Page 1

908.42 MHz Low Power Communication Device Transceiver

IC Radio Standards Specification: RSS-210

ACS Report Number: 07-0186 - 15C

Manufacturer: Wayne-Dalton Corporation

Certification Test Report

372 MHz Discrete Receiver

FCC ID: KJ8-0001715

IC: 3540A-0001715

FCC Rule Part: 15.249

Model: 3790-Z

Installation Guide

Section4

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Page 2

D

21

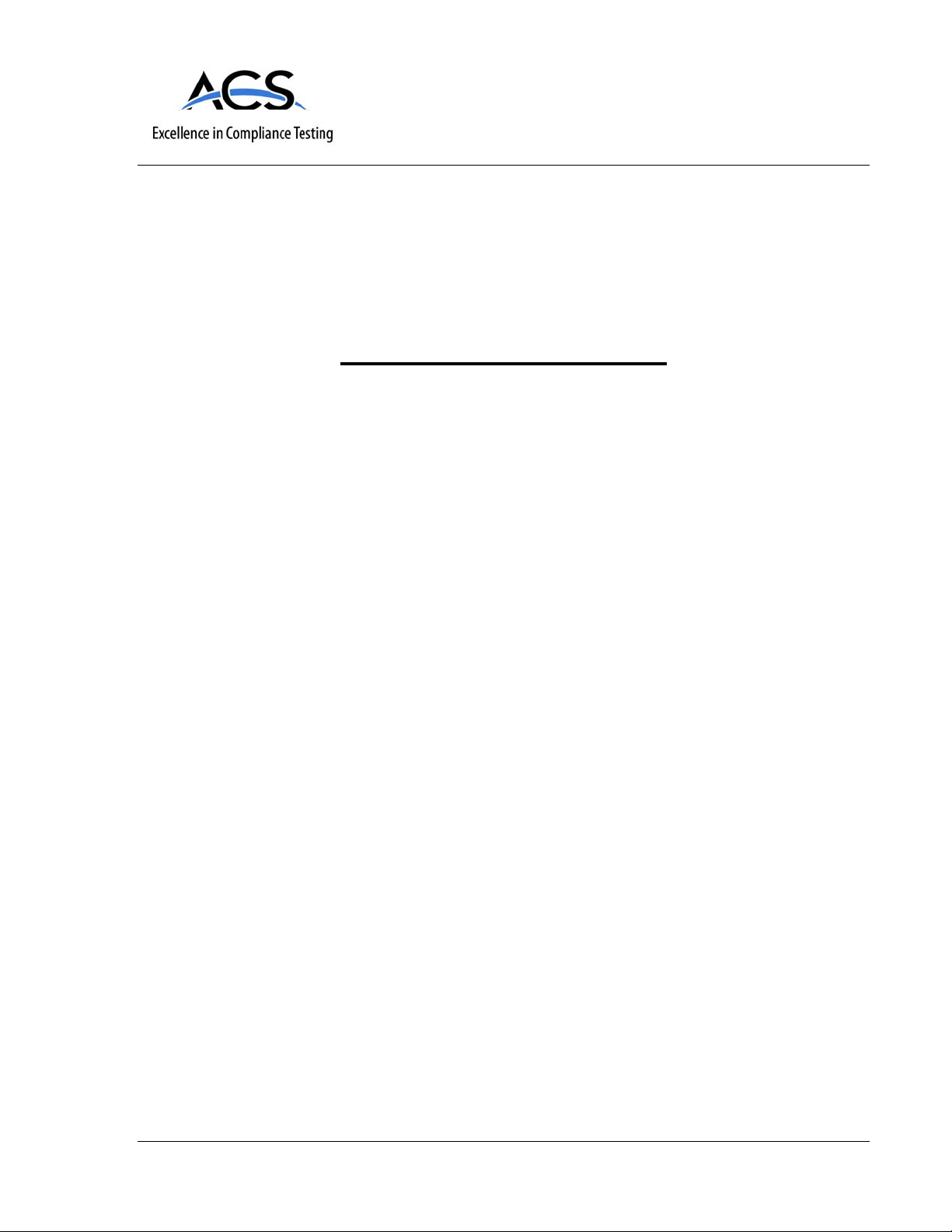

Sensor Wire Installation

(Required on 8000 Series Doors)

Wire Routing

Tools Needed:

Flat Tip

Screwdriver

Pliers/Wire

Cutters

Uncoil wires from photoelectric sensors and route

wires up garage wall and along door header

towards the right side of the opener.

Route wires behind torque tube and tack wires in

place with insulated staples (not supplied).Take

care to run wires in a location where they will not

interfere with the operation of the door.

Do Not Staple Through Wire.

NOTE: If wires must be lengthened or spliced

use wire nuts or suitable connectors.

NOTE: Take care to run wires in a location where

they will not interfere with the operation of the

door and do not staple through wire.

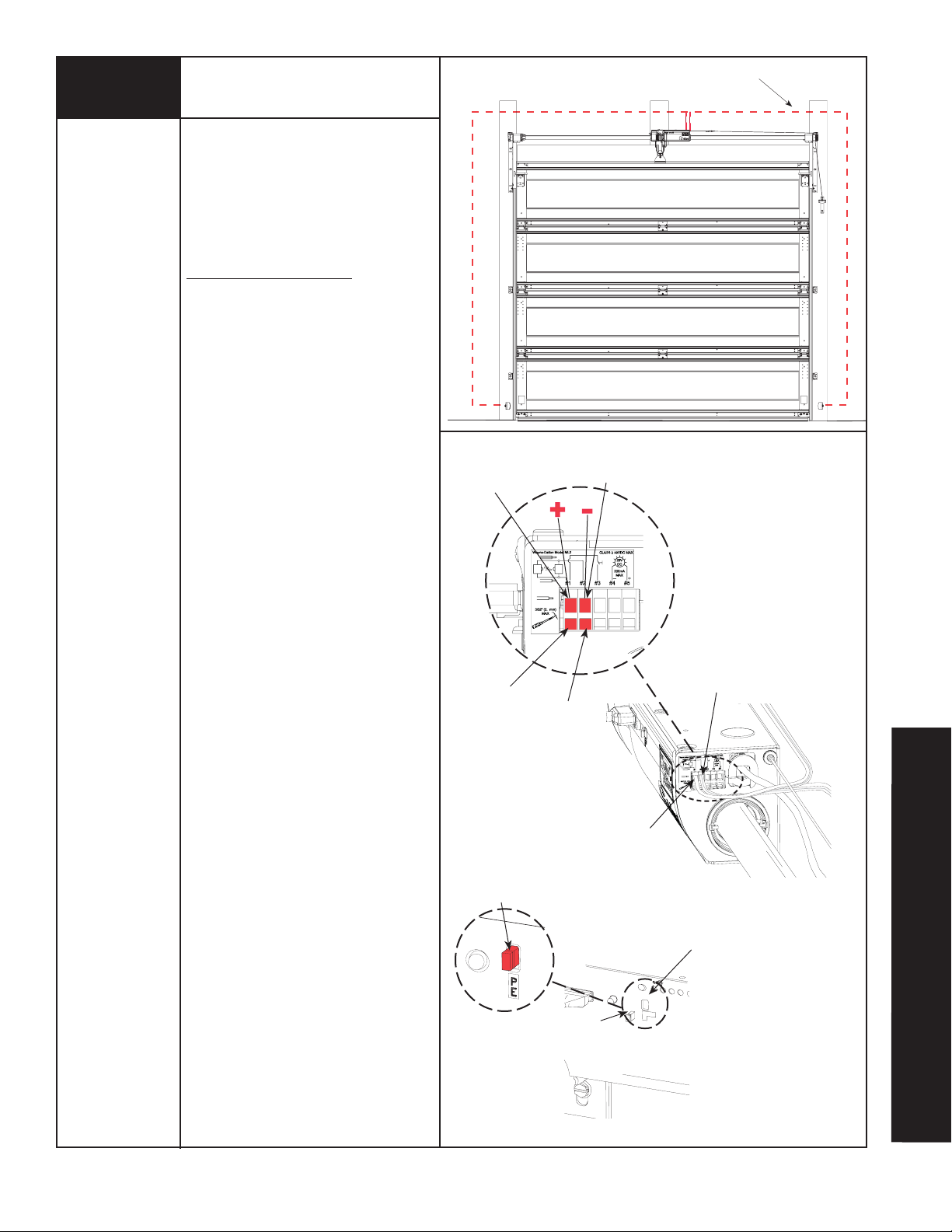

Connect photoelectric sensors to the opener

terminal block on right side of the opener. Separate wire ends and strip about 1/2” of insulation

off each of the wire ends.

Insert a 3/32” (2.5mm) max. width fl atblade

screwdriver into the lower hole #1 of the

terminal block. Twist screwdriver to open wire

clamp in upper hole #1 of terminal block. Insert

both sender and receiver solid white wires into

upper hole #1 until the wires bottom out and

release screwdriver tension. Insert and twist

screwdriver in lower hole #2 and insert both

sender and receiver wires (white with black

stripe) into upper hole #2 until wires bottom

out and release screwdriver tension. Be sure to

observe polarity.

Once wires are connected, install jumper

through the front opener cover on to the pins

labeled PE.

