Page 1

Sewage/Effluent Pumps

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

Operating Instructions and Parts Manual Sewage/Effluent

SPECIFICATIONS

POWER SUPPLY

REQUIREMENTS 120 V, 60 Hz

MOTOR Single Phase, Dielectric Oil Filled

HORSEPOWER

LIQUID TEMPERATURE 40° F - 120° F

CIRCUIT REQUIREMENTS 15 A (minimum)

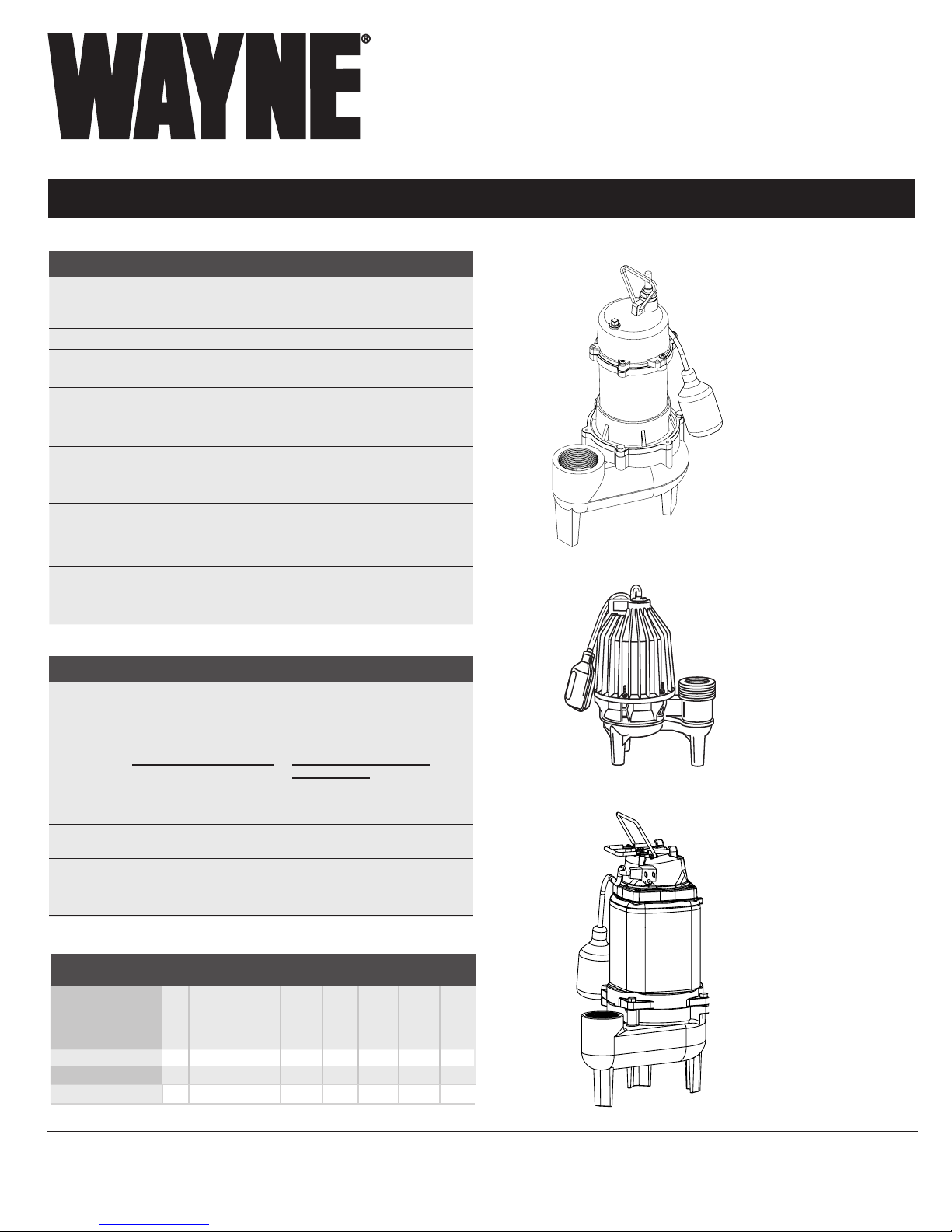

1/2 HP............ Sewage

Efuent

(RPP50, SEL50, WCS50T)

(EFL50)

RPP50

DIMENSIONS

ON LEVEL (FACTORY SET)

OFF LEVEL (FACTORY SET) Approximately 7.5 in.

14 in. high x 12 in. base

13-1/2 in. high x 11 in. base

16-5/8 in. high x 9-5/8 in. base

Approximately 16. in.

Approximately 17 in.

Approximately 19 in.

Approximately 7 in.

Approximately 10.5 in.

