Page 1

Operating Instructions and Parts Manual

T50S10-2, T50S10-4, T51S10-4,

T75S10-2, T75S10-4, T100S10-2

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Deep Well

Submersible Pumps

Description

This submersible pump is designed to

supply water at the required pressure with

high efficiency and a long service life. To

maximize pump life, care must be taken in

its installation and usage.

Unpacking

After unpacking the submersible pump,

carefully inspect for any damage that

may have occurred during transit. Check

for loose, missing or damaged parts.

Safety Guidelines

This manual contains information

that is very important to know

and understand. This information

is provided for SAFETY and to

PREVENT EQUIPMENT PROBLEMS. To

help recognize this information, observe

the following symbols.

Danger indicates an

imminently

hazardous situation which, if NOT

avoided, WILL result in death or serious

injury.

Warning indicates a

potentially

hazardous situation which, if NOT

avoided, COULD result in death or serious

injury.

Caution indicates a

potentially

hazardous situation which, if NOT

avoided, MAY result in minor or moderate

injury.

Notice indicates

important

information, that if NOT followed, MAY

cause damage to equipment.

NOTE: Information that requires special

attention.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product

contains chemicals,

including lead, known to the State of

California to cause birth defects and

other reproductive harm. Wash hands

after handling.

GENERAL SAFETY

1. Read the instruction manual

included with the product carefully.

Be thoroughly familiar with the

controls and the proper use of the

equipment.

2. Know the pump application,

limitations and potential hazards.

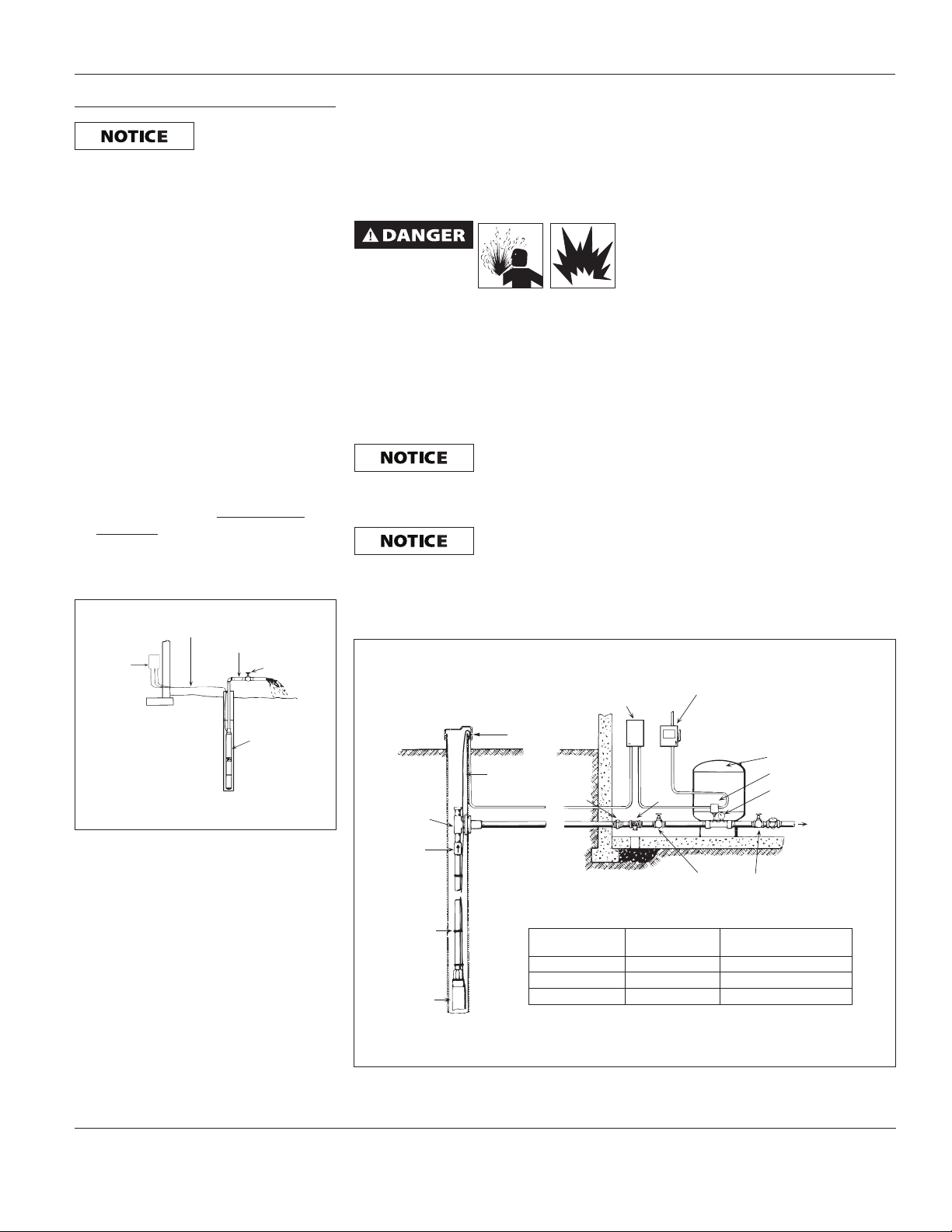

Do NOT use to

pump flammable

or explosive fluids such as gasoline,

fuel oil, kerosene, etc. Do NOT use in

explosive atmospheres. Pump SHOULD

only be used with liquids compatible

with pump component materials.

Failure to follow this warning can result

in personal injury and/or property

damage.

Disconnect power

and release all

pressure from the system before

attempting to install, service, relocate

or perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

3. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean, uncluttered

and properly lit.

c. Keep visitors at a safe distance from

work area.

4. Do NOT pump chemicals or corrosive

liquids. Pumping these liquids

shortens the life of the pumps seals

and moving parts and WILL void

warranty.

5. When installing pump, prevent

foreign matter from falling into

well, contaminating the water and

damaging internal mechanical

components.

6. Always test the water from the well

for purity before use. Check with

local health department for test

procedure.

7. Do NOT run the pump dry or

damage will occur and WILL void

warranty.

All wiring SHOULD

be performed by a

licensed or certified electrician.

8. For maximum safety, the unit should

be connected to a grounded circuit

equipped with a ground fault circuit

interrupter (GFCI) device.

9. Make sure the line voltage and

frequency of electrical current

supply agrees with the motor wiring.

10. Do NOT attempt repairs to the

electric motor. All repairs to the

motor must be completed at a

licensed or certified electrical motor

repair shop.

11. Avoid kinking electrical cord

and protect electrical cord from

sharp objects, hot surfaces,

oil and chemicals. Replace or

repair damaged or worn cords

immediately.

Risk of electric

shock! NEVER

connect the green wire (or green and

yellow wire) to a live terminal!

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.waynepumps.com

340601-001 5/11© 2011 WAYNE/Scott Fetzer Company.

Page 2

Operating Instructions and Parts Manual Deep Well Submersible Pump

General Safety

Information (Continued)

12. Use wire of adequate size to

minimize voltage drop at the motor.

13. Pipe joint compound can cause

cracking in plastics. Use only

plumbers seal tape when sealing

threaded joints in plastic pipe

or when connecting pipe to

thermoplastic pumps.

Do NOT handle

pump or pump

motor with wet hands, when standing

on a wet or damp surface or when

standing in water. Fatal electrical shock

COULD occur!

Pump motor is

equipped with an

automatic resetting thermal protector

and MAY restart unexpectedly. Protector

tripping is an indication of motor

overloading because of operating

pump at low heads (low discharge

restriction), excessively high or low

voltage, inadequate wiring, incorrect

motor connections, inadequate cooling

or defective motor or pump.

Pre-Installation

1. Inspect pump and motor for delivery

damage.

2. Before installing pump, remove

all fine sand particles and foreign

matter. See Initial Startup section (on

page 4) for more information.

3. Install pump at least 15-20 feet

below the lowest water level

reached with pump running (lowest

drawn-down water level), and at

least 5 feet above bottom of well.

To maximize performance, pump should

process only cold water that is clear and

free of entrained air.

Warranty is void if (1) system pumps

excessive sand resulting in early

pump wear, (2) water is corrosive, (3)

entrained gas or air causes reduced flow

and cavitation, or (4) pump operates

with discharge valve closed, resulting in

serious damage.

Electrical System

WIRING/GROUNDING

Hazardous voltage! The

electrical system in this

pump can cause electrical

shock and death. Permanently ground

pump, motor and control box before

connecting to electrical supply. Ground

pump and motor in accordance with all

codes and ordinances that apply. Use

copper grounding wire with a diameter

no less than wires carrying current to

motor.

1. Permanently ground pump, motor

and control box before connecting

power cable to power supply.

Connect ground wire to approved

ground first, and then connect to

equipment being installed.

2. Motor is supplied with copper

grounding wire. Splice wire to

copper conductor that matches wire

size shown in Table 3, on page 3. See

Wire Splicing under Installation, on

page 4.

Do NOT ground to

gas supply line.

Fire, explosion,

and death or serious injury COULD

result.

Fire and electrical

shock hazard! If

using a power

supply wire larger than No. 10 (5 mm2)

between pump and control box, run

wire to separate junction box. Connect

junction box to control box with a No.

10 (5 mm2) wire.

For more information, contact your

local code officials.

