Page 1

Auto On-Off Water Removal

Pool Cover Pump

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

O

perating Instructions and Parts Manual WAPC250

SPECIFICATIONS

POWER SUPPLY REQUIREMENTS 120 V, 60 Hz

MOTOR Single Phase, Auto ON/OFF

HORSEPOWER

CIRCUIT REQUREMENT

LIQUID TEMPERATURE RANGE 40° F- 120° F

1/4 HP

15 A (minimum)

Model HP

WAPC250 1/4 Gal/hr 3000 2350 1600 900

CONSTRUCTION

MOTOR HOUSING Thermoplastic

MOTOR SHAFT Stainless Steel

IMPELLER Thermoplastic

VOLUTE Thermoplastic

PUMP DISCHARGE 1-1/4 in. with Check Valve & 3/4 in. Hose

Threads

PERFORMANCE

Discharge Head 0 ft. 5 ft. 10ft. 15 ft.

www.waynepumps.com

690001-001 B 08/18© 2018, WAYNE/Scott Fetzer Company

Page 2

Operating Instructions and Parts Manual

TOP

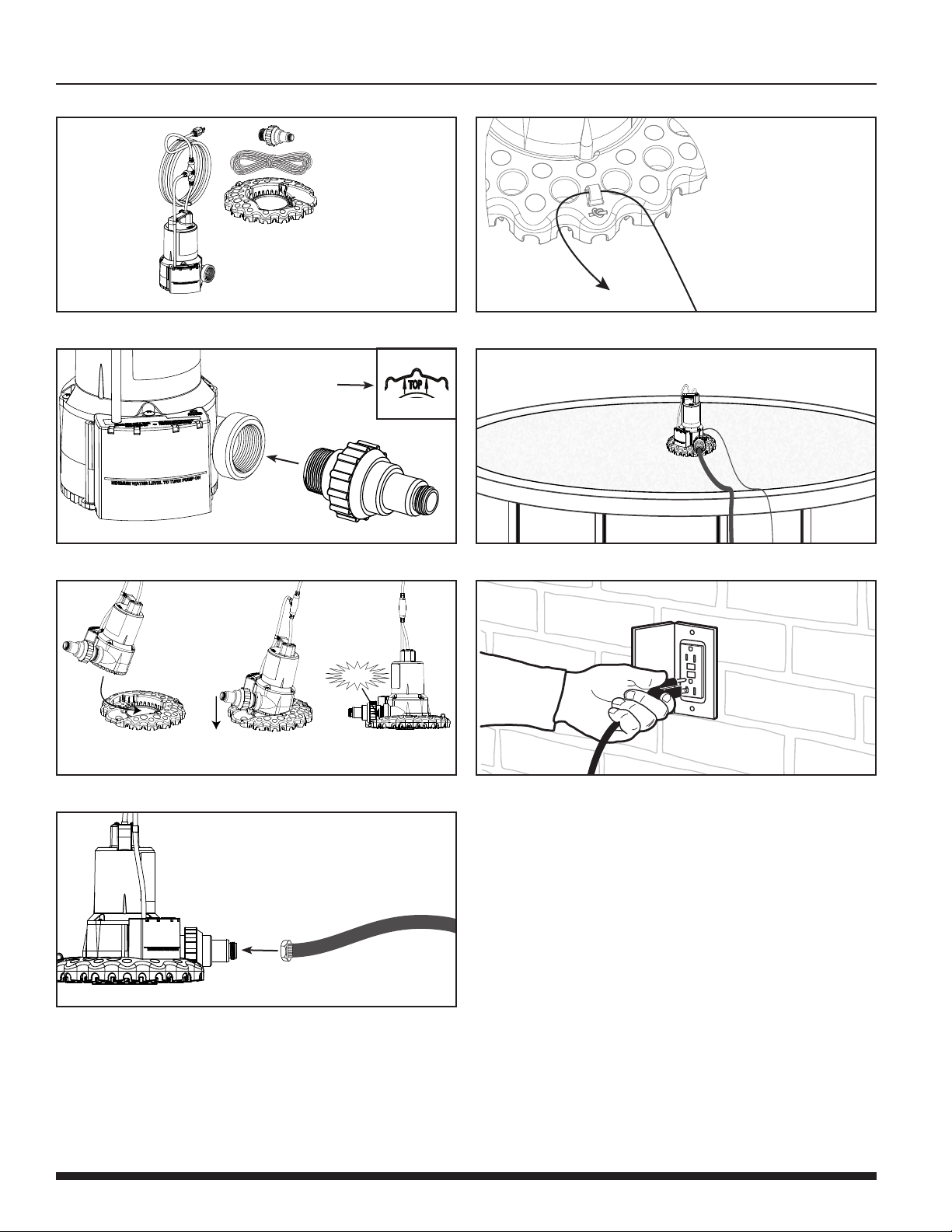

STEP 1 - VERIFY PACKAGE CONTENTS

(1) POOL COVER PUMP

(1) CHECK VALVE/

HOSE ADAPTER

(1) 25' ROPE

(1) PUMP STRAINER

STEP 2 - INSTALL CHECK VALVE

INSTALL CHECK VALVE

SO ARROWS ARE

POINTING UPWARD

STEP 5 - SECURE ROPE TO STRAINER

FEED ROPE THROUGH

LOOP ON STRAINER AND

SECURE WITH KNOT

STEP 6 - POSITION ON POOL COVER

