Page 1

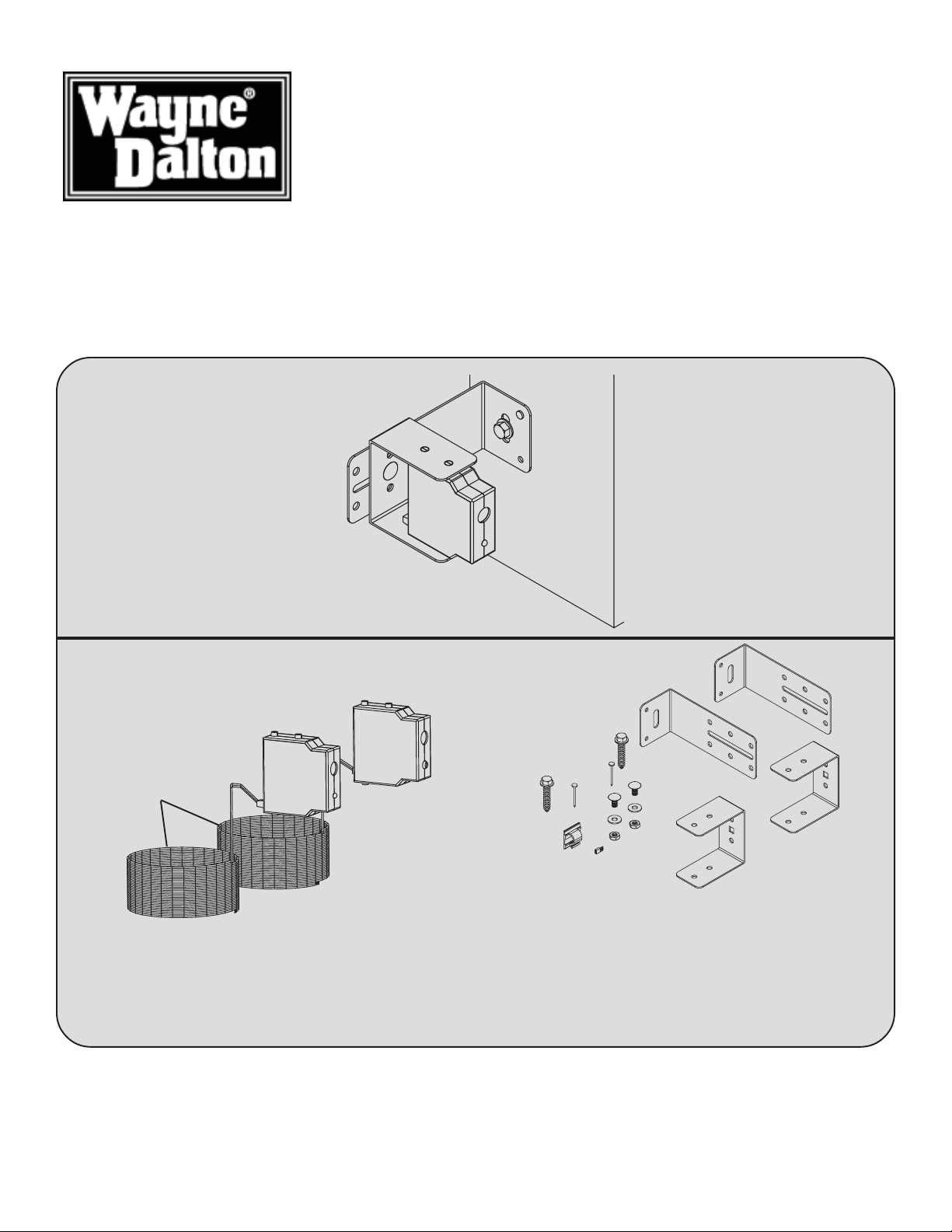

Photoelectric Safety Sensors

Installation Instructions

and Owner’s Manual

Wayne-Dalton Corp.

