Page 1

Bulletin F-76-SSV

TM

C

A

B

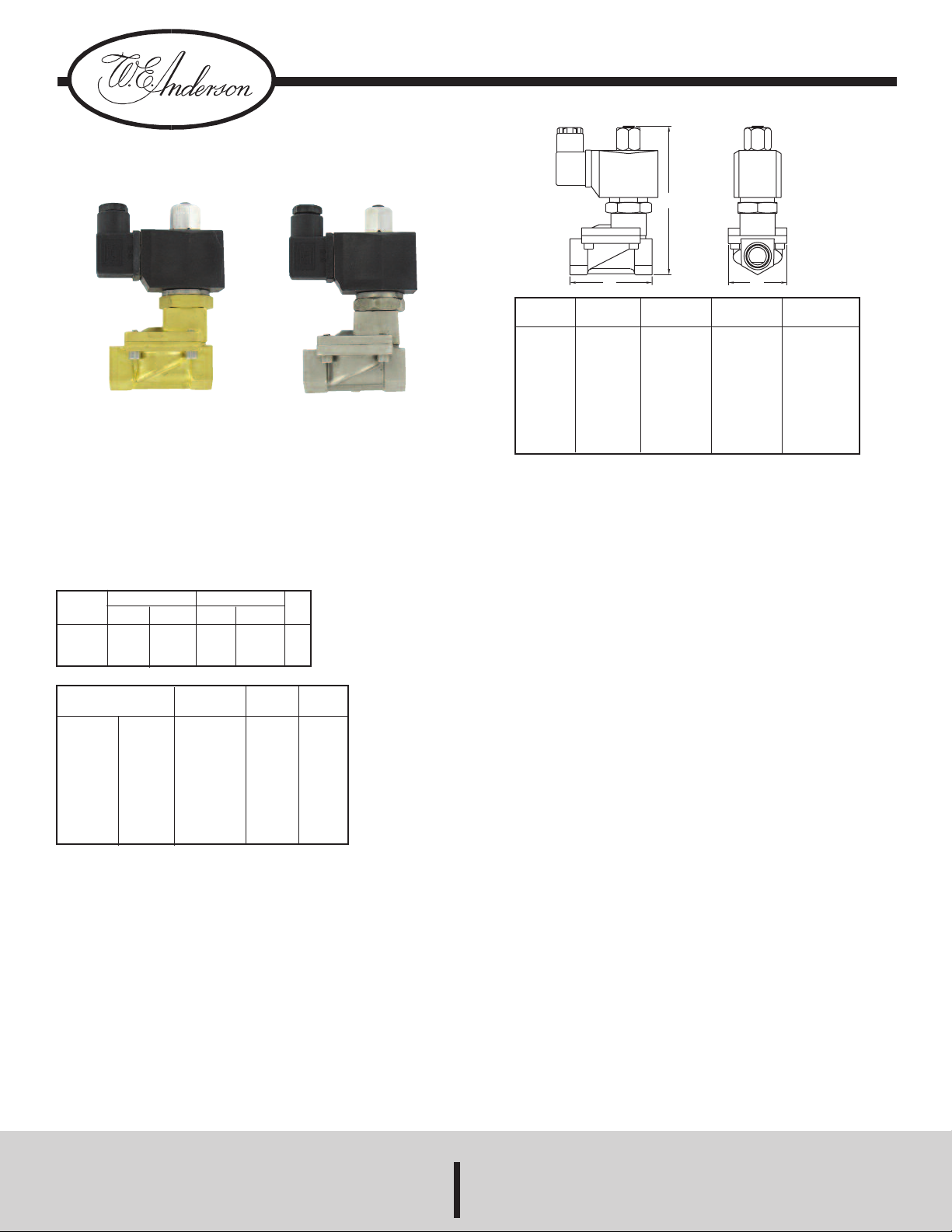

Series SSV Solenoid Valves

Specifications - Installation and Operating Instructions

SSV-B SSV-S

Series SSV Solenoid Valves are compact, general-service, two-way guide type

solenoid valves for air, gas, water, and other liquid applications. They are available

n brass and stainless steel with a normally open design and can be oriented in any

i

osition. The solenoid enclosure provides protection against dust, while also

p

rotecting against seepage of oil and non-corrosive coolants. The Series SSV have

p

a maximum process temperature of 248°F (120°C). The series offers a wide range

of valve sizes and flow ranges, with connection sizes from 1/8˝ to 2˝ NPT and

orifices from 3 mm to 50 mm.

