Page 1

INSTALLATION INSTRUCTIONS AND OWNER’S MANUAL

GARAGE DOOR OPENER

Chain/ Belt Drive

Models: 3220C, 3221C, 3222C, 3224C, 3320B, 3322B, 3324B

3220C-Z, 3221C-Z, 3222C-Z, 3224C-Z, 3320B-Z, 3322B-Z, 3324B-Z

®

FOR RESIDENTIAL SECTIONAL OVERHEAD GARAGE DOORS ONLY!

DO NOT USE ON ONE PIECE DOORS!

IMPORTANT! THE DOOR AND OPENER WILL NOT FUNCTION PROPERLY UNTIL

INFRARED SAFETY SENSORS ARE INSTALLED AND PROPERLY ADJUSTED!

IMPORTANT NOTICE!

Read the enclosed instructions carefully before installing/operating

this garage door opener. Pay close attention to all warnings and

notes. This manual MUST be attached to the wall in close proximity

to the garage door.

GARAGE DOORS & OPENERS

Copyright 2007 Wayne-Dalton Corp. Part No. 325809 Rev.3 7/19/2007

Page 2

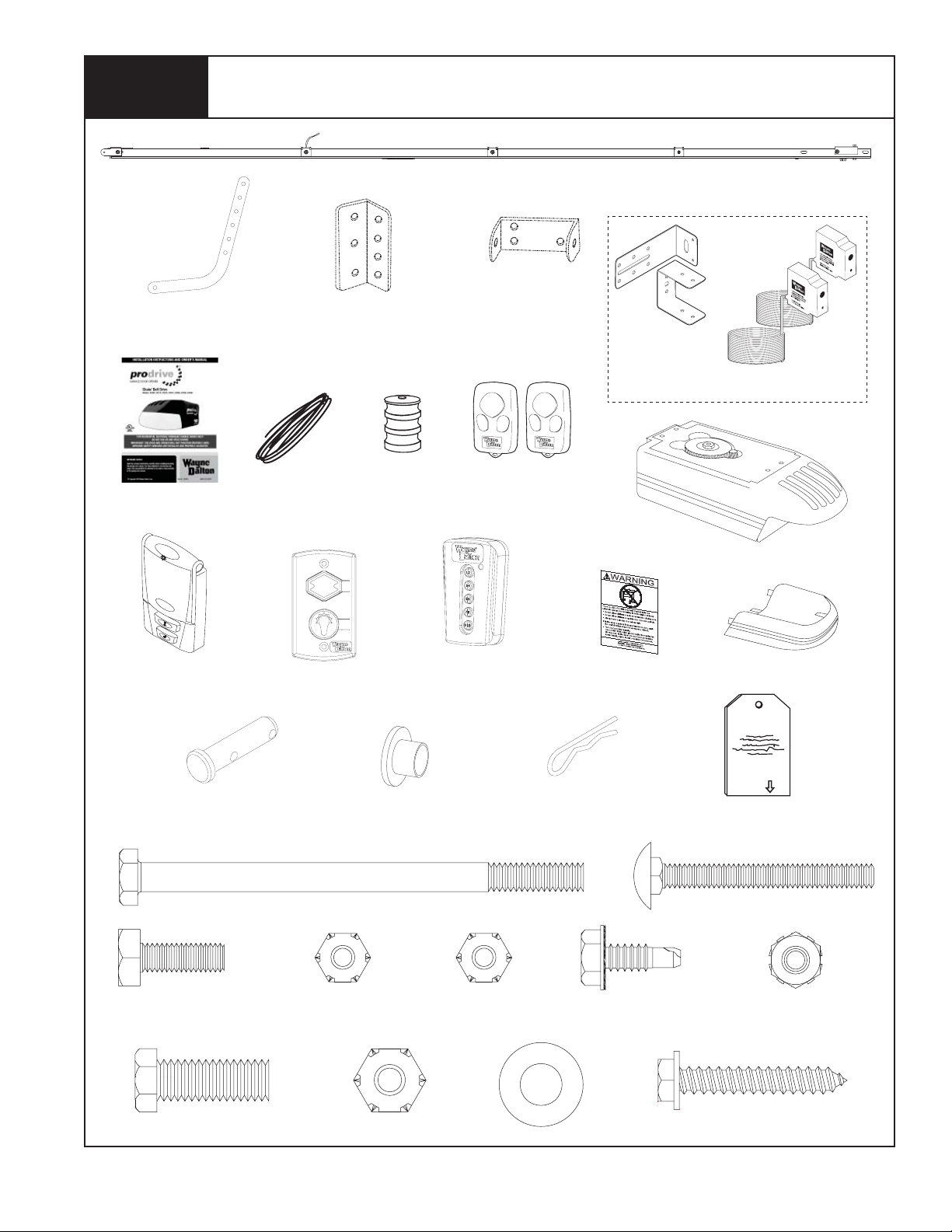

Door Arm

Lower

Package Contents

Door Bracket

NOTE: Depending on the opener model, some parts

listed may not be supplied.

Rail Assembly W/Upper

Door Arm

Wired Safety Sensors W/ Hardware

Wall Mounting

Brackets

(2) Safety Sensor

Brackets

Infrared Safety Sensors

(1 Sender + 1 Receiver)

Owner’s Manual

e

r

p

a

O

t

e

o

T

D

o

Press

o

r

Here

Multifunction

Wall Station

W/Hardware

Clevis Pin

Bell Wire

Wired Deluxe Wall

Station W/Hardware

1/4” x 4” Hex Head Bolt

Red Emergency

Release Knob

Nylon Shoulder Bushing5/16” x 1-1/4” Multi Grip

Keychain/Visor

Transmitter (1 or 2)

5 Button Wireless

Keyless Entry W/

Hardware

Entrapment Label

Hairpin Cotter

Opener

Light Diffuser

EMERGENCY

RELEASE

Emergency Release Tag

(2) 1/4” - 20 x 2” Carriage Bolts

(2) 1/4”-20 x 3/4” Machine Bolts (2) 1/4” Nylock Nuts

3/8”-16 x 1” Machine Bolt 3/8” Plastic Insert

Locking Nut

I

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

1/4” Plastic Insert

Locking Nut

3/8” Flat Washer

(2) 1/4” - 20 x 5/8”

Self Drilling Screws

(2)1/4” Locking Nuts

(2) 1/4” x 1-1/2” Lag Screws

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 3

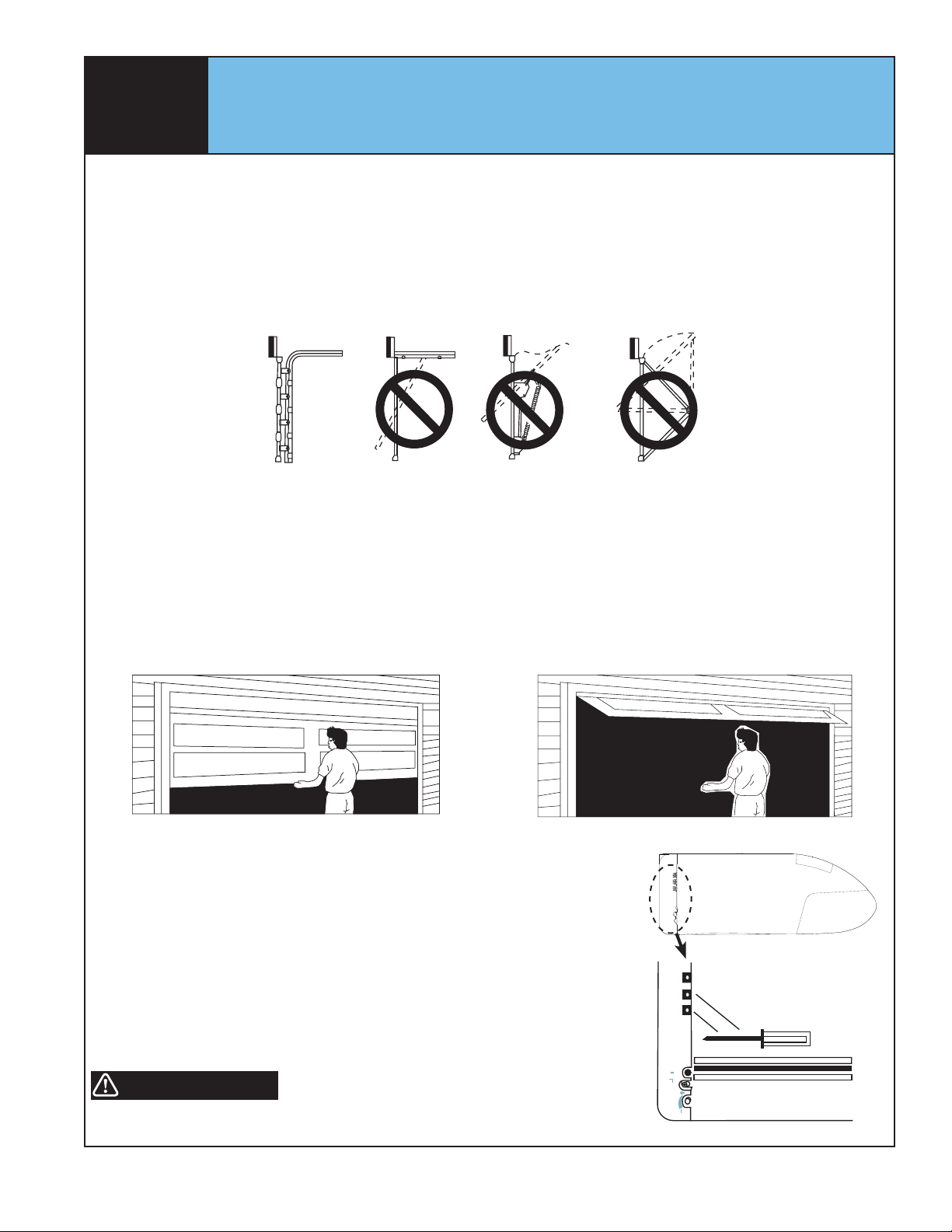

PRE-INSTALLATION INSPECTION OF YOUR GARAGE DOOR

PRIOR TO PRODRIVE ® OPENER INSTALLATION

To ensure your new Prodrive ® opener works as intended, your garage door must be properly

installed and balanced.

Before installing your garage door opener, open and close you door manually to ensure it

operates smoothly from top to bottom. A properly balanced door should not take a lot of

effort to open or close by hand. The door should stay in the open and in the closed

position without drifting down or creeping up. If a door opens fast, the door may need spring

tension reduced. If the door drops fast, the door may need spring tension increased.

If the door operates properly, then proceed to your Prodrive™ installation manual for

®

instructions on how to install the Prodrive

If the operation of the door does not meet these requirements, adjust the spring

balance per your door’s installation manual or call a professional installer to make

adjustments before installing Prodrive

Instruction manuals are available for download on www.wayne-dalton.com. Use the web site to

also nd the location of your nearest professional dealer.

garage door opener.

®

.

Once the door is properly balanced and operates smoothly, you may proceed with the

installation of your Prodrive ® garage door opener.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

II

Page 4

Pre-Installation

IMPORTANT! Before starting the installation read these instructions thoroughly to

familiarize yourself with all aspects of installation and adjustment.

IMPORTANT: IF YOUR GARAGE HAS NO SERVICE ENTRANCE DOOR, INSTALL AN OPTIONAL OUTSIDE QUICK RELEASE LOCK. THIS ACCESSORY

ALLOWS MANUAL OPERATION OF GARAGE DOOR FROM OUTSIDE IN CASE OF POWER FAILURE.

IDENTIFY YOUR DOOR

Identify your door by referring to illustrations below and verify that your door type is a sectional door with curved track. Do not install if the door

is any type of one piece door.

NOTE: The opener has been designed for sectional doors. Do not attempt to install this opener on any style one piece door. Using this opener on

a one-piece door may result in serious personal injury or property damage.

TEST YOUR DOOR

Before you begin, complete the following two tests to insure that the door is balanced and working properly. A door that binds, sticks or is out

of balance could cause severe injury. Do not attempt to compensate for an improperly adjusted door by the installation of an opener. This will

interfere with the proper operation of the opener’s safety features and/or may damage the door or opener. Have a qualifi ed service person

make any needed adjustments or repairs before proceeding with installation.

Door Test One

Raise and lower the door and check closely for any sticking or binding

that may occur. Lift the door approximately half way open, as

illustrated. When releasing the door, it should stay in position. If spring

tension pulls the door further open or door weight pulls it down, your

door is not properly adjusted.

Door Test Two

When properly installed, a door should remain clear of the

opening, when allowed to rest at its natural, full open position.

If “door drift” pulls door back into opening or spring tension is

not suffi cient to pull door totally clear of opening, the door is not

properly adjusted.

PRE-ASSEMBLY CHECK

Every opener is factory tested and shipped with the limit switch adjustment in the door CLOSED

position. If the opener has been powered up before assembly, perform the following steps to insure

that the limit switch adjustment is in the door CLOSED position. Connect the opener to a power

source and short across the screw terminals labeled “PB” and “COM” with a metal screw driver.

Motor should start; run through a full OPEN cycle, (driven gear rotates clockwise) and stop. This

will leave opener in OPEN position. To get the opener back to full CLOSE position, short and hold

“PB” and “COM” terminals again (driven gear rotates counter clockwise). Continue to short

terminals until opener stops in the CLOSED position. If the contact between “PB” and “COM” is

lost, the motor will stop, reverse, and travel back to the open limit, repeat with a constant short

across “PB” and “COM”.

CAUTION: KEEP CLEAR OF ALL ROTATING AND MOVING PARTS.