STEP 3 - ATTACH STRAINER

ROTATE PUMP

DOWN TO LOCK

LISTEN FOR PUMP TO

"CLICK" IN PLACE

STEP 4 - CONNECT GARDEN HOSE

STEP 7 - PLUG INTO GFCI OUTLET

CLICK

FOR FURTHER PLACEMENT TECHNIQUES AND DETAILED INSTALLATION FOR

INGROUND AND ABOVE GROUND POOL APPLICATIONS, REFER TO PAGES 5

and 7- FIGURES (A-E).

The most common cause for the pump not removing water can be

resolved by following step 6 of the troubleshooting section. (Page 9)

2

www.waynepumps.com

Page 3

Operating Instructions and Parts Manual

WAPC250

DESCRIPTION

This portable, Auto On-Off Pool Cover pump is designed for

automatic removal of water, from a pool or spa cover. The units

are equipped with a 25 ft. 3-prong grounding type power cord

(WAPC250) or GFCI Protected Power Cord (WAPC250G). The

provided discharge check valve prevents short cycling and it's 3/4 in.

adapter can be used for convenient attachment to a standard garden

hose.

UNPACKING

Inspect this unit before it is used. Occasionally, products are

damaged during shipment. If the pump or components are

damaged, contact Customer Support at 1-800-237-0987.