P.O. Box 67 Mt. Hope, OH 44660

(888) 827-3667

www.wayne-dalton.com

Quantum™/Classicdrive™ models: 3012, 3014, 3016, 3018, 3212, 3213, 3214, 3312, 3313, 3314, 3316, 3412, 3414, 3512, 3514.

DoorMaster™ models: BDOR-2000 & BIRW-2000

idrive™ models: 3660-372, 3661-372, 3662-372, 3760-372, 3751-372.

Opener Models:

Torsion idrive™ models: 3651-372, 3750-372.

WIRES ARE

PRE-ATTACHED

Photoelectric Sensors Hardware: 297218

(2) 5/16 x 1-1/2” Lag Screws

(2) 1” Flat Head Nails

Photoelectric Sensors

(1) Sender w/Wire: 260600

(1) Receiver w/Wire: 260597

(2) 1/4-20 x 1/2” Carriage Bolts, Washers & Nuts

(2) Wall Mounting Brackets

(2) “U” Brackets

(1) Power Cord Clip (adhesive back)

(1) Jumper

Important Notice!

DOOR OPENER WILL NOT OPERATE PROPERLY UNTIL PHOTOELECTRIC

SENSORS ARE INSTALLED AND PROPERLY ADJUSTED! DO NOT OPERATE

DOOR OPENER UNTIL IT IS FULLY INSTALLED, ADJUSTED AND YOU ARE

INSTRUCTED TO DO SO!

© Copyright 2003 Wayne-Dalton Corp. New 9/4/2003

Part No: 306736

Page 2

Table of Contents

Important Safety Instructions For Installation And Use 2.

Bracket Installation 3.

Wiring Installation “Quantum™/Classicdrive™” 4.

Wiring Installation “DoorMaster™” 4.

Wiring Installation “idrive™” 5.

Wiring Installation “Torsion idrive™” 5.

Photoelectric Safety Sensor Alignment 6.

Photoelectric Obstruction Sensing Test 6.

Important Safety Instructions 7.

Warranty 7.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Customer Service Number 7.

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL

PERSONAL INJURY HAZARDS. OBEY ALL SAFETY MESSAGES THAT FOLLOW THIS

SYMBOL TO AVOID POSSIBLE INJURY OR DEATH.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○

WARNING DISCONNECT ALL POWER FROM GARAGE DOOR OPENER BEFORE SERVICING

OR INSTALLING ACCESSORY PRODUCTS.

IMPORTANT SAFETY INSTRUCTIONS FOR

INSTALLATION AND USE

READ AND FOLLOW ALL

INSTALLATION INSTRUCTIONS.

DO NOT USE SENSITIVITY

ADJUSTMENT TO COMPENSATE

FOR A POORLY OPERATING DOOR.

THIS WILL INTERFERE WITH THE

PROPER OPERATION OF THE

SAFETY REVERSE MECHANISM.

DO NOT CONNECT OPENER TO

ELECTRICAL OUTLET UNTIL

INSTRUCTED TO DO SO.

AFTER INSTALLING OPENER,

THE DOOR MUST REVERSE

WHEN IT CONTACTS A 1 INCH

HIGH SOLID TEST OBJECT ON

THE FLOOR.

OPEN DOOR MUST NOT CLOSE

AND CLOSING DOOR MUST

OPEN IF PHOTOELECTRIC

SYSTEM IS OBSTRUCTED BY

6”X HIGH OBJECT, USING TEST

PROCEDURE DESCRIBED IN

STEP 4.

INSTALLATION AND WIRING MUST

COMPLY WITH LOCAL BUILDING

AND ELECTRICAL CODES.

CONNECT THE POWER CORD TO A

PROPERLY GROUNDED OUTLET.

DO NOT REMOVE ROUND GROUND

PIN FROM POWER CORD.

DO NOT WEAR RINGS, WATCHES

OR LOOSE CLOTHING WHEN

INSTALLING OR SERVICING A

GARAGE DOOR SYSTEM. USE A

STURDY, NONMETALLIC STEP

LADDER AND WEAR EYE

PROTECTION.