(RPP50)

(SEL50, EFL50)

(WCS50T)

(RPP50)

(SEL50, EFL50)

(WCS50T)

(RPP50)

(SEL50, EFL50)

(WCS50T)

CONSTRUCTION

MOTOR HOUSING

VOLUTE

IMPELLER Glass Reinforced Thermoplastic

SHAFT Steel

DISCHARGE 2 in. NPT

Cast Iron (RPP50, WCS50T)

Cast Iron

Cast Iron (RPP50, WCS50T)

Reinforced Thermoplastic (SEL50, EFL50)

Reinforced Thermoplastic

(SEL50, EFL50)

Glass Reinforced Thermoplastic

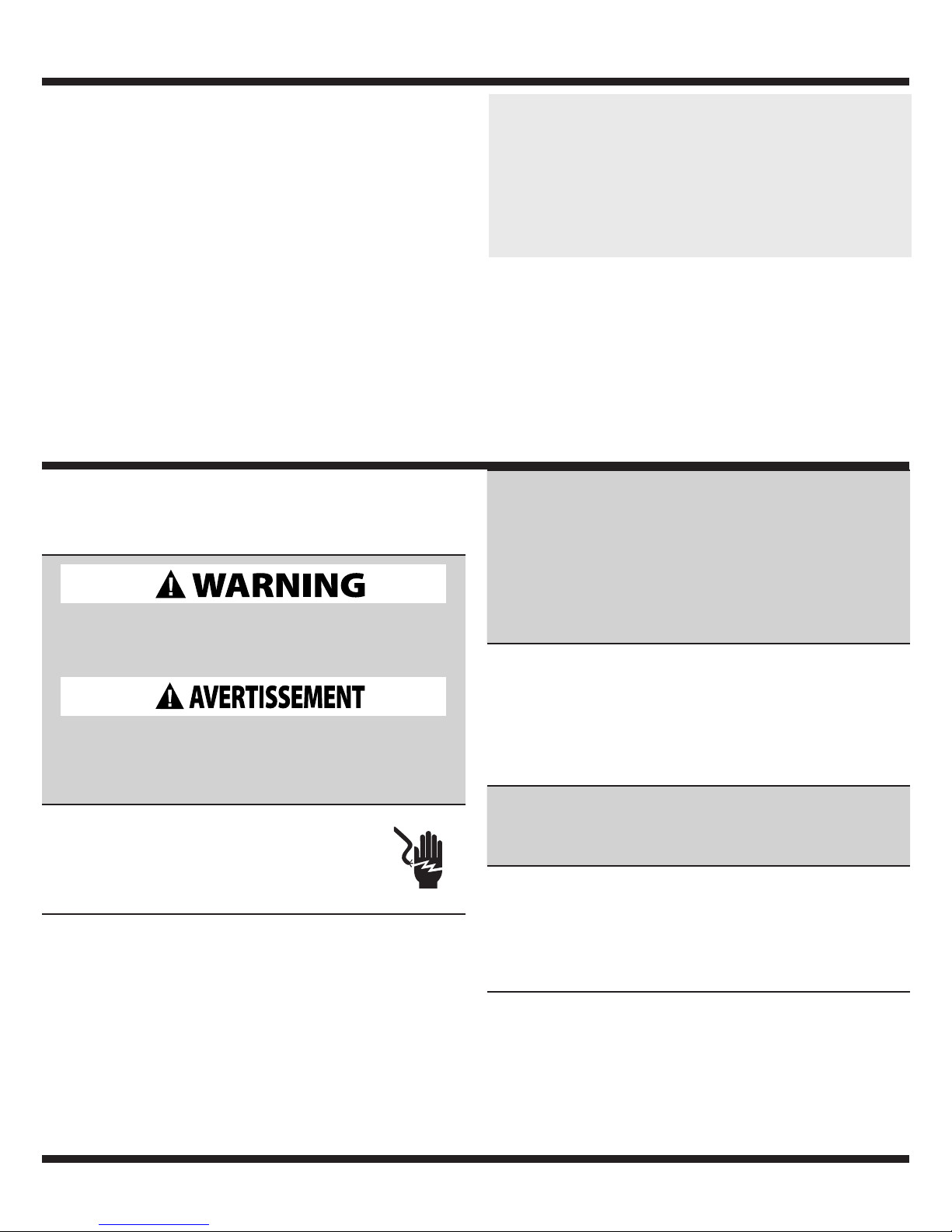

Sewage- SEL50

Efuent- EFL50

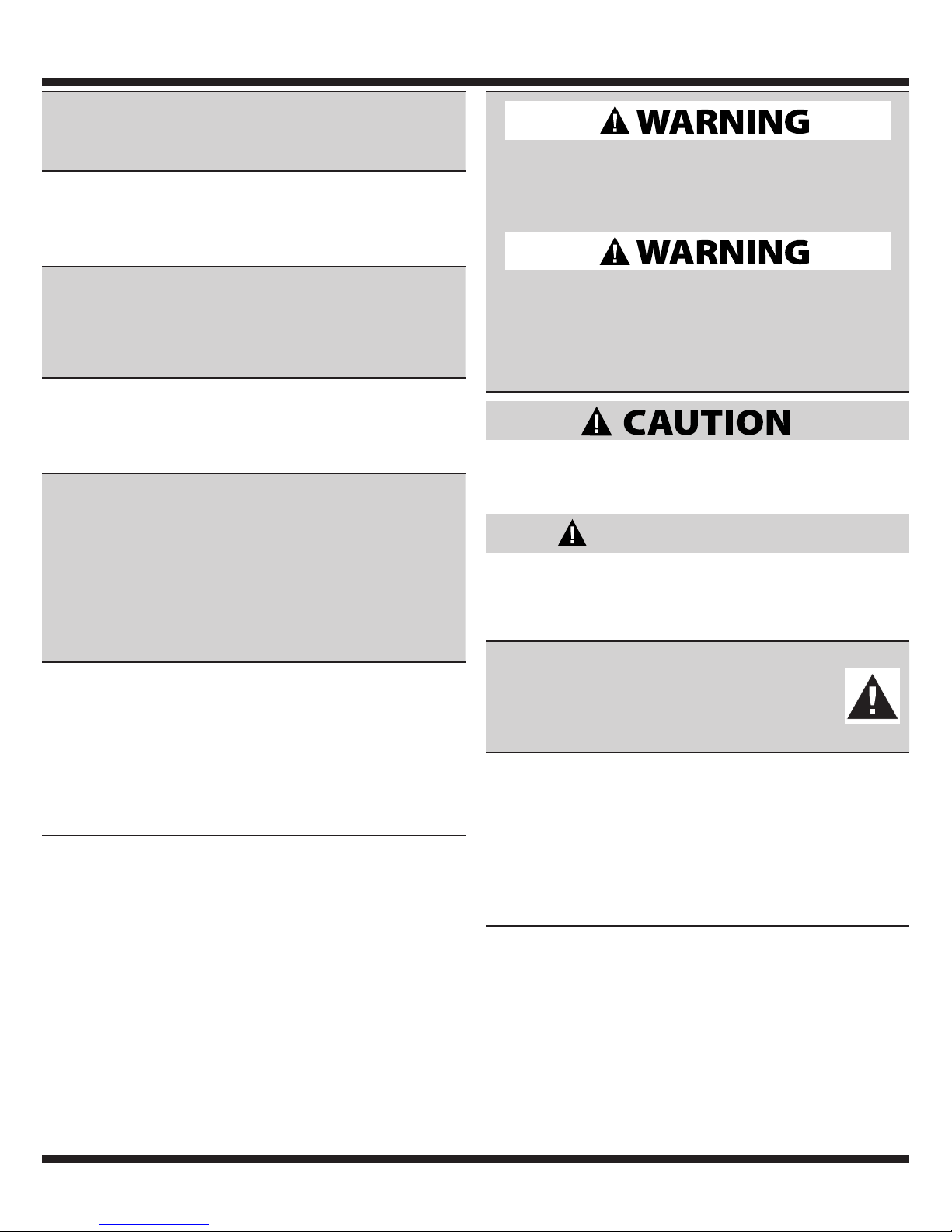

WCS50T

PERFORMANCE

Model HP Discharge Head

RPP50 ½

SEL50 ½

WCS50T ½

EFL50 ½

Gal / hr 6200 4800 3240 1500 -

Gal / hr 10000 9000 7200 5000 2000

Gal / hr 10000 9600 8000 3300 -

Gal / hr 10000 9000 7200 5000 2000

© 2018, WAYNE/Scott Fetzer Company.

0 ft 5 ft 10 ft 15 ft 20 ft

Intended for Indoor Use Only

www.waynepumps.com

610001-001 B 08/18

Page 2

INSTALLATION MANUAL

SEWAGE/EFFLUENT PUMP

DESCRIPTION

Sewage pumps are pumps used to remove waster water that

contains solids up to 2 inches in diameter. The most common

application is for draining bathroom waster water to a sewer or

septic line.

Effluent pumps are pumps used to remove gray water from

septic tanks, sump pits, or laundry tray systems. Gray water is

waste water from bathtubs, sinks, washing machines, and other

