Page 1

INSTALLATION MANUAL

MODEL 1200 FULL SIZE TRUCK

MODEL 1205 COMPACT SIZE TRUCK

- ATTENTION -

Read and understand all instructions and warnings before installing and using this

product. Confirm contents of the shipping carton with the "Parts Identification" page

before beginning installation. If a part is missing, or if you have any questions,

please call WEATHER GUARD

® customer service at 1-800-456-7865.

WARNING

This product is only intended for, and only safe for, transporting ladders, lumber,

pipe and other similar materials. It is the responsibility of the user to secure these

materials to the rack before transporting. Any modifications made to this product,

or use of this product for any other purpose than its intended use, could create a

hazardous condition that can cause serious personal injury or property damage.

Ladders must be secured per ANSI standard A142.2-1990 paragraph 8.4.4. Ladder

damage will occur from road shock and vehicle vibration if the ladder is not properly

secured to the ladder rack. Bouncing and side to side motion of a improperly

secured ladder will cause wear and weaken the ladder. Using a damaged ladder

could lead to a structural collapse and could result in a serious injury or death.

- NOTICE -

Any modification or unintended use of this product shall immediately void all

manufacturers warranties. Manufacturer disclaims all liability for injuries to persons

or property resulting from any modification to, or unintended use of this product.

Some vehicle manufacturers require a reinforcing kit, available through the vehicle

dealership, to be installed on the truck bed prior to mounting any kind of rack or tool

box. Contact your dealership to see if your vehicle requires a reinforcing kit before

installation.

Load capacity: Up to 800 lbs. evenly distributed.

Approximate Assembly and Installation Time:

60 min. (1 hr.) depending on truck equipment installation experience.

This LIMITED WARRANTY is madebyKnaackManufacturingCompany, 420 E. TerraCottaAve.,Crystal

Lake,Illinois to theoriginalretailpurchaserofKNAACK

KNAACKMANUFACTURING COMPANY WARRANTS THAT KNAACKOR WEATHER GUARD

EQUIPMENT WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP FOR A PERIOD OF

TWO (2)YEARS FROM DATE OF PURCHASE BY THE ORIGINAL RE TAIL PURCHASER.

If, beforetheexpirationoftheWarrantyperiod,purchaserdiscoversthattheKNAACKor

WEATHER GUARDEquipmentfails to fulfill theWarranty, purchasershall contactKnaackManufacturing

Companytomakearrangementsfor aninspectionof theproduct. If KnaackMfg.Co.determinesa

defectexists, KnaackMfg.Co.shall, atits optionandexpense,repairor replaceanydefectivepart.

All Warrantyrepairsshall bemadebyan authorizedKNAACKEquipmentdealeror KnaackMfg.Co.

approvedservicecompany.

This Warrantyshall notapplyif theKNAACK or WEATHER GUARD Equipmenthasbeensubjectedto

misuse, abnormalserviceor handling,impropermaintenance,or alterationsmadeby anyoneotherthan

aKNAACKor WEAT HER GUARD Equipmentdealeror aKnaackMfg.Co.approvedservicecompany.

THE WARRANTY PRINTED ABOVE IS THE ONLY WARRANTY APPLICABLE TO THIS PURCHASE.

ALL OTHER WARRANTIES, EXPRESS ORIMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY ANDFITNESS FOR A PARTICULAR PURPOSE ARE HEREBY

DISCLAIMED.

KNAACKMANUFACTURING COMPANY SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGESARISING OUT OF ANY BREACH OF THIS WARRANTY. NOR SHALL

THE DAMAGESEXCEED THE RETURN AMOUNT OF THE PURCHASE PRICE PAID BY THE ORIGINAL

PURCHASER.

This Warrantyis in lieu of all Warrantiesexpress or implied.The terms of this Warrantyshallnotbe

modifiedby anyparty, their successors or assigns. This Warrantygives youspecificlegalrights, and

youmayalso haveotherrights whichvaryfromstatetostate.

LIMITED WARRANTY

or WEATHER GUARD Equipmentproducts.

