Page 1

Series

WE33

3-Way Tri-Clamp Stainless Steel Ball Valve

Cavity Filled, Electric and Pneumatic Actuators

he pneumatic double acting actuator uses

T

n air supply t o drive the valve open and

a

losed. The actuator has two supply ports,

c

with one driving the valve open and the

other driving the valve closed. Spring

return pneumatic actuators use the air

upply to open the valve, and internally

s

oaded springs return the valve to the

l

losed position. Also available is the SN

c

olenoid valve to electrically switch the air

s

supply pressure between the air supply

ports for opening and closing the valve.

Actuators are constructed of anodized and

poxy coated aluminum for years of

e

orrosion free service.

c

FEATURES

• Capable of being configured to fit any

application

• Limit switches can be mounted to

anual valves for remote monitoring

m

Cavity filled valve for sanitary

•

pplications

a

WE33-DHD00-T2

E33-ESR03-T1-NN07

W

he Series WE33 incorporates a full port

T

-way tri-clamp SS ball valve for great flow

3

ates with minimal pressure drop. The

r

alve features a blowout-proof stem for

v

added safety, reinforced PTFE seats and

seals for longer life, and a 316 SS (ASTM

CF8M) ball for better performance.

ctuators are direct mounted creating a

A

ompact assembly for tight spaces. Limit

c

witches are able to be mounted directly to

s

the valves allowing for remote position

indication.

The Ser ies WE33 can be configured with

either an electric or pneumatic actuator.

lectric actuators are available in

E

eatherproof or explosion-proof, a variety

w

f supply voltages and two-position or

o

modulating control. Two-position actuators

use the supply volt age to drive the valve

open or close, while the modulating

actuator accepts a 4 to 20 mA input for

alve positioning. Actuators feature

v

hermal overload protection and

t

ermanently lubricated gear train.

p

SPECIFICATIONS

VALVE

Service: Compatible liquids and gases.

Body: 3-way.

Line Sizes: 1/2 to 2˝.

End Connections: Tri-clamp ends.

Pressure Limits: 20˝ Hg to 1000 psi

WE33-DDA01-L1-AA06

VALVES

WE33-DTD01-T3-A

Automated Valve

WE33-DTI01-T2-A

(-0.7 to 69 bar).

Wetted Materials:

Body and ball: 316 SS (CF8M);

Stem: 316 SS;

Seat: RTFE/PTFE;

Seal, Washer, and Packing: PTFE.

Temperature Limits: -20 to 392°F

(-29 to 200°C).

Other Materials:

O-ring: Fluoroelastomer;

Handle: 304 SS;

Washer: 301 SS;

Stem Nut, Locking Device,

Gland Ring: 304 SS;

Handle Sleeve: PVC.

ACTUATORS

Pneumatic “DA” and “SR” Series

Type: DA series is double acting and

SR series is spring return (rack and

pinion).

Normal Supply Pressure:

DA: 40 to 115 psi (2.7 to 7.9 bar);

SR: 80 psi (5.5 bar).

Maximum Supply Pressure: 120 psi

(8.6 bar).

Air Connections:

DA01: 1/8˝ female NPT;

DA02 to DA03: 1/4˝ female NPT;

SR02 to SR04: 1/4˝ female NPT.

Housing Material: Anodized aluminum

body and epoxy coated aluminum end

caps.

Temperature Limits: -40 to 176°F

(-40 to 80°C).

Accessory Mounting: NAMUR

standard.

Electric “TD” and “MD” Series

Power Requirements: 110 VAC,

220 VAC, 24 VAC or 24 VDC (MD

models not available in 24 VDC).

Power Consumption: See manual.

Cycle Time (per 90°):

TD01: 4 s;

MD01: 10 s;

TD02 and MD02: 20 s.

Duty Rating: 85%.

Enclosure Rating: NEMA 4X (IP67).

Housing Material: Powder coated

aluminum.

Temperature Limits: -22 to 140°F

(-30 to 60°C).

Electrical Connection: 1/2˝ female

NPT.

Modulating Input: 4 to 20 mA.

Standard Features: Manual override,

position indicator, and TD models come

with two limit switches.

Electric “TI” and “MI” Series

Power Requirements: 110 VAC,

220 VAC, 24 VAC or 24 VDC.

Power Consumption: See manual.

