Page 1

Submersible Multi-Use Pumps

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

Operating Instructions and Parts Manual VIP Series

SPECIFICATIONS

POWER SUPPLY REQUIREMENTS 120 V, 60 Hz

MOTOR Single Phase

HORSEPOWER

CIRCUIT REQUIREMENT 15 A (minimum)

LIQUID TEMPERATURE RANGE 40° F- 120° F

1/2 HP ..................(VIP50)

1/5 HP...................(VIP15)

Model HP

VIP50 1/2 Gal/hr 2600 2160 1680 1080 300

VIP15 1/5 Gal/hr 2050 1740 1350

CONSTRUCTION

MOTOR HOUSING Thermoplastic

MOTOR SHAFT Stainless Steel

IMPELLER Thermoplastic

VOLUTE Thermoplastic

PUMP DISCHARGE 1-1/4 in. NPT or 3/4 in. Hose Threads

PERFORMANCE

Discharge Head 0 ft. 5 ft. 10 ft. 15 ft. 20 ft.

880 -

www.waynepumps.com

620007-001 B 08/18© 2018, WAYNE/Scott Fetzer Company.

Page 2

Operating Instructions and Parts Manual

DESCRIPTION

This portable, submersible multi-use pump is designed and in tend ed for

non-automatic use in water. The units are equipped with an 8-ft. 3-prong

ground ing-type power cord. The motor is oil filled and sealed for cooler

running and designed to operate under water. The non-clogging impeller

design minimizes debris from stopping the pump. The elbow fitting

allows convenient discharge through a garden hose.

NOTE: THIS PUMP IS NOT SUITABLE FOR AQUATIC LIFE OR

DRINKING WATER!

UNPACKING

Inspect this unit before it is used. Occasionally, products are

damaged during shipment. If the pump or components are

damaged, return the unit to the place of purchase for replacement,

or call Customer Support (800-237-0987).

SAFETY SIGNAL WORDS

To help recognize this information, observe the following signal

words/hazard classifications.

Danger indicates an imminently hazardous

situation which, if NOT avoided, WILL result in death or serious injury.

La mention Danger indique une situation

dangereuse imminente qui, si elle n’est pas évitée, ENTRAÎNE la mort ou

des blessures graves.

Warning indicates a potentially hazardous

situation which, if NOT avoided, COULD result in death or serious injury.

La mention avertissement indique une

situation potentiellement dangereuse qui, si elle n’est pas évitée, risque

d’entraîner des lésions corporelles graves ou même la mort.

Caution indicates a potentially hazardous

situation which, if NOT avoided, MAY result in minor or moderate injury.

MISE EN GARDE

situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures mineures ou modérées.

NOT followed, MAY cause damage to equipment.

This is the safety alert symbol. It is used to alert you to

potential bodily injury hazards. Obey all safety messages

that follow this symbol to avoid possible harm.

La mention mise en garde indique une

Notice indicates important information, that if

GENERAL SAFETY INFORMATION

CALIFORNIA PROPOSITION 65

This product can expose you to chemicals, including DEHP,

which is known to the State of California to cause cancer,

birth defects and reproductive harm. For more information,

go to www.P65Warnings.ca.gov.

Ce produit peutvous exposer à des produits chimiques,

notamment du DOP, reconnus par l’État de Californie comme

étant cancérigènes et à l’origine d’anomalies congénitales

et de problèmes de l’appareil reproductif. Pour plus de

renseignements, visiter le site www.P65Warnings.ca.gov.

GENERAL SAFETY

1. Read manual included with this product carefully. Be

thoroughly familiar with the controls and the proper use

of the equipment.

2. Know the pump application, limitations, and potential

hazards. Read these rules and the instructions carefully. Failure

to follow them could cause serious bodily injury and/or property

damage.

Do NOT use to pump flammable or explosive

fluids such as gasoline, fuel oil, kerosene, etc. Do not use in a

flammable and/or explosive atmosphere. Pump SHOULD be used to

pump clear water ONLY. Personal injury and/or property

damage WILL result, and void warranty.

NE PAS utiliser pour pomper des

fluides inflammables ou explosifs tels que l’essence,

le mazout, le kérosène, etc. Ne pas utiliser dans un environnement

inflammable ou explosif. La pompe DEVRAIT être utilisée pour pomper

de l’eau claire SEULEMENT. Si tel n’est pas le cas, des blessures

corporelles ou des dégâts matériels pourraient en résulter et annuler la

garantie.

