Page 1

Suction Outlet

(Main Drain)

Suction Outlet

(Main Drain)

Valves OK Between

Pump and Tee

Pump

At Least

3 Feet

ANSI/APSP-16 (2011) Certified

Component Anti-Entrapment

Cover/Grate or Suction Fitting

ANSI/APSP-16 (2011) Certified

Component Anti-Entrapment

Cover/Grate or Suction Fitting

No Valves Between

Tee and Main Drains

SWIMMING POOL PUMP

OPERATING INSTRUCTIONS & PARTS MANUAL

MODELS - WIP150 / WIP100 / WIP90 (TITLE 20 COMPLIANT)

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD.

Failure to follow these instructions could result in property damage, serious injury or death.

Installer: Please leave this manual for the owner's use.

QUICK START INSTRUCTIONS

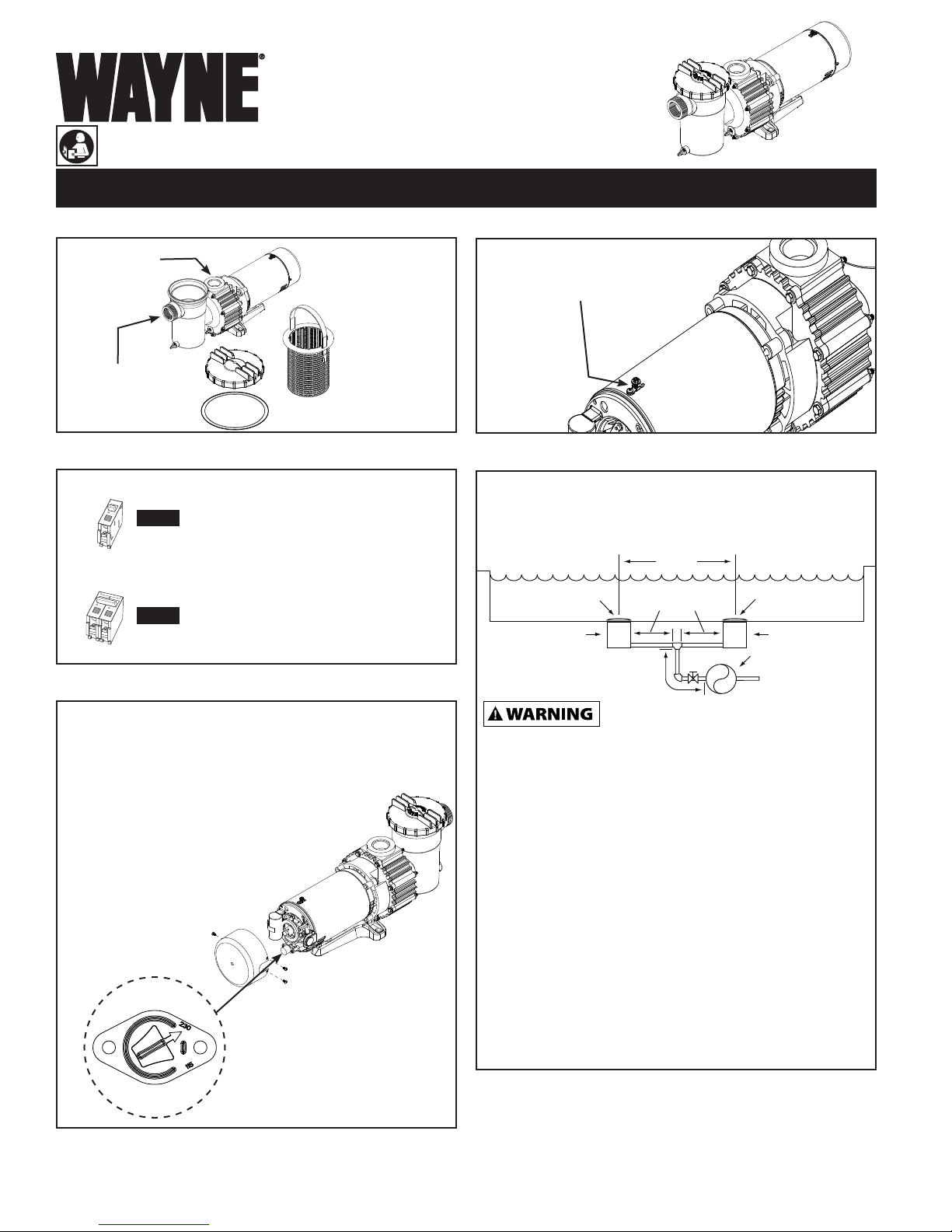

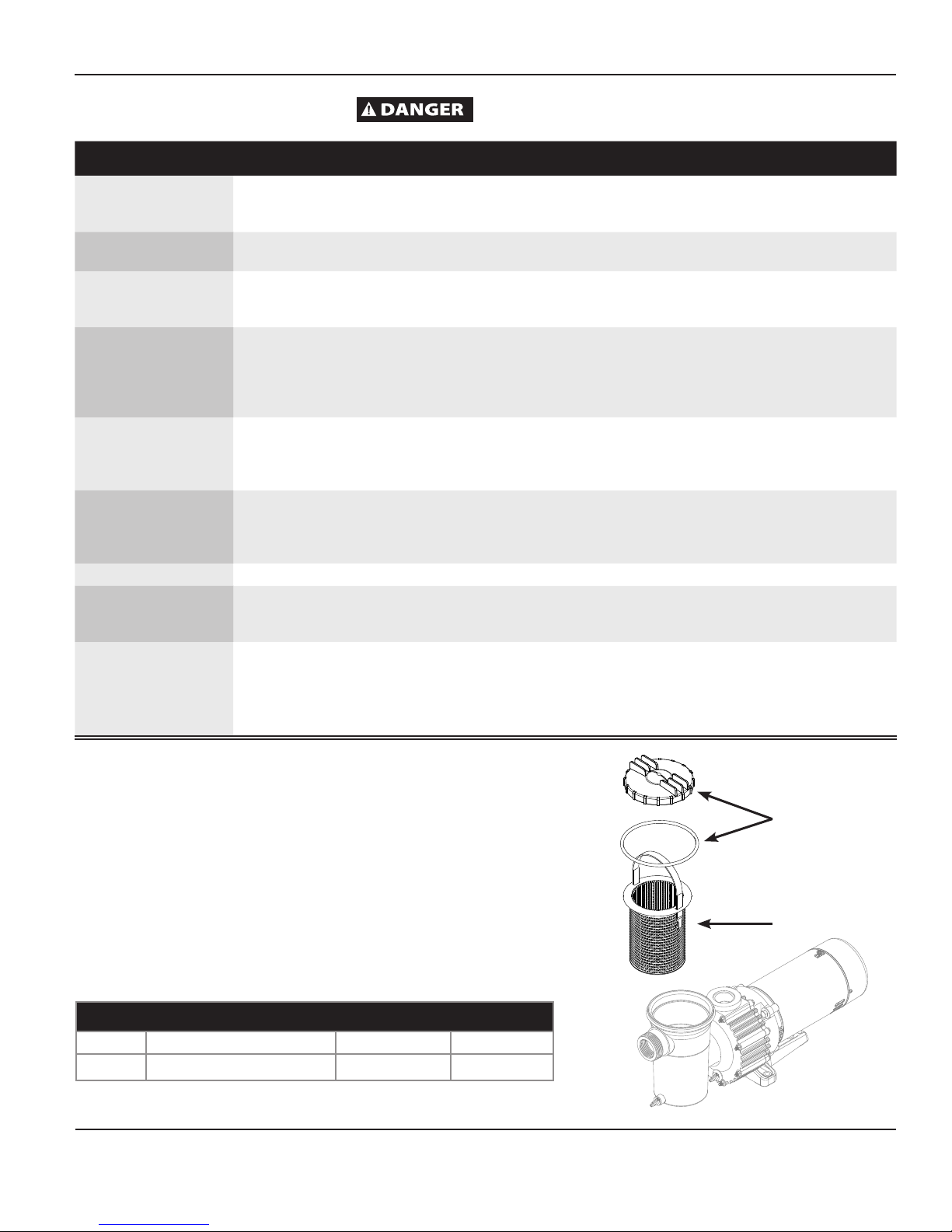

STEP 1 - VERIFY PACKAGE CONTENTS

WIP SERIES

SWIMMING POOL PUMP

STEP 4 - ELECTRIC BONDING

DISCHARGE

(1) PUMP

(1) LID

(1) GASKET

SUCTION

INLET

(1) STRAINER

STEP 2 - VERIFY EXISTING PUMP VOLTAGE

115 V

230 V

All electrical wiring or service should

be done by a qualified electrician.

You

must match the voltage of our pump to

the existing power supply.

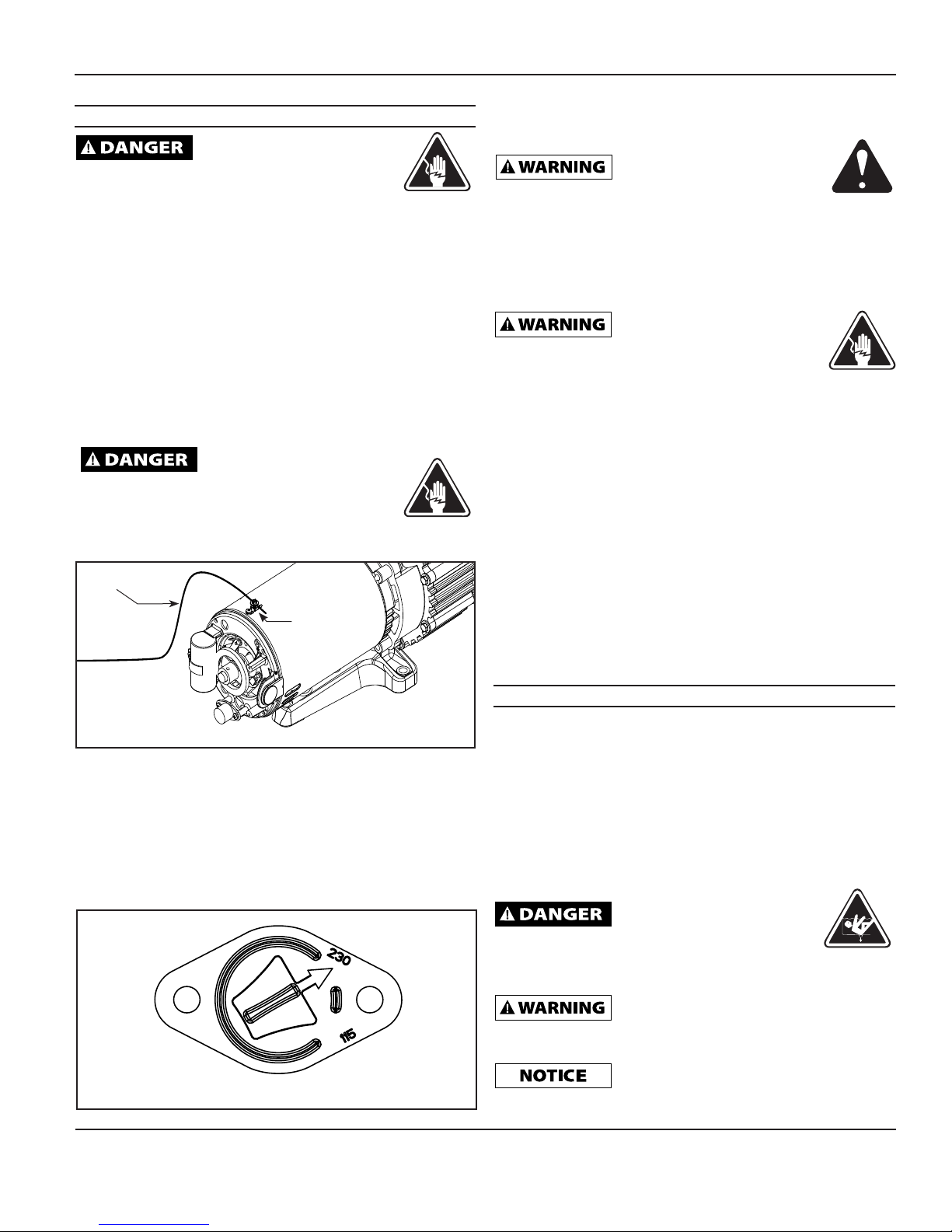

STEP 3 - HOW TO CHANGE VOLTAGE SELECTOR

This pump is factory wired for 230 volts. To change the voltage to

115 volts follow the steps below:

1. Disconnect the pump from power.

2. Remove cover from back of motor to find voltage selector.

3. Pull selector knob out.

4. Rotate selector knob to correct voltage setting.

5. Push selector knob back in place.

6. Reinstall cover to back of motor.

Use solid copper bonding conductor

not smaller than 8 AWG (8.4 mm2).

