Page 1

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Model 1280 Full Size Truck Rack ( 8 ft. Bed)

IMPORTANT

BEFORE YOU

BEGIN

Read these instructions

and warnings completely

before assembly and

installation.

NOTE: If your vehicle has a bedliner

you may need to drill, trim, or cut

the liner for proper installation of

this product. If the bedliner extends

over the top rail on the sides of the

bed, this rack will not work unless

the entire over the top section is removed.

Approximate Assembly and Installation time:

1 hour 18 min. per unit (1.299 hrs.)

Depending on truck equipment installation experience.

PARTS LIST

1 - Driver Side Leg/Base/Rail

1 - Passenger Side Leg/Base/Rail

1 - Driver Side Front Rail

1 - Passenger Side Front Rail

Tube, E-6000 Sealant

NOTE: Crossmembers are packaged

separately per vehicle model

1281 = GM Crossmembers

1282 = Dodge Crossmembers

Model 1500 through

2001

Models 2500/3500

through 2002

1283 = Ford Crossmembers

1284 = Super Duty Ford

Crossmembers

1287 = Dodge Crossmembers

2002 Model 1500 and

2003 Models 2500/3500

and newer

BOLT KIT

Bolt Kit #32-0102 is provided with

your ladder rack. Check this bolt kit

to be sure the following parts are

included:

Quan. Description

8 5/16-18 Nylon Lock Nut

6 5/16-18 x 1" Carriage Bolt

4 5/16-18 x 1-1/2" Hex Hd.

Bolt

2 5/16-18 x 1-1/4" Carriage

Bolt

8 5/16 Flat Washer

4 5/16" Lock Washer

4 5/16-18 Blind Fastener

4 1/4-20 x 1-1/4" Hex Hd.

8 1/4-20 Nylon Lock Nut

12 1/4 Flat Washer

1 Blind Fastener Installation

Tool

1 5/16-18 x 2-1/4" Black

Oxide Bolt

4 Black Tie Downs

8 10-24 x 2-3/4" F.H. Screws

8 10-24 Nylon Lock Nuts

4 1/4-20 x 1-1/2" Carriage Bolt

WARNING

This product is only intended for, and only safe for, transporting ladders,

lumber, pipe and other similar materials. It is the responsibility of the

user to secure these materials to the rack before transporting. Any

modifications made to this product, or use of this product for any other

purpose than its intended use, will create a hazardous condition that will

cause serious personal injury or property damage.

CAUTION

Never load your rack to exceed the safe rated capacity of your vehicle.

Heavy loads carried high can dangerously alter the center of gravity.

TOOLS REQUIRED

Electric Drill

Drill Bits - 7/32", 1/4", & 1/2"

Screwdriver - common

Open or Box End Wrenches - 7/16",

1/2", & 9/16"

3/8" Drive Ratchet

Sockets - 7/16" & 1/2"

