Page 1

ASSEMBLY AND INSTALLATION INSTRUCTIONS

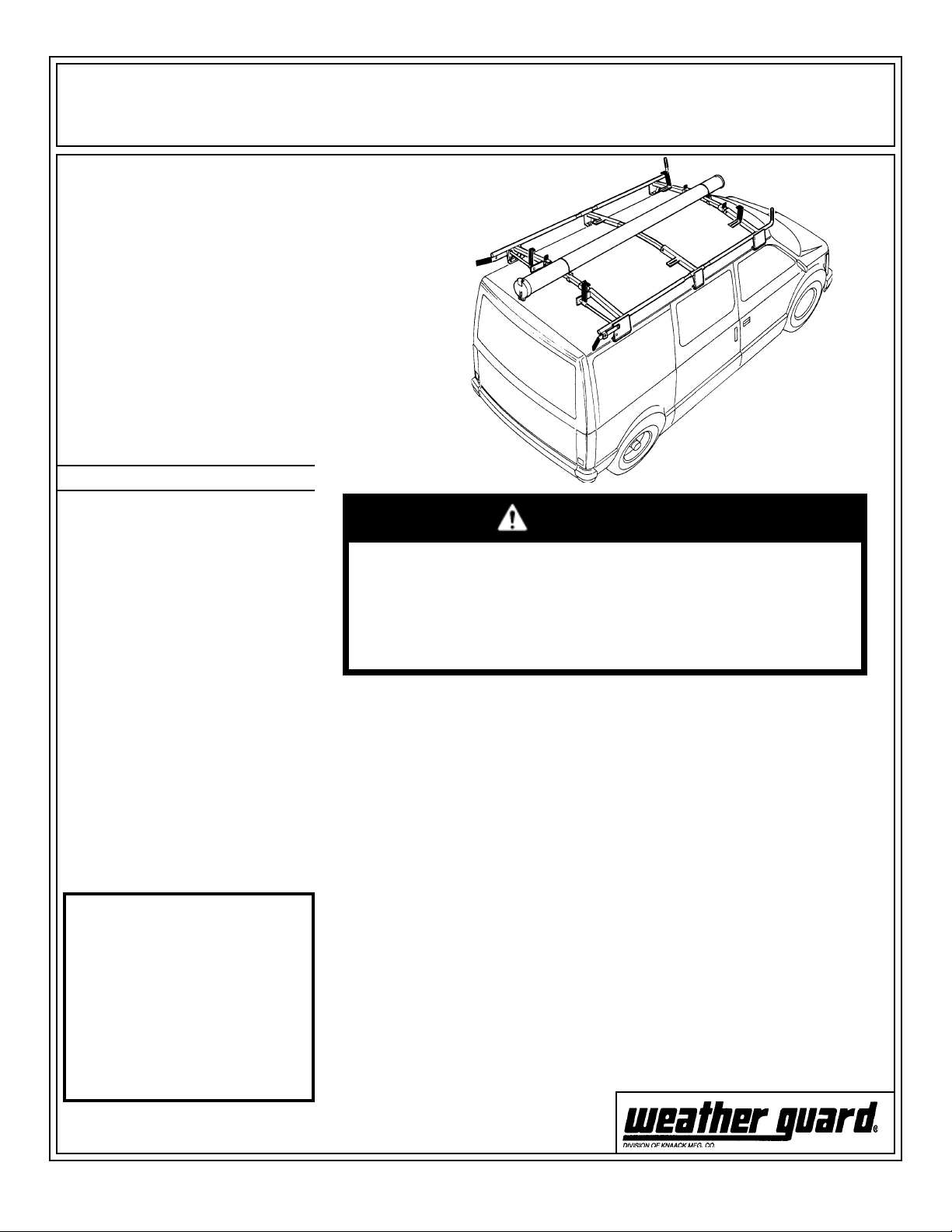

CONDUIT CARRIER - Model 239

IMPORTANT

BEFORE YOU BEGIN

Read these instructions and

warnings completely before

installation.