CAUTION

Never load your rack to exceed the safe capacity of your vehicle. Heavy loads when

carried high can dangerously alter the center of gravity of your vehicle. Consult your

vehicle owners manual for specifications on load ratings and recommendations

from the vehicle manufacturer regarding installation of aftermarket racks and tool

boxes.

420 E. TERRA COTTA AVENUE, CRYSTAL LAKE, ILLINOIS, USA 60014

KNAACK MANUFACTURING COMPANY

815-459-6020, info@knaack.com

© 2003 Knaack Manufacturing Company

Part No. 24-0154 Rev. 11/03

BED LINER NOTE

The Model 1200 and 1205 are design to be installed on a truck bed without a

traditional plastic bed liner. Installation is possible with minimal trimming with

an under-the-rail plastic bed liner. Excessive trimming will be required with an

over-the-rail plastic bed liner. Spray-On bed liners do not interfere with the installation of the Model 1200 or 1205.

WEATHER GUARD® products are protected by one or more of the following patents or trademarks:

U.S. - 4509787, 842268, 1661625, 1663369, 2228051, 2434963; U.K. - 1400720; NZ - 296049;

Aus. - 761964; Canada - 1218968, 282725.

Page 1 of 8

Page 2

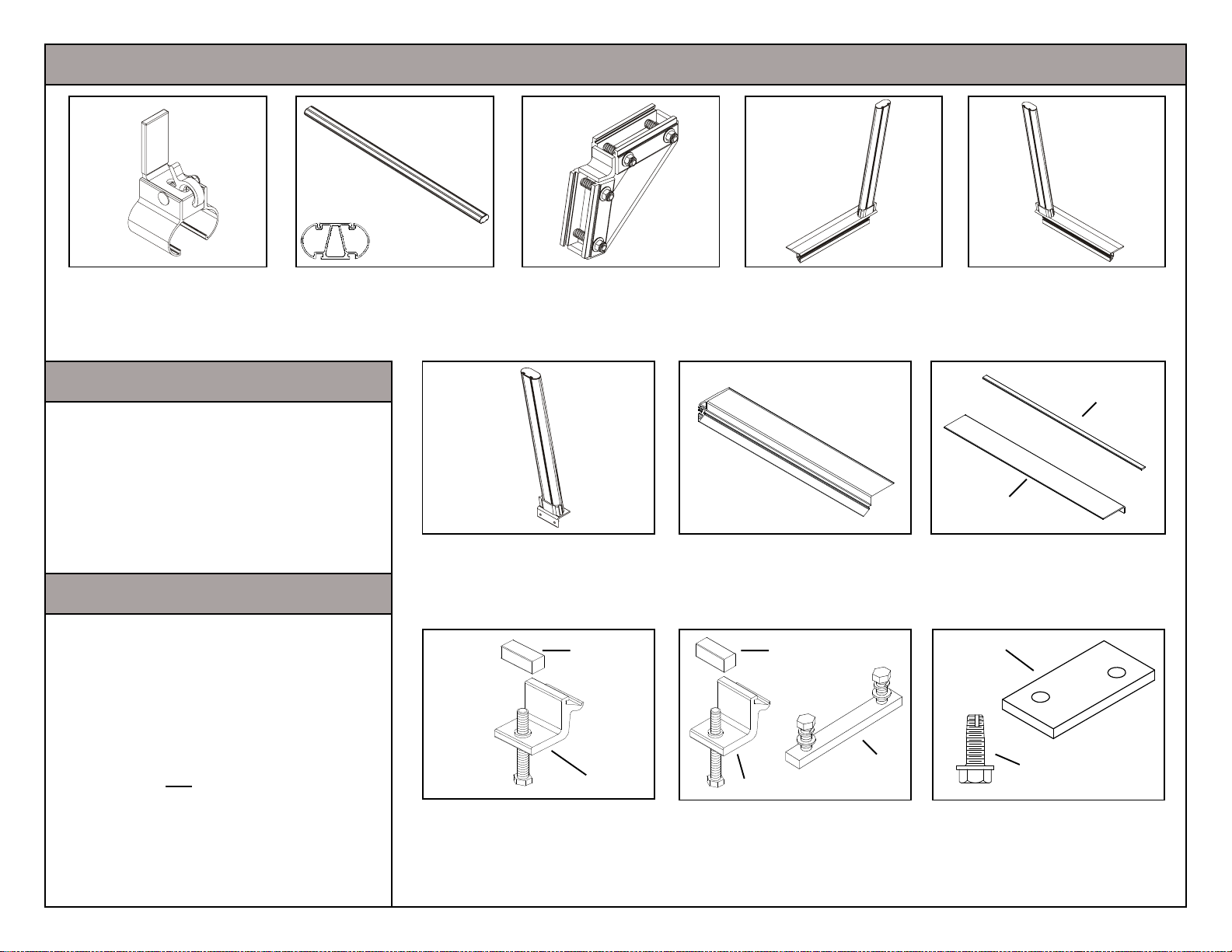

PART IDENTIFICATION & REPLACEMENT PART NUMBERS

Cross

Section

Part A (Qty. 4)

Universal

Ladder Stop

Replacement Part #7611

Part B (Qty. 2)

Cross Member

Replacement Part #7608

TOOLS REQUIRED