STEP 5 - PUMP PLUMBING

Before attempting installation of any swimming pool pump, read and

understand ALL guidelines (ANSI/APSP/ICC-15 2011) regarding suction

and installation. Suction pipe should be as large or larger than discharge

pipe. Avoid using a suction pipe smaller than pump connection.

WARNING – DO NOT attempt installation

of swimming pool pump unless you have read

and understand the following standards, guidelines and regulations:

ANSI/APSP-16 (2011); ANSI/APSP-7 (2006); ANSI/ASME A112.19.17

(2010); ASTM F2387 (2004); Virginia Graeme Baker Pool and Spa Safety

Act (2007); CPSC’s publication entitled Guidelines for Entrapment

Hazards; and any successor standards or state law requirements.

DO NOT enter the swimming pool if any drain cover is broken or

missing. Close the swimming pool or spa. Immediately call your

professional to make repairs. Prime pump before attempting to operate.

To prime pumps located above water level, remove strainer cover, fill

strainer body with water then replace cover. If pump and all piping is

located below water level, the pump will self prime.

VOLTAGE SELECTOR

© 2012,

WAYNE/Scott Fetzer Company.

After pump has been primed, energize motor and open all suction and

discharge line valves. If no flow is observed in five minutes, stop the

motor and re-prime. If the pump fails to operate, check for air leaks.

Refer to troubleshooting section.

After about 10 minutes of operation, check the return fittings for air

bubbles. A continuous flow of air indicates leaks in the suction line.

Locate and correct any leaks immediately.

FOR FURTHER INSTRUCTIONS, SAFETY REQUIREMENTS/

STANDARDS/ REGULATIONS FOR INSTALLATION REFER

TO THE INFORMATION PROVIDED IN THIS MANUAL.

For parts, product & service information

visit www.waynepumps.com

320405-001 10/12

Page 2

SWIMMING POOL PUMP

OPERATING INSTRUCTIONS & PARTS MANUAL

MODELS - WIP150 / WIP100 / WIP90 (TITLE 20 COMPLIANT)

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD.

Failure to follow these instructions could result in property damage, serious injury or death.

Installer: Please leave this manual for the owner's use.

INSTALLATION AND OPERATING INSTRUCTIONS

DESCRIPTION

Swimming pool pumps are a part of a water filtration system for swimming

pools. These pumps circulate water as part of an in-ground or an aboveground swimming pool.

UNPACKING

Inspect this unit before it is used. Occasionally, products are

damaged during shipment. If the pump or components are

damaged, contact customer service at 1-800-237-0987.

SAFETY GUIDELINES

To help recognize this information, observe the following signal

words/hazard classifications.

This is the safety alert symbol. It is used to alert you to

potential bodily injury hazards. Obey all safety messages

that follow this symbol to avoid possible harm.

Danger indicates an imminently hazardous

in death or serious injury.

Warning indicates a potentially hazardous

result in death or serious injury.

Caution indicates a potentially hazardous

in minor or moderate injury.

Notice indicates important information, that if

equipment.

NOTE: Note indicates information that requires special attention.

situation which, if NOT avoided, WILL result

situation which, if NOT avoided, COULD

situation which, if NOT avoided, MAY result

NOT followed, MAY cause damage to

GENERAL SAFETY INFORMATION

GENERAL SAFETY

1. Read the manual(s) included with this product

carefully. Be thoroughly familiar with the controls

and the proper use of the equipment. Follow all

instructions.

2. Only persons well acquainted with these rules of

safe operation should be allowed to use the unit.

Do NOT allow children to use this pump.

3. Wear safety glasses at all times when working

with pumps.

4. The unit MUST be wired into a properly grounded

GFCI circuit. Consult with a qualified electrician

for proper installation of a GFCI circuit.

swimming pools. If specified, the pump may

be used with hot tubs and spas. Do NOT use with storable pools. A

permanently installed pool is constructed in or on the ground or in a

building such that it CANNOT be readily disassembled for storage. A

storable pool is constructed so that it MAY be readily disassembled for

storage and reassembled to its original integrity.

This pump is for use with permanently installed

clear water. Do NOT pump

flammable or explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do NOT use in a flammable and/or explosive

atmosphere. Failure to follow these instructions COULD

result in personal injury and/or property damage.

that is familiar with swimming pool/spa operations

and in accordance with the NFPA 70 - National Electric

Code.

allow leaves, debris, or foreign matter to collect around the

pump motor. Keep ventilation holes open. Allow motor to

cool before handling. Keep flammable liquids away.

ABBREVIATED TERMS AND DEFINITIONS

ASHRAE: American Society of Heating, Refrigeration and Air

Conditioning Engineers

ANSI: American National Standards Institute

APSP: The Association of Pool and Spa Professionals

ASME: American Society of Mechanical Engineers

CPSC: Consumer Products Safety Commission

NEC: National Electric Code

NFPA: National Fire Protection Association

Do NOT use pump if any part of the housing

Electric Shock

Hazard.

DISCONNECT power before servicing.

Apply a fixed lock or tag to prevent

unexpected application of power.

This unit is NOT designed for use

in sump, septic tanks or

underground vaults. NEVER use in hazardous or explosive

locations.

SWIMMING POOL SAFETY GUIDELINES

RESPONSIBLE ADULT SUPERVISION

Constant and responsible adult supervision is mandatory in the swimming

pool or spa environment. ALWAYS supervise children around swimming

pools and spas. NEVER allow a child to play in a way that COULD permit

the child’s hair to come near the drain cover.

Do NOT allow children to use

this pump.

Do NOT install multiple pumps in one hydraulic circuit. The pump is not

designed to accept output flow from another pump. Do NOT allow water

to backflow through the pump. Water flowing in the discharge and out

the suction during an upset condition can cause the motor to rotate

Risk of explosion! Pump only

This pump must be installed by a

licensed or certified electrician

Risk of fire and burn hazard! Motors

run at high temperatures. Do NOT

is cracked, broken, or missing.

WIP SERIES

SWIMMING POOL PUMP

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

For parts, product & service information visit www.waynepumps.com

© 2012,

WAYNE/Scott Fetzer Company.

2

Page 3

WIP SERIES POOL PUMP

backwards. NEVER attempt to start pump if shaft is rotating due to a

hydraulic turbine action, this COULD cause pump to operate in reverse

and damage internal components.

DRAINS, SUCTION FITTINGS AND JETS

1. Do not allow anyone, child or adult, to play with or sit on any suction

outlet (drain) or wall vacuum fittings!

2. Pull long hair back into a ponytail or a bathing cap.

3. Remove jewelry before entering the swimming pool.

4. Have a licensed professional inspect all suction outlets.

5. Ensure that drain covers are ANSI/APSP-16 (2011) certified and wall

vacuum fittings are self closing/self latching.

6. Replace any broken drain covers, missing covers or uncertified covers

with ANSI/APSP-16 (2011) certified covers.

ELECTRICAL HAZARDS

A licensed electrician, experienced in swimming pools and spas, SHOULD

inspect your equipment to make sure everything is properly grounded,

bonded and protected by proper GFCI circuits according to Article 680 of

the National Electric Code.

INDOOR INSTALLATIONS

Swimming pools and spas located indoors must comply with ANSI/

ASHRAE Standard 62-2001 to ensure adequate ventilation and safe use.

Do NOT enter the swimming pool if the drain

cover is broken or missing. CLOSE the

swimming pool or spa. Immediately call your swimming pool

professional to make repairs.

At Least

3 Feet

ANSI/APSP-16 (2011) Certified

Component Anti-Entrapment

Cover/Grate or Suction Fitting

Suction Outlet

(Main Drain)

Valves OK Between

Pump and Tee

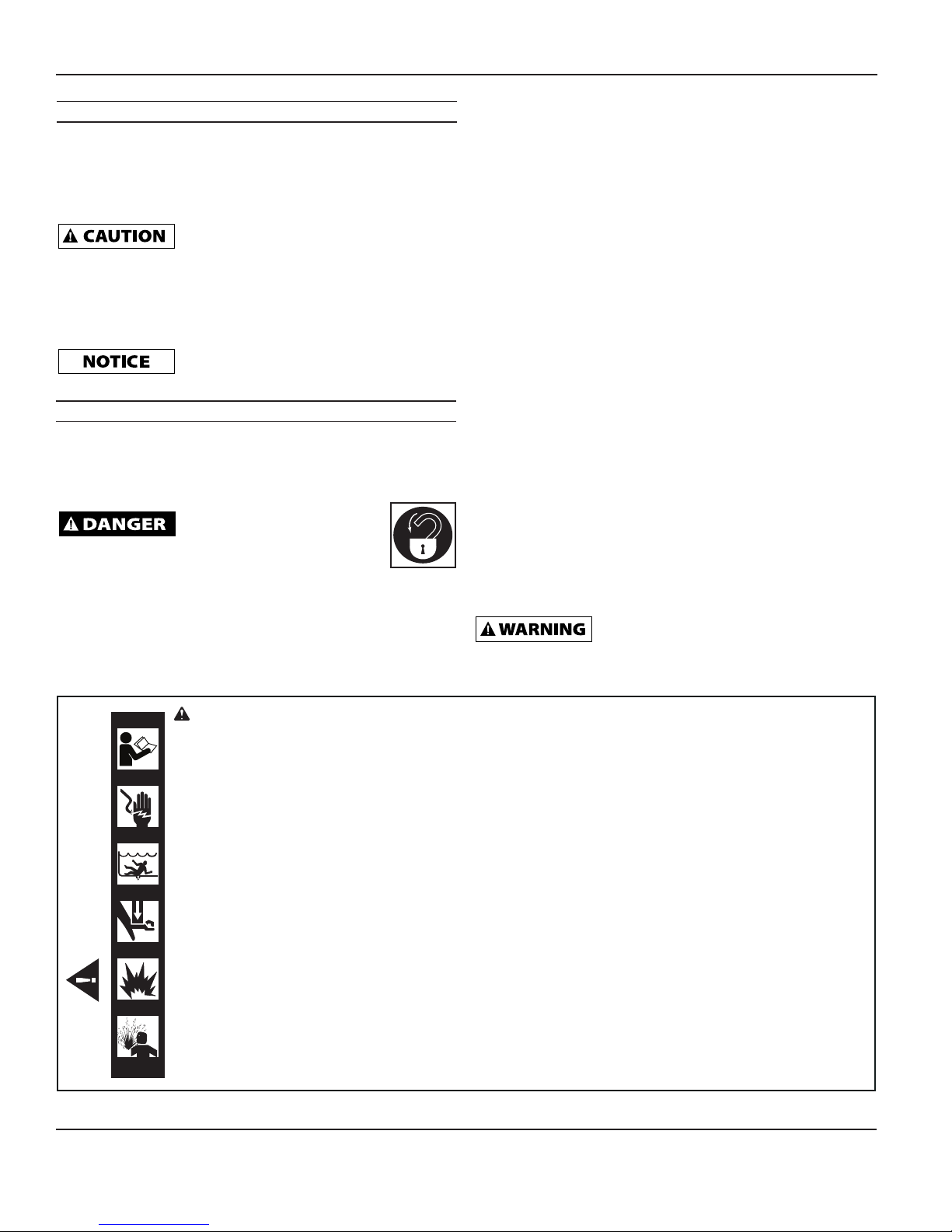

Figure A - Outlet Cover Certification

No Valves Between

Tee and Main Drains

ANSI/APSP-16 (2011) Certified

Component Anti-Entrapment

Cover/Grate or Suction Fitting

Suction Outlet

(Main Drain)