kitchen appliances.

UNPACKING

Inspect this unit before it is used. Occasionally, products are damaged

during shipment. If the pump or components are damaged, return

the unit to the place of purchase for replacement, or call Customer

Support (800-237-0987).

SAFETY SIGNAL WORDS

This manual contains information that is very important

to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT PROBLEMS. To

help recognize this information, observe all safety information

labeled danger, warning, caution, and notice.

IMPORTANT SAFETY INFORMATION

CONSIGNES DE SÉCURITÉ

IMPORTANTES

WARNING INDICATES A POTENTIALLY HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH OR

SERIOUS INJURY.

LA MENTION AVERTISSEMENT INDIQUE UNE SITUATION

POTENTIELLEMENT DANGEREUSE QUI, SI ELLE N’EST PAS

ÉVITÉE, RISQUE D’ENTRAÎNER DES LÉSIONS CORPORELLES

GRAVES OU MÊME LA MORT.

RISK OF ELECTRIC SHOCK. TO REDUCE THIS RISK,

OBSERVE THE FOLLOWING WARNINGS:

RISQUE DE CHOC ÉLECTRIQUE. POUR RÉDUIRE CE

RISQUE, TENIR COMPTE DES AVERTISSEMENTS

SUIVANTS

MAKE SURE THERE IS A PROPERLY GROUNDED RECEPTACLE

AVAILABLE. This pump is supplied with a grounding conductor

and grounding-type attachment plug. To reduce the risk of electric

shock, be certain that it is connected only to a properly grounded,

grounding-type receptacle.