3/8" Drive Ratchet

3/8" Drive Socket 1/2" Deep Well

3/8" Drive Socket 9/16"

3/8" Drive Torque Wrench (foot lbs.)

Utility Knife

Masking Tape

Tape Measure

FIT-UP

Product fit-up is based on vehicle design

available at the revision date of this installation manual. The ATR

TM

is designed for a variety of bed lengths and

cab designs on most pickup trucks.

Part C (Qty. 4)

Universal

Triangle Bracket

Replacement Part #7622

Part F (Qty. 2)

Universal

Rear Leg

Replacement Part #7610

Part K

Part D (Qty. 1)

Driver Side

Front Leg

Replacement Part #7605

Part G (Qty. 2)

Universal

Rear Mounting Rail

Replacement Part #7607

Part K

Part E (Qty. 1)

Passenger Side

Front Leg

Replacement Part #7606

Part I

Part H

Mounting Pad & Wedge Kit

Part H - Mounting Pad (Qty. 4)

Part I - Mounting Wedge (Qty. 2)

Replacement Part #7609

Part M

The ATR

TM

is not recommended on the

following vehicles:

GMC Sonoma Crew Cab 4.5 Bed

Chevy S-10 Crew Cab 4.5 Bed

Toyota Tacoma

Page 2 of 8

Part J

Front Assembly Hardware Kit

Part J - Clamp Assembly (Qty. 4)

Part K - Clamp Block (Qty. 4)

Replacement Part #7612

Part L

Part J

Rear Assembly Hardware Kit

Part J - Clamp Assembly (Qty. 4)

Part K - Clamp Block (Qty. 4)

Part L - Mounting Bar (Qty. 2)

Replacement Part Number #7615

Part N

Tool Box Mounting Kit (May not use)

Part M - Shim (Qty. 4)

Part N - 5/16-18 x 3/4"

Self Tapping Bolt (Qty. 4)

