Page 1

Pool Pumps

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

© 2002 Wayne Water Systems

Operating Instructions and Parts Manual Inground and Above Ground Units

To reduce the risk

of injury, do not

permit children to use this product

unless they are closely supervised at

all times.

This pump is for

use with permanently installed pools. If specified, the

pump may be used with hot tubs and

spas. Do not use with storable pools.

A permanently installed pool is constructed in or on the ground or in a

building such that it cannot be readily

disassembled for storage. A storable

pool is constructed so that it may be

readily disassembled for storage and

reassembled to it’s original integrity.

Pump only clear water. Do

not pump flammable or

explosive fluids such as

gasoline, fuel oil, kerosene, etc. Do not

use in a flammable and/or explosive

atmosphere. Personal injury and/or

property damage could result.

All wiring must be performed by a qualified electrician. The pump must be

installed in compliance with all local

codes and the National Electrical Code.

2. Do not install within an outer

enclosure or beneath the skirt of

the hot tub or spa, unless so

marked.

Installation

LOCATION

Disconnect, tag and lock out

power source before

attempting to install, service, relocate or perform any maintenance.

Locate pump as close to pool/spa as

possible. Install the pump on a hard,

level surface that is dry, well ventilated

321700-001 6/02

and away from direct sunlight. The surrounding area should provide protection from the elements and ample

room for maintenance and service.

Ensure the drainage will flow away

from the pump.

Above ground pool pumps are not

self-priming. If suction line valves are

installed, the pump may be located

above water level. Keep the vertical distance from the water level to a minimum. Otherwise, the pump must be

located below filled water level to facilitate priming.

Inground pool pumps are self-priming. Mount pump below water level for

easy priming. If the pump must be

located above the filled water level,

keep the vertical distance to a minimum.

GENERAL PLUMBING

SOLVENT WELD CONNECTIONS

Use rigid or flexible PVC pipe. Ensure

pipe ends are clean and free of any

flash caused by the cutting operation.

Use the proper adhesive for the type of

pipe specified.

NOTE: Use an adhesive primer to

ensure adhesive joints are secure.

Suregard P-3000 has a purple tracer to

qualify in areas where codes specify a

primer must be used.

Description

This swimming pool pump is designed for

use with permanently installed pools only.

Unpacking

After unpacking the unit, carefully

inspect for any damage that may have

occurred during transit. Check for

loose, missing or damaged parts.

Danger indicates

an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Notice indicates

important information, that if not followed, may cause

damage to equipment.

This manual contains information that

is very important to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this

information, observe the following:

1. Read these rules and

instructions carefully.

Failure to follow these

instructions could

cause serious bodily

injury and/or property

damage.

READ &

FOLLOW ALL

INSTRUCTIONS

SAVE THESE

INSTRUCTIONS DO

NOT DISCARD

IMPORTANT

SAFETY

INSTRUCTIONS

PVC - PVC Joint PVC - ABS Joint

Uni-Weld Uni-Weld

Pool-Tite 2000 Pool-Tite 2000

Suregard Flex 20 Suregard Weld

All No. 5

IPS Weld-On 705 IPS Weld-On 794

*

These recommendations are examples only

and are not intended to restrict brands

RECOMMENDED ADHESIVES*

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.waynepumps.com

!

DANGER

!

WARNING

!

CAUTION

NOTICE

!

WARNING

!

CAUTION

!

WARNING

!

WARNING

MANUAL

!

DANGER

Page 2

2

Operating Instructions and Parts Manual

Installation (Continued)

Consider climatic conditions when

applying adhesives. Atmospheric conditions with high humidity will make the

adhesive action of certain glues less

effective. Follow the manufacturer's

instructions.

THREADED CONNECTIONS

Use only Teflon

®

tape or equivalent on

threaded plumbing connections. Other

pipe compounds may damage threads.

Do not use silicone or petroleum based

compounds. Do not overtighten. Hand

tightening plus 1/2 turn is sufficient.

PUMP PLUMBING

Suction pipe should be as large or larger

than discharge pipe. Avoid using a suction pipe smaller than pump connection.