S’ASSURER QU’UNE PRISE DE MISE À LA TERRE EST DISPONIBLE.

Cette pompe est fournie avec un conducteur et une fiche de mise à

la terre. Pour réduire le risque de choc électrique, s’assurer qu’elle

est branchée seulement à une prise de courant correctement mise

à la terre.

FOR ADDED SAFETY the receptacle must be protected with a ground

fault circuit interrupter (GFCI). All wiring must be performed by a

qualified licensed electrician and comply with the National Electric

Code and all applicable local codes and ordinances.

POUR PLUS DE SÉCURITÉ, la prise de courant doit être protégée par

un disjoncteur de fuite à la terre. Tout le câblage doit être effectué

par un électricien qualifié et être conforme au Code électrique

national et à tous les codes et règlements locaux applicables.

NEVER REMOVE THE GROUND PRONG from the plug or bypass the

grounding wires.

NE JAMAIS RETIRER LE CONNECTEUR DE MISE À LA TERRE de la prise

ou contourner les fils de mise à la terre.

MAKE SURE THE POWER SUPPLY HAS A FUSE OR CIRCUIT BREAKER

rated to handle the current (amps) noted on the pump nameplate

or cordtag.

S’ASSURER QUE L’ALIMENTATION ÉLECTRIQUE EST MUNIE D’UN

FUSIBLE OU D’UN DISJONCTEUR d’une valeur nominale appropriée

pour supporter l’intensité du courant (ampérage) indiquée sur la

plaque signalétique ou l’étiquette du cordon de la pompe.

PLEASE SEE WWW.WAYNEPUMPS.COM FOR PRODUCT INFORMATION AND INSTALLATION VIDEOS

2

Intended for Indoor Use Only

Page 3

ALWAYS DISCONNECT THE PUMP from power supply before installing,

MISE EN GARDE

servicing or making any adjustments.

TOUJOURS METTRE LA POMPE HORS TENSION avant de procéder à

l’installation, à l’entretien ou à des réglages.

DO NOT WALK on the floor when water is present until all power is

turned off. If the electric panel is in the basement, call an electrician.

NE PAS MARCHER sur un sol mouillé avant que l’alimentation

générale ne soit coupée. Si le tableau électrique est en sous-sol,

appeler un électricien.

INSTALLATION MANUAL

DO NOT USE AN EXTENSION CORD OR SURGE PROTECTOR. Extension

cords and/or surge protectors could present a safety hazard if not

sized properly, become damaged or the connection falls into the

sump. If receptacle is not within reach of the pump’s power cord,

contact a qualified licensed electrician to install a new receptacle.

NEVER HANDLE A PUMP or motor with wet hands or when standing

on a wet or damp floor while the pump is plugged into the power

supply.

NE JAMAIS MANIPULER UNE POMPE ou un moteur de pompe avec

les mains mouillées ou debout dans l’eau ou sur une surface

humide.

RISK OF ELECTRIC SHOCK. This pump has not been investigated for

use in swimming pool and marine areas.

RISQUE DE CHOC ÉLECTRIQUE. Cette pompe n’a pas fait l’objet

de vérification pour une utilisation dans les piscines et les aires

marines.

DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS such as

gasoline, fuel oil, kerosene, etc. Do not use in a flammable and/or

explosive atmosphere. Pump should only be used to pump clear

water. Personal injury and/or property damage will result and void

warranty.

NE PAS UTILISER POUR POMPER DES FLUIDES INFLAMMABLES OU

EXPLOSIFS tels que l’essence, le mazout, le kérosène, etc. Ne

pas utiliser dans un environnement inflammable et/ou explosif.

La pompe ne doit être utilisée que pour pomper de l’eau claire.

Des blessures corporelles et/ou des dégâts matériels pourraient

en résulter.

PUMPS ARE NOT DESIGNED TO TRANSFER WATER INTENDED FOR

DRINKING. Do not use the pump for moving water that will be

used for portable/drinking water. Pump should only be used

in applications for which it is designed.

LES POMPES NE SONT PAS CONÇUES POUR L’ACHEMINEMENT D’EAU

DESTINÉE À LA CONSOMMATION. Ne pas utiliser la pompe

pour transporter de l’eau qui sera utilisée comme de l’eau

potable/destinée à la consommation. La pompe doit être

utilisée uniquement dans les applications pour lesquelles

elle est conçue.

NE PAS UTILISER DE RALLONGE NI DE PROTECTEUR DE SURTENSION.

Les rallonges et/ou les protecteurs de surtension peuvent présenter

un danger pour la sécurité s’ils ne sont pas correctement calibrés,

s’ils sont endommagés ou si le raccordement tombe dans le

puisard. Si la prise n’est pas à portée du cordon d’alimentation

de la pompe, contacter un électricien qualifié pour installer une

nouvelle prise.

CAUTION INDICATES A POTENTIALLY HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR

MODERATE INJURY.

LA MENTION MISE EN GARDE INDIQUE UNE SITUATION

POTENTIELLEMENT DANGEREUSE QUI, SI ELLE N’EST PAS

ÉVITÉE, POURRAIT ENTRAÎNER DES BLESSURES MINEURES

OU MODÉRÉES.