Replacement Part #7616

Page 3

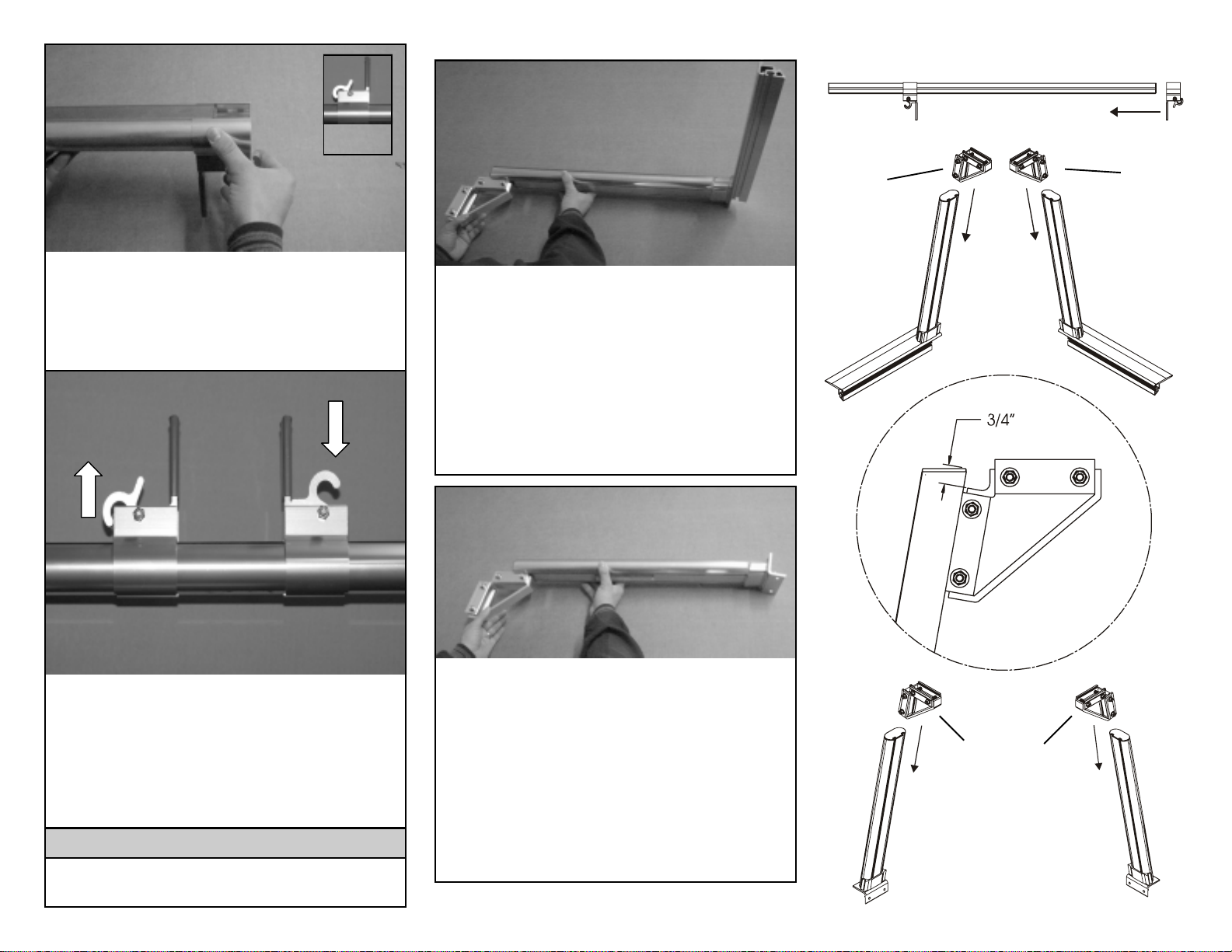

STEP ONE

STEP

PART B

Unlocked

Position

Holding the ladder stops, Part A, upside

down and in the unlocked position, slide

them onto each end of the cross member,

Part B. Repeat the process for the other

cross member.

STEP TWO

To Lock

To Unlock

THREE

Slide the triangle brackets, Part C, into the

driver side front leg, Part D, and passenger side front leg, Part E, from the top.

The 5/16-18 nuts are to face towards the

rail side of the leg. Using the triangle dimension diagram to the right as a guide,

position the triangle brackets 3/4" from the

top of the leg. Tighten the 5/16-18 fasteners to 15 foot pounds of torque.

STEP FOUR

PART A

5/16-18

PART C

Nuts

Face

towards

rail side

PART D PART E

Rail Side

PART C

5/16-18

Nuts

Face

towards

rail side

Rail Side

Unlocked

Position

Locked

Position

The ladder stops are designed to slide the

entire length of the cross member. Once

in the desired location, lock ladder stops

in place by lifting up on the lever. To unlock, push down on the lever. For purpose

of installation position them two feet from

either end.

IMPORTANT!

Do not operate vehicle with ladder

stops in the unlocked position.

Slide the triangle brackets, Part C, into

each of the universal rear legs, Part F, from

the top. Create a driver side and passenger side rear leg by facing the 5/16-18 nuts

one direction on a leg and the other direction on the other. Using the triangle dimension diagram to the right as a guide,

position the triangle brackets 3/4" from the

top of the leg. Tighten the 5/16-18 fasteners to 15 foot pounds of torque.