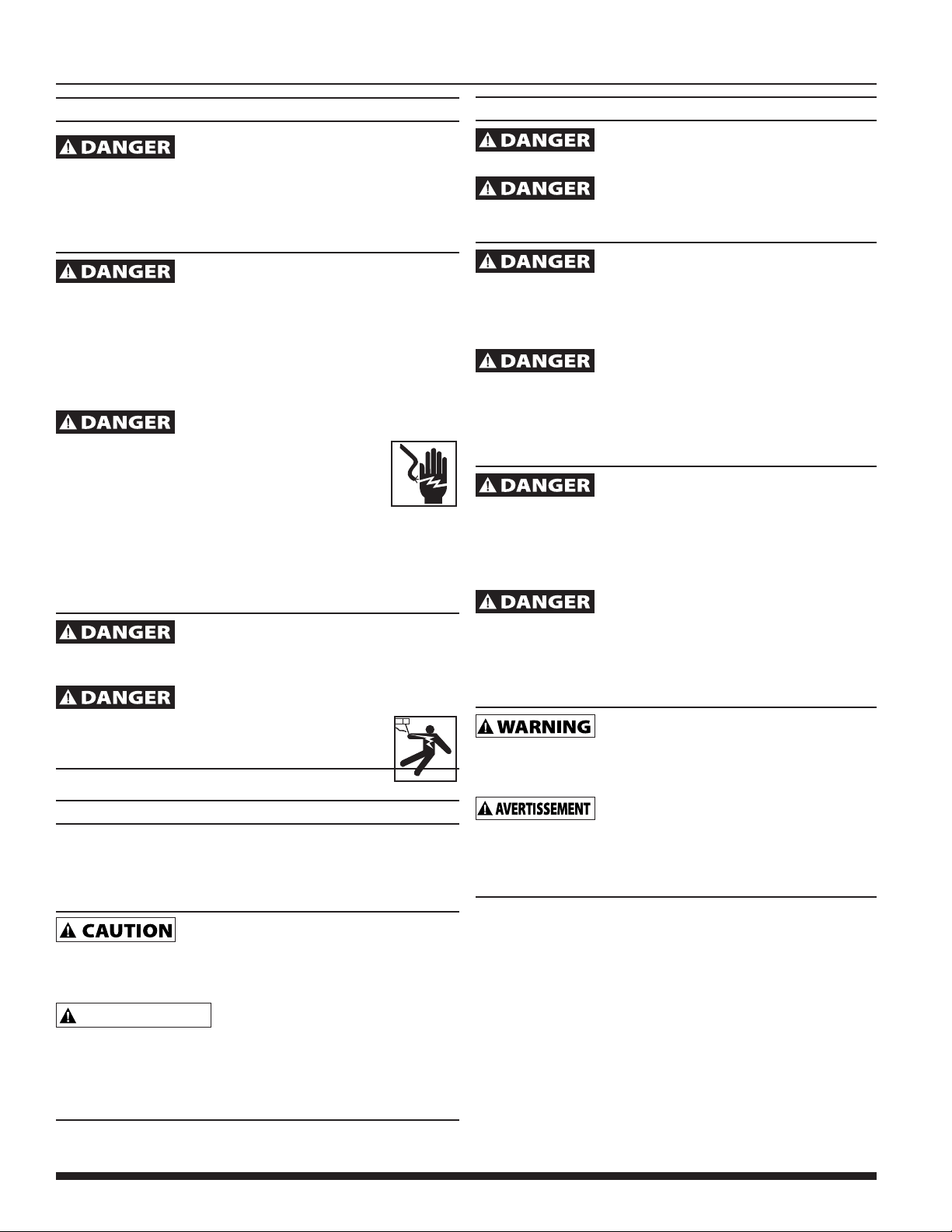

SAFETY SIGNAL WORDS

This manual contains information that is very important to know

and understand. This information is provided for SAFETY and

to PREVENT EQUIPMENT PROBLEMS. To help recognize this

information, observe

the following symbols.

Danger indicates an imminently hazardous

situation which, if NOT avoided, WILL result in death or serious injury.

La mention Danger indique une situation

dangereuse imminente qui, si elle n’est pas évitée, ENTRAÎNE la mort ou

des blessures graves.

Warning indicates a potentially hazardous

situation which, if NOT avoided, COULD result in death or serious injury.

La mention avertissement indique une

situation potentiellement dangereuse qui, si elle n’est pas évitée, risque

d’entraîner des lésions corporelles graves ou même la mort.

Caution indicates a potentially hazardous

situation which, if NOT avoided, MAY result in minor or moderate injury.

MISE EN GARDE

situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures mineures ou modérées.

NOT followed, MAY cause damage to equipment.

This is the safety alert symbol. It is used to alert you to

potential bodily injury hazards. Obey all safety messages

that follow this symbol to avoid possible harm.

La mention mise en garde indique une

Notice indicates important information, that if

GENERAL SAFETY INFORMATION

CALIFORNIA PROPOSITION 65

This product can expose you to chemicals, including DEHP,

which is known to the State of California to cause cancer,

birth defects and reproductive harm. For more information,

go to www.P65Warnings.ca.gov.

Ce produit peutvous exposer à des produits chimiques,

notamment du DOP, reconnus par l’État de Californie comme

étant cancérigènes et à l’origine d’anomalies congénitales

et de problèmes de l’appareil reproductif. Pour plus de

renseignements, visiter le site www.P65Warnings.ca.gov.

GENERAL SAFETY

• Read all manuals included with this product carefully.

Be thoroughly familiar with the controls and the proper

use of the equipment. Follow all instructions.