Cycle Time (per 90°):

TI01 and MI01: 2.5 s;

TI02 and MI02: 5 s;

TI03 and MI03: 5 s.

Duty Rating:

Two-Position: TI01-TI03: 25%;

Modulating: MI01-MI03: 75%.

Enclosure Rating: NEMA 7

Housing Material: Powder coated

aluminum.

Temperature Limits: -40 to 140°F

(-40 to 60°C).

Electrical Connection: 1/2˝ female

NPT.

Modulating Input: 4 to 20 mA.

Standard Features: Position indicator

and two limit switches.

.

Page 2

Popul

Si

z

1

/

2

3

/

4

1

˝

1

-

1

2

˝

W

E3

Ex

a

Se

r

Si

z

A

c

t

Va

lv

Pos

Sole

Sole

Volta

Pos

a

nd

Sw

a

e

˝

˝

/

2

˝

3

m

i

e

s

e

a

ua

e

ition

noid

noid

ge

itione

itc

r

M

ode

v

C

gal/min)

(

4.39

1

2.25

4

86.17

223.61

437.98

H

a

nd

pl

e

nd

t

or

r

he

s

l

s

pring Return

id

t

e

r

ch

ch

r

S

neumatic Model

P

E33-CSR02-T2

W

E33-DSR02-T2

W

WE33-ESR03-T2

WE33-GSR03-T2

WE33-HSR04-T2

W

Ex

Se

Si

A

Va

Pos

A

Volta

E3

3

a

m

r

i

e

z

e

c

t

ua

lv

e

ition

c

tua

ouble Acting

t

ua

t

or

W

3

1

1

/

2

3

/

4

1

˝

1

-

1

2

˝

1

/

2

3

/

4

1

˝

1

-

1

2

˝

1

/

2

3

/

4

1

˝

1

-

1

2

˝

Flo

Flo

Flo

Flo

Flo

No

NE

No

11

2

2

2

4

2

4

1

2

No

4

2

4

5

4

2

4

2

V

P

Q

V-

V

P

2

6

2

8

D

neumatic Model

P

E33-CDA01-T2

W

E33-DDA01-T2

W

WE33-EDA02-T2

WE33-GDA02-T2

WE33-HDA03-T2

M

ode

l

C

ha

E

3

3

-

C

S

R

0

2

˝

˝

˝

o

o

DC

DC

1

a

RR-

-

S

3

-

W

a

y

a

n

d

O

p

e

a

n

d

O

p

e

n

d

O

p

e

r

a

H

a

n

d

O

p

n

d

O

p

e

r

a

o

u

b

le

A

c

o

u

b

le

A

c

u

b

le

A

c

t

in

D

o

u

b

le

A

u

b

le

A

c

t

in

p

r

in

g

R

e

p

r

in

g

R

e

r

in

g

Re

t

u

S

p

r

in

g

Re

r

in

g

Re

t

u

P

a