BOLT KIT

Bolt kit #32-2390 is provided with

your Conduit Carrier. Check this

bolt kit to be sure the following

parts are included:

Quan. Description

4 #12-24 Nylon Lock Nuts

(black dichromate)

PARTS LIST

• 2 - "U" Clamps

• 1 - Front End Cap

• 1 - Rear End Cap with Door

• 4 - Clamp Brackets

TOOLS & MATERIALS

NEEDED

• 3/8" Open or Box End Wrench

• Plastic Pipe Cement

• PVC Primer

• PVC Pipe

NOTE: Use only the recommended ASTM material, which

is PVC 1120 Schedule #40.

The 6" diameter pipe should

fit snugly on the end cap. If it

does not, this is an indication

that you have the wrong size

pipe. Be sure to follow application instructions found on

the cement container.

WARNING

This product is only intended for, and only safe for, storing and

transporting tubing, pipe and conduit. Any modifications made

to this product, or use of this product for any other purpose than

its intended use, could create a hazardous condition that can

cause serious personal injury or property damage.

ASSEMBLY AND

INSTALLATION INSTRUCTIONS

1. Be sure the 6 in. PVC Pipe is cut

squarely on both ends and to correct

length (10 ft.). Any rough edges should

be smoothed with a file.

2. Before cementing the end caps in

place, be sure to clean away any dirt,

grease or moisture from both ends of

the PVC pipe.

3. Use a plastic primer to remove surface gloss from pipe ends and inside

flanges of end caps.

NOTE: Keep the door End Cap open

during priming, gluing and curing

steps to prevent possibility of sealing

the door shut.

4. Assemble Rear End Cap to PVC

pipe. Apply a thin coat of Plastic Cement to the inside flange of the end

cap...then quickly apply a liberal cement coat around the outside of the

PVC pipe.

5. While the cement is still wet, push

the End Cap onto the PVC pipe with

a slight turning motion until it is fully

seated on the pipe.

NOTE: Keep pressure on the end

cap for approximately 30 seconds

for a good seal.

6. To assemble the Front Cap to the

PVC pipe, repeat steps 4 and 5,

making sure the Triangular Tab lines

up with the center of the hinge pin on

the rear end cap (

see Figure 1.

).

Rev. D 4/97 Part No. 24-0239

Page 2

W ARNING

Rear end cap door must be padlocked during transit to prevent

accidental spillage of contents,

which could cause serious personal injury or property damage.