• Only persons well acquainted with these rules of safe

operation should be allowed to use the unit. Keep

away from children.

This pump is NOT rated for use with flammable/

combustible liquids, vapors, or dusts. Do NOT use to pump flammable/

combustible liquids, vapors, or dusts. Do NOT use in a flammable and/

or explosive atmosphere. Pump SHOULD be used to pump clear water

ONLY. Failure to follow these instructions WILL result in bodily injury or

death, and will void warranty.

Cette pompe N’est PAS homologuée pour être

utilisée avec des vapeurs, des poussières, des liquides inflammables

ou combustibles. NE PAS utiliser pour pomper des vapeurs liquides ou

des poussières inflammables ou combustibles. NE PAS utiliser dans

un environnement inflammable et/ou explosif. L’usage de la pompe est

EXCLUSIVEMENT LIMITÉ au pompage de l’eau claire. Le non-respect de

ces instructions risque d’entraîner des blessures corporelles ou la mort,

et annulera la garantie.

NOTE: Information that requires special attention.

provide protection against line to ground faults only. The ground fault

receptacle does NOT limit the magnitude of fault current and will NOT

prevent an electrical shock. Replace damaged cord immediately.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

www.waynepumps.com

Electric shock hazard! GFCI receptacles will

3

Page 4

Operating Instructions and Parts Manual

GENERAL SAFETY INFORMATION (CONT’D)

Risque de choc électrique! Le disjoncteur de

fuite à la terre fournira une protection uniquement contre les défauts

entre les lignes et les fuites à la terre. Le boîtier du disjoncteur de fuite

à la terre ne limite PAS l’amplitude du courant de défaut et n’empêchera

PAS les chocs électriques. Remplacer immédiatement tout cordon

endommagé.

Risk of electric shock. This pump has NOT been

tested for use in marine areas. NEVER place pump in pools while people

are in the water. Do NOT handle pump with wet hands or when standing

in water or on a damp surface. Pump is designed to be used in closed

and covered pools only. Water accumulated on pool cover can cause

injury or death. Proper installation of pool cover pump and periodic

maintenance is recommended. Failure to follow COULD result in death or

serious injury.

Risque de choc électrique. Cette pompe n’a

PAS été testée pour une utilisation dans les aires marines.

NE JAMAIS placer la pompe dans les piscines pendant

que les gens sont dans l’eau. NE PAS manipuler la pompe

avec les mains humides ou debout dans l’eau ou sur une

surface humide. La pompe est conçue pour être utilisée

uniquement dans les piscines fermées et couvertes. L’eau accumulée

sur la couverture de la piscine peut causer des blessures ou la mort.

Une installation correcte de la pompe de couverture de piscine et

un entretien périodique sont recommandés. Le non respect de ces

instructions POURRAIT entraîner la mort ou des blessures graves.

Do NOT disassemble or alter this product in any

way. Failure to follow these instructions WILL result in serious injury or

death and will void warranty.

NE PAS démonter ou modifier ce produit

de quelque manière que ce soit. Le non-respect de ces

instructions ENTRAÎNERA de graves blessures ou la mort, et

annulera la garantie.

APPLICATION AND OPERATION

Do NOT use pump if any part of the housing

switch or probe is cracked, broken, or missing.

NE PAS utiliser la pompe si une partie

quelconque du commutateur de boîtier ou de la sonde de capteur est

fissurée, brisée ou manquante.

Always disconnect electric supply before

attempting to install, service, relocate, or perform any maintenance. If

the power source is out of sight, lock and tag in open (off) position to

prevent unexpected power application. Failure to do so WILL result in

fatal electrical shock!

Toujours couper le courant avant d’essayer

d’installer, de réparer, de déplacer ou d’effectuer toute opération de

maintenance. Si la source d’alimentation est hors de vue, verrouiller

et étiqueter en position ouverte (off) pour éviter tout rétablissement

inattendu de l’électricité. Ne pas le faire ENTRAÎNERA un choc électrique

mortel!

If using an extension cord, do NOT allow pump

cord/extension cord connection to fall into swimming pool or come in

contact with water. Pump/extension cord connection must be kept dry

and away from moisture. Do NOT handle plug connector near water.