Pump

ENTRAPMENT PROTECTION

Refer to ANSI/APSP-7-2006 or latest version for avoiding suction

entrapment. The pump suction must be designed to eliminate the possibility

of suction entrapment or hair entrapment/entanglement.

SUCTION COVERS

Do NOT enter the swimming pool if drain cover is broken or missing. Call

your swimming pool professional immediately to make repairs.

TESTING AND CERTIFICATION

All suction inlet covers must comply with ANSI/APSP-16 (2011)

specifications for suction fittings for use in swimming pools, spas

and whirlpool bathtub applications. The product must be tested for

compliance with the standards and the certification must be included with

the components.

OUTLETS PER PUMP

Provide at least two hydraulically balanced main drains, with covers for

each swimming pool pump suction line. The centers of the main drain's

suction fitting must be at least 3 feet apart (Figure A). The system must

be built so that it cannot operate with the swimming pool pump drawing

water from only one main drain. Two main drains must be connected to the

swimming pool pump whenever it is running. A valve in each suction line

is not allowed.

1. Keep the piping as straight and short as possible, and of suitable size.

2. Do not connect an elbow directly into the pump inlet. A length of

straight pipe will allow proper entry of the water to the pump.

3. Slope horizontal runs upward to the pump to prevent trapping air.

4. Use independent piping supports to alleviate strain on the pump.

5. Keep as much of the suction line as possible below the water level to

reduce priming time.

6. Install valves and unions in the pump suction and return lines to

facilitate servicing. Do not use valves to throttle the pump. Valves are

essential for pump maintenance if the system is installed below deck

level.

INSTALLATION

NOTE:

Refer to ANSI/APSP/ICC-15-2011 or latest version for guidelines on

proper pump selection.

LOCATION

Locate pump as close to swimming pool/spa as possible on a noncombustible surface. Install the pump on a hard, level surface that is dry,

well ventilated and away from direct sunlight. The surrounding area should

provide protection from the elements and ample room for maintenance

and service. Ensure the drainage will flow away from the pump.

Mount pump below water level for easy priming. If the pump must be

located above the filled water level, keep the vertical distance to a minimum.

alignment may cause pump housing failure.

PUMP PLUMBING

Explosion/fire hazard:

adhesive in a well ventilated area.

SOLVENT WELD CONNECTIONS

Use rigid or flexible PVC pipe. Ensure pipe ends are clean and

free of any flash caused by the cutting operation. Use the proper

adhesive for the type of pipe specified.

NOTE: Use an adhesive primer to ensure adhesive joints are

secure. Primers are available with a purple tracer to qualify in areas

where codes specify a primer must be used.

Consider climatic conditions when applying adhesives.

Atmospheric conditions with high humidity will make the adhesive

action of certain glues less effective. Follow the manufacturer’s

instructions.

THREADED CONNECTIONS

Use only plumber’s seal tape or equivalent on threaded plumbing

connections. Other pipe compounds may damage threads. Do not

use silicone or petroleum based compounds. Do not overtighten.

Hand tightening plus 1/2 turn is sufficient.

Excessive pipe strain caused by incorrect

ONLY apply

www.waynepumps.com

3

Page 4

Operating Instructions and Parts Manual

INSTALLATION (ELECTRICAL)

power source before

attempting to install, service, relocate or perform any

maintenance.

NOTE: This pump must be installed by a licensed electrician that

is familiar with swimming pool/spa operations and in accordance

with the NFPA 70 – National Electric Code.

Follow all national and local wiring codes. If unsure of code

requirements consult a professional electrician. Pump must be

permanently connected to a dedicated circuit. If unsure consult

a licensed electrician.

IMPORTANT: Use copper conductors only.

Refer to information on motor nameplates for electrical service

data. Install motors with a fused disconnect switch or a dedicated

circuit breaker. Be sure wire size is sufficient for pump HP and

distance from power source.

Electric shock hazard. Connect

this pump to a properly

grounded GFCI (Ground Fault Circuit Interrupter)

receptacle that is rated for at least 15 amps. Test the

operation of the GFCI receptacle according to the

manufacturer’s recommended intervals.

Disconnect, tag, and lock out

GFCI is required in the circuit. For size of GFCI required and test

procedures for GFCI, see manufacturer’s instructions.

NEVER ground to a gas supply

line, use dedicated grounding

system

.

GFCI tripping indicates an electrical problem. If GFCI trips, determine

the reason for tripping. If you are uncertain, have a l

icensed or certified

electrician that is familiar with swimming pool/spa operations and

in accordance with the NFPA 70 – National Electric Code

inspect

and repair the electrical system.

This pump MUST be installed by

a licensed or certified electrician

that is familiar with swimming pool/spa operations

and in accordance with the NFPA 70 - National Electric

Code.

Verify supply voltage matches the nameplate voltage. Incorrect voltage

can cause fire or seriously damage motor and voids warranty.

GROUNDING/BONDING

Install, ground, bond and wire motor according to local or National

Electrical Code requirements. Permanently ground the motor. Use ground

terminal provided in the terminal box on the back of the motor. Use size

and type wire required by local codes. Connect motor ground terminal to

electrical service ground.

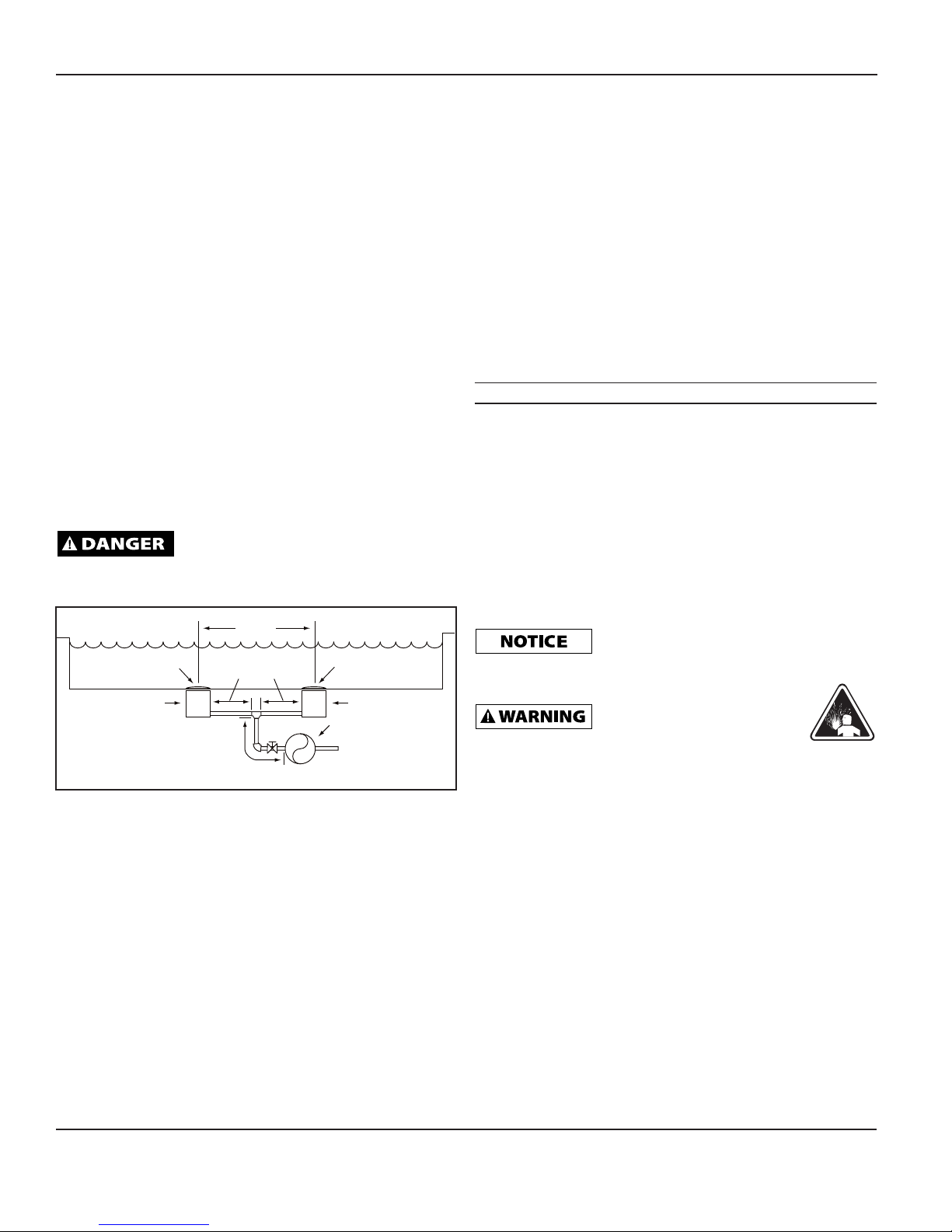

BONDING WIRE

BONDING LUG

CONNECTION

Figure B - Remove back motor cover

This pump is factory wired for 230 volts. To change the voltage to 115 volts

follow the steps below:

1. Disconnect the pump from power.

2. Remove cover from back of motor to find voltage selector (Figure B).

3. Pull selector knob out.

4. Rotate selector knob to correct voltage setting (Figure C).

5. Push selector knob back in place.

6. Reinstall cover to back of motor.

Bond motor to swimming pool structure. Bonding connects all metal parts

within and around the swimming pool with a continuous wire. Bonding

reduces the risk of current passing between metal objects which could

cause electrical shock. Reference NEC local codes for all wiring standards.

Use a solid copper conductor, size No. 8 AWG or larger. Run wire from

external bonding lug located on top of motor (Figure B) to reinforced rod

or mesh.