TO REDUCE THE RISK OF HAZARDS THAT CAN CAUSE

INJURY OR PROPERTY DAMAGE, OBSERVE THE FOLLOWING

WARNINGS:

POUR RÉDUIRE LE RISQUE DE DANGERS POUVANT CAUSER

DES BLESSURES OU DES DÉGÂTS MATÉRIELS, RESPECTER

LES MISES EN GARDE SUIVANTES :

IT IS THE INSTALLER’S RESPONSIBILITY TO MAKE SURE THE

PUMPS AUTOMATIC SWITCH IS ABLE TO OPERATE WITHOUT ANY

OBSTRUCTIONS WITHIN THE BASIN. It is recommended that the

installer test and observe the pump’s operation for several cycles

after installation.

IL EST DE LA RESPONSABILITÉ DE L’INSTALLATEUR DE S’ASSURER QUE

L’INTERRUPTEUR AUTOMATIQUE DE POMPE PEUT FONCTIONNER SANS

AUCUN BLOCAGE À L’INTÉRIEUR DU SYSTÈME. Il est recommandé

que l’installateur teste et observe le fonctionnement de la pompe

pendant plusieurs cycles après l’installation.

3

Page 4

INSTALLATION MANUAL

IT IS REQUIRED TO USE RIGID PIPING AND FITTINGS to secure the

pump in the basin and reduce pump movement. Pump movement

can prevent the switch from operating correctly. Do not use flexible

hosing.

IL EST NÉCESSAIRE D’UTILISER DES TUYAUX ET DES RACCORDS

RIGIDES pour fixer la pompe dans le système et réduire les

mouvements de la pompe. Les mouvements de la pompe peuvent

empêcher l’interrupteur de fonctionner correctement. Ne pas

utiliser de tuyaux flexibles.

This product can expose you to chemicals, including DEHP,

which is known to the State of California to cause cancer, birth

defects and reproductive harm. For more information, go to

www.P65Warnings.ca.gov.

IT IS REQUIRED TO USE A CHECK VALVE with this pump to prevent the

back-flow of clear ground water after each pump cycle.

Cette pompe NÉCESSITE L’UTILISATION D’UNE VANNE DE CONTRÔLE

pour empêcher le reflux d’eau souterraine claire après chaque

cycle de pompage.

DO NOT INSTALL OR OPERATE THE PUMP IF IT HAS BEEN DAMAGED

IN ANY WAY.

NE PAS INSTALLER OU FAIRE FONCTIONNER LA POMPE SI ELLE A ÉTÉ

ENDOMMAGÉE DE QUELQUE MANIÈRE QUE CE SOIT.

DO NOT LIFT OR CARRY THE PUMP BY THE POWER CORD. Use the

pump’s handle or lift ring.

NE PAS SOULEVER OU PORTER LA POMPE PAR LE CORDON

D’ALIMENTATION. Utiliser la poignée ou la bague de levage de la

pompe.

AN INDEPENDENT HIGH WATER ALARM OR BACK UP PUMP SHOULD BE

USED when risk of property damage from high water levels exists.

UNE ALARME AUTONOME DE? NIVEAU D’EAU ÉLEVÉ OU UNE POMPE DE

SAUVEGARDE DOIVENT ÊTRE UTILISÉES en cas de risque de dégâts

matériels causés par des niveaux d’eau élevés.

REPLACE THE SWTICH EVERY T?WO (2) YEARS. This maintenance will

reduce the risk of improper pump operation, switch failure and/or

flooding.

REMPLACER LE COMMUTATEUR TOUS LES DEUX (2) ANS. Cet entretien

réduira le risque d’utilisation incorrecte de la pompe, de défaillance

de l’interrupteur ou d’inondation.

Ce produit peut vous exposer à des produits chimiques,

notamment du DOP, reconnus par l’État de Californie comme

étant cancérigènes et à l’origine d’anomalies congénitales et de

problèmes de l’appareil reproductif. Pour plus de renseignements,

visiter le site www.P65Warnings.ca.gov.

TETHER FLOAT SWTICH This float is adjustable. By adjusting the

tether switch it can affect the specifications of the application of

the pump and can change the life expectancy of the unit.

L’INTERRUPTEUR DU FLOTTEUR À AMARRE est réglable. L’ajuster

peut affecter les spécifications d’utilisation de la pompe et peut en

modifier la durée de vie.