t

h

A

P

a

t

h

B

P

a

t

h

C

P

a

t

h

D

P

a

t

h

E

le

n

o

id

4

X

NA

MUR

le

n

o

id

C

C

C

E

xp

L

imit

E

xp

P

o

-

B

ATE

X

-

I

E

I

E

CE

1

L

imit

0

1

0

1

P

o

n

d

P

1

P

D5

P

o

sit

D5

S

ma

6

0

0

A

V

A

A

5

5

˝

˝

H

/

H

˝

˝

D

/

D

˝

˝

S

/

S

w

w

w

w

w

S

MA

S

VA

V

V

n

I

S

-

E

E

2

2

p

2

p

VA

e

D0

D0

D0

D0

2

S

H

H

a

a

D

D

o

o

S

S

VA

M0

r

t

T4

-

N

N

0

7

r

a

t

e

d

r

a

t

e

d

t

e

d

e

r

a

t

e

d

t

e

d

t

in

g

t

in

g

g

c

t

in

g

g

t

u

r

n

t

u

r

n

r

n

t

u

r

n

r

n

S

o

le

n

o

S

wit

ch

sit

io

n

T

r

a

n

S

ly

r

o

smit

L

imit

S

wit

X

ch

L

imit

S

wit

wit

ch

L

imit

S

wit

x

S

wit

ch

io

n

e

r

r

t

P

o

sit

io

n

e

and Operated

H

odel

M

E33-CHD00-T2

W

E33-DHD00-T2

W

WE33-EHD00-T2

WE33-GHD00-T2

WE33-HHD00-T2

O

pe

r

a

t

e

d

a

nd

Pne

um

a

t

i

c

A

c

W

E3

3

C

SR

0

2

N

T4

0

7

W

E3

3

C

H

D

H

EH

G

H

H

H

C

D

D

D

ED

G

D

H

D

C

SR

D

SR

ESR

G

SR

H

SR

D

D

D

D

D

A0

A0

A0

A0

A0

N

0

0

0

0

0

0

0

0

0

0

1

1

2

2

3

0

2

0

2

0

3

0

3

0

4

T1

T2

T3

T4

L

1

N

A

N

A

B

C

D

E

0

0

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

a

ge

El

e

c

t

r

i

c

pl

e

W

E3

s

W

E3

nd

t

or

tor

NEMA 4X Two-

osition Electric

P

110 VAC) Model

(

E33-CTD01-T2-A

W

E33-DTD01-T2-A

W

WE33-ETD01-T2-A

WE33-GTD02-T2-A

WE33-HTD02-T2-A

A

c

t

ua

t

or

M

ode

l

3

3

D

M

C

TD

D

TD

ETD

G

TD

H

TD

C

M

D

M

EM

G

M

H

M

C

TI

D

TI

ETI0

G

TI0

H

TI0

C

M

D

M

EM

G

M

H

M

T2

B

D

0

1

0

1

0

1

0

1

0

2

0

2

D

0

1

D

