Page 1

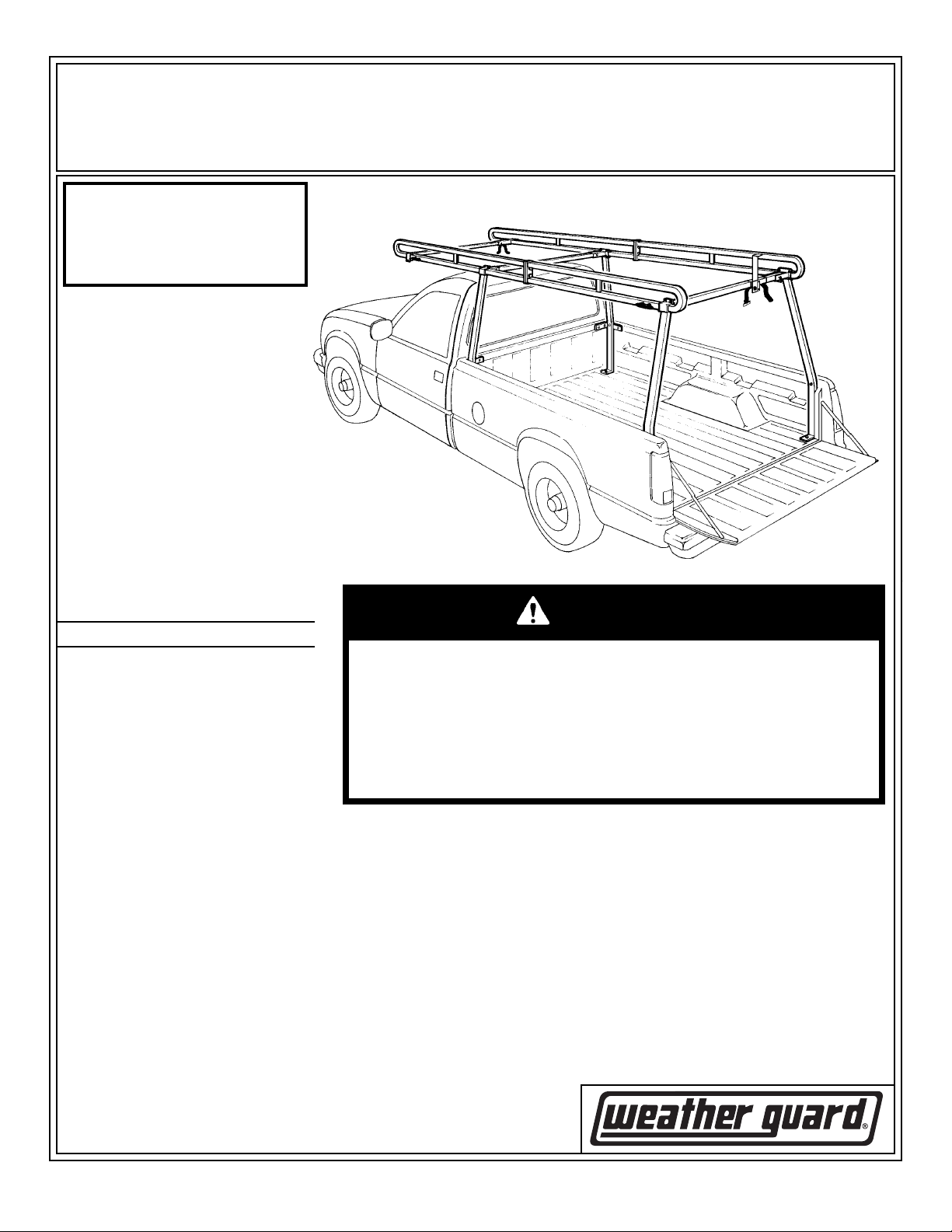

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Ladder Rack - Models 1245 and 1275

Model 1245 - Full Size Pickup Short Beds Model 1275 - Full Size Pickup Long Beds

Approximate Assembly and

Installation Time:

5 hours per unit (5.0 hrs.)

depending on truck equipment

installation experience.

IMPORTANT

BEFORE YOU BEGIN

Read these instructions and

warnings completely before

installing.

