Page 1

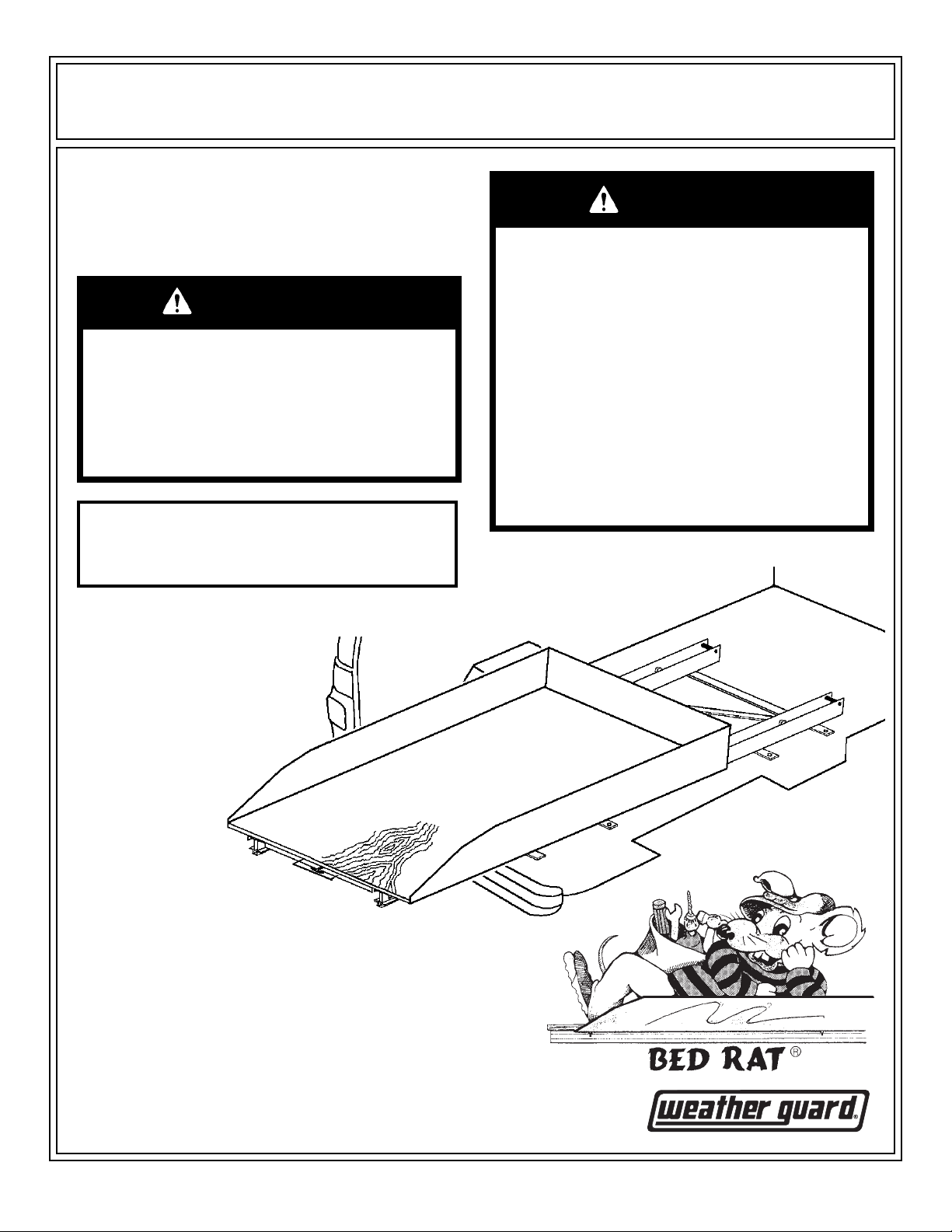

ASSEMBLY AND INSTALLATION INSTRUCTIONS

BED RAT® Sliding Platform Model 3100 3200 3300 3400

IMPORTANT

BEFORE YOU BEGIN

DANGER

Read these instructions and warnings

completely before installing.

WARNING

These instructions are to be followed for

proper installation of this product. Improper

installation or any modifications made to this

product, could create a hazardous condition

that can cause serious personal injury or

property damage.

Approximate Assembly and Installation time:

5 hours per unit (5.0 hrs.)

Depending on Van equipment

installation experience.