Failure to follow these instructions WILL result in death or serious

injury.

Si une rallonge est utilisée, NE PAS LAISSER le

cordon/la rallonge d’alimentation de la pompe tomber dans la piscine

ou entrer en contact avec l’eau. Le cordon/la rallonge d’alimentation

de la pompe doivent être gardés au sec et à l’abri de l’humidité. NE

PAS manipuler le connecteur près de l’eau. Le non-respect de ces

instructions ENTRAÎNERA de graves blessures ou la mort.

This unit is NOT designed for use as a sump

pump or in sump applications. This unit is NOT designed for use in

septic tanks or underground vaults to pump raw sewage or effluents.

NEVER use in hazardous or explosive locations.

PERSONAL SAFETY

1. Wear safety glasses at all times when working with pumps.

2. The unit MUST be plugged into a properly grounded GFCI outlet.

Consult with a qualified electrician for proper installation of a GFCI

OUTLET.

Do not move, position, retrieve, or carry

pump using the power cord or the discharge hose, damage to the

pump or power cord may occur. Use the handle supplied on the

pump or attach a string to the strainer to position as instructed.

MISE EN GARDE

récupération ou de transporter la pompe à l’aide du cordon

d’alimentation ou le tuyau de refoulement, des dommages à la

pompe ou le cordon d’alimentation peut se produire. Utiliser la

poignée fournie sur la pompe ou attacher un fil à la passoire de

position comme indiqué.

4

Ne bougez pas, de position, de

Cette unité n’est PAS conçue pour être utilisée

comme pompe de puisard ou dans des applications de puisard. Cette

unité n’est PAS conçue pour être utilisée dans des fosses septiques ou

des enceintes souterraines pour pomper les eaux usées ou les effluents.

Ne JAMAIS utiliser dans des environements dangereux ou explosifs.

This unit is not designed for use as a sump pump or in sump

applications. This unit is not designed for use in septic tanks or

underground vaults to pump raw sewage or effluents. Never use in

hazardous or explosive locations.

www.waynepumps.com

Page 5

Operating Instructions and Parts Manual

WAPC250

APPLICATION AND OPERATION (CONT’D)

PUMPING HEIGHT

When water is pumped to an elevated position, any volume that

has not reached the discharge outlet can flow back through the

pump when the pump shuts off. This back-flow can cause the water

level in small areas to rise enough to re-start the pump. The check

valve/hose adapter included is required in this situation. For proper

operation, make certain the check valve is oriented as instructed on

check valve body.

to prevent backflow. Without a check valve the pump may cycle

continuously and potentially wear out the pump components.

1. This pump has been designed with 1-1/4 in. NPT discharge

connection size. Attach pipe or fitting to the discharge or use the

supplied garden hose adapter/check valve. Thread the female

end of the garden hose to the male end of the garden hose

adapter/check valve.

2. Use a hose washer (not included) on the garden hose for correct

pump operation.

3. For best pump performance, unwind the hose before starting the

pump. This will help remove any kinks or binds in the hose and

allow the unit to pump with less restriction.

or leaking pool cover. Placing the pump on a damaged pool cover could

cause the cover to give way, or could allow the pump to remove treated

swimming water from the pool in addition to rainwater.

In small areas a check valve is required

DO NOT place the pump on a weak, damaged,

DROP-IN PUMP APPLICATION

13' MAXIMUM

PUMPING HEIGHT

POOL

COVER

Figure A - In-Ground Pool Installation

(cut-away view)

A3

DISCHARGE HOSE

A1. Connect discharge hose to pump check valve and place hose end

away from pool, where water will be displaced.

A2. Attach provided 25 ft. rope to handle of pump, and lower pump onto

pool cover where water will collect.

A3. Do NOT exceed the 13 ft. maximum pumping height for this pump or

switch may not function properly. Plug in pump to allow for automatic

operation.

For removal unplug pump and retrieve using rope.

AVOID PINCHING

OR DAMAGING

POWER CORD

AND HOSE ON

POOL EDGE

A2

A1

4. Install the “snap-on” debris strainer. Begin by lining up the pump

base profile with the profile of the strainer base using the switch

housing as a guide. Tilt the pump back and guide the rear of the

pump (opposite the discharge) into the strainer base. Once the

rear of the pump is in place, gently rotate the pump down until the

latch engages.