BOLT KIT

Bolt Kit #32-0105 is provided with

your ladder rack. Check this bolt kit

to be sure the following parts are

included:

Quan. Description

WARNING

4 3/8-16 x 3/4" Hex Head,

Thread Cutting

20 5/16-18 Nylon Lock Nut

4 3/8-16 x 1-1/4" Carriage Bolt

4 3/8" Flat Washer

4 3/8-16 Nylon Lock Nut

4 5/16-18 x 2" Hex Hd. Bolt

2 5/16-18 x 2-3/4" Hex Hd. Bolt

12 5/16-18 x 1-1/4" Hex Hd. Bolt

16 5/16-18 x 3/4" Carriage Bolt

34 5/16 Flat Washer

14 5/16" Lock Washer

14 5/16-18 Blind Fastener

1 Installation Tool

2 5/16-18 x 2-1/4" Black

Oxide Bolt

2 5/16" x 2-3/4" Latch Pins

4 Black Tie Downs

8 10-24 x 2-3/4" F.H. Screws

8 10-24 Nylon Lock Nuts

2 Sq. Cap Plugs (black)

2 5/16-18 x 2" Carriage Bolt

4 5/16 x 2" Dia. Blk. Oxide

Flat Washer

This product is only intended for, and only safe for, transporting

ladders, lumber, pipe and other similar materials. It is the responsibility of the user to secure these materials to the rack before transporting. Any modifications made to this product, or use of this

product for any other purpose than its intended use, could create

a hazardous condition that can cause serious personal injury or

property damage.

PARTS LIST

4 - Top Rail Halves

Cushion Strip (bulk)

2 - Closed Top Tube Sleeves

2 - Open Top Tube Sleeves

4 - Legs

2 - Crossmembers (open ends)

1 - Front Crossmember

1 - Front Crossmember Sleeve

2 - Bed Reinforcing Brackets

2 - Front Leg Spacer

Tube, Sealant

1 - Ladder Stop

2 - Straps

Electric Drill

Drill Bits - 5/16", 3/8" & 1/2"

3/8" Open or Box End Wrench

1/2" Open or Box End Wrench (2)

9/16" Open or Box End Wrench (2)

Screwdriver - common

Framing Square

Pencil or Marker

TOOLS REQUIRED

1

Part No. 24-0132 REV. B ECN 5315 05/13

Page 2

NOTE:

Some vehicle manufacturers

require a manufacturer supplied

after market reinforcing kit be

installed prior to mounting any

kind of ladder rack or truck box

on your vehicle. Kits can be

purchased from your local

vehicle dealership. Contact

your local dealer to see if your

vehicle is effected.