WARNING

FAILURE TO KEEP CLEAR OF ROTATING AND MOVING PARTS CAN RESULT IN SEVERE INJURY.

Disconnect from power source and proceed to assembly.

III

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

OBS

COM

P. B .

STATUS

PROGRAM

SW

FORCE ADJ.

Right Side Of Opener

Page 5

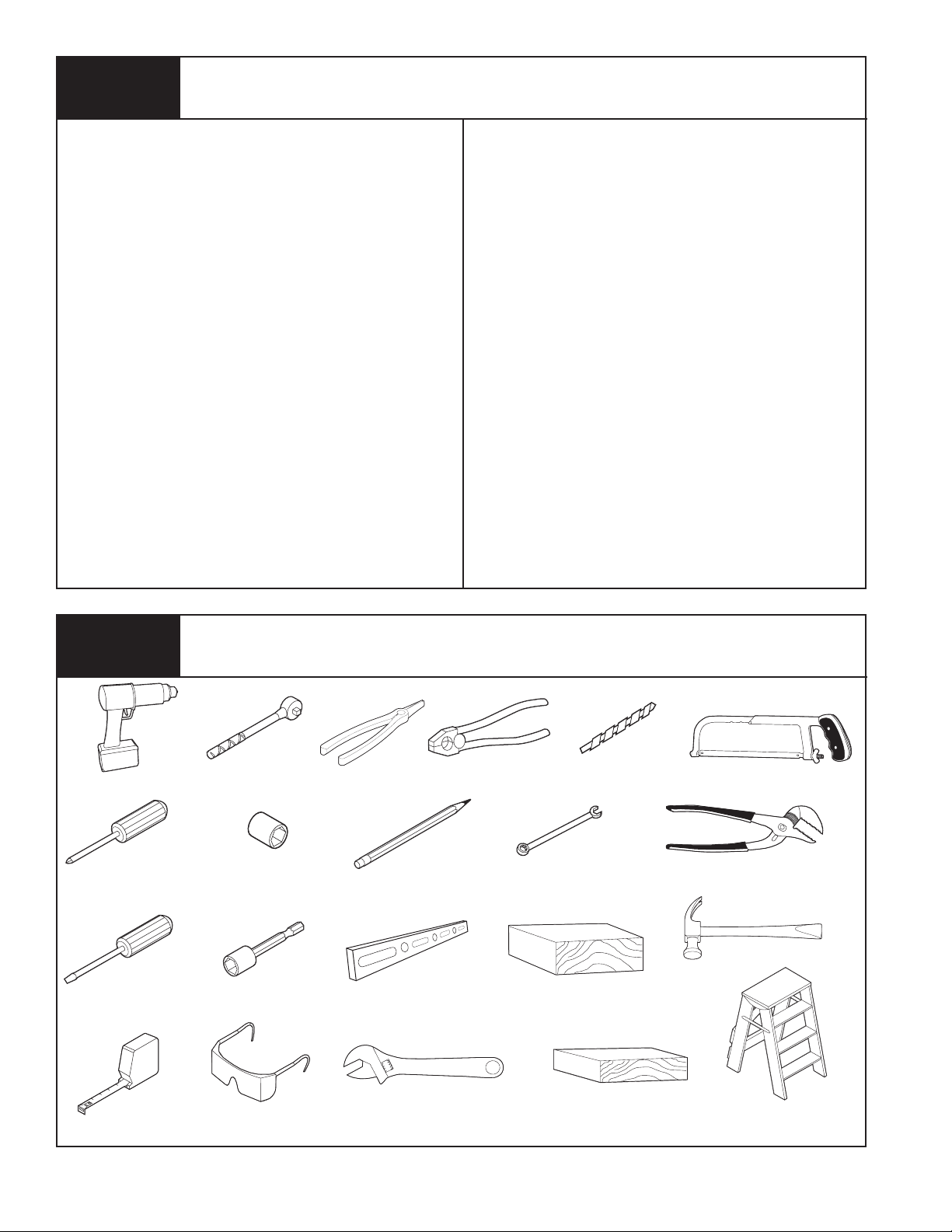

System Features

1. Open and Close Cycle Control:

Allows garage door to be started and stopped by push button,

transmitter or wall station. The next impulse sends a stopped garage

door in opposite direction.

2. Emergency Disconnect:

Manual disconnect permitting operation of door during power failure

with automatic reconnect when opener is reactivated. See page 27.

3. Opener light:

Automatically turns on when opener is activated and remains on for

four minutes for convenience and safety.

4. Mechanical Door Lock:

When properly adjusted, opener locks door in closed position

preventing unwanted entry. See Adjustment # 3 on page 32.

5. Obstruction Warning Light:

The convenience light will fl ash after sensing an obstruction in the

down direction and/or if the safety system malfunctions while in the

open position.

6. Motor:

Permanently lubricated, thermally protected, heavy duty motor with

automatic reset.

7. Safety System:

Independent up and down force adjustments. When properly adjusted,

the safety system will automatically reverse the door when obstructed

in down direction and return to fully open position. The door will stop

when obstructed in the up direction. See Adjustment #2 on page 32.

8. Infrared Safety Sensors:

Wired infrared safety sensors detect an obstruction in door path and

react by reversing door.

9. Multi-Function Wall Station:

Wired wall station provides up/down door motion control and

independent overhead light on/off control. Wireless multi-function wall

station provides up/down door motion control, independent overhead

light on/off control, door down delay, adjustable “pet position” function,

and “pet position” program button.

10. Homelink

Opener is capable of “learning” automobile equipped Homelink

transceivers. Visit: www.homelink.com.

®

Compatibility:

®

11. Rolling Code Technology:

Wireless transmitters, multi-function wall stations and wireless keyless

entry use rolling code which prevent would be thieves from “grabbing”

the transmitter’s digital code.

Power Drill

Phillips Head

Screwdriver

Flat Tip

Screwdriver

Tools Needed

Ratchet Wrench

1/4”, 3/8”, 7/16”,

1/2”, 9/16” Sockets

Needle Nose Pliers

Pencil

Level7/16” Socket Driver

Pliers/Wire Cutters

5/64”, 3/32”, 1/8”, 3/16”

Drill Bits

7/16” Wrench

2 x 4 Board

Hacksaw

Pliers

Hammer

Tape Measure

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

Safety Glasses

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Adjustable Wrench

2 x 6 x 12 Solid Test

Object

Non-Metallic

Step Ladder

IV

Page 6

Table of Contents

Package Contents ..............................................................................I.

WARNING

INCORRECT INSTALLATION CAN

Pre-Installation Inspection ............................................................. II, III

Tools Needed ................................................................................... IV.

Important Safety Instructions ............................................................V.

Prodrive ® Installation ..................................................................1-5.

Pre-Operation .............................................................................6-19.

Optional Installations ................................................................20-26.

Operation .................................................................................27-32.

Programing Wireless Wall Station Or Transmitter(s) to Opener ....... 33.

Maintenance .................................................................................. 34.

Troubleshooting ............................................................................. 35.

Parts Breakdown Rail Assembly ..................................................... 36.

Parts Breakdown Opener Assembly ............................................... 37.

Accessories .................................................................................... 38.

Templates ......................................................................................39.

Customer Service Number ............................................................. 40.

Warranty ........................................................................................ 41.

Defi nition of key words used in this manual:

WARNING

INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH,

IF NOT AVOIDED, COULD RESULT IN SEVERE OR FATAL

INJURY.

CAUTION: PROPERTY DAMAGE OR INJURY CAN RESULT FROM

FAILURE TO FOLLOW INSTRUCTIONS.

IMPORTANT: REQUIRED STEP FOR SAFE AND PROPER OPENER

OPERATION.

NOTE: Information assuring proper installation of the opener.

LEAD TO SEVERE OR FATAL

INJURY. FOLLOW THESE

INSTRUCTIONS CAREFULLY.

IMPORTANT INSTALLATION

INSTRUCTIONS

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2. Do not connect the opener to electrical power until instructed to do so.

3. Install the entrapment warning label next to the wall station in a

prominent location. Install the emergency disconnect label on the

emergency disconnect cord.

4. Remove all ropes and remove, or make inoperative in the unlocked

position, all locks connected to the garage door before installing the

opener.

5. Do not wear rings, watches or loose clothing when installing or servicing

a garage door system.

6. It is important that you install all the components supplied with the

7. Wear protective eye wear when installing or servicing the opener or door.

8. Install opener on a properly balanced and operating garage door. Have a

9. Where possible, install the opener seven feet or more above the floor.

10. Locate the wall station: (a) within sight of door, (b) at a minimum height

11. After installing the opener, the door must reverse when it contacts a

12. Installation and wiring must comply with local building and electrical

13. To reduce the risk of injury to persons, use this opener only with

sectional overhead doors.

14. Top section of garage door may need to be reinforced before

attaching opener. Check with your garage door manufacturer for

their recommendations.

15. Do not use sensitivity adjustments to compensate for a poorly

operating door. This will prevent proper operation of the safety

reverse feature and may damage the door and cause possible

severe or fatal injury.

16. An open door must not close and closing door must reverse and open

if infrared safety sensors are obstructed by 6” high object placed on

garage fl oor.

17. Use a sturdy, non-metallic step ladder when installing opener.

AFTER INSTALLATION IS COMPLETE, FASTEN

THIS MANUAL NEAR GARAGE DOOR. PERFORM

OBSTRUCTION TESTS MONTHLY AND

MAINTENANCE AS RECOMMENDED. SEE PAGES

17 & 34.

®

Prodrive

supplied by Wayne-Dalton Corp. may cause the opener to malfunction

and create unsafe conditions.

qualified service person make adjustments/repairs to cables, spring

assemblies, and other hardware before installing the opener. An

improperly balanced door could cause severe or fatal injury.

Mount the emergency disconnect six feet above the floor.

of five feet, so small children cannot reach it, and (c) away from all

moving parts of the door.

1-1/2” high object (or 2 x 4 board laid flat) on the floor.

codes. Connect the power cord to a properly grounded outlet. Do not

remove the ground pin from power cord.