PART C

PART F

Drivers

Side

Triangle

Dimension

Diagram

PART C

5/16-18 nuts

face in one

direction

PART F

Passenger

Side

Page 3 of 8

Page 4

STEP

FIVE

Work on level

ground.

Place the cross member assembly, Part B,

on its side with the WEATHER GUARD

Product logo facing down. Insert the driver

and passenger side front leg assemblies,

Parts D & E, into the cross member assembly by sliding them in from both ends.

®

PART F

PART B

PART D

PART B

PART E

Now place the second cross member assembly, Part B, on its side with the

WEATHER GUARD

® Product logo facing

up. Insert the two universal rear leg assemblies, Part F, with the 5/16-18 nuts facing

up, into the cross member assembly by

sliding them in from both ends.

STEP SIX

Work on level

ground.

Using a torque wrench tighten the 5/16-18

fasteners to 15 foot pounds at the dimension shown in the chart to the right. Column A is for the front assembly and

column B is for the rear assembly.

Page 4 of 8

PART F

REAR ASSEMBLY

ATR MODEL1200

FULLSIZE TRUCKS

VEHICLE DIMENSION CHART

All GM Sierra/Chevy Silverado Trucks 5.50" 6.25"

All Dodge Ram Trucks 4.75" 6.25"

All Ford F-150 (2003 & 2004) Trucks 6.25" 6.00"

All Ford F-250 & F350 Trucks 5.00" 5.50"

Toyota Tundra 8’ Bed 6.50" 6.50"

Toyota Tundra 6.25" Bed 6.75" 6.75"

ATR MODEL 1205

CO MPACT SIZE TRUCKS

VEHICLE DIMENSION CHART

All GM Sonoma/Chevy S-10 Trucks 3.00" 6.25"

All Dodge Dokota Trucks 2.75" 2.75"

All Ford Ranger Trucks 4.25" 4.50"

DIMENSION A

FRO N T

ASSEMBLY

DIMENSION A

FRO NT

ASSEMBLY

DIMENSION A

REAR

ASS EMB LY

DIM ENSION A

REAR

ASSEMBLY

FRONT ASSEMBLY

"A"

Both ends of cross

member

NOTE: If your vehicle is not

shown in the chart, adjust the

rack on the ground and test fit it

on the truck bed until you reach

a snug fit between the bed

rails.

Page 5

STEP

SEVEN

1/8"

Place mounting pads, Part H, on top of

the truck bed rails. Cut the notch into the

mounting pad. Place the front assembly,

from Step Six, onto the truck with the

notched ends approximately 1/8" from the

front of the truck bed.

NOTE: Some truck beds will not allow

the notch to travel all the way forward.

STEP

EIGHT

Place clamp block, Part K, on the

threaded end of the clamp assembly,

Part J. The clamp block has an offset

hole. The thick side should face in towards the clamp. Use the thin side if

extra clearance is needed.

PART H

PART K

STEP NINE

Sliding the clamp assembly, Part J, into

the front assembly, place them as far away

from each other and as close to the ends

of the mounting rails as possible. Clamps

can not be more than 9.5" from either end

of the mounting rail. Clamp blocks, Part

K, are to be flush with the steel underside

of the bed rail. Using a torque wrench,

tighten the 3/8-16 fasteners in the clamp

assembly to 10 foot pounds.

PART J

IMPORTANT!

Clamps can not be

more than 9.5" from

either end of the

mounting rail.

STEP NINE NOTE: For Ford F250/

350 and some Dodge Dakota vehicles

place the front assembly 3" from front

of truck bed. Hold the clamp assembly, Part J, in place and slide the

mounting rail into the clamp until it is

1/8" from the front of the truck.

Page 5 of 8

Page 6

Mounting Wedge Location

Must be level

on both axis.

STEP TEN

With the tailgate closed place the

mounting pads, Part H, on top of the truck

bed rails. Tape in place the mounting

wedge, Part I, on top of the mounting pad

using the diagram to the right as a guide.