4

Page 5

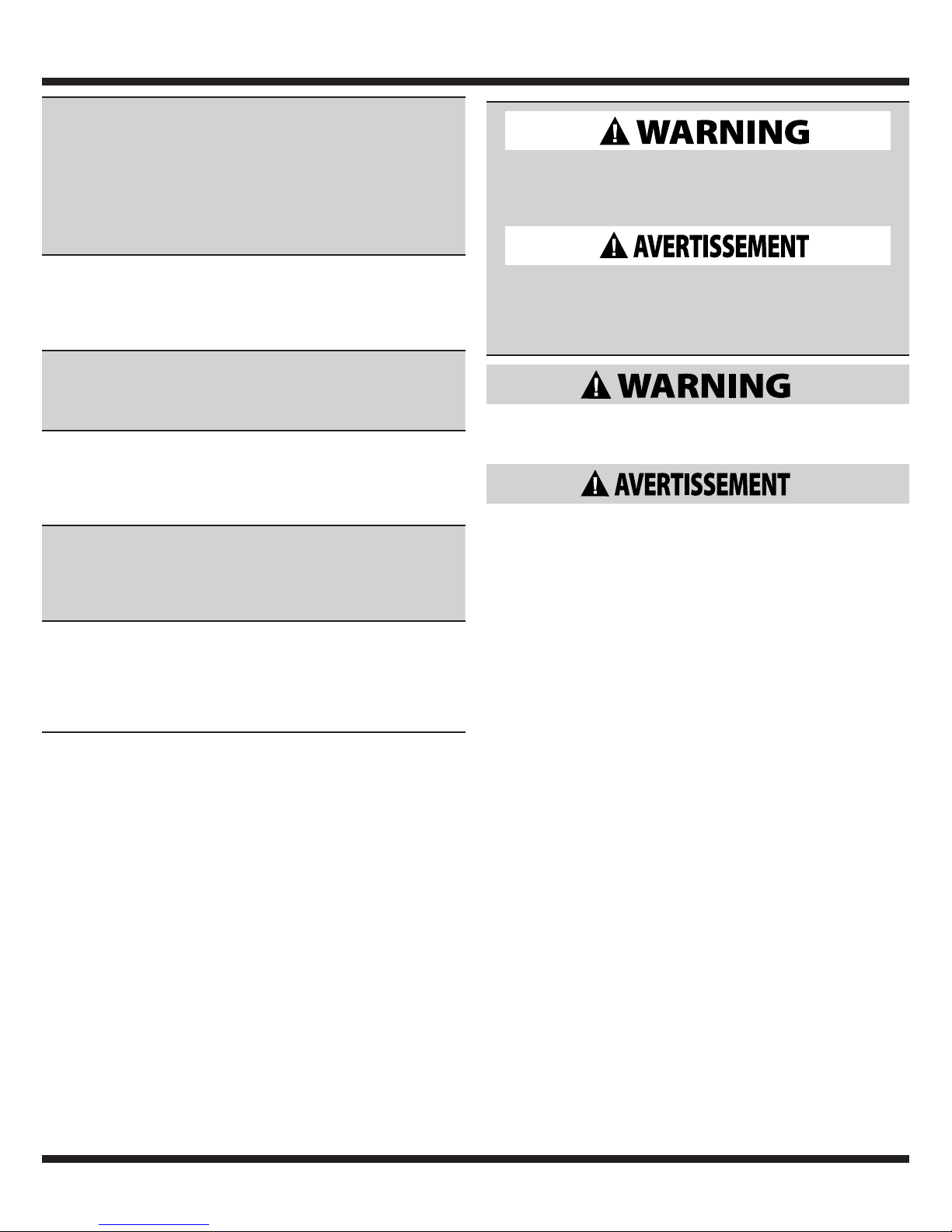

TYPICAL SEWAGE INSTALLATION

1. This installation must be in accordance with the National

Electric Code and all applicable local codes and

ordinances.

2. Use a basin that is large enough to accommodate the

pump. The basin diameter should be a minimum of 18

inches and the depth a minimum of 24 inches.

3. Clean the basin of all debris.

INSTALLATION MANUAL

Submersible Sewage

Pumps

1

2

11

10

4. Set the pump on a solid, level surface. Do not place pump

directly on clay, earth, gravel, or sand. A brick or block may

be installed under the pump to provide a solid base.

5. Position pump in the basin so the switch is away from

incoming water. Verify the float switch has at least 1 inch

clearance to the side wall of the basin and is free of any

possible obstructions.

6. Install discharge plumbing according to local, regional and

state codes. Do not reduce the discharge pipe size below

that which is provided on the pump.

7. If optional control device or float is used, follow mounting

instruction supplied with device or float.

8. A union should be installed above the basin to allow easy

removal of the pump for cleaning and service.

9. Install a check valve (required) to prevent back-flow.

It should be installed above the union.

10. A gate valve or ball valve should be installed above the

check valve as required by local, regional or state codes.

11. Connect remaining discharge pipe. The remainder of

the discharge line should be as short as possible with a

minimum number of turns.

12. A vent pipe is required. It removes gases and odors and

should be installed as required by local, regional or state

codes.

13. Secure power supply cord to discharge pipe using cable or

zip ties to prevent possible switch entanglement.

14. Connect pump power supply cord to a ground fault circuit

interrupter (GFCI) receptacle.

15. Fill the basin with water. The pump will start when the

water level has reached the switch-on level. Verify the

pump is operating normally.

3

4

5

6

9

7

ON LEVEL

(RPP50-APPROX. 16 IN.

SEL50-APPROX. 17 IN.

WCS50T-APPROX. 19 IN.)

OFF LEVEL

(RPP50-APPROX. 7.5 IN.

SEL50-APPROX. 7 IN.

WCS50T-APPROX. 10.5 IN.)