OPERATION

Prime pump before attempting to operate. To prime pumps located

above water level, remove strainer cover, fill strainer body with water, then

replace cover. If pump and all piping are located below water level, the

pump will self prime. After pump has been primed, energize motor and

open all suction and discharge line valves. If no flow is observed in five

minutes, stop the motor and re-prime. If the pump fails to operate, check

for air leaks. Refer to troubleshooting section. After about 10 minutes

of operation, check the return fittings for air bubbles. A continuous flow

of air indicates leaks in the suction line. Locate and correct any leaks

immediately.

Suction hazard. Do NOT block

the pump suction with your

body. Failure to do so WILL result in death or serious

bodily injury.

NOTE:

Small children using pool must ALWAYS have close adult supervision.

temperatures, to reduce the risk of fire, do

NOT allow debris or foreign matter to collect around the pump motor.

Allow motor to cool prior to handling or performing maintenance.

Fire and burn hazard. Motor runs at high

Figure C - Voltage selector setting

www.waynepumps.com

Do NOT operate pump without strainer.

Foreign material may interfere with

impeller causing pump to stop.

4

Page 5

WIP SERIES POOL PUMP

OPERATION (CON'T)

The motor is equipped with an internal thermal protection circuit to guard

against overheating. The maximum ambient temperature for motor

operation must not exceed rating on motor model plate.

If the thermal overload protection in the motor trips or if the GFCI trips,

determine the reason and correct the problem before re-starting pump.

Do NOT operate pump with closed or partially

closed suction or discharge valves.

WATER CHEMISTRY

Proper and consistent use of chemicals is necessary to manage a water

system. Chlorine is the most commonly used chemical to provide clean,

sanitary water. Daily administration of dry or liquid chlorine (calcium or

sodium hypochlorite) is essential.

Maintain the correct level of acidity or alkalinity

of the pool water. Readings above pH 7.0 are alkaline. A

pH 7.0 is neutral. Readings below pH 7.0 are acidic. A desirable range is 7.2 to 7.4.

MAINTENANCE

1. Motors are self-lubricating, no additional lubrication is required.

2. Visually inspect motor for blockage of air vents on motor shell. Remove

any debris after shutting off the breaker.

3. Replace worn seals.

Disconnect, tag and lock out

power source before attempting

to install, service, relocate or perform any maintenance.

HAIR AND LINT STRAINER

1. Switch off the power.

2. Close the valves in the suction and return line.

3. Turn strainer cover counterclockwise and remove strainer cover.

4. Lift strainer basket away from the pump.

5. Clean and then reposition the basket into the pump. Take care to seat the

basket properly.

6. Clean the o-ring and re-lubricate with petroleum jelly if necessary.

7. Clean o-ring seats on the cover and pump.

8. Refit the cover and strainer locking ring. Hand tighten only.

9. Open the valves then switch on power to return pump to operation.

WATER LEAKING AROUND MOTOR

A water leak in the area of the motor to pump connection indicates a

mechanical seal failure and a shock hazard. Take pump out of service and

replace seal immediately to avoid damage to other components and to

reduce risk of electric shock. Contact customer service at 1-800-237-0987.

WINTERIZING

Always protect system from freezing temperatures. Drain the system if there

is a possibility of freezing. To drain the system:

1. Units with a filter:

a. Sand filter: Backwash for 3 to 5 minutes and then set dial valve to

winterize position.

b. Cartridge filter: Clean the filter element and store in dry area.

2. Drain system by removing both drain plugs and removing strainer

cover. Removing strainer cover will facilitate draining also. Store drain

plugs in strainer basket, and re-attach strainer cover.

SPRING START-UP

1. Clean and replace drain plugs.

2. Lubricate strainer o-ring with petroleum jelly if needed.

3. Clean o-ring seat, strainer basket and install o-ring in lid.

4. Fill strainer body with water and refer to the Operation Section (Page 4).

CALIFORNIA PROPOSITION 65

This product or its power cord may contain

chemicals, including lead, known to the

State of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

WARNING This is the Safety Alert Symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Avoid Injury. Read and Understand Owner’s Manual Before Operating this Product.

SHOCK HAZARD - Disconnect and lock out power before servicing. GFCI (Ground Fault Circuit Interrupter) required. Unit must be

properly grounded. All electrical components in the system must be bonded together for proper grounding. Location must be wellventilated, out of sun, out of sleeping areas, away from flammable liquids. Keep out of wet areas. Close valves before opening the

strainer cover and drain housing before opening pump housing.

ENTRAPMENT HAZARD - Pumps installed with only one suction outlet can trap, disembowel and drown swimmers. Install pump only

in a pool plumbing system that meets the ASME/ANSI A112.19.8 requirements. Two suction outlets at least 3 feet apart are required.

All suction fittings must be agency approved for anti-entrapment, anti-hair entanglement, correctly installed and not damaged. Do not

use pool if drain or outlet covers are broken or missing.

MECHANICAL HAZARD - Contains moving parts. Switch off and lock-out power before working on pump. Pump designed for

WARNING

permanent pool applications only. Any other use could be hazardous.

EXPLOSION HAZARD - Use water to pressure test. Compressed air could cause pump to explode violently. Securely tighten and

center the basket clamp ring prior to pressure testing system. Bleed off all trapped air in system before pressure testing. Never use air

or gas to detect leaks. Do not use a leak test pressure greater than 25 PSI higher pressure will permanently damage pump. Use only

piping and fittings that are designed for pools. Never leave water in the pump or filter during freezing weather. Ice will cause housing

to break.

WATER UNDER PRESSURE - Water under pressure could cause serious bodily injury. Keep people and pets away from fountains,

jets and outlets while filling pool or spa.

www.waynepumps.com

5

Page 6

Troubleshooting and Replacement Parts

Electrocution hazard! Pump can start automatically. Disconnect

Troubleshooting Chart

Symptoms Possible Cause(s) Corrective Action

the power before attempting any repairs. Failure to follow these

instructions WILL result in serious injury or death.

Motor does not start 1. Disconnect switch or circuit breaker in OFF position

2. Fuses blown or thermal overload open

3. Disconnected or defective wiring

Motor does not reach full

speed

Motor overheats

(protector trips)

Pump does not deliver

water

Noisy pump and motor 1. Plugged basket in skimmer or hair in lint strainer

Low pump capacity 1. Valve in suction or discharge line partly closed

Leakage of water at shaft 1. Shaft seal requires replacement 1. Replace seal

High pump pressure 1. Discharge valve closed

Air bubbles collecting in

strainer

1. Low voltage

2. Motor windings connected for wrong voltage

1. Low voltage

2. Motor windings connected for wrong voltage

3. Inadequate ventilation

1. Pump is not primed

2. Suction or discharge valve is closed

3. Leakage or air into suction system

4. Hair and lint strainer is full

5. Water level in swimming pool is too low

2. Valve in suction line partly closed

3. Vacuum hose plugged or too small

4. Pump not supported properly

2. Suction or discharge line too small

3. Plugged basket in skimmer or hair in lint strainer

4. Dirty filter

2. Return lines too small

3. Dirty filter

1. Leakage of air into suction line at connections or valve

stem

2. Strainer cover leaking

3. Restriction in suction line

4. Low water level in swimming pool

1. Reset breaker

2. Check voltage

3. Check wiring

1. Check voltage settings

2. Inspect motor voltage selector

1. Check voltage settings

2. Inspect motor voltage selector

3. Remove obstructions around pump

1. Prime pump as directed in the “Operation” section

2. Open the valve

3. Eliminate leaks in suction line

4. Clean strainer (see maintenance section)

5. Fill swimming pool to proper level

1. Clean skimmer and lint strainer

2. Open all valves during operation

3. Check for collapsed hose and replace

4. Add additional supports

1. Open all valves

2. Use larger supply line

3. Clean skimmer and lint strainer

4. Clean filter (see filter manual)

1. Always run with valves open

2. Replace with larger lines

3. Clean filter (see filter manual)

1. Eliminate leaks in suction line

2. Remove and clean o-ring

3. Increase suction line size

4. Fill swimming pool to correct level

For Replacement Parts or

Technical Assistance, call

1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

WAYNE Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

Ref. No. Description Order No. Quantity

1 Strainer Cover and Gasket 69010-001 1

2 Strainer 28477-001 1

www.waynepumps.com

1

2

6

Page 7

WIP SERIES POOL PUMP

Limited Warranty

For one year from the date of purchase, WAYNE Water Systems Division ("WAYNE Pumps") will repair or re place, at its

option, for the original purchaser any part or parts of its Water Pumps (“Product”) found upon examination by WAYNE to be

defective in materials or work man ship. Please call WAYNE Pumps (1-800-237-0987) for instructions. Be pre pared to provide

the model number and the serial number when exercising this warranty. All transportation charges on Products or parts

submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper application, improper maintenance, or failure to operate in accordance with WAYNE Pumps' written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANT ABIL ITY AND FITNESS FOR A PARTICULAR PUR POSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE.

THIS IS THE EXCLUSIVE REM E DY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL

DAM AG ES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above lim i ta tions might not apply to you. This limited war ran ty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise, shall WAYNE Pumps

or its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit

or revenues, loss of use of the products or any associated equipment, damage to associated equip ment, cost of capital, cost

of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s cus tom ers for such

damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call WAYNE Pumps (800-237-0987)

for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE PUMPS. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ DATE_____________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

7

Page 8

Sortie d'aspiration

(Drain principal)

Sortie d'aspiration

(Drain principal)

Vannes OK entre

la pompe et le T

Pompe

0,9 m minimum

(3 pieds)

Composant certifié ANSI/APSP-16

(2011) : couvercle/grille ou raccord

d'aspiration anti-piégeage

Aucune vanne entre le T et

les drains principaux

Composant certifié ANSI/APSP-16

(2011) : couvercle/grille ou raccord

d'aspiration anti-piégeage

POMPE DE PISCINE

MODE D'EMPLOI ET LISTE DES PIÈCES DÉTACHÉES

MODÈLES : WIP150 / WIP100 / WIP90 (CONFORMES À LA NORME 20 DE CALIFORNIE)

LIRE, S’ASSURER DE COMPRENDRE ET SUIVRE TOUTES LES INSTRUCTIONS DE CE MANUEL - NE PAS JETER.

Le non-respect de ces instructions pourrait entraîner des dommages matériels, de graves blessures ou la mort.

Installateur : Veuillez laisser ce manuel à la disposition du propriétaire.

INSTRUCTIONS DE DÉMARRAGE RAPIDE

ÉTAPE 1 : VÉRIFICATION DU CONTENU DU PAQUET

ÉTAPE 4 : MÉTALLISATION

SÉRIE WIP

POMPE DE PISCINE

ÉVACUATION

ENTRÉE

D'ASPIRATION

ÉTAPE 2 : VÉRIFICATION DE LA TENSION DE LA POMPE EXISTANTE

115 V

Tout le travail de câblage et

d’entretien doit être effectué par un

(1) POMPE

(1) COUVERCLE

(1) JOINT

D'ÉTANCHÉITÉ

(1) FILTRE

électricien qualifié. Vous devez faire

correspondre le voltage de notre

pompe avec l'alimentation électrique

existante.

230 V

ÉTAPE 3 : COMMENT CHANGER LE SÉLECTEUR DE TENSION

Cette pompe est câblée en usine pour 230 volts. Pour passer à une

tension de 115 volts, suivre les étapes suivantes :

1. Couper l’alimentation électrique de la pompe.

2. Retirer le couvercle à l'arrière du moteur pour trouver le sélecteur

de tension.

