Page 1

12 Volt Advanced

Select Language

English Español

Français

Last Auto Test: --/--/--

MENU MUTE RESET

12.1 V

System Armed & Ready

100%

12

3

6

9

Notification System

OPERATING INSTRUCTIONS & PARTS MANUAL

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD.

Failure to follow these instructions could result in property damage, bodily injury or death.

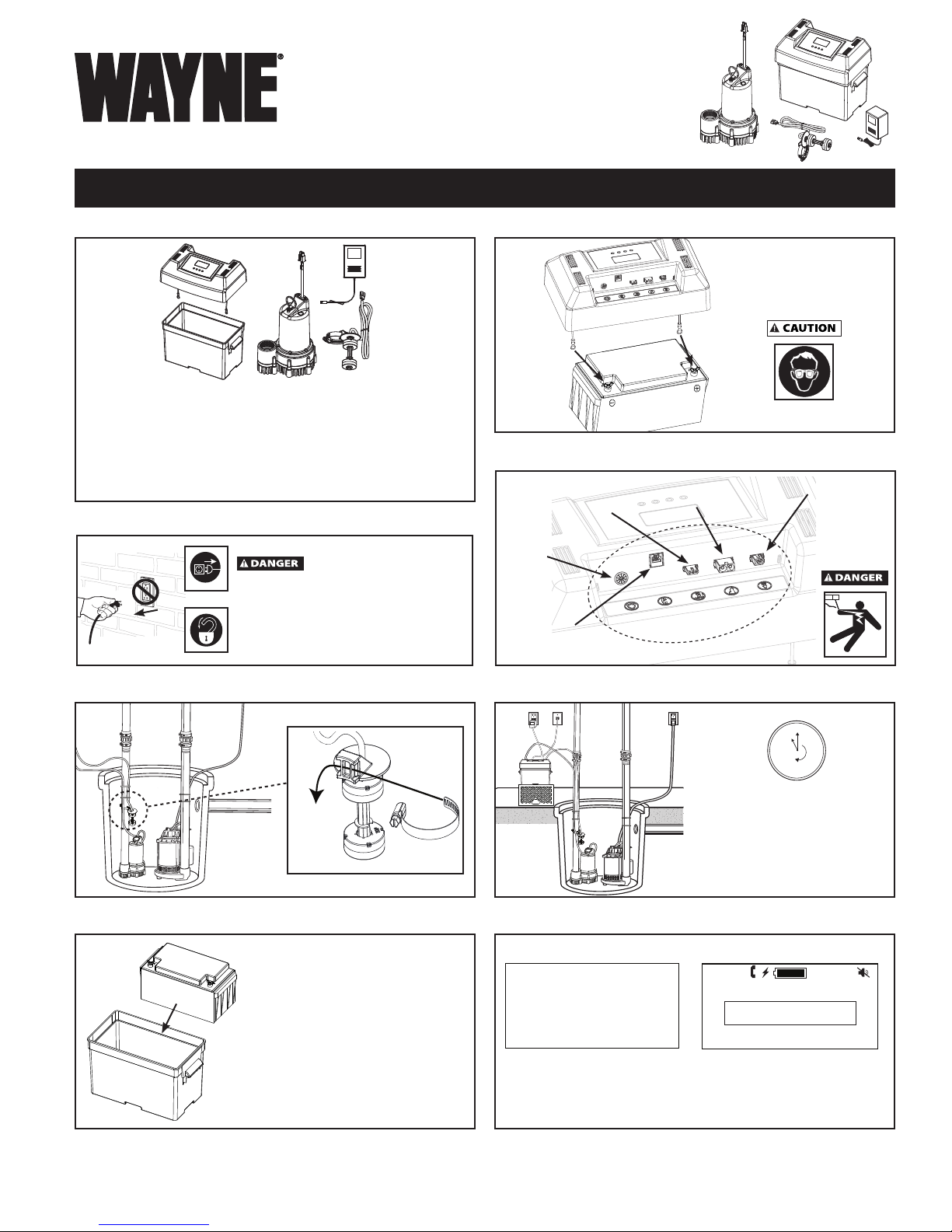

QUICK START INSTRUCTIONS WSM3300

STEP 1 - VERIFY PACKAGE CONTENTS

Transformer (1)

Lid and Controller Assembly (1)

Battery box (1)

12 Volt DC back-up pump (1)

Switch with clamp (1)

Requires active telephone land line service

Does not include:

12 Volt DC deep cycle

battery, phone jack,

phone line, pipe, and

necessary fittings.

STEP 2 - DISCONNECT POWER

If the power disconnect

is out of sight, lock in the open

position and tag it to prevent

unexpected application of power.

Failure to do so COULD result in fatal

electric shock!