Insert wires

into upper

hole #1

Insert screw

driver into

lower hole #1

Insert wires

into upper

hole #2

White wires with

black stripe

Insert screw

driver into lower

hole #2

IMPORTANT! KEEP SENDER/RECEIVER WIRES

AWAY FROM MOVING COMPONENTS.

Lightly pull on external wires to test for secure

connection. Check that the wires are stapled in

Jumper

installed

Solid white wires

RIGHT HAND SIDE VIEW OF OPENER

place and staples have not cut wire

insulation.

Learn

P

Jumper

E

Pins labeled

“PE”

Controls

S

1

S2 S3 S

4

1

2

VIEW OF THE OPENER FROM THE FRONT

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

PRE-OPERATION

27

Page 3

22

Tools Needed:

Pliers

Safety Sensor Alignment

Align the safety sensors by moving the

sending and receiving units in or out until

the alignment light on the receiving unit

comes on. The 1/4”-20 carriage bolt can be

loosened to move the safety sensor in or

out, as required. If you have difficulty

aligning the beams, check that both

mounting brackets are mounted at the

same height and remount if necessary.

Additional minor adjustments can be made

by slightly bending the mounting brackets.

Once the alignment light comes on, tighten

all bolts and mounting screws. Finish

securing all wires making sure not to break

or open any of the conductors. Loop and

secure any excess wire.

In

Out

Top View

In

Out

1/4”-20 Carriage

Bolts

For this adjustment, bend

Bracket at wall mount

Top View

23

Tools Needed:

7/16” Wrench

Step Ladder

Securing the Opener

and Checking for Obstructions

With the emergency disconnect still in the

manual door operated position, manually

raise the door to the fully open position.

Then, manually lower the door to the fully

closed position verifying freedom of

movement and good door balance.

Tighten both 1/4”-20 flange nuts, securing

the opener to the support bracket.

NOTE: Good door balance and freedom of

movement are essential for proper opener

performance. If door is heavy to lift, hard to

close or if door sticks or binds in

the track, make proper adjustments now.

Support

Bracket

1/4” - 20

Flange Nuts

Controls

Learn Delete

S1 S2 S3 S4

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

28

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 4

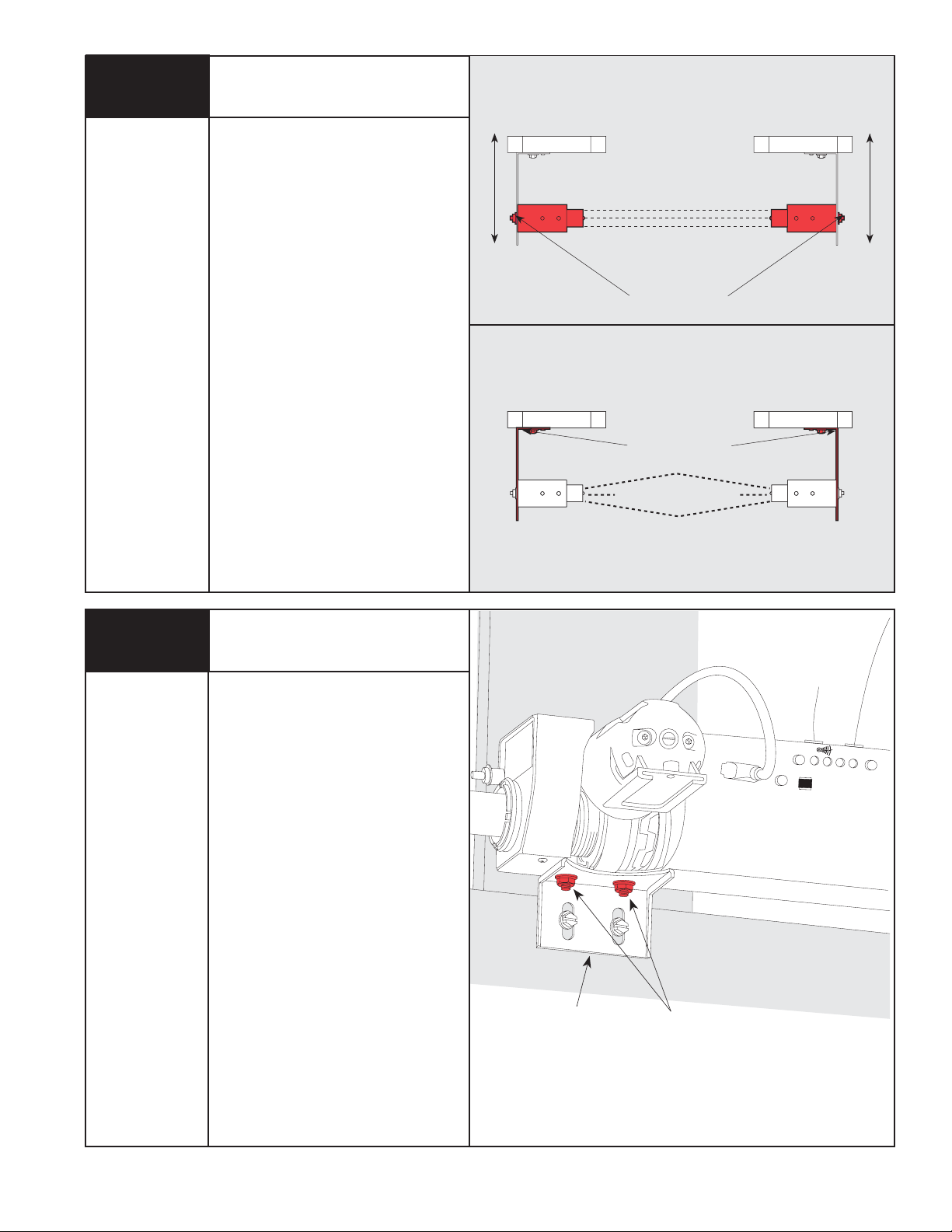

24

Programming Light Fixture

Program Button

LED

Tools Needed:

Step Ladder

25

Tools Needed:

None

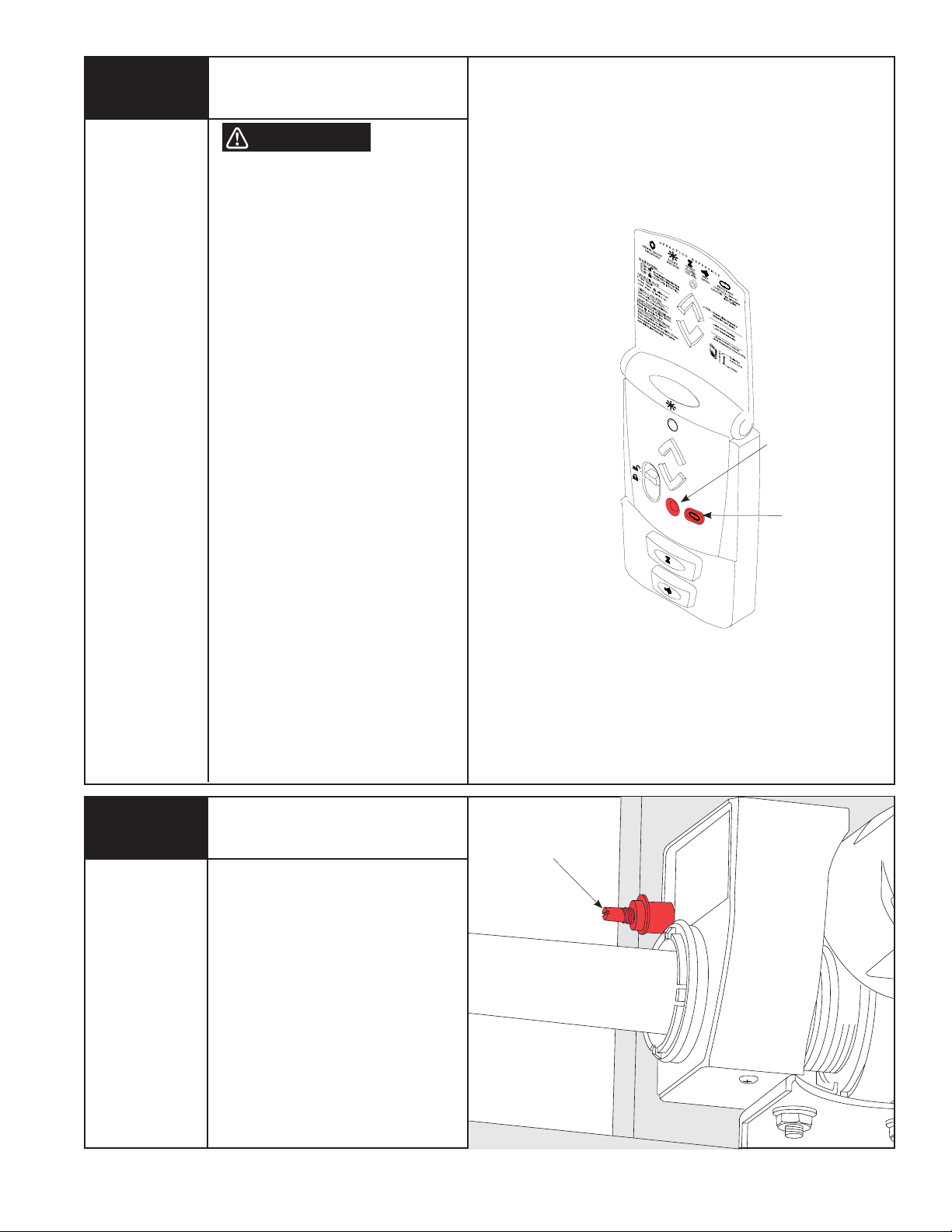

Press the red program button on the light

fixture. The LED on the light fixture will turn

on and remain on for 30 seconds

or until a opener is learned to the light

fixture. The incandescent lamp will also turn

on when program button is pushed.