5. To remove debris strainer release latch and guide pump out of

strainer in the reverse motion of installation.

6. With pump unplugged set the pump on the pool cover, where

water will collect. Do not set the pump directly on mud, sand

surfaces or in leaves. For best results make sure the pump

strainer is making full contact with a clean area of the pool cover.

This will allow the strainer to properly filter debris and help prevent

clogging of the pump. If necessary clear an area of the pool cover

before placing the pump. For further placement techniques see

(Figures A-E).

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual

ABOVE GROUND PUMP INSTALLATION

To aid in pump placement on pool cover, secure provided 25 ft. rope

to the pull to shore loop (Figure B).

D2

D1

THROUGH LOOP AND

SECURE WITH KNOT

Figure B - Pull to shore loop

FEED ROPE

Connect provided 25 ft. rope to pull to shore loop (see Figure B) and

discharge hose to the pump.

AVOID PINCHING

OR DAMAGING

POWER CORD

AND HOSE ON

POOL EDGE

25 FT.

POWER

CORD

(INCLUDED)

25 FT.

(INCLUDED)

ROPE

Figure D - Above Ground Installation

(top view)

D1. Holding the provided 25 ft. rope, walk around pool until you are

even with the pump on the opposite side.

D2. Pull the 25 ft. rope towards you until the pump is in the center

of the pool cover where water will collect. Secure rope for easy

removal (see Figure E) when weather permits. Plug in pump to

allow for automatic operation.

Always use debris strainer when placing pump

on a pool cover. The strainer helps protect the pool cover from damage,

filters debris, and increases pump stability.

DISCHARGE

HOSE

Figure C - Above Ground Installation

(side view)

Place pump on pool cover near edge of pool (see Figure C). If

floatation device is used under the pool cover, place pump at the

lowest point on the pool cover where water will collect.

6

www.waynepumps.com

Page 7

Operating Instructions and Parts Manual

WAPC250

ABOVE GROUND – PUMP REMOVAL

Figure E - Above Ground Pump Removal

(top view)

Disconnect power to pump. Using the included 25 ft. rope, safely

pull pump to edge of pool, disconnect discharge hose and remove.

Do NOT handle pump with wet hands or when

standing in water or on a damp surface when the unit is operating

or fails to operate. ALWAYS disconnect pump power cord from power

source before handling. Do NOT bury cord. Visually locate cord to

prevent damage caused by lawn mowers, hedge trimmers

and other equipment. Failure to do so WILL result in fatal

electrical shock.

NE PAS manipuler la pompe avec

les mains humides ou debout dans l’eau ou sur une surface humide

lorsque l’appareil fonctionne ou ne fonctionne pas corectement.

TOUJOURS débrancher le cordon d’alimentation de la pompe de la

source de courant avant toute manipulation. Ne PAS enterrer le cordon.

Repérer visuellement le cordon pour éviter les dommages causés par

les tondeuses à gazon, les taille-haies et autres équipements. Ne pas le

faire ENTRAÎNERA un choc électrique mortel.

9. The pump will stop automatically once water has been removed

to a depth of approximately 3/4 of an inch. The pump will not

restart until the water depth rises to 2-1/8 inches or greater.

10. The pump will not allow itself to run dry. Once the pump

detects that water is no longer being removed, it will shut down

automatically. The pump must remain upright at all times in

order for the water detection to function. Do not allow the pump

to operate on its side or inverted The shaft seal depends on

water for lubrication, allowing the pump to remain in any other

orientation than upright could cause shaft seal failure or pump

failure.

Do not alter the pump to override the automatic

water detector. The shaft seal depends on water for lubrication.

Overriding this pump feature can cause the pump to run dry and may

damage the shaft seal and cause pump failure, and will void warranty.

Pump starts automatically. Always disconnect

electric supply before attempting to install, service, relocate, or perform

any maintenance.

La pompe démarre automatiquement. Toujours

couper le courant avant d’essayer d’installer, de réparer, de déplacer ou

d’effectuer toute opération de maintenance.