1. Check Valve 7. Switch

2. Union 8. Minimum Diameter (18 in.)

3. Discharge Pipe 9. Minimum Depth (24 in.)

4. Inlet Pipe 10. Gasket/Basin Lid

5. Basin/Septic Tank 11. Vent Pipe

6. Pump (RPP50,

SEL50, WCS50T)

8

18 IN. DIAMETER MIN.

24 IN. DEPTH MIN.

16. Install a basin cover and gasket to prevent debris from

falling into the basin, prevent personal injury and to contain

gases and odors.

5

Page 6

INSTALLATION MANUAL

TYPICAL EFFLUENT INSTALLATION

1. This installation must be in accordance with the National

Electric Code and all applicable local codes and ordinances.

2. Clean the basin of all debris.

Effluent Pump in

Septic Tank

2

1

3. Set the pump on a solid, level surface. Do not place pump

directly on clay, earth, gravel, or sand. A brick or block may

be installed under the pump to provide a solid base.

4. Verify the float switch has at least 1 inch clearance to

the side wall of the basin and is free of any possible

obstructions.

5. If optional control device or float is used, follow mounting

instructions supplied with device or float.

6. Install discharge plumbing according to local, regional and

state codes. Do not reduce the discharge pipe size below

that which is provided on the pump.

7. Install a union to allow easy removal of the pump for

cleaning and service.

8. Install a check valve (required) to prevent back-flow. It

should be installed above the union.

9. A gate valve or ball valve should be installed above the

check valve as required by local, regional or state codes.

10. Connect remaining discharge pipe. The remainder of

the discharge line should be as short as possible with a

minimum number of turns.

5

6

7

8

4

12

3

11. Secure power supply cord to discharge pipe using cable or

zip ties to prevent possible switch entanglement.

12. Connect pump power supply cord to a ground fault circuit

interrupter (GFCI) receptacle.

13. Fill the basin with water. The pump will start when the water

level has reached the switch-on level. Verify the pump is

operating normally. If the discharge line is exposed to freezing

temperatures, the pipe must be positioned in a downward

slope away from the foundation so any remaining water will

drain away and not freeze.

14. Secure a basin/tank cover and gasket to the basin to prevent

debris from falling into the basin, prevent personal injury, and to

contain gases and/or odors.

9

10 11

1. Discharge Outlet Pipe 7. Septic Tank/ Basin

2. Junction Box 8. Effluent Pump

(EFL50)

3. Pump/Switch Wires 9. Brick or Block

4. Union 10. Discharge Pipe

5. Effluent Inlet Pipe 11. Check Valve

6. Switches 12. Tank Lid

6

Page 7

TROUBLESHOOTING WARNINGS

INSTALLATION MANUAL

1. Submersible pump models have permanently lubricated

bearings and require no additional lubrication.

ALWAYS DISCONNECT THE PUMP FROM POWER SUPPLY before

installing, servicing or making any adjustments.

TOUJOURS METTRE LA POMPE HORS TENSION avant de procéder à

l’installation, à l’entretien ou à des réglages.

LET PUMP COOL FOR A MINIMUM OF 2 HOURS BEFORE ATTEMPTING TO

SERVICE. Submersible pumps contain oil that become pressurized

and hot under normal operating conditions.

LAISSER REFROIDIR LA POMPE PENDANT AU MOINS 2 HEURES AVANT

D’ESSAYER DE LA RÉPARER. Les pompes submersibles contiennent

de l’huile qui devient pressurisée et chaude dans des conditions

normales de fonctionnement.

2. Submersible pumps contain dielectric oil for cooling.

Dielectric oil can be harmful to the environment. Follow

state environmental laws when disposing of oil.

3. The pump motor is equipped with automatic resetting

thermal protector and may restart unexpectedly. Protector

tripping is an indication of motor overloading as a result of

operating the pump at low heads, excessively high or low

voltage, inadequate wiring, incorrect motor conditions, or at

the end of its life.

TROUBLESHOOTING

Symptoms Possible Cause(s) Suggested Remedies

Pump will not

start or run

1. Water level too low

2. Blown fuse or tripped circuit breaker

3. Low supply voltage

4. Motor

5. Switch

6. Inlet clogged

7. Switch obstruction

1. Water must be at the appropriate level to activate switch

2. If blown, determine cause and then either replace with proper

sized fuse or reset breaker

3. Contact an electrician

4. Replace pump

5. Replace switch

6. Remove debris

7. Remove obstruction to verify free motion of switch

Pump starts and

stops too often

Pump shuts off

and turns on

independently

of switch (trips

thermal overload

protection)

1. Back-flow of water from discharge

pipe

2. Switch

3. Check valve not functioning properly

or leaking

1. Switch

2. Switch obstruction

3. Obstruction in discharge pipe

4. Low supply voltage

7

1. Install check valve

2. Replace switch

3. Remove and examine check valve for prop er in stal la tion and free

operation. Replace check valve if necessary.