opener, i.e., wall stations, safety sensors, etc. Use of parts not

V

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 7

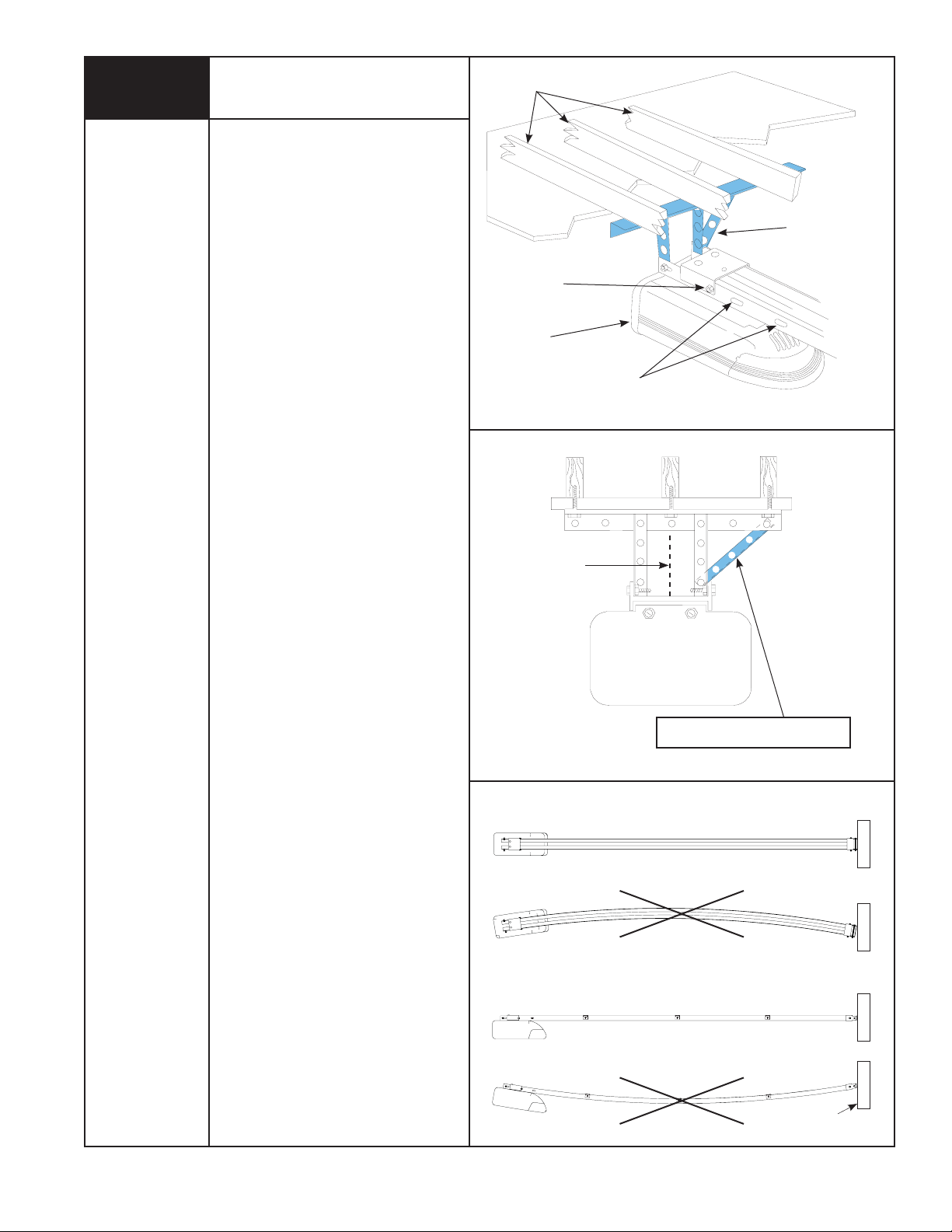

1

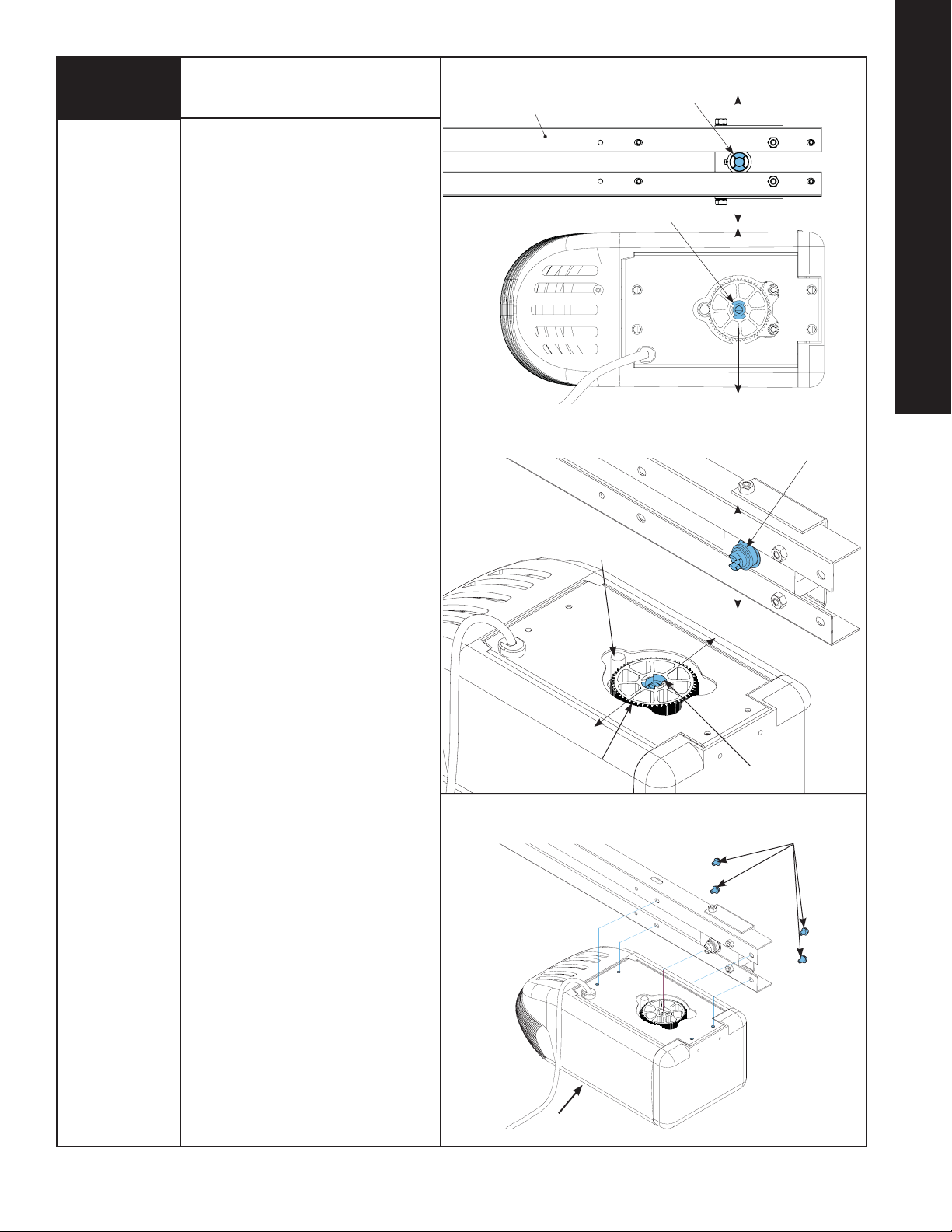

Attaching Opener to Rail

Rail Bottom

(Facing Upwards)

Sprocket / Coupling Cogs

Tools Needed:

3/8” Socket

Ratchet Wrench

IMPORTANT: THE DRIVER GEAR IN THE

OPENER MUST BE PROPERLY ALIGNED

WITH THE SPROCKET/ COUPLING COGS IN

THE RAIL ASSEMBLY AND THE MOUNTING

BOLTS FULLY TIGHTENED, BEFORE

POWERING UP THE OPENER. NEGLECTING

TO DO THIS WILL RESULT IN GEAR FAILURE.

Before assembly, align sprocket/ coupling

cogs to match notches of driver gear. Rotate

the motor spline to position driver gear so

the nearest notch in driver gear is directly

behind motor spline, as illustrated.

NOTE: Do not rotate more than 1/2 turn.

Place opposite end of rail on temporary

support approximately 6” in height.

Proceed with attaching rail to opener,

ensuring proper engagement between

sprocket/coupling cogs and driver gear

notches. Realign if necessary, making sure

to keep any rotation only to the nearest

notch. Using the (4) pre-attached

1/4”-20 x 5/8” hex head bolts, assemble

rail to opener using 3/8” socket; tighten

securely.

Notches

INSTALLATION

Opener

Top View

Sprocket / Coupling Cogs

Motor Spline

NOTE: Do not plug the opener power cord

into electrical outlet until opener is fully

installed and you are instructed to do so in

this manual.

Opener

Driver Gear

Notches

1/4” - 20 x 5/8”

Hex Head Bolts

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

1

Page 8

2

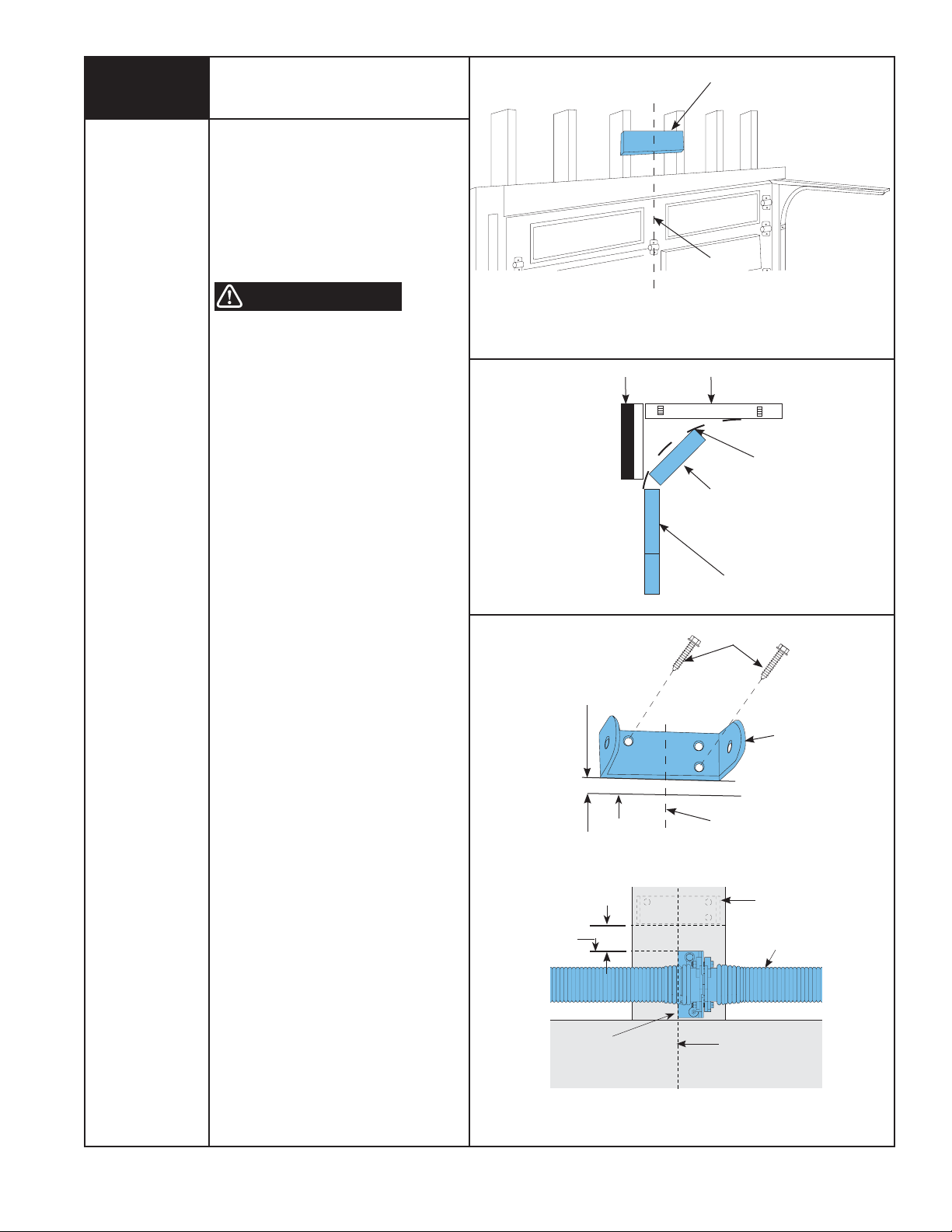

Positioning and Installing

Front Wall Bracket

Reinforce with 2” x 6” as required to

insure rigid mounting.

Tools Needed:

Carpenter’s Level

7/16” Socket

Driver

Power Drill

Tape Measure

1/8” Drill Bit

NOTE: It is recommended that the door

opener be installed 7 feet or more above the

garage floor.

REINFORCE THE HEADER WALL

Reinforce the header wall (wall above door

opening) as required, to ensure rigid

mounting of the front wall bracket.

WARNING

DO NOT ATTEMPT TO LOOSEN OR

REMOVE ANY PORTION OF DOOR SPRING

SYSTEM IN ORDER TO REINFORCE

HEADER WALL OR TO MOUNT WALL

BRACKET. SPRING SYSTEM IS UNDER

EXTREME TENSION AND CAN CAUSE

SEVERE OR FATAL INJURY. SUCH WORK

SHOULD BE DONE BY A QUALIFIED

SERVICE PERSON.

Locate the vertical center line of the garage

door and mark it on the header above the

door.

Raise the door slightly until the top section

reaches the highest point of travel (High Arc

Point); using a carpenter’s level, transfer

and mark the highest point of travel onto the

header wall and close the door.

Mount the front wall bracket with its lower

edge approximately 1/2” -1” above the

mark showing the highest point of travel and

centered on the vertical center line.

1/2” - 1” Above

High Arc Mark

Header

Vertical Center Line

Carpenter’s Level

High Arc Point

Top Section

Sectional Door

Curved Track

1/4” X 1 1/2”

Lag Screws

Front Wall

Bracket

NOTE: For low headroom torsion

counterbalance, hold the wall bracket’s

bottom edge typically at 1/2” - 1” (room

permitting) above the torsion spring center

bracket and centered on the vertical line, see

illustration.

Mark the two mounting holes and pilot drill

with a 1/8” drill bit. Mount wall bracket using

High Arc

Mark

1/2” - 1” Above

Center Bracket

(Room Permitting)

Top Edge Of

Center Bracket

Center of

Door

Front Wall

Bracket

Torsion Spring

the 1/4” x 1-1/2” lag screws supplied to

ensure rigid mounting.

Center Bracket

2

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Center Line

Page 9

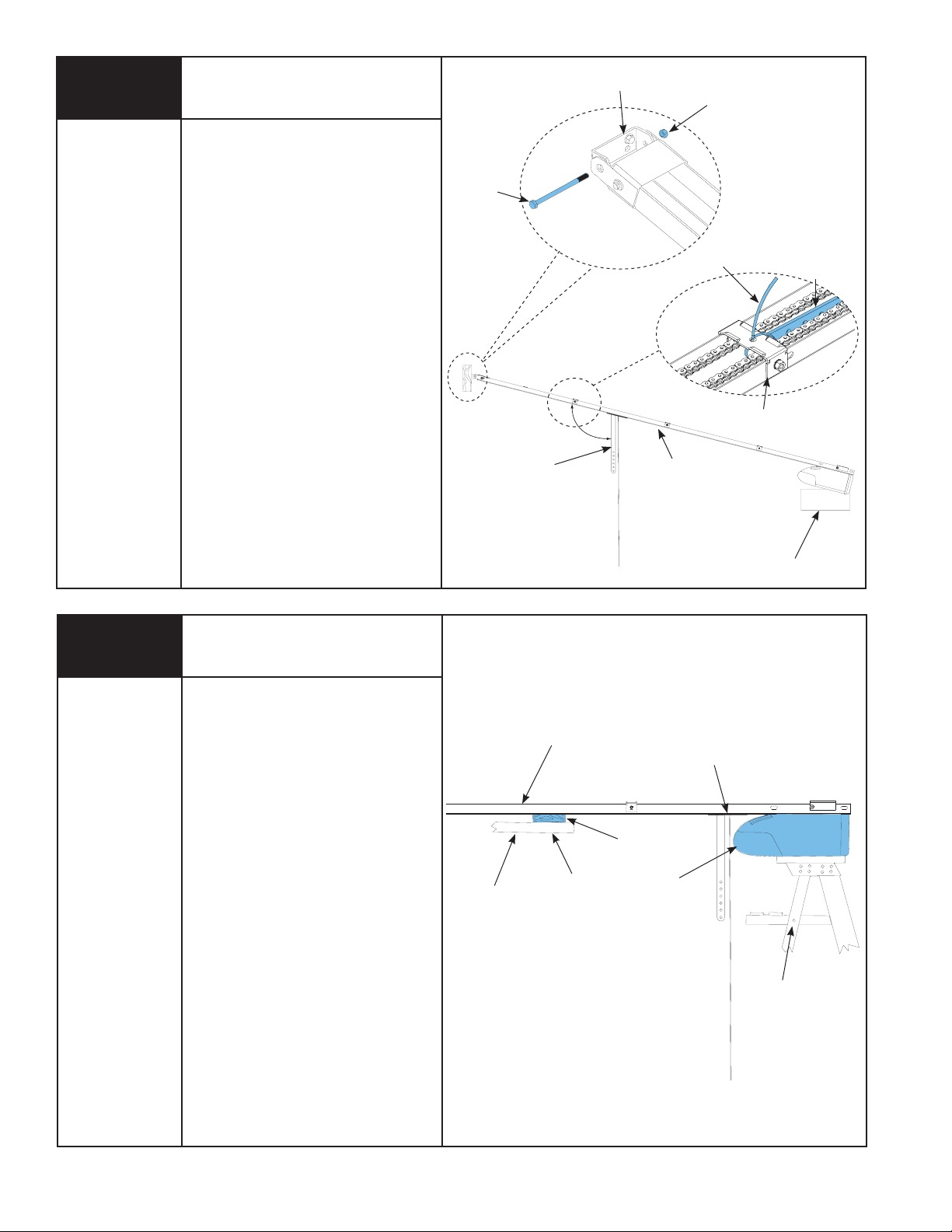

3

Attach Unit to Front Wall Bracket

Front Wall

Bracket

1/4” Plastic Insert

Locking Nut

Tools Needed:

7/16” Socket

Ratchet Wrench

Adjustable Wrench

Raise the front end of the rail

assembly and attach it to the front wall

bracket, using the 1/4” x 4” hex head bolt

and the supplied 1/4” plastic insert

locking nut. Take care not to over tighten

nut. Tighten only until end of bolt is flush

with outside of nut.