NOTE: Information that requires special attention.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

2

www.waynepumps.com

Page 3

Operating Instructions and Parts Manual

VIP Series

GENERAL SAFETY INFORMATION (CONT’D)

Disconnect power before servicing. If the power

disconnect is out of sight, lock in the open (OFF) position and tag it to

prevent unexpected application of power. Failure to do so COULD result

in fatal electrical shock!

Débrancher l’alimentation avant de procéder

à l’entretien. Si la source de courant n’est pas visible, verrouiller en

position ouverte (OFF) et étiqueter pour éviter tout rétablissement

inattendu de l’électricité. Ne pas suivre ces instructions POURRAIT

mener à une décharge électrique mortelle.

4. Release all pressure within the system before ser vic ing any

component.

5. Drain all liquids from the system before servicing.

6. Secure the discharge line before starting the pump. An unsecured

discharge line will whip, possibly caus ing personal injury and/or

property damage.

7. Check hoses for weak and worn condition before each use, making

certain that all connections are secure, and open ended.

8. Periodically inspect the pump and system com po nents. Perform

routine maintenance as required (See Main te nance Section, on

page 3).

This pump is not designed to handle salt water,

brine, laundry discharge, water softner, sewage, grey water, or any

other application which may contain caustic chemicals and/or foreign

materials. Pump and/or property damage could occur if used in these

applications and will void warranty.

This equipment is only for use on 120 volt

(single-phase) and is equipped with an ap proved 3-conduc tor cord and

3-prong, grounding-type plug.

1. To reduce the risk of electric shock, the motor must be securely and

adequately grounded. This can be ac com plished by inserting pump

power cord plug directly into a properly installed and grounded

3-prong (GFCI), ground ing-type re cep ta cle.

Where a 2-prong wall receptacle is en coun tered, it must be re-

placed with a properly grounded 3-prong (GFCI) re cep ta cle installed

in accordance with the NEC and local codes and ordinances.

2. Protect electrical cord from sharp ob jects, hot sur fac es, oil, and

chemicals. Do not operate with damaged cord.

3. Do not handle a pump or pump motor with wet hands or when

standing on a wet or damp surface, or in water.

If your basement or room has water or moisture

on the floor, do NOT walk on wet area until all power has been turned

off. If the shut-off box is in the basement, call the electric company

to shut-off service to the house, or call your local fire department for

instruction. Failure to follow this warning WILL result in fatal electrical

shock.

Si le sous-sol ou la pièce a de l’eau ou de

l’humidité sur le plancher, ne PAS marcher aux endroits mouillés

avant que le courant ne soit coupé. Si le boîtier de coupure de courant

se trouve au sous-sol, appeler la société d’électricité pour couper le

courant de la maison, ou encore appeler le service d’incendie local pour

des instructions. Le non-respect de cet avertissement ENTRAÎNERA un

choc électrique mortel.

Personal Safety

a. Wear safety glasses at all times when working with pumps.

b. Keep work area clean, uncluttered and prop er ly light ed; replace

all unused tools and equipment.

c. Keep visitors at a safe distance from the work area.

When using an electrically driven pump such

as this, follow all electrical and safety codes, as well as the most recent

National Electrical Code (NEC) and the Occupational Safety and Health

Act (OSHA). All wiring should be performed by a qualified electrician.

En utilisant une pompe électrique comme

celle-ci, respecter tous les codes de sécurité et d’électricité en plus du

Code national de l’électricité (CNE) le plus récent et aux États-Unis, la

loi Occupational Safety and Health Administration Act (OSHA). Tout le

câblage doit être effectué par un électricien qualifié.

www.waynepumps.com

3

Page 4

Operating Instructions and Parts Manual

APPLICATION

Important: This pump is not designed for use in septic tanks or

underground vaults to handle raw sewage or gray water. It should

never be used in hazardous or explosive locations. Do not use

power cord or discharge hose to lift pump. Always use the handle.

Pump should be located and should rest on a

level solid foundation. Pump requires 2-5/8 in. of water minimum to

operate. Do not suspend pump by means of the discharge pipe or power

cord. Keep pump inlet clear. Do not place pump directly on clay, earth,

or sand surfaces. protect pump from extreme heat and cold. Use pipe

joint sealant to ensure airtight pipe connections.