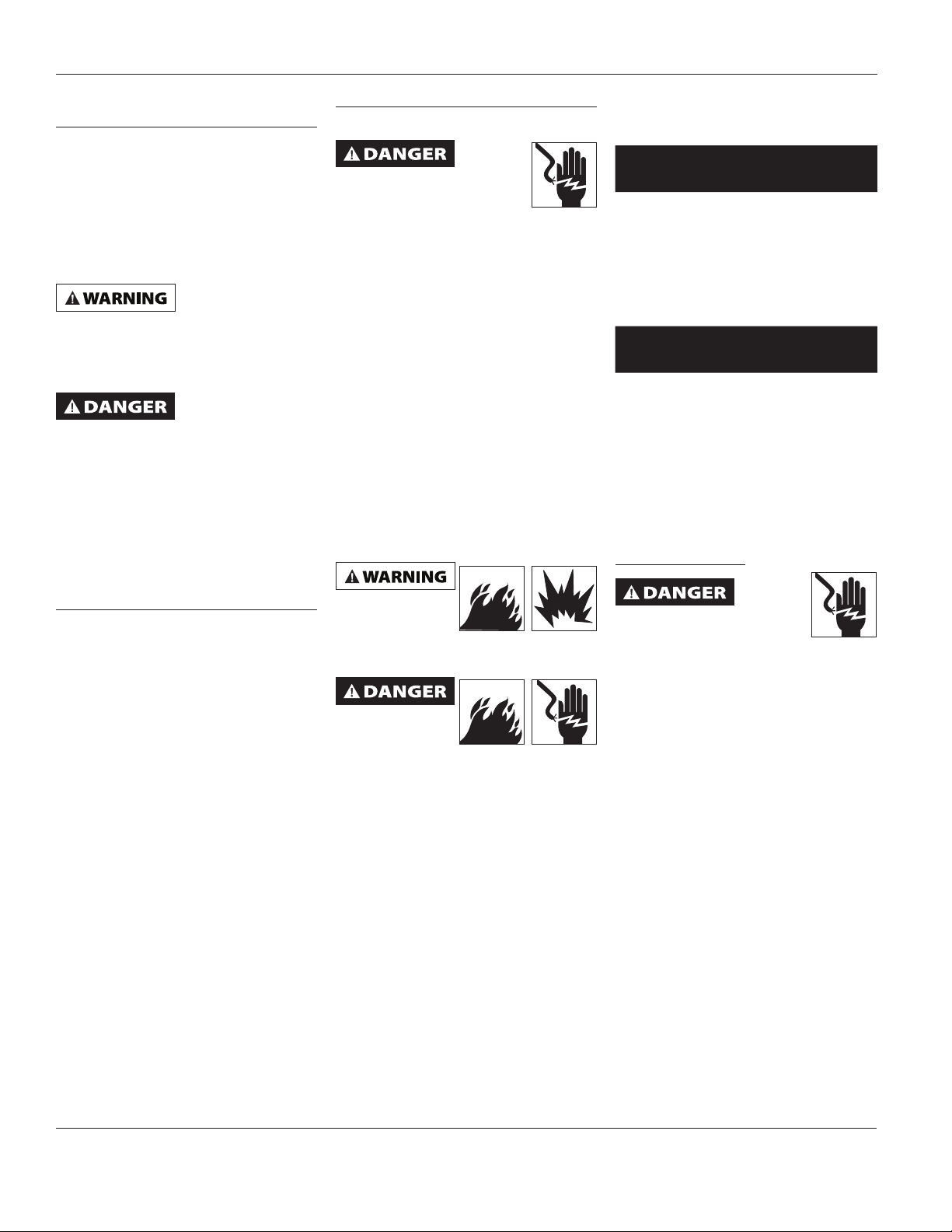

WIRING CONNECTIONS

All wiring must meet National Electrical

Code requirements, as well as local code

requirements.

Use only copper wiring for connections

to pump and control box.

To prevent wire overheating and

excessive voltage drop at motor, use

wire size at least as large as size shown

in Table 3 on page 3 (based on HP and

length of wire run).

NOTE: See Installation Wiring Diagrams

for typical wiring hookups and control

box identification.

Fuse Size

HP Volts Standard Dual Elem.

1/2 230 20 10

3/4 230 25 5

1 230 30 20

Table 1 - Recommended fusing data

for 60 Hz, single phase, 3-WIRE

submersible pump/motor

Fuse Size

HP Volts Standard Dual Elem.

1/2 230 20 10

3/4 230 25 5

1 230 30 20

Table 2 - Recommended fusing data

for 60 Hz, single phase, 2-WIRE

submersible pump/motor

WIRING INSTALLATION

Single Phase, 3 Wire

Hazardous voltage! The

electrical system in this pump

CAN cause electrical shock

and death. Permanently ground control

box, metal plumbing, and motor frame

in accordance with national and local

codes. Use copper grounding wire with

a diameter no less than wires carrying

current to motor.

1. At well head, connect grounding

wire to grounding terminal.

Grounding system must meet

all applicable national and

local electrical codes. For more

information, contact local code

officials.

2. Permanently close all unused

openings in this and other

equipment. Disconnect power

before working on or around control

box, pipes, cable, pump, or motor.

3. Install control box vertically on wall

with top side up.

NOTE: Three-wire pumps have three

power supply wires (Red/Black/Yellow)

and one ground wire (Green). When

operated without a control box, threewire pumps will not operate properly

and will likely cause motor to burn out.

www.waynepumps.com

2

Page 3

Operating Instructions and Parts Manual

Deep Well Submersible Pump

Cable Size

14

Volts HP

(2 mm

1/2 400

(121.9)

230 3/4 300

(91.4)

1 250

(76.2)

2

)

12

(3 mm2)

650

(198.1)

480

(146.3)

400

(121.9)

10

(5 mm2)8 (7 mm2)6 (13 mm2)4 (21 mm2)3 (25 mm2)2 (34 mm2)1 (41 mm2)0 (50 mm2)

1020

(310.9)

760

(231.6)

630

(192)

1610

(490.7)

1200

(365.8)

990

(301.8)

2510

(765)

1870

(570)

1540

(469.4)

3880

(1182.6)

2890

(880.9)

2380

(725.4)

4810

(1466.1)

3580

(1091.2)

2960

(902.2)

5880

(1792.2)

4370

(1332)

3610

(1100.3)

7170

(2185.4)

5330

(1624.6)

4410

(1344.2)

8720

(2657.9)

6470

(1972.1)

5360

(1633.7)

NOTE: Specified maximum wire lengths are valid with motor voltage greater than or equal to 95% of service entrance

voltage and motor running at maximum nameplate amperes. If service entrance voltage is at least motor nameplate voltage

under normal load conditions, 50% additional length is permissible for all sizes shown.

Table 3 - Power supply wire (cable) length in feet (m)

1 phase, 2 or 3 wire cable, 60 Hz (copper wire size—service to motor)

Electrical System

(Continued)

Use only control

box specified

for your pump. Make sure motor and

control box match (see Table 4, on page

3). Failure to do so WILL void warranty.

4. Install circuit protection and

component protection in compliance

National Electrical Code, Part 1.

Consult with appropriate code

HP Voltage Wires

1/2 230 3 T50S10-2 16965-002

1/2 230 2 T50S10-2 None

1/2 115 2 T51S10-4 None

3/4 230 3 T75S10-2 16966-002

3/4 230 2 T75S10-4 None

1 230 3 T100S10-2 16967-002

Table 4 - Control box chart

Pump Model

No.

Control Box

No.

officials for more information on

how to do this.

If main overload trips, look for the

FUSED

SWITCH

GROUND

L1 M1

M2L2

RED

BLACK

PRESSURE

SWITCH

following:

1. Shorted capacitor

2. Voltage problems

3. Overloaded or locked pump.

Single Phase, 2 Wire

Two-wire pumps have two power supply

wires and one ground wire (Green). A

control box is not required. See Figure

1b for correct hookup for 230 volt

2-wire motors only.

115V or

230V LINE

GROUND

FUSED

DISCONNECT

SWITCH

L1 M1

M2L2

RED

YELLOW

BLACK

CONTROL

L1L2R Y B

PRESSURE

SWITCH

TO LINE

BOX

DISCONNECT

WELL

CASING

Follow color coding when

connecting control box wires.

(Yellow = Y, Red = R, Black = B)

Figure 1a - 3 wire, 1/2-1HP quick

disconnect box

GROUND

3

GROUND

WELL

CASING

Figure 1b - Single phase, 2 wire

connections

www.waynepumps.com

(GREEN)

Page 4

Operating Instructions and Parts Manual Deep Well Submersible Pump

Installation

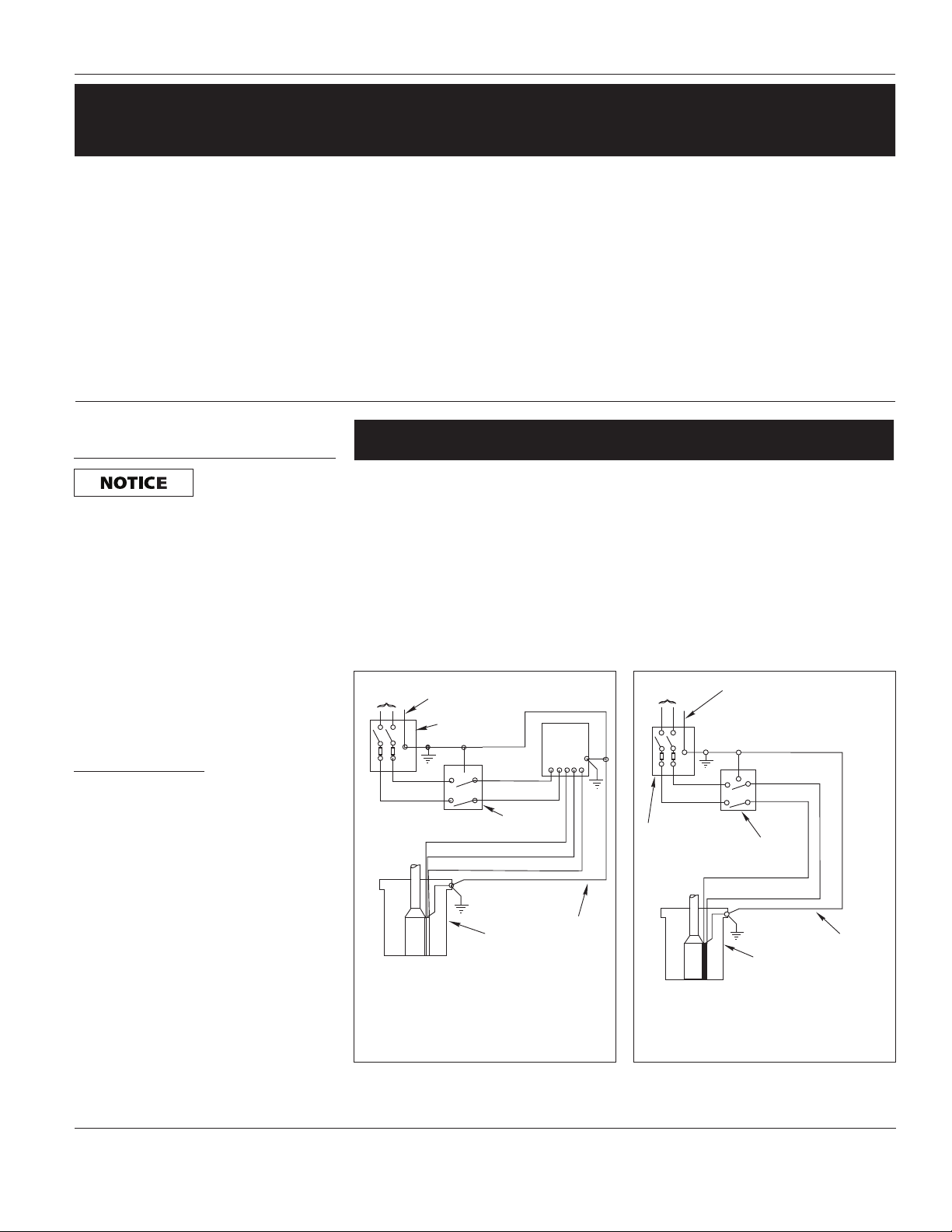

WIRE SPLICING

Splice wire to motor leads. Use only

copper wire for connections to pump/

motor assembly and control box.

Heat shrink splice instructions (wire sizes

No. 14, 12 and 10 AWG [2, 3 and 5mm

1. Remove 3/8" (9.5 mm) insulation

from ends of motor leads and power

supply wires.

2. Place heat shrink tubing over motor

leads. Position tubing between

power supply and motor.

3. Match colors of supply wires with

colors of motor leads.

4. Insert supply wire and lead ends

into butt connector and crimp (see

Figures 2 and 3). Match colors of

supply wires with colors of motor

leads. Check lead connections by

gently pulling on them.

1/2 inch

(12.7mm)

Figure 2

Figure 3

BUTT CONNECTOR

INDENT HERE

5. Center tubing over butt connector

and apply heat evenly with torch

(match or lighter will not supply

enough heat).

Keep torch moving.

Too much

concentrated heat MAY damage tubing

(see Figure 4).