2

Page 3

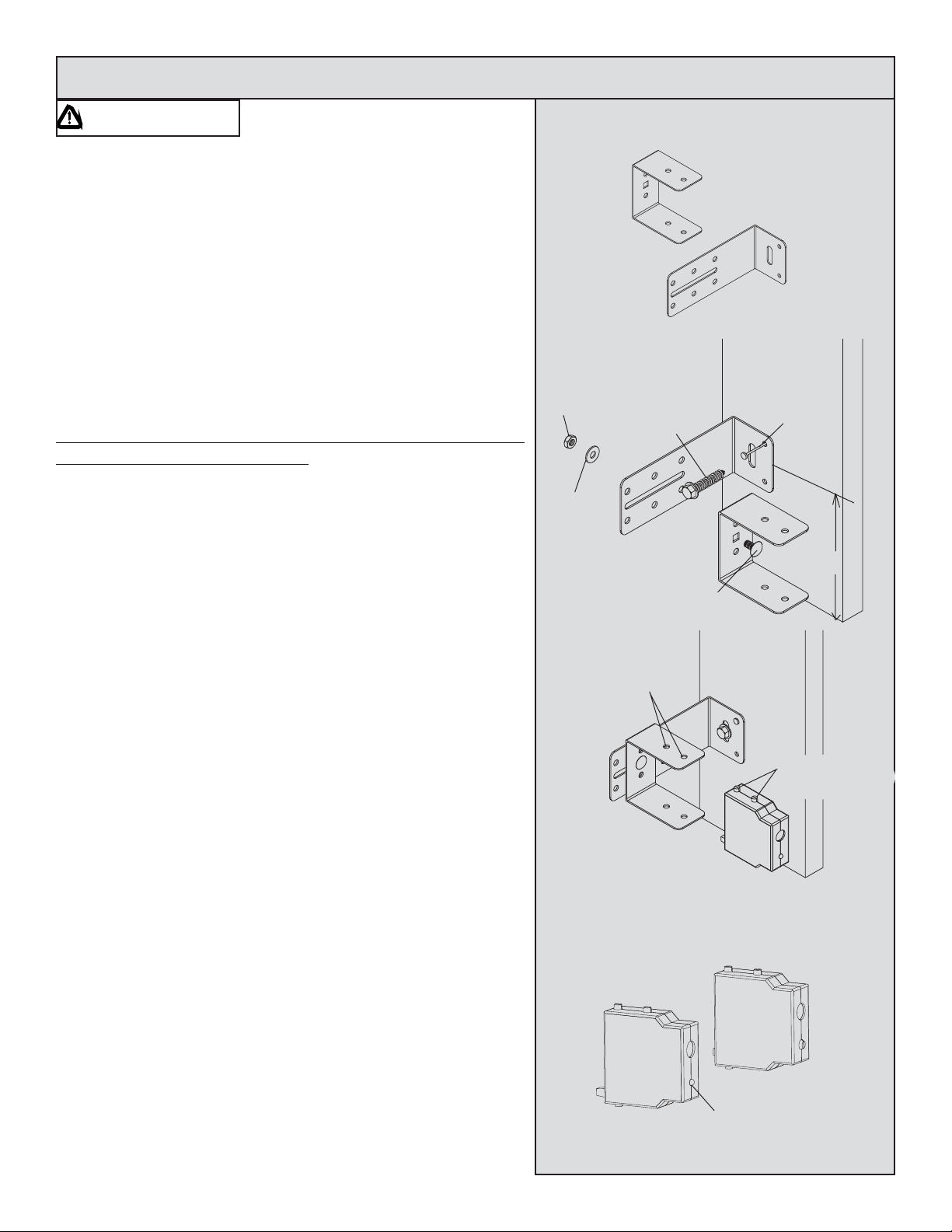

Step 1: Photoelectric Safety Sensor Bracket Installation

WARNING

GARAGE DOOR OPENER BEFORE SERVICING OR

INSTALLING ACCESSORIES OR PHOTOELECTRIC

SAFETY SENSORS. FOR ALL OPENERS, UNPLUG 120 V

AC POWER CORD FROM RECEPTACLE. FOR

DOORMASTER, ALSO UNPLUG TELEPHONE CORD TYPE

COMMUNICATIONS CABLE.