1. Thread discharge (outlet into pump body carefully to avoid stripping

or cross threading.

2. To install garden hose, install the elbow adapter provided with the

pump. The elbow adapter uses an o-ring seal to provide better

water removal. Rotate the elbow adapter until the o-ring seals

against the pump body and the discharge is in the desired direction.

Thread garden hose onto the elbow fitting.

Note: The garden hose must be 3/4 in. or larger to keep friction as low

as possible. A 1-1/4 in. sump discharge hose adapter can be

connected directly to the pump body using plumber’s seal

tape.

3. Run discharge pipe/hose away from the pump.

OPERATION

Do NOT touch pump, pump motor, water or

discharge piping when the pump is connected to electrical power. Do

NOT handle a pump or pump motor with wet hands or when standing on

wet or damp surface, or in water. NEVER touch the pump or discharge

piping when unit is operating or fails to operate. ALWAYS disconnect the

pump cord (power) before handling.

NE PAS toucher la pompe, le moteur de la

pompe ou la tuyauterie d’évacuation lorsque la pompe est connectée à

une source d’alimentation. NE PAS manipuler la pompe ou le moteur de

pompe avec les mains humides ou debout dans l’eau ou sur une surface

humide. Ne JAMAIS toucher la pompe ou la tuyauterie d’évacuation

lorsque l’unité fonctionne ou ne fonctionne pas correctement.

TOUJOURS débrancher le cordon d’alimentation de la pompe avant

toute manipulation.

Risk of electrical shock! This pump is supplied

with a grounding conductor and grounding type attachment plug. Use a

grounded (GFCI) receptacle to reduce the risk of fatal electrical shock.

Risque de choc électrique! Cette pompe est

fournie avec un conducteur de mise à la terre et une fiche de terre.

Utiliser une prise équipée d’un disjoncteur de fuite à la terre (GFCI) pour

réduire le risque de choc électrique mortel.

Do NOT cut off the round grounding prong.

Cutting cord or plug WILL void warranty and MAY make pump

inoperable.

Ne PAS couper la broche de terre ronde sur

le cordon. Couper le cordon ou les bornes de la batterie ANNULERA la

garantie et PEUT rendre la pompe inutilisable.

1. Pump should never be allowed to run dry. Do not operate the pump

unless it is submerged in water. Dry running (pump not pumping

water) will reduce pump life.

The motor is equipped with an automatic

reset thermal protector. This means if the temperature in the motor

should rise unduly, the protector will cut off all power before damage

can be done to the motor. When the motor has cooled sufficiently, the

switch will reset automatically and restart the motor. If protector trips

repeatedly (cycling of protector) pump should be removed and checked.

Low head (low discharge restriction), excessively high or low voltage,

inadequate wiring, excessive water temperature, inadequate water

supply, excessive surrounding air temperature, bound impeller/motor, or

a defective motor or pump could all be causes for the protector to cycle.

Cycling of protector will cause eventual motor burnout.

Le moteur est équipé d’un protecteur thermique

à réarmement automatique. Cela signifie que si la température dans le

moteur augmente indûment, le protecteur coupera toute l’alimentation

avant d’endommager le moteur. Lorsque le moteur a suffisamment

refroidi, l’interrupteur se réinitialise automatiquement et redémarre

le moteur. Si le protecteur se déclenche à plusieurs reprises (cycle du

protecteur), la pompe doit être retirée et vérifiée. Une charge basse

(restriction de faible débit), une tension excessivement élevée ou

basse, un câblage inadéquat, une température d’eau excessive, une

alimentation en eau insuffisante, une température ambiante excessive,

un rouet ou un moteur ou une pompe défectueux pourraient tous être

des causes de déclenchement du protecteur. Le déclenchement du

protecteur provoquera éventuellement le grillage du moteur.

4

www.waynepumps.com

Page 5

Operating Instructions and Parts Manual

VIP Series

OPERATION (CONT’D)

A pump that has a tripped thermal protector

may start suddenly!

Une pompe dotée d’un protecteur thermique

activé peut démarrer soudainement!

2. The pump will pump water down to 1/4 in., therefore the pump will

not remove all of the water. Shut off the pump immediately if the

unit has been operating and suddenly no water comes out of the

discharge hose. The water level is probably very low and the pump

has broken prime. Use a mop or squeegee to remove the remaining

water.

