Page 1

1/3 HP Sink Pump

System

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain

the product described. Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Operating Instructions & Parts Manual SYLT30

Description

This system pumps water up to an

existing water drain and is designed for

residential use in laundry trays, washing

machines, wet bar sinks, sinks and tubs,

dehumidifiers, and air conditioners.

The submersible sump pump included

in this system is equipped with an 8-ft

long, 3-prong grounding type power

cord. Motor is oil filled and sealed for

cooler running and designed to operate

under water. A float switch is provided

for automatic pump operation. This

pump is not suitable for aquatic life.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged during

shipment. If the pump or components

are damaged, call our customer service

department at 1-800-237-0987.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates an

imminently

hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates a

potentially

hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates a

potentially

hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important

information, that if not followed, MAY

cause damage to equipment.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product or

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

GENERAL SAFETY INFORMATION

1. Know the pump application,

limitations, and po ten tial hazards.

Do NOT

pump fl ammable or explosive

fl uids such as gasoline, fuel oil,

kerosene, etc. Do NOT use in

fl ammable and/or explosive atmospheres.

Use pump only with liquids compatible

with pump component materials. Failure

to follow this warning can result in

personal injury and/or property damage.

Disconnect

before servicing. If the power

dis con nect is out of sight, lock

in the open po si tion and tag

it to prevent unexpected application of

power. Failure to do so could result in fatal

electrical shock!

2. Drain all liquids from the system

before servicing.

3. Periodically inspect the pump

and system com po nents. Perform

routine maintenance as required

(See maintenance section).

4. When wiring an elec tri cal ly driven

pump such as this, fol low all

electrical and safety codes, as well as

the most recent National Electrical

Code (NEC) and the Oc cu pa tion al

Safety and Health Act (OSHA).

5. All wiring should be performed by a

qualified elec tri cian.

6. It is strongly recommended that this

unit is plugged into a Ground Fault

Circuit Interrupter (GFCI). Con sult a

its power cord may

use to

power

local electrician for installation and

availability.

7. This pump is designed to transfer

water in cycles. Using this pump in

a continuous duty application by

ma nip u lat ing the switch to stay on,

will effect the per for mance and the

life of the product.

8. Protect electrical cord from sharp

objects, hot sur fac es, oil, and

chemicals. Avoid kinking the cord.

Re place or repair damaged or worn

cords im me di ate ly. Use wire of

adequate size to minimize voltage

drop at the motor.

9. Do not handle a pump or pump motor

with wet hands or when standing on a

wet or damp surface, or in water.

Do NOT

walk on

wet area until all power has

been turned off. If the shut-off

box is in basement, call the

electric company to shut-off service to the

house, or call the local fi re department for

instructions. Remove pump and repair or

replace. Failure to follow this warning can

result in fatal electrical shock.

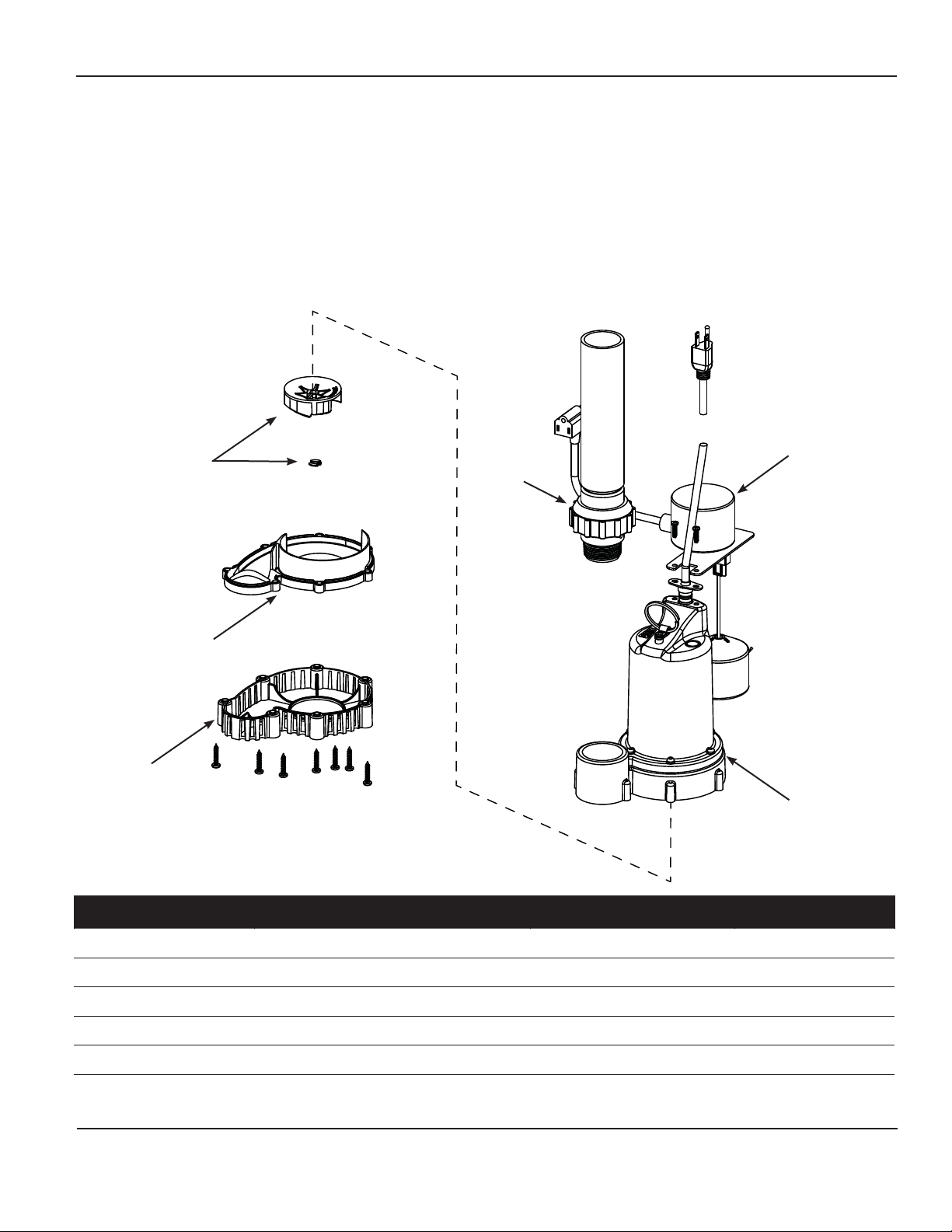