Danger of explosion. Do not use this product

for storing or transporting flammables, explosives, hazardous materials, or hazardous

waste, such as containers of gasoline, solvents, gun powder, dynamite, propane tanks,

acetylene tanks, cutting torches and gas

powered equipment. This product is only intended and safe for use in storing and transporting small tools, equipment and other

similar materials. Any modifications made

to, or unintended use of this product, will

create a hazardous condition that will cause

death, serious personal injury or property

damage.

- Load Rating 750 lbs.

evenly distributed

TOOLS REQUIRED

Electric Drill

3/16", 5/16", 3/8" and 1/2" Drill Bits

1/2" Open or Box End Wrench

7/16" Open or Box End Wrench (2)

9/16" Open or Box End Wrench

Part No. 24-3201 REV. H ECN 5282 03/13

Page 2

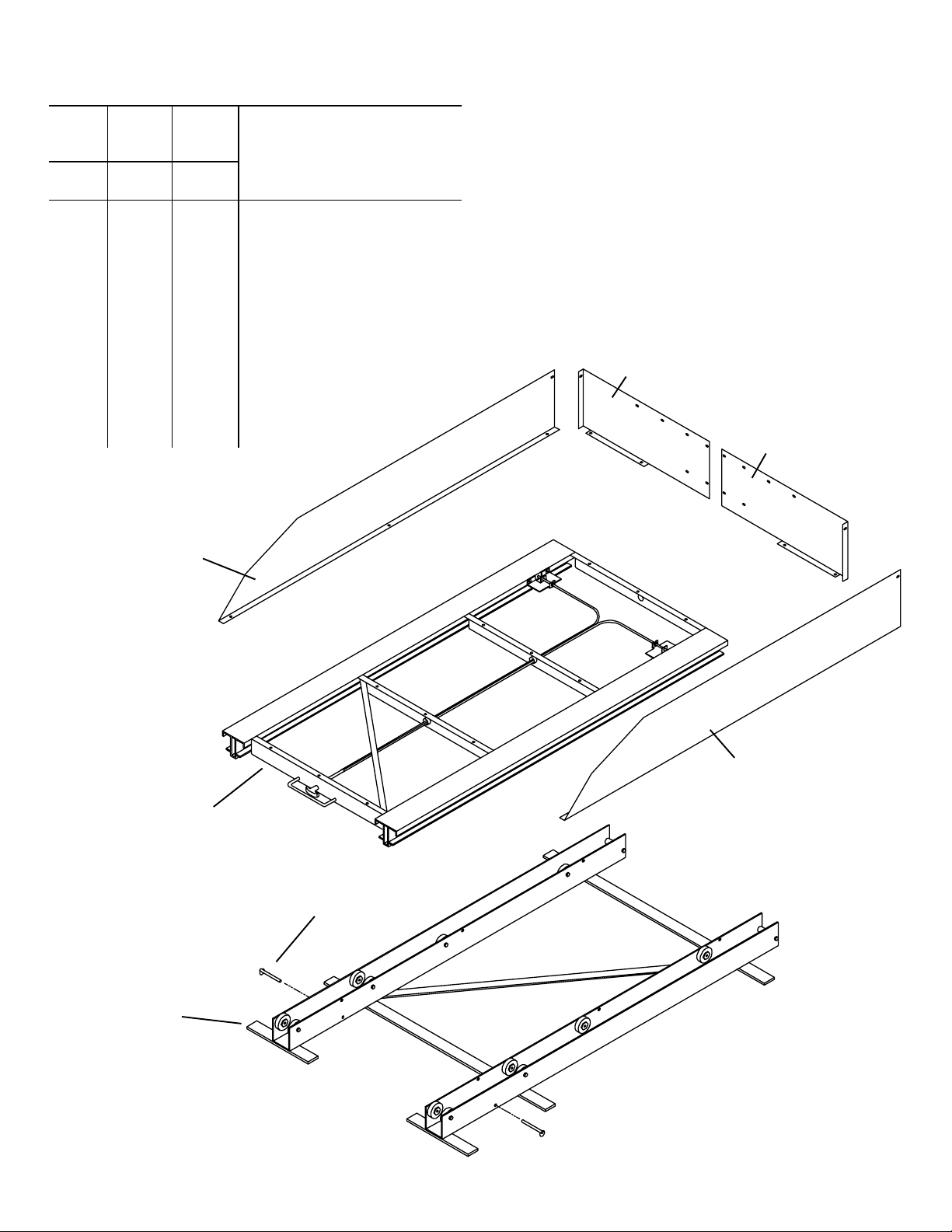

BOLT KITS - The following are provided with each

model:

Model 3100 3300

3200 3400

Description

Bolt Kit 32-3200 32-3400

8 12 5/16-18 x 1-1/2" Bolt, Hex

22 22 5/16-18 x 1-1/4" Carriage Bolt

4 4 1/4-20 x 5/8" Bolt, Hex

4 4 1/4-20 Whiz Nut

12 16 5/16" Flat Washer

8 12 5/16-18 Blind Fastener

1 1 5/16-18 x 2-1/4" Blk. Ox. Bolt

8 12 5/16 Lock Washer

22 22 5/16-18 Whiz Nut

1 1 Installation Tool

2 2 3/8 x 4 Stop Pin

4 4 5/16-18 Nylon Lock Nut

4 0 Spacers

Left Side Retainer

3100 p/n 20-3620

3200 p/n 20-3603

3300 p/n 20-3605

3400 p/n 20-3607

PARTS LIST

1 Deck Assembly

1 Base Assembly

1 Left End Retainer

1 Right End Retainer

1 Left Side Retainer

1 Right Side Retainer

Left End Retainer

p/n 20-3609

Right End Retainer

p/n 20-3608

Deck Assembly

3100 p/n 25-3101

3200 p/n 25-3201

3300 p/n 25-3301

3400 p/n 25-3401

Base Assembly

3100 p/n 25-3100

3200 p/n 25-3200

3300 p/n 25-3300

3400 p/n 25-3400

2

Right Side Retainer

3100 p/n 20-3619

3200 p/n 20-3602

3300 p/n 20-3604

3400 p/n 20-3606

3/8" x 4"

Stop Pin

Figure 1. Parts Identification

Page 3

ASSEMBLY INSTRUCTIONS for

Models 3200 3300 3400

(see back page for Model 3100)

NOTE: To prevent rust from occurring, touch-up any

drilled holes.

1. Place the Base Assembly centered in the vehicle. See

Figure 1. for correct location. Close the tailgate or doors to

make sure the unit is properly placed. If installing a Model

3100 out a van side door(s), make sure to take into account

the door opening width. If installing a bulkhead, this should

be done first.

2. Mark hole locations on the mounting bars, centering the

holes on the bars and on the top portion of the floor ribs if

possible. If it is not possible, four Spacers have been provided to fill the space between the mounting bars and the

lower part of the floor ribs. NOTE: Twelve holes are required

for Models 3300 & 3400, eight holes for Model 3200 (see

Figure 2. for mounting holes) and four for Model 3100 (see

Figure 3.). Drill through the mounting bar and the floor at

one rear location, and insert a 5/16-18 x 1-1/2" Hex Hd. Bolt

into the hole. Drill one front mounting bar location, and insert

a bolt. Drill the rest of the mounting bar/floor holes.

WARNING

CAUTION

To keep debris out of your eyes when checking

the underside of the vehicle, or when drilling,

always wear protective eyewear.

WARNING

Prior to drilling, so as not to cut or puncture fuel

tanks, fuel lines, brake lines, electrical lines, etc.,

check under vehicle for locations.

All floor mounting bolts near the gas tank area

should be installed from the underside of the vehicle, to guard against the gas tank being punctured in the event of a collision. This would mean

not using Blind Fastener in this area. Holes drilled

in this area should be 3/8".

3. Remove the Base Assembly and re-drill the floor holes

using a 1/2" drill bit.

2" For most Pickups

and all Vans

No Holes

Required

Inside edge of

tailgate or van

doors

Figure 2. Base Assembly marking/drilling (Model 3400 shown)

3/8" Hole

1/2" Hole

3

Page 4

5/16 Flat

Washer

5/16-18 x 1-1/2"

Hex Hd. Bolt

5/16 Lock

Washer

Figure 3. Model 3100 marking/drilling

4. Install Blind Fastener in the floor holes. See the Blind Fastener installation instructions on the back page. Replace the

Base Assembly in the vehicle and fasten it to the floor (see

Figure 4.).