3. Tirer sur le bouton de sélection.

4. Tourner le bouton de sélection jusqu’au réglage

de tension adapté.

5. Repousser le bouton de sélection en place.

6. Réinstaller le couvercle à l'arrière du moteur.

Utiliser un conducteur de connexion en

cuivre massif dont la taille minimale ne doit

pas être inférieure à 8 AWG (8,4 mm2).

ÉTAPE 5 : PLOMBERIE DE LA POMPE

Avant d’entreprendre l'installation d'une quelconque pompe de piscine,

lire et s’assurer de comprendre TOUTES les directives (ANSI/APSP/ICC15 2011) concernant l'aspiration et l'installation. Le tuyau d'aspiration doit

être aussi large ou plus large que le tuyau d'évacuation. Éviter d'utiliser un

tuyau d'aspiration plus petit que le raccord de pompe.

NE PAS entreprendre d’installer une pompe de

piscine sans avoir lu et compris les normes,

directives et réglementations suivantes : ANSI/APSP-16 (2011); ANSI/

APSP-7 (2006); ANSI/ASME A112.19.17 (2010); ASTM F2387 (2004);

Virginia Graeme Baker Pool and Spa Safety Act (2007) (Loi sur la sécurité

des piscines et spas) ; publication du CPSC dénommée Guidelines for

Entrapment Hazards (Directives contre les risques de piégeage); ainsi

que toutes les normes ultérieures et lois des différents états.

NE PAS entrer dans une piscine si un couvercle de drain est brisé ou

absent. Fermer la piscine ou le spa. Appelez immédiatement votre piscinier

pour faire effectuer les réparations. Amorcer la pompe avant de la faire

fonctionner. Pour amorcer les pompes situées au-dessus du niveau de

l'eau, retirer le couvercle du filtre, remplir d'eau le corps de l'épurateur,

puis remettre le couvercle en place. Si la pompe et toute la tuyauterie sont

situées en-dessous du niveau d'eau, la pompe s'auto-amorcera.

Une fois la pompe amorcée, stimuler le moteur et ouvrir toutes les vannes

de la conduite d'aspiration et de refoulement. Si aucun débit n'est observé

dans les cinq minutes, arrêter le moteur et réamorcer. Si la pompe ne

fonctionne pas, rechercher des fuites d'air. Se reporter à la section

dépannage.

SÉLECTEUR DE TENSION

© 2012,

WAYNE/Scott Fetzer Company.

Après environ 10 minutes de fonctionnement, vérifier les raccords

d'évacuation pour déceler toute bulle d'air. Un flux continu d'air indique

des fuites dans la conduite d'aspiration. Localiser et corriger toute fuite

immédiatement.

POUR DES INSTRUCTIONS SUPPLÉMENTAIRES, LES EXIGENCES DE

SÉCURITÉ, LES NORMES ET LA RÉGLEMENTATION CONCERNANT

L’INSTALLATION, SE RÉFÉRER AUX INFORMATIONS CONTENUES

DANS CE MANUEL.

Pour des renseignements sur les pièces, les produits et l’entretien,

visiter www.waynepumps.com

Page 9

POMPE DE PISCINE

MODE D'EMPLOI ET LISTE DES PIÈCES DÉTACHÉES

MODÈLES : WIP150 / WIP100 / WIP90 (CONFORMES À LA NORME 20 DE CALIFORNIE)

LIRE, S’ASSURER DE COMPRENDRE ET SUIVRE TOUTES LES INSTRUCTIONS DE CE MANUEL - NE PAS JETER.

Le non-respect de ces instructions pourrait entraîner des dommages matériels, de graves blessures ou la mort.

Installateur : Veuillez laisser ce manuel à la disposition du propriétaire.

INSTRUCTIONS D’INSTALLATION ET MODE D'EMPLOI

DESCRIPTION

Les pompes de piscine font partie du système de filtration d'eau des

piscines. Ces pompes font circuler l'eau des piscines enterrées ou

hors-sol.

DÉBALLAGE

Inspecter cet appareil avant de l'utiliser. Il arrive parfois que les

installées de façon permanente. Si ceci est spécifié,

la pompe peut être utilisée avec les jacuzzis et les spas. Ne pas l’utiliser avec

les piscines démontables. Une piscine installée de façon permanente est

construite dans ou sur le sol ou encore à l'intérieur d'un bâtiment de telle

sorte qu'elle ne peut pas être facilement démontée en vue de son stockage.

Une piscine démontable est construite de manière à être facilement

démontée en vue de son stockage et remontée dans son intégrité d'origine

produits soient endommagés durant le transport. Si la pompe

ou les composants sont endommagés, contacter le service

clientèle au 1-800-237-0987.

DIRECTIVES DE SÉCURITÉ

Pour aider à reconnaître cette information, consulter les

uniquement de l'eau claire. Ne pas pomper

de liquide inflammable ou explosif tel que l'essence, le mazout, le

kérosène, etc. Ne pas utiliser dans un environnement inflammable et/

ou explosif. Le non-respect de ces instructions pourrait entraîner des

blessures corporelles et/ou des dommages matériels.

mots-indicateurs et classifications de dangers qui suivent.

dangers possibles de blessures corporelles. Respecter tous les messages de

sécurité qui suivent ce symbole pour éviter toutes blessures possibles

Ceci est le symbole d'alerte de sécurité. Il est utilisé pour vous prévenir des

.

certifié connaissant le fonctionnement des piscines/

spa conformément aux directives du Code électrique

national NFPA 70.

Danger indique une situation dangereuse

imminente qui, si elle n'est PAS évitée,

MÈNERA à la mort ou à des blessures graves.

Avertissement indique une situation

i hasardeuse potentielle qui peut résulter

en perte de vie ou blessures graves.

Attention indique une situation potentiellement

dangereuse qui, si elle n’est PAS évitée,

POURRAIT entraîner des lésions corporelles mineures ou modérées

Avis indique des informations importantes

à respecter. Le NON-RESPECT de ces

instructions POURRAIT endommager l’équipement.

REMARQUE: Remarque indique une information qui exige une attention

particulière.

températures élevées. Ne pas laisser de feuilles, de débris

ou de matières étrangères s’accumuler autour du moteur

de la pompe. Garder les ouvertures d'aération ouvertes.

Laisser le moteur refroidir avant de le manipuler. Tenir éloignés les

liquides inflammables.

SIGLES ET DÉFINITIONS

ASHRAE : American Society of Heating, Refrigeration and Air

.

Conditioning Engineers (Société américaine des ingénieurs thermiciens)

ANSI: American National Standards Institute (Institut américain

des normes)

APSP: The Association of Pool and Spa Professionals

(Association des professionnels des piscines et spas)

ASME: American Society of Mechanical Engineers (Société

CONSIGNES GÉNÉRALES DE SÉCURITÉ

GÉNÉRALITÉS SUR LA SÉCURITÉ

1. Lire attentivement le(s) manuel(s) inclus avec ce

produit. Bien se familiariser avec les commandes et

la bonne utilisation de l’équipement. Suivre toutes

les instructions.

2. Seules les personnes bien familiarisées avec ces consignes

de sécurité d'utilisation doivent être autorisées à utiliser cet

appareil.

Ne PAS laisser les enfants utiliser

cette pompe.

3. Porter en tout temps des lunettes de sécurité

avant d’effectuer toute manoeuvre sur une

pompe.

4. L’appareil DOIT être branché sur un circuit

disposant d'un disjoncteur de fuite de terre correctement

installé. Consulter un électricien qualifié pour une installation

en bonne et due forme d’un circuit avec disjoncteur de fuite

de terre.

américaine des ingénieurs mécaniciens)

CPSC: Consumer Products Safety Commission (Commission

pour la sécurité des produits de consommation)

NEC: National Electric Code (Code électrique national)

NFPA: National Fire Protection Association (Association

nationale de protection contre l'incendie)

NE PAS utiliser la pompe si une partie

quelconque du boîtier est fissurée, brisée ou

manquante.

Risque de secousse

électrique. COUPER

LE COURANT avant tout entretien

ou réparation. Installer un cadenas

fermé ou une étiquette pour éviter tout

rétablissement inattendu de l'électricité.

Cet appareil n'est pas conçu pour

être utilisé comme pompe de

puisard, dans les fosses septiques ou dans les enceintes

souterraines. Ne jamais l’utiliser dans des endroits

dangereux ou explosifs.

Cette pompe est conçue pour les piscines

Risque d'explosion ! Pomper

Cette pompe doit être installée

par un électricien agréé ou

Risque d’incendie et de brûlure !

Les moteurs tournent à des

SÉRIE WIP

POMPE DE PISCINE

.

RAPPEL : Conserver votre preuve d’achat datée aux fins de la garantie ! Fixer le reçu à ce manuel ou le ranger en lieu sûr.

Pour des renseignements sur les pièces, les produits et l’entretien,

© 2012,

WAYNE/Scott Fetzer Company.

visiter www.waynepumps.com

9 Fr

Page 10

POMPE DE PISCINE DE LA SÉRIE WIP

DIRECTIVES DE SÉCURITÉ POUR LES PISCINES

SURVEILLANCE PAR UN ADULTE RESPONSABLE

Une surveillance constante par un adulte responsable est obligatoire

autour de la piscine ou du spa. Toujours surveiller les enfants autour

des piscines et des spas. Ne jamais laisser un enfant jouer de sorte qu’il

puisse approcher les cheveux du couvercle du drain.

Ne PAS laisser les enfants

utiliser cette pompe.

Ne PAS installer de multiples pompes sur un même circuit hydraulique.

La pompe n'est pas conçue pour accepter le débit de sortie d'une autre

pompe. Ne PAS laisser l'eau refluer dans la pompe. De l'eau coulant dans

l'évacuation et sortant par la sortie d'aspiration pendant une situation

problématique peut amener le moteur à fonctionner en sens inverse. Ne

JAMAIS entreprendre de démarrer la pompe si l'arbre d'entraînement

tourne sous l'effet de l'action d’une turbine hydraulique; ceci POURRAIT

amener la pompe à fonctionner en sens inverse et endommager les

composantes internes.

DRAINS, RACCORDS D'ASPIRATION ET JETS

1. Ne laisser personne, enfant ou adulte, jouer à proximité de ou s'asseoir

sur une quelconque sortie d'aspiration (drain) ou un quelconque raccord

d'aspiration mural !

2. Ramener les cheveux longs en queue de cheval ou sous un bonnet de

bain.

3. Retirer vos bijoux avant d'entrer dans la piscine.

4. Demander à un professionnel agréé d'inspecter toutes les sorties

d'aspiration.

5. S’assurer que les couvercles de drain sont certifiés ANSI/APSP-16

(2011) et que les raccords d'aspiration muraux sont à fermeture

verrouillage automatique.

6. Remplacer tout couvercle de drain brisé, manquant ou non certifié par un

couvercle certifié ANSI/APSP-16 (2011).

DANGERS ÉLECTRIQUES

Un électricien agréé, expérimenté en piscines et spas doit inspecter

votre équipement pour s'assurer que tout est correctement mis à la terre,

métallisé et protégé par des circuits de disjoncteur de fuite à la terre,

conformément à l'Article 680 du Code électrique national.

INSTALLATIONS À L'INTÉRIEUR

Les piscines et spas intérieurs doivent être conformes à la norme ANSI/

ASHRAE 62-2001 pour garantir une ventilation adéquate et une utilisation

sans risque.