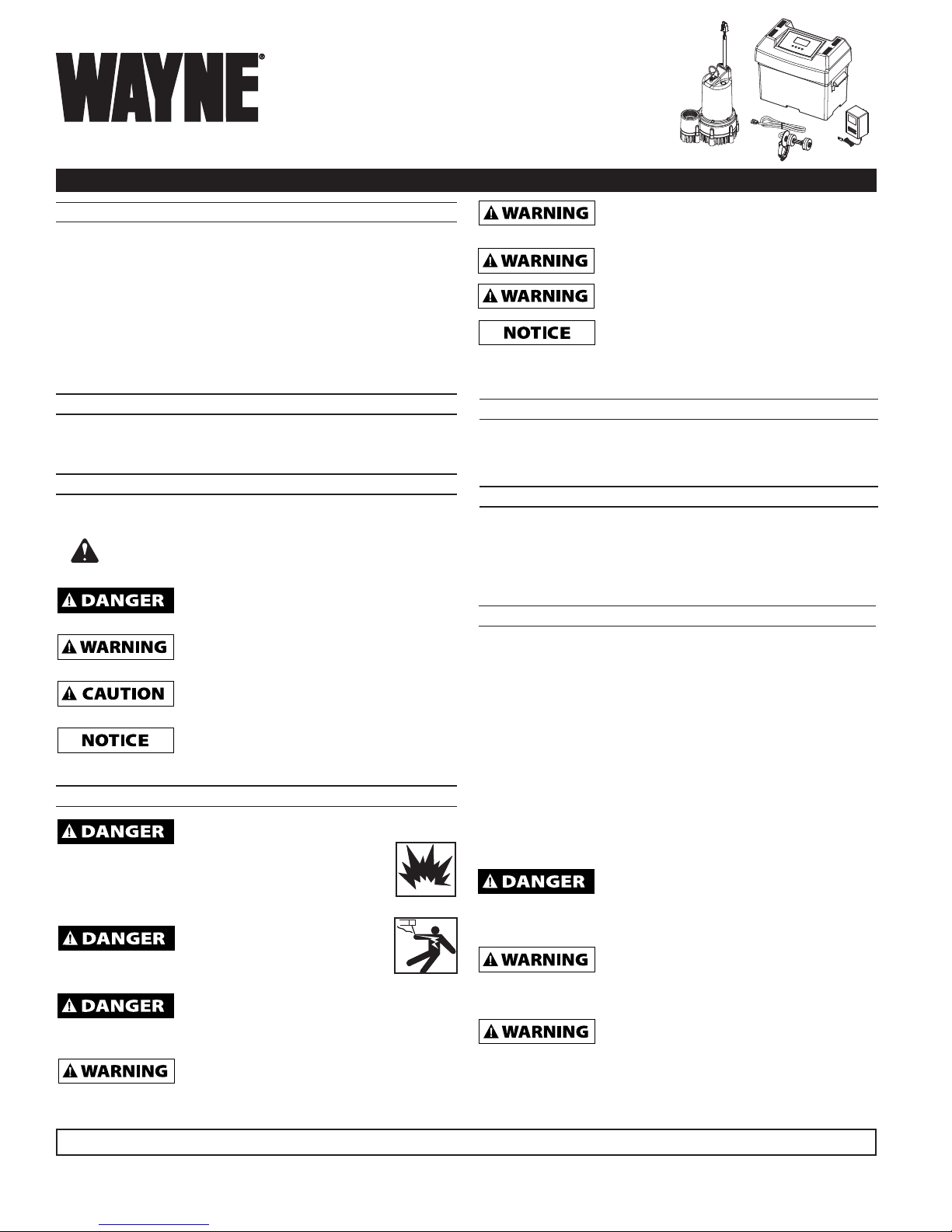

STEP 5 - CONNECT LID TO BATTERY

Wear safety glasses when

connecting the battery

Red

Black

STEP 6 - CONNECT WIRES

Transformer

Security

Phone

Float Switch

DC Pump

STEP 3 - INSTALL BACK-UP AND FLOAT SWITCH

STEP 4 - INSTALL BATTERY

Acceptable Batteries

WAYNE - WSB1275

WAYNE - WSB1240

or

12 Volt Deep Cycle Marine Battery

12 Volt SLA (Sealed Lead Acid)

12 Volt Deep Cycle Battery

12 Volt Wet Cell Battery

Size = min 40Ah

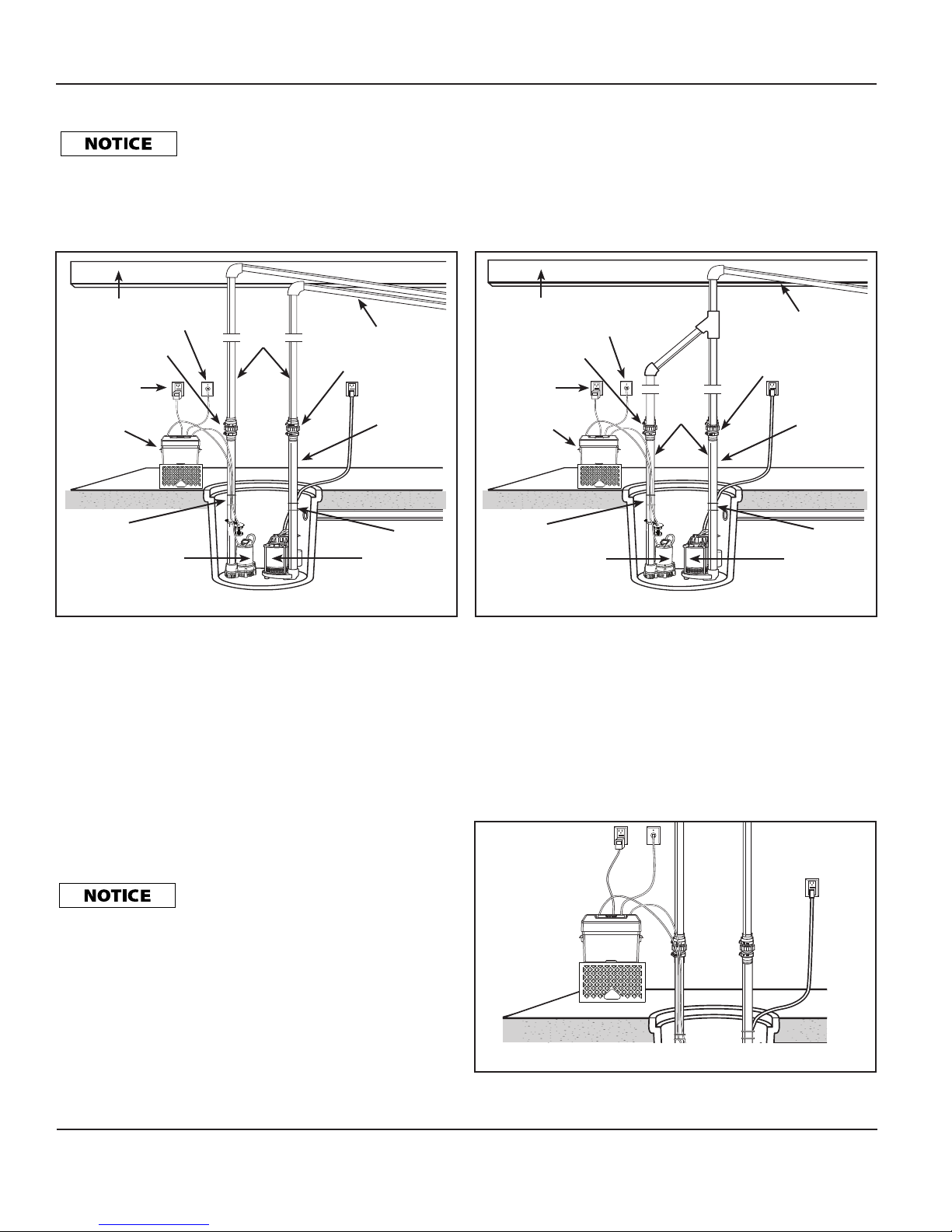

STEP 7 - POSITION BATTERY AND CONTROLLER

Minimum charge time

before usage is 24 hours

Drain

Tile

STEP 8 - CONTROLLER SETUP

Home DisplayStartup Display

Select the starting language and follow the on-screen

instructions to set up the controller. Upon completion of

controller setup, restore AC power and test the main pump as

described in the operation section of the manual.

© 2012, WAYNE/Scott Fetzer Company.

For parts, product & service information

visit www.waynepumps.com

354100-001 10/12

Page 2

12 Volt Advanced

Notification System

OPERATING INSTRUCTIONS & PARTS MANUAL

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD.

Failure to follow these instructions could result in property damage, bodily injury or death.

INSTALLATION AND OPERATING INSTRUCTIONS

DESCRIPTION

The 12 Volt Advanced Notification System includes a DC backup sump pump, an electronic controller with digital display, and

an auto-dialer. Optimal back-up power is supplied by a 12 volt

battery (not included). The system is designed for home sump

applications. When an electrical power outage occurs, the

electronic controller automatically switches the sump pump to

battery power. Power loss will initiate a phone call via the autodialer to the phone number(s) entered by the homeowner. With

a 24-hour monitor and a predetermined full system check, the

system tells you it’s status via a digital display and alerts you to

potential problems with an audible horn and phone call.

UNPACKING

Inspect this unit before it is used. Occasionally, products are

damaged during shipment. If the pump or components are

damaged, contact customer service at 1-800-237-0987.

SAFETY GUIDELINES

To help recognize this information, observe the following signal

words/hazard classifications.

This is the safety alert symbol. It is used to alert you to

potential bodily injury hazards. Obey all safety messages that

follow this symbol to avoid possible harm.

Danger indicates an imminently hazardous

in death or serious injury.

Warning indicates a potentially hazardous

result in death or serious injury.

Caution indicates a potentially hazardous

in minor or moderate injury.