Set the rear mounting rail, Part G, on top

of the wedge and pad 1/8" from the closed

tail gate.

Wedge locations are

approximate. Make

All Chevy/GM

Dodge Ram

Ford F150 2003

Ford Ranger

Ford 250 / 350

No Wedge Necessary for the following vehicles:

Ford 150 2004 Toyota Tundra

Dodge Dakota

adjustments to ensure mounting rail,

Part G, is level on

both axis when

clamped to top of bed

rail.

Must be level

on both axis.

PART K

PART J

PART G

PART I

PART H

IMPORTANT!

Clamps can not be

more than 9.5" from

either end of the

mounting rail.

STEP

ELEVEN

Sliding the assembly clamps, Part J, into

the rear mounting rail, Part G, place them

as far away from each other and as close

to the ends of the mounting rails as possible. Clamps can not be more than 9.5"

from the ends of the mounting rails.

Clamp blocks, Part K, are to be flush with

the steel underside of the bed rail. Using a

torque wrench, tighten the 3/8-16 fasteners in the clamps to 10 foot pounds.

Page 6 of 8

Close Tailgate

for Steps 6 & 7

Page 7

STEP

TWELVE

PART L

IMPORTANT!

Before operating vehicle check to ensure the 3/8" bolts in the clamp assembly, Part J, are set to a torque

rating of 10 foot pounds and all the

5/16" fasteners are set to a torque rating of 15 foot pounds.

Disassemble the mounting bar, Part L, from

the rear assembly hardware kit and reassemble on the rear leg assembly, from Step

Six. Repeat process for other rear leg.

STEP

THIRTEEN

With the tailgate open, slide the rear cross

member assembly, from Step Six, into the

mounting rail channels with the logo facing

towards the rear. The driver side and passenger side need to slide into the mounting rail at the same time in order to avoid

binding. Legs can be placed at any location along the mounting rail. Using a

torque wrench, tighten the four 5/16" hex

head bolts to 15 foot pounds.

At the end of the first week of use

check all fasteners for proper tightness and then every three months

there after.

now complete.

ONLY OPERATE VEHICLE WITH OR WITHOUT

ENTIRE REAR CROSS MEMBER ASSEMBLY.

Installation is

DO NOT OPERATE VEHICLE

WITH OUT THE REAR

CROSS MEMBER

NOTE: Due to the taper of some truck

beds, it may be necessary to shorten the

distance between the legs as you slide the

assembly towards the front of the vehicle.

Page 7 of 8

Page 8

Tool Box Mounting Procedure

If a bed rail mounted tool box is to be installed with the Model 1200 or 1205, use

the 1/4" thick shims, Part M, that are provided in the tool box mounting hardware

TM

kit (came with the ATR

) a lon g wi th the

"J" bolts (supplied with the tool box). This

will insure a level mounting of the tool box

on the truck bed rails.

Where the mounting rails (Parts D, E, & F)

obstruct the use of a "J" Bolt, use a 5/1618 x 3/4" self-tapping bolt, Part N, in its

place which is supplied in the tool box

mounting hardware kit that came with the

TM

ATR

.

Place the tool box in the desired location

on the truck and trace the mounting slot in

the bottom of the tool box directly onto the

mounting rail.

Drill 1/4" Dia. Hole

3/4"

Part N

5/16-18 x 3/4"

Self Tapping Bolt

Ladder Rack

Fasteners

Supplied

with Box

Move the tool box out of the way and drill a

1/4" dia. hole 3/4" from the inside edge of

the mounting rail. (See diagram)

Reset the tool box in the desired position

and install the 5/16-18 x 3/4" self tapping

bolt and fender washer. The fender

washer came with the "J" bolts. If needed,

use the 1/4" shims, Part M, to level the tool

box on the truck.

IMPORTANT!

Do not overtighten the

self-tapping bolts.

Page 8 of 8

See Drilling Detail Above

Part M

1/4" Shim

Shim Pad

(Cut from the

tool box

mounting pad)

"J" Bolt

Supplied

with Box

Loading...

Loading...