DISCONNECT ALL POWER TO

“U” BRACKETS

Select a mounting position, no more than 5 inches above the

floor to center line of wall mounting bracket. The sending and

receiving units should be mounted inside the door opening to

minimize any interference by the sun. However, the sensors

should be mounted as close to the door track or inside edge of

the door as possible to offer maximum entrapment protection.

It is very important that both wall brackets be mounted at the

same height for proper alignment.

The brackets may be temporarily mounted to the jamb with a 1”

flat head nail (provided) using the small hole above the slot.

Using two 5/16 x 1-1/2” lag screws (provided), permanently

mount the wall mounting brackets to both door jambs. In some

installations it may be necessary to attach a wooden spacer to

the wall to achieve the required clearance.

Attach the “U” brackets to the wall brackets with a

1/4-20 carriage bolt, washer and nut (provided). Insert

the bolt from the inside of the “U” bracket and hand tighten only

at this time.

NUT

WASHER

(1) 5/16 X 1-1/2”

LAG SCREW

(1)1/4-20 X 1/2”

CARRIAGE BOLT

TAB HOLES

TOP & BOTTOM

WALL MOUNTING

BRACKETS

NAIL

5”

Identify which side of the garage door opening (if any) is “likely”

to be exposed to sunlight. Since sunlight may affect photoelectric

sensors, you should mount the sending unit (not the receiving

unit) on the side of the door opening exposed most to the sun.

NOTE: If wires must be lengthened or spliced into prewired

installation, use wire nuts or suitable connectors.

Attach the sending and receiving units to the “U” brackets by

inserting their tabs into the respective holes.

3

TABS

TOP & BOTTOM

RECEIVING UNIT

SENDING

UNIT

(NO LED)

LED ALIGNMENT

LIGHT

Page 4

Step 2: Photoelectric Safety Sensor Wiring Installation For:

Quantum™/Classicdrive™ models: 3012, 3014,

3016, 3018, 3212, 3213, 3214, 3312, 3313, 3314,

3316, 3412, 3414, 3512, 3514.

Uncoil wires from the photoelectric sensors and route wires up the

garage walls and along ceiling towards the right side of the opener

(see Fig. 1). Route wires behind torque tube and tack wires in place

with insulated staples (not supplied).

Opener

Take care to run wires in a location where they will not interfere with

the operation of the door and do not staple through wire.

IMPORTANT! Keep sender/receiver wires away from moving

members.

Connect photoelectric sensors to opener per diagram (Fig. 1). Shorten

the wires as necessary and separate the wire ends. Strip about 1/2” of

insulation off each wire and attach the solid color wires to the COM

terminal and the wires with a black stripe to the OBS terminal. Tighten

terminal screws securely, using a small blade screw driver. Be sure

to observe polarity. Pull on external wires to test for secure connection.

Check that the wires are stapled in place and staples have not cut

wire insulation. Reconnect the power to the garage door opener.

Proceed to Step 3.

DoorMaster™ models: BDOR-2000 & BIRW-2000

Uncoil wires from the photoelectric sensors and route wires up the

garage walls and along door towards the right side of the opener (see

Fig. 2). Route wires behind torque tube and tack wires in place with

insulated staples (not supplied).

FIG. 1 Wire Routing

Black striped wires

(OBS terminal)

Sender

wires

Solid color wire

(COM terminal)

Receiver

wires

Solid color wire

(COM terminal)

Quantum™/Classicdrive™

Take care to run wires in a location where they will not interfere with

the operation of the door and do not staple through wire.

IMPORTANT! Keep sender/receiver wires away from moving

members.