50 Hz (VA)

Voltage

220 VAC

110 VAC

24 VDC

Model

SSV-B1N1

SSV-B2N1

SSV-B3N1

SSV-B4N1

SSV-B5N1

SSV-B6N1

SSV-B7N1

SSV-B8N1

SSV-B9N1

Note: Add -BSPP to the end of the model number for

female BSPP end connections.

Inrush

82

82

-

SSV-S1F1

SSV-S2F1

SSV-S3F1

SSV-S4F1

SSV-S5F1

SSV-S6F1

SSV-S7F1

SSV-S8F1

SSV-S9F1

Holding

33

33

-

60 Hz (VA)

Inrush

82

82

-

Connection,

NPT

1/8˝

1/4˝

3/8˝

1/2˝

3/4˝

1˝

1-1/4˝

1-1/2˝

2˝

Holding

28

28

-

Orifice

in (mm)

0.12 (3)

0.12 (3)

0.51 (13)

0.51 (13)

0.79 (20)

0.98 (25)

1.38 (35)

1.57 (40)

1.97 (50)

DC

(W)

-

32

Voltage

110 VAC

110 VAC

110 VAC

110 VAC

110 VAC

110 VAC

110 VAC

110 VAC

110 VAC

odel

M

SV-S1FX

S

SV-S2FX

S

SV-S3FX

S

SSV-S4FX

SSV-S5FX

SSV-S6FX

SSV-S7FX

SV-S8FX

S

SV-S9FX

S

PECIFICATIONS

S

ervice: Compatible gases and liquids.

S

ine Size: 1/8 to 2˝ NPT or BSPP.

L

End Connections: Female NPT or BSPP.

Operating Pressure:

1/8 to 1/4˝: 0 psi (0 bar) to 87 psi (6 bar);

3/8 to 2˝: 7.3 psi (0.5 bar) to 116 psi (8 bar).

Pressure Limit: 174 psi (12 bar).

Wetted Material:

SSV-B: Body: Brass; Spring: 304 SS; Seal: NBR;

SSV-S: Body: 316 SS; Spring: 304 SS; Seal: Fluoroelastomer.

Temperature Limits:

Process: 248°F (120°C);

Ambient: 32 to 149°F (0 to 65°C).

Power Requirements: Standard: 110 VAC; Optional: 220 VAC; 24 VDC consult

factory. See Series SRC Solenoid Coils.

Power Consumption: See table.

Enclosure Rating: NEMA 13 (IP54).

Electrical Connection: DIN connection.

Other Materials: Nylon.

Mounting Orientation: Any position, best if solenoid vertically above valve.

Weight: See table.

Type of Operation: NO.