Ne PAS entrer dans la piscine si le couvercle

du drain est brisé ou manquant. Fermer la

piscine ou le spa. Appeler immédiatement votre piscinier pour faire

effectuer les réparations.

0,9 m minimum

(3 pieds)

Composant certifié ANSI/APSP-16

(2011) : couvercle/grille ou raccord

d'aspiration anti-piégeage

Sortie d'aspiration

(Drain principal)

Figure A - Certification de couvercle de sortie

www.waynepumps.com

Aucune vanne entre le T et

les drains principaux

Vannes OK entre

la pompe et le T

Composant certifié ANSI/APSP-16

(2011) : couvercle/grille ou raccord

d'aspiration anti-piégeage

Sortie d'aspiration

(Drain principal)

Pompe

PROTECTION CONTRE LE PIÉGEAGE

Se reporter à la norme ANSI/APSP-7-2006 ou à la version la plus récente

pour éviter un piégeage par aspiration. L'aspiration de la pompe doit

être conçue pour éliminer la possibilité de piégeage par aspiration ou de

piégeage/emmêlement des cheveux.

COUVERCLES D'ASPIRATION

NE PAS entrer dans la piscine si un couvercle de drain est brisé ou

manquant. Appelez immédiatement votre piscinier pour faire effectuer les

réparations.

TEST ET CERTIFICATION

Tous les couvercles d'entrée d'aspiration doivent se conformer aux

spécifications ANSI/APSP-16 (2011) pour les raccords d'aspiration à

utiliser dans les piscines, spas et baignoires à remous. Le produit doit être

testé pour conformité aux normes et la certification doit être incluse avec

les composants.

SORTIES PAR POMPE

Fournir au moins deux drains principaux hydrauliquement équilibrés, avec

couvercles pour chaque conduite d'aspiration de pompe de piscine. Les

centres de chaque raccord d'aspiration principal doivent être séparés d'au

moins 0,9 m (3 pi) l'un de l'autre (Figure A). Le système doit être bâti de

manière à ce qu'il ne puisse pas fonctionner si la pompe aspire de l'eau

par un seul drain. Les deux drains principaux doivent être connectés à

la pompe de piscine chaque fois qu'elle fonctionne. L'installation d'une

vanne sur chaque conduite d’aspiration n'est pas permise.

1. Installer une tuyauterie aussi rectiligne et courte que possible, et d'une

taille adaptée.

2. Ne pas brancher de coude directement à l'entrée de la pompe. Une

longueur de tuyau droit permettra une entrée adéquate de l'eau dans

la pompe.

3. Une dénivellation horizontale remonte vers la pompe pour éviter

d'emprisonner l'air.

4. Utiliser des supports de tuyauterie indépendants pour atténuer la

tension sur la pompe.

5. Conserver autant que possible la conduite d'aspiration en-dessous du

niveau d'eau pour réduire le temps d'amorçage.

6. Installer les vannes et les raccords dans les conduits d'aspiration et

de refoulement de la pompe pour faciliter l'entretien. Ne pas utiliser de

vannes pour contrôler le débit de la pompe. Les vannes sont

essentielles pour l'entretien de la pompe si le système est installé en

dessous du pourtour de la piscine.

INSTALLATION

REMARQUE : Se référer à la norme ANSI/APSP/ICC-15-2011 ou

à la version la plus récente pour bien choisir la pompe.

EMPLACEMENT

Placer la pompe aussi près que possible de la piscine/du spa sur une

surface non combustible. Installer la pompe sur une surface dure, plane,

au sec, bien ventilée et protégée de la lumière directe du soleil. La zone

environnante doit fournir une protection contre les éléments et un ample

espace permettant l'entretien et la réparation. S’assurer que le drainage

s'écoulera à partir de la pompe.

Monter la pompe sous le niveau d'eau pour faciliter l'amorçage. Si la pompe

doit être placée au-dessus du niveau d'eau rempli, maintenir la distance

verticale à un minimum.

10 Fr

Page 11

Mode d'emploi et liste des pièces détachées

exercée par un mauvais alignement des

tuyaux peut provoquer une rupture du carter de pompe.

Une contrainte excessive sur la pompe

TUYAUTERIE DE LA POMPE

Risque d'explosion/d’incendie :

N'utiliser des adhésifs/colles que

dans un endroit bien ventilé.

RACCORDS SOUDÉS À L'AIDE DE SOLVANTS

Utiliser un tuyau en PVC rigide ou souple. S’assurer que les

extrémités du tuyau sont propres et exemptes de tout éclat causé

par l'opération de découpe. Utiliser l'adhésif approprié pour le type

de tuyau spécifié.

REMARQUE : Utiliser un apprêt pour adhésif pour s’assurer que

les collages des joints sont solides. Certains apprêts possèdent

un traceur mauve d'éligibilité dans les zones où la règlementation

spécifie qu'un apprêt doit être utilisé.

Tenir compte des conditions climatiques lors de l'application

d'adhésifs/colles. Des conditions atmosphériques avec une

humidité élevée rendront l'action adhésive de certaines colles

moins efficace. Suivre les indications du fabricant.

RACCORDS FILETÉS

Utiliser seulement un ruban d'étanchéité de plombier (ou

l'équivalent) sur les raccords filetés. D'autres composés pour tuyau

pourraient endommager les filetages. Ne pas utiliser de silicone ou

de composés à base de pétrole. Ne pas trop serrer. Un serrage à

la main plus 1/2 tour est suffisant.

INSTALLATION (ÉLECTRIQUE)

verrouiller la source

d'alimentation avant d'installer, de réparer, ou de

déplacer l’appareil, ou encore avant d'effectuer une

opération d’entretien.

REMARQUE : Cette pompe doit être installée par un électricien

agréé connaissant le fonctionnement des piscines/spa

conformément aux directives du Code électrique national NFPA 70.

Respecter tous les codes locaux et nationaux concernant le

câblage. Si vous n'êtes pas certain des exigences du code,

contactez un électricien professionnel. La pompe doit être

branchée en permanence à un circuit dédié. En cas de doute,

contacter un électricien agréé.

IMPORTANT :

Se reporter aux informations indiquées sur les plaques

signalétiques du moteur pour les données d'entretien électrique.

Installer les moteurs avec un interrupteur sectionneur à fusible ou

un disjoncteur dédié. S’assurer que la taille du fil est suffisante

pour la puissance de la pompe et la distance par rapport à la

source de courant.

Risque de secousse électrique.

Raccorder cette pompe

à un réceptacle de disjoncteur de fuite de terre

correctement installé pour une intensité nominale

minimum de 5 A. Tester le fonctionnement du

disjoncteur de fuite de terre conformément aux

intervalles recommandés par le fabricant.

Débrancher, étiqueter et

Utiliser uniquement des fils conducteurs en cuivre.

FIL DE

CONNEXION

Figure B - Retirer le couvercle arrière du moteur

RACCORDEMENT

DE LA VIS DE

CONNEXION

Cette pompe est câblée en usine pour 230 volts. Pour passer à une tension

de 115 volts, suivre les étapes suivantes :

1. Couper l'alimentation électrique de la pompe.

2. Retirer le couvercle de l'arrière du moteur pour trouver le sélecteur de

tension (figure B).

3. Tirer sur le bouton de sélection.

4. Tourner le bouton de sélection jusqu’au réglage de tension adapté

(Figure C).

5. Repousser le bouton de sélection en place.

6. Réinstaller le couvercle à l'arrière du moteur.

Figure C - Réglage du sélecteur de tension

Le circuit doit comporter un disjoncteur de fuite de terre. Pour la

taille du disjoncteur de fuite à la terre et les procédures de test du

disjoncteur de fuite à la terre, voir les directives du fabricant.

sur une canalisation de gaz;

utiliser un système de mise à la terre dédié.

Ne JAMAIS mettre à la terre

Le déclenchement du disjoncteur de fuite de terre indique

l'existence d'un problème électrique. Si le disjoncteur de fuite de terre se

déclenche, en déterminer la raison. Si vous n'êtes pas certain de la cause,

demandez à un électricien agréé ou certifié connaissant le fonctionnement

des piscines/spa, conformément aux directives du Code électrique

national - NFPA 70 d'inspecter et de réparer le système électrique.

Cette pompe DOIT être installée

par un électricien agréé ou

certifié connaissant le fonctionnement des piscines/

spa conformément aux directives du Code électrique

national - NFPA 70.

S'assurer que la tension de l'alimentation correspond à celle indiquée sur

la plaque signalétique. Une tension incorrecte peut provoquer un incendie

ou endommager gravement le moteur tandis qu’elle annule la garantie.

MISE À LA TERRE/MÉTALLISATION

L'installation, la mise à la terre, la métallisation et le câblage du moteur

doivent être réalisés conformément aux exigences du Code électrique

local ou national. Le moteur doit être relié à la terre en permanence.

www.waynepumps.com

11 Fr

Page 12

POMPE DE PISCINE DE LA SÉRIE WIP

Utiliser la borne de mise à la terre présente dans la boîte de la borne

à l'arrière du moteur. Utiliser un fil de taille et de type conforme aux

exigences des codes locaux. Raccorder la borne de mise à la terre du

moteur à la mise à la terre du réseau électrique.

Relier le moteur à la structure de la piscine. La métallisation relie toutes les

pièces métalliques au sein et autour de la piscine avec un câble continu.

La métallisation réduit le risque de laisser passer du courant entre des

objets métalliques, ce qui pourrait provoquer un choc électrique. Se

référer aux codes NEC locaux à propos des normes de câblage. Utiliser

un conducteur en cuivre massif de taille nº 8 AWG ou supérieure. Tirer le

câble depuis la vis extérieure de la borne située sur le moteur (Figure B)

jusqu’à une tige ou maille renforcée.

FONCTIONNEMENT

Amorcer la pompe avant de la faire fonctionner. Pour amorcer les pompes

situées au-dessus du niveau d'eau, retirer le couvercle du filtre, remplir

d'eau le corps du filtre, puis remettre le couvercle en place. Si la pompe

et toute la tuyauterie sont situées en-dessous du niveau d'eau, la pompe

s'auto-amorcera. Une fois la pompe amorcée, stimuler le moteur et ouvrir

toutes les vannes de la conduite d'aspiration et de refoulement. Si aucun

débit n'est observé dans les cinq minutes, arrêtez le moteur et réamorcez.

Si la pompe ne fonctionne pas, rechercher des fuites d'air. Se reporter à la

section dépannage. Après environ 10 minutes de fonctionnement, vérifier

les raccords d'évacuation pour déceler toute bulle d'air. Un flux continu

d'air indique des fuites dans la conduite d'aspiration. Localiser et corriger

toute fuite immédiatement.

Risque d'aspiration Ne PAS

bloquer l'aspiration de la

pompe en vous plaçant devant. Le non-respect de cet

avertissement ENTRAÎNERAIT la mort ou de graves

blessures corporelles.

REMARQUE : Les jeunes enfants utilisant la piscine doivent

TOUJOURS être sous la surveillance attentive d'un adulte.

fonctionne à des températures élevées; pour

réduire le risque d'incendie, ne PAS laisser de débris ou de matières

étrangères s'accumuler autour du moteur de la pompe. Laisser

le moteur refroidir avant de le manipuler ou de procéder à son

entretien.

filtre. Des matières étrangères peuvent

entraver le fonctionnement de l'impulseur et provoquer l'arrêt de la

pompe.