Press the light button on the wall station.

This must be done within 30 seconds of

pressing the program button on the light

fixture. The light fixture lamp and LED will

blink three times to indicate successful

programming. The light fixture can now be

turned on and off from this wall station.

NOTE: In order to program the opener to

the light fixture, the installer must have the

wall station already programmed to the

opener.

Profile Routine

(Standard Upper Limit)

WARNING

TO AVOID INJURY, NO ONE SHOULD

CROSS THE PATH OF A MOVING DOOR!

FPO

Light Button

e

r

p

a

O

t

e

o

T

D

o

Press

o

r

Here

The profile routine automatically sets the

door open and close limits and calibrates

obstruction sensing. During the profile

routine, the door will move up and down

twice.

NOTE: If an object such as a ceiling beam

obstructs the door from opening completely,

skip this step. Set a Custom Upper Limit, see

Step 26.

NOTE: The door must be in its fully closed

position and the disconnect handle must

be in the motor operated position (upper

position) to initiate the profile routine.

NOTE: Profile routine will not run if safety

sensors are not aligned (only if required

installation).

Press and hold the profile button for

five (5) seconds. The opener will beep

twice, release the profile button, indicating

the activation of the profile routine. The door

will now move to the fully open position and

stop, beep twice and then the door will close

completely.

Next, the door will go through one more up/

down cycle. Once this is complete, the door

limits are set and the profile is complete.

NOTE: Upon successful completion proceed

to Step 27.

Profile

Button

PRE-OPERATION

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

29

Page 5

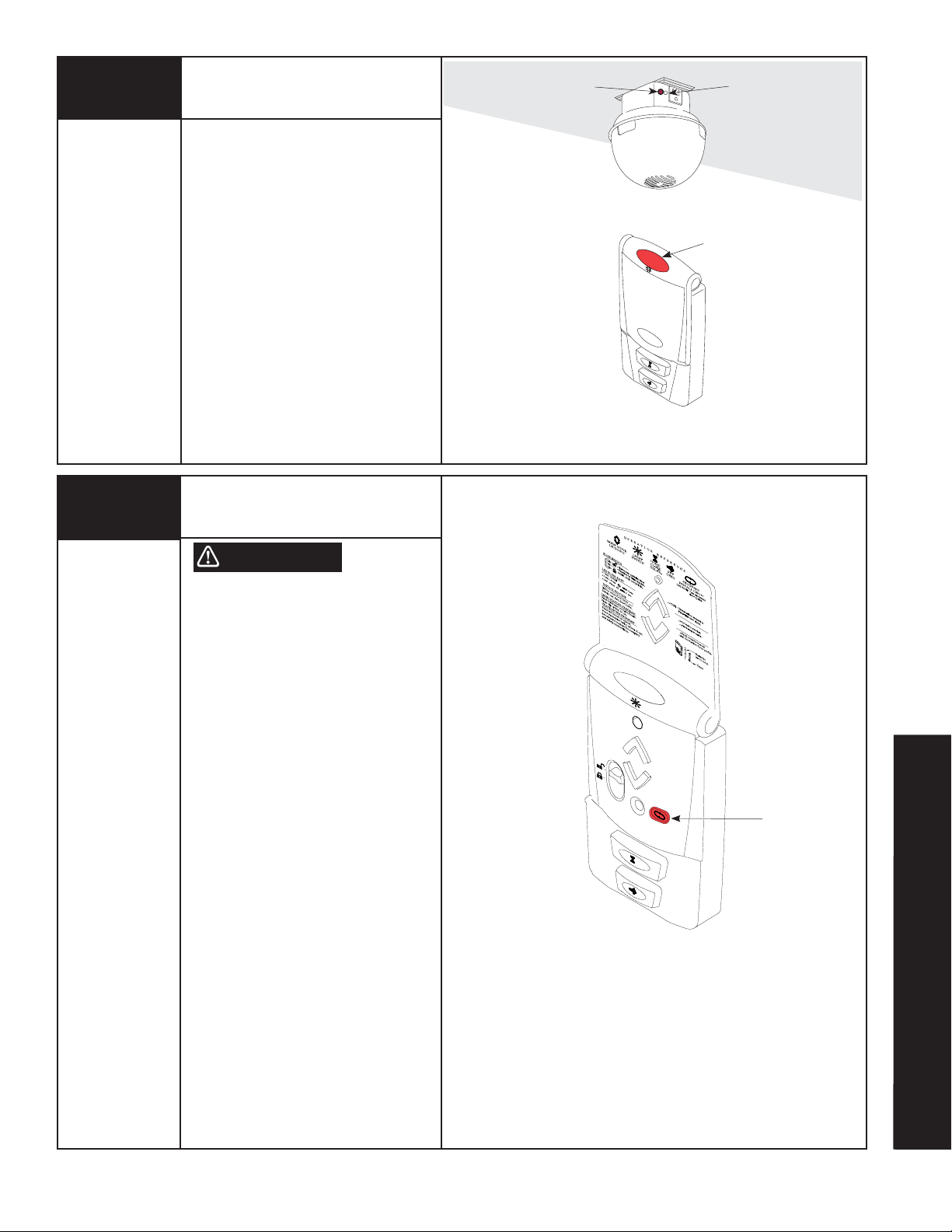

26

Install Routine

(Custom Upper Limit)

Tools Needed:

None

WARNING

TO AVOID INJURY, NO ONE SHOULD

CROSS THE PATH OF A MOVING DOOR!

NOTE:

If no obstruction interferes with a

standard upper limit, skip this step.

NOTE: The door must be in its fully closed

position and the disconnect handle must be

in the motor operated position (upper

position) to initiate the profile routine.

NOTE: Install profile will not run if safety

sensors are not aligned (Only if required for

your door).

Press and hold the profile button for

five (5) seconds. The opener will beep

twice, release the profile button, indicating

the activation of the profile routine.

When the door moves to the desired upper

limit, press and hold the Up/Down button on

the wall station until the door stops. Next,

the door will close completely. The Up/Down

button (when door is closed) can be

activated by pressing center of flip cover.

Next, the door will go through one more Up/

Down cycle. Once this is complete, the door

limits are set and the profile is complete.

Alternately, once an profile routine has been

successfully completed, disconnect door

and manually move to desired upper limit.

Re-connect door and press and hold the

profile button for five (5) seconds. The

door will close, open and close to complete

the profile routine with the new custom

upper limit.

NOTE: For a more precise location of the

custom upper limit, see “Customizing the

Settings” on page 39.

Up/Down

Button

Profile

Button

Adjusting Detent

27

Tools Needed:

Flat Tip

Screwdriver

Step Ladder

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

30

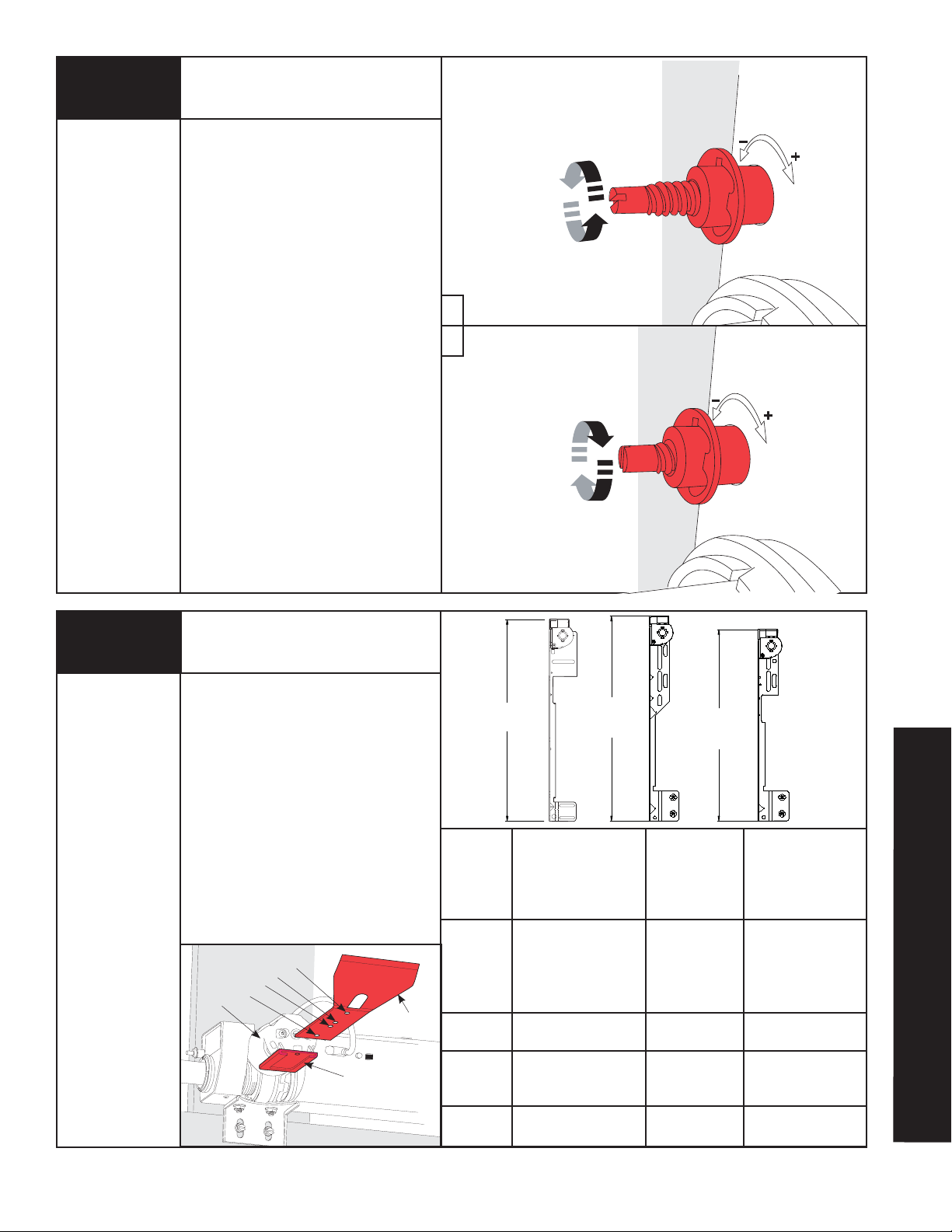

The amount of pressure the opener

uses to pivot the motor downward is

preset at the factory via the detent pin

adjustment screw.

Due to variations in door installations,

a detent pin adjustment may need to

be made in order to insure proper pivoting

of the motor.

IMPORTANT! FOR SYSTEM SECURITY:

THE MOTOR IS DESIGNED TO PIVOT DOWN

AFTER THE DOOR CLOSES COMPLETELY. IF

THE MOTOR DOES NOT PIVOT OR PIVOTS

TOO SOON, THE DETENT PIN ADJUSTMENT

SCREW MAY NEED TO BE ADJUSTED IN

ORDER FOR THE DOOR LOCK FEATURE TO

WORK PROPERLY.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Detent Pin

Adjustment Screw

Page 6

Tools Needed:

Adjusting Detent

(Continued)

If the motor does not pivot down, or only

a.

pivots down partially, the detent pin is set

too hard.

Using a flat tip screwdriver, turn the

detent pin counterclockwise in 1/8

turn increments.

Operate the door to confirm adjustment.

Repeat procedure until motor pivots

to full down position when the door

is completely closed.

b. If the motor pivots down prematurely

(before the door is completely closed) or

if the motor is “slapping” too aggressively

against the top of the door, the detent pin

is set too soft.

Using a flat tip screwdriver, turn the

detent pin clockwise in 1/8 turn

increments. Operate the door to

confirm adjustment.

a

b

28

Tools Needed:

Tape Measure

Step Ladder

Repeat procedure until motor pivots

to full down position when the door

is completely closed.

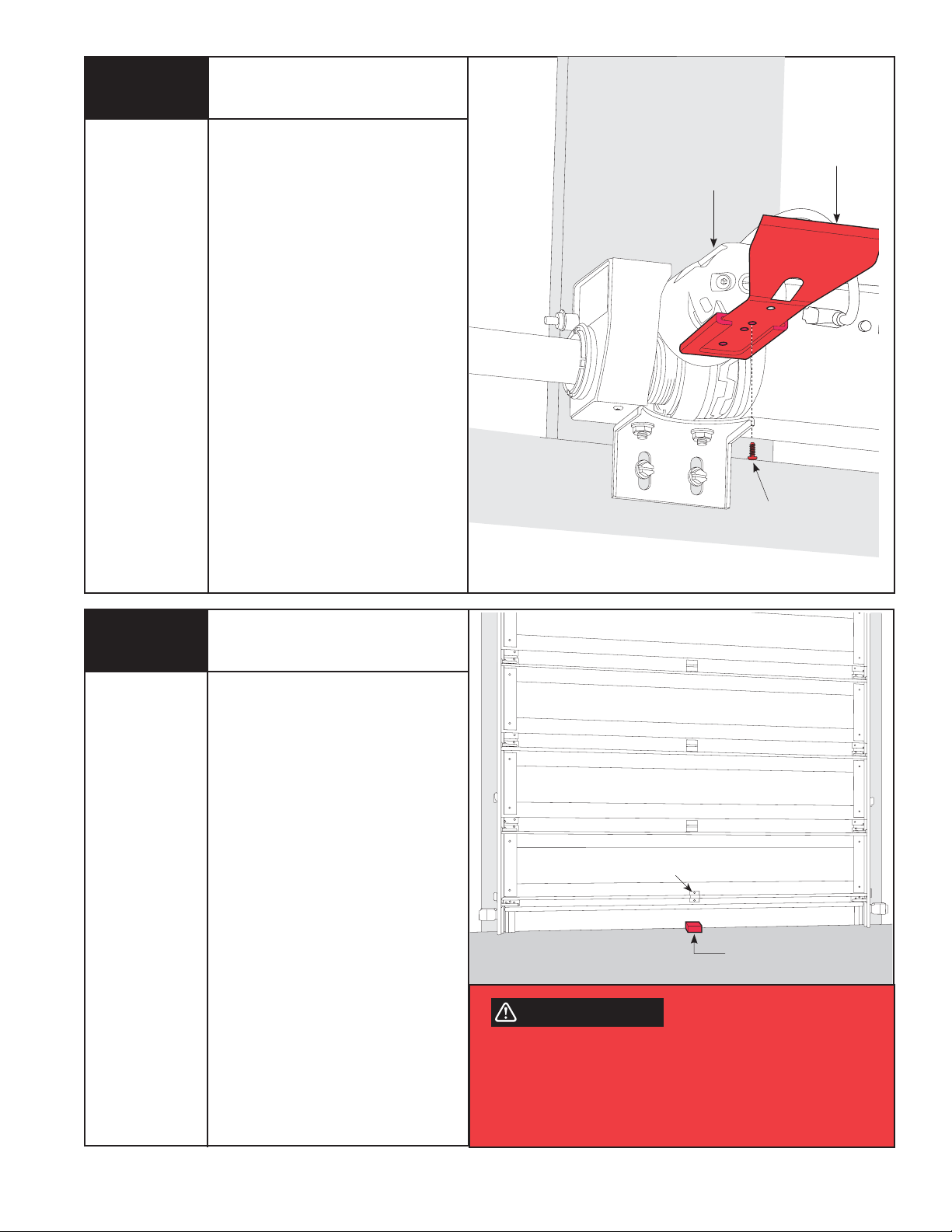

Lock Arm Installation

NOTE: If you have a low headroom double

track system, skip this step and continue

with Step 29.

Place the emergency disconnect in the manual

operated position, Motor will pivot to the up

position (see Step 10).

Insert the lock arm into the motor groove and

align with the proper hole depending on your

track radius. To determine the Wayne-Dalton

track radius being used, measure the length of

the flagangle and Torquemaster

and compare to the diagram on the right (all

Portland tracks are stamped with radius on the

side of the track).

4

Motor

®

end bracket

1

2

3

Lock

Arm

WD

WD

PO

PO

Mt. HOPE/

PENSACOLA

15” RADIUS

21-1/8”

Mt. HOPE/

PENSACOLA

12” RADIUS

19-3/4”

Track Radius Door Model

15”(380mm)

12”(305mm)

12”

10”

PORTLAND

TRACK

20-3/4”

Lock

Arm

Position

1

2 PO 12” 8000 Series

Track Type

WD - Mt. Hope &

Pensacola

PO - Portland

9700

8000, 9000

9000 Series

8000, 9000

PRE-OPERATION

Motor

Groove

3

4 PO 14” 8000 Series

WD

PO

15”(308mm)

14”

8000, 9000

9000 Series

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

31

Page 7

Lock Arm Installation

(Continued)

Tools Needed:

Once track radius has been determined,

secure the lock arm to the motor with

(1) 5mm x .8mm phillips pan head screw.

NOTE: If unsure of track radius, begin with

lock arm in position 1.

After assembly of the lock arm, manually

raise and lower the door and verify that the

lock arm does not interfere with the door. If

there is interference between the door and

the lock arm, see Page 43

troubleshooting.

NOTE: Do not operate the door or opener if

there is interference between the lock arm

and the door.

Reconnect the door to the motor operated

position. Activate a motor operated up/down

cycle to confirm clearance.

for lock arm

Lock Arm

Motor

5mm x 8mm

Phillips

Pan Screw

29

Tools Needed:

2 x 4 Board

Contact Obstruction Test

After installing the opener, the door must

reverse when it contacts a 1-1/2” high

object (or a 2 x 4 board laid flat) on the

garage floor.

Using the wall station, activate the door

to the fully open position.

Place a 2 x 4 board flat on the garage

floor, under the door path.

Activate the door to the closed position

with the wall station. Upon contacting the

2 x 4 board, the door should stop, then

reverse direction within two seconds and

travel to the full open position.