MAINTENANCE

Make certain that the pump is unplugged

before attempting to service or remove any component. This pump

is assembled in the factory using special equipment; therefore only

authorized service dealers or qualified electricians should attempt

to repair this unit. Improper repair COULD cause an electrical shock

hazard.

Toujours s’assurer que la pompe est

débranchée avant de procéder à un entretien, une réparation ou de

retirer tous composants. Cette pompe est assemblée en usine utilisant

de l’équipement spécial, par conséquent seuls des concessionnaires

ou des électriciens qualifiés peuvent essayer de réparer cet appareil.

Une réparation inadéquate POURRAIT provoquer un risque de choc

électrique.

1. No oiling is required for this pump.

The pump contains oil that may be under

pressure because of heat. Let the pump cool for a minimum of two

hours before servicing this unit.

La pompe contient de l’huile qui pourrait

être sous pression en raison de la chaleur. Laisser la pompe refroidir

pendant au moins deux heures avant tout entretien ou réparation de cet

appareil.

Disassembly of the motor prior to expiration

of warranty will void the warranty. It might also cause internal leakage

and damage to the unit. If repairs are re quired, return the pump to the

dealer from whom it was purchased or contact local electrical repair

shop station.

2. Inlet should be kept clean and free of all foreign objects and debris.

This pump contains dielectrical motor oil for

lubrication and motor heat transfer. This oil CAN be harmful to the

environment. Check the state environmental laws before disposing of

this oil.

Cette pompe contient de l’huile à moteur

diélectrique pour la lubrification et le transfert de chaleur du moteur.

Cette huile PEUT être dangereuse pour l’environnement. Vérifier les lois

environnementales de l’État avant de la mettre au rebut.