0

1

D

0

1

D

0

2

D

0

2

0

1

0

1

2

2

3

I0

1

I0

1

I0

2

I0

2

I0

3

T1

T2

T3

T4

L

1

A

B

C

D

C

ha

r

t

NEMA 4X

M

(

W

W

WE33-EMD01-T2-A

WE33-GMD02-T2-A

WE33-HMD02-T2-A

W

E

3

3

-

D

MD

3

1

6

S

S

3

1

/

2

˝

N

E

MA

3

/

4

˝

N

E

MA

1

˝

N

E

MA

1

-

1

/

2

˝

N

E

2

˝

N

E

MA

1

/

2

˝

N

E

MA

3

/

4

˝

N

E

MA

1

˝

N

E

MA

1

-

1

/

2

˝

N

E

2

˝

N

E

MA

1

/

2

˝

E

x

p

T

3

/

4

˝

E

x

p

T

1

˝

E

xp

T

wo

1

-

1

/

2

˝

E

xp

2

˝

E

xp

T

wo

1

/

2

˝

E

xp

3

/

4

˝

E

xp

1

˝

E

xp

E

le

1

-

1

/

2

˝

E

xp

2

˝

E

xp

E

le

Flo

w

P

a

t

h

Flo

w

P

a

t

h

Flo

w

P

a

t

h

Flo

w

P

a

t

h

Flo

w

P

a

t

h

11

0

VA

C

2

2

0

VA

C

2

4

VA

C

2

4

V

DC

odulating Electric

110 VAC) Model

E33-CMD01-T2-A

E33-DMD01-T2-A

0

1

-

T2

-

B

-

W

a

y

4

X

T

w

o

P

o

s

it

T

w

o

P

o

s

it

w

o

P

o

s

it

io

X

T

w

o

P

o

w

o

P

o

s

it

io

Mo

d

u

la

t

in

Mo

d

u

la

t

in

d

u

la

t

in

g

X

Mo

d

u

la

d

u

la

t

in

g

o

s

it

io

n

o

s

it

io

n

sit

io

n

P

o

sit

io

n

sit

io

n

r

ic

Mo

d

u

la

r

ic

Mo

d

u

la

Mo

d

u

la

t

in

ct

r

ic

Mo

d

u

Mo

d

u

la

t

in

4

MA

4

4

MA

4

E

E

4

X

X

T

4

X

T

4

X

4

X

X

Mo

4

X

Mo

w

o

P

w

o

P

P

o

T

wo

P

o

le

ct

le

ct

ct

r

ic

E

le

ct

r

ic

A

B

C

D

E

io

n

io

n

n

s

it

io

n

n

g

g

t

in

g

t

in

g

t

in

g

g

la

t

in

g

g

VALVES

ACCESSORIES

R2-2120, Air Regulator

AFR2-2, Instrument Air Filter Regulator

VB-01, Volume Booster

Valves, Ball, Automated

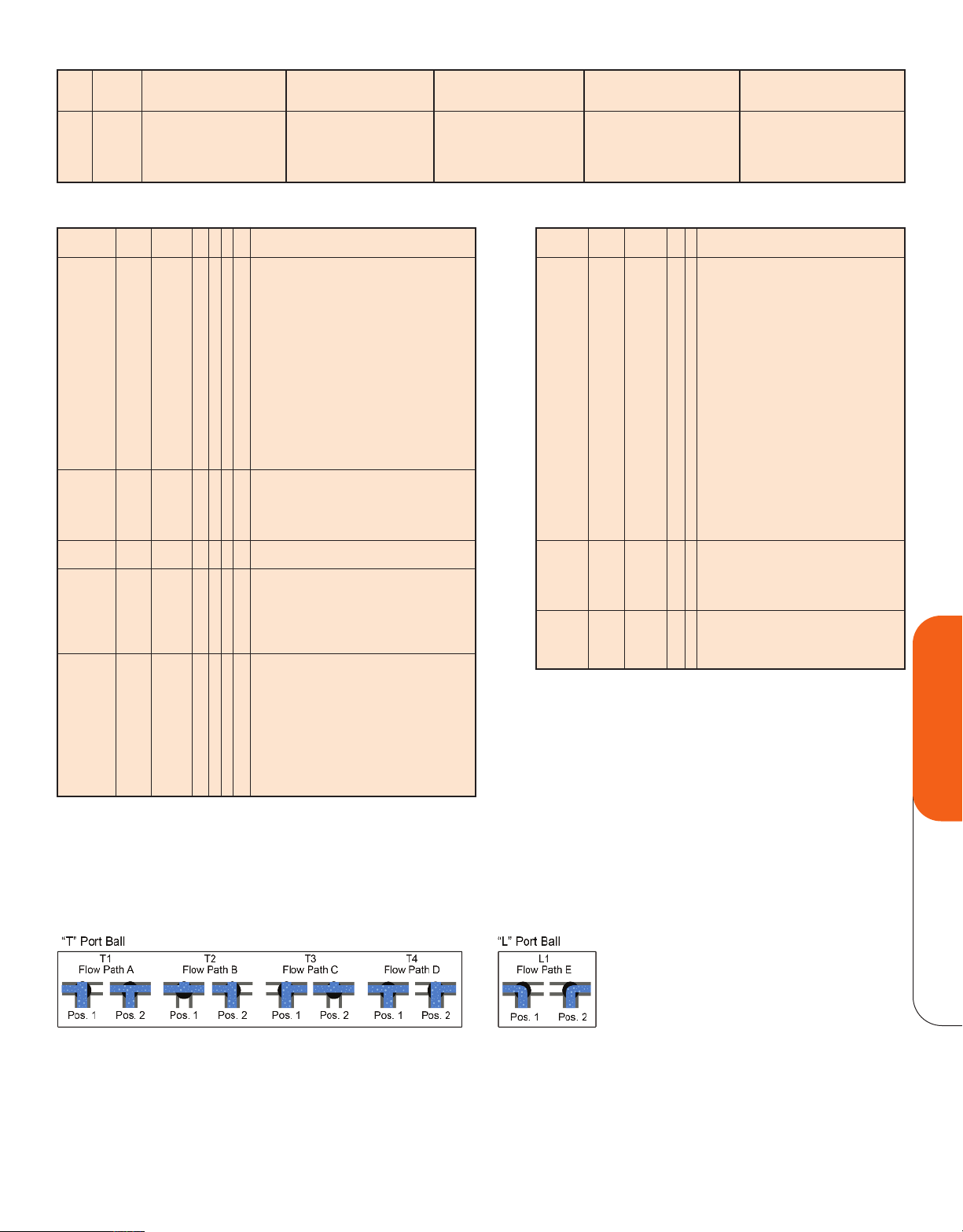

Flow Paths

Loading...

Loading...