CONNECTOR

HEAT SHRINK TUBING

Figure 4

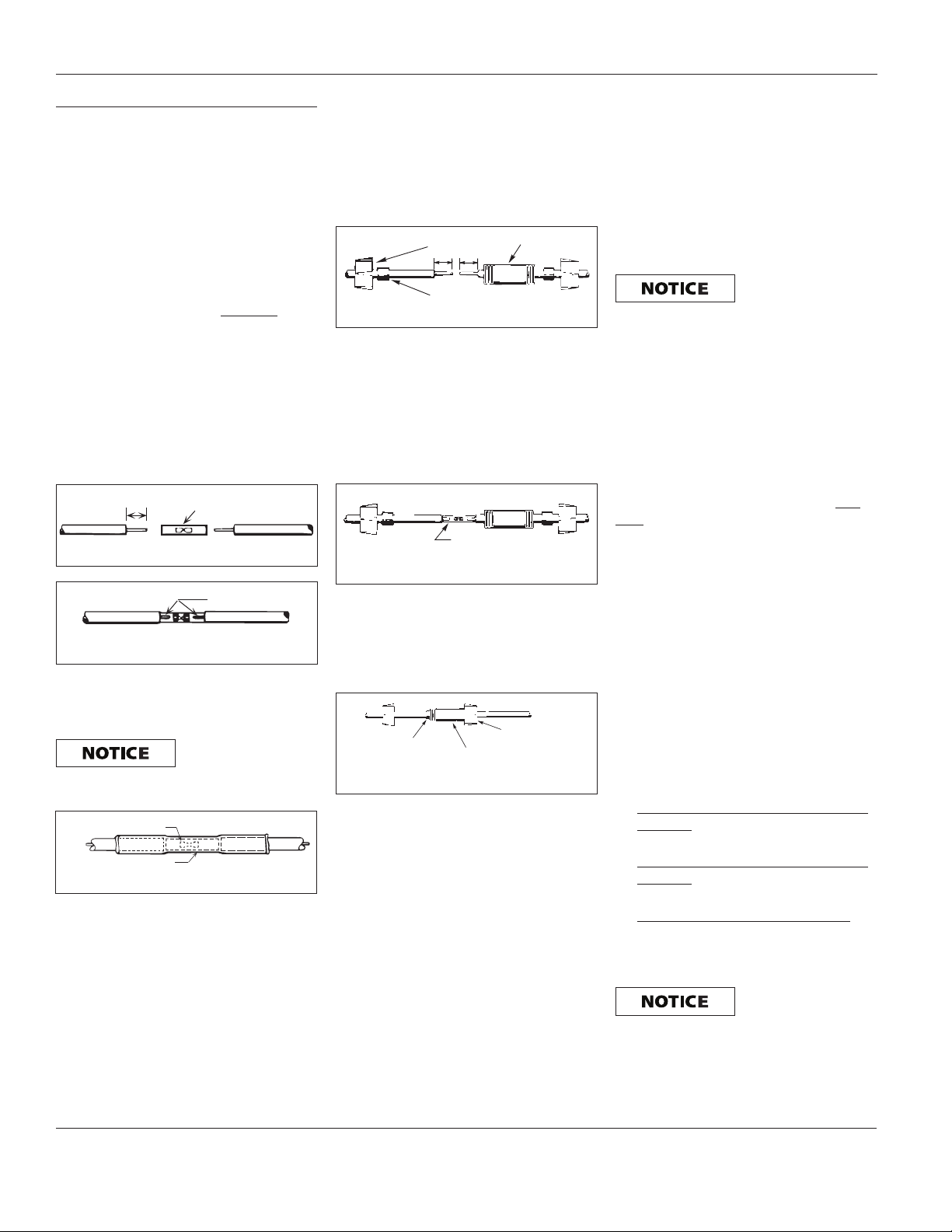

Instructions for mechanical splice kit

with plastic insulators (wire sizes 14, 12,

and 10 AWG [2, 3, and 5 mm

2

]):

1. With wire cutting tool, cut off motor

leads. Stagger lead and wire length

so that second lead is 4" (101.6 mm)

longer than first lead and third lead

is 4" (101.6 mm) longer than second.

2. With wire cutting tool, cut off wire

ends. Match colors and lengths of

wires between power supply and

motor.

2

]):

3. With wire stripping tool, trim

insulation back 1/2" (12.7 mm) from

power supply wire and motor lead

ends.

4. Unscrew plastic caps from insulators.

Place a cap and neoprene gasket

sleeve on each wire to be spliced

(see Figure 5).

1"

2

INSULATOR BODY

END CAP

1"

2

12.7mm 12.7mm

GASKET

Figure 5 - Ready to splice

5. Slide insulator body onto one wire

end (Figure 5).

6. Insert wire end into butt connector

and crimp. Match wire colors

between power supply and

motor (see Figure 6). Check lead

connections by gently pulling on

them.

BUTT CONNECTOR OR

CRIMP OR SOLDER

Figure 6 - Wire ends spliced

7. Center insulator body over splice

and slide gasket sleeves into body as

far as they will go. Screw caps onto

insulator body (Figure 7) and tighten

by hand for a strong, waterproof

splice.

GASKET SLEEVE IN PLACE

CENTERED OVER SPLICE

Figure 7 - Tighten end caps

CAP SCREWED ON

INSULATOR BODY

POWER SUPPLY WIRE INSTALLATION

1. To test pump, connect it to proper

power supply for a short amount

of time (no more than 30 seconds).

Power supply frequency and

voltage must be within 10% of

frequency and voltage shown on

product nameplate.

2. Fasten power supply wire leads to

pump discharge block. Then fasten

leads to plastic pipe within 6"

(150 mm) of discharge block. Use

centering guides to prevent wire

and pipe from rubbing well casing.

3. Connect copper grounding wire

to motor bracket. Grounding wire

must have a diameter at least that

of wires supplying current to motor.

Consult National Electrical Code, as

well as local code, for grounding

information and safety guidelines.

4. Use only submersible power

supply wires supplied by pump

manufacturer. When lowering

pump into well, secure supply wires

to discharge pipe at 10 ft. (3,1 m)

intervals with #33 electrical tape.

Take care not to damage pump

wires.

To avoid dropping

pump down well or

damaging wires or splices, NEVER allow

pump wires to support weight of pump.