Notice indicates important information, that if

situation which, if NOT avoided, WILL result

situation which, if NOT avoided, COULD

situation which, if NOT avoided, MAY result

NOT followed, MAY cause damage to equipment.

GENERAL SAFETY INFORMATION

combustible liquids vapors or dusts.

Do NOT use to pump flammable/combustible liquids vapors

or dusts. Do NOT use in a flammable and/or explosive

atmosphere. Pump SHOULD be used to pump clear water

ONLY. Failure to follow these instructions WILL result in bodily

injury or death.

Electric shock hazard.

power before servicing. Apply a fixed

lock or tag to prevent unexpected application of power.

Electric shock hazard. DO NOT walk

on wet floor until power is disconnected. Use a

licensed electrician to perform service in accordance with the National

Electrical Code and all local codes.

This pump is NOT rated for use with flammable/

Disconnect

NEVER allow children to use pump.

clothing. Eye protection MUST be worn when

handling the battery.

and back-up sump discharge.

water. This pump is NOT designed to handle

effluent, salt water, brine, laundry discharge, or any other application

which MAY contain caustic chemicals and/or foreign materials. Pump

damage MAY occur if used in these applications and WILL void warranty.

SPECIFICATIONS

Power Supply Requirements ......120 V, 60 Hz

Motor ..........................................12 V DC Motor

Pump Dimensions ......................11 in. high x 8 3/4 in. base

CONSTRUCTION

Motor Housing ...........................

Impeller ......................................

Shaft ..........................................

Discharge ..................................

Float Switch ..............................

BATTERY INFORMATION

The system is designed to operate most efficiently

deep cycle, sealed lead (Pb) acid (SLA) battery. A deep cycle

marine battery can also be used. Sealed lead acid batteries cost

slightly more, but they can last longer than a wet cell battery and

are maintenance free. The oversize battery case (included) will

accomodate one 12 Volt battery up to a 27-frame size. Use a new

battery. Chart 1 illustrates the expected performance with various

battery combinations. Do not use batteries rated below 40 amp

hours. Be certain that the area around the battery is well ventilated.

Before servicing the battery, blow away gasses by waving a piece

of cardboard near the battery. An assistant should be present or

close enough to come to your aid in the event of an emergency.

Have a reliable source of fresh water and soap nearby in case

battery acid contacts clothing, skin or eyes. Wear eye and clothing

protection when working around lead acid batteries. Avoid touching

your eyes when working around lead acid batteries.

Explosion hazard. Smoking and open flames

prohibited. Battery recharging and

connections MUST be performed in a well ventilated area

CALIFORNIA PROPOSITION 65

This product or its power cord MAY contain

chemicals, including lead, known to the

State of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

Chemical hazard. If battery acid contacts

your eyes, immediately flush eyes with

copious amounts of clean, tepid water for at least 30 minutes. Seek

medical attention.

WSM3300

Battery acid is corrosive. Avoid spilling on skin or

A check valve MUST be used on the primary

A ground fault circuit interrupter is required.

This pump MUST only be used to pump clear

Thermoplastic

Thermoplastic

Stainless Steel

1-1/2 in. NPT

Dual Reed

with a

.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2012, WAYNE/Scott Fetzer Company.

www.waynepumps.com

2

Page 3

Operating Instructions and Parts Manual

WSM3300

TRANSFORMER FEATURES

• Whenpluggedinto120VAC,thetransformerautomatically

provides power to the battery charging circuitry.

• Thetransformercanbeleftconnectedtothewalloutlet

indefinitely.

• Thetransformerisdesignedforthesystemonly,DONOT

use for any other purpose.

CONTROL BOX FEATURES

CHART 1 - STANDBY POWER PUMPING CAPACITY

*Hours of Protection During A Rain Event

If Your Sump Pump Runs...

Deep Cycle

Battery Size

40 A-Hr

75 A-Hr

1X Per

Min

12 Hours

23 Hours

1X Every

5 Min

53 Hours

100 Hours

*Assumes a typical 10 ft. rise on the discharge pipe, and

17 in. diameter sump pit. Results may vary.

BACK-UP PUMP:

1. The pump will turn on when either the bottom or top float

rises.

2. The pump motor will keep running for 15 seconds after the

float drops.

3. An auto-test of the back-up pump will occur every 14 days

between the hours of 5pm-7pm. The controller will report

any known issues and record the date of the last auto-test

on the home screen.

4. The last known float activated back-up pump run date can

be found by scrolling through the main menu selections.

Before disabling your main pump, have a stand by

pump ready or an appropriate means of evacuating the sump.

before servicing. Apply a fixed lock or tag to

prevent unexpected application of power.

Installation of this unit MAY take several hours.

Electric shock hazard. DISCONNECT power

1X Every

10 Min

92 Hours

172 Hours

PUMP INSTALLATION

1. Turn power to main pump off.

2. Pump must be installed using 1-1/4 in. or 1-1/2 in. rigid

PVC piping.

PUMP INSTALLATION

The 12 Volt Advanced Notification System can be installed as

a back-up system with a separate dedicated discharge line

(Method 1), or tied into an existing sump pump line (Method 2).

1. Verify that the existing AC pump is in good working order. If

the AC pump is questionable, replace with the same HP

pump or increase the HP rating if you have experienced

flooding or the pump is not keeping up with the inflow of

water.

2. Remove any silt or accumulated debris from the sump pit

and surrounding area.

3. Make sure that disconnecting the AC pump will not create a

flood in your basement. A pump should be available to

evacuate water in the event incoming water rates should

change.