If the door does not respond to the

required tests, repeat install routine Step

25 or 26, making sure the door is in the

fully closed position prior to activation.

Center Of Door

2 x 4 Laid Flat

On Floor

WARNING

IF OPENER DOES NOT RESPOND PROPERLY TO THESE TESTS (STEPS

29 AND 30), DO NOT USE DOOR UNTIL A QUALIFIED SERVICE PERSON

HAS MADE NECESSARY ADJUSTMENTS/REPAIRS, OR SEVERE OR FATAL

INJURY COULD RESULT FROM OPERATING THE DOOR/OPENER.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

32

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 8

30

Testing the Safety Sensors

(If Installed)

Tools Needed:

6” Height Object

WARNING

WHEN PERFORMING THIS PART OF THE

TEST, DO NOT PLACE YOURSELF UNDER

DESCENDING DOOR, OR SEVERE OR

FATAL INJURY MAY RESULT.

Starting with the door fully open, place

a 6” high object on the floor, in line with

sensors, one foot from the left side of

the door.

Activation of the opener with the wall

station Up/Down button should cause the

door to move no more than one foot, stop

and then reverse to fully open position.

Repeat this test with the 6” high object

placed at the center of the door and then

one foot from the right side of the door.

The 6” high object, when placed on the

floor in line with sensors, while door is

closing, should also cause the door to

reverse.

6”

12”

WARNING

IF OPENER DOES NOT RESPOND PROPERLY TO THESE TESTS (STEPS

29 AND 30), DO NOT USE DOOR UNTIL A QUALIFIED SERVICE PERSON

HAS MADE NECESSARY ADJUSTMENTS/REPAIRS, OR SEVERE OR FATAL

INJURY COULD RESULT FROM OPERATING THE DOOR/OPENER.

12”

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

PRE-OPERATION

33

Page 9

❉

IMPORTANT SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF SEVERE

INJURY OR DEATH:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with the door controls.

Keep remote controls away from children.

3. Always keep a moving door in sight and keep people and objects

away until it is completely closed. NO ONE SHOULD CROSS THE

PATH OF A MOVING DOOR.

4. NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

5. Test the Door/Opener monthly. The garage door MUST reverse on

contact with a 1-1/2” high object (or a 2 x 4 board laid flat) on the

floor. The door MUST also reverse when a 6” high object is placed on

the floor in line with safety sensors. If Door/Opener fails these tests,

have adjustments/repairs made immediately. Failure to make

adjustments/repairs may cause severe or fatal injury.

6. When possible, use the Emergency Disconnect only when the door is

in the closed position. Be very cautious using the Emergency

Disconnect when the door is open. Weak or broken spring(s) may

allow the door to fall rapidly, causing a severe or fatal injury.

7. KEEP THE GARAGE DOOR PROPERLY BALANCED. See the owner’s

manual included with the door. An improperly balanced door could

cause a severe or fatal injury. Have a qualified service person make

repairs to the cables, spring assemblies, and other hardware.

8. SAVE THESE INSTRUCTIONS.

WARNING

ALWAYS KEEP MOVING DOOR IN SIGHT AND KEEP PEOPLE AND

OBJECTS AWAY UNTIL IT IS COMPLETELY CLOSED. TO PREVENT A

SEVERE OR FATAL INJURY, AVOID STANDING IN A OPEN DOOR WAY

OR WALKING THROUGH THE DOORWAY WHILE THE DOOR IS

MOVING.

WARNING

NEVER LET CHILDREN OPERATE DOOR OR PLAY WITH THE DOOR

CONTROLS. KEEP REMOTE CONTROLS AWAY FROM CHILDREN.

FATAL INJURY COULD RESULT SHOULD A CHILD BECOME TRAPPED

BETWEEN THE DOOR AND FLOOR.

WARNING

KEEP THE GARAGE DOOR PROPERLY BALANCED. AN IMPROPERLY

BALANCED DOOR COULD CAUSE SEVERE OR FATAL INJURY. HAVE A

QUALIFIED SERVICE PERSON MAKE ADJUSTMENTS/REPAIRS TO

CABLES, SPRING ASSEMBLIES, AND OTHER HARDWARE.

Emergency Disconnect:

WARNING

THE EMERGENCY DISCONNECT SHOULD ONLY BE USED WHEN DOOR

IS CLOSED. USE EXTREME CAUTION IF OPERATING THE EMERGENCY

DISCONNECT ON AN OPEN DOOR. WEAK OR BROKEN SPRING(S) MAY

ALLOW THE DOOR TO FA LL R APIDLY, CAUSING SEVERE OR FATAL

INJURY.

The opener is equipped with an emergency disconnect that allows the

door to be moved manually and independently from the opener.

Door activation:

Upon activation by either the Wall Station Up/Down Button or

Transmitter, the door will move in the following manner:

1. If closed, the door will open. If open completely, the door will close. If

partially open, the door will close.

2. If closing, the door will stop, reverse, and return to the open position.

Next activation will close the door.

3. If opening, the door will stop. Next activation will close the door.

4. If an obstruction is encountered or an out-of-balance condition is

detected while the door is closing, the door will reverse, return to the

open position, and the opener will beep 3 or 4 times. The next

activation will close the door.

5. If an obstruction is encountered or an out-of-balance condition is

detected while opening the door, the door will stop. The next

activation will close the door.

6. When door is in motion any button on the wall station functions the

same as the Up/Down button.

With the door closed, pull down on the disconnect handle and place the

handle under the lower section of the handle bracket. This motion

causes the motor on the opener to pivot upwards and the opener to

disconnect from the torque tube.

Releasing the disconnect handle from the lower section on the handle

bracket and returning the handle to its original position will reconnect

the opener to the torque tube.

NOTE: The motor will not pivot down completely when the handle is

released. After one motorized up/down door cycle, the motor will once

again pivot down, and all cable slack will be taken up. The garage door

is not secured from forced entry until the motor is back in the down

position.

Disconnect Label: The label is located next to the disconnect handle.

The label shows the handle in both the motor operated and manual

operated positions. View on the left side of the label shows the handle

position when the opener is engaged to the torque tube. The view on the

right side of the label shows the handle when the opener is disconnected

from the torque tube.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

34

Page 10

❉

Operating the Wireless Wall Station

Up-Down Button:

Momentarily pressing the Up/Down button activates the door. If an

out-of-balance condition causes the door to stop while opening or

reverses the door while closing, apply constant pressure to the

Up/Down button until the door is fully open or closed. This will allow

the opener to move the door in an out of balance condition, until the

problem is corrected (see Troubleshooting). The Up/Down button

(when unit is closed) can be activated by pressing flip cover.

WARNING

THE SEVERE OUT-OF-BALANCE CONDITION MUST BE CORRECTED

IMMEDIATELY. FAILURE TO MAKE ADJUSTMENTS/REPAIRS, COULD

RESULT IN SEVERE OR FATAL INJURY.

Light Button:

Momentarily pressing the Light Button turns on the light fixture. The

light fixture will remain on until either the Light Button is pressed again

or the door is activated. The light fixture automatically turns on with a

door activation and remains on for five minutes. Pressing the light

fixture button before the five minutes has elapsed will turn off the light

fixture. While the door is in motion, the Light Button functions identically

as the Up/Down button, stopping or reversing the door immediately.

Timer Button:

Momentarily pressing the Timer Button causes a delayed activation of a

stationary fully open door. The opener will signal seven beeps (approx.

8 seconds) then beep constantly for two seconds prior to closing the

door, allowing time to exit the garage when the opener is in the timer

mode. Pressing any button, except for the profile button while the

opener is beeping cancels the timer mode.

NOTE: The Timer feature will only function with the door in the

full open position. Pressing the Timer Button with a stationary

door in any other position will cause the opener to beep four

times and the door will not be activated.

While the door is in motion, the Timer Button functions identically as

the Up/Down button, stopping or reversing the door immediately.

Slide Switch:

The Slide Switch has two positions: Normal, and Door lock.

Normal position:

Move the Slide Switch to normal position for all normal functions of the

opener. The normal position will cancel the door lock feature.

NOTE: When the Slide Switch is moved to the unlocked

position the opener will beep once.

Door Lock position:

If the door is stopped (fully open, fully closed or partially open) move

the Slide Switch to the door lock position to suspend all normal

functions of the opener. The opener will remain completely disabled

and non-operational in this mode. All wall stations, transmitters and

keyless entry units are ignored until the Slide Switch is moved to the

normal position. If the door is moving when the Slide Switch is moved

to the door lock position, the door lock mode is not activated and all

functions of the opener remain active.

NOTE: When the Slide Switch is moved to the locked position

the opener will beep twice.

Backlit LED Light:

The red LED blinks intermittently to help you locate the wall

station in a dark garage. This blink rate can be changed for longer

battery life or can be turned off. The default blink rate is one blink

every 3 seconds. For longer battery life the blink rate can be

changed to blink once every 6 seconds. To change the blink rate,

remove the battery cover and remove one battery. Re-install the

battery and within 2 seconds, press the Light button. Re-install

the battery cover.

For longest battery life, the blink can be turned off. To turn off

the blink, remove the battery cover and remove one battery.

Re-install the battery and within 2 seconds, press the pet button.

Re-install the battery cover.

NOTE: The wall stations red LED will light while any wall

station button remains pressed.