PUMP INSTALLATION

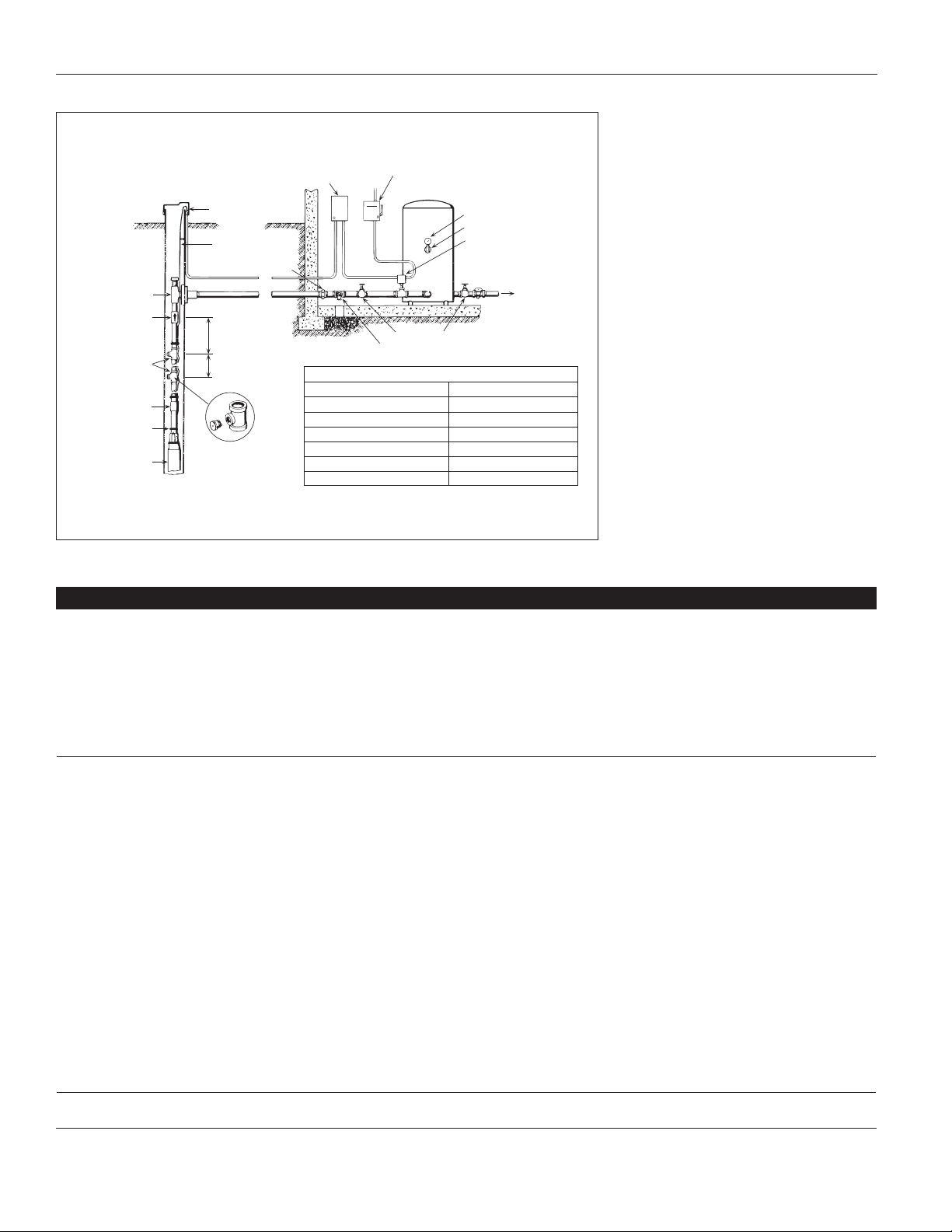

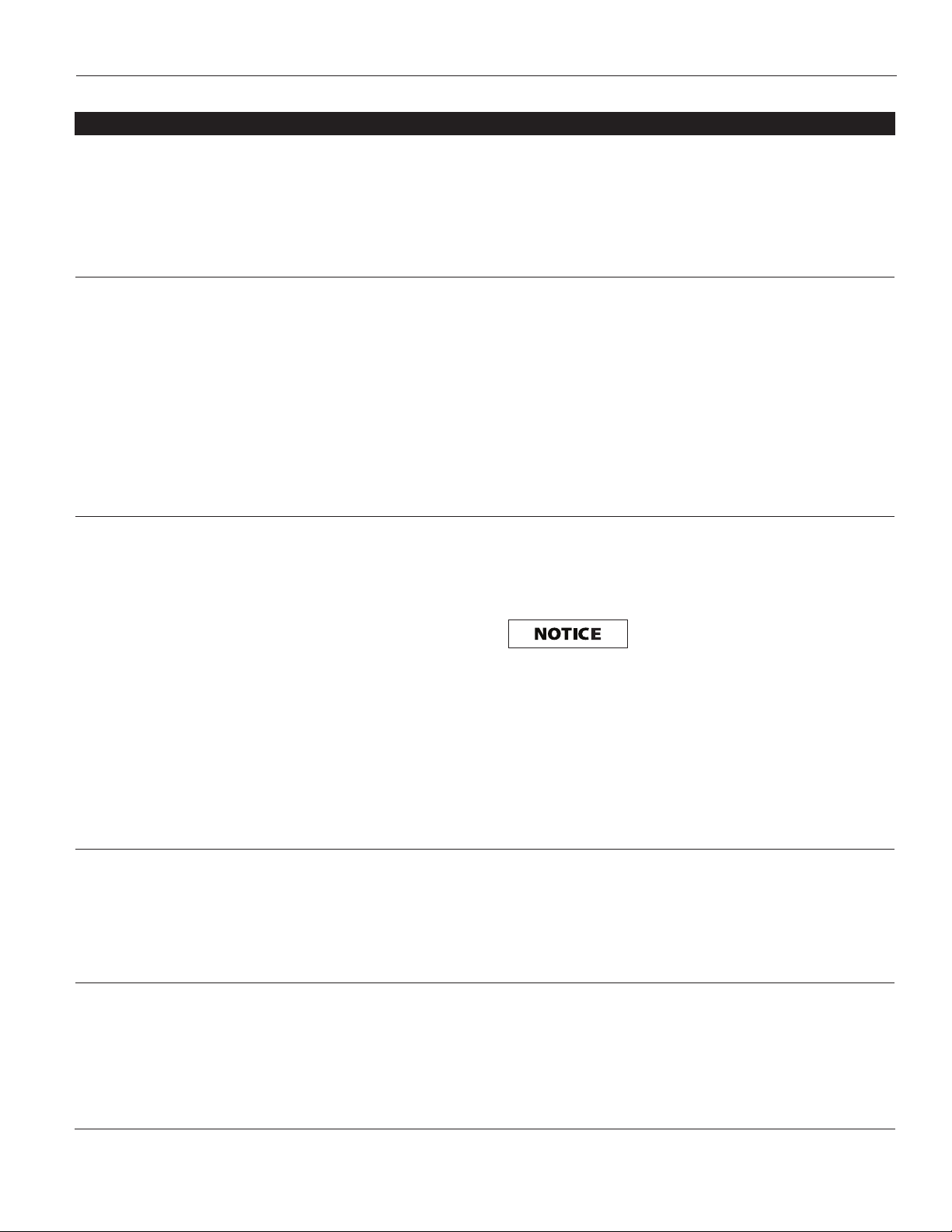

1. If standard air-over-water pressure

tank is used, install two bleeder

orifices about 2 ft. (0.6 m) apart

as shown in Figure 10, on page 6.

Orifices will automatically charge the

tank with air. See Figure 10 to help

determine orifice location.

NOTE: If precharged tank is used, DO

NOT install bleeder orifices. If pump

and pre-charged tank are replacing a

standard tank system, remove bleeder

orifices before installing pump in well.

2. To prevent losing pump down the

well, connect safety rope strong

enough to support pump and drop

pipe (minimum 5/16" [8 mm] twisted

polypropylene or pronila rope) to

eyelet on pump discharge. Tie off

other end of safety rope securely to

well seal, well cap or pitless adapter.

NOTE: Discharge outlet is 1-1/2" NPT

threaded.

3. Install piping based on these

guidelines:

For installations up to 100’ (30.5 m)

in depth, use 100 psi (689.5 kPa)

rated polyethylene plastic pipe.

For installations up to 220’ (67.1 m)

in depth, use 160 psi (1103.2 kPa)

rated polyethylene plastic.

For depths beyond 220’ (67.1 m),

use galvanized steel pipe for the

entire drop pipe.

INITIAL STARTUP/NEW WELLS

NEVER operate

pump with

discharge valve completely closed. This

CAN cause significant pump damage

and WILL void the warranty.

www.waynepumps.com

4

Page 5

Operating Instructions and Parts Manual Deep Well Submersible Pump

Installation (Continued)

To prevent sand-

locking pump,

follow this procedure when starting

pump for the first time. Do NOT start

pump with discharge valve completely

open unless you have followed this

procedure first.

1. Connect a pipe elbow, a short length

of pipe, and a gate valve to pump

discharge (at well head).

2. Mount motor control box (for a

3-wire pump) or fused disconnect

switch (for a 2-wire pump) in a

permanently weatherproof place.

Make sure that controls will not be

subjected to extreme heat or excess

moisture.

3. Make sure controls are in OFF

position.

4. Connect motor leads and power

supply to motor control box or

magnetic starter (see Installation

Wiring Diagrams). Do NOT start

pump yet.

5. Open gate valve on discharge one-

third of the way. Start pump (see

Figure 8).

CONTROL

CENTER

OR

ELECTRICAL

DISCONNECT

BOX

TEMPORARY WIRING

TO CONTROL CENTER OR

ELECTRICAL DISCONNECT BOX

TEMPORARY PIPING

GATE VALVE

10. Install sanitary well seal or pitless

adapter unit, well unit, electrical

conduit and surface piping.

Installation must meet all applicable

national and local codes.

CONNECTING TO TANK/WATER

SYSTEM

High pressure and

tank explosion

hazard! To prevent

overpressurization, install a pressure

relief valve capable of releasing pump

air flow at 75 psi (517.1 kPa) when

using air-over-water pressure tank.

When using a pre-charged pressure

tank, install a pressure relief valve that

will release entire air flow at 100 psi

(690 kPa). Install this valve between

pump and tank.

Use only plumber's

seal tape on

threaded joints in plastic pipe. Pipe

joint compound CAN cause cracking in

plastics.

Do NOT allow pump

or piping system to

freeze. Failure to do so COULD result in

serious damage to equipment and WILL

void warranty.

CONTROL BOX

(3 WIRE MODELS)

CONNECTING TO TANK/WATER

SYSTEM

See Figure 9 for illustration of piping

connections to pre-charged pressure

tanks.

Before starting pump, check to make

sure that pre-charged air pressure is

2 psi (13.8 kPa) below pump cut-in

setting. (For example, in a tank used

with a 30-50 psi pressure switch, the

pre-charged pressure should be 28 psi

[193.1 kPa].) Adjust pressure by adding

or releasing air from the tire valve

located on top of tank. Check precharged pressure annually and adjust as

needed.

STANDARD TANK HOOKUP

See Figure 10, on page 6, for illustration

of piping connections to standard

pressure tank as well as distance

between air release ports and tank.

ELECTRICAL DISCONNECT

PUMP IN WELL

Figure 8 - Temporary connections

while cleaning well for startup

6. Let water run until it is clear. (To

check solids in water, fill a container

with water from pump. If any solids

settle after a minute, continue

running pump.)

7. Once water runs clear, open gate

valve two-thirds of the way and

repeat step 6.

8. Once water runs clear at this setting,

open gate valve completely and run

pump until water is completely clear.

9. Remove gate valve (see Figures 9

and 10).

VENTILATED

WELL CAP

SUBMERSIBLE

CABLE

PITLESS

ADAPTOR

CHECK

VALVE

TAPE CABLE

TO PIPE

PUMP

Figure 9 - Typical Pre-charged Tank Installation

UNION

CUT IN CUT OFF Pre-charge Tank

PSI (kPa) PSI (kPa) PSI (kPa)

20 (137.9) 40 (275.8) 18 (124.2)

30 (206.8) 50 (344.7) 28 (193.1)

40 (275.8) 60 (413.7) 38 (262)

RELIEF VALVE

PRE-CHARGED TANK

PRESSURE SWITCH

PRESSURE GAUGE

TO HOUSE

SERVICE

GATE VALVE

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual Deep Well Submersible Pump

Installation (Continued)

PITLESS

ADAPTOR

CHECK

VALVE

BLEEDER

ORFICE &

TEE

PIPE COUPLING

TAPE CABLE

TO PIPE

PUMP

VENTILATED

WELL CAP

SUBMERSIBLE

CABLE

SEE TABLE

2 ft.

(.6m)

CONTROL BOX

(3 WIRE MODELS)

UNION

CHECK VALVE DISTANCE TO TOP BLEEDER ORIFICE

TANK SIZE/GALLON (L) DISTANCE FT. (M)

ELECTRICAL DISCONNECT

PRESSURE GAUGE

AIR VOLUME CONTROL

PRESSURE SWITCH

GATE VALVE

RELIEF VALVE

42 (159) 2 (.6)

82 (310.4) 3 (.9)

120 (454.2) 5 (1.5)

220 (832.7) 5 (1.5)

315(1192.3) 10 (3)

525 (1987.1) 15 (4.6)

TO HOUSE

SERVICE

Figure 10 - Typical Standard Tank Installation

Troubleshooting Chart

Symptom(s) Possible Cause(s) Corrective Action(s)

Motor will not start, but fuses are

not blown

Fuses blow or overload protector

trips when motor starts

1. No voltage at control box or

1. Install correct fuse or time delay fuse.

disconnect switch

2. No voltage at pressure switch 2. Replace faulty pressure switch.

3. No voltage at control box 3. Rewire supply to control box.

4. Cable or splices bad 4. Consult licensed electrician or serviceperson.

5. Control box incorrectly wired 5. Reconnect control box correctly (see Wiring Installation

Diagrams on page 3).

1. Wrong size fuse or wrong size time

1. Install fuse or time delay fuse of correct size.

delay fuse

2. Wire size too small 2. Install wire of correct size.

3. Start capacitor defective, blown, or

3. Replace start capacitor. Replace start relay if defective.

wrong size

4. Low or high voltage 4. If voltage variation is greater than 10% of nameplate

rating, call power company or water supply to adjust

voltage.

5. Power supply wire leads not

properly connected to control box

5. Reconnect leads to match wiring diagram in control box

cover. Reconnect power supply wires so wire color code

matches motor lead color code.

6. Broken wire in control box 6. Disconnect power. Repair or replace defective wire.

7. Pump or motor stuck or binding 7. Make all possible aboveground checks. If necessary, pull

pump. If pump is locked, replace it. Clean well of all sand

and lime before reinstalling pump.

8. Wire and/or wire splices for power

supply or motor leads grounded,

8. Consult licensed electrician or qualified serviceperson. Do

not attempt to disassemble pump or motor.

shorted, or open

www.waynepumps.com

6

Page 7

Operating Instructions and Parts Manual Deep Well Submersible ump

Troubleshooting Chart

Symptom(s) Possible Cause(s) Corrective Action(s)

Fuses blow or overload protector

trips while motor is running

Pump starts too frequently 1. Leaks in system 1. Check tank connections with soapy water. Check plumbing for

1. Low or high voltage 1. If voltage variation is greater than 10% of nameplate rating,

call power company to adjust voltage.

2. Ambient temperature too high 2. Check temperature of control box. If necessary, move pump

out of direct sunlight.

3. Control box uses wrong voltage

or horsepower rating

4. Wire size too small 4. Install wire of correct size.

2. Defective pressure switch or

switch out of adjustment

3. Leak in check valve(s) 3. Replace if needed.

4. Waterlogged tank 4. Pre-charged tanks: Adjust air pressure to 2 psi (13.8 kPa) less

5. Leak in drop pipe 5. Raise drop pipe by increments of one length until water stands

6. Pressure switch is too far from

tank

3. Replace control box if voltage and horsepower ratings on

control box nameplate do not match those shown inside box

cover.

leaks. Ensure system is airtight and watertight.

2. Adjust or replace pressure switch.

than cut-in pressure. Replace bladder if needed.

Air-over-water tanks: Repair or replace tanks. Replace air

volume control (AVC) if needed.

in pipe. Replace pipe above that point.