1. Keep the piping as straight and

short as possible, and of suitable

size.

2. Do not connect an elbow directly

into the pump inlet. A length of

straight pipe will allow proper entry

of the water to the pump.

3. Slope horizontal runs upward to the

pump to prevent trapping air.

4. Use independent piping supports to

alleviate strain on the pump.

5. Keep as much of the suction line as

possible below the water level to

reduce priming time.

6. Install valves and unions in the

pump suction and return lines to

facilitate servicing. Valves will throttle the pump discharge. Valves are

also essential for pump maintenance if the system is installed

below deck level.

7. Use a check valve in the suction pipe

for inground pumps at or below the

water level if the suction lift is more

than 5 feet or the dry suction is

more than 10 feet long. Keep the

valve in the suction line fully open

during operation.

WIRING

All wiring must be performed by a qualified electrician. The pump must be

installed in compliance with all local

codes and the National Electrical Code.

When motor installation is within 5 ft.

(1.5 m) of the pool’s interior walls, a

solid copper bonding conductor (minimum size No. 8 AWG/8.4 mm

2

) should

be connected from the accessible wire

connector on the motor.

• to all metal parts of the swimming

pool

• to all electrical equipment

• to metal conduit

• to metal piping within 5 ft. (1.5 m)

of the pool’s interior walls

Refer to information on motor nameplate for electrical service data. Install

motors with a fused disconnect switch

or dedicated circuit breaker. Be sure

wire size is sufficient for pump HP and

distance from power source. Install a

ground fault circuit interrupter for

maximum safety.

Disconnect, tag,

and lock out power

source before attempting to install, service, relocate, or perform any maintenance.