Connect photoelectric sensors to opener per diagram (Fig. 2). Shorten

wires as necessary and separate wire ends. Strip about 1/2” of

insulation off each wire and attach the solid color wires to the COM

terminal and the wires with the black stripe to the OBS terminal.

Tighten terminal screws securely, using a small blade screwdriver.

Be sure to observe polarity. Pull on external wires to test for secure

connection. Check that the wires are stapled in place and staples

have not cut wire insulation. Remember to connect telephone type

cord for Doormaster™ installation. Once wires are connected, switch

the jumper (model BDOR-2000 only) from “Disable” to “Enable”

by pulling jumper off pins 2 and 3 and reinstalling jumper on pins 1

and 2.

NOTE: The jumper is set to disable from the factory.

Reconnect the power to the garage door opener. Proceed to Step 3.

4

FIG. 2 Wire Routing

NOTE: If wires must be lengthened or spliced into

prewired installation, use wire nuts or a suitable

connector. Pay attention to polarity.

Black striped wire

(OBS terminal)

Jumper

(Model: BDOR-

2000 only)

Right endcap

Sender wires

Solid color wires

(COM terminal)

Receiver

wires

Black striped wire

(OBS terminal)

DoorMaster™

Page 5

Step 2: Photoelectric Safety Sensor Wiring Installation For:

idrive™ models: 3660-372, 3661-372, 3662-372,

3760-372, 3751-372.

Uncoil wires from photoelectric sensors and route wires up garage wall

and along door header towards the right side of the opener

Route wires behind torque tube and tack wires in place with insulated

staples (not supplied).Take care to run wires in a location where they will

not interfere with the operation of the door and do not staple through wire.

Connect photoelectric sensors to the opener terminal block on right side

of the opener. Separate wire ends and strip about 1/2” of insulation off

each of the wire ends. Insert a 3/32” (2.5mm) max. width flathead

screwdriver into the lower hole #1 of the terminal block. Twist screwdriver

to open wire clamp in upper hole #1 of terminal block. Insert both sender

and receiver solid white wires into upper hole #1 until the wires bottom

out and release screwdriver tension. Insert both sender and receiver wires

(white with black stripe) into upper hole #2 by the same process on lower

hole #2 of terminal block. Be sure to observe polarity. Once wires are

connected, install jumper on to the left most set of pins labeled “PE” of

the opener.

(see Fig. 3 ).

FIG. 3 Wire Routing

Insert wires

into upper

hole #1

Insert wires

into upper

hole #2

Jumper

Jumper

installed

IMPORTANT! Keep sender/receiver wires away from moving members.

Pull on external wires to test for secure connection. Check that the wires

are stapled in place and staples have not cut wire insulation. Reconnect

the power to the garage door opener. Proceed to Step 3.

Torsion idrive™ models: 3651-372, 3750-372.

To locate the terminal block for the infrared sensor sender/receiver wires,

you must first move the right hand gear assembly. Loosen the set screw

and slide the gear assembly away from the opener. Uncoil wires from

photoelectric sensors and route wires up garage wall and along door header

towards the right side of the opener (see Fig. 4). Route wires behind

torque tube and tack wires in place with insulated staples (not supplied).

Connect photoelectric sensors to the opener terminal block on right side

of the opener. Separate wire ends and strip about 1/2” of insulation off

each of the wire ends. Insert a 3/32” (2.5mm) max. width flathead

screwdriver into the upper hole #1 of terminal block. Twist screwdriver

to open wire clamp in lower hole #1 of terminal block. Insert both sender

and receiver solid white wires into lower hole #1 until the wires bottom

out and then release screwdriver tension. Insert both sender and receiver

wires (white with black stripe) into lower hole #2 by the same process. Be

sure to observe polarity. Keep the sender and receiver wires straight and

organized by wrapping them around the backside of the opener and securing

them using the cord clip (adhesive backed) provided.(Insure the surface

the cord clip is attached to is clean and oil free.

IMPORTANT! Keep sender/receiver wires away from moving members.