6. Position switch within 1 foot (0.3 m) of tank.

Little or no water pumped 1. Check valve stuck or installed

backwards (standard tank only)

2. Low water level (water source) 2. Determine lowest water level in well while pump is running.

3. Low voltage 3. Install larger wire from meter to control box. Install larger wire

4. Clogged intake screen 4. Clean or replace if needed.

5. Check valve at pump discharge

stuck

6. Worn impellers and diffusers 6. Make sure that system is clear of debris and that pump is

7. Cracks or leaks in pipe 7. Replace as necessary

Air, milky, or tea colored water

discharge from faucets

1. Gas in well water 1. Remove air release ports and plug tees. Make sure that

2. Air volume control (AVC) not

working properly (standard tanks

only)

3. Recent Shocking Well 3. Pump out well to remove chemicals. Test for chemicals in

1. If stuck, free valve. If installed backwards, reverse valve

position.

Compare to pump depth setting. Lower pump further into

well, but at least 5 feet (1.5 m) from bottom of well. Throttle

pump discharge until discharge equals recovery rate of well.

Running pump while airlocked

CAN cause loss of prime and serious

damage to pump.

from control box to pump. Have power company raise supply

voltage if needed.

5. Free check valve.

running normally in clear water. If there are no obstructions in

system, replace pump.

plugged tees do not leak. If necessary, separate gas from air

before it enters pressure tank.

2. Make sure ports and ball check valves are clear. Replace air

volume control if needed.

water, to determine when flushing is complete.

www.waynepumps.com

7

Page 8

Operating Instructions and Parts Manual

Deep Well Submersible Pump

Limited Warranty

For one year from the date of purchase, WAYNE Water Systems (“WAYNE”) will repair or replace, at its option, for the original

purchaser any part or parts of Deep Well Submersible Pumps (“Product”) found upon examination by WAYNE to be defective

in materials or workmanship. Please call WAYNE (800-237-0987) for instructions or see your dealer. Be prepared to provide the

model and serial number when exercising this warranty. All transportation charges on Products or parts submitted for repair

or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Wayne’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES

WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall WAYNE or its

suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or

revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call WAYNE (800-237-0987) for return

authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO. _____________________ SERIAL NO. ________________________ INSTALLATION DATE _____________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

8

Page 9

Instructions D’utilisation et Manual de Pièces

T50S10-2, T50S10-4, T51S10-4,

T75S10-2, T75S10-4, T100S10-2

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut

résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Puits profond

pompes submersibles

Description

Cette pompe submersible est conçue

pour approvisionner de l'eau à la pression

requise avec une haute efficacité et une

longue durée de vie utile. Pour maximiser

la durée de vie utile de la pompe, des

précautions particulières doivent être prises

dans son installation et utilisation.

Déballage

Après avoir déballé la pompe

submersible, inspecter attentivement

pour tout signe de dommage en

transit. Vérifier pour des pièces dégagées,

endommagées, ou manquantes.

Directives de Sécurité

Ce manuel contient de l’information

très importante de connaître et de

savoir qui est fournie pour la SÉCURITÉ

et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger indique une

situation

hasardeuse imminente qui RÉSULTERA

en perte de vie ou blessures graves.

Avertissement

indique une

situation hasardeuse potentielle

qui PEUT résulter en perte de vie ou

blessures graves.

Attention indique

une situation

hasardeuse potentielle qui PEUT résulter

en blessures.

Avis indique de

l’information

importante pour ÉVITER le dommage de

l’équipement.

REMARQUE : Information qui exige

une attention spéciale.

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2011 WAYNE/Scott Fetzer Company. 340601-001 5/11

Généralités Sur La

Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques qui, de

l’avis de l’État de Californie, causent le

cancer et des anomalies congénitales ou

autres problèmes de reproduction. Lavezvous les mains après la manipulation.

GÉNÉRALITÉS SUR LA SÉCURITÉ

1. Lire attentivement le manuel

d'instructions inclus avec le produit.

Bien se familiariser avec les

commandes et la bonne utilisation

de l’équipement.

2. Connaître l'application, les limites et

les dangers possibles de la pompe.

Ne PAS pomper

les fluides explosifs

tels que l’essence, l’huile à chauffage,

le kérosène etc. NE PAS utiliser dans

des atmosphères explosives. La pompe

ne DEVRAIT être utilisée qu'avec

des liquides compatibles avec ses

matériaux composants. Le non-respect

de cet avertissement peut mener à des

blessures et/ou à des dommages à la

propriété.

Mettre hors tension

et ensuite dissiper

toute la pression du système avant

d’essayer d’installer, de réparer, de

déplacer ou de procéder à l’entretien.

Verrouiller le sectionneur de courant

en position ouverte. Étiqueter le

sectionneur de courant pour éviter

toute mise sous tension imprévue.

3. Sécurité personnelle :

a. Porter des lunettes de sécurité en

tout temps en travaillant avec les

pompes.

b. Garder l'aire de travail propre, en

ordre et bien éclairée.

c. Garder tous les visiteurs à distance

sans danger du secteur de travail.

9-Fr

4. NE PAS pomper des produits

chimiques ou des liquides corrosifs.

Le pompage de ces liquides réduit la

durée de vie des joints d'étanchéité

et des pièces mobiles de la pompe et

ANNULERA la garantie.

5. Lors de l'installation de la

pompe, éviter que des matières

étrangères ne tombent dans

le puits, contaminant l'eau et

endommageant les composants

mécaniques internes.

6. Toujours tester la pureté de l'eau

du puits avant toute utilisation.

Vérifier la procédure de test avec le

département local du ministère de la

santé.

7. NE PAS faire fonctionner la pompe

à sec pour éviter que des dommages

ne se produisent et ANNULENT la

garantie.

Toute installation

électrique DOIT être

effectuée par un électricien agréé ou

certifié.

8. Pour une sécurité maximale, l'unité

doit être connectée à un circuit

mis à la terre équipé d'un appareil

à disjoncteur de fuite à la terre

(DDFT).

9. S'assurer que la tension secteur et

la fréquence du courant électrique

d'alimentation sont corrects avec le

câblage du moteur.

10. NE PAS essayer de réparer le moteur

électrique. Toute réparation sur le

moteur doit être effectuée dans

un atelier de réparation de moteur

électrique agréé ou certifié.

11. Éviter le tortillement du cordon

d'alimentation et protéger le

cordon des objets tranchants, des

surfaces chaudes, de l'huile et des

produits chimiques. Remplacer ou

Page 10

Instructions D’utilisation et Manual de Pièces Puits profond pompes submersibles

Généralités Sur La

Sécurité (Suite)

réparer immédiatement les cordons

endommagés ou usés.

Risque de choc

électrique! NE

JAMAIS brancher le fil vert (ou vert et

jaune) à une borne sous tension!

12. Utiliser un fil de taille adéquate pour

réduire toute chute de tension au

moteur.

13.Les pâtes à joint peuvent causer des

fissures sur les plastiques. N'utiliser

que du ruban d'étanchéité de

plombier pour sceller les joints

filetés sur les tuyaux en plastique ou

raccorder les tuyaux à des pompes

thermoplastiques.

NE PAS manipuler

la pompe ou le

moteur de la pompe avec les mains

humides ou debout dans l'eau ou sur

une surface humide. On POURRAIT avoir

un choc électrique mortel.

Le moteur de la

pompe est

doté d'un protecteur thermique

á réinitialisation automatique et

POURRAIT redémarrer de manière

imprévue. Le déclenchement du

protecteur est une indication de

surcharge du moteur à cause d'une

utilisation de la pompe á faible

hauteur de chute (restriction de faible

décharge), d'une tension excessivement

haute ou basse, d'un câblage inadéquat,

d'un branchement incorrect du moteur,

d'un refroidissement inadéquat ou d'un

moteur ou d'une pompe défectueuse.

Pré-Installation

1. Inspecter la pompe et le moteur

pour des dommages de livraison.

2. Avant d'installer la pompe, enlever

les particules fines de sable et les

matières étrangères. Voir la section

Démarrage Initial (en page 13-Fr)

pour plus d'information.

3. Installer la pompe au moins à 4,6-

6,1 mètres (15-20 pi) en dessous

du niveau d'eau le plus bas atteint

par la pompe en marche (niveau

d'abaissement de l'eau le plus bas),

et au moins à 1,5 mètre au dessus du

fond du puits.

Pour maximiser sa performance, la

pompe ne devrait traiter que de l'eau

froide claire et sans air entraîné.

La garantie sera annulée si (1) le

système pompe du sable en quantité

excessive menant à une usure

prématurée de la pompe, (2) l'eau

est corrosive, (3) du gaz ou de l'air

entraîné provoque une réduction du

débit et une cavitation, ou (4) la pompe

opère la soupape de décharge fermée,

provoquant de graves dommages.

Système électrique

INSTALLATION ÉLECTRIQUE/MISE À

LA TERRE

Tension dangereuse! Le

système électrique de cette

pompe peut provoquer des

chocs électriques et la mort. Mettre en

permanence la pompe, le moteur et la

boîte de contrôle à la terre avant de

brancher le courant. Mettre la pompe et le

moteur à la terre conformément à tous les

codes et ordonnances en vigueur. Utiliser

un fil de terre en cuivre dont le diamètre

n'est pas inférieur aux fils conduisant du

courant au moteur.

1. Mettre en permanence la pompe, le

moteur et la boîte de contrôle à la

terre avant de brancher le courant.

Connecter d'abord le fil de terre à

une masse de terre approuvée, puis

brancher à l'équipement à installer.

2. Un fil de terre en cuivre est fourni

avec le moteur. Épisser le fil à un

conducteur en cuivre qui correspond

à la taille du fil comme indiqué dans

la Table 3, en page 3. Voir l'épissure

des fils dans Installation, en page

12-Fr.

NE PAS mettre à la

terre sur une ligne

d'alimentation en

gaz. un incendie, une explosion, et la mort

ou des blessures graves POURRAIENT en

résulter.

Risque d'incendie

et de choc

électrique! Si un

fil d'alimentation électrique plus grand

que le No. 10 (5 mm2) est utilisé entre

la pompe et la boîte de contrôle, faire

passer le fil à une boîte de jonction

séparée. Brancher la boîte de jonction

à la boîte de contrôle avec un fil 10 (5

mm2)

Pour plus de renseignement, veuillez

contacter les autorités chargées

d'appliquer les codes de votre localité.

BRANCHEMENTS ÉLECTRIQUES

Toutes les installations électriques

doivent être conformes aux exigences

du Code national de l'électricité ou

National Electrical Code.

N'utiliser que des câbles en cuivre pour

les branchements à la pompe et à la

boîte de contrôle.

Pour éviter un surchauffage des fils et

une chute de tension au moteur, utiliser

un fil dont la taille est aussi grande que

celle indiquée dans la Table 3 en page

11-Fr (basée sur la puissance du moteur

et la longueur du trajet du fil).

REMARQUE : Voir Diagrammes

de Câblage d'Installation pour les

branchements recommandés et

l'identification de la boîte de contrôle.

Dimension du fusible

Double

HP Volts Standard

élém.