NOTE: If you have a torsion spring

counterbalance system, it will be necessary

to raise the opener and support it on a

step ladder to attach the front end of the rail

assembly to the wall bracket.

The upper door arm is secured to the spacer

bracket with one tie wrap for shipping.

Remove tie wrap attaching upper door arm

to the spacer bracket, allowing door arm to

swing down (see caution).

CAUTION: Support upper door arm with your

free hand, to prevent door arm from

swinging down uncontrolled.

1/4” x 4”

Hex Head Bolt

Upper Door Arm

Rail Assembly

Tie Wrap

Upper Door Arm

Spacer Bracket

Cardboard or Cloth to

Protect the Housing

4

Tools Needed:

2” x 4” Board

Non-Metallic

Step Ladder

Positioning Motor

End of Opener

IMPORTANT: TO PREVENT DAMAGE TO

DOOR, DO NOT REST THE OPENER ON THE

DOOR WITHOUT USING A 2” X 4” BOARD

AT LEAST 3 FEET LONG.

Raise the motor end of the opener and

support it so you can open the door to its

fully open position. You may need help

raising motor end if ladder is not high

enough.

IMPORTANT: TO PREVENT DAMAGE TO

DOOR OR OPENER, POSITION TROLLEY AS

CLOSE TO OPENER AS POSSIBLE, BEFORE

OPENING DOOR.

Open the door and place a 2” x 4” x 36”

minimum board along the top section of the

garage door. Rest the rail assembly on the

2” x 4” board.

Support top section of door to prevent

excessive sagging.

Support Door to

Prevent Sagging

Rail Assembly

Door

Trolley

2” x 4”

Board

Opener

Non-Metallic

Step ladder

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

3

Page 10

5

Tools Needed:

Power Drill

Hacksaw

1/8” Drill Bit

1/2” Socket

7/16” Socket

Ratchet Wrench

Adjustable Wrench

Tape Measure

Perforated Angle

Iron (Not Supplied)

Mounting Opener End

CAUTION: Do not use gear cap bolt or nut

for hanger attachment. This may cause

sprocket, chain or Belt misalignment,

resulting in damage to opener or possible

personal injury!

Align the center of opener’s rail assembly

with the center line previously marked on

the top section of the garage door to ensure

rail will be parallel with the direction of door

travel.

Using perforated angles (cut to proper

length) hang opener end from ceiling joist.

Be sure to locate and mount to ceiling joists,

as illustrated.

Pilot drill with 1/8” drill bit and use

1/4” x 1-1/2” lag screws (not supplied) to

ensure a rigid mount. Attach opener to

perforated angles using 5/16” x 3/4” bolts,

5/16” lock washer, and 5/16” nuts (not

supplied).

NOTE: Bracing should be at an angle to

provide rigid support.

Ceiling Joist

Cut Perforated

Angles to Fit

Gear Cap

Nut/ Bolt

Opener

Alternate Hanger

Mounting Holes

Center Line

Of Door

When opener is securely attached to

perforated angles, remove the 2” x 4” (used

to support rail assembly in Step 4) and

close the door.

NOTE: It is recommended that 10’ rails be

supported in the center to prevent sagging.

Opener rail should be aligned perpendicular

to the garage door when properly installed.

There should be no sagging of the rail in

any direction.

Use angled brace to ensure rigid installation.

PROPER INSTALLATION

Top view

correct

incorrect

Side view

correct

incorrect

4

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

header

Page 11

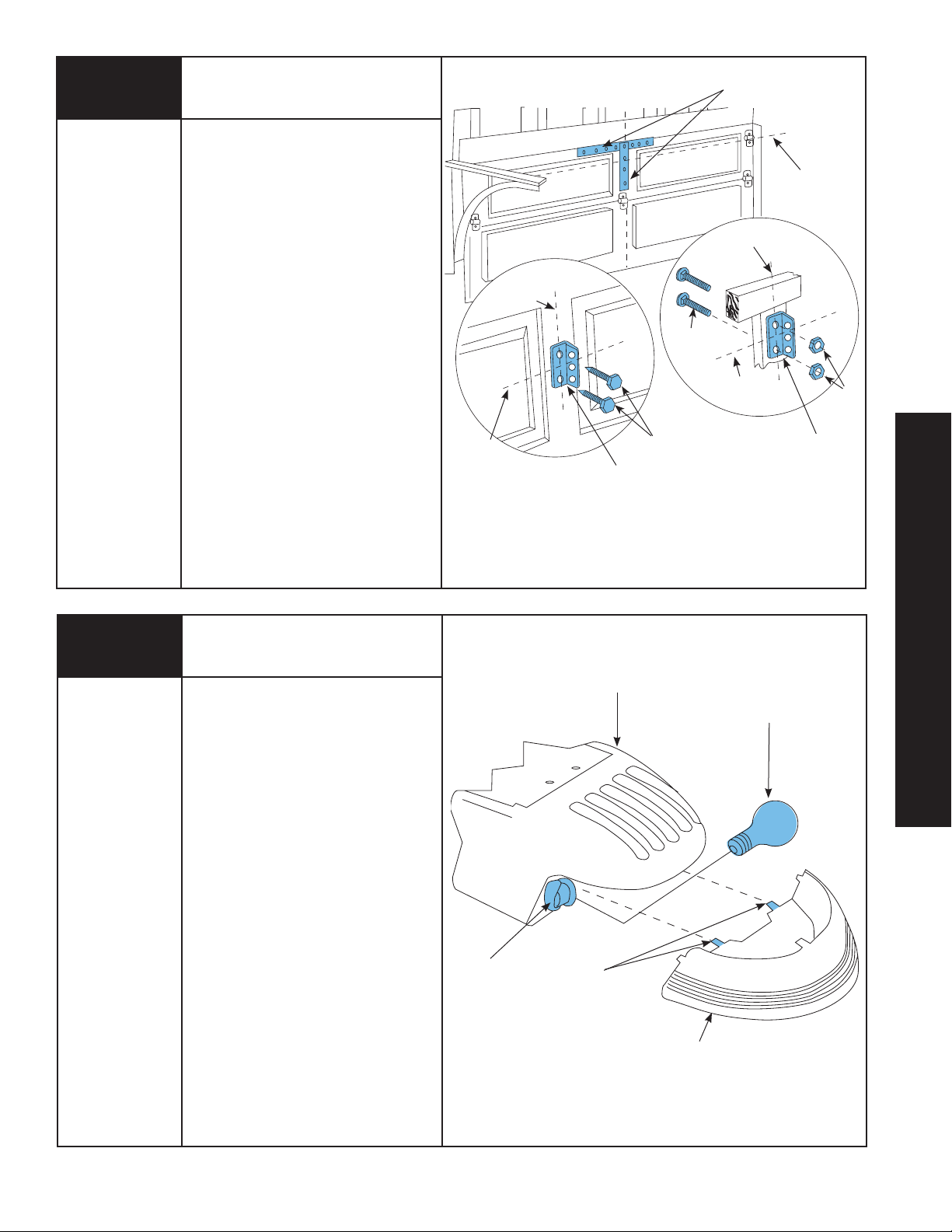

6

Mounting Door Bracket

Reinforce Door Vertically and

Horizontally

Tools Needed:

7/16” Socket

Ratchet Wrench

NOTE: If you have a 5120, 5140, 9100,

9400, 9600, 9700 or 9800 series door,

do not install this door bracket, install the

door bracket supplied with the door, see the

Installation Instructions and Owner’s Manual

supplied with the door. Instructions manuals

are available for download at www.waynedalton.com or call 1-888-827-3667.

IMPORTANT: DOORS MAY NEED TO BE

REINFORCED TO PREVENT DAMAGE TO THE

DOOR. CHECK WITH THE GARAGE DOOR

MANUFACTURER FOR PROPER

REINFORCING OF YOUR DOOR.

For wood doors, mount door bracket,

using two 1/4”-20 x 2” carriage bolts and

1/4” locking nuts supplied, on center line of

door with middle hole in line with top rollers.

For metal doors, mount door bracket,

using two 1/4”-20 x 5/8” self drilling screws

supplied, on center line of door with middle

hole in line with top rollers.

Top Roller

Guideline

Door Center

Line

STEEL

DOORS

1/4”-20 x 1/2”

Self Drilling Screws

Door

Bracket

1/4”-20 x 2”

Carriage Bolts

Door Center

Line

Top Roller

Guideline

WOOD

DOORS

Top Roller

Guideline

1/4”

Locking Nuts

Door

Bracket

7

Tools Needed:

None

Installing Light

Remove lens by pressing up on both sides

of the bottom of the lens at the junction of

the housing, releasing the locking tabs, and

pulling forward.

Screw a 60 watt (Maximum) bulb into

socket. For maximum bulb life, “rough

service” bulbs are recommended.

Align the top and bottom tabs on the lens

with the housing and push straight on until

lens locks in place.

Socket

Housing

Locking Tabs

Bulb - 60 Watt

PRE-OPERATION

Maximum

(Not Supplied)

Lens

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

5

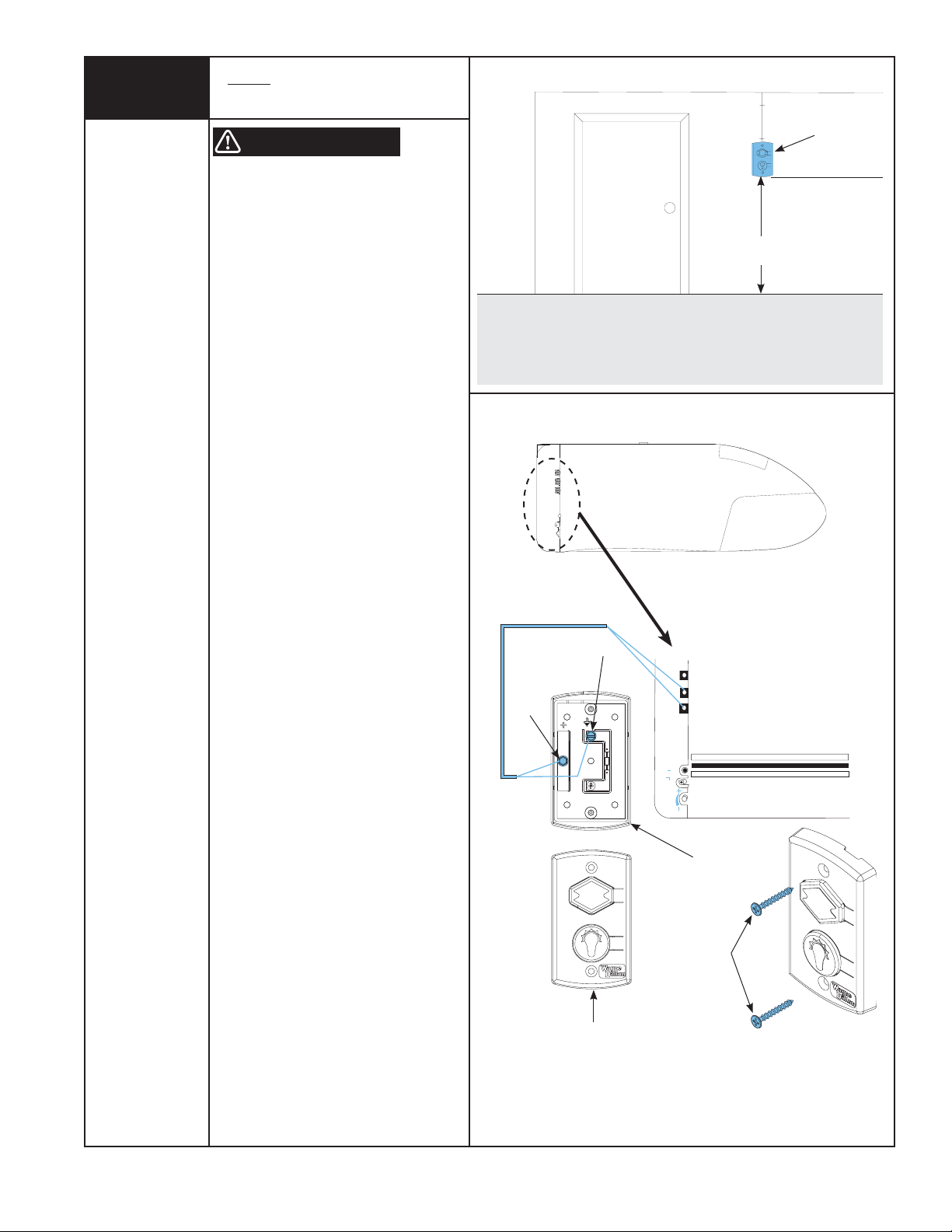

Page 12

8

Tools Needed:

Power Drill

Phillips Head

Screwdriver

Flat Tip

Screwdriver

Wired Wall Station Installation

(If Included)

WARNING

TO PREVENT POSSIBLE INJURY, INSTALL

WALL STATION OUT OF THE REACH OF

CHILDREN AND IN A LOCATION WHERE

THE DOOR CAN BE SEEN WHEN THE

OPENER IS ACTIVATED. DO NOT MOUNT

WALL STATION NEAR OR NEXT TO

GARAGE DOOR.