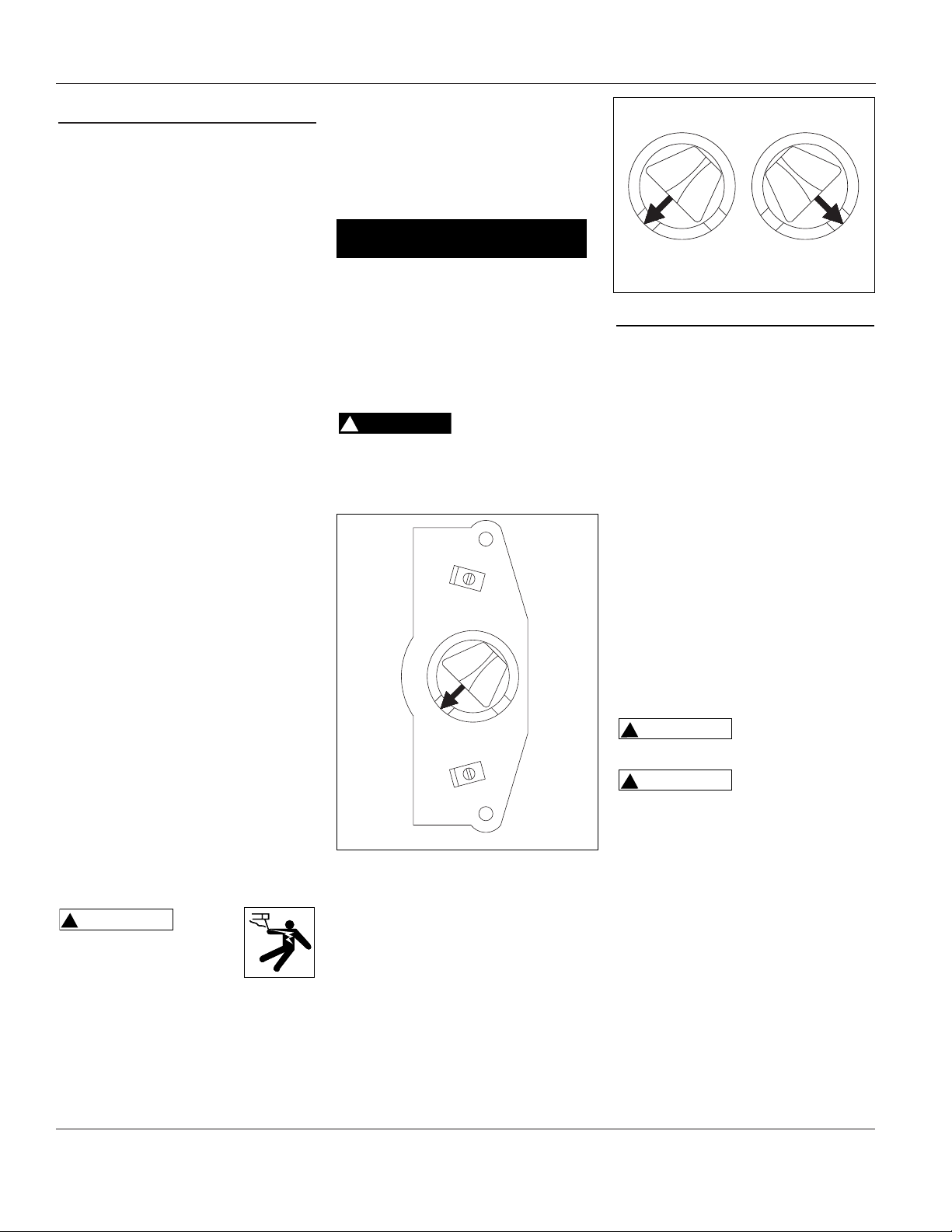

VOLTAGE SELECTOR

This pump is factory wired for 115 volts.

To change the voltage to 230 volts follow the steps below:

1. Disconnect the pump from power.

2. Remove cover from back of motor

to find voltage selector (Figure 1a).

3. Pull selector knob out.

4. Rotate selector knob to correct volt-

age setting (Figure 1b).

5. Push selector knob back in place.

6. Reinstall cover to back of motor.

Operation

Prime pump before attempting to operate. To prime pumps located above water

level, remove strainer cover, fill strainer

body with water then replace cover. If

pump and all piping is located below

water level, the pump will self prime.

After pump has been primed, energize

motor and open all suction and discharge line valves. If no flow is

observed in five minutes, stop the

motor and reprime. If the pump fails to

operate, check for air leaks. Refer to

troubleshooting section.

After about 10 minutes of operation,

check the return fittings for air bubbles.

A continuous flow of air indicates leaks

in the suction line. Locate and correct

any leaks immediately.

CONTROLLING PUMP DISCHARGE

Keep the gate valve in the suction line

fully open during operation. To control

the discharge, use a valve in the return

line.

Do not retighten

strainer Ring-Lok

during operation.

Do not operate

pump with closed

suction or discharge valve.

WATER CHEMISTRY

Proper and consistent use of chemicals

is necessary to manage a water system.

Chlorine is the most commonly used

chemical to provide clean, sanitary

water. Daily administration of dry or

liquid chlorine (calcium or sodium

hypochlorite) is essential.

IMPORTANT: Maintain the correct

level of acidity or alkalinity of the pool

water. Readings above pH 7.0 are alkaline. A pH 7.0 is neutral. Readings

below pH 7.0 are acidic. A desirable

range is 7.2 to 7.4.

IMPORTANT: Use copper

conductors only.

Figure 1a

www.waynepumps.com

Figure 1b

!

WARNING

!

DANGER

L1

LO

L2

HI

Volt

115 Volts 230 Volts

LO

Volt

HI

LO

Volt

HI

!

CAUTION

!

CAUTION

Page 3

WINTERIZING

Always protect system from freezing

temperatures. Drain the system if there

is a possibility of freezing. To drain the

system:

1. Units with a filter:

a. Sand filter: Backwash for 3 to 5

minutes and then set dial valve to

winterize position.

b. Cartridge filter: Clean the filter

element and store in dry area.

2. Drain system by loosening drain

plug. The drain plug does not have

to be completely removed.

Removing pipe caps will facilitate

draining also.

3

Operating Instructions and Parts Manual

Maintenance

Disconnect, tag and lock

out power source before

attempting to install, service, relocate or perform any maintenance.

1. Motors are self-lubricating - no

additional lubrication is required.

2. Clean pool pump strainer of hair

and lint.