Pet Position:

Pressing the Pet button opens a closed door to a preset position

between eight and thirty inches above the floor, allowing pets to

enter and exit the garage without the door being fully open. The

door must be fully closed to activate the pet open feature.

Pressing the Pet button with a stationary door in the pet open

position will cause the door to close. Pressing the Up/Down

button while the door is in the pet position will cause the door to

open. While the door is in motion, the pet button functions

identically to the Up/Down button, stopping or reversing the door

immediately. The pet feature allows for custom setting of the pet

position door height. See Customizing the Settings on page 38.

NOTE: A door in the “pet position” (open 8-30 inches) is not

locked and should not be used as a secured door position.

Profile Routine:

Press and hold the Profile button for 5 seconds to initiate the

“Profile Routine”. See Customizing the Settings on page 38.

NOTE: The wall stations red LED will light while any wall station

button remains pressed. See Maintenance section for battery

replacement.

Light Button

Up/Down Button

Slide Switch

Timer Button

Profile Button

OPERATION

Pet Button

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

35

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 11

Programming HomeLink® System to the Torquemaster® idrive® (Primary)

❉

NOTE: This step can only be done on automobiles equipped with the

HomeLink

NOTE: Programming HomeLink® requires a Wayne-Dalton Transmitter

that is programmed to the opener (the wallstation and transmitter(s)

supplied with the opener, come pre-programmed from the factory). Any

additional wallstation(s) or transmitter(s) will need to be programmed to

the opener, see page 41.

IMPORTANT! Use the programming instructions provided with your

vehicle first. Follow these instructions if the HomeLink

learn the transmitter, when using the vehicle’s instructions.

NOTE: If Primary programming does not work then use the Alternate

procedure on next page.

NOTE: Vehicle may need to be in accessory position when

programming. Check car owner’s manual.

NOTE: HomeLink® is a registered trademark of Johnson Controls.

®

system.

®

unit does not

Programming/Training HomeLink® Unit

WARNING

GARAGE DOOR MAY OPERATE DURING PROGRAMMING. TO AVOID

POSSIBLE SEVERE OR FATAL INJURY, PLACE THE EMERGENCY

DISCONNECT HANDLE IN THE MANUAL OPERATED POSITION.

1. Pull the manual disconnect to put the opener in the disengaged

position.

2. Verify the HomeLink

desired HomeLink® button and observe the LED – if it flashes

slowly, the channel is empty and ready for programming. If

pressing the desired channel/button causes the LED to blink

rapidly, or come on without blinking this channel is already

programmed. You either need to choose a different channel/

button on the HomeLink®, or perform Step 3 below.

3. OPTIONAL – To completely clear all channels on the HomeLink®

unit, press and hold the two outside buttons on the HomeLink®

unit until the HomeLink® LED light begins to flash rapidly

(approx. 20 seconds), then release both buttons. (Do not perform

this step to train additional hand-held transmitters.) NOTE: This

operation erases all previously learned transmitters and you will

need to re-teach any other transmitters to your HomeLink® unit.

4. Hold the end of the Wayne Dalton hand-held transmitter

approximately 1 to 3 inches away from the HomeLink® surface –

keeping the HomeLink® indicator light in view.

5. Simultaneously press and hold the Wayne Dalton transmitter

large button and desired button on the HomeLink® module,

continue to hold both buttons. In less than 10 seconds the LED

on the HomeLink® module will either go solid or give a single

quick flash, release both buttons when either occur.

NOTE: If this procedure is unsuccessful, perform Alternate procedure

on next page.

®

unit has an empty channel – press the

Teaching HomeLink® to the idrive® opener

6. Press and release the red program button on the idrive® opener.

The idrive® unit will beep once, indicating that it is ready to learn.

NOTE: The idrive® will remain in the learn mode for 30 seconds.

7. Press the HomeLink® button used in Step 5 above for 1 to 3

seconds. The idrive® will beep indicating a successful learn.

8. Return the manual disconnect to the engaged position.

9. Press the HomeLink® button once more to operate the door.

NOTE: The first transmitter command after programming will only move

the door through a six inch up/down cycle. Normal door operations will

occur on the second use of the transmitter.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

36

Page 12

Programming HomeLink

®

System to the Torquemaster

❉

NOTE: This Step can only be done on automobiles equipped with the

HomeLink® system.

NOTE: Programming HomeLink® requires a Wayne-Dalton Transmitter

that is programmed to the opener (the wallstation and transmitter(s)

supplied with the opener, come pre-programmed from the factory). Any

additional wallstation(s) or transmitter(s) will need to be programmed to

the opener, see page 41.

IMPORTANT! Use the programming instructions provided with your

vehicle first. Follow these instructions if the HomeLink

learn the transmitter, when using the vehicle’s instructions.

NOTE: Vehicle may need to be in accessory position when

programming. Check car owner’s manual.

NOTE: HomeLink® is a registered trademark of Johnson Controls.

®

unit does not

®

idrive® (Alternate)

Programming/Training HomeLink® Unit

WARNING

GARAGE DOOR MAY OPERATE DURING PROGRAMMING. TO AVOID

POSSIBLE SEVERE OR FATAL INJURY, PLACE THE EMERGENCY

DISCONNECT HANDLE IN THE MANUAL OPERATED POSITION.

1. Pull the manual disconnect to put the opener in the disengaged

position.

2. Press and hold the two outside buttons on the HomeLink

unit until the HomeLink® light begins to flash rapidly (approx. 20

seconds), then release both buttons. (Do not perform this step to

train additional hand-held transmitters.) NOTE: This operation

erases all previously learned transmitters and that you need to

re-teach any other transmitters to your HomeLink® unit by

repeating steps 3 - 6 below.

3. Hold the end of the Wayne®Dalton hand-held transmitter

approximately 1 to 3 inches away from the HomeLink® surface –

keeping the HomeLink® indicator light in view.

4. Use the large button on the Wayne Dalton transmitter.

Simultaneously press and hold desired Homelink® button and the

Wayne Dalton transmitter large button. Continue to press both

buttons counting LED flashes on the HomeLink® module;

between 50 to 60 LED flashes the LED will either come on solid

or do one “quick flash”; when either of these occur release both

Wayne Dalton transmitter and HomeLink® buttons.

®

OPERATION

Teaching HomeLink® to the idrive® Opener

5. Press and release the red program button on the idrive® opener.

The idrive® unit will beep, indicating that it is ready to learn.

NOTE: The idrive® will remain in the learn mode for 30 seconds.

6. Press the HomeLink® button used in Step 4 above for 1 to 3

seconds. The idrive® will beep indicating a successful learn.

7. Return the manual disconnect to the engaged position.

8. Press the HomeLink® button once more to operate the door.

NOTE: The first transmitter command after programming will only move

the door through a six inch up/down cycle. Normal door operations will

occur on the second use of the transmitter.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

37

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 13

❉

NORMAL

DOOR LOCK

Custom pet position:

Normal install routine sets the pet position to approximately 8 inches

above the ground. The pet opening height may be changed to open

anywhere between 8” and 30” above the ground. To change the

automatic pet opening height refer to the following procedure:

a. After completion of the normal install routine, with the door in the

closed position, place the disconnect handle in the manual operated

position.

Manually position the door to the desired pet opening height

(between 8” and 30” above ground) and return disconnect handle to

the motor operated position.

b.

Move the slide switch from the NORMAL (Unlock) position to

the DOOR LOCK (Lock) position and then back to the NORMAL

(Unlock) position. The opener will beep once. The pet button is

now programmed to automatically open the door to this custom

height.

Customizing the Settings

Up/Down Button

NOTE: The opener will NOT accept programmed pet lock position if

door is below 8” or higher than 30”.

NOTE: Activation of the normal install routine will reset the pet position

to the default 8” target height. For use of the pet button see operation

section.

Multi-Door Programming:

Momentarily pressing the button programmed in the transmitter

programming step activates the door. Other buttons can also be

programmed to activate different doors, for multi-door installations.

Each button or a combination of two buttons pressed simultaneously

can be programmed to activate a different door. Only one button at a

time can be programmed to activate a specific opener.

Custom Upper Limits

Disconnect door and manually move it to the desired upper limit.

NOTE: The door must be positioned more than halfway open.

Reconnect door.

Press and hold the profile button for 5 seconds. The opener will beep

twice, indicating the activation of the profile routine. The door will now

move to the closed position. Then, the door will open to the new upper

limit.

Pet Button

Next, the door will go down to the closed position. Once this is

complete, the door limits are set and the installation is complete.

For more profile options go to page 29 and 30.

NOTE: Before performing custom upper limit, first profile must be done

from closed position.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

Up/Down Button

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Profile Button

38

Page 14

❉

Erasing Remote Controls:

Customizing the Settings (Continued)

CAUTION:

USING THE EMERGENCY DISCONNECT HANDLE PRIOR TO ERASING

REMOTE CONTROLS.

To clear programming of all remote control devices, press and hold

the opener’s red program button for approximately 10 seconds.

When the opener beeps 3 times, all remote controls are erased.

Multi Opener Light Control:

A single light fixture can be controlled by up to 6 openers. Follow

the procedure outlined on Step 24 to program additional openers.