C-clamp

Rev. A 7/04 Part No. 24-0136

®

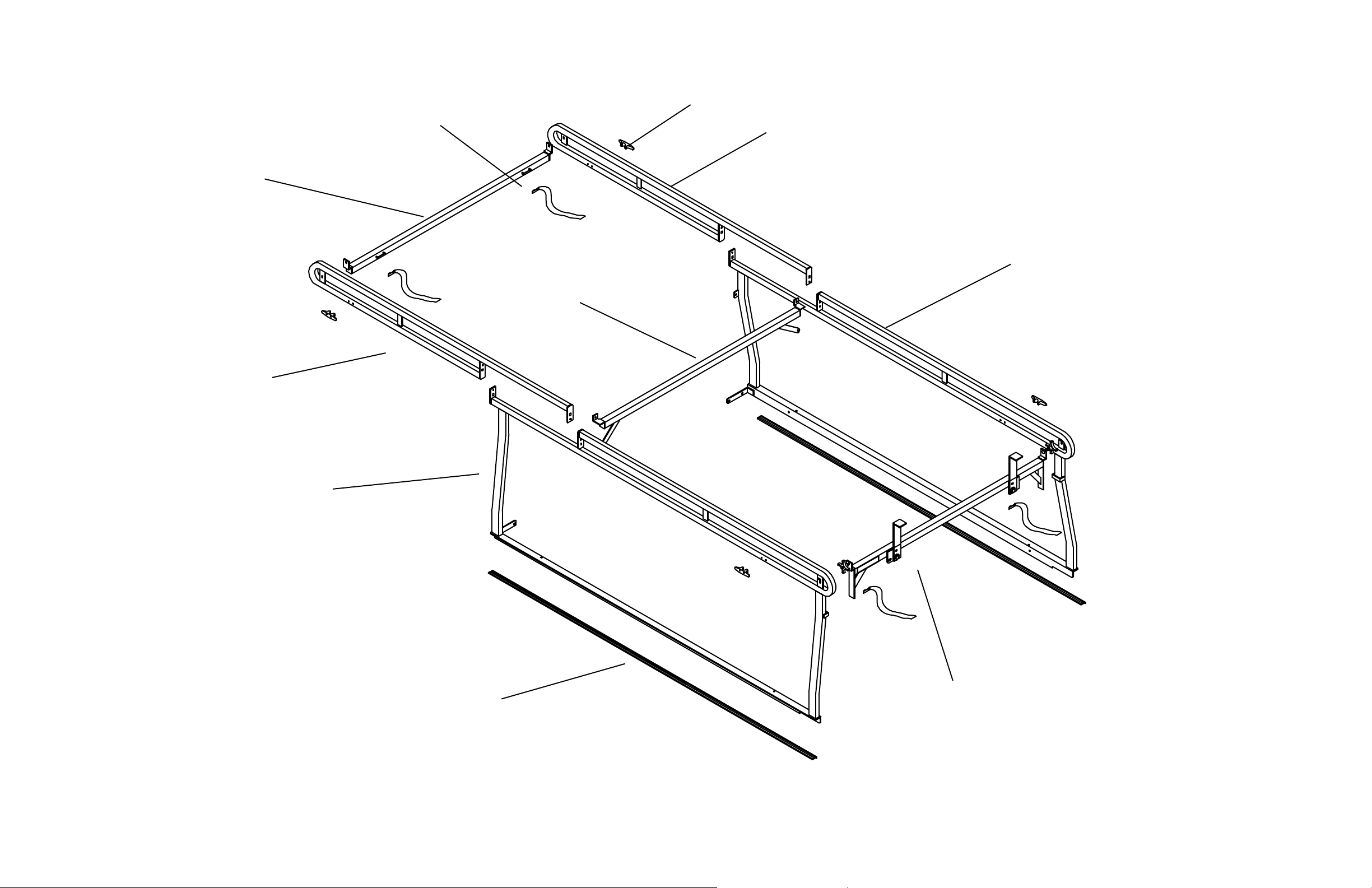

Page 2

Tie Down

Front Crossmember

Driver Side

Front Rail

Strap (4)

Passenger Side

Front Rail

Passenger Side

Leg/Base/Rail

Center Crossmember

Driver Side

Leg/ Base/Rail

Mounting Pad

Rear Crossmember

2

Page 3

STEP 2. Tie Down Installation.

Install tie downs where desired.

Put E-6000 sealant on the back of the

tie downs and under nuts before installing.

STEP 3. Mounting Pad Installation.

Place pads on the top of the bed. It may be necessary to

hold the pads in place with small pieces of tape.

10-24 x 2-3/4"

Flat Head Screw

7/32" Hole

CAUTION

To keep debris out of your

eyes when drilling, always

wear protective eyewear.

Mounting

Pad

Tie Down

Inside of

truck bed

10-24 Nylon

Lock Nut

STEP 1. Rail Assembly.

Driver Side (shown)

or Passenger Side

Decal

5/16-18 x 1"

Carriage Bolt

This bolt does not get installed until

the Center Crossmember is attached.

5/16 Flat

Washer

5/16-18 Nylon

Lock Nut

STEP 4. Rail and Rear Crossmember Installation

With the help of at least two other people lift one of the

assembled sections onto the truck. One person should be in

the truck to hold the first section while the other section is

being lifted into position. Once both sections are positioned,

install the rear crossmember as shown in STEP 5.

3

Page 4

STEP 6. Front Crossmember Assembly.

5/16 Flat

Washer

5/16-18 Nylon

Lock Nut

5/16-18 x 1"

Carriage Bolt

5/16-18 x 1-1/4"

Carriage Bolt

5/16-18 x 1"

Carriage Bolt

STEP 7. Center Crossmember Assembly.

5/16 Flat

Washer

5/16-18 Nylon

Lock Nut

STEP 5. Rear Crossmember Assembly.

(Ladder Stop not shown for clarity)

4

Page 5

PERFORM THE FOLLOWING STEPS TO THE DRIVER SIDE

& PASSENGER SIDE (Passenger Side Shown)

STEP 11. Unfasten Side, Move Rack out of the Way,

Redrill Front Holes, and Install Blind Fasteners

STEP 12. Install Front, Top, and Side Fasteners

STEP 8. Tape Washer, Clamp, and Drill Front Side

Tape a 5/16" Flat Washer

between front of Mounting Base

and bed

Drill

1/4" dia.