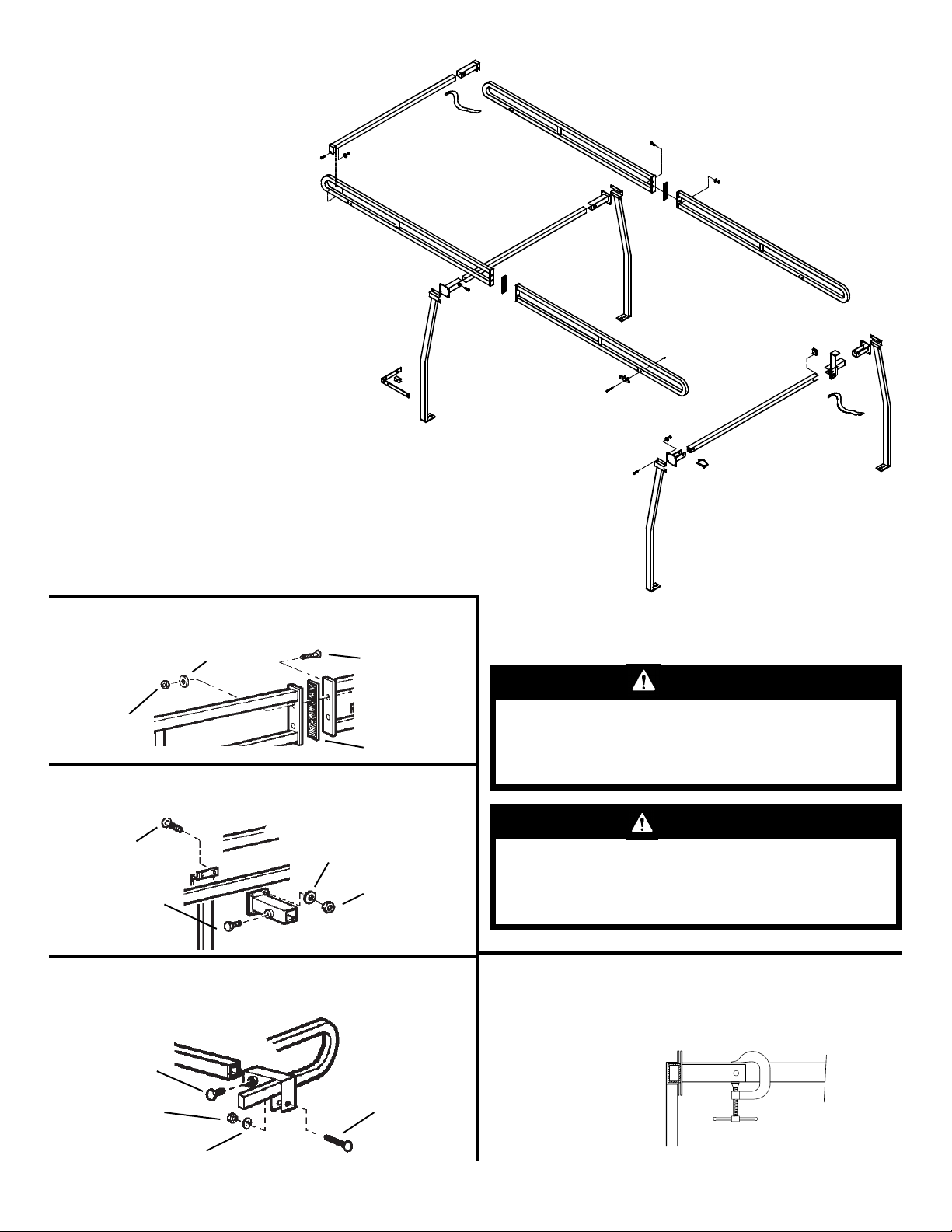

STEP 1. Bolt front and rear rail halves together (two bolts

per rail).

3/8-16

Nylon Lock

Nut

3/8" Flat

Washer

3/8-16 x 1-1/4"

Carriage Bolt

Cushion

Strip

STEP 2. Attach all legs and sockets. Do not tighten. (Four bolts

required per leg)

CAUTION

To keep debris out of your eyes when checking

the underside of the vehicle, or when drilling,

always wear protective eyewear.

5/16" Flat

5/16-18 x 3/4"

Carriage Bolt

3/8-16 x 3/4" Hex

Head Thread

Cutting Bolt

Washer

5/16-18 Nylon

Lock Nut

STEP 3. Assemble front crossmember.

Turn crossmember upside down for clearance on king cabs.

3/8-16 x 3/4"

Thread

Cutting Bolt

5/16-18 Nylon

Lock Nut

5/16" Flat Washer

5/16-18 x 2"

Carriage Bolt

CAUTION

Never load your rack to exceed the safe rated

capacity of your vehicle. Heavy loads carried

high can dangerously alter the center of gravity.

STEP 4. Check width of rack and truck bed. If rack is nar-

rower, clamp rear crossmember in rear open sockets temporarily,

but DO NOT drill, proceed to Step 5. If the rack is too wide, remove rear cross-member and cut to fit. Note - Double check all

measurements before cutting.

2

Page 3

WARNING

All floor mounting bolts near the gas tank area

should be installed from the underside of the vehicle, to guard against the gas tank being punctured in the event of a collision. This would mean

not using Blind Fasteners in this area.

WARNING

Prior to drilling, so as not to cut or puncture fuel

tanks, fuel lines, brake lines, electric wires, etc.,

check under vehicle for locations.

STEP 5. If the manufacturers reinforcing kit is not required on

your vehicle, install two Bed Reinforcing Brackets.

See Blind Fastener instructions for installation.

1/2" Hole

5/16-18

Blind Fastener

5/16" Flat

Washer

5/16" Lock Washer

5/16" Lock

Washer

Install this

bolt when using

Step 7 Option

5/16-18 x 1-1/4"

Hex Head Bolt

3/8" Hole

STEP 6. Rear leg installation.

For maximum strength, the rear legs must be bolted to the tailgate

stops (as shown).

A) Before drilling leg mounting holes, use a framing square to insure accuracy of alignment.

B) Fasten leg to floor and leg to side.

STEP 7. Front leg installation.

(See STEP 7. Option for installation due to obstructions in the bed

floor.)

5/16-18 x 2"

Hex Hd. Bolt

3/8" Hole

5/16" Lock

Washer

5/16-18 x 1-1/4"

Hex Hd. Bolt

5/16" Lock

Washer

1/2" Hole

2" Dia. Leg

Washer

5/16-18 Blind

Fastener

5/16" Flat Washer

5/16-18 x 2"

Hex Hd. Bolt

5/16-18 x 1-1/4"

Hex Hd. Bolt

5/16" Lock

Washer

5/16" Flat Washer

1/2" Hole

2" Dia. Leg Washer

1/2" Hole

5/16-18 Blind

Fastener

STEP 7. Option - Front Leg Spacers are provided.

3/8" Hole

Front Leg

Spacer

5/16-18

Nylon

Lock Nut

5/16" Flat

Washer

3/8" Holes

5/16-18 x 2-3/4"

Hex Hd. Bolt

2" Dia. Leg

Washer

STEP 8. Tightening fasteners.