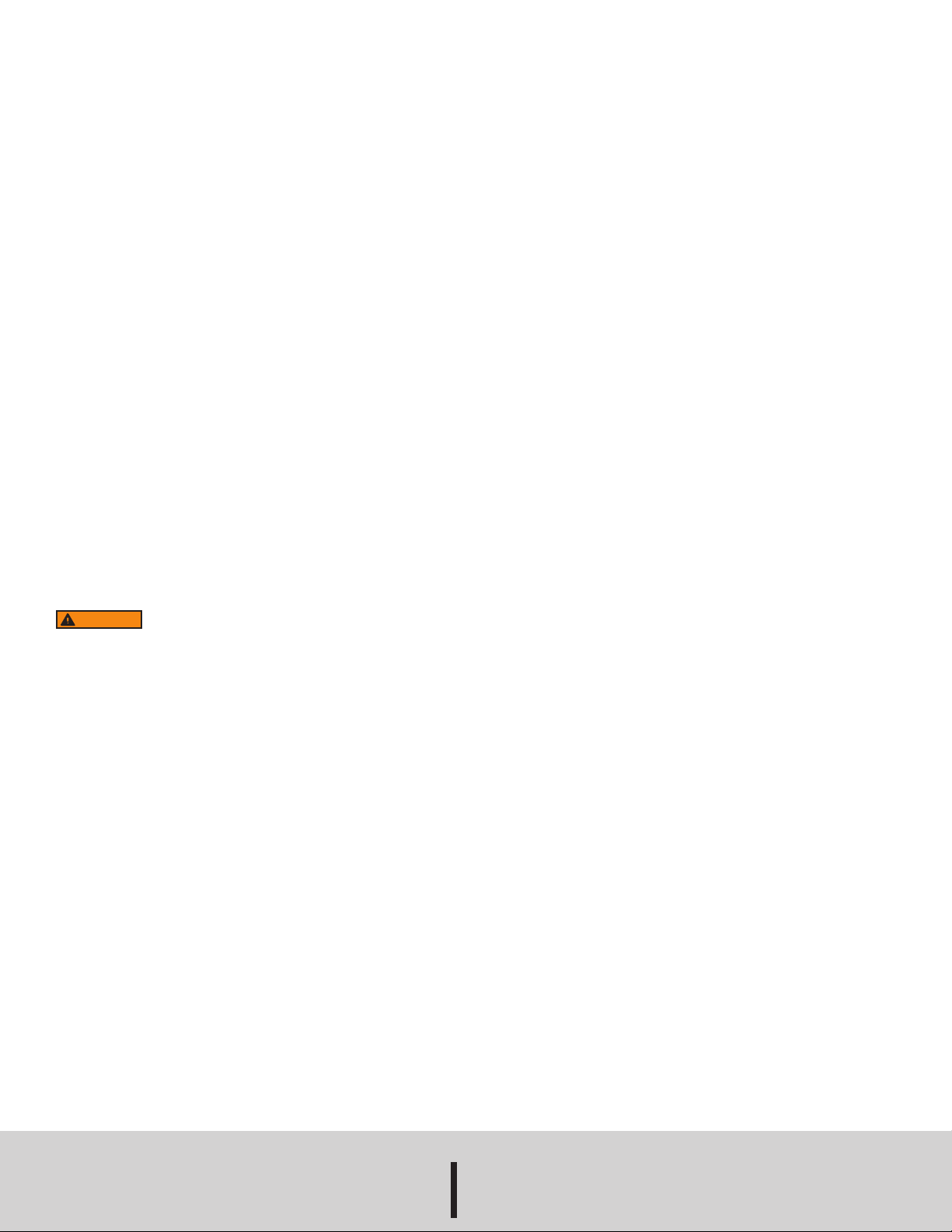

A

in [mm]

-5/8 [41]

1

-5/8 [41]

1

-19/32 [66]

2

2-19/32 [66]

2-61/64 [75]

3-25/32 [96]

5-5/32 [131]

-5/32 [131]

5

-1/2 [165]

6

B

in [mm]

-9/64 [29]

1

-9/64 [29]

1

-57/64 [48]

1

1-57/64 [48]

2-9/32 [58]

2-3/4 [70]

3-25/32 [96]

-25/32 [96]

3

-47/64 [120]

4

C

in [mm]

-15/32 [88]

3

-17/64 [83]

3

-57/64 [124]

4

4-57/64 [124]

5-1/8 [130]

5-5/8 [143]

6-7/32 [158]

-7/32 [158]

6

-3/64 [179]

7

Weight lb [kg]

SSV-S

.88 [0.40]

0

.86 [0.39]

0

.09 [0.95]

2

1.98 [0.90]

2.42 [1.10]

3.30 [1.50]

6.16 [2.80]

.94 [2.70]

5

0.1 [4.60]

1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

NSTALLATION

I

heck the product label for correct catalog number and voltage.