Erasing Light Fixtures:

To clear programming of all openers from a light fixture, press

and hold the light fixture program button for approximately 10

seconds. When the light fixture lamp and LED flash 3 times, all

openers are erased.

MANUALLY DISCONNECT THE DOOR FROM OPENER

Program Button

Controls

Learn

S1

S2

S3 S4

Red

Program

Button

FPO

Delete

OPERATION

❉

Monthly Maintenance:

1. Lubricate hinges and rollers of garage door.

2. Inspect the door for loose fasteners, worn or frayed

counterbalance cables and the presences of legible safety labels/

tags. Have repairs made by a qualified service person.

Contact customer assistance for safety labels/ tags.

3. With door fully closed, move the emergency disconnect to the

manual door operated position and manually operate door. If the

door feels unbalanced or binds, have a qualified service person

make necessary adjustments or repairs to the door.

4. Perform the contact/obstruction tests. See Steps 29 and 30 for

the contact/obstruction test instructions. If Door/Opener fails

Contact/Obstruction test run install routine Steps 25 or 26

making sure door is completely closed prior to activation. If

opener still fails, have a qualified service person make

adjustments/repairs or this could result in severe or fatal injury.

5. Failure of Door/Opener to respond to transmitter or wall station

may be due to a weak or dead battery. Replace the battery.

Maintenance

Battery replacement for Wall Station:

Remove the battery cover completely (right-hand side of wall

station) by disengaging the battery cover’s lower clip. Install two

AAA batteries into the wall station observing the polarity, (+) and (-),

of both batteries. After a few seconds, the red LED will begin to

blink every three seconds. If it is desired to slow the red LED blink

rate refer to the wall station operation section on page 35 “Backlit

LED Light”. Re-install the battery cover by first inserting its top into

the wall station then inserting and securing its bottom.

Note: Use only 2 AAA batteries.

Battery replacement for Transmitter:

Insert a coin in the coin slot of the transmitter and twist coin to

access the dead battery. Replace the battery, being careful to match

the positive (+) symbols on the circuit boards with the battery.

Note: Use (1) CR2016 or equivalent battery.

Note: Dispose of dead battery properly.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

39

Page 15

❉

Power Connection — Permanent Wiring Option

If required by local codes, the opener can be permanently

wired. Services of a licensed electrician should be obtained,

to permanently wire the Unit. Disconnect electrical power at

fuse/breaker box.

WARNING

TO AVOID ELECTRICAL SHOCK, DISCONNECT POWER AT FUSE/

BREAKER BOX BEFORE PROCEEDING.

a.

Using a phillips head screwdriver, remove the two screws from the

right hand cover and unplug motor power cable. Remove right

hand cover from the opener to expose electronics and wiring.

b. Remove potentiometer gear. Unsnap the circuit board from the

chassis stand-offs and lower the circuit board as shown.

NOTE: Do not disconnect the two ground wires (A & B) from the

circuit board or the chassis.

c. Using pliers, compress 3 snaps of the strain relief fitting inside

the chassis and push fitting out of the chassis . Cut opener power

cord to a length that will leave 6” inside of the junction box.

Potentiometer Gear

d. Route opener power cable through the conduit. Strip 2 to 3

inches of outer jacket off power cable, insuring individual wire

insulation is not nicked or cut. Strip approximately 3/4” of

insulation off each individual wire. Using wire nuts, splice each

conduit wire with the corresponding wire inside the opener as

follows: opener black (line), opener white (neutral), and opener

yellow and green (ground).

NOTE: Select 1/2” conduit fitting/ J-box that will not interfere with

the opener disconnect cable fittings when disconnect is pulled.

e. Reinstall the circuit board back into the opener chassis and snap

the board back into the chassis stand-offs.

NOTE: Make sure antenna wire is routed through the chassis

grommet and angled 45 degrees to right when board is installed.

f. Confirm pot nut position* shown below.

g. Reinstall the potentiometer gear, right hand cover, and screws.

h. Reconnect Power

Chassis

Standoff

*Potentiometer

Gear Clip

“A”

1/8” – 3/16”

Gap

Grommet

*Position Pot Nut

1/8” - 3/16” Away

from Left Stop

Antenna

Green and Yellow

(Ground)

“B”

Strain

Relief Fitting

Chassis

Standoff

Junction

Box

Black

(Line)

White

(Neutral)

No Interference

Between Conduit

And Disconnect

View Of Right Hand Side

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

40

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 16

❉

Tools Needed:

None

Programming Wireless Wall

Station(s) or Transmitter(s)

to Opener

WARNING

TO AVOID POSSIBLE SEVERE OR FATAL

INJURY, MANUALLY DISCONNECT THE

OPENER, USING THE EMERGENCY

DISCONNECT HANDLE PRIOR TO

PROGRAMMING REMOTE CONTROLS.

NOTE:

The opener can be activated by up

to six remote control devices (including

Wall Station, Transmitter, and Keyless Entry

Devices). If a seventh control is

programmed, the first of the program

controls will be overwritten and will no

longer activate the opener.

Motor in

Up Position

Handle In Manual

Door Operated

Position

Red Program

Button

a. Pull the emergency disconnect handle to

the manual door operated position (lower

position).

b. On the front cover of the opener, press

and release the red program button; the

opener will beep once, indicating

activation of the program mode. The

opener will remain in program mode for

30 seconds. If at the end of 30 seconds

the opener has not learned an RF

device, the opener will beep once,

indicating the learn mode is no longer

active.

c. Press and hold the desired transmitter

button or wall station light button until

the opener beeps once. The transmitter

of wall station is now programmed.

No beeping response from the opener

during the transmitter or wall station

programming indicates a programming

failure. Repeat programming Steps a-c.

d. Return the emergency disconnect

handle to the motor operated position

(upper position).

a

b

c

LED

e

r

p

O

o

T

Press

Here

Light Button

a

t

e

D

o

o

r

Large Button

d

Handle In Motor

Operated

Position

NOTE: The first transmitter command

after programming will only move the

door through a six inch up/down cycle.

Normal door operations will occur on the

second use of the transmitter or wall

station.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

41

Page 17

✓

Symptom Probable Cause Corrective Action

Opener does not respond to the Wall Station or

Transmitter.

Troubleshooting

No power to the Opener.

Controls are not programmed.

Check the Opener Power Cord to outlet connection.

See Activation and Programming section.

Opener works from the Wall Station but not from the

Transmitter.

Opener works from the Transmitter but not from the

Wall Station.

Door does not move and the Opener beeps two times. The install routine has not been performed. Perform the install routine.

Door does not move with a Wall Station or Transmitter

command and no beeps come from the Opener.

Door does not move with a Wall Station or Transmitter and

Opener beeps one time.

Door stops or reverses, and the Opener beeps three or four

times.

Door does not close properly. Counterbalance Cables are not on the Cable Drums

Door will not close. Thermal delay: The door has cycled eight times

Transmitter is not programmed.

Weak or dead Transmitter battery.

Wall Station is not programmed.

Weak or dead Wall Station battery.

Blown fuse or tripped circuit breaker.

No power to the Opener.

Possible loose Motor connection. Check Motor plug connection.

Obstruction encountered.

Safety Sensor misalignment (if applicable).

Out-of-balance condition detected.

properly.

in a five-minute period.

Safety Sensor misalignment (if applicable).

Contact obstruction test failure.

See Activation and Programming section.

See Maintenance section for battery replacement.

See Activation and Programming section.

See Maintenance section for battery replacement.

Reset the circuit breaker or contact a qualified service

person for fuse information.

Check Power Cord connection.

Clear the door path.

Re-align Safety Sensors Step 22.

Run new Install Routine Steps 25 or 26.

Apply constant pressure to the Wall Station’s

Up/Down Button to close the door.

Door will operate after a one-minute waiting period.

Re-align Safety Sensors Step 22.

Apply constant pressure to Wall Station Up/Down

Button until door is closed

Repeat the install routine Steps 25 or 26 or contact a

qualified service person.

Door does not travel to the full open or full close position. Door is out of balance.

Door limits are set improperly.

Door is not sealing to the floor. Bottom door limit is set too high.

Outside door seal is set too tightly against the face of the

door.

Motor does not pivot up fully when door is opening. Counterbalance springs have too much tension. Adjust the springs to correct the balance or call a qualified

Door is reversing at or near the floor. Outside door seal is too tight against the face

of the door.

Counterbalance springs have too much tension (torsion).

Vertical Track is spaced too close to the bottom door

section, causing the door to bind.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

42

Adjust the springs to correct the balance or call a qualified

service person.

Repeat the install routine Steps 25 or 26.

Disconnect the Opener and force the door to the floor.

Reconnect the Opener and activate the install routine Steps

25 or 26.

Adjust weather seal position.

service person.

Install routine may have to be rerun. Steps 25 or 26.

Reinstall the door seal so as to be not so tight against the

face of the door.

Adjust Track away from the door until binding is removed.

Contact a qualified service person.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 18

✓

Symptom Probable Cause Corrective Action

Light fixture will not light during the door operation or by

pressing the Wall Station light button.

Troubleshooting (Continued)

Faulty light bulb.

No power to receptacle.

Opener not programmed to light.

Install new bulb (75W Max).

Check circuit breakers.

Program per Step 24.

Motor does not pull fully up when using the Emergency

Disconnect.