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual

Operating Instructions and Parts Manual

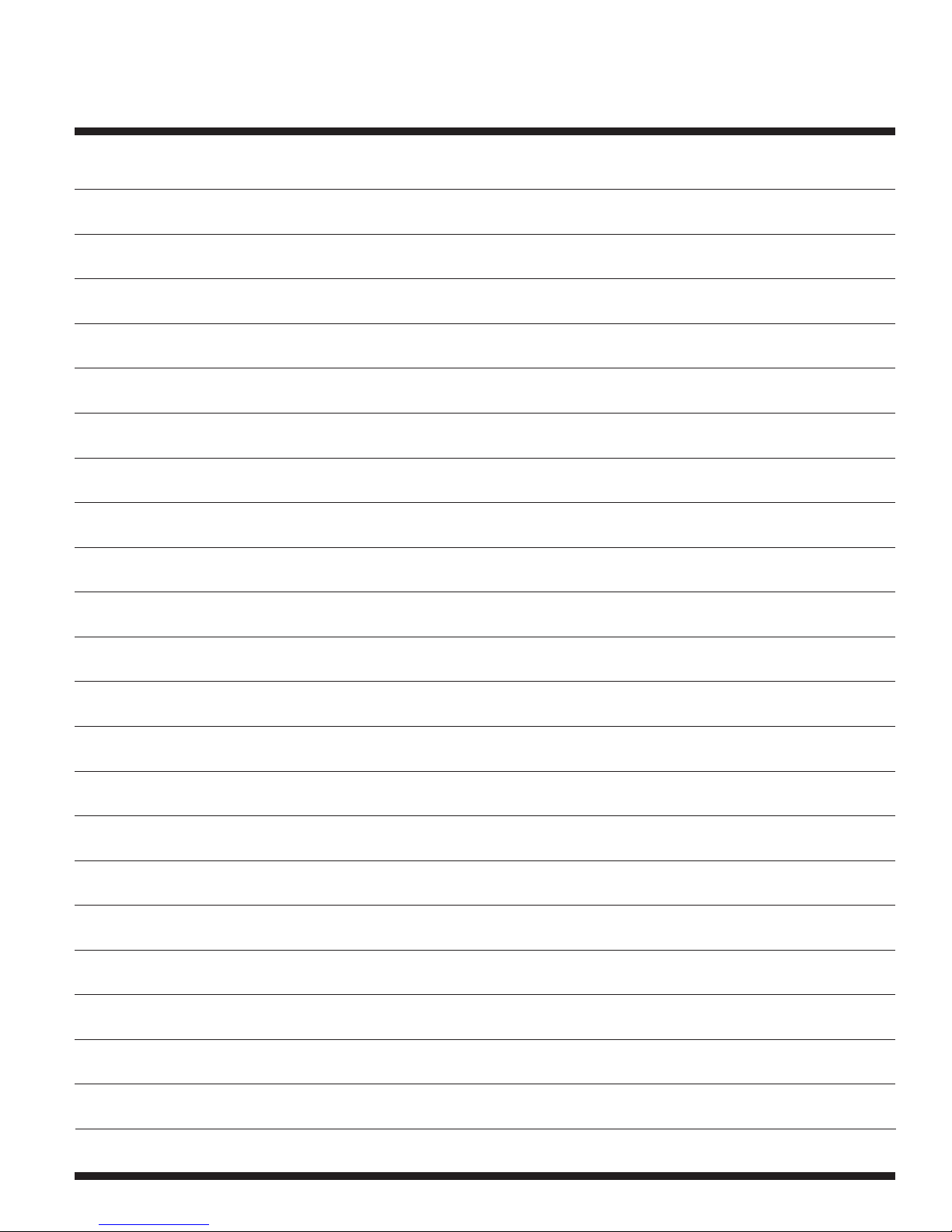

TROUBLESHOOTING CHART

Symptoms Possible Cause(s) Suggested Remedies

Pump will not

start or run

1. Blown fuse or tripped circuit breaker

2. Low supply voltage

3. Defective motor

4. Impeller obstrcuted

5. Not properly primed

1. If blown, replace with proper sized fuse or reset breaker

2. Contact an electrician

3. Replace pump

4. If impeller will not turn, remove base and remove debris

5. Reposition pump in at least 2-5/8 in. of water to properly

operate

Pump shuts off

and turns on

independently

of switch (trips

thermal overload

protection)

Pump operates

noisily or vibrates

excessively

Pump operates

but delivers little

or no water

1. Excessive water temperature

2. Pump has run dry or insufficient fluid

level for pump to prime

3. Low supply voltage

1. Worn bearings

2. Impeller obstructed

1. Low supply voltage

2. Impeller obstructed

3. Worn or defective pump parts or

plugged impeller

4. Pump not properly sized for

application

5. Air trapped in volute

1. Pump should not be used in water above 120°

2. Reposition pump in adequate water (pump uses water for

cooling)

3. Contact an electrician

1. Replace pump

2. Remove base, and clean impeller

1. Contact an electrician

2. Clean and check for tightness

3. Clean part if required, or replace pump

4. Recheck all sizing calculations to determine proper pump

size

5. Start and stop unit until air is not present in discharge

5a. Tilt pump on its side underwater and allow air to escape

from inlet

6

6

www.waynepumps.com

Page 7

Operating Instructions and Parts Manual

VIP Series

LIMITED WARRANTY

For one year for VIP models from the date of purchase, from an authorized dealer, Wayne Water Systems will repair or replace, at its option for the original purchaser,

any part or parts of its Multi-Use Pumps or Water Pumps (“Product”) found upon examination by Wayne Water Systems to be defective in materials or workmanship.

Please call Wayne Water Systems (800-237-0987) for warranty instructions. Be prepared to provide the model number and the serial number when exercising this

warranty. All transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper installation, improper maintenance,

or failure to operate in accordance with Wayne Water Systems’ written instructions.

THIS WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, OBLIGATIONS OR AGREEMENTS, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND ANY RIGHTS OR REMEDIES AGAINST ANY PERSON OR ENTITY UNDER THE UNIFORM

COMMERCIAL CODE OR OTHERWISE WITH RESPECT TO THE SALE OF THE PRODUCT. THE REMEDIES AND OBLIGATIONS STATED IN THIS WARRANTY ARE THE SOLE

AND EXCLUSIVE REMEDIES OF AND OBLIGATIONS TO THE OWNER FOR ANY AND ALL MATTERS ARISING WITH RESPECT TO OR IN ANY WAY CONNECTED WITH

THE PRODUCT, REGARDLESS OF THE SOURCE OR PROVIDER OF SUCH GOODS. IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, WARRANTY TORT

(INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL WAYNE WATER SYSTEMS OR ANY AFFILIATE BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a copy of the purchase receipt along

with the material or correspondence. Please call Wayne Water Systems (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO Wayne Water Systems. Use this form only to maintain your records.

MODEL NO._____________________ SERIAL NO._________________________ INSTALLATION DATE __________________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

7

Page 8

NOTES

8

www.waynepumps.com

Loading...

Loading...