1/2 230 20 10

3/4 230 25 5

1 230 30 20

Table 1 - Caractéristiques de fusible

recommandées pour une pompe/un

moteur SUBMERSIBLE À 3 fils de 60 Hz

monophasé(-e)

Dimension du fusible

Double

HP Volts Standard

élém.

1/2 230 20 10

3/4 230 25 5

1 230 30 20

Table 2 - Caractéristiques de fusible

recommandées pour une pompe/un

moteur submersible à 2 FILS DE 60 HZ

MONOPHASÉ(-E)

INSTALLATION ÉLECTRIQUE

Monophasée à 3 fils

Tension dangereuse! Le

système électrique de cette pompe PEUT

provoquer des chocs électriques et la

mort. Mettre en permanence la boîte

de contrôle, la tuyauterie en métal et le

châssis du moteur à la terre conformément

aux codes locaux et nationaux. Utiliser

un fil de terre en cuivre dont le diamètre

n'est pas inférieur aux fils conduisant du

courant au moteur.

1. À la bouche du puits, brancher

le fil de terre au borne de mise à

10-Fr

Page 11

Instructions D’utilisation et Manual de Pièces

Puits profond pompes submersibles

Taille du câble

14

Volts HP

(2 mm

1/2 400

(121.9)

230 3/4 300

(91.4)

1 250

(76.2)

2

)

12

(3 mm2)

650

(198.1)

480

(146.3)

400

(121.9)

10

(5 mm2)8 (7 mm2)6 (13 mm2)4 (21 mm2)3 (25 mm2)2 (34 mm2)1 (41 mm2)0 (50 mm2)

1020

(310.9)

760

(231.6)

630

(192)

1610

(490.7)

1200

(365.8)

990

(301.8)

2510

(765)

1870

(570)

1540

(469.4)

3880

(1182.6)

2890

(880.9)

2380

(725.4)

4810

(1466.1)

3580

(1091.2)

2960

(902.2)

5880

(1792.2)

4370

(1332)

3610

(1100.3)

7170

(2185.4)

5330

(1624.6)

4410

(1344.2)

8720

(2657.9)

6470

(1972.1)

5360

(1633.7)

REMARQUE : Les longueurs de fil maximales spécifiées sont valides avec une tension de moteur supérieure ou égale à

95% de la tension au tableau de distribution et avec le moteur tournant à l'ampérage maximum indiqué sur la plaque

signalétique. Si la tension au tableau de distribution est au moins égale à la tension indiquée sur la plaque signalétique du

moteur dans des conditions de charge normales, une longueur additionnelle de 50% est autorisée pour toutes les tailles

indiquées.

Table 3 - Longueur du fil d'alimentation électrique (câble) en mètre (pi)

Câble monophasé à 2 ou 3 fils, 60 Hz (taille du fil en cuivre—du tableau au moteur)

Système électrique

(Suite)

la terre. Le système de mise à la

terre doit être conforme à tous

les codes de l'électricité locaux et

nationaux en vigueur. Pour plus de

renseignement, veuillez contacter

les autorités chargées d'appliquer les

codes de votre localité.

2. Fermer définitivement toutes les

ouvertures non utilisées dans cet

Modèle

HP Tension Fils

pompe No.

1/2 230 3 T50S10-2 16965-002

1/2 230 2 T50S10-2 Aucune

1/2 115 2 T51S10-4 Aucune

3/4 230 3 T75S10-2 16966-002

3/4 230 2 T75S10-4 Aucune

1 230 3 T100S10-2 16967-002

Table 4 - Tableau de la boîte de contrôle

Boîte de

contrôle No.

équipement ainsi que dans les

autres. Couper le courant avant

d'effectuer des tâches sur la boîte

de contrôle, les tuyaux, les câbles, la

pompe, le moteur ou autour.

3. Fixer la boîte de contrôle

verticalement sur un mur, le dessus

vers le haut.

REMARQUE : Les pompes à trois fils

ont trois fils d'alimentation électrique

(Rouge/Noir/Jaune) et un fil de mise

à la terre (Vert). Si utilisé sans boîte

de contrôle, les pompes à trois fils ne

fonctionneront pas correctement et

provoqueront probablement le brûlage

du moteur.

N'utilisez qu'une

boîte de contrôle

spécifiée pour votre pompe. S'assurer

que le moteur et la boîte de contrôle

correspondent bien (voir Table 4, en

page 11-Fr) Le non-respect de cette

consigne ANNULERA la garantie.

4. Installer la protection du circuit et

des composants conformément au

LIGNE DE

115V ou 230V

contrôle. (Jaune = Y [Yellow], Rouge = R

Figure 1a - Boîtier de sectionnement

rapide à 3 fils de 1/2-1 HP

MASSE

SECTIONNEUR

À FUSIBLE

L1 M1

M2L2

PRESSOSTAT

ROUGE

JAUNE

NOIR

TUBAGE DE PUITS

Suivre le codage de couleur lors du

branchement des fils de la boîte de

[Red], Noir = B [Black])

BOÎTE DE

CONTRÔLE

L1L2R Y B

MASSE

VERS

MASSE

LIGNE

L1 M1

M2L2

SECTIONNEUR

À FUSIBLE

Figure 1b - Monophasé à 2 fils

Branchements

PRESSOSTAT

ROUGE

NOIR

TUBAGE

DE PUITS

MASSE (VERT)

Code de l'électricité national ou

National Electrical Code, Partie 1.

11-Fr

Page 12

Instructions D’utilisation et Manual de Pièces Puits profond pompes submersibles

Système électrique

(Suite)

Consulter les autorités compétentes

chargées d'appliquer les codes

pour plus de renseignement sur la

manière de procéder.

Si une surcharge du conducteur

principal est déclenchée, rechercher les

causes possibles suivantes :

1. Condensateur court-circuité

2. Problèmes de tension

3. Pompe surchargée ou verrouillée.

Monophasée à 2 fils

Les pompes à deux fils ont deux fils

d'alimentation électrique et un fil de

mise à la terre (Vert). Une boîte de

contrôle n'est pas requise. Voir Figure

1b pour le branchement correct d'un

moteur à 2 fils 230V seulement.

Installation

ÉPISSURE DE FIL

Épisser le fil aux fils du moteur.

N'utiliser que du fil en cuivre pour

les branchements à l'assemblage de

pompe/moteur et à la boîte de contrôle.

Instructions pour une épissure

thermorétrécissante (tailles de fil No.

14, 12 et 10 AWG [2, 3 et 5 mm

1. Enlever l'isolant de 9,5 mm (3/8 po)

des extrémités des fils du moteur et

d'alimentation électrique.

2. Placer la gaine thermorétrécissable

sur les fils du moteur. Positionner la

gaine entre l'alimentation électrique

et le moteur.

3. Assortir les couleurs des fils

d'alimentation à celles des fils du

moteur.

4. Insérer le fil d'alimentation et les

extrémités des fils du moteur dans le

connecteur de bout, puis sertir (voir

Figures 2 et 3). Assortir les couleurs

des fils d'alimentation à celles des

fils du moteur. Vérifier la connexion

des fils en les tirant doucement.

1/2 po

(12.7mm)

Figure 2

Figure 3

CONNECTEUR DE BOUT

2

]):

ENFONCER ICI

5. Centrer la gaine sur le connecteur

de bout, puis y appliquer de la

chaleur de manière uniforme avec

un chalumeau (une allumette ou un

briquet ne fournit pas une chaleur

suffisante).

Ne pas arrêter de

remuer le

chalumeau. De la chaleur concentrée en

excès PEUT endommager la gaine (voir

Figure 4).

CONNECTEUR

GAINE THERMORÉTRÉCISSABLE

Figure 4

Instructions pour la trousse d'épissure

mécanique avec des isolants en

plastiques (tailles de fil No. 14, 12 et 10

AWG [2, 3 et 5 mm

2

]):

1. Couper les fils du moteur avec un

outil coupe-fils. Décaler la longueur

des fils du moteur et d'alimentation

de manière à ce que le second fil soit

de 101,6 mm (4 po) plus long que le

premier et le troisième de 101,6 mm

(4 po) plus long que le second.

2. Couper les extrémités des fils avec

un outil coupe-fils. Assortir les

couleurs et la longueur des fils

entre l'alimentation électrique et le

moteur.

3. Avec un dénudeur de fil, raccourcir

l'isolant de 12,7 mm (1/2 po) par

rapport aux extrémités des fils

d'alimentation électrique et du

moteur.

4. Dévisser les capuchons en plastique

des isolants. Mettre un capuchon et

un manchon de joint d'étanchéité

néoprène sur chaque fil à épisser

(voir Figure 5).

BOUCHON

D’EXTRÉMITÉ

1"

2

12.7mm 12.7mm

Figure 5 - Prêt à épisser

JOINT D'ÉTANCHÉITÉ

1"

2

CORPS DE L'ISOLANT

5. Faire glisser le corps de l'isolant sur

l'extrémité de l'un des fils (Figure 5).

6. Insérer l'extrémité du fil dans le

connecteur de bout, puis sertir.

Assortir les couleurs des fils entre

l'alimentation électrique et le

moteur (voir Figure 6). Vérifier

la connexion des fils en les tirant

doucement.

7. Centrer le corps de l'isolant sur

l'épissure, puis faire glisser les

EMBOUTIR OU SERTIR

OU SOUDER

Figure 6 - Les extrémités des fils

épissées

manchons de joint d'étanchéité

sur tout le corps aussi loin qu'ils le

peuvent. Visser les capuchons sur

le corps de l'isolant (Figure 7), puis

serrer à la main pour avoir une

épissure solide et étanche.

MANCHON DE JOINT

D'ÉTANCHÉITÉ

EN PLACE

Figure 7 - Resserrer les bouchons

d'extrémité

BOUCHON RESSERRÉ

CORPS DE L'ISOLANT

CENTRÉ SUR L'ÉPISSURE

INSTALLATION DU FIL

D'ALIMENTATION ÉLECTRIQUE

1. Pour tester la pompe, la brancher à

une source d'alimentation électrique

pendant une courte durée (pas plus

de 30 secondes). La fréquence

et la tension de l'alimentation

électrique ne doivent pas

dépasser 10% de la fréquence

et la tension indiquées sur la

plaque signalétique du produit.

2. Attacher les fils d'alimentation

électrique au bloc de décharge de

la pompe. Puis attacher les fils au

tuyau en plastique à moins de 150

mm (6 po) du bloc de décharge.

Utiliser des guides de centrage pour

éviter que le fil et le tuyau ne se

frottent contre le tubage du puits.

3. Connecter le fil de terre en cuivre

au support du moteur. Le fil de terre

doit avoir un diamètre au moins égal

à celui des fils conduisant du courant

au moteur. Consulter le Code

d'électricité national ou National

Electrical Code, ainsi que le code

local, pour les informations de mise

à la terre et les directives de sécurité.

4. N'utiliser que des fils d'alimentation

électrique submersibles fournis

par le fabricant de la pompe. Lors

de l'abaissement de la pompe

dans le puits, bien fixer les fils

d'alimentation au tuyau de

décharge à un intervalle de 3,1

m (10 pi) avec un ruban adhésif

d'électricité No. 33. Faire attention

de ne pas endommager les fils

de la pompe.

12-Fr

Page 13

Instructions D’utilisation et Manual de Pièces Puits profond pompes submersibles

Installation (Suite)

Pour éviter de faire

tomber la pompe

dans le puits ou d'endommager les fils

ou les épissures, NE JAMAIS laisser les

fils supporter le poids de la pompe.