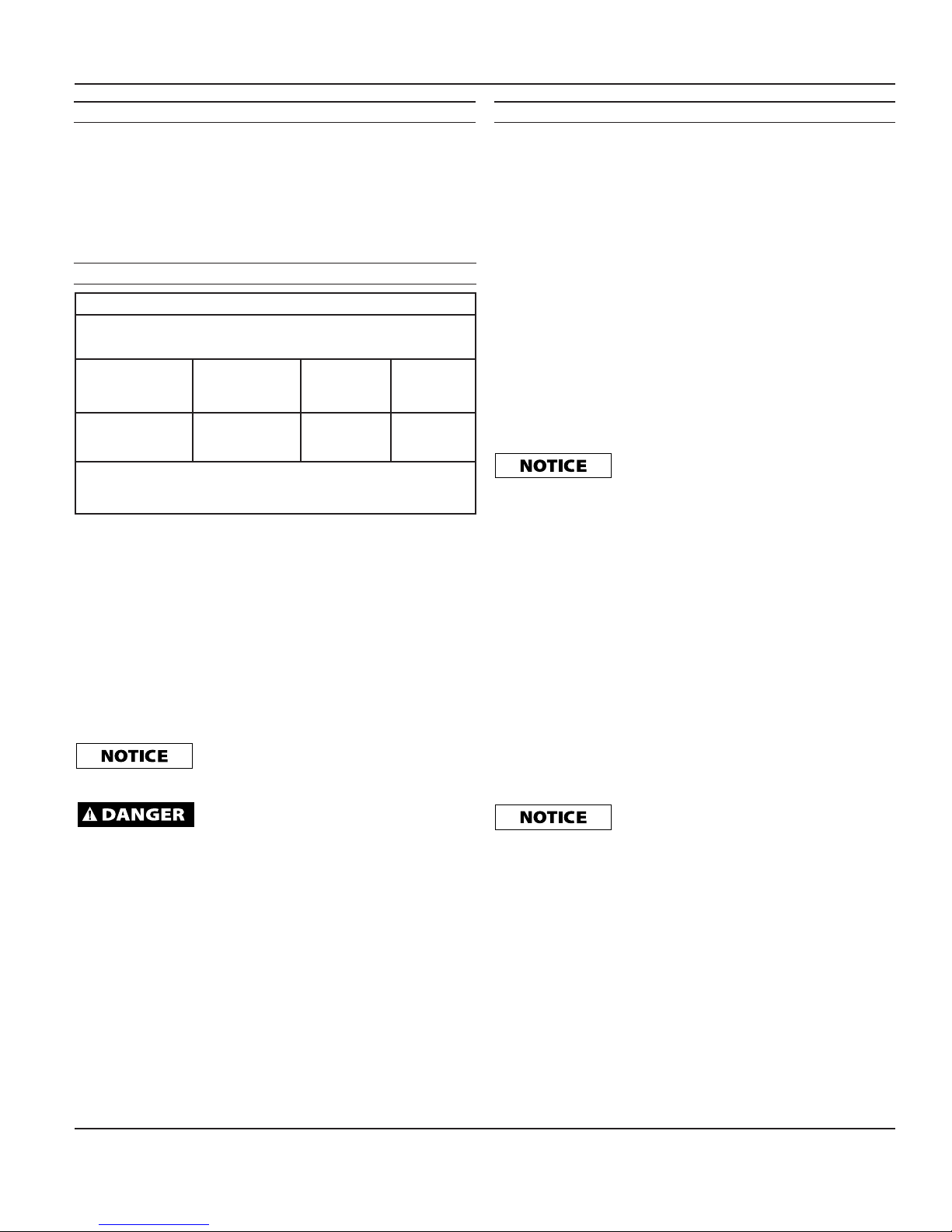

METHOD 1 (PREFERRED) - See Figure 1

discharge line of both the main AC pump and the

back-up DC pump. Failure to install the check valves MAY allow water to

recirculate into the sump pit. See Figures 1 and 2.

1. Locate the DC pump on a solid, level surface in the sump pit. Do

NOT place the pump on a loose or sandy surface. Small stones or

sand may damage the pump resulting in pump failure.

2. This pump has a 1-1/2 in. NPT discharge. If a 1-1/4 in.

discharge pipe is desired, an adapter (not included) will

be necessary. Smaller diameter piping will reduce pump

flow-rate and performance.

3. A check valve is required in the discharge line of both the

Main AC pump and the Back-Up DC Pump to prevent

recirculation of water into the sump pit. The system will not

function without two check valves.

4. Cut a 4 ft. section of 1-1/4 in. or 1-1/2 in. diameter rigid PVC

pipe. Cement 1-1/4 in. or 1-1/2 in. pipe to a threaded fitting.

Cement 1-1/4 in. or 1-1/2 in. pipe into pipe coupling. Attach

1-1/4 in. or 1-1/2 in. pipe section to the Back-Up DC Pump

discharge adapter.

5. Screw into pump discharge.

DO NOT over tighten or cross-thread plastic

fittings or check valves. USE rigid PVC or metal

pipe for permanent installation.

6. Place the pump with the 4 ft. section of PVC pipe on a solid,

level surface in the sump pit on an elevated surface.

7. Attach a rubber check valve (sold separately) to the top of

the discharge pipe. This will allow the pump or check valve

to be removed easily for servicing.

8. Check valve is recommended for effective operation of

system.

The remainder of the discharge pipe installation will vary

depending on individual circumstances. Using sound plumbing

practices, route the discharge pipe to an exterior wall by the

shortest path. Keep turns to a minimum because they reduce

flow output of the pump. The pipe that exits the building structure

should be sloped downward so that water will not freeze in the

pipe.

When installing the separate discharge pipe, drill through

the outside wall with appropriate drilling equipment. Seal the

hole to prevent water from entering.

Check valves MUST be installed in the

www.waynepumps.com

3

Page 4

Operating Instructions and Parts Manual

WSM3300

METHOD 2 - See Figure 2

discharge line of both the main AC pump and

the back-up DC pump. Failure to install the check valves MAY allow

water to recirculate into the sump pit. See Figures 1 and 2.

Check valves MUST be installed in the

If a separate, dedicated discharge is not possible as in Method

1, the Back-Up DC Pump can be tied into the AC-operated

pump’s discharge pipe by installing a “Y” or "T" connector.

Two check valves will be required.

Floor Joist

Phone Jack

Check Valve

Transformer

12 Volt

Advanced

Notification

System

Zip Tie

Back-Up DC Pump

Rigid

PVC

Pipe

Slope Pipe Down

Check Valve

1-1/4 in.

or

1-1/2 in.

PVC Pipe

Zip Tie

Primary Pump

9. Glue a 45º elbow to the short pipe on the Back-Up DC

Pump. Glue a “Y” adapter to the short pipe on the existing

pump, as shown in illustration for Method 2.

10. Glue a short piece of PVC pipe between the 45º elbow and the

“Y”.

The remainder of the discharge pipe installation will vary

depending on individual circumstances. Using sound plumbing

practices, route the discharge pipe to an exterior wall by the

shortest distance

Floor Joist

Check Valve

Transformer

12 Volt

Advanced

Notification

System

Zip Tie

Back-Up DC Pump

.

Phone Jack

Rigid

PVC

Pipe

Slope Pipe Down

Check Valve

1-1/4 in.

or

1-1/2 in.

PVC Pipe

Zip Tie

Primary Pump

Figure 1 - Method 1 (Preferred Installation)

1. Locate the Back-Up DC Pump on a solid, level surface in the

sump pit. Do not place the pump on a loose or sandy surface.

Small stones or sand may damage the pump resulting in

pump failure.

2. This pump has a 1-1/2 in. NPT discharge. If a 1-1/4 in.

discharge pipe is desired, an adapter (sold separately, part

#66002-WYN1 WAYNE adapter or equivalent) will be

necessary. Smaller diameter piping will reduce pump

flow-rate and performance.

3. A check valve will be required in the discharge line of both

the Main AC pump and the Back-Up DC pump to prevent

recirculation of water into the sump pit. System will not

Figure 2 - Method 2 (Alternate Installation)

METHODS 1 AND 2

Install float switch at least 10 in. -12 in. above bottom of sump

pit so that back-up unit turns on only when the water level is

higher than the normal “on” level for main pump. Make sure

power wires and hose clamp ends do not interfere with float

switch, pump inlet, or main pump operation. The back-up

pump must not be allowed to run dry except during the 20

second "auto-test. Incoming water can not flow directly onto

the float switch. Failure to position properly may cause improper

operation. Position the float switch so that it will not interfere

with any portion of the plumbing, wiring, or sump pit. Check for

clearance by lifting both floats.

function without two check valves.

4. Cut a 4 ft. section of 1-1/4 in. or 1-1/2 in. diameter rigid PVC

pipe. Cement 1-1/2 in. pipe to a threaded fitting. Cement

1-1/4 in. pipe into pipe coupling. Attach 1-1/4 in. pipe

section to the Back-Up DC Pump discharge adapter.

Do NOT strip or cross thread plastic

fittings or check valves. Flex hose is NOT

recommended. Rigid PVC or metal pipe is required for permanent installation.