Motor starts but the door will not move. Opener is disconnected from the Torque Tube. Ensure Disconnect Handle is in the Motor Operated Position.

Motor does not pivot down.

Motor pivots partially after the door closes.

Motor pivots down prematurely (before the door closes

completely).

Light Kit will work with light control but Wall Station will

not move the door when Up/Down Button is pressed and

the overhead light blinks three times.

Wall Station not operational. Wall Station mounted incorrectly.

Disconnect Cable has slipped inside of Handle. Re-install Handle per instructions in Step 9.

Re-install Handle per instructions in Step 9.

Detent Pin is set too hard. Using a Flat Tip Screwdriver, rotate the Detent Pin counter-

Detent Pin is set too soft. Using a Flat Tip Screwdriver, rotate Detent Pin clockwise in 1/8

Opener is in the vacation mode. Move wall switch to the “Lock” position, wait 5 seconds return

Low battery.

clockwise in 1/8 turn increments until the Motor fully pivots

down after the door closes see Steps 27.

turn increments until Motor fully pivots down after door closes,

and Opener immediately shuts off Steps 27.

slide switch to “Normal” (Unlock) position to unlock vacation

mode. Opener will emit one beep. Opener will now move the

door. If not, try again.

If Opener now emits two beeps when commanded

then Opener needs to be profiled. See Opener profiling page

29 or 30.

Ensure Wall Station is mounted on a fl at surface.

Change battery see page 39.

✓

Symptom Probable Cause Corrective Action

The door interferes with the Lock Arm when

manually verifying clearance.

Lock Arm Troubleshooting

Lock Arm is set too far out.

The Torque Tube is not level (Opener needs to be raised).

The door top brackets and/or track configuration are not

set correctly (Set top brackets higher).

Motor not fully rotated up to Detent Pin engaged position.

TROUBLESHOOTING

Ensure the Lock Arm is mounted using the correct hole

location stated in Step 28.

Remount the Opener per Steps 5 and 6 , ensuring the

Opener and Torque Tube are level prior to fastening.

For new door and Opener installations, refer back to the

instructions included with the door for top bracket and/or

track configurations.

For retro-fit installations on current doors, refer back to

the section of this manual titled: Retro fit installation for

idrive, for top bracket and/or track configurations.

Remount the Disconnect Handle per Step 9, ensuring

proper Cable tension between the Opener and the Handle.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

43

Page 19

®

®

Lifetime Limited Warranty

idrive® for TorqueMaster® and TorqueMaster® Plus

Subject to the terms and conditions contained in this Lifetime Limited Warranty, Wayne-Dalton Corp. (“Manufacturer”) warrants the opener,

including electronic components (Batteries are not warranted), which is described at the top of this page, for a period of FIVE (5) YEARS

from the date of installation against:

(i) Any defects in material or workmanship.

The Manufacturer provides a Lifetime Limited Warranty on the motor only, against defects in material and workmanship.

After a period of TWENTY(20) YEARS, from time of installation, replacement of Lifetime Limited Warranty materials will be

pro-rated at 50 per cent of Manufacturer’s published list pricing at time of claim, and you must pay this amount.

This Limited Warranty is extended only to the person who purchased the product and continues to own the premises (where the

opener is installed) as his/her primary residence (“Buyer”).This Limited Warranty does not apply to residences other than primary, or to

commercial or industrial installations, or to installations on rental property (even when used by a tenant as a residence). This Limited

Warranty is not transferable to any other person (even when the premises. is sold), nor does it extend benefits to any other person. As a result

this Limited Warranty does NOT apply to any person who purchases the product from someone other than an authorized WayneDalton dealer or distributor.

The Manufacturer will not be responsible for any damage attributable to improper storage, improper installation, or any alteration

of the opener or its components, abuse, damage from corrosive fumes or substances, salt spray or saltwater air, fire, Acts of God, failure to

properly maintain the opener, or attempt to use the opener, its components or related products for other than its intended purpose and its

customary usage. This Limited Warranty does not cover ordinary wear.

THIS LIMITED WARRANTY COVERS A CONSUMER PRODUCT AS DEFINED BY THE MAGNUSON-MOSS ACT. NO WARRANTIES,

EXPRESS OR IMPLIED (INCLUDING BUT NOT LIMITED TO THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE) WILL EXTEND BEYOND THE TIME PERIOD SET FORTH IN UNDERSCORED BOLD FACE TYPE IN THIS LIMITED WARRANTY, ABOVE.

• Some States do not allow limitations on how long an implied warranty lasts, so the above limitations may

not apply to you.

Any claim under this Limited Warranty must be made in writing, within the applicable warranty period, to the dealer from which the

product was purchased. Unless the dealer is no longer in business, a written claim to the Manufacturer will be the same as if no claim had

been made at all.

At the Manufacturer’s option, a service representative may inspect the product on site, or Buyer may be required to return the

product to the Manufacturer at Buyer’s expense. Buyer agrees to cooperate with any representative of the Manufacturer and to give such

representative full access to the product with the claimed defect and full access to the location of its installation.

If the Manufacturer determines that the claim is valid under the terms of this Limited Warranty, the Manufacturer will repair or

replace the defective product. The decision about the manner in which the defect will be remedied will be at the discretion of the

Manufacturer, subject to applicable law. THE REMEDY WILL COVER ONLY MATERIAL. THIS LIMITED WARRANTY DOES NOT COVER OTHER

CHARGES, SUCH AS FIELD SERVICE LABOR FOR REMOVAL, INSTALLATION, SHIPPING, ETC.

Any repairs or replacements arranged by Manufacturer will be covered by (and subject to) the terms, conditions, limitations and

exceptions of this Limited Warranty; provided, however, that the installation date for the repaired or replaced product will be deemed to be

the date the original product was installed, and this Limited Warranty will expire at the same time as if there had been no defect. If a claim

under this Limited Warranty is resolved in a manner other than described in the immediately preceding paragraph, then neither this Limited

Warranty nor any other warranty from the Manufacturer will cover the repaired or replaced portion of the product.

THE REMEDIES FOR THE BUYER DESCRIBED IN THIS LIMITED WARRANTY ARE EXCLUSIVE and take the place of any other remedy.

The liability of the Manufacturer, whether in contract or tort, under warranty, product liability, or otherwise, will not go beyond the Manufacturer’s obligation to repair or replace, at its option, as described above. THE MANUFACTURER WILL NOT UNDER ANY

CIRCUMSTANCES BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, including (but not limited to) damage or loss of

other property or equipment, personal injury, loss of profits or revenues, business or service interruptions, cost of capital , cost of purchase or

replacement of other goods, or claims of third parties for any of the foregoing.

• Some States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

No employee, distributor, dealer, representative, or other person has the authority to modify any term or condition contained in this

Limited Warranty or to grant any other warranty on behalf of or binding on the Manufacturer, and anyone’s attempt to do so will be null and

void.

Buyer should be prepared to verify the date of installation to the satisfaction of the Manufacturer.

The rights and obligations of the Manufacturer and Buyer under this Limited Warranty will be governed by the laws of the State of

Ohio, USA, to the extent permitted by law.

• This Limited Warranty gives you specific legal rights and you may also have other rights, which may vary

from State to State.

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

44

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Page 20

Please Do Not Return This Product To The Store

Call Us Directly! Our Trained Technicians Will Answer

Your Questions and /or Ship Any Parts You May Need

Call Us Toll-Free:

(888) 827-3667

Thank you for your purchase

www.wayne-dalton.com

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

45

Page 21

✁

Cut-Out Template to Aid Installation

DRILL TEMPLATE

Pre-drill 3/32” pilot hole

Wall Station Template Keyless Entry Template

Pre-drill 5/64” pilot hole

46

Page 22

Patent Information

Models:

Covered under one or more of the following U.S. patents: D413,579; D466,141; D472,568; D472,910;

D473,573; D473,574; D474,215; D505,393; D517,580; 5,929,580; 6,078,249; 6,145,570; 6,164,014;

6,253,824; 6,263,947; 6,325,134; 6,326,751; 6,326,754; 6,401,792; 6,561,255; 6,561,256; 6,568,454;

6,588,156; 6,605,910; 6,667,591; 6,739,372; 6,845,804; 6,851,465; 6,873,127; 6,880,609; 6,903,650;

7,053,571; 7,061,197; 7,075,256; 7,109,677; 7,123,128; 7,143,804; 7,173,389; 7,173,514; 7,173,516;

7,183,732; 7,190,266; 7,193,502; 7,207,142; 7,211,975. other U.S. and foreign patents pending

3790/3790-Z/3791/3791-Z

FCC and IC Statement

FCC Regulatory Information:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

IC Regulatory Information:

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device

must accept any interference, including interference that may cause undesired operation of the device.

NOTE: This equipment has been tested and found to comply with limits for a Class B digital device, pursuant to

Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with these instructions, may cause harmful interference to radio communication;

however, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning equipment off and

on, user is encouraged to try to correct interference by one or more of the following measures: Reorient or

relocate receiving antenna. Increase separation between equipment and receiver. Connect equipment into an

outlet on a circuit different from that which receiver is connected. Consult your dealer or/and experienced radio/

television technician for help.

WARNING: Changes or modifications to this unit not expressly approved by party responsible for compliance

could void user’s authority to operate this equipment.

Loading...

Loading...