maximum visibility, including but not limited to, changing mirror and

seating positions. State and local laws may prohibit obstruction

of windows in a moving vehicle.

TOOLS REQUIRED

• 1/2" Open or Box End Wrench (2)

• Ratchet Wrench

w/ 1/2" deep well socket

• Electric Drill

• 1/2" & 3/8" Drill Bits

• Carpenters Square

• Utility Knife or Scissors

• Tape

• 9/16" Open or Box End Wrench

• 1 - Hi-Side (or Super Side) Box

• 2 - Legs

• 2 - Mounting Pads

PARTS LIST

(20" and/or 27" and/or 45")

Page 2

13. Stand the box upright and turn the “J” bolts to the side so they won’t interfere when placing the box on the bed of the truck. Set the box in place on the

truck bed.

NOTE 2: When placing the box back in position, if it was necessary to drill a

stake pocket, that "J" bolt will have to be held on an angle from the underside of the box and guided into the hole in the stake pocket.

14. Fasten the Leg feet to the floor.

15. Turn the “J” bolts so they are under the lip of the bed. Pull the “J” Bolt up until

it contacts the lip of the bed. Push the Plastic Retaining Washer down, using the

Fender Washer, so the “J” Bolt is held in position. Tighten the Nylon Lock Nut,

making sure the “J” Bolt hook remains under the lip of the truck bed.

Note: Periodically check the tightnessof "J" bolts to insure proper

attachment.

16. Snap the Cap Plug into the bottom hole. (plug may be pulled when cleaning

inside of box).

WEATHER GUARD® PRODUCT

REFINISHING PROCEDURES

All WEATHER GUARD® products

are finished with a polyester powder

coating, and it is important to follow

these procedures to get proper

adhesion. As Knaack Manufacturing

Co. cannot control the finishing of

the products, the warranty for

WEATHER GUARD® products on

paint is not applicable on refinished

products.

1. Sand the surface to be painted

with 180-200 grit sand paper to

rough up the surface. This should be

followed by wet sanding with a 400

grit wet or dry paper.

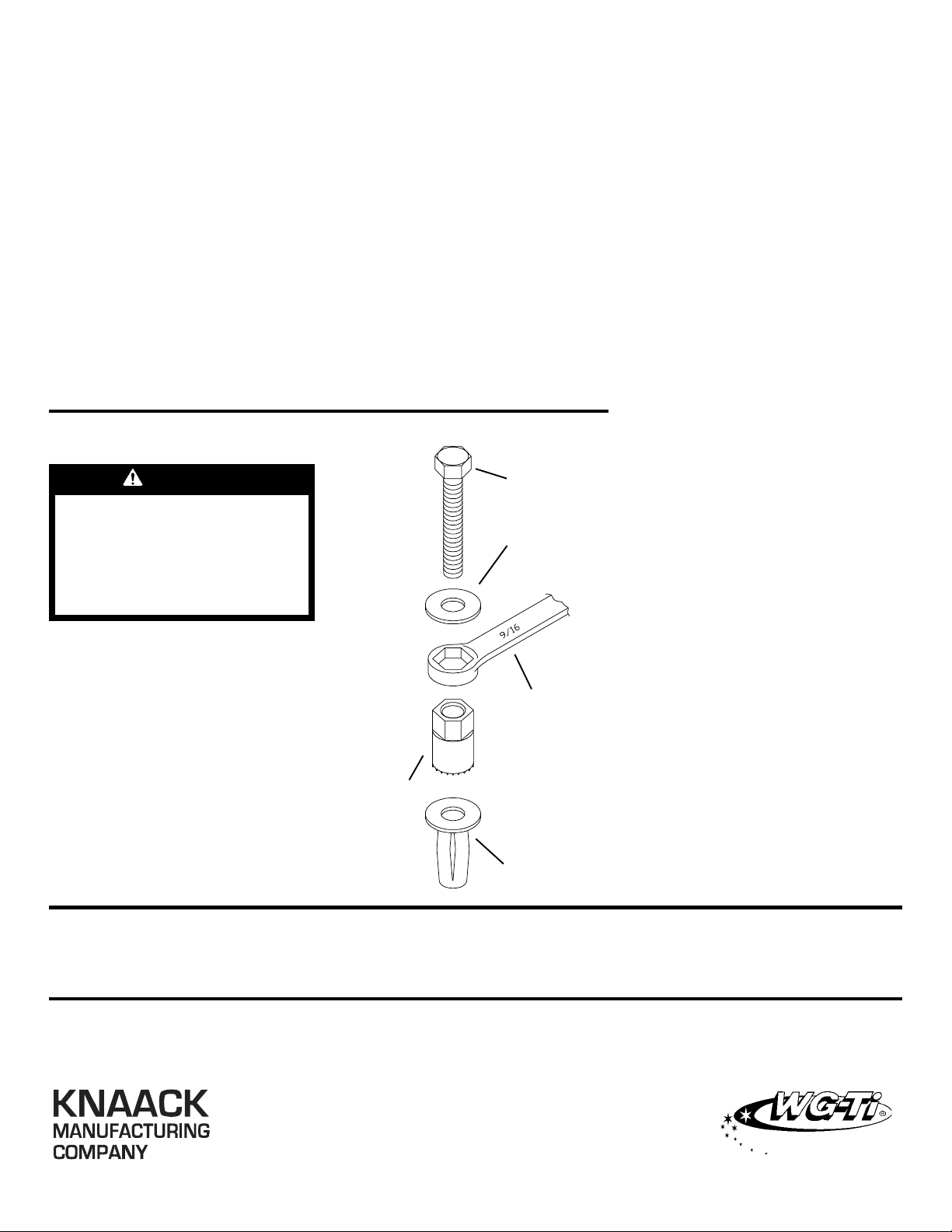

INSTALLATION PROCEDURE USING BLIND FASTENERS

WARNING

Prior to drilling, so as not to

cut or puncture fuel tanks, fuel

lines, brake lines, electric

wires, etc., check under vehicle for locations.

Place a drop of oil on the black

oxide bolt before assembling

as shown on right. Place the

Blind Fastener in the hole and

use a 1/2” or 7/16” wrench to

tighten black hex bolt until the

blind fastener is fully seated.

When setting black hex bolt, it

will start out hard. As the Blind

Fastener “bulbs” out it will get

easier, until it bottoms out or

sets. Make sure the Blind

Fastener and Installation Tool

do not turn during installation.

Installation

Tool

Black

Oxide

Bolt

Flat

Washer

9/16”

Wrench

Blind

Fastener

2. Wipe down the sanded surface

with ketone based thinner. This

removes the dust and softens the

powder coating for better paint

adhesion.

3. Wipe sanded area with a tack rag

to remove loose dust and particles

before painting.

NOTE: Do not use a lacquer over

the powdered coating.

- NOTICE -

Any modification or unintended use of this product shall immediately void all manufacturer’s warranties.

Manufacturer disclaims all liability for injuries to persons or property resulting from any modification to, or

unintended use of this product.

If you have any questions, please give us a call. Call Toll Free 1-800-456-7865

U.S. - 842268, 1661625, 1663369, 2228051, 2362167; Canada - 282725; U.K. - 1400720; N.Z. -296049; Aus. - 761964

WEATHER GUARD® products are protected by one or more of the following trademarks:

KNAACK MANUFACTURING COMPANY

420 E. TERRA COTTA AVENUE - CRYSTAL LAKE, ILLINOIS, USA 60014

815-459-6020

©2001 Knaack Manufacturing Company

Loading...

Loading...