5. Screw into pump discharge.

6. Place the pump with the 4 ft. section of PVC pipe on the

sump floor or on an elevated surface if required.

7. Attach a rubber check valve (sold separately) to the top of

the discharge pipe. This will allow the pump or check valve

to be removed easily for servicing.

8. Duplicate the discharge piping arrangement for the primary

AC pump if the existing discharge line has to be adjusted to

accommodate a second pump.

Figure 3 - 12 Volt Advanced Notification System elevated

www.waynepumps.com

4

Page 5

*

Operating Instructions and Parts Manual

WSM3300

CONTROL BOX INSTALLATION

result, and warranty WILL be void.

transformer to a properly grounded

GFCI (Ground Fault Circuit Interrupter) receptacle that is rated

for at least 5 amps. Test the operation of the GFCI receptacle

according to the manufacture's recommended intervals

DISCONNECT AC power before connecting or disconnecting the battery.

Use the system indoors, in a well ventilated

area. Do NOT expose to rain or snow. Do NOT use

an extension cord. Do NOT disassemble. Be sure battery box ventilation

holes are unobstructed. If dropped or damaged, do NOT operate; contact

manufacturer for service.

flames prohibited. Battery

recharging and connections MUST be performed in a well

ventilated area. Before servicing the batteries, blow away

the gases by waving a piece of cardboard near the batteries.

1. Place battery box and controller within six feet of the sump

and a 120 VAC separately fused outlet. The outlet must be

protected by a ground fault circuit interrupter (GFCI). The

area must also be clean, dry, and well-ventilated.

2. Wave cardboard over batteries to blow away any gas that

may be present.

3. Connect the power wires from the 12 Volt Advanced

Notification System to the battery terminals as shown in

(Figure 4). Connect the red wire to the positive

terminal of the battery and then connect the black wire

to the negative terminal of the battery. The display

should be lit up at this time. If connected improperly an

alarm will sound until corrected.

4. Plug the pump and float switch connectors into the

12 Volt Advanced Notification System. The connections are

marked. (See Step 6 in the Quick Start Guide)

5. Follow the on-screen instructions. Test pump operation

by filling the sump with water while the main pump is

unplugged. If the back-up pump operates properly, plug the

transformer into the GFCI protected outlet to begin charging

the battery.

surfaces, oil, and chemicals. Avoid kinking the

cord and replace damaged components immediately.

Black

Figure 4 - Battery terminal connection

If battery cables are reversed, damage to the

transformer

Electric shock hazard. Connect this

Explosion hazard. Smoking and open

Protect electrical cord from sharp objects, hot

, controller or battery COULD

.

Be sure to

connect the

cables as

shown, reversing

Red

the cables will

cause damage

to the product.

PHONE LINE INSTALLATION

PHONE SYSTEM INFORMATION

Sharing the phone jack:

The 12 Volt Advanced Notification System and your existing

phone/fax can share the same wall jack. A standard phone

jack splitter also known as a line splitter (not provided) can be

purchased at your local hardware store. Install as shown in

Figure 5. The splitter allows independent operation of both units

without interference.

Open

Phone Jack

If you have an

open phone

service jack

available, a line

splitter is not

required.

The phone cords

may need to be longer depending

upon the distance to the available

phone service jack.

Figure 5 - Phone line splitter/hookup

PHONE SERVICE AND POWER OUTAGES

The 12 Volt Advanced Notification System is designed and

certified by the FCC to operate on a standard telephone line and

connects to a standard phone jack. The System dials out using

touch tone dialing only. Must have an active phone line that is

detectable by the 12 Volt Advanced Notification System.

The 12 Volt Advanced Notification System does work with

DSL, Cable, or Digital phone services with the appropriate

in-line filters. If the modem doesn’t produce a “dial tone” it

will not be able to place a phone call. If the 12 Volt Advanced

Notification System is unable to place a call while using one of

these services, please contact your phone service provider for

assistance.

POWER OUTAGES: DSL, Digital, and Cable

provided phone services DO NOT WORK

when AC Power is lost. The 12 Volt Advanced Notification System

will NOT be able to call out if the power is out when using these

phone services. A back-up battery system (UPS-uninterrupted

power supply) is required to keep the modem and/or system active

for a minimum of 8 hours. Check with your phone service provider

for details regarding UPS sizing for your installation. Standard

telephone lines are self-powered by the telephone company and

usually not affected unless the phone service itself is interrupted.

PHONE NUMBER ENTRY AND STORAGE

The 12 Volt Advanced Notification System uses an onboard

auto-dialer and microprocessor to place pre-recorded phone

calls regarding the status of your back-up system. The System

is capable of notifying up to three phone numbers (60 digits

each) of your choice. The System stores each of your phone

numbers locally and will not lose or erase your phone numbers

due to a power outage or battery dying. Before you start

entering phone numbers, DO NOT enter phone numbers of

emergency services (fire, police, or ambulance).

CELL PHONES: The 12 Volt Advanced Notification System will

call all phones that a basic telephone will connect with. It does

not differentiate between a cellular phone or land line phone.

Cellular calls are based upon having adequate reception.

Shared

Phone Jack

Line Splitter

(not provided)

Phone/FAX

Cord

12 Volt Advanced

Notification System

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual

WSM3300

CRITICAL STEP: It is recommended that a person at the call-to

location confirms receiving the test phone call. Validate all calls

before concluding that the system setup is finished.

ENTERING AND CHANGING PHONE NUMBERS

When programming phone numbers into the System, enter each

phone number into the phone setup screens exactly as you

would when making a personal phone call.

Two phone number entry methods:

1. As part of the Installation Setup procedure (follow the on

screen prompts) or,

2. From the “Home Screen”, select “MENU”, enter the security

code (if prompted), then locate the “Phone Setup” option

and then press the button for “ENTER”.

a. You can modify, delete, or verify within this selection.

b. To delete any number, simply press “DEL” and it will

backspace as needed.

c. To EDIT a number, re-enter the phone number and it

will overwrite the existing number.

PROPER PHONE NUMBER ENTRY

System can place local calls, long distance calls, and even

international calls. The use of calling cards is not recommended

for they are difficult to enter and can change without notice and

result in a phone call never being made.

Example:

*Local Number: 123-4567

*Long Distance: 1 (555) 123-4567

* International: Country code, followed by 1, then the

phone number. For proper dialing instructions or

further assistance, contact your service provider.

Enter the phone number exactly as you would when

dialing a call yourself. If your local number requires the

area code, enter as needed.

CREATING PAUSES WHEN ENTERING PHONE NUMBERS:

Some phone calls require accessing an outside telephone line

from a digital system. Obtain the digit(s) necessary to access

the outside line (dialing “9” to access an outside line is most

common). A time delay may be required to let the system fully

access the outside line and this is accomplished by entering

two “stars” (**) after dialing the 9.

The following examples use a “9” to access the outside phone

line followed by a 2 second delay before the auto-dialer is

initiated to place an automated phone call by the System:

Local call: 9** then 123-4567

Long distance call: 9** then 1 (555) 123-4567

TIME DELAYS

** = 2 seconds, **** = 4 seconds, ****** = 6 seconds

All stars (*) must be entered in multiples of 2 or the system will

not recognize them as actual time delays.

