Page 1

VENT

PROCESS

ISOLATE

INSTRUMENT

BV-0F

B

Bulletin V-BBV-0

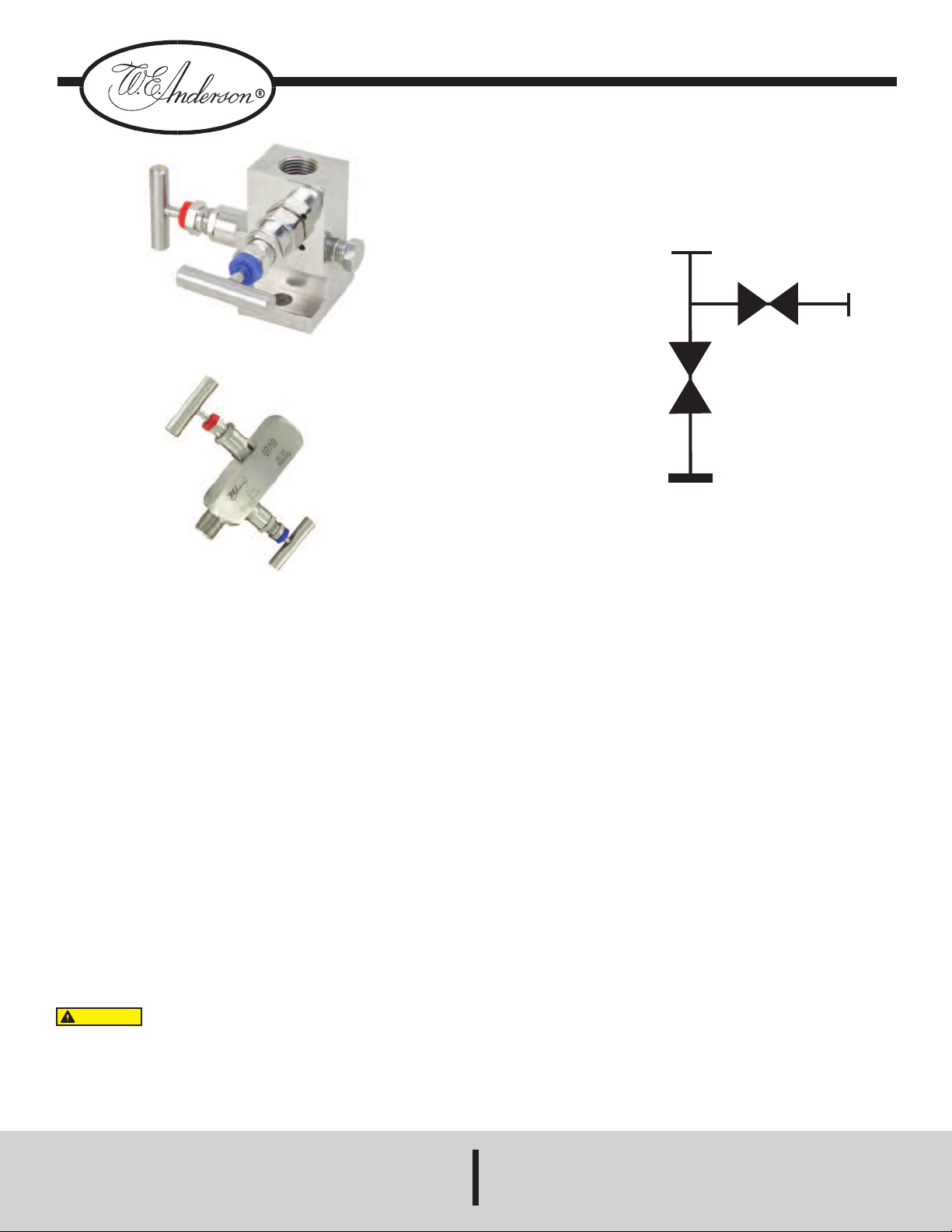

Series BBV-0 2-Valve Block Manifold

Specifications - Installation and Operating Instructions

BBV-0N

The Series BBV-0 2-Valve Block Manifold is perfect for use over a

broad range of industrial applications including oil refineries, nuclear

power stations, petrochemical processing, and more. The Series BBV-0

is forged from 316 stainless steel bar stock and designed to withstand

repeated open and close operations. Suited to control oil, water, toxic

fluids, chemicals, air, and steam; the 2-valve block manifold has (1)

isolate and (1) vent valves. Each valve stem is precision machined with

hard seats to reduce operating torque.

The BBV-0F and BBV-0N are designed to mount directly to industrial

pressure transmitters. The BBV-0F comes with two 7/16-20 UNF

mounting bolts and one PTFE gasket.

INSTALLATION

Refer to the drawing shown above. The connections to the device must

be made accordingly. The BBV-0 2-Valve Block Manifold can be mounted

in any position. The BBV-0 is fitted with color-coded caps for valve

identification:

ISOLATE (Blue)

VENT (Red)

The BBV-0 2-Valve Block Manifold require periodic maintenance. It is

recommended to change the sealing gaskets periodically for safety.

FLOW DIAGRAM

SPECIFICATIONS

Service: Compatible liquids, gases, or steam.

End Connections:

Process connection: 1/2˝ female NPT;

Instrument connection:

No flange: 1/2˝ male NPT;

Flange: 1/2˝ DIN 19213 flange;

Vent/test: 1/4˝ female NPT.