C

OSITIONING/MOUNTING

P

The solenoid is designed to perform properly when mounted in any position. However

for optimum life and performance, the solenoid should be mounted vertical and

upright so as to reduce the possibility of foreign matter accumulating in the core tube

rea.

a

MPORTANT: For the protection of the solenoid valve, install a strainer or filter

I

uitable for the service involved on the inlet side of the valve as close to the valve as

s

possible.

WIRING

iring must comply with local codes and the National Electrical Code. To facilitate

W

iring, the solenoid may be rotated 360°.

w

1. The open-frame solenoid is provided with DIN terminals to accommodate the

plug connector kit.

2. Remove center screw from plug connector. Remove the screw from the terminal

block and using a small screwdriver, pry the terminal block from the connector

over.

c

. Use #12-18 AWG stranded copper wire rated at 90°C or greater for connections.

3

trip the wire leads back approximately 1/4˝ for installation in socket terminals. The

S

use of wire-end sleeves is also recommended for these socket terminals. Maximum

length or wire-end sleeves to be approximately 1/4˝. Thinning of the ends of the

lead wires is not recommended.

4. Thread wire through gland nut, gland gasket, washer and connector cover. NOTE:

onnector cover may be rotated in 90° increments for alternate positioning of cable

C

ntry.

e

. Check DIN connector terminal block for electrical markings. Then make electrical

5

connection to terminal block according to markings on it. Snap terminal block into

connector cover and install the terminal block and center screw.

6. Install the plug connector on the solenoid.

SOLENOID TEMPERATURE

Standard catalog valves are supplied with coils designed for continuous duty service.

When the solenoid is energized for a long period, the solenoid enclosure becomes hot

and should not be touched.

WARNING

pipelines for repairs.

Turn off electrical power supply and depressurize valve before

making repairs. It is not necessary to remove the valve from the

LEANING

C

periodic cleaning of all solenoid valves is desirable. The time between cleaning will

A

ary depending on medium and service conditions. In general, if the voltage to the coil

v

s correct, sluggish valve operation, excessive noise or leakage will indicate cleaning

i

is required. Clean valve strainer or filter when cleaning the solenoid valve.

PREVENTIVE MAINTENANCE

. Keep the medium flowing through the valve as free from dirt and foreign material

1

s possible.

a

. While in service, operate the valve at least once a month to insure proper opening

2

nd closing.

a

3. Periodic inspection (depending on medium and service conditions) of internal valve

parts for damage or excessive wear is recommended. Thoroughly clean all parts.

Replace any parts that are worn or damaged.

MPROPER OPERATION

I

. Faulty Control Circuit: Check the electrical system by energizing the solenoid. A

1

metallic click signifies the solenoid is operating. Absence of the click indicates loss

of power supply. Check for loose or blown fuses, open-circuit or grounded coil,

broken lead wires or spliced connections.

2. Burned-Out Coil: Check for open-circuit coil. Replace coil if necessary.

. Voltage: Check voltage across the coil leads. Voltage must be at least 85% of

3

tated rating.

s

SOLENOID REPLACEMENT

1. Disconnect the conduit, coil leads, and grounding wire.

2. Remove the center screw from the DIN plug connector. Disconnect the DIN plug

connector from the adapter. Remove the locknut, DIN terminal adapter, and gasket

rom the solenoid.

f

. Remove the coil from the plunger tube assembly.

3

. Reassemble reversing the previous steps.

4

MAINTENANCE/REPAIR

Upon final installation of the Series SSV, no routine maintenance is required. The

Series SSV is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 3/14 FR# RV-443574-00 Rev.1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...