PHONE TEST

After entering all phone numbers, it is crucial that you test your

System to verify that it can reach the call list phone numbers.

System is in "test mode".

TESTING YOUR 12 VOLT ADVANCED NOTIFICATION SYSTEM

PHONE NUMBERS

To test the System, do the following:

1. Make sure the System is powered up, phone line is

connected, and the "Home Screen" has no error messages.

The CANCEL key does not function when the

To make sure all timers and errors are cleared from the

system memory, press and hold the "RESET" button for

a minimum of 3-5 seconds.

2. Press the MENU button followed by the “Phone Setup”

option.

3. Scroll to the desired phone number, hit ENTER, then select

the TEST option.

The system will immediately dial the desired phone number.

Upon answering, the unit will play the following message: “This

is a test of the back-up system.” It will repeat this message for

approximately “1” minute and then hang up. The display will

prompt you asking if the test was successful, if Yes, it returns to

the home screen. If “NO”, it will retest.

4. Repeat Steps 2 and 3 to test the remaining phone numbers.

The System does not provide any indication of call success;

therefore, you must verify that the call was made successfully.

TESTING FOR A SPECIFIC ALARM CONDITION

To test for a specific alarm condition you will have to simulate

that specific alarm condition and then verify if the alarm phone

calls went through. In those scenarios, you must cancel the

alarm call out sequence and correct the alarm condition by

pressing and holding the RESET button for a minimum of 5

seconds.

HOW THE SYSTEM WORKS WITH VOICE MAIL OR AN

ANSWERING MACHINE

When it is necessary to connect an answering machine or voice

mail device to the same phone line as the System, you can still

use all the features of these devices, along with being able to

check status and cancel an alarm call out of the System.

HOW THIS WORKS:

The System can answer incoming calls to check the system

status. To do this, the ring count must be set to answer on

either “5” or “10” rings (default setting is 10 rings, change this

setting from the Main Menu>Set Ring Count).

Set your answering machine or voice mail to answer in fewer

rings than the System. (For example, if the System is set to

answer on 5 rings, set the answering machine/voice mail to

answer in “4” or fewer rings.) Therefore, when a call comes into

the location of the System, the answering machine/voice mail

will respond first because it is set to answer in fewer rings than

the System.

RING COUNT TIMER

The ring count timer works in the following way: when the first

call comes in during an alarm event, the internal system timer

starts counting down for “3” continuous minutes. If the System

receives enough rings to answer (within “3” minutes), it will

respond, and the ring counter will reset to “0” regardless if the

three minutes have elapsed or not. Also, the timer will reset

to “0” if no additional calls are received during a three minute

period (multiple calls to the System within “3”minutes will not

reset the ring timer).

CALLING THE 12 VOLT ADVANCED NOTIFICATION SYSTEM

DURING AN ALARM EVENT

Example:

1) The back-up system is set to answer in 5 rings (ring count

setting).

2) The answering machine/voice mail is set to answer in "4"

rings or fewer.

To get the System to respond given the above example criteria,

do the following:

1. Call the phone number of the location where the

System is located, and let the phone ring “3” times

and then hang up. The internal 3-minute timer starts and

www.waynepumps.com

6

Page 7

Operating Instructions and Parts Manual

WSM3300

the System tallies and remembers the number of rings.

2. On your second call within “3” minutes, let the phone ring

until the System answers. The System will answer

first because it remembered the first “3” rings, and then

answers with an audible system status. If done properly, the

answering machine/voice mail will not answer.

If the System is set to answer in 10 rings (one of

the Menu selectable options), you will need to

place more calls within "3" minutes to get the System to eventually answer.

HOW TO CANCEL ALARM PHONE CALLS FROM YOUR

SYSTEM

To cancel the alarm phone call from one of the numbers in the

phone call list:

To cancel a call out sequence from the System while listening to

an alarm message, do the following:

1. Answer the phone call.

2. Listen to the alarm message.

3. When told, press the number “1” key followed by the

pound (#) key within “1” minute to cancel the alarm call

out. You can cancel the call at anytime during the

message.

4. You can listen until you hear the System say goodbye

or just hang up the phone.

5. If you do not cancel the call, the system will call the next

number in your phone number list. The first cancel will

stop all calls for all numbers. This sequence will repeat

every 15 minutes until a call is cancelled.

To cancel the alarm phone call using the System display:

Press and hold the RESET button once to cancel the call (phone

icon is present) and the RESET up to 5 seconds if multiple

errors/alarms are present on the display to stop receiving phone

calls. You will then be required to also clear/reset the message(s)

on the display.

Canceling the call out sequence does not

cancel an active alarm. System will continue

to beep and the alarm message will be displayed on the digital display

until you hit reset for each message/condition. If you do not hit reset, each

alarm message on the display system will recall the phone number(s) in

the last 72 hours as a reminder for the uncleared alarm conditions.

PLACE A PHONE CALL TO YOUR SYSTEM TO CANCEL AN

ALARM

To cancel a call out sequence during an active alarm condition,

do the following:

1. Make the call to the System (phone number at alarm

location)

2. Wait for the System to answer (5 or 10 rings Menu option

selectable)

3. Listen to the alarm message.

4. Press the number “1” key followed by the pound (#) key

anytime during the message to cancel the alarm call out

and then hang up the phone.

REMOTE STATUS CHECK

The System will answer incoming calls if a warning condition

exists on the display. When no alarm issue exists, you will get

a general status update. If the call out sequence has been

cancelled for an alarm by pressing "1" then "#" on the phone,

but the alarm condition still exists on the display, the System will

answer and describe the alarm condition.

CANCELING AN ALARM CALL OUT SEQUENCE WITH AN

ANSWERING MACHINE/VOICE MAIL DEVICE ON THE SAME

PHONE LINE

To cancel the alarm call out-sequence, do the following:

STEP ACTION

1. Make the call to the System (phone number at alarm

location).

2. Let the phone ring the desired number of times (before the

other in-line answering machine/voice mail can answer), Hang

the phone up.

3. Call the number a second time within three minutes (The

System keeps track of all the rings from the previous

calls, accumulates them until the total ring count matches its

ring count number, 5 or 10, and then it will answer). Listen to

the alarm message.

4. Press the number “1” key followed by the pound (#) key

anytime during the message to cancel the alarm call out. Hang

up the phone.

OPERATION

1. After installation, the back-up pump will start once the water

level raises the bottom float.

2. The System has a charging circuitry designed to optimize the

recharging time of your battery and to prevent overcharging.

In addition, the control box has a time delay which keeps the

pump from repeated, short cycles when it shuts off. This

time delay feature will allow the pump to run 15 seconds

after the switch reaches the off position.

3. MUTE FUNCTION: Press the mute button once to silence the

alarm for 12, 24, or 48 hours (menu selectable). To turn off the

mute timer, press and hold the RESET button down for 5

seconds.

BATTERY CARE AND MAINTENANCE

and open flames prohibited.

Battery recharging and connections MUST be performed

in a well ventilated area. Before servicing the batteries,

blow away the gases by waving a piece of cardboard near

the batteries.

1. Unplug the transformer.

2. For batteries with top caps that can be removed, the

electrolyte level should be checked and filled to

manufacturer’s specifications. The charge for each cell

should be checked with a hydrometer. A specific gravity of

1.265 indicates the battery is at full charge. If the specific

gravity of any of the cells varies more than .050, the battery

should be replaced.