Wall Station

5 Foot

Minimum

3/32” Drill Bit

IMPORTANT: THE STANDARD PUSH

BUTTON OR THE DELUXE WALL

STATION MUST BE THE ONLY TYPE USED

FOR PROPER DOOR OPERATION. THE USE

OF ANOTHER PUSH BUTTON OR WALL

CONTROL STATION NOT SUPPLIED BY

WAYNE-DALTON COULD CAUSE OPENER TO

MALFUNCTION.

Wired Wall Station:

Wire the garage door opener wall station

using bell wire connected to COM and P.B.

screws, as illustrated.

Locate push button adjacent to service

entrance door at a minimum height of 5 ft.,

and at least 6 ft. away from garage door.

Fasten the wall station in a safe location with

the (2) phillips head screws, making sure not

to over tighten. Pilot drill mounting holes

using a 3/32” bit. Additional wired wall

stations may also be installed in accordance

with these instructions.

CAUTION: Over tightening the screws could

deform plastic case.

Right Side Of Opener

COM

OBS

PB

COM

P. B .

STATUS

PROGRAM

SW

FORCE ADJ.

IMPORTANT: CONNECT THE LOW

VOLTAGE WIRE TO THE WALL STATIONS

Wall Station Back

USING A “J” HOOK CONFIGURATION. IF WIRE

IS COMPLETELY LOOPED AROUND

TERMINAL SCREW, IT CAN PREVENT

PROPER CONTACT.

Phillips Head Screws

Wall Station Front

6

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 13

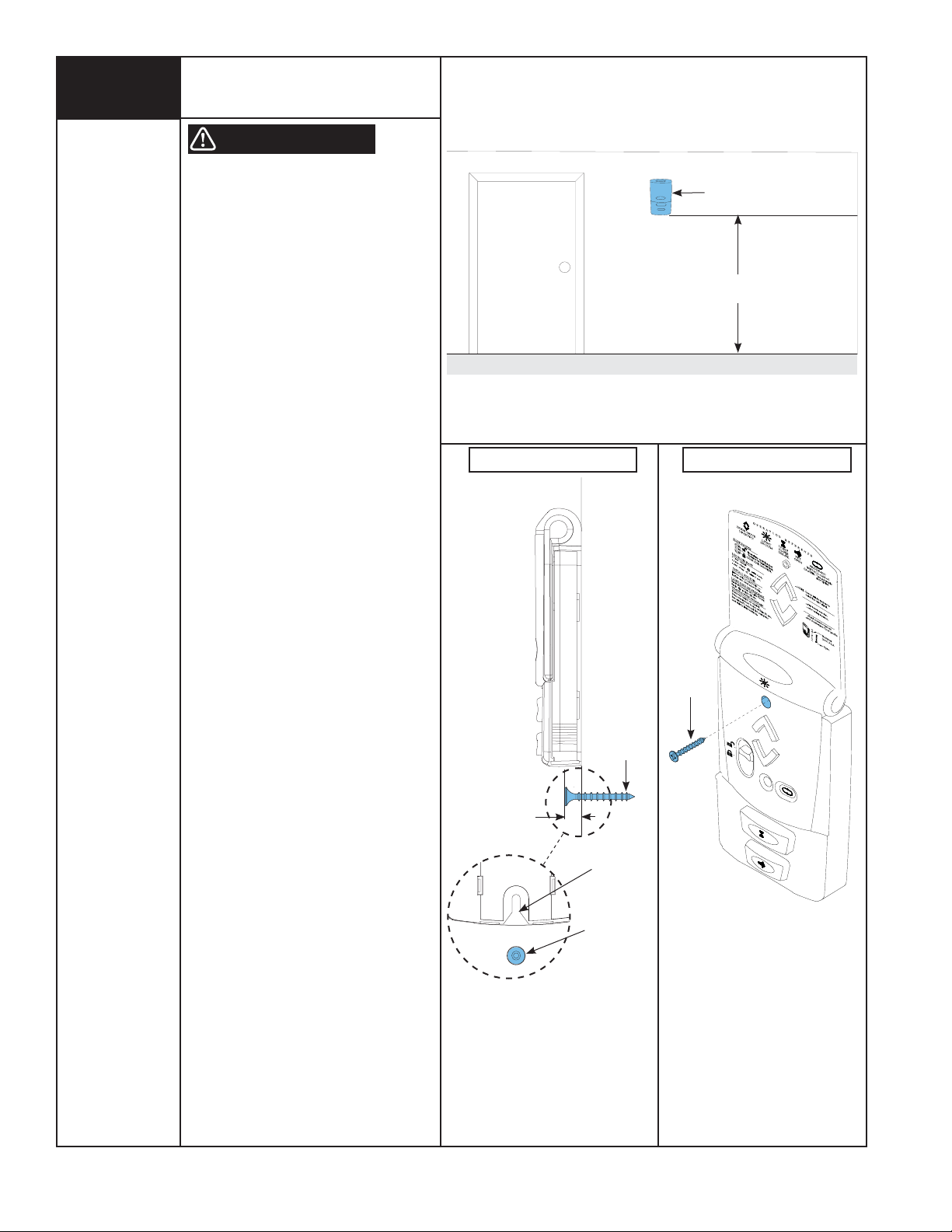

9

Tools Needed:

Power Drill

3/32” Drill Bit

Phillips Head

Screwdriver

Deluxe Multi-Function Wireless

Wall Station Installation

(If Included)

WARNING

TO PREVENT POSSIBLE INJURY, INSTALL

WALL STATION OUT OF THE REACH OF

CHILDREN AND IN A LOCATION WHERE

THE DOOR CAN BE SEEN WHEN THE

OPENER IS ACTIVATED. DO NOT MOUNT

WALL STATION NEAR OR NEXT TO

GARAGE DOOR.

NOTE: For proper operation, mount the wall

station on a flat surface.

The wall station can be mounted to a NEMA

standard electrical box or directly to any wall

surface. No wiring is required.

Locate wall station adjacent to service

entrance door at a minimum height of 5 ft.,

and at least 6 ft. away from garage door.

If mounting to a NEMA electrical box, use

machine thread screws provided in place of the

wood screws. No drilling is required. If high

voltage wiring is contained in the box,

a standard NEMA solid faceplate must be

installed between the box and the wall station. If

fastening into drywall or concrete, use anchors

provided. When mounting to wood use a 3/32"

drill bit and the drilling template located on

page 39. Drill the two 3/32” mounting holes

using the drill template. Drill 3/16" holes if

using anchors.

Install lower screw leaving 7/16" of the screw

exposed. Slide wall station keyhole slot onto the

lower phillips head screw. Wall station should

slide onto screw, providing a snug fit. If

necessary remove wall station and loosen or

tighten lower phillips head screw until a snug fit

is achieved.

Once wall station is fitted on lower screw, install

upper screw. Do not over-tighten.

CAUTION: Over tightening the upper screw

could deform plastic case.

Wall Station

5 Foot

Minimum

Lower Screw Installation Upper Screw Installation

Phillips

Head Screw

Phillips Head

Screw

7/16”

Keyhole

Slot

Phillips

Head Screw

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

7

Page 14

Deluxe Multi-Function Wireless

Wall Station Installation Continued

(If Included)

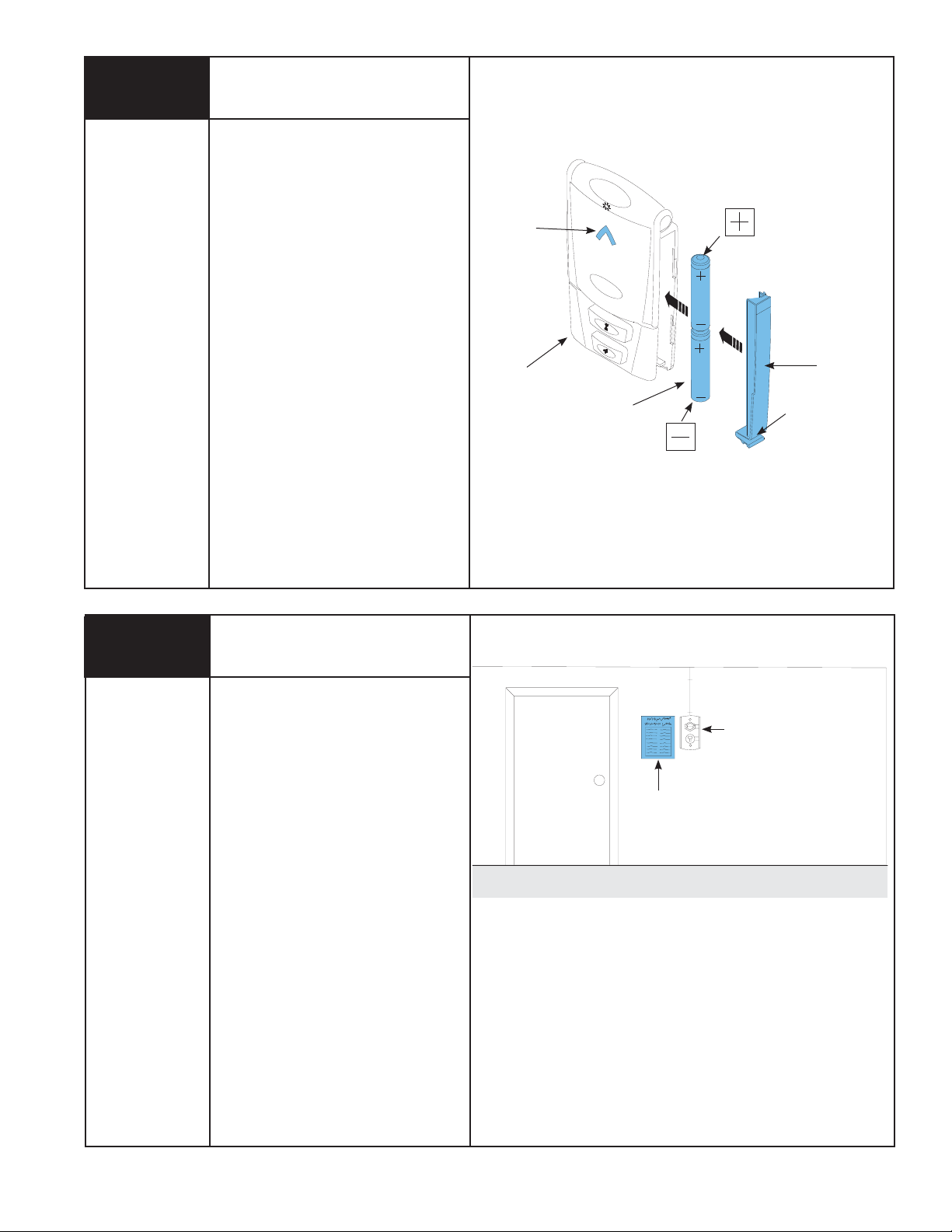

Remove the battery cover (right-hand side of

wall station) by disengaging the battery cover’s

lower clip. Install two AAA batteries into the wall

station observing the polarity, (+) and (-), of

both batteries. After about three seconds, the

red LED will begin to blink every three seconds.

Re-install the battery cover by first inserting its

top into the wall station then inserting and

securing its bottom.

NOTE: To slow blink rate or turn off, refer to

wall station operation page 28 “Back Lit LED

Light”.

Up/Down

LED

e

r

p

O

o

T

Press

Here

a

t

e

D

o

o

r

10

Tools Needed:

None

Entrapment

Warning Label

Apply entrapment warning label in a

convenient location next to the wall station.

Use mechanical fasteners if adhesive will

not adhere.