Pull on external wires to test for secure connection. Check that the wires

are stapled in place and staples have not cut wire insulation. Reconnect

the power to the garage door opener. NOTE: Reinstall the right hand

gear assembly onto the drive gear. Ensure that the gear assembly is

installed correctly. Proceed to Step 3

.

Insert screw

driver into

lower hole #1

White wires

with black

stripe

Solid white

wires

Insert screw

driver into lower

hole #2

idrive™

FIG. 4 Wire Routing

Right hand

Insert screwdriver

into upper holes

Insert wires

into lower holes

gear assembly

Cord clip

Torsion idrive™

Pins

labeled

“PE”

Set screw

5

Page 6

Step 3: Photoelectric Safety Sensor Alignment

IMPORTANT! - This infrared safety sensor sends an invisible

beam of light from the sending unit to the receiving unit across

the door opening. The door opener will not operate until the

IN

FIG.5

IN

1/4-20 Carriage bolts

safety sensor is connected to the power unit and properly

aligned. If the invisible beam of light is misaligned or obstructed,

an open door cannot be closed by the transmitter or a momentary

activation of the wall mounted push button. However, the door

may be closed by holding your finger on the wall push button

(constant pressure) until the door travels to a fully closed

position.

WARNING

FAILURE TO MAKE ADJUSTMENTS

COULD RESULT IN SEVERE OR FATAL INJURY.

OUT

For this adjustment bend

Top View

Align In Center

(In/Out)

FIG.6

bracket at wall mount

Top view

Align in Center

OUT

At this point you will be able to activate the opener; it will open, but will not close the door unless the sensors are

aligned and unobstructed. The safety sensors can be aligned by moving the sending and receiving units in or out

(see Fig. 5) until the alignment light on the receiving unit comes on. The 1/4-20 carriage bolt can be loosened to

move the unit in or out, as required. If you have difficulty aligning beams, check that both brackets are mounted at

the same height and remount if necessary. Additional minor adjustments can be made by lightly bending the

mounting brackets (see Fig. 6).Once the alignment light comes on, tighten all bolts and mounting screws. Finish

securing all wiring. Make sure not to break or pierce any of the wires. Loop and secure any extra wire. Now, using

the wall station’s up/down button, activate the opener and check that it will operate through full open and close

cycles.

Step 4: Photoelectric Obstruction Sensing Test

Starting with the door in the fully open position,

place a 6” high object on the floor progressively

one foot from the left side of the door, center of

door and one foot from the right side of the door.

(Fig. 7) In each position, activation of the opener

with the wallstation up/down button should cause

the door to move no more than one foot, stop and

then reverse to fully open position. The same 6”

high object when placed on the floor, while door is

closing, should also cause the door to reverse.

12”

FIG. 7

6”

WARNING WHEN PERFORMING THIS PART OF THE TEST, DO NOT PLACE YOURSELF

UNDER DESCENDING DOOR, OR SEVERE OR FATAL INJURY MAY RESULT.

WARNING

HAVE A QUALIFIED SERVICE PERSON MAKE NECESSARY ADJUSTMENTS/REPAIRS.

TO MAKE ADJUSTMENTS COULD RESULT IN SEVERE OR FATAL INJURY.

IF THE OPENER DOES NOT RESPOND PROPERLY, OR FAILS THESE TEST,

FAILURE

12”

6

Page 7

IMPORTANT SAFETY INSTRUCTIONS

WARNING TO REDUCE THE RISK OF SEVERE INJURY OR DEATH: Please thoroughly read

safety rules on Page 2 and the following operating instructions. Operate only when opener is properly adjusted and

the door is visible and unobstructed.

Always keep moving door insight and keep

people and objects away from the door

until it is completely closed. NO ONE

SHOULD CROSS THE PATH OF THE

MOVING DOOR.

Use the emergency release only when the

door is closed. Use caution when using

this release with door open. Weak or

broken springs may cause the door to fall

rapidly, causing serious injury or death.