3. If the battery fluid levels are low or battery plates are exposed,

refer to the manufacturer's recommendations on how to

replenish properly.

4. Inspect the terminals and clamps for corrosion and

tightness. Clean and tighten as required.

An inexpensive hydrometer can be purchased at

an automotive parts dealer.

EXTENSION CORDS

We DO NOT recommend using extension cords, but if you find it

absolutely necessary then:

1. Use at least a 16 gauge cord that does not exceed 50 feet

in length.

Explosion hazard. Smoking

www.waynepumps.com

7

Page 8

Operating Instructions and Parts Manual

ADVANCED NOTIFICATION

MESSAGE ON UNIT SCREEN

PRIMARY PUMP STATUS

AC Power Interrupted

Primary Pump Suspect

BACK-UP DC PUMP STATUS

DC Pump In Operation

DC Pump Not Operable (Failed Test)

Check Floats For Debris

Capacity Overflow Possible

DC Impeller Locked

BATTERY TRANSFORMER

Transformer Bad

Blown Controller Fuse

MICROPROCESSOR CONTROLLER

CONDITION

12 V BATTERY STATUS

DC Pump Under Test

Battery Fully Charged

Battery 80% Charged

Battery 60% Charged

Battery 40% Charged

Battery 20% Charged

Battery Dead

Battery Condition Questionable

CALL PHONE

AUDIBLE ALARM

SECURITY SYSTEM

Reverse Polarity

WSM3300

2. The extension cord must have a ground wire and plug pin

and be connected to a properly functioning GFCI

receptacle.

3. Make sure the connection between the transformer and

extension cord are elevated off the floor.

SECURITY SYSTEM INSTALLATION AND SETUP

Electric shock hazard.

power before servicing. Apply a fixed

lock or tag to prevent unexpected application of power.

The advanced notification system produces auto-dialer alerts

and can also notify your 3rd party home security system

provider (if available). A qualified home security technician is

required when making connections between the two systems.

An access port is available on the back of the lid in which

the qualified technician can properly connect the advanced

notification system to the security system. (See Figure 5)

Figure 5 - Security system setup

this step. Be sure not to damage any

components on the control board.

The inner shield will have to be removed during

Disconnect

FOR SIGNAL

USAGE ONLY. NC/NO Output:

12 Volt DC, 2 amp max.

must be provided to the telephone company.

PLUG AND JACK USE

A plug and jack used to connect this equipment to the premises

wiring and telephone network must comply with the applicable

FCC Part 68 rules and requirements adopted by the ACTA.

A compliant modular plug is provided with this product. It is

designed to be connected to a compatible modular jack that is

also compliant. See installation instructions for details.

RING EQUIVALENCE NUMBER (REN)

The REN is used to determine the number of devices that may be

connected to a telephone line. Excessive REN’s on a telephone line

may result in the devices not ringing in response to an incoming

call. In most, but not all areas, the sum of RENs should not exceed

five (5.0). To be certain of the number of devices that may be

connected to a line, as determined by the total REN’s, contact your

local telephone company. The REN for this product is listed on the

inside of the controller lid with the FCC identifier.

TELEPHONE NETWORK INTERFERENCES

If this System causes harm to the telephone network, the

telephone company will notify you in advance that temporary

discontinuance of service may be required. But if advance notice

isn’t practical, the telephone company will notify the customer

as soon as possible. Also, you will be advised of your right to

file a complaint with the FCC if you believe it is necessary. The

telephone company may make changes in its facilities, equipment,

operations or procedures that could affect the operation of the

equipment. If this happens, the telephone company will provide

advance notice in order for you to make necessary modifications

to maintain uninterrupted service. If the equipment is causing harm

to the telephone network, the telephone company may request

that you disconnect the equipment until the problem is resolved.

If your home has specially wired alarm equipment connected to

the telephone line ensure the installation of your System does not

disable your alarm equipment. If you have questions about what

will disable alarm equipment, consult your telephone company or a

qualified installer.

At this time, you may wish to change the system settings.

Since both the auto-dialer and security system cannot access

the phone line at the same time, you must choose which

system the software accesses first. If you wish the security

system to have first priority, on the main menu, scroll to and

select the "SECURITY SETUP" option, select "Security has

Priority" and hit "Enter" to confirm. The factory default setting

is "Back-up has Priority".

If you choose, you can test the security notification by

simulating any of the security notification alerts. (See Figure 6)

DO NOT overtighten screw.

Replace the inner shield once all connections and tests have

been validated.

OPERATING INSTRUCTIONS

1. To test the back-up pump, unplug the main pump and

transformer and fill sump with water until the water lifts the

bottom float therefore activating the back-up pump. Repeat

this process two times to be sure pump is operating

normally.

2. If pump operates normally, plug the transformer into wall

outlet and plug the main pump back in. Verify the main

pump is operational by repeating step 1 above.

FCC STATEMENT

This equipment complies with Part 68 of the FCC rules and

the requirements adopted by the ACTA (American Council

for Terminal Attachments). On the inside cover of your unit

is a label that contains, among other information, the FCC

registration number for this product. If requested, this number

www.waynepumps.com

Figure 6 -Notification alerts chart

8

Page 9

Operating Instructions and Parts Manual

Troubleshooting Chart

Message Possible Cause(s) Corrective Action

BACK-UP PUMP

Pump Won't Run 1. Connections not secure

2. Low or defective battery

3. Float switch stuck

4. Defective or blown fuse

Motor Hums But Pump

Won't Run

Pump Runs But Pumps

Very Little or No Water

Pump Cycles Too

Frequently

CONTROLLER

Flood Emergency 1. Inflow exceeds pump rating

Check AC Pump 1. Float stuck or obstructed

Check Back-up Pump 1. Defective pump

Check BU Pump Fuse 1. Fuse blown 1. Replace fuse

AC Power Failure 1. Defective wall transformer

Less Than 1 Hr Run Time 1. Power outage

Replace Battery 1. Battery weak

Replace/Inspect Float 1. Float stuck

Check Power Supply 1. Wall transformer defective 1. Replace wall transformer

1. Defective battery

2. Impeller is locked

1. Check valve missing or improperly installed

2. Obstruction in discharge pipe

3. Discharge pipe length and/or height exceeds

capacity of pump

4. Low or defective battery

5. Blocked vent hole

1. Check valve problem 1. Check to make sure check valves installed between

2. Inflow exceeds pump rating

3. Battery has become depleted

2. Switch defective

3. AC power interrupted

4. Inlet clogged

5. Defective pump

2. Pump jammed

2. GFCI Tripped

3. Circuit breaker tripped

4. Power outage

2. Extended power outage

2. Battery more than 5 years old

3. Discharged and left uncharged for more than 3 days

4. Charging cycles exceed max

2. Float defective

1. Check all connections

2. Check battery and replace if low or defective

3. Make sure nothing is interfering with operation of switch

4. Check internal fuse located inside the controller lid. Pull

the transformer from the wall outlet and remove. If the

fuse is blown, replace with onboard 20 amp automotive

type fuse or equivalent

1. Check battery and replace if low or defective

2. Unplug pump, remove screen, and check to see if

impeller is free to turn. If impeller is locked, remove

the 7 screws on the bottom of the pump to release the

housing around the impeller. Remove the obstruction.