Wall

Station

Service

Entrance

Door

(2) AAA

Batteries

Battery

Cover

Lower

Clip

Wall Station

Entrapment

Warning Label

8

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 15

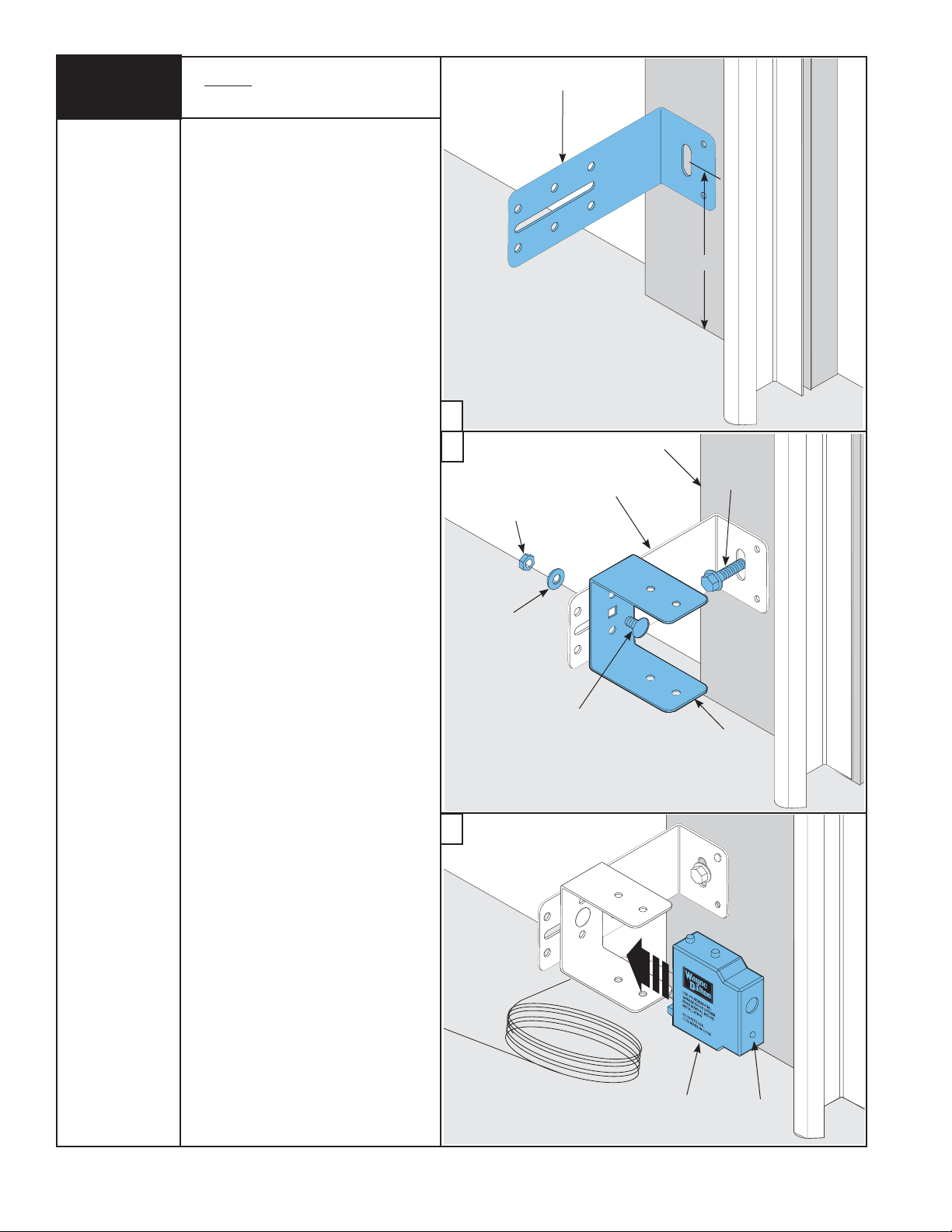

11

Wired Infrared Safety Sensor

Installation

Wall Mounting Bracket

Tools Needed:

Ratchet Wrench

Tape Measure

Power Drill

3/16” Drill Bit

7/16” Socket

Driver

7/16” Wrench

Pencil

IMPORTANT: BOTH WALL BRACKETS

MUST BE MOUNTED AT THE SAME HEIGHT

FOR PROPER ALIGNMENT.

Note: Use Steps a-c for installing sensors

on both sides of the garage door.

a. Select and mark with a pencil, a

mounting location no more than

5 inches above the floor to center line of

wall mounting bracket. The safety sensors

should be mounted as close to the door

track or inside edge of the door as

possible to offer maximum entrapment

protection. It is very important that both

wall mounting brackets be mounted at

the same height for proper alignment.

b. Drill pilot holes, using a 3/16” drill bit.

Using two 5/16” x 1-1/2” lag screws,

permanently mount the wall mounting

brackets to both door jambs. In some

installations it may be necessary to attach

a wooden spacer to the wall to achieve

the required alignment.

5”

a

b

Wall Mounting

Nut

Door Jam

5/16” x 1-1/2”

Lag Screw

Bracket

Attach the “U” brackets to the wall

mounting brackets with 1/4”-20 x 1/2”

carriage bolts, washers and nuts.

Insert the bolts from the inside of the

“U” bracket and hand-tighten.

IMPORTANT: IDENTIFY WHICH SIDE OF THE

GARAGE DOOR IS EXPOSED TO THE MOST

SUNLIGHT. MOUNT THE SENDING UNIT (UNIT

WITHOUT LED) ON THE SIDE WHICH IS

EXPOSED TO THE MOST SUN. SUNLIGHT

MAY AFFECT THE SAFETY SENSORS, AND

THIS ORIENTATION WILL HELP REDUCE THE

EFFECT.

c. Attach the sending and receiving safety

sensors to the “U” brackets by inserting

all three tabs into the respective holes.

Washer

1/4”-20 x 1/2”

Carriage Bolt

U-Bracket

c

Receiving

Unit

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

LED

9

Page 16

12

Installation of Wiring for Wired

Infrared Safety Sensor

Tools Needed:

Hammer

Uncoil the wires from the infrared safety

sensors and route the wire up the garage

wall across the ceiling and down to the back

of the opener. Tack the wires in place using

staples (Not Supplied). Take care to run

the wires in a location where they will not

interfere with the operation of the door and

do not staple through wire.

NOTE: If wires must be lengthened or

spliced into pre wired installation, use wire

nuts or other suitable connectors.

To Opener

Wire to Opener

13

Tools Needed:

Phillips Head

Screwdriver

Connecting Wired Infrared Safety

Sensor to Opener

Connect infrared safety sensors to the

opener as shown. Shorten wires as

necessary and separate wire ends. Strip

about 1/2” of insulation off each wire, being

careful not to nick wires, and attach wires

to the proper terminal screws, then tighten

securely, using phillips head screwdriver.

One wire has marking on it (numbers, black

stripe, etc). Be sure to observe polarity. Apply

tension to external wires to test for secure

connection. Check that the wires are stapled

in place properly.

Sending Unit

Right Side Of Opener

Black Strip

OBS

COM

P.B .

Solid

Color

Receiving Unit

LED

10

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 17

14

Connecting Opener

To Outlet

Tools Needed:

None

WARNING

TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT CHANGE THE POWER

CORD IN ANYWAY.

IMPORTANT: THE OPENER MUST BE

CONNECTED TO A PROPERLY GROUNDED 3

PRONG, 120 VOLT OUTLET.

The opener can be permanently wired. To

permanently wire the unit, see permanent

wiring option on page 20.

Plug the power cord into the closest

grounding type receptacle. Excess power

cord length must be routed and contained

safely away from any moving parts.

As soon as power is applied to the opener,

the light on the opener will blink once to

indicate a successful self-check of the

controls.

Outlet

Power Cord

15

Tools Needed:

None

Connecting Trolley

To Latch Assembly

Slide the trolley until it snaps onto the latch

assembly.

Attach warning label to the red release cord.

Thread the red release cord through the pull

knob so knot is inside pull knob. Tie a double

knot at the end of the red release cord to

secure pull knob.

NOTE: Pull knob should hang 6 feet above

floor. Ensure that the rope and handle clear

the tops of all vehicles to avoid

entanglement.

Latch Assembly

Trolley

Use a Double Knot

To Secure The Red

Pull Knob

Upper Door Arm

Release Cord

Trolley

Tag

Pull Knob

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

11

Page 18

16

Alignment of Wired Infrared

Safety Sensors

Tools Needed:

Pliers

WARNING

TO AVOID POSSIBLE SEVERE OR FATAL

INJURY, KEEP PEOPLE AND OBJECTS

CLEAR OF THE MOVING DOOR ARM TO

PREVENT POSSIBLE PERSONAL INJURY.

IMPORTANT: THE SAFETY SENSOR SENDS

AN INVISIBLE BEAM OF LIGHT FROM THE

SENDING UNIT TO THE RECEIVING UNIT

ACROSS THE PATHWAY OF THE DOOR. THE

OPENER WILL NOT OPERATE UNTIL THE

SAFETY SENSORS ARE CONNECTED TO THE

OPENER AND PROPERLY ALIGNED. IF THE

INVISIBLE BEAM OF LIGHT IS OBSTRUCTED,

AN OPEN DOOR CANNOT BE CLOSED BY

THE TRANSMITTER OR A MOMENTARY

ACTIVATION OF THE WALL STATION UP/

DOWN BUTTON. HOWEVER, THE DOOR MAY

BE CLOSED BY CONTINUOUSLY

HOLDING YOUR FINGER ON THE WALL

STATION UP/DOWN BUTTON (CONSTANT

PRESSURE) UNTIL THE DOOR TRAVELS TO A

FULLY CLOSED POSITION.

Out

In

1/4”-20 Carriage Bolts

For this adjustment, bend mounting brackets

at wall mount

Top View

In

Out

At this point you will be able to activate the

opener. The trolley/ upper arm will move

to the open position, but will not move to

the closed position unless the beams are

aligned.

The safety sensors must be aligned by

moving the sending and receiving units in or

out until the alignment light on the receiving

unit comes on. The 1/4”-20 carriage bolt

can be loosened to move the unit in or out,

as required. If you have difficulty

aligning beams, check that both brackets are

mounted at the same height (see Step 11)

and remount if necessary. Additional minor

adjustments can be made by lightly bending

the mounting brackets.

Once the alignment light comes on, tighten

all bolts and mounting screws.

Finish securing all wiring making sure not to

break or open any of the conductors. Loop

and secure any extra wire.

Up/Down

Button

Up/Down

Button

Wired Wall station

a

t

r

e

e

D

p

o

O

o

o

r

T

Press

Here

Using the wall station up/down button,

activate the opener and check that it will

operate through full open and close. Ensure

trolley and trolley latch are in the closed

position prior to proceeding to next step.

12

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Multi-Function Wall Station

RF Transmitter

Page 19

17

Tools Needed:

Pliers/Wire Cutters

Tape Measure

Flat Tip

Screwdriver

Setting Trolley Close Position

WARNING

TO AVOID POSSIBLE INJURY OR

PROPERTY DAMAGE, KEEP PEOPLE AND

OBJECTS CLEAR OF THE MOVING DOOR

ARM.

NOTE: If necessary, activate the opener

to move the trolley/ upper door arm to the

closed position.

NOTE: If you have a 9100, 9400,9600,

5120, 5140 or 9700 series door, with one of

the door brackets shown at the right and a

Torquemaster® or Extension Spring(s)

counterbalance system, see “Setting Trolley

Close Position/ Connecting Door Arm To

Door” on pages 23-24. If not, complete this

step.

NOTE: If you have a 9100, 9400, 9600,

5120, 5140 or 9700 series door, with one of

the door brackets shown at the right and a

Torsion Spring(s), see “Setting Trolley Close

Position/ Connecting Door Arm To Door” on

pages 25-26. If not, complete this step.

Single and Double Tab Door Brackets

Models: 9100, 9400, 9600, 5120 and 5140.

Double Tab

Bracket

Single Tab

Bracket

11” to 13”

(13” Minimum

For Belt Drive)

Door Bracket

Double Tab

Bracket

(Closed Limit Position)

Model: 9700

Single Tab

Bracket

Trolley

Upper Arm

Trolley and latch assembly must be at the

factory preset fully closed position, (see

illustration).

Verify preliminary trolley and latch assembly

close position is 11” to 13” between trolley

clevis pin and the inside face of the door.

If adjustment of the trolley/latch assembly

position is required, use the close travel

adjustment screw located on the bottom of

the opener. A 1/4 turn equals approximately

1” of trolley travel; turn clockwise to decrease distance between header and trolley

and counter-clockwise to increase distance

between header and trolley.

TRAVEL ADJUSTMENT

OPEN

LESS

MORE

CLOSE

MORE

Tag

Release Cord

Pull Knob

Bottom Of Opener

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

13

Page 20

18

Tools Needed:

Adjustable Wrench

Ratchet Wrench

7/16” Socket

9/16” Socket

Connecting Door Arm to Door

Typical Installation:

Place nylon shoulder bushing in lower arm

hole in curved end (single hole). Place door

arm on right side of door bracket. Insert

5/16” x 1-1/4” multi-grip clevis pin through

nylon shoulder bushing, lower door arm and

middle hole of door bracket. Install hairpin

cotter through hole (Closest to door bracket)

of multi grip clevis, as shown.

For Models: 9100, 9400, 9600, 5120,

5140 And 9700

Place nylon shoulder bushing in lower arm

hole in curved end (single hole). Place the

lower door arm between the tabs (or the right

side of single tab) and insert 5/16” x 1-1/4”

multi-grip clevis pin through nylon shoulder

bushing, lower door arm and hole(s) of door

bracket. Install hairpin cotter through hole

(Closest to door arm “Double Tab” or door

bracket “Single Tab”) of multi grip clevis, as

shown.

For Models: 9700 And 9800

Place nylon shoulder bushing in lower arm

hole in curved end (single hole). Place the

lower door arm between the tabs and insert

5/16” x 1-1/4” multi-grip clevis pin through

nylon shoulder bushing, lower arm and holes

of door bracket. Install hairpin cotter through

hole (Closest to door arm) of multi grip clevis,

as shown.