3. Visually inspect motor for blockage

of air vents on motor shell. Remove

any debris after shutting off breaker.

4. Replace worn shaft seals.

HAIR AND LINT STRAINER

1. Switch off the power.

2. Close the valves in the suction and

return line.

3. Turn strainer Ring-Lok counterclockwise and remove stainer cover.

4. Lift strainer basket away from the

pump.

5. Clean and reposition the basket

into the pump. Take care to seat

the basket properly.

6. Clean the o-ring and relubricate

with petroleum jelly if necessary.

7. Clean o-ring seats on the cover and

strainer.

8. Refit the cover and strainer RingLok; hand tighten only.

9. Open the valves to return pump to

operation.

Do not retighten

strainer Ring-Lok

during operation.

Troubleshooting Chart

Symptom Possible Cause(s)

Motor does not

start

Motor does not

reach full speed

Motor overheats

(protector trips)

Pump does not

deliver water

Low pump capacity

1. Disconnect switch or circuit breaker

in OFF position

2. Fuses blown or thermal overload open

3. Locked motor shaft

4. Motor windings burned out

5. Defective starting switch inside single-phase motor

6. Disconnected or defective wiring

7. Low voltage

1. Low voltage

2. Motor windings connected for wrong

voltage on dual voltage model

1. Low voltage

2. Motor windings connected for wrong

voltage on dual voltage model

3. Inadequate ventilation

1. Pump is not primed

2. Closed valve in suction or discharge

line

3. Leakage or air into suction system

4. Impeller clogged

1. Valve in suction or discharge line

partly closed

2. Suction or discharge line partly plugged

3, Suction or discharge line too small

4. Pump running at reduced speed (see

previous)

5. Plugged basket in skimmer or hair

and lint strainer

6. Dirty filter

7. Impeller clogged

8. Wrong rotation (3 phase only)

1. Pump running at reduced speed (see

previous)

2. Wrong rotation (three phase models

only)

3. Discharge valve or inlet fittings

open too wide

1. Discharge valve or inlet fittings

closed too much

2. Return lines too small

3. Dirty filter

1. Plugged basket in skimmer or hair in

lint strainer

2. Worn motor bearings

3. Valve in suction line partly closed

4. Suction line partly plugged

5. Vacuum hose plugged or too small

6. Pump not supported properly

Shaft seal requires replacement

1. Leakage of air into suction line at

connections or valve stem

2. Cover gasket around hair and lint

strainer needs cleaning

3. Restriction in suction line

4. Low water level in pool

Low pump capacity

(continued)

Low pump pressure

High pump pressure

Noisy pump and

motor

Leakage of water

at shaft

Air bubbles at inlet

fittings

Symptom Possible Cause(s)

www.waynepumps.com

!

DANGER

!

CAUTION

Page 4

4

Operating Instructions and Parts Manual

1 Pump kit 69006-001 69007-001 69004-001 69005-001 1

2 Shaft seal kit 21009-001 21009-001 21009-001 21009-001 1

3 Motor kit 32023-001 32023-002 69000-001 69001-001 1

Ref. Part Number for Models:

No. Description WAP75 WAP100 WIP100 WIP150 Qty.

Pool Pumps

For Replacement Parts, call 1-800-237-0987

Limited Warranty

For one year from the date of purchase, Wayne Water Systems ("Wayne") will repair or replace, at its option, for the original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by Wayne to be

defective in materials or workmanship. Please call Wayne (800-237-0987) for instructions or see your dealer. Be prepared

to provide the model number and the serial number when exercising this warranty. All transportation charges on

Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Wayne’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS

THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR

EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations

of incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you

specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Wayne or

its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital,

cost of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for

such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you

MUST send a copy of the purchase receipt along with the material or correspondence. Please call Wayne (800-237-0987)

for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Wayne Water Systems

100 Production Drive

Harrison, OH 45030 U.S.A.

Replacement Parts Illustration for

Models WAP75 and WAP100

Replacement Parts Illustration for

Models WIP100 and WIP150

1

2

3

3

2

1

www.waynepumps.com

Loading...

Loading...