5. To determine the size of the deck for pickups, the width

must clear between the wheel wells, and the length must be

just short of the inside length of the bed with the tailgate

closed. For vans, the width must clear not only the wheel

wells, but also any shelving or cabinetry fastened to the

sides of the van and fit out the rear doors. The length must

be just short of the inside length of the load area with the

doors closed. In either case, the size of the deck may be

considerably wider than the width of the bed rails, depending

on the space available. We suggest using 3/4" plywood that

is 2" less than the inside length of the pickup bed. In full size

vans, the width should be 1" less than the inside dimension

of the rear doors when fully open.

Mounting

5/16-18 Whiz Lock Nut

(12 places)

(6 places Model 3100)

Angles

Spacer (used only if

mounting through

the lower part of the

floor ribs as shown)

Figure 4. Fastening

6. Lay the decking material across two sawhorses. With the

help of another person, place the Deck Assembly upside

down on the deck material, 1" from the rear edge, and centered side to side. Using the Deck Assembly mounting angle

holes as a drilling template, drill 5/16" holes through the

deck material. Bolt the Deck Assembly to decking material

(see Figure 5.).

Installed

Blind

Fastener

Plywood should

extend 1" past

upper unit.

5/16-18 x 1-1/4"

Carriage Bolt

(12 places)

(6 places Model 3100)

4

Figure 5. Decking drilling and fastening

Page 5

7. With the Deck Assembly fastened to the decking material

and still upside down, place a Side Retainer lip on the decking, flush with the front of the decking. Mark the Side Retainer mounting holes. Repeat this for the other Side

Retainer. Place a Front Retainer on the decking at the front,

with the flange butted up to the decking side. Mark the Front

Retainer mounting holes. Repeat this for the other Front Retainer. Drill all marks with a 5/16" drill bit. Bolt the Side and

Front Retainers to the Deck Assembly. Bolt the Side and

Front Retainers together at the corners. The Front Retainers

have slotted holes at the center that will align to bolt them

together if using a decking with a width of 28", 30", 32", 35",

39", 40", 44" or 48". If using a decking with a non-standard

width, it will be necessary to drill a set of 5/16" holes to fasten the Front Retainers together. Bolt the Front Retainers

together (see Figure 6.).

8. With the help of another person, upright the Deck Assembly and slide it into the Base Assembly while holding the

black release handle out. Install the two 3/8" x 4" Safety

Stop Pins in the Base Assembly (see Figure 1.).

WARNING

Both safety stop pins must be installed in the

lower base to keep the upper deck unit from

rolling off the lower base unit, which could result

in serious personal injury or property damage.

5/16" Holes

(10 places)

5/16-18

Whiz Nut

(10 places)

5/16-18 x 1-1/4"

Carriage Bolt

(10 places)

1/4-20 x 5/8"

Hex Head Bolt

(4 places)

1/4-20 Nylon

Lock Nut

(4 places)

Figure 6. Side and End Retainer drilling and fastening

5

Page 6

INSTALLATION PROCEDURE USING BLIND FASTENERS

WARNING

Prior to drilling, so as not to cut

or puncture fuel tanks, fuel

lines, brake lines, electrical

wires, etc., check under vehicle

for locations.

Place a drop of oil on the

black oxide bolt before

assembling as shown on

right. Place the Blind Fastener in the hole and use

a 1/2 or 7/16 wrench to

tighten black hex bolt until

the blind fastener is fully

seated. When setting

black hex bolt, it will start

out hard. As the Blind

Fastener bulbs out it will

get easier, until it bottoms

out or sets. Make sure the

Blind Fastener and Installation Tool do not turn during installation.

Black

Oxide

Bolt

Flat

Washer

9/16

Wrench

Installation

Tool

Blind

Fastener

- NOTICE -

Any modification or unintended use of this product shall immediately void all manufacturers warranties.

Manufacturer disclaims all liability for injuries to persons or property resulting from any modification to, or

unintended use of this product.

WEATHER GUARD® products are protected by one or more of the following trademarks:

U.S. - 842268, 1661625, 1663369, 1840451, 1901674, 2228051, 2362167; Canada - 282725; U.K. - 1400720; N.Z. - 296049 other trademarks pending.

Knaack LLC

ATTN: War

0 E. Terra Cotta Avenue

42

Crystal Lake, IL 60014

If you have any questions, ple

ranty Claims

ase call toll free at 1-800-456-7865.

©2013 Knaack LLC

Part No. 24-3201 REV. H ECN 5282 03/13

Loading...

Loading...