CONNECTING UPPER AND LOWER DOOR

ARMS

WARNING

FAILURE TO USE LOCKING NUT CAN

RESULT IN ARM RELEASING AND

POSSIBLE RESULTING IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

Hairpin Cotter

(Hole Closest to

Door Bracket)

TOP VIEW

Lower Arm

TOP VIEW

5/16” x 1-1/4”

Multi-grip Clevis pin

Door

Bracket

1/4”-20 x 3/4”

Hex Head Bolt

Lower Arm

TOP VIEW

Typical Installation

5/16” x 1-1/4”

Bushing

Multi-grip Clevis pin

1/4”-20 x 3/4”

Hex Head Bolt

Hairpin Cotter

(Hole Closest to

Door Bracket)

TOP VIEW

Nylon Shoulder

Bushing

Door

Bracket

1/4”-20 x 3/4”

Hex Head Bolt

Lower Arm

Door Bracket

Upper Arm

Hairpin

Cotter

Single TabDouble Tab

Door Bracket

Hairpin Cotter

Nylon Shoulder

Door Bracket

Models: 9100, 9400,9600, 5120, 5140 or 9700

Hairpin Cotter

(Hole Closest to

Door Arm)

Upper Arm

Nylon Shoulder

Hairpin Cotter

1/4”

Nylock Nuts

Lower Arm

Bushing

Models: 9700 And 9800

Hairpin Cotter

(Hole Closest to

Door Arm)

Door

Bracket

Lower Arm

Hairpin Cotter

Upper Arm

Upper Arm

1/4”

Nylock Nuts

5/16” x 1-1/4”

Multi-grip Clevis pin

1/4”

Nylock Nuts

Lower Arm

Align upper and lower door arm pieces to

nearest matching holes.

NOTE: It may be necessary to apply downward pressure on the door or slightly raise

the door during this process.

5/16” x 1-1/4”

Multi-grip Clevis pin

Nylon Shoulder

Bushing

1/4”-20 x 3/4”

Hex Head Bolt

Secure upper and lower door arms to each

other using two 1/4”-20 x 3/4” hex head

bolts and nylock nuts.

NOTE: Install the hex head bolts as far apart

as possible, when positioning the upper and

lower arms.

NOTE: Door arm angle must be 10° to 30°

degrees (see illustration). If not, repeat “Setting Trolley Close Position” and increase or

decrease distance between trolley clevis pin

and inside face of the door.

14

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

10° To 30°

1/4”

Nylock Nuts

Page 21

19

Setting Door Close Travel

Tools Needed:

Flat Tip

Screwdriver

Using the wall control up/down button,

activate door to full open position;

reactivate to close position.

The door should stop on the floor with the

bottom door seal slightly compressed.

If the door reverses off the floor, turn close

travel knob 1/4 turn “less”.

If door is not completely closed, turn travel

knob 1/4 turn “more”.

Repeat as necessary.

NOTE: 1/4 turn equals 1” of door travel.

Bottom Of Opener

TRAVEL ADJUSTMENT

OPEN

MORE

LESS

CLOSE

MORE

20

Tools Needed:

Flat Tip

Screwdriver

Setting Door Opening Travel

The door opener is assembled with the open

travel adjustment preset for a typical door,

but all doors should be adjusted to stop as

close as possible to the door’s “natural” fully

open, resting position.

To determine the door’s “natural” fully open,

resting position, disconnect door from

opener using the emergency release

disconnect (see page 27, EMERGENCY

DISCONNECT) and manually raise door to its

“natural” fully open, resting position. Use this

location for your open limit setting. To

determine if door needs adjustment, activate

the opener to bring door to fully open

position.

Bottom Of Opener

TRAVEL ADJUSTMENT

OPEN

MORE

LESS

CLOSE

MORE

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

15

Page 22

Setting Door Opening Travel

(Continued)

NOTE: If door does not open fully and

opener light flashes (make sure the bulb

is installed and operating) check for an

obstruction or see Adjustment #1, page 32

(Adjusting Opening Force).

To adjust for a non-standard door or to

precisely set the open position: Using

the wall station, operate the door and stop

it in mid-travel position. Using a flathead

screwdriver turn the OPEN travel adjuster for

more (counter-clockwise) or less (clockwise)

travel. A 1/4 turn equals approximately 1” of

trolley movement.

NOTE: Confirm that the door has stopped in

the UP position as a result of the upper limit

switch and not because the trolley has hit

the stop bolt, which is mounted in the rail

near the opener. The correct condition can

be verified by observing that the openers

convenience light does not flash after the

fully open door comes to a stop. The faulty

condition may also be confirmed visually

by checking to see if the trolley is resting

against the stop bolt.

Stop Bolt

Trolley

Opener

To confirm final OPEN travel adjustment,

activate the opener to bring door to fully

open position. The opener light should not

be flashing.

16

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 23

21

Contact Obstruction Test

Tools Needed:

2 x 4 Board

After installing the opener, the door must

reverse when it contacts a 1 1/2” inch high

object (or a 2 x 4 board laid flat) on the

garage floor.

Using the wall station, activate the door to

the fully open position. Place a 2 x 4 flat

on the garage floor, under the door path.

Activate the door to the closed position with

the wall station. Upon contacting the 2 x 4

board, the door should reverse.

If door stops on the 2 x 4 board, adjust

the close travel knob 1/8-1/4 turn “more”

until door reverses upon contact with 2 x 4

board.

When the door reverses, remove the

2 x 4 board and run the full cycle of open

and close of the door. Door should not

reverse when it comes to the fully closed

position on the floor.

NOTE: If opener fails to pass this test,

repeat Step 19. Also see Adjustment #2,

page 32 (Contact Obstruction Test).

2 x 4 Laid Flat

On The Floor

WARNING

IF OPENER DOES NOT RESPOND PROPERLY TO THESE TESTS (STEPS

21 AND 22), HAVE A QUALIFIED SERVICE PERSON MAKE NECESSARY

ADJUSTMENTS/REPAIRS, OR SEVERE OR FATAL INJURY COULD

RESULT FROM OPERATING THE DOOR/OPENER.

22

Safety Sensor Obstruction Test

Tools Needed:

2” x 6” x 12”

Solid Test Object

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

WARNING

WHEN PERFORMING THIS PART OF THE

TEST, DO NOT PLACE YOURSELF UNDER

DESCENDING DOOR, OR SEVERE OR

FATAL INJURY MAY RESULT.

Starting with the door fully open, place a 6”

high object on the floor, in line with sensors,

12” from the left side of the door.

Activation of the opener with the wall station

Up/Down button should cause the door to

move no more than one foot, stop and then

reverse to fully open position.

Repeat this test with the 6” high object

placed at the center of the door and then

12” from the right side of the door.

The 6” high object, when placed on the floor

in line with sensors, while door is closing,

should also cause the door to reverse.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Sensor

WARNING

IF OPENER DOES NOT RESPOND PROPERLY TO THESE TESTS (STEPS

21 AND 22), HAVE A QUALIFIED SERVICE PERSON MAKE NECESSARY

ADJUSTMENTS/REPAIRS, OR SEVERE OR FATAL INJURY COULD RESULT

FROM OPERATING THE DOOR/OPENER.

12”

6”

Sensor

12”

17

Page 24

23

FORCE ADJ.

STATUS

SW

PROGRAM

Programming Wireless Keyless

Entry (If Included)

Tools Needed:

None

WARNING

DURING PROGRAMMING THE GARAGE

DOOR MAY OPERATE. KEEP PEOPLE AND

OBJECTS CLEAR OF THE MOVING DOOR

TO PREVENT DOOR DAMAGE OR

POSSIBLE PERSONAL INJURY.

NOTE: To simplify installation, program the wireless keyless entry to the opener before mounting

to the wall.

NOTE: Before programming ensure garage door

is in the “down” position.

1. Press and release the PROGRAM button. The

red PROGRAM STATUS light on the opener and

the overhead lamp will turn on and remain lit for

one minute, indicating that it is ready to learn the

keyless entry.

2. Press the desired five digit PIN (PERSONAL

IDENTIFICATION NUMBER), example 1-3-8-2-5.

The PROGRAM STATUS light will turn on and off

three times indicating a successful learn.

NOTE: Do not set a code that presents the numbers in sequential order, as an example 1/2, 3/4,

5/6, 7/8, 9/0. Studies show that people naturally

press the buttons in a sequential pattern. Also,

do not select a code that uses the same button

five times consecutively. Thieves can easily

figure out these types of codes.

Right Side Of Opener

Program Status

LED

Program

Button

NOTE: If at anytime, an error was made entering

the code, simultaneously press and release the

7/8 and 9/0 buttons to reset the keyless entry;

then repeat programming steps above.

NOTE: A single wireless keyless entry device may

be programmed to operate multiple garage door

openers. To program additional openers, repeat

programming steps using a different five digit PIN

for each additional opener.

How Your Keyless Entry Operates Your Door:

The following explains how your Keyless Entry

can be used to OPEN, CLOSE, START, and STOP

your door.

1. Enter your 5-digit PIN (personal identification

number); door will move.

NOTE: If you inadvertently enter an incorrect

code, the door will not move. To reset,

simultaneously press and release the 7/8 and

9/0 buttons and reenter your PIN number.

2. Unit remains active for next 25 seconds.

Pressing any key, will stop the door if opening,

and stop or reverse the door if closing during the

25 seconds active period.

Keyless Entry

18

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 25

24

Tools Needed:

Power Drill

5/64” Drill Bit

Phillips Head

Screwdriver

Installing Wireless Keyless Entry

(If Included)

IMPORTANT: INSTALL ALL WALL

CONTROLS OUT OF THE REACH OF

CHILDREN AND IN A LOCATION WHERE THE

DOOR CAN BE SEEN BEFORE ACTIVATING.

Locate a convenient place to mount the

wireless keyless entry, that does not

interfere with the normal opening and

closing of the door. To keep keyless entry

out of the reach of children, measure and

mark a spot at least 5 feet up from the floor.

Use the drilling template located on Page 39

to determine hole positions. Drill 5/64” pilot

holes 3/4” deep at each screw location.

Snap open the wireless keyless entry case

with a coin. Secure keyless entry base into

wood framing using the two screws

provided. Snap the front case half back onto

the base. Remove paper backing from

instruction label and apply to a clean

surface inside garage.

Keyless Entry

5’

NOTE: Two screws are included for

mounting to wood structures. Ensure proper

hardware is used for mounting to other

materials.

NOTE: After completing this step, continue

with page 27.

Keyless Entry Base

Keyless Entry Front

Case

Screws

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

19

Page 26

I

Tools Needed:

Needle Nose Pliers

Pliers/Wire Cutters

Power Connection

(Permanent Wiring Option)

WARNING

TO AVOID ELECTRICAL SHOCK,

DISCONNECT POWER AT THE FUSE/

BREAKER BOX BEFORE PROCEEDING.

Power Cord

Strain Relief Bushing

1/2” To 1”

Opener

Flat Tip

Screwdriver

IMPORTANT: CHECK YOUR LOCAL

ELECTRICAL CODES. IF YOUR LOCAL CODE

REQUIRES PERMANENT WIRING, USE THE

SPECIFICATIONS CALLED FOR AND

INSTRUCTIONS ILLUSTRATED.

Permanent Wiring Procedure

1. Ensure power cord is disconnected from

electrical power.

2. Cut power cord 1/2” – 1” from strain

relief/bushing.

3. Use needle nose pliers to remove strain

relief bushing from frame. Squeeze tabs in

on underside of bushing and work bushing

out of hole.

4. Pull or strip off remaining section of outer

insulation from power cord.

5. Remove lens by pressing up on both sides

of the bottom of the lens at the junction of

the housing, releasing the locking tabs,

and pulling forward; remove light bulb (if

installed).

6. Remove the housing from the chassis by

removing the screw securing the

housing to the chassis. Press on the

locking tabs and slide the cover off the

chassis.

7. Pull the three wires into the opener;

strip 1/2” of insulation from the black,

white, and green wires.

8. Using wire nuts for 14-18 AWG wire,

connect the black wire to black wire, the

white wire to white wire and the green

wire to green wire. Make sure connections

are secure.

9. Replace opener cover.

Strain Relief

Bushing

Tabs

Housing

Live & Neutral

Light Bulb

Ground

Tab

Screw

Wire Nuts

Chassis

Lens

Tabs

Reconnect the power at the fuse/ breaker

box, as soon as power is applied to the unit,

the light on the opener will blink once to

indicate a successful self check of the

controls.

20

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 27

I

Tools Needed:

Power Drill

7/16” Socket

Driver

Mounting Door Bracket To

A 9700 Series Door

IMPORTANT: WHEN CONNECTING A

TROLLEY TYPE GARAGE DOOR OPENER

TO A 9700 SERIES DOOR, A WAYNEDALTON OPENER/TROLLEY BRACKET

MUST BE SECURELY ATTACHED TO THE

TOP SECTION OF THE DOOR, ALONG WITH

ANY U-BARS PROVIDED WITH THE DOOR.

THE INSTALLATION OF THE OPENER MUST

BE ACCORDING TO MANUFACTURER’S

INSTRUCTIONS AND FORCE SETTINGS

MUST BE ADJUSTED PROPERLY.

Door Bracket

Align Tab With Center

Line Of Top Section

FIG. 1.1 FIG. 1.2

Or Ubar

Male Part Of Top

Section

Door Bracket

Locate the center of the top section or

factory attached u-bar as shown in FIG 1.1.

FOR TOP SECTION WITH U-BAR:

Remove and retain 4-6 screws from the

center of the u-bar, allowing the door

bracket to slide between the section and the

u-bar.