Reassemble pump and reconnect

1. Check to make sure check valves installed between

primary pump discharge and back-up sump pump are

functioning properly

2. Check for obstruction and clear if necessary

3. If discharge is too high, a separate line may be required

with a lower discharge height

4. Check battery and replace if low or defective

5. Check to make sure the back-up pump is not air locked.

Locate the vent hole, inspect, and clear the hole using a

pipe cleaner

primary pump discharge and back-up sump pump are

functioning properly

1. Restore AC pump

2. Incorporate auxiliary pump

3. Replace battery

1. Free float

2. Replace switch

3. Reset breaker or GFCI outlet

4. Clear debris

5. Replace pump

1. Replace pump

2. Clear obstruction

1. Replace wall transformer

2. Check for moisture and reset

3. Reset breaker

4. Notify Utilities Company

1. Notify Utilities Company

2. Prepare spare battery

1. Replace battery asap

2. Replace battery

3. Replace battery

4. Replace battery

1. Clear float and debris

2. Replace float

WSM3300

www.waynepumps.com

9

Page 10

Operating Instructions and Parts Manual

WSM3300

For Replacement Parts or

Technical Assistance, call

1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

WAYNE Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

Ref. No. Description Order No. Quantity

1 Lid/Controller Assembly 60157-001 1

2 Float Switch with Clamp 60158-001 1

3 Transformer 60159-001 1

4 Back-up Sump Pump 60160-001 1

Limited Warranty

1

4

3

2

For two years from the date of purchase, WAYNE Water Systems Division ("WAYNE Pumps") will repair or re place, at its

option, for the original purchaser any part or parts of its Water Pumps (“Product”) found upon examination by WAYNE to

be defective in materials or work man ship. Please call WAYNE Pumps (1-800-237-0987) for instructions. Be pre pared to

provide the model number and the serial number when exercising this warranty. All transportation charges on Products or

parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse,

neglect, improper application, improper maintenance, or failure to operate in accordance with WAYNE Pumps' written

instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANTABIL I TY AND FITNESS FOR A PARTICULAR PUR POSE, ARE LIMITED TO ONE YEAR FROM THE DATE

OF PURCHASE. THIS IS THE EXCLUSIVE REM E DY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR

CONSEQUENTIAL DAM AG ES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations

of incidental or consequential damages, so the above lim i ta tions might not apply to you. This limited war ran ty gives you

specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise, shall WAYNE

Pumps or its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to

loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated equip ment,

cost of capital, cost of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s

cus tom ers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you

MUST send a copy of the purchase receipt along with the material or correspondence. Please call WAYNE Pumps (800237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE PUMPS. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ DATE_____________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

10

Page 11

Operating Instructions and Parts Manual

Copy, cut out and save the following Quick Reference Cut-A-Way Card for your records. These are especially useful when you are not at home

and need to contact the System to check the status, retrieve or cancel messages and alarms. It would also be useful to give this card to others

who are on the call notification list for your System.

Quick Reference Cut-A-Way Card

WSM3300

CALL YOUR SYSTEM TO CHECK SYSTEM STATUS:

(no answering machine or digital voice mail service)

1. Make a phone call to the System (phone number at alarm location).

2. Wait for the System to answer (either five (5) or ten (10) rings).

3. Listen to the message(s). If no alarms, hang up.

4. If alarm(s) exist, cancel calls by pressing the "1" key then pound (#) key, hang up.

TO CANCEL A CALL FROM YOUR SYSTEM:

1. Listen to the message(s). If no alarms, hang up.

2. If alarm(s) exist, cancel calls by pressing the "1" key then pound (#) key, hang up.

CALL YOUR SYSTEM TO CHECK SYSTEM STATUS:

(answering machine/digital voice mail set to 4 rings, the System set to 5 rings)

1. Make a phone call to the System (phone number at alarm location), let ring three (3) times, hang up.

2. Make a second call to the System within 3 minutes, the System will answer on the second ring

(3 rings + 2 rings, System answers on fifth (5th) ring).

3. Listen to the alarm messages.

4. Press the "1" key then pound (#) key anytime during the message to acknowledge and cancel the alarm.

5. Note: if answering service answers before the System does, start over and adjust additive rings.

www.waynepumps.com

11

Page 12

Système de notification

Select Language

English Español

Français

Last Auto Test: --/--/--

MENU MUTE RESET

12.1 V

System Armed & Ready

100%

12

3

6

9

préalable de 12 volts

MODE D’EMPLOI ET LISTE DES PIÈCES

LIRE, S’ASSURER DE COMPRENDRE ET SUIVRE TOUTES LES INSTRUCTIONS DE CE MANUEL - NE PAS JETER.

Le non-respect de ces instructions pourrait entraîner des dommages matériels, des blessures corporelles ou la mort.

INSTRUCTIONS DE DÉMARRAGE RAPIDE WSM3300

DÉTACHÉES

ÉTAPE 1 : VÉRIFICATION DU CONTENU DE L’EMBALLAGE

N’inclut pas :

la batterie à décharge

poussée de 12

volts c.c., la prise

téléphonique, la ligne

téléphonique, le

tuyau et les raccords

nécessaires.

Transformateur (1)

Assemblage couvercle et contrôleur (1)

Boîte de batterie (1)

Pompe de secours de 12 volts c.c. (1)

Interrupteur avec pince (1)

Requiert un service de ligne terrestre téléphonique actif

ÉTAPE 2 - METTRE HORS TENSION

Si la source de courant

n’est pas visible, verrouiller en

position ouverte (arrêt) et étiqueter

pour éviter tout rétablissement

inattendu de l’électricité. Le nonrespect de cette directive POURRAIT

entraîner une décharge électrique

mortelle !

ÉTAPE 3 - INSTALLER LA POMPE DE SECOURS ET

L’INTERRUPTEUR À FLOTTEUR

ÉTAPE 5 - BRANCHER LE COUVERCLE À LA BATTERIE

MISE EN GARDE Porter

des lunettes de sécurité

au moment de brancher la

batterie

Rouge

Noir

ÉTAPE 6 - BRANCHER LES FILS

Interrupteur

à flotteur

Pompe c.c.

Transformateur

Sécurité

Téléphone

ÉTAPE 7 - POSITIONNER LA BATTERIE ET LE CONTRÔLEUR

ÉTAPE 4 - INSTALLER LA BATTERIE

Batteries adaptées

WAYNE - WSB1275

WAYNE - WSB1240

Batterie marine à décharge poussée

de 12 volts

Batterie au plomb-acide scellée de

12 volts

Batterie à décharge poussée de 12

Batterie à cellule humide de 12 volts

Capacité = 40 Ah minimum

© 2012, WAYNE/Scott Fetzer Company.

ou

volts

Le temps de charge

minimum avant utilisation

est de 24 heures

Tuile de

drainage

ÉTAPE 8 - CONFIGURATION DU CONTRÔLEUR

Affichage principalAffichage au démarrage

Sélectionner la langue de départ et suivre les instructions à

l’écran pour configurer le contrôleur. Une fois la configuration

du contrôleur terminée, rétablir l’alimentation c.a. et vérifier la

pompe principale conformément à la description donnée dans

la section Fonctionnement de ce manuel.

Pour des renseignements sur les pièces, les produits et l’entretien,

visiter www.waynepumps.com

Loading...

Loading...