Wetted Materials:

Body, stem, valve assembly: 316 SS;

Stem packing: PTFE.

Pressure Limit: 6000 psi (400 bar).

Temperature Limit: 464°F (240°C).

Other Materials: Handle: 304 SS.

MAINTENANCE

After final installation of the block valve, some routine maintenance is

required. The Series BBV-0 is not field repairable, with the exception of

previously stated maintenance, and should be returned if repair is

needed (field repair should not be attempted and may void the warranty).

Be sure to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return goods

authorization (R.G.A.) number before shipping.

CAUTION

2. Do not remove the safety pin provided on the body.

3. Do not use the BBV-0 2-Valve Block Manifold above the recommended working

pressure and temperature given in the specifications.

1. Do not remove the instrument from BBV-0 2-Valve Block

Manifold when the system is under pressure.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

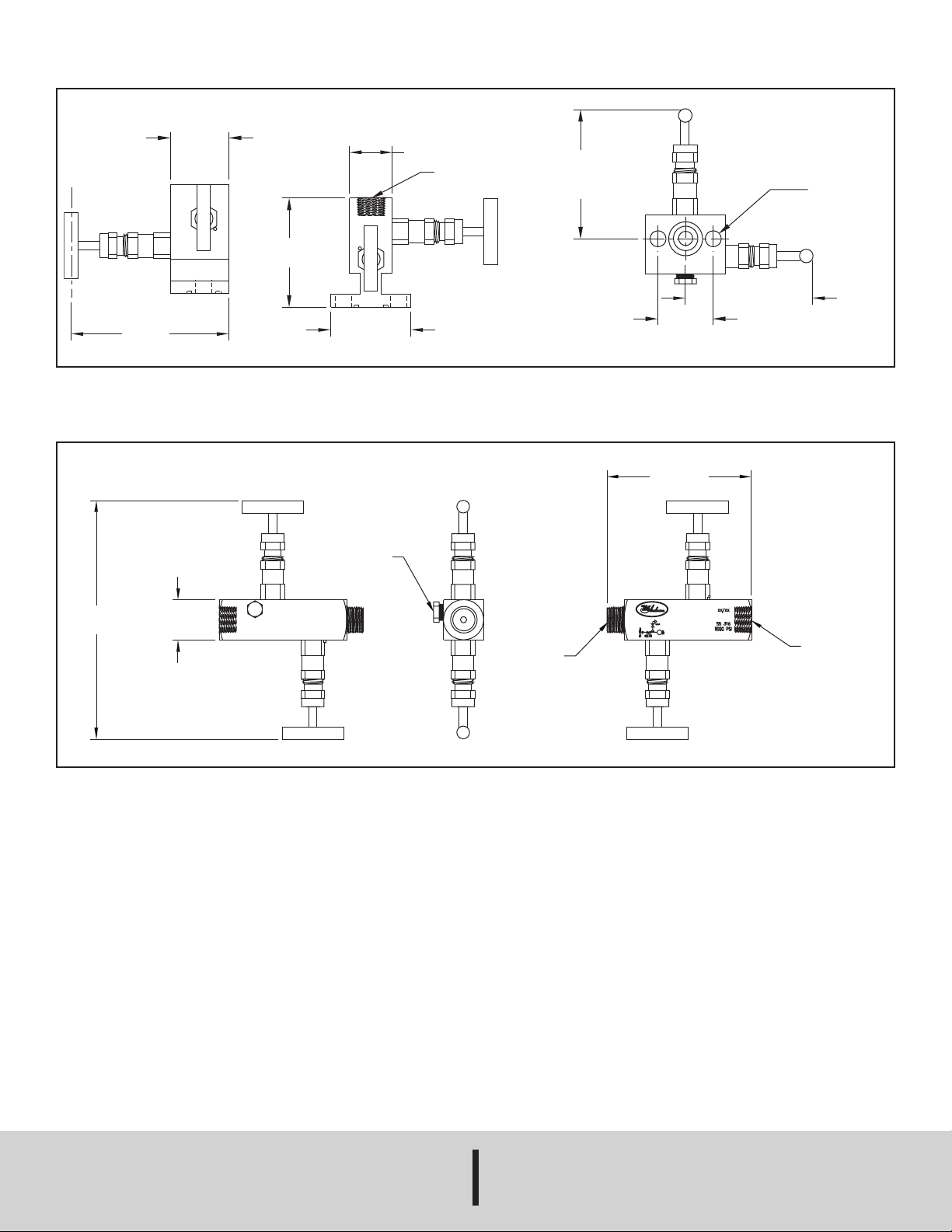

4

-41/64

[

118.00]

1

-47/64

[

44.00]

3

-15/64

[

82.00]

2-23/64

[60.00]

3

-3/4

[

95.00]

M

AX OPEN

3

-5/8

[

92.00]

M

AX. OPEN

1

-5/8

[

41.30]

2X Ø15/32

MOUNTING HOLES

[Ø12.00]

1

/2˝ NPT PROCESS

C

ONNECTION

1

-17/64

[

32.00]

DIMENSIONS

4

-17/32

[

115.00]

1/2˝ NPT MALE

1/2˝ NPT FEMALE

1/4˝ NPT VENT

PORT (PLUGGED)

1-17/64

[32.00]

7-31/64

[190.15]

BBV-0F

BBV-0N

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 3/14 FR# RV-443874-00 Rev.1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...