Tighten all nuts and bolts in the following order:

First - leg bolts. Tighten evenly so crossmember sleeves stay

parallel. (Start with rear legs)

Second - top of legs to rails, center and rear. Make sure bolts

are evenly tightened.

Third - crossmembers (center and front only).

STEP 10. Tie Downs.

Install four Tie Downs where desired. We suggest putting

sealant on the back of the tie downs and under nuts before

installing.

10-24 Nylon

Lock Nut

Tie Down

10-24 x 2-3/4"

Flat Head Screw

STEP 9. Rear Crossmember.

Drill a 3/8" hole through the

sleeve and crossmember to

accept the insertion of the

Latch Pin. The wire loop of

the latch pin swings around

the sleeve and over the end

of the pin.

STEP 11. Ladder Stop.

Remove rear Crossmember and slide Ladder

Stop onto it. Install Crossmember on rack. With a Ladder on the

rack, locate the Ladder Stop inside

of the ladder and then secure. Insert a

strap through the loop on the Ladder

Stop and on the front Crossmember

Socket. Refer to the warning decal on

the Ladder Stop.

3/8-16 x 3/4"

Thread Cutting

Bolt

3

Square

Cap

Plug

Latch

Pin

Strap

Page 4

STEP 12. Sealant.

Seal all nuts, bolts, and crossmember to

sleeve seam with sealant.

WARRANTY WILL BE VOID IF

SEALANT IS NOT APPLIED TO

ALL SEAMS AND CREVICES

INSTALLATION PROCEDURE USING BLIND FASTENERS

WARNING

Black

Prior to drilling, so as not to

cut or puncture fuel tanks,

fuel lines, brake lines, electric

wires, etc., check under vehicle for locations.

Oxide

Bolt

Flat

Washer

WARNING

Ladders must be secured per

ANSI standard A142.2-1990 paragraph 8.4.4. Ladder damage will

occur from road shock and vehicle vibration if the ladder is not

properly secured to the ladder

rack. Bouncing and side to side

motion of a improperly secured

ladder will cause wear and

weaken the ladder. Using a damaged ladder could lead to a structural collapse and could result in

a serious injury or death.

Place a drop of oil on the black oxide bolt

before assembling as shown on right. Place

the Blind Fastener in the hole and use a

1/2 or 7/16 wrench to tighten black hex

bolt until the blind fastener is fully seated.

When setting black hex bolt, it will start out

hard. As the Blind Fastener bulbs out it

will get easier, until it bottoms out or sets.

Make sure the Blind Fastener and Installation Tool do not turn during installation.

10-24

Nylon Lock Nuts

5/16

3/8

9/16

Wrench

Installation

Tool

Blind

Fastener

Bolt Size Chart

WEATHER GUARD® PRODUCT

REFINISHING PROCEDURES

All WEATHER GUARD® products are finished

with a polyester powder coating, and it is important to follow these procedures to get

proper adhesion. As Knaack LLC cannot

control the finishing of the prod-ucts, the

warranty for WEATHER GUARD®

products on paint is not applicable on refinished products.

1. Sand the surface to be painted with 180-200

grit sand paper to rough up the surface. This

should be followed by wet sanding with a 400

grit wet or dry paper.

2. Wipe down the sanded surface with ketone

based thinner. This removes the dust and softens the powder coating for better paint adhesion.

3. Wipe sanded area with a tack rag to remove

loose dust and particles before painting.

NOTE: Do not use a lacquer over the

powder coating

10-24 x 2-3/4"

F.H. Screw

5/16-18 x 2"

Hex Hd. Bolt

5/16-18 x 2"

Carriage Bolt

5/16-18 x 2-3/4"

Hex Hd. Bolt

5/16-18 x 1-1/4"

Hex Hd. Bolt

3/8-16 x 1-1/4"

Carriage Bolt

5/16-18 x 3/4"

Carriage Bolt

3/8-16 x 3/4"

Bolt, Thd. Cut

- NOTICE -

Any modification or unintended use of this product shall immediately void all manufacturers warranties. Manufacturer disclaims all

liability for injuries to persons or property resulting from any modification to, or unintended use of this product.

If you have any questions, please give us a call. Call Toll Free 1-800-456-7865

WEATHER GUARD® products are protected by one or more of the following patents or trademarks:

U.S. - 4509787, 842268, 1661625, 1663369, 2228051, 2434963; Canada - 1218968, 282725; U.K. - 1400720; NZ - 296049; Aus.- 761964

KNAACK LLC

420 E. TERRA COTTA AVENUE - CRYSTAL LAKE, ILLINOIS, USA 60014 - 815-459-6020

© 2002 Knaack LLC

4

Part No. 24-0132 REV. B ECN 5315 05/13

Loading...

Loading...