NOTE: Minimal service is required for this pump. The motor housing

of the pump is completely sealed and requires no internal service or

lubrication.

7. The water level must be at least 2-1/8 inches for the pump to

cycle, prime, and operate. Water levels less than 2-1/8 inches will

not allow the impeller to contact water therefore no water will be

pumped.

8. Plug the pump into a properly grounded 120 volt GFCI protected

outlet. The pump will start automatically when the water reaches

a depth of 2-1/8 inches. A priming delay of 2 seconds is

programmed into the control to allow time for air to escape from

the pumping chamber.

www.waynepumps.com

7

Page 8

Operating Instructions and Parts Manual

MAINTENANCE

1. Periodic cleaning is required to maintain performance of the

pump. Follow the cleaning steps listed below:

a. Disconnect pump from power source.

b. Remove the strainer.

c. Remove the four (4) base screws (Figure 1).

d. Remove the base and impeller plate.

e. Remove the debris and make sure the impeller turns freely.

f. Reinstall impeller plate, base, screws, and strainer.

g. Use a pin or paperclip to clean the priming hole and air escape

channel.

IMPELLER PLATE

PRIMING HOLE

WHEN REATTACHING THE BASE (INLET SCREEN), BE SURE THAT

THE "PLUGGED" SCREEN IS ORIENTED BELOW THE SWITCH.

Figure 1 - Priming Hole Location

BASE SCREWS (4)

INLET SCREEN/

BASE

TROUBLESHOOTING

1. Verify pumping height does NOT exceed 13 feet (See Figure A). If

pumping height is greater than 13 feet, this pumps automatic feature

will not operate correctly.

2. Verify water depth is 2-1/8 inches or greater.

3. To verify pump is operating correctly.

a. Disconnect pump from power source.

b. Connect hose adapter/check valve and discharge hose to

pump.

c. Immerse pump in a bucket or tub of water at least 2-1/8

inches

in depth.

d. Place the other end of the discharge hose outside the bucket,

so the water will pump out.

e. Plug power cord into a grounded 120 volt GFCI power outlet.

The pump should start after 2 seconds of detecting water.

Once the pump removes the water to a depth of 3/4 inch, the

pump will stop automatically.

f. If pump does NOT operate, unplug power cord and proceed

to maintenance –refer to cleaning instructions.

4. To verify discharge hose is free from a blockage.

a. Connect hose to another water source such as a faucet.

If water flows through hose, return to step 3a. If water is

restricted, verify discharge hose is unwound. Remove all

kinks, bends, or obstructions in hose.

b. If pump is still NOT operating, refer to cleaning instructions

5. If pump runs continuously, unplug the unit. Once unplugged,

remove the strainer and check for debris stuck inside the sensor body

(Figure 2). Remove any trapped leaves, debris or dirt.

CLEAN

DEBRIS

INSIDE

SENSOR

BODY

SENSOR

PROBE

Figure 2 - Remove Debris From Sensor

8

www.waynepumps.com

Page 9

Operating Instructions and Parts Manual

WAPC250

TROUBLESHOOTING (CONT’D)

6. If the pump cycles on and off too often the electronic switch

may need cleaning. Disconnect pump from power source, remove

the strainer and turn the pump upside down. The sensor probe

will be visible inside the switch housing. Clean inside the housing

gently scrubbing with a small brush using soapy water. Then rinse

automatically shutdown to protect the motor from overheating. The

pump will continue this on/off cycle for a period of time to attempt to

“free” the impeller until eventually the unit will remain off for a period of

12 hours checking twice a day for a “freed” impeller. Once the pump

is able to operate correctly the pump will resume normal operation.

To reset this delay without waiting 12 hours momentarily unplug the

pump.

thoroughly with clean water.

7. When temperatures drop below freezing remove pump from

service and store indoors to protect pump from damage due to ice.

The pump has a unique protection circuit to protect the motor from a

housing or probe is cracked, broken or missing.

locked impeller condition possibly caused by debris buildup or from a

“frozen” impeller situation caused by ice formation. When the pump

is activated and a locked impeller condition is detected the unit will

boîtier de l’interrupteur ou de la sonde est fissuré, cassé ou manquant.