Position the door bracket until it seats on

the male part of the section as shown in FIG

1.2. The door bracket must be centered and

positioned on the top section so it bridges

the transition point of the section thickness.

Attach the door bracket using

1/4” - 14 x 5/8” self tapping screws as

shown in FIG 1.4. Re-attach the u-bar using

(2) 1/4” - 20 x 11/16” self drilling screws

through the door bracket as shown in

FIG 1.3. Finish re-attaching the u-bar using

the self tapping screws removed previously.

FOR TOP SECTION WITHOUT U-BAR:

Position the door bracket until it seats on

the male part of the section as shown in FIG

1.2. The door bracket must be centered and

positioned on the top section so it bridges

the transition point of the section thickness.

Attach the door bracket using

1/4” - 14 x 5/8” self tapping screws as

shown in FIG 1.4.

Door Bracket

U-BAR

(2) 1/4”-20 x 11/16”

Self Drilling Screws

FIG. 1.3

Door Bracket

(8) 1/4”-14 x 5/8”

Self Tapping Screws

FIG. 1.4

Door Bracket

Top Section With U-Bar

Door Bracket

NOTE: After completing this step, continue

with Step 7.

Top Section Without U-Bar

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

OPTIONAL INSTALLATIONS

21

Page 28

I

Tools Needed:

Power Drill

7/16” Socket

Driver

Vice Clamps

Phillips Head

Screwdriver

Mounting Door Bracket To A

(9100, 9400, 9600, 5120 & 5140 Series Door)

IMPORTANT: WHEN CONNECTING A

TROLLEY TYPE GARAGE DOOR OPENER

TO THE ABOVE LISTED DOORS, A WAYNEDALTON OPENER/TROLLEY BRACKET

MUST BE SECURELY ATTACHED TO THE

TOP SECTION OF THE DOOR, ALONG WITH

ANY U-BARS PROVIDED WITH THE DOOR.

THE INSTALLATION OF THE OPENER MUST

BE ACCORDING TO MANUFACTURER’S

INSTRUCTIONS AND FORCE SETTINGS

MUST BE ADJUSTED PROPERLY.

Locate the center of the top section and seat

the door bracket on male part of the top

section. The door bracket must be centered

and positioned on top section so it bridges

the transition point of the section thickness,

as shown in FIG. 1.1 and 1.2. Install (2) #12

x 1/2” phillips head screws on the opposite

side of door bracket, as shown in FIG. 1.3. If

initially supplied ubar is on the door,

door bracket to u-bar, as shown in FIG. 1.4.

First attach (3) 1/4” - 14 x 5/8” self-tapping

screws to the door bracket, as shown in

FIG. 1.5. Then attach (2) 1/4” - 14 x 5/8”

self-tapping screws to the door bracket, as

shown in FIG. 1.6. Remove vice clamps.

NOTE: If you have a 9100 door, you can use

two of the 1/4” - 20 x 11/16” self-drilling

screws used to attach the u-bar instead of

the 1/4” - 14 x 5/8” self-tapping screws

when attaching door bracket to u-bar, as

shown in FIG. 1.6.

clamp

Align Tab With Center

Line Of Top Section

FIG. 1.1

Opposite Side Of

Door Bracket

FIG. 1.3

Door Bracket

Top Section With Or

Without U-Bar

(2) #12 x 1/2”

Phillips Head Screws

Door Bracket

Male Part Of Top

Section

Door Bracket

FIG. 1.2

Door Bracket

U-BAR

Vice Clamp

NOTE: Not Required

For J-Struts

FIG. 1.4

(2) 1/4”-14 x 5/8”

Self Tapping Screws

Door Bracket

U-BAR

NOTE: When attaching door bracket to top

section with u-bar, apply additional pressure

to thread fasteners into the u-bar.

NOTE: See FIG. 1.7 for installing door

bracket on top section without u-bars.

(3) 1/4”-14 x 5/8”

Self Tapping Screws

FIG. 1.5

U-BAR

(2) 1/4”-20 x 11/16”

Self Drilling Screws

FIG. 1.6

NOTE: After completing this step, continue

with Step 7.

Bracket

Door

(5) 1/4”-14 x 5/8”

Self Tapping Screws

Fig. 1.7 Top Section Without U-Bar

22

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 29

I

12”

Tools Needed:

Needle Nose Pliers

Adjustable Wrench

Ratchet Wrench

7/16” Socket

9/16” Socket

Hacksaw

Setting Trolley Close Position/

Connecting Door Arm

(Models 9100, 9400, 9600, 5120, 5140 & 9700)

With TorqueMaster® Or Extension Springs

DETERMINE THE WAYNE-DALTON TRACK

RADIUS BEING USED:

FOR MOUNT HOPE AND PENSACOLA

TRACK:

Measure the curved ends of the horizontal

track

to determine if you have a 12” or 15”

radius horizontal track, as shown in FIG. 1.

FOR PORTLAND TRACK:

The horizontal tracks are stamped with

radius on the side of the horizontal track, as

shown in FIG. 1.1.

NOTE: If necessary, remove the upper arm

(straight arm) from the trolley, to use the

lower arm (curved arm). Remove the hairpin

cotter from the clevis pin at the front of

trolley and slide clevis pin out far enough

to slide the upper arm out between the left

and right side of trolley body. Position the

lower door arm so the end with the single

hole lines up with the clevis pin. Slide clevis

pin completely back into trolley and reinstall

hairpin cotter.

LOW HEADROOM:

If you have low headroom track, as shown

in FIG. 1.6 on page 24, then proceed with

“Low Headroom Trolley Positioning Charts”

on page 24.

STANDARD LIFT:

Using the STANDARD LIFT TROLLEY

POSITIONING CHARTS, refer to DIM “X” to

set the distance from header to trolley, as

shown in FIG. 1.2.

Horizontal

Track

Clevis Pin

Hairpin Cotter

Curved

Arm

12” OR 15”

FIG. 1

TOP VIEW

“X”

Trolley

Top Section

Straight Arm

Horizontal

Track

Stamped

Radius

FIG. 1.2

12”

10”, 12”, 14”, OR 15”

Standard Lift Track

Straight Arm

FIG. 1.1

Curved Arm

NOTE: Depending on your setup, you may

have to cut straight arm to accomplish trolley

settings.

STANDARD LIFT TROLLEY POSITIONING CHART

FOR (MODELS 9100, 9400, 9600, 5120 & 5140)

DIM “X”

11 1/2”

10” AND 12” RADIUS

TYPE OF ARM

BEING USED

CURVED /

STRAIGHT

ILLUSTRATIONS

REFERENCE

FIG. 1.4

If adjustment of the trolley position is

FIG. 1.3

STANDARD LIFT TROLLEY POSITIONING CHART

FOR (MODELS 9100, 9400, 9600, 5120 & 5140)

DIM “X”

Cut Straight Arm To

Accomplish Trolley

Setting

14” AND 15” RADIUS

TYPE OF ARM

BEING USED

FIG. 1.4

REFERENCE

ILLUSTRATIONS

required, use the close travel adjustment

screw located on the bottom of the opener,

as shown in FIG 1.5 on page 24. A 1/4 turn

13”-15”

CURVED /

STRAIGHT

FIG. 1.4

equals approximately 1” of trolley travel; turn

clockwise to decrease distance (forward)

and counter-clockwise to increase distance

(forward).

NOTE: Proceed with “Connecting Door Arm

To Door” Step 18, on page 14.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

STANDARD LIFT TROLLEY POSITIONING CHART

FOR (MODEL 9700) 15” RADIUS

DIM “X”

10 9/16”-

14 5/8”

TYPE OF ARM

BEING USED

STRAIGHT /

CURVED

REFERENCE

ILLUSTRATIONS

FIG. 1.3

Cut Straight Arm To

Accomplish Trolley

Setting

23

Page 30

Setting Trolley Close Position/

Connecting Door Arm

(Continued)

LOW HEADROOM:

Using the LOW HEADROOM TROLLEY

POSITIONING CHARTS, refer to

to set the distance from header to trolley, as

shown in FIG. 1.6.

NOTE: Depending on your setup, you may or

may not have to cut straight arm to

accomplish trolley settings.

If adjustment of the trolley position is

required, use the close travel adjustment

screw located on the bottom of the opener,

as shown in FIG 1.5. A 1/4 turn equals

approximately 1” of trolley travel; turn

clockwise to decrease distance (forward)

and counter-clockwise to increase distance

(forward).

LOW HEADROOM TROLLEY POSITIONING CHART

FOR (MODELS 9100, 9400, 9600, 5120 & 5140)

DIM “X”

14 1/2”

10” - 14” STRAIGHT FIG. 1.7a

TYPE OF ARM

BEING USED

CURVED /

STRAIGHT

OPTIONAL HOOKUP

DIM “X”

REFERENCE

ILLUSTRATIONS

TO THE RIGHT

FIG. 1.7

TRAVEL ADJUSTMENT

OPEN

LESS

MORE

CLOSE

MORE

Bottom Of Opener

FIG. 1.5

“X”

Low Headroom Track

Top

Section

FIG. 1.6

LOW HEADROOM TROLLEY POSITIONING CHART

DIM “X”

14 3/4”-

17 11/16”

10” - 14” STRAIGHT FIG. 1.7a

FOR (MODEL 9700)

TYPE OF ARM

BEING USED

CURVED /

STRAIGHT

OPTIONAL HOOKUP

REFERENCE

ILLUSTRATIONS

FIG. 1.7

NOTE: Proceed with “Connecting Door Arm

To Door” Step 18, on page 14.

Curved Arm

Cut Straight Arm To

Accomplish Trolley

Setting

FIG. 1.7

Straight Arm

FIG. 1.7a

24

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 31

12”

I

Tools Needed:

Needle Nose Pliers

Adjustable Wrench

Ratchet Wrench

7/16” Socket

9/16” Socket

Hacksaw

Setting Trolley Close Position/

Connecting Door Arm

(Models 9100, 9400, 9600, 5120, 5140 & 9700)

With Torsion Springs

DETERMINE THE WAYNE-DALTON

TRACK RADIUS BEING USED:

FOR MOUNT HOPE AND PENSACOLA

TRACK:

Measure the curved ends of the horizontal

track to determine if you have a 12” or 15”

radius horizontal track, as shown in FIG. 1.

FOR PORTLAND TRACK:

The horizontal tracks are stamped with

radius on the side of the horizontal track, as

shown in FIG. 1.1.

NOTE: If necessary, remove the upper arm

(straight arm) from the trolley, to use the

lower arm (curved arm). Remove the hairpin

cotter from the clevis pin at the front of

trolley and slide clevis pin out far enough

to slide the upper arm out between the left

and right side of trolley body. Position the

lower door arm so the end with the single

hole lines up with the clevis pin. Slide clevis

pin completely back into trolley and reinstall

hairpin cotter.

LOW HEADROOM:

If you have low headroom track, as shown

in FIG. 1.5 on page 26, then proceed with

“Low Headroom Trolley Positioning Charts”

on page 26.

STANDARD LIFT:

Using the STANDARD LIFT TROLLEY

POSITIONING CHARTS, refer to DIM “X”

to set the distance from header to trolley, as

shown in FIG. 1.2.

NOTE: Depending on your setup, you may

have to cut straight arm to accomplish

trolley settings.

STANDARD LIFT TROLLEY POSITIONING

CHART FOR 10” AND 12” RADIUS

FOR (MODELS 9100, 9400, 9600, 5120 & 5140)

Horizontal

Track

Clevis Pin

Hairpin Cotter

12” OR 15”

FIG. 1

“X”

TOP VIEW

Trolley

Top Section

Curved

Arm

Horizontal

Track

FIG. 1.2

12”

FIG. 1.1

10”, 12”, 14”, OR 15”

Standard Lift Track

Straight Arm

Cut Straight Arm To

Accomplish Trolley

Setting

Stamped

Radius

DIM “X”

11 1/2”-13”

TYPE OF ARM

BEING USED

STRAIGHT /

CURVED

If adjustment of the trolley position is

required, use the close travel adjustment

screw located on the bottom of the opener,

as shown in FIG 1.4 on page 26. A 1/4

turn equals approximately 1” of trolley

REFERENCE

ILLUSTRATIONS

FIG. 1.3

FIG. 1.3

STANDARD LIFT TROLLEY POSITIONING CHART

FOR 14” AND 15” RADIUS

(MODELS 9100, 9400, 9600, 5120 & 5140)

DIM “X”

10”-12”

TYPE OF ARM

BEING USED

STRAIGHT /

CURVED

REFERENCE

ILLUSTRATIONS

FIG. 1.3

travel; turn clockwise to decrease distance

(forward) and counter-clockwise to increase

distance (forward).

NOTE: Proceed with “Connecting Door Arm

To Door” Step 18, on page 14.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

STANDARD LIFT TROLLEY POSITIONING CHART

FOR (MODEL 9700) 15” RADIUS

DIM “X”

11 1/16”-

16 7/8”

TYPE OF ARM

BEING USED

STRAIGHT /

CURVED

REFERENCE

ILLUSTRATIONS

FIG. 1.3

25

Page 32

Setting Trolley Close Position/

Connecting Door Arm

(Continued)

LOW HEADROOM:

Using the LOW HEADROOM TROLLEY

POSITIONING CHART, refer to

set the distance from header to trolley, as

shown in FIG. 1.5.

NOTE: Depending on your setup, you may or

may not have to cut straight arm to

accomplish trolley settings.

If adjustment of the trolley position is

required, use the close travel adjustment

screw located on the bottom of the opener.

A 1/4 turn equals approximately 1” of trolley

travel; turn clockwise to decrease distance

(forward) and counter-clockwise to increase

distance (forward).