INSTALLATION DE POMPE

1. Si un réservoir hydropneumatique

standard est utilisé, installer deux

orifices de purge à une distance de

0,6 m. (2 pi) l'un de l'autre comme

indiquée sur la Figure 10, en page

14-Fr. Ces orifices chargeront

automatiquement le réservoir d'air.

Voir Figure 10 pour une illustration

de l'emplacement des orifices.

REMARQUE : Si un réservoir chargé

d'avance est utilisé, NE PAS installer

d'orifices de purge. Si une pompe et un

réservoir chargé d'avance remplacent

un système à réservoir standard, enlever

les orifices de purge avant d'installer la

pompe dans le puits.

2. Pour éviter de perdre la pompe

dans le puits, y attacher une corde

de sécurité suffisamment solide

pour supporter la pompe, puis faire

descendre le tuyau (corde tordue en

polypropylène ou Pronila de 8 mm

[5/16 po] minimum) jusqu'à l'œillet

sur le bloc de décharge de la pompe.

Nouer l'autre extrémité de la corde

de sécurité au dispositif d'étanchéité

du puits, au couvercle du puits ou à

l'adaptateur coulisseau.

REMARQUE : : La sortie de décharge

est de 38,1 mm (1-1/2 po) filetée.

3. Installer la tuyauterie à partir de ces

directives :

Pour des installations allant jusqu'à

30,5 m (100 pi) de profondeur,

utiliser un tuyau en plastique

polythène d'une pression nominale

de 100 psi (689,5 kPa).

Pour des installations allant jusqu'à

67,1 m (220 pi) de profondeur,

utiliser un tuyau en plastique

polythène d'une pression nominale

de 160 psi (1103,2 kPa).

Pour des profondeurs allant au-delà

de 67,1 m (220 pi), utiliser un tuyau

en acier galvanisé pour toute la

tuyauterie à chute.

DÉMARRAGE INITIAL/NOUVEAUX

PUITS

NE JAMAIS FAIRE

fonctionner la

pompe avec la soupape de décharge

entièrement fermée. Cela PEUT

provoquer des dommages importants à

la pompe et ANNULERA la garantie.

Pour éviter que

la pompe ne se

coince à cause du sable, suivre la

procédure suivante lors du premier

démarrage de la pompe. NE PAS

démarrer la pompe avec la soupape de

décharge entièrement ouverte à moins

d'avoir d'abord suivi la procédure

suivante.

1. Raccorder un coude pour tuyau, un

petit bout de tuyau, et une vanne à

obturateur au bloc de décharge de

la pompe (à la bouche du puits).

2. Fixer la boîte de contrôle du

moteur (pour une pompe à 3

fils) ou le sectionneur à fusible

(pour une pompe à 2 fils) dans un

lieu constamment imperméable.

S'assurer que les contrôles ne sont

pas soumis à une chaleur extrême ou

une humidité excessive.

3. S'assurer que les contrôles sont en

position d'arrêt ("OFF").

4. Brancher les fils du moteur et

l'alimentation électrique à la

boîte de contrôle du moteur

BOÎTE DE CONTRÔLE

(MODÈLES À 3 FILS)

COUVERCLE DE

PUITS VENTILÉ

CÂBLE

SUBMERSIBLE

ADAPTATEUR

COULISSEAU

CLAPET DE

NON-RETOURCHECK

ATTACHER LE

CÂBLE AUX

TUYAUX

POMPE

RACCORD UNION

ENCLENCHEMENT

PSI (kPa)

20 (137.9) 40 (275.8) 18 (124.2)

30 (206.8) 50 (344.7) 28 (193.1)

40 (275.8) 60 (413.7) 38 (262)

ou à un démarreur magnétique

(voir Diagrammes de Câblage

d'Installation). NE PAS encore

démarrer la pompe.

5. Ouvrir la vanne à obturateur sur

le bloc de décharge à un tiers de

parcours. Démarrer la pompe (voir

Figure 8).

BRANCHEMENT TEMPORAIRE

AU CENTRE DE CONTRÔLE

OU AU BOÎTIER DE

CENTRE DE

CONTRÔLE OU

BOÎTIER DE

SECTIONNEMENT

ÉLECTRIQUE

Figure 8 - Branchements temporaires

pendant le nettoyage du puits pour le

démarrage

SECTIONNEMENT ÉLECTRIQUE

TUYAUTERIE TEMPORAIRE

VANNE À OBTURATEUR

POMPE DANS LE PUITS

6. Laisser couler l'eau jusqu'à ce qu'elle

devienne claire. (Pour vérifier la

présence de solides dans l'eau,

remplir un récipient d'eau de la

pompe. Si un dépôt de solides se

forme après une minute, continuer à

faire marcher la pompe.)

7. Une fois que l'eau est claire, ouvrir la

vanne à obturateur à deux tiers de

parcours, puis répéter l'étape 6.

SECTIONNEUR ÉLECTRIQUE

RÉSERVOIR CHARGÉ

D'AVANCE

PRESSOSTAT

RELIEF VALVE

VANNE À OBTURATEUR

COUPURE

PSI (kPa)

Réservoir chargé d'avance

MANOMÈTRE

VERS

DISTRIBUTION

RÉSIDENTIELLE

PSI (kPa)

Figure 9 - Installation typique d'un réservoir chargé d'avance

13-Fr

Page 14

Instructions D’utilisation et Manual de Pièces Puits profond pompes submersibles

Installation (Suite)

8. Une fois que l'eau est claire à ce

stade, ouvrir entièrement la vanne

à obturateur, puis faire marcher la

pompe jusqu'à ce que l'eau devienne

complètement claire.

9. Enlevez la vanne à obturateur (voir

Figures 9 et 10).

10. Installer le dispositif d'étanchéité

hygiénique de puits ou l'adaptateur

coulisseau, les éléments du puits, les

conduits électriques et la tuyauterie

en surface. L'installation doit être

conforme à tous les codes locaux et

nationaux en vigueur.

RACCORDEMENT À UN RÉSERVOIR/

UN AQUEDUC

Risque

d'explosion du

réservoir due à

un excès de pression! Pour éviter une

surpression, installer une soupape

de décharge de pression capable de

libérer le débit d'air à 75 psi (517,1

kPa) si un réservoir hydropneumatique

est utilisé. Si un réservoir de pression

chargé d'avance est utilisé, installer une

soupape de décharge de pression qui

libèrera tout le débit d'air à 100 psi (690

kPa). Installer cette soupape entre la

pompe et le réservoir.

N'utiliser que du

ruban d'étanchéité

de plombier sur les joints filetés sur les

tuyaux en plastique. Les pâtes à joint

PEUVENT causer des fissures sur les

plastiques.

Ne PAS laisser la

pompe ou la

tuyauterie geler. Le non-respect de cette

consigne POURRAIT mener à de graves

dommages à l'équipement et ANNULERA

la garantie.

ADAPTATEUR

COULISSEAU

CLAPET DE

NON-RETOUR

ORIFICE DE

PURGE ET TÉ

RACCORD DE

TUYAUTERIE

ATTACHER LE

CÂBLE AUX

TUYAUX

POMPE

(.6m)

Figure 10 - Installation typique d'un réservoir standard

RACCORDEMENT À UN RÉSERVOIR/

UN AQUEDUC

Voir Figure 9 pour une illustration du

raccordement de la tuyauterie à des

réservoirs de pression chargés d'avance.

Avant de démarrer la pompe, vérifier

pour s'assurer que la pression de

l'air chargé d'avance est de 2 psi

(13,8 kPa) en dessous des réglages

d'enclenchement de la pompe. (Par

exemple, dans un réservoir utilisé avec

un pressostat à 30-50 psi, la pression de

l'air chargé d'avance devrait être de 28

psi [193,1 kPa].) Ajuster la pression en

chargeant ou libérant de l'air à travers

la valve de pneu au-dessus du réservoir.

Vérifier annuellement la pression de

l'air chargé d'avance et l'ajuster au

besoin.

BOÎTE DE CONTRÔLE

(MODÈLES À 3 FILS)

COUVERCLE DE

PUITS VENTILÉ

CÂBLE

SUBMERSIBLE

RACCORD UNION

VOIR TABLEAU

2 ft.

SECTIONNEUR ÉLECTRIQUE

MANOMÈTRE

PRESSOSTAT DE CONTRÔLE

PRESSOSTAT

VERS

DISTRIBUTION

RÉSIDENTIELLE

VANNE À OBTURATEUR

SOUPAPE DE SURPRESSION

DISTANCE ENTRE CLAPET DE NON-RETOUR ET

ORIFICE DE PURGE

TAILLE DU RÉSERVOIR/EN

LITRE (GALLON)

42 (159) 2 (.6)

82 (310.4) 3 (.9)

120 (454.2) 5 (1.5)

220 (832.7) 5 (1.5)

315(1192.3) 10 (3)

525 (1987.1) 15 (4.6)

DISTANCE EN

MÈTRE (PI)

RACCORDEMENT À UN RÉSERVOIR

STANDARD

Voir Figure 10, en page 14-Fr, pour

une illustration du raccordement de la

tuyauterie à un réservoir de pression

standard ainsi que de la distance entre

les orifices de libération d'air et le

réservoir.

14-Fr

Page 15

Instructions D’utilisation et Manual de Pièces Puits profond pompes submersibles

Notes

15-Fr

Page 16

Instructions D’utilisation et Manual de Pièces Puits profond pompes submersibles

Tableau de dépannage

Symptôme(s) Cause(s) Possible(s) Mesures Correctives

Le moteur ne démarre pas, mais

les fusibles ne sont pas grillés

Fusibles grillés ou protecteur de

surcharge déclenché lorsque le

moteur démarre

Fusibles grillés ou protecteur de

surcharge déclenché lorsque le

moteur est en marche

La pompe démarre trop

fréquemment

1. Aucune tension à la boîte de

contrôle ou au sectionneur

2. Aucune tension au pressostat 2. Remplacer le pressostat défectueux.

3. Aucune tension à la boîte de

contrôle

4. Câble ou épissures défectueuses 4. Consulter un électricien ou réparateur agréé.

5. Boîte de contrôle incorrectement

câblée

1. Mauvaise dimension de fusible ou de

fusible de type de surcharge

2. Taille de fil trop petite 2. Installer un fil de la taille appropriée.

3. Condensateur de démarrage

défectueux, grillé ou de la mauvaise

dimension

4. Tension basse ou haute 4. Si la variation de tension est supérieure à 10% par

5. Fils d'alimentation électrique

incorrectement branchés à la boîte

de contrôle

6. Fil endommagé dans la boîte de

contrôle

7. Pompe ou moteur bloqué ou grippé 7. Effectuer toutes les vérifications en surface possibles. Retirer

8. Fil et/ou épissures des fils

d'alimentation ou du moteur mis à

la terre, court-circuité(s) ou ouvert(s)

1. Tension basse ou haute 1. Si la variation de tension est supérieure à 10% par rapport

2. Température ambiante trop élevée 2. Vérifier la température de la boîte de contrôle. Si

3. Boîte de contrôle alimentée par

une tension ou puissance nominale

inadéquate

4. Taille de fil trop petite 4. Installer un fil de la taille appropriée.

1. Fuites dans le système 1. Vérifier les raccords du réservoir avec de l'eau savonneuse.

2. Pressostat défectueux ou mal ajusté 2. Ajuster ou remplacer le pressostat.

3. Fuite dans le(s) clapet(s) de nonretour

4. Réservoir saturé d'eau 4. Pre-charged tanks: Adjust air pressure to 2 psi (13.8 kPa) less

5. Fuite sur le tuyau à chute 5. Remonter le tuyau à chute par paliers d'une longueur

6. Pressostat trop éloigné du réservoir 6. Placer le pressostat à moins de 0,3 m (1 pi) du réservoir.

1. Installer un fusible ou un fusible de type de surcharge

approprié.