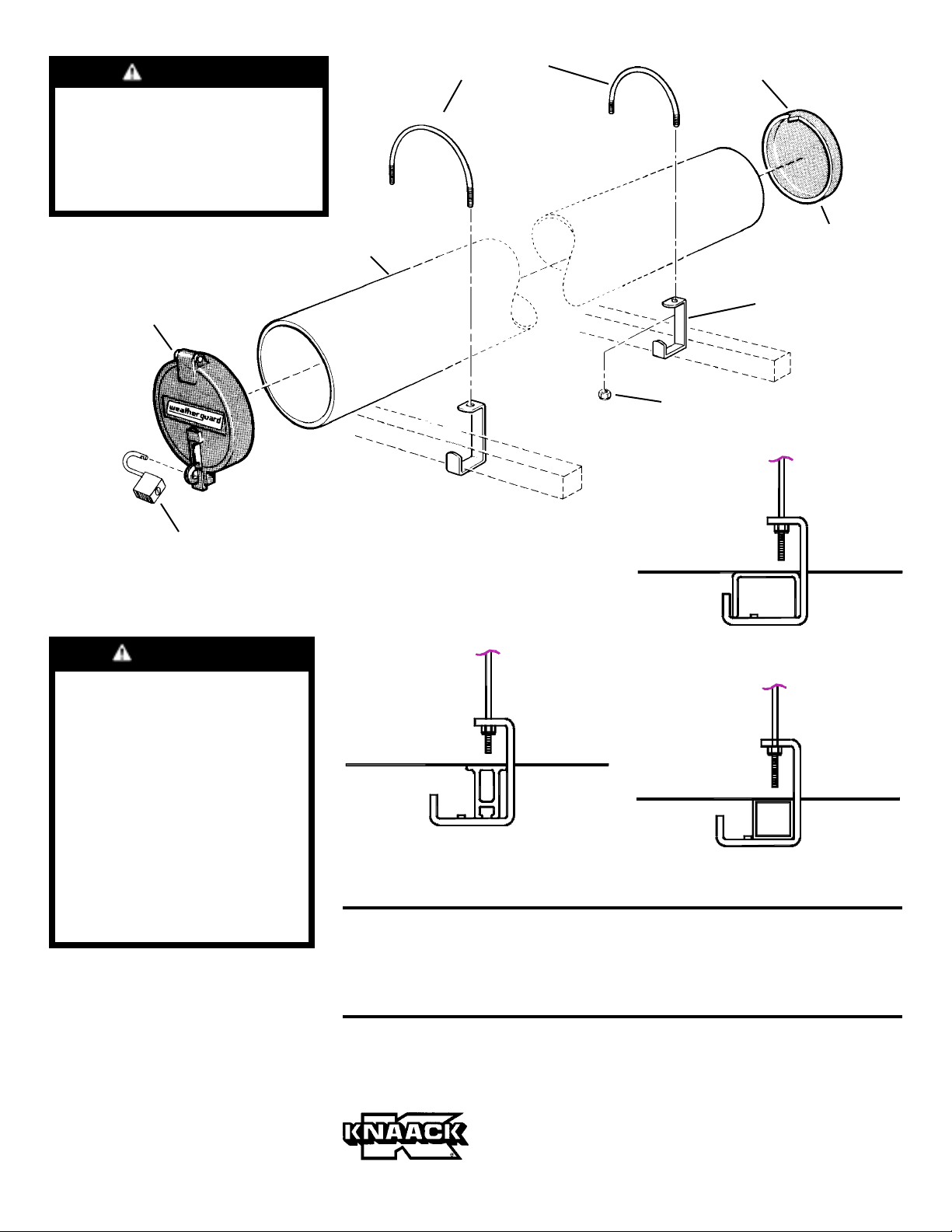

U-Clamps

p/n 21-1017

(2 places)

Triangular

Tab

Rear End Cap

p/n 7073

WARNING

PVC Pipe

Padlock

(customer supplied)

Front Cap

p/n 21-1015

Clamp Bracket

p/n 20-2390

#12-24 Nylon Lock Nut

(black dichromate)

(4 places)

Figure 1. Assembly and Installation

on a square shaped crossmember

Figure 2b. Installation on a channel

shaped crossmember

Allow at least 15 minutes for

cement cure time before handling, and we strongly suggest a 24 hour full-cure time

before loading any materials.

If assembled Conduit Carrier

is used before the 24 hour

cure time, the material in the

conduit carrier could push

the end caps out and spillage

of material could occur

causing serious injury to

persons and property.

7. Place the Conduit Carrier in position

on your ladder rack. Install the "U"

Clamps and Clamp Brackets (

ure 1.

). (

See Figures 2a, 2b and 2c for

see Fig-

installation of "U" Clamps and Clamp

Brackets for your crossmember

). Before tightening the nuts, make sure the

conduit carrier is correctly positioned

and the rear door latch is pointing

down as shown in the illustration.

Figure 2a. Installation on a 211

aluminum crossmember

Figure 2c. Installation on a square

shaped crossmember

- NOTICE -

Any modification or unintended use of this product shall immediately void

all manufacturers warranties. Manufacturer disclaims all liability for injuries

to persons or property resulting from any modification to, or unintended

use of this product.

If you have any questions, please give us a call. Call Toll Free 1-800-456-7865

Weather Guard® products are protected by one or more of the following patents or trademarks:

U.S. - 842268, 1661625, 1663369; Canada - 282725; U.K. - 1400720; other patents pending.

KNAACK MANUFACTURING COMPANY

420 E. TERRA COTTA AVENUE

CRYSTAL LAKE, ILLINOIS, 60014 - 815-459-6020

© 1993 Knaack Manufacturing Company

Loading...

Loading...