1. Replace tether switch

2. Remove obstruction to verify free motion of switch

3. Remove obstruction in discharge piping

4. Contact an electrician.

Page 8

INSTALLATION MANUAL

TROUBLESHOOTING (CONTINUED)

Symptoms Possible Cause(s) Suggested Remedies

Pump operates

noisily or vibrates

excessively

Pump will not

shut off

Pump operates

but delivers little

or no water

1. Worn bearings

2. Impeller broken

3. Piping attachments to building

structure too rigid or too loose

1. Switch

2. Switch obstructions

3. Restricted discharge (obstruction in

piping)

4. Excessive inflow or pump not

properly sized for application

1. Low supply voltage

2. Inlet clogged

3. Broken impeller

4. Pump not properly sized for

application

5. Check valve stuck closed or

installed backwards

6. Shut off valve closed

1. Replace pump

2. Replace pump

3. Install rubber coupling (available at local hardware stores) to isolate

pump vibration from discharge plumbing

1. Replace switch

2. Remove obstruction to verify free motion of switch

3. Remove obstruction from discharge piping

4. Recheck all sizing calculations to determine proper pump size

1. Contact an electrician

2. Remove debris

3. Replace pump

4. Recheck all sizing calculations to determine proper pump size

5. Remove and examine check valve for proper installation and free

operation

6. Open valve

ROUTINE MAINTENANCE

The pump should be inspected 3-4 times per year for pump movement or buildup of debris on the switch or floar. Reposition

pump if it has moved. Remove any debris that could interfere with the operation of the switch. Lack of proper routine maintenance

will void warranty.

• Make sure the pump is plugged in to a working ground fault circuit interrupter (GFCI) outlet and the cord is in good shape. In

damp areas, GFCI breakers may trip, effectively shutting off the effluent pump. Check in on your sewage pump and reset the

GFCI if necessary.

• Ensure the pump itself is standing upright. Vibrations during operation can cause it to fall or tilt onto one side. This can jam the

float arm so it can’t activate the pump.

• Pour a bucket of water into the pit to make sure the pump starts automatically and the water drains quickly once the pump is

on. If the pump doesn’t start, have it serviced or replaced.

• Replace the switch every two (2) years. This maintence will reduce the risk of improper pump operation, switch failure and/or

flooding.

8

Page 9

WARRANTY & SERVICE PARTS SHEET - REPLACEMENT PARTS

REPAIR KITS

REF. NO. DESCRIPTION MODELS

Sewage- RPP50, SEL50, WCS50T

Efuent- EFL50

1 TETHER SWITCH

(ALL MODELS)

2

10 FT. CORD

(WCS50T ONLY)

56835-WYN1

31006-WYN2

2

9

Page 10

INSTALLATION MANUAL

FOR REPLACEMENT

PARTS OR CUSTOMER SUPPORT,

CALL 1-800-237-0987

Please provide following information:

- Model number

- Serial number on cord tag (not to be removed)

- Part description and number as shown in parts list

Thank you for making Wayne Water Systems a key part of your

home maintenance program. If properly installed, maintained

and operated in accordance with Wayne Water Systems’ written

instructions, your pump should provide you with approximately

( * ) years of service.

Product Warranty ( * ) Expected Life

1 3

3 6

ADDRESS PARTS CORRESPONDENCE TO:

WAYNE Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

LIMITED WARRANTY

For one year for RPP50, SEL50, and EFL50 models, and three years for WCS50T model from the date of purchase, from an authorized dealer, Wayne Water Systems

will repair or replace, at its option for the original purchaser, any part or parts of its Sewage or Effluent Pumps or Water Pumps (“Product”) found upon examination

by Wayne Water Systems to be defective in materials or workmanship. Please call Wayne Water Systems (800-237-0987) for warranty instructions. Be prepared to

provide the model number and the serial number when exercising this warranty. All transportation charges on Products or parts submitted for repair or replacement

must be paid by purchaser. This Limited Warranty is not transferrable.This Limited Warranty does not cover Products which have been damaged as a result of

accident, abuse, misuse, neglect, improper installation, improper maintenance, or failure to operate in accordance with WAYNE’s written instructions.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper installation, improper

maintenance, or failure to operate in accordance with Wayne Water Systems’ written instructions.

THIS WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, OBLIGATIONS OR AGREEMENTS, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND ANY RIGHTS OR REMEDIES AGAINST ANY PERSON OR ENTITY UNDER THE

UNIFORM COMMERCIAL CODE OR OTHERWISE WITH RESPECT TO THE SALE OF THE PRODUCT. THE REMEDIES AND OBLIGATIONS STATED IN THIS WARRANTY

ARE THE SOLE AND EXCLUSIVE REMEDIES OF AND OBLIGATIONS TO THE OWNER FOR ANY AND ALL MATTERS ARISING WITH RESPECT TO OR IN ANY WAY

CONNECTED WITH THE PRODUCT, REGARDLESS OF THE SOURCE OR PROVIDER OF SUCH GOODS. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT,

WARRANTY TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL WAYNE WATER SYSTEMS OR ANY AFFILIATE BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a copy of the purchase receipt along

with the material or correspondence. Please call Wayne Water Systems (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO Wayne Water Systems. Use this form only to maintain your records.

MODEL NO._____________________ SERIAL NO._________________________ INSTALLATION DATE __________________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

10

Page 11

INSTALLATION MANUAL

NOTES

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

11

Page 12

www.waynepumps.com

12

Loading...

Loading...