KEEP GARAGE DOORS PROPERLY

BALANCED. See owner’s manual. An

improperly balanced door could cause

severe injury or death. Have a qualified

service person make repairs to cables,

spring assemblies and other hardware.

Photoelectric Safety Sensors

90-DAY LIMITED WARRANTY

The Manufacturer warrants that the PHOTOELECTRIC SAFETY SENSORS will be free from defects in materials and workmanship including electronic components for

a period of 90-DAYS from the date of installation, provided it is properly installed, maintained and cared for under specified use and service.

Never let children operate or play with

door controls. Keep remote control away

from children

Test door opener monthly. Open garage

door MUST NOT close and closing door

MUST open if photoelectric obstruction

sensors system is obstructed by 6” high

object, using test procedure described in

Step 4. If opener fails this test, disconnect

immediately and call for technical support.

Malfunctioning opener can cause severe

injury or death.

Test door opener monthly. The garage door

MUST reverse on contact with a 1-1/2 inch

high object (or a 2 x 4 board laid flat) on

the floor. On Quantum™ openers, if

adjusting either the force or the limit of

travel, retest the door opener. Failure to

adjust the opener properly could cause

severe injury or death.

This Warranty extends to the original homeowner, providing the PHOTOELECTRIC SAFETY SENSORS are installed in his/her place of primary residence. It is not

transferable. The warranty applies to residential property only and is not valid on commercial or rental property.

NO EMPLOYEE, DISTRIBUTOR, OR REPRESENTATIVE IS AUTHORIZED TO CHANGE THE FOREGOING WARRANTIES IN ANY WAY OR GRANT ANY

OTHER WARRANTY ON BEHALF OF MANUFACTURER.

The Manufacturer shall not be responsible for any damage resulting to or caused by its products by reason of installation, improper storage, unauthorized service,

alteration of products, neglect or abuse, any acts of nature beyond Manufacturer’s control (such as, but not limited to, lightning, power surges, water damage, etc.), or

attempt to use the products for other than the customary usage or for their intended purposes. The above warranty does not cover normal wear or any damage beyond

Manufacturer’s control or replacement labor.

THIS WARRANTY COVERS A CONSUMER PRODUCT AS DEFINED BY THE MAGNUSON-MOSS WARRANTY ACT. NO WARRANTIES, EXPRESSED OR

IMPLIED, (INCLUDING, BUT NOT LIMITED TO, THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), SHALL EXTEND

BEYOND THE APPLICABLE TIME PERIOD STATED IN BOLD FACE TYPE ABOVE.

Claims for defects in material and workmanship covered by this warranty shall be made in writing to the dealer from whom the product was purchased within the warranty

period. Manufacturer may either send a service representative or have the product returned to the Manufacturer at Buyer’s expense for inspection. If judged by

Manufacturer to be defective in material or workmanship, the product will be replaced or repaired at the option of the Manufacturer, free from all charges except

authorized transportation and replacement labor.

THE REMEDIES OF BUYER SET FORTH HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER REMEDIES, THE LIABILITY OF MANUFACTURER,

WHETHER IN CONTACT, TORT, UNDER ANY WARRANTY OR OTHERWISE, SHALL NOT EXTEND BEYOND ITS OBLIGATION TO REPAIR OR REPLACE,

AT ITS OPTION, ANY PRODUCT OR PART FOUND BY MANUFACTURER TO BE DEFECTIVE IN MATERIAL OR WORK SHALL NOT BE RESPONSIBLE FOR

ANY DIRECT, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

This Warranty gives you specific legal rights and you may have other rights, which may vary from state to state. However, some states do not allow limitation on how long

an implied warranty lasts or the exclusion or limitation of incidental or consequential damages so the above limitations or exclusions may not apply to you.

Questions??

For quick answers and helpful advise, call

Wayne-Dalton Customer Service

© Copyright Wayne-Dalton Corp. 2003

(888) 827-3667

7

Loading...

Loading...