TROUBLESHOOTING CHART

Symptom Possible Cause(s) Corrective Action

Pump will not start

or run

1. Tripped home electrical breaker

2. GFCI tripped

3. Low supply voltage

4. Defective motor

5. Dirty switch

6. Impeller obstructed

7. Inlet screen or strainer clogged

8. Priming hole plugged

1. Reset breaker

2. Check for damaged wiring or moisture

3. Contact electrician

4. Replace pump

5. Rinse out switch with clean water (Figure 2)

6. Remove strainer, base, and impeller plate (Figure1) check for debris; clean

7. Clean inlet screen and debris strainer (Figure 1)

8. Clean hole, inside volute housing, with a pin or paper clip (Figure 1)

Do NOT use pump if any part of the switch

Ne PAS utiliser la pompe si une partie du

Pump starts and

stops too often

Pump will not

shut off or runs

continuously

Pump operates

but delivers little or

no water

1. Backflow of water from piping

2. Dirty switch

3. Priming hole plugged

4. Pump is sitting uneven on pool or spa

cover

1. Debris in switch

2. Discharge height exceeds capability

1. Impeller obstructed

2. Priming hole plugged

3. Obstructed hose

4. Discharge height exceeds capability

5. Strainer clogged

1. Install or replace check valve

2. Rinse out switch with clean water (Figure 2)

3. Clean hole, inside volute housing, with a pin or paper clip (Figure 1)

4. Reposition pump so pump sits level on cover

1. Rinse out switch with clean water (Figure 2)

2. Reduce discharge height

1. Remove strainer, base, and impeller plate (Figure 1), check for debris; clean

2. Clean hole, inside volute housing, with a pin or paper clip (Figure 1)

3. Check for kinks, reposition hose or check for debris

4. Reduce discharge height

5. Unplug pump. Remove strainer and rinse with clean water to remove debris

www.waynepumps.com

9

Page 10

Operating Instructions and Parts Manual

For Replacement Parts or Customer Support, Call 1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

1

Address parts correspondence to:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

3

2

Ref. No. Description Order No. Quantity

1

2 Strainer 62067-WYN1 1

3 25' Rope 67152-WYN1 1

Check valve /

garden hose adapter

62061-WYN1 1

10

www.waynepumps.com

Page 11

Operating Instructions and Parts Manual

WAPC250

LIMITED WARRANTY

For three years for WAPC250 model from the date of purchase, from an authorized dealer, Wayne Water Systems will repair or replace, at its option for the original

purchaser, any part or parts of its Pool Cover Pump or Water Pumps (“Product”) found upon examination by Wayne Water Systems to be defective in materials or

workmanship. Please call Wayne Water Systems (800-237-0987) for warranty instructions. Be prepared to provide the model number and the serial number when

exercising this warranty. All transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper installation, improper maintenance,

or failure to operate in accordance with Wayne Water Systems’ written instructions.

THIS WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, OBLIGATIONS OR AGREEMENTS, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND ANY RIGHTS OR REMEDIES AGAINST ANY PERSON OR ENTITY UNDER THE UNIFORM

COMMERCIAL CODE OR OTHERWISE WITH RESPECT TO THE SALE OF THE PRODUCT. THE REMEDIES AND OBLIGATIONS STATED IN THIS WARRANTY ARE THE SOLE

AND EXCLUSIVE REMEDIES OF AND OBLIGATIONS TO THE OWNER FOR ANY AND ALL MATTERS ARISING WITH RESPECT TO OR IN ANY WAY CONNECTED WITH

THE PRODUCT, REGARDLESS OF THE SOURCE OR PROVIDER OF SUCH GOODS. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, WARRANTY TORT

(INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL WAYNE WATER SYSTEMS OR ANY AFFILIATE BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a copy of the purchase receipt along

with the material or correspondence. Please call Wayne Water Systems (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO Wayne Water Systems. Use this form only to maintain your records.

MODEL NO._____________________ SERIAL NO._________________________ INSTALLATION DATE __________________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

11

Page 12

NOTES

12

www.waynepumps.com

Loading...

Loading...