Hole

STEP 9. Unclamp, Remove Flat Washer, and Fasten Side

1/4-20 x 1-1/4"

Hex Hd. Bolt

Drill (2)

1/2" dia.

Hole

5/16-18

Blind Fastener

5/16" Lock

Washer

5/16-18 x 1-1/2"

Hex Hd. Bolt

1/4" Flat

1/4-20 x 1-1/4"

Hex Hd. Bolt

Washer

STEP 13. Clamp, Drill, and Fasten Rear Side

1/4-20 x 1-1/4"

Hex Hd. Bolt

1/4-20 x 1-1/2"

Carriage Bolt

1/4-20 Nylon

Lock Nut

1/4" Flat

Washer

STEP 10. Drill Front and Top

Centered in

3/8" dia. holes

1/4" Flat

Washer

1/4-20 Nylon

Lock Nut

Drill

1/4" dia.

Hole

INSTALLATION PROCEDURE USING BLIND FASTENERS

Place a drop of oil on the

black oxide bolt before

assembling as shown at

right. Place the Blind

Fastener in the hole and

Black

Oxide

Bolt

Flat

Washer

use a 1/2 or 7/16

wrench to tighten black

hex bolt until the blind

fastener is fully seated.

When setting black hex

9/16

Wrench

bolt, it will start out hard.

As the Blind Fastener

bulbs out it will get

easier, until it bottoms

Installation

Tool

out or sets. Make sure

the Blind Fastener and

Installation Tool do not

turn during installation.

Blind

Fastener

Drill

1/4" dia.

Hole

1/4-20 Nylon

Lock Nut

STEP 14. Remove Clamp, Drill, and Fasten Rear Top

1/4-20 x 1-1/2"

Carriage Bolt

1/4" Flat

Washer

Drill

1/4" dia.

Hole

Drill (2)

1/4" dia.

Hole

1/4-20 Nylon

Lock Nut

5

Page 6

Bolt Chart

Nylon Lock Nuts

10-24 x 2-3/4"

F.H. Screw

5/16-18 x 1-1/2"

Hex Hd. Bolt

10-24 5/16-18

1/4-20 x 1-1/4"

Hex Hd. Bolt

WEATHER GUARD® PRODUCT

REFINISHING PROCEDURES

All WEATHER GUARD® products are finished with a polyester powder coating, and it is important to follow these procedures to get proper adhesion. As Knaack

Manufacturing Co. cannot control the finishing of the products, the warranty for WEATHER GUARD® products on paint is not applicable on refinished products.

5/16-18 x 1-1/4"

Carriage Bolt

5/16-18 x 1"

Carriage Bolt

1/4-20

1/4-20 x 1-1/2"

Carriage Bolt

WARNING

Ladders must be secured per ANSI

standard A142.2-1990 paragraph 8.4.4. Ladder

damage will occur from road shock and

vehicle vibration if the ladder is not properly

secured to the ladder rack. Bouncing and side

to side motion of a improperly secured ladder

will cause wear and weaken the ladder. Using

a damaged ladder could lead to a structural

collapse and could result in a serious injury or

death.

1. Sand the surface to be painted with 180-200 grit sand paper to rough up the surface. This should be followed by wet sanding with a 400 grit wet or dry paper.

2. Wipe down the sanded surface with ketone based thinner. This removes the dust and softens the powder coating for better paint adhesion.

3. Wipe sanded area with a tack rag to remove loose dust and particles before painting.

NOTE: Do not use a lacquer over the powdered coating.

- NOTICE -

Any modification or unintended use of this product shall immediately void all manufacturers warranties.

Manufacturer disclaims all liability for injuries to persons or property resulting from any modification to,

or unintended use of this product.

If you have any questions, please give us a call. Call Toll Free 1-800-456-7865

WEATHER GUARD® products are protected by one or more of the following patents or trademarks:

U.S. - 2228051, 842268, 1661625, 1663369, 4509787, 2434963; Canada - 282725, 1218968; U.K. - 1400720; N.Z. - 296049; Aus. - 761964

KNAACK MANUFACTURING COMPANY

420 E. TERRA COTTA AVENUE - CRYSTAL LAKE, ILLINOIS, USA 60014 - 815-459-6020

©2004 Knaack Manufacturing Company

Loading...

Loading...