3. Recâbler l'alimentation de la boîte de contrôle.

5. Rebrancher correctement la boîte de contrôle (voir

Diagrammes de Câblage d'Installation en page 11-Fr).

1. Installer un fusible ou un fusible de type de surcharge de la

dimension appropriée.

3. Remplacer le condensateur de démarrage. Remplacer le

relais de démarrage.

rapport à la valeur nominale sur la plaque signalétique,

veuillez appeler les services publics d'électricité ou

d'approvisionnement en eau pour ajuster la tension.

5. Rebrancher les fils pour correspondre au diagramme de

câblage sur le couvercle de la boîte de contrôle. Rebrancher

les fils d'alimentation électrique pour que leurs codes de

couleur correspondent à ceux des fils du moteur.

6. Couper le courant. Réparer ou remplacer les fils défectueux.

la pompe si nécessaire. Remplacer la pompe si elle est

bloquée. Débarrasser le puits de tout dépôt de sable et de

chaux avant de réinstaller la pompe.

8. Consulter un électricien agréé ou un réparateur qualifié. Ne

pas essayer de démonter la pompe ou le moteur.

à la valeur nominale sur la plaque signalétique, veuillez

appeler les services publics d'électricité pour ajuster la

tension.

nécessaire, déplacer la pompe loin des rayons directs du

soleil.

3. Remplacer la boîte de contrôle si la tension et la puissance

nominales sur la plaque signalétique de la boîte ne

correspondent pas à celles indiquées à l'intérieur du

couvercle de la boîte.

Vérifier les fuites sur la plomberie. S'assurer que le système

est étanche et imperméable.

3. Remplacer si nécessaire.

than cut-in pressure. Replace bladder if needed.

Réservoir hydropneumatiques: Réparer ou remplacer les

réservoirs. Remplacer le Contrôle de volume d'air (CVA) si

nécessaire.

jusqu'à ce que l'eau ne soit plus agitée dans le tuyau.

Remplacer la partie du tuyau au-delà de ce point.

16-Fr

Page 17

Instructions D’utilisation et Manual de Pièces Puits profond pompes submersibles

Tableau de dépannage

Symptôme(s) Cause(s) Possible(s) Mesures Correctives

Très peu d'eau ou rien n'est

pompé

De l'eau gazéifiée, laiteuse ou

de la couleur du thé coule des

robinets

1. Clapet de non-retour bloqué

ou installé à l'envers (réservoir

standard seulement)

2. Niveau d'eau bas (source d'eau) 2. Déterminer le niveau le plus bas du puits pendant que la

3. Tension basse 3. Installer un fil plus grand entre le manomètre et la boîte de

4. Écran d'entrée obstrué 4. Nettoyer ou remplacer si nécessaire.

5. Clapet de non-retour sur le bloc

de décharge de la pompe bloqué

6. Impulseurs et diffuseurs usés 6. S'assurer que le système est libre de débris et que la pompe

7. Fissures ou fuites sur les tuyaux 7. Remplacer si nécessaire

1. Présence de gaz dans l'eau du

puits

2. Le contrôle de volume d'air (CVA)

ne fonctionne pas correctement

(réservoirs standard seulement)

3. Puits chloré récemment 3. Vider le puits pour enlever les produits chimiques. Tester la

1. Libérer la soupape si bloquée. Inverser la position de la

soupape si installée à l'envers.

pompe est en marche. Comparer au réglage de profondeur

de la pompe. Faire descendre la pompe plus bas dans le puits,

mais au moins à 1,5 m (5 pi) du fond du puits. Étrangler la

décharge de la pompe jusqu'à ce qu'elle soit égale au taux de

récupération du puits.

Faire marcher la pompe en dépit de la

présence de poches d'air PEUT

provoquer un désamorçage et de graves dommages à la

pompe.

contrôle. Installer un fil plus grand entre la boîte de contrôle

et la pompe. Demander aux services publics d'électricité

d'élever la tension d'alimentation si nécessaire.

5. Libérer le clapet de non-retour.

fonctionne normalement dans l'eau claire. Remplacer la

pompe s'il n'y a aucune obstruction dans le système.

1. Enlever les orifices de libération d'air et les raccords en té.

S'assurer que les raccords en té ne fuient pas. Si nécessaire,

séparer le gaz de l'air avant qu'il n'entre dans le réservoir de

pression.

2. S'assurer que les orifices et les clapets de non-retour à bille

sont dégagés. Remplacer le Contrôle de volume d'air si

nécessaire.

présence de produits chimiques dans l'eau pour déterminer si

la vidange est achevée.

17-Fr

Page 18

Instructions D’utilisation et Manual de Pièces

Puits profond pompes submersibles

Garantie Limitée

Pendant un an à compter de la date d’achat, WAYNE Water Systems (“WAYNE”) va réparer ou remplacer, à sa discrétion, pour

l’acheteur original toute pièce ou pièces de Pompes submersibles pour puits profond (“Produit”) déterminées défectueuses

après examen par WAYNE en termes de matériaux ou de fabrication. Veuillez appeler WAYNE (800-237-0987) pour obtenir

des instructions ou contacter votre marchand. S'assurer de pouvoir fournir le numéro du modèle et le numéro de série afin

d’exercer cette garantie. Tous les frais de transport des Produits ou des pièces soumises pour la réparation ou le remplacement

sont la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits endommagés suite à un accident, mauvais traitement, mauvais usage,

négligence, installation incorrecte, entretien incorrect, ou ne pas faire fonctionner conformément aux instructions écrit de

Wayne.

IL N'Y A AUCUNE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS CELLES QUI INDIQUE SI

LE PRODUIT EST VENDABLE OU CONVENABLE À UN USAGE PARTICULIER, SONT LIMITÉES À UN AN À COMPTER DE

LA DATE D’ACHAT CECI EST LE SEUL RECOURS ET TOUTE RESPONSABILITÉ POUR TOUT DOMMAGE INDIRECT OU

CONSÉCUTIF OU DÉPENSE QUELCONQUE EST EXCLUE.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des

dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée vous

donne des droits légaux précis, et vous pouvez avoir d'autres droits légaux qui varient d’une juridiction à l'autre.

En aucun cas, soit par suite d’une rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autre,

ni WAYNE ni ses fournisseurs ne seront responsables de tout dommage spécial, consécutif, indirect ou punitif, y compris,

mais sans s'y limiter à la perte de profits ou recettes, la perte d’usage des produits ou de tout équipement associé,

dommage à l’équipement associé, coût de capital, coût de produits de remplacement, aménagements, services ou capacité

de remplacement, coût de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur pour ces

dommages.

Vous DEVEZ garder votre reçu d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une copie du reçu d’achat avec le

produit ou la correspondance afin d’effectuer une réclamation sous la garantie. Veuillez appeler WAYNE (800-237-0987) pour

l’autorisation et les instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE _____________________ Nº DE SÉRIE ________________________ DATE D’INSTALLATION _____________________

FIXER VOTRE FACTURE ICI

18-Fr

Page 19

Manual de instrucciones de operación y piezas

T50S10-2, T50S10-4, T51S10-4,

T75S10-2, T75S10-4, T100S10-2

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto

aquí descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. ¡El no cumplir con las instrucciones puede

ocasionar daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Bombas sumergibles

para pozos profundos

Descripción

Esta bomba sumergible está diseñada para

suministrar agua a la presión requerida

con alta eficiencia y una larga duración de

servicio. Para maximizar la vida útil de la

bomba, se deberá tener precaución en su

instalación y uso.

Para Desempacar

Después de desempacar la

bomba sumergible, inspecciónela

cuidadosamente para detectar cualquier

daño que pueda haber ocurrido

durante el envío. Verifique que no haya

piezas sueltas, faltantes o dañadas.

Medidas de Seguridad

CON EL EQUIPO. Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le indica una

información

importante, que de NO SEGUIRLA, le

PODRÍA ocasionar daños al equipo.

NOTA: Información que requiere

atención especial.

Informaciones

Generales de Seguridad

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o su

cordón eléctrico,

puede contener productos químicos

conocidos por el estado de California

como causantes de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lave sus manos después de usar.

SEGURIDAD GENERAL

1. Lea con atención el manual de

instrucciones que se incluye con el

producto. Familiarícese bien con

los controles y el uso adecuado del

equipo.

2. Conozca la aplicación, limitaciones y

posibles riesgos de la bomba.

NO bombee líquidos

inflamables ni

explosivos como por ejemplo gasolina,

fuel oil, queroseno, etc. NO la use en

entornos explosivos. USE la bomba

sólo con líquidos compatibles con los

materiales de la bomba. El no seguir

esta advertencia podría resultar en

lesiones personales y/o daños a la

propiedad.

Desconecte la

energía y libere

toda la presión del sistema antes de

intentar instalar, realizar un servicio,

reubicar o realizar cualquier tipo de

mantenimiento. Trabe la desconexión

de la energía en la posición abierta.

Etiquete la conexión de la energía

para evitar la aplicación de energía

inesperada.

3. Seguridad personal:

a. Use gafas de seguridad en todo

momento al trabajar con bombas.

b. Mantenga el área de trabajo

limpia, ordenada y debidamente

iluminada.

c. Mantenga a los visitantes a una

distancia segura del área de trabajo.

4. NO bombee productos químicos ni

líquidos corrosivos. Bombear esos

líquidos acorta la vida útil de los

sellos y piezas móviles de la bomba y

anulará la garantía.

5. Al instalar la bomba, evite que

materiales extraños caigan dentro

del pozo, contaminando el agua y

dañando los componentes mecánicos

internos.

6. Siempre pruebe la pureza del agua

del pozo antes de usar. Verifique con

el departamento de salud local para

saber el procedimiento de la prueba.

7. NO haga funcionar la bomba en seco

o la dañará y anulará la garantía.

Un electricista

calificado o licenciado

debe realizar todo el cableado.

8. Para una máxima seguridad, la

unidad debería conectarse a un

circuito con conexión a tierra

equipado con un dispositivo

interruptor de circuito de descarga a

tierra (GFCI).

9. Asegúrese de que la línea de voltaje

y la frecuencia del suministro de

corriente eléctrica coincidan con el

cableado del motor.

10. NO intente reparar el motor eléctrico.

Todas las reparaciones realizadas al

motor deberán efectuarse con un

mecánico de motores licenciado o

certificado.

11. Evite pellizcar el cable eléctrico

y protéjalo de objetos afilados,

superficies calientes, aceite y

productos químicos. Reemplace

o repare de inmediato los cables

dañados o gastados.

¡Riesgo de choque

eléctrico! ¡NUNCA

conecte el cable verde (o verde y

amarillo) a un terminal con corriente!

12. Use cables del tamaño adecuado para