Risque d’incendie et de brûlure. Le moteur

Ne PAS faire fonctionner la pompe sans

FONCTIONNEMENT

Le moteur est doté d'un circuit interne de protection thermique qui

le protége de la surchauffe. La température ambiante maximum de

fonctionnement du moteur ne doit pas dépasser la température indiquée

sur la plaque signalétique du moteur. Si la protection contre la surcharge

thermique du moteur se déclenche ou si le disjoncteur de fuite à la terre

se déclenche, en déterminer la raison et corriger le problème avant de

redémarrer la pompe.

Ne PAS faire fonctionner la pompe avec des

vannes d'aspiration ou d’évacuation fermées

ou partiellement fermées.

CHIMIE DE L'EAU

L'entretien d'un système d'eau nécessite l'utilisation appropriée et

cohérente de produits chimiques. Le chlore est le produit chimique le plus

couramment utilisé pour fournir une eau propre et salubre. L'administration

quotidienne de chlore sec ou liquide (hypochlorite de calcium ou de

sodium) est essentielle.

Maintenir un niveau correct d'acidité ou d'alcalinité de

l'eau de piscine. Les valeurs de pH supérieures à pH 7,0

sont basiques. Un pH de 7,0 est neutre. Les valeurs de pH inférieures à 7,0 sont

acides. La fourchette souhaitable est de 7,2 à 7,4.

ENTRETIEN

1. Les moteurs sont autolubrifiants : aucune lubrification supplémentaire

n'est nécessaire.

2. Inspecter visuellement le moteur pour déceler toute obstruction des

prises d'air sur la coque du moteur. Retirer les débris après avoir

coupé le disjoncteur.

3. Remplacer les joints usagés.

Débrancher, étiqueter et

verrouiller la source

d'alimentation avant d'installer, de réparer, ou de

déplacer l’appareil, ou encore avant d'effectuer une

opération d’entretien.

FILTRE À CHEVEUX ET PELUCHES

1. Couper l'alimentation.

2. Fermer les vannes des conduits d'aspiration et de refoulement.

3. Tourner le couvercle du filtre dans le sens contraire des aiguilles d'une

montre et le retirer.

4. Soulever le panier du filtre et le retirer de la pompe.

5. Nettoyer puis repositionner le panier dans la pompe. Prendre soin de

placer le panier correctement.

6. Nettoyer le joint torique et le lubrifier de nouveau avec de la vaseline si

nécessaire.

7. Nettoyer les emplacements du joint torique sur le couvercle et sur le filtre.

8. Remettre en place le couvercle et l'anneau de verrouillage du filtre.

Resserrer uniquement à la main.

9. Ouvrir les vannes, puis rétablir le courant pour remettre la pompe en

marche.

FUITE D'EAU AUTOUR DU MOTEUR

Une fuite d'eau dans le secteur du raccord entre le moteur et la pompe

indique une défaillance mécanique du joint d'étanchéité et un risque de

choc électrique. Mettre la pompe hors service et remplacer immédiatement

le joint pour éviter que d'autres composants ne soient endommagés, et

pour réduire le risque de choc électrique. Contacter le service clientèle au

1-800-237-0987.

HIVÉRISATION

Toujours protéger le système contre le gel. Vidanger le système en cas de

risque de gel. Pour vidanger le système :

1. Appareils avec un filtre :

a. Filtre à sable : Laver à contre-courant pendant 3 à 5 minutes et

mettre ensuite les vannes en position d'hivernage

b. Filtre à cartouche : Nettoyer l'élément filtrant et le stocker dans un

endroit sec.

2. Purger le système en retirant les deux bouchons de drainage et en

retirant le couvercle du filtre. Le fait de retirer le couvercle du filtre

facilitera également la vidange. Ranger les bouchons de drainage dans

le panier du filtre et réinstaller le couvercle du filtre.

REMISE EN ROUTE AU PRINTEMPS

1. Nettoyer et remettre en place les bouchons de drainage.

2. Lubrifier le joint torique du filtre avec de la vaseline si nécessaire.

3. Nettoyer le siège du joint torique, le filtre et son panier, puis installer le

joint torique dans le couvercle.

4. Remplir d'eau le corps du filtre et se reporter à la section Mode

d’emploi (page 13).

www.waynepumps.com

12 Fr

Page 13

AVERTISSEMENT Ceci représente le symbole d'alerte de sécurité. Il est utilisé pour vous prévenir des risques possibles de blessures

corporelles. Respecter tous les messages de sécurité qui suivent ce symbole pour éviter tout risque de blessure ou la mort.

Évitez les blessures. Lire et s’assurer de comprendre le Manuel du propriétaire avant de faire fonctionner ce produit.

RISQUE D’ÉLECTROCUTION - Couper et neutraliser l’alimentation avant l’entretien. Disjoncteur de fuite de terre requis. L'appareil doit être

correctement relié à la terre. Tous les composants électriques du système doivent être correctement mis au contact les uns avec les autres

pour une mise à la terre correcte. L'emplacement choisi doit être bien ventilé, ne pas être exposé à la lumière directe du soleil, et se trouver à

distance des zones de repos et des liquides inflammables. Garder à l'abri des endroits humides. Fermer les vannes avant d'ouvrir le couvercle

du filtre, et le carter du drain avant d'ouvrir le carter de la pompe.

RISQUE DE PIÉGEAGE - Les pompes mises en place avec une seule sortie d'aspiration peuvent piéger les nageurs, les éventrer et les

conduire à la noyade. N'installer la pompe que dans une piscine dont le système de tuyauterie répond aux exigences des normes ASME/ANSI

A112.19.8. Deux sorties d'aspiration distantes d'au moins 0,9 m (3 pi) sont requises. Tous les raccords d'aspiration doivent : être homologués,

munis d'un dispositif évitant le piégeage des personnes ou l’emmêlement des cheveux, correctement installés et non-endommagés. Ne pas

utiliser la piscine si les couvercles de drain ou de sortie sont brisés ou absents.

DANGER MÉCANIQUE - Comporte des pièces mobiles. Couper et neutraliser l'alimentation électrique avant d’effectuer toute manoeuvre sur

la pompe. La pompe n'est conçue que pour les installations de piscines permanentes. Toute autre utilisation pourrait s’avérer dangereuse.

RISQUE D'EXPLOSION - Utiliser de l'eau pour tester la pression. L'air comprimé pourrait provoquer une explosion violente de la pompe.

Resserrer et centrer soigneusement le collier de serrage du panier avant d'effectuer un test de pression du système. Purger le système de tout

AVERTISSEMENT

l'air emprisonné avant d’effectuer le test de pression. Ne jamais utiliser d'air ou de gaz pour détecter une fuite. Ne pas utiliser une pression

de test de fuite supérieure à 172 kPa (25 PSI) : une pression supérieure endommagerait définitivement la pompe. N'utiliser que des tuyaux

et raccords conçus pour les piscines. Ne jamais laisser d'eau dans la pompe ou dans le filtre par temps de gel. La glace provoquerait une

rupture du carter.

EAU SOUS PRESSION - L'eau sous pression peut causer de graves blessures corporelles. Tenir les personnes et animaux d’appartement à

distance des fontaines, jets et sorties pendant le remplissage de la piscine ou du spa.

Tableau de dépannage

Risque d'électrocution ! La pompe peut démarrer automatiquement.

Couper le courant avant d’entreprendre une quelconque réparation.

Tableau de dépannage

Le non-respect de ces instructions ENTRAÎNERAIT de graves

blessures ou la mort.

Symptômes Cause(s) Possible(s) Mesure Corrective

Le moteur ne démarre

pas

Le moteur n'atteint pas sa

pleine vitesse

Le moteur surchauffe (la

protection se déclenche)

La pompe ne fournit pas

d'eau

Pompe et moteur

bruyants

1. Couper le courant ou mettre le disjoncteur sur la

position OFF (arrêt)

2. Fusibles grillés ou surcharge thermique ouverte

3. Câblage débranché ou défectueux

1. Basse tension

2. Les bobinages du moteur sont raccordés au mauvais

voltage.

1. Basse tension

2. Les bobinages du moteur sont raccordés au mauvais

voltage.

3. Ventilation inadéquate

1. La pompe n'est pas amorcée

2. La valve d'aspiration ou d’évacuation est fermée

3. Fuite ou présence d'air dans le système d'aspiration

4. Le filtre à cheveux et peluches est plein

5. Le niveau de l'eau dans la piscine est trop bas

1. Panier bloqué dans l'écumoire ou cheveux dans le filtre

à peluches

2. La vanne de la conduite d'aspiration est partiellement

fermée

3. Tuyau d'aspiration obstrué ou trop petit

4. La pompe n'est pas soutenue correctement

1. Réinitialiser le fusible

2. Vérifier la tension (voltage)

3. Vérifier le câblage de l’installation électrique

1. Vérifier le réglage de la tension

2. Inspecter le sélecteur de tension du moteur

1. Vérifier le réglage de la tension

2. Inspecter le sélecteur de tension du moteur

3. Supprimer les obstructions entourant la pompe

1. Amorcer la pompe comme indiqué dans la section

"Fonctionnement"

2. Ouvrir la vanne

3. Supprimer les fuites sur la conduite d'aspiration

4. Nettoyer le filtre (voir la section « Entretien »)

5. Remplir la piscine à un niveau adéqua

1. Nettoyer l'écumoire et le filtre à peluches

2. Ouvrir toutes les vannes pendant le fonctionnement

3. Recherchez un tuyau écrasé et remplacez-le.

4. Ajouter des soutiens supplémentaires

www.waynepumps.com

13 Fr

Page 14

Tableau de dépannage / PIÈCES DE RECHANGE

Risque d'électrocution ! La pompe peut démarrer automatiquement.

Couper le courant avant d’entreprendre une quelconque réparation.

Tableau de dépannage

Symptômes Cause(s) Possible(s) Mesure Corrective

Le non-respect de ces instructions ENTRAÎNERAIT de graves

blessures ou la mort.

Faible capacité de la

pompe

Fuite d'eau au niveau de

l'arbre

Haute pression de la

pompe

Accumulation de bulles

d'air dans le filtre

1. Vanne du conduit d'aspiration ou de refoulement

partiellement fermée

2. Conduit d'aspiration ou de refoulement trop petit

3. Panier bloqué dans l'écumoire ou cheveux dans le filtre

à peluches

4. Filtre sale

1. Le joint d'arbre a besoin d'être remplacé 1. Remplacez le joint d'étanchéité

1. Vanne d’évacuation fermée

2. Conduits de refoulement trop petits

3. Filtre sale

1. Fuites d'air dans la conduite d'aspiration au niveau des

raccords ou des tiges de vannes

2. Fuite du couvercle du filtre

3. Rétrécissement de la conduite d'aspiration

4. Niveau d'eau bas dans la piscine

1. Ouvrir toutes les vannes

2. Utiliser un conduit d'arrivée plus grand

3. Nettoyer l'écumoire et le filtre à peluches

4. Nettoyez le filtre (voir le manuel du filtre)

1. Toujours faire fonctionner la pompe avec les vannes

ouvertes

2. Remplacer par des tuyaux de plus grand diamètre

3. Nettoyer le filtre (voir le manuel du filtre)

1. Supprimer les fuites sur la conduite d'aspiration

2. Retirer et nettoyer les joints toriques

3. Augmenter la taille de la conduite d'aspiration

4. Remplir la piscine à un niveau adéquat

PROPOSITION 65 DE L'ÉTAT DE CALIFORNIE :

Ce produit ou son cordon peut contenir des produits chimiques, dont le plomb, qui sont reconnus par l'État de

Californie comme cancérigènes et à l’origine d’anomalies congénitales ou d’autres problèmes de l’appareil

reproductif. Se laver les mains après toute manipulation.

Pour des pièces de rechange

ou une assistance technique,

appeler le 1-800-237-0987

Veuillez fournir les renseignements suivants :

- Numéro de modèle

- Numéro de série (le cas échéant)

- Description et numéro de pièce indiqués dans la liste des pièces

Adresser toute correspondance relative aux pièces à :

WAYNE Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

Nº de

Référence

Description

1 Couvercle du filtre et joint

d'étanchéité

2 Filtre 28477-001 1

Nº de

Commande

69010-001 1

1

2

Quantité

www.waynepumps.com

14 Fr

Page 15

POMPE DE PISCINE DE LA SÉRIE WIP

Garantie Limitée

Pendant un an à compter de la date d’achat, WAYNE Water Systems Division (« WAYNE Pumps »), s’engage auprès

de l’acheteur d’origine à réparer ou à remplacer, à sa discrétion, toute pièce de ses (« Produits ») pompes à eau dont la

défectuosité en termes de matériaux ou de fabrication aura été établie par Wayne après examen. . Veuillez appeler WAYNE

Pumps (1-800-237-0987) pour les démarches à suivre. Pour le service sous garantie, préparer le numéro de modèle et

le numéro de série du produit. Tous les frais de transport des produits ou des pièces soumises pour la réparation ou le

remplacement sont à la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les produits endommagés suite à un accident, une utilisaiton abusive, un usage non

conforme, la négligence, une utilisation inappropriée, un entretien inadéquat, ou un fonctionnement non conforme aux

instructions écrites stipulées par WAYNE Pumps.

AUCUNE AUTRE GARANTIE EXPRESSE NE SERA FOURNIE. LES GARANTIES TACITES, Y COMPRIS CELLES

DE COMMERCIABILITÉ ET D’APTITUDE À UN USAGE PARTICULIER, SONT LIMITÉES À UN AN À COMPTER

DE LA DATE D’ACHAT LA PRÉSENTE GARANTIE CONSTITUE L’UNIQUE RECOURS CEPENDANT QUE TOUTE

RESPONSABILITÉ RELATIVE À TOUT DOMMAGE INDIRECT OU IMMATÉRIEL OU À TOUS FRAIS IMPUTABLES,

SERA REJETÉE.

Certains états et certaines provinces n’autorisent pas de limitations de durée concernant les garanties tacites, ni l’exclusion

ou la limitation des dommages fortuits ou immatériels. Les limitations précédentes ne s’appliquent donc pas forcément à

tous les cas. Cette garantie limitée vous confère des droits juridiques précis auxquels peuvent venir s’ajouter d'autres droits

qui varient d’une juridiction à l'autre.

Qu’il s’agisse des suites d’une rupture du contrat de garantie, d’un acte dommageable (y compris la négligence) ou

autre, WAYNE Pumps et ses fournisseurs ne sauraient en aucun cas être tenus responsables d’un quelconque dommage

particulier, immatériel ou punitif, incluant sans s’y limiter, la perte de profits ou de recettes, la perte d’usage des produits ou

de tout équipement associé, un dommage à l’équipement associé, le coût du capital, le coût de produits de remplacement,

les aménagements, les services ou la capacité de remplacement, le coût d’indisponibilité, ou les réclamations des clients de

l’acheteur en relation avec ces dommages.

Vous DEVEZ conserver le reçu d'achat ainsi que ce formulaire. En cas de réclamation sous garantie, le matériel ou la

correspondance DOIT impérativement être accompagné d'une copie du reçu d'achat. Appeler WAYNE Pumps (800-237-

0987) pour obtenir une autorisation de renvoi et connaître les démarches s’y rattachant.

NE PAS ENVOYER CE FORMULAIRE À WAYNE PUMPS. Ce formulaire est destiné à être archivé.

Nº DE MODÈLE._______________ Nº DE SÉRIE.__________________________ DATE_____________

AFIXER VOTRE REÇU ICI

www.waynepumps.com

15 Fr

Page 16

Al menos

91,44 cm

Las válvulas entre

la bomba y el conector

en T están OK

Salida de succión

(desagüe principal)

Salida de succión

(desagüe principal)

Bomba

Cubierta/rejilla anti atrapamiento o

conector de succión con certificación

ANSI/ASME A112.19.8

Cubierta/rejilla anti atrapamiento o

conector de succión con certificación

ANSI/ASME A112.19.8

No hay válvulas entre el conector

en T y los desagües principales

BOMBA PARA PISCINA

MANUAL DE INSTRUCCIONES DE FUNCIONAMIENTO Y PIEZAS DE REPUESTO

MODELOS - WIP150 / WIP100 / WIP90 (CUMPLEN CON EL TÍTULO 20)

LEA, ENTIENDA Y SIGA TODAS LAS INSTRUCCIONES DE ESTE MANUAL. NO LO DESECHE.

No seguir estas instrucciones podría provocar daño a la propiedad, lesiones graves o la muerte.

Instalador: deje este manual para uso del propietario.

INSTRUCCIONES DE INICIO RÁPIDO

SÉRIE WIP

BOMBA PARA PISCINA

PASO 1: EXAMINE EL CONTENIDO DEL PAQUETE

DESCARGA

ENTRADA DE

SUCCIÓN

PASO 2: VERIFIQUE EL VOLTAJE ACTUAL DE LA BOMBA

115 V

Todo el cableado eléctrico o servicio

debe ser realizado por un electricista

(1) BOMBA

(1) TAPA

(1) JUNTA

(1) FILTRO

calificado. Debe hacer coincidir el

voltaje de nuestra bomba con el

suministro de energía existente.

230 V

PASO 3: CÓMO CAMBIAR EL SELECTOR DE VOLTAJE

Esta bomba está cableada de fábrica para 230 voltios. Para

cambiar el voltaje a 115 voltios siga los pasos siguientes:

1. Desconecte la bomba de la fuente.

2. Retire la tapa de la parte de atrás del motor para ver el selector

de voltaje.

3. Saque la perilla del selector.

4. Gire la perilla del selector para la definición correcta

de voltaje.

5. Vuelva a poner la perilla del selector en su lugar.

6. Vuelva a colocar la tapa en la parte

de atrás del motor.

PASO 4: CONEXIÓN ELÉCTRICA

Use un cable de retorno de cobre macizo

de al menos 8 AWG (8,4 mm2).

PASO 5: PLOMERÍA DE LA BOMBA

Antes de intentar instalar cualquier bomba para piscina, lea y comprenda

TODAS las pautas (ANSI/APSP/ICC-15 2011) relacionadas con la succión

e instalación. La tubería de succión debe ser tan grande como la tubería

de descarga o más grande. Evite utilizar una tubería de succión más

pequeña que la conexión de la bomba.

NO intente realizar esta instalación de una

bomba para piscina a menos que haya leído y

comprendido los siguientes estándares, pautas y reglamentos: ANSI/

APSP-16 (2011); ANSI/APSP-7 (2006); ANSI/ASME A112.19.17 (2010);

ASTM F2387 (2004); Ley de seguridad en piscinas e hidromasajes Virginia

Graeme Baker (2007); la publicación de CPSC llamada Guidelines for

Entrapment Hazards (Pautas para evitar el peligro de quedar atrapado);

y cualquier estándar subsiguiente o requisito de la ley estatal.

NO entre a la piscina si la tapa de cualquier drenaje está rota o falta. Cierre

la piscina o hidromasaje. Llame inmediatamente a un profesional para que

realice la reparación. Cebe la bomba antes de intentar hacerla funcionar.

Para cebar bombas que se encuentran sobre el nivel del agua, retire la

tapa del filtro, llene el cuerpo del filtro con agua y vuelva a colocar la tapa.

Si la bomba y todas las tuberías se encuentran debajo del nivel del agua,

la bomba se cebará automáticamente.

Después de que la bomba se haya cebado, active el motor y abra todas

las válvulas de las líneas de succión y descarga. Si no se observa flujo

en cinco minutos, detenga el motor y vuelva a cebarla. Si la bomba no

funciona, compruebe que no haya puntos de entrada de aire. Consulte la

sección de diagnóstico de averías.

SELECTOR DE VOLTAJE

© 2012,

WAYNE/Scott Fetzer Company.

Después de aproximadamente 10 minutos de funcionamiento, compruebe

las conexiones de retorno en busca de burbujas de aire. Un flujo continuo

de aire indica que hay agujeros en la línea de succión. Encuentre y corrija

todos los agujeros inmediatamente.

PARA OBTENER MÁS INSTRUCCIONES Y REQUISITOS/ESTÁNDARES/

REGLAMENTOS DE SEGURIDAD PARA LA INSTALACIÓN, CONSULTE

LA INFORMACIÓN PROPORCIONADA EN ESTE MANUAL.

Para obtener información sobre piezas de repuesto, productos y

servicio, visite www.waynepumps.com

Page 17

BOMBA PARA PISCINA

MANUAL DE INSTRUCCIONES DE FUNCIONAMIENTO Y PIEZAS DE REPUESTO

MODELOS - WIP150 / WIP100 / WIP90 (CUMPLEN CON EL TÍTULO 20)

LEA, ENTIENDA Y SIGA TODAS LAS INSTRUCCIONES DE ESTE MANUAL. NO LO DESECHE.

No seguir estas instrucciones podría provocar daño a la propiedad, lesiones graves o la muerte.

Instalador: deje este manual para uso del propietario.

INSTRUCCIONES DE INSTALACIÓN Y OPERACIÓN

DESCRIPCIÓN

Las bombas para piscinas son parte del sistema de filtrado de agua

para piscinas. Estas bombas hacen circular el agua como parte de

una piscina enterrada o una piscina elevada.

DESEMBALAJE

Inspeccione esta unidad antes de usarla. Ocasionalmente,

los productos se dañan durante el envío. Si la bomba o los

componentes están dañados, llame al servicio de atención al

cliente al 1-800-237-0987.

PAUTAS DE SEGURIDAD

Para ayudar a reconocer esta información, observe las

siguientes señales/clasificaciones de riesgos.

alertarle sobre los peligros potenciales de lesiones

corporales. Obedezca todos los mensajes de seguridad que

siguen a este símbolo para evitar posibles daños.

TENDRÁ como resultado la muerte o una lesión grave.

potencialmente peligrosa que, si NO se evita,

PUEDE tener como resultado una lesión leve o moderada.

NOTA: Nota indica información que requiere atención especial.

Este es el símbolo de alerta de seguridad. Se utiliza para

Peligro indica una situación

inminentemente peligrosa que, si NO se evita,

Esto le indica que hay una situación que

PODRIA ocasionarle la muerte o heridas

de gravedad.

Precaución indica una situación

Aviso indica información importante que, si NO se

respeta, PUEDE causar daño al equipo.

INFORMACIÓN GENERAL DE SEGURIDAD

SEGURIDAD GENERAL

1. Lea atentamente el o los manuales que se incluyen con este

producto. Familiarícese bien con los controles

y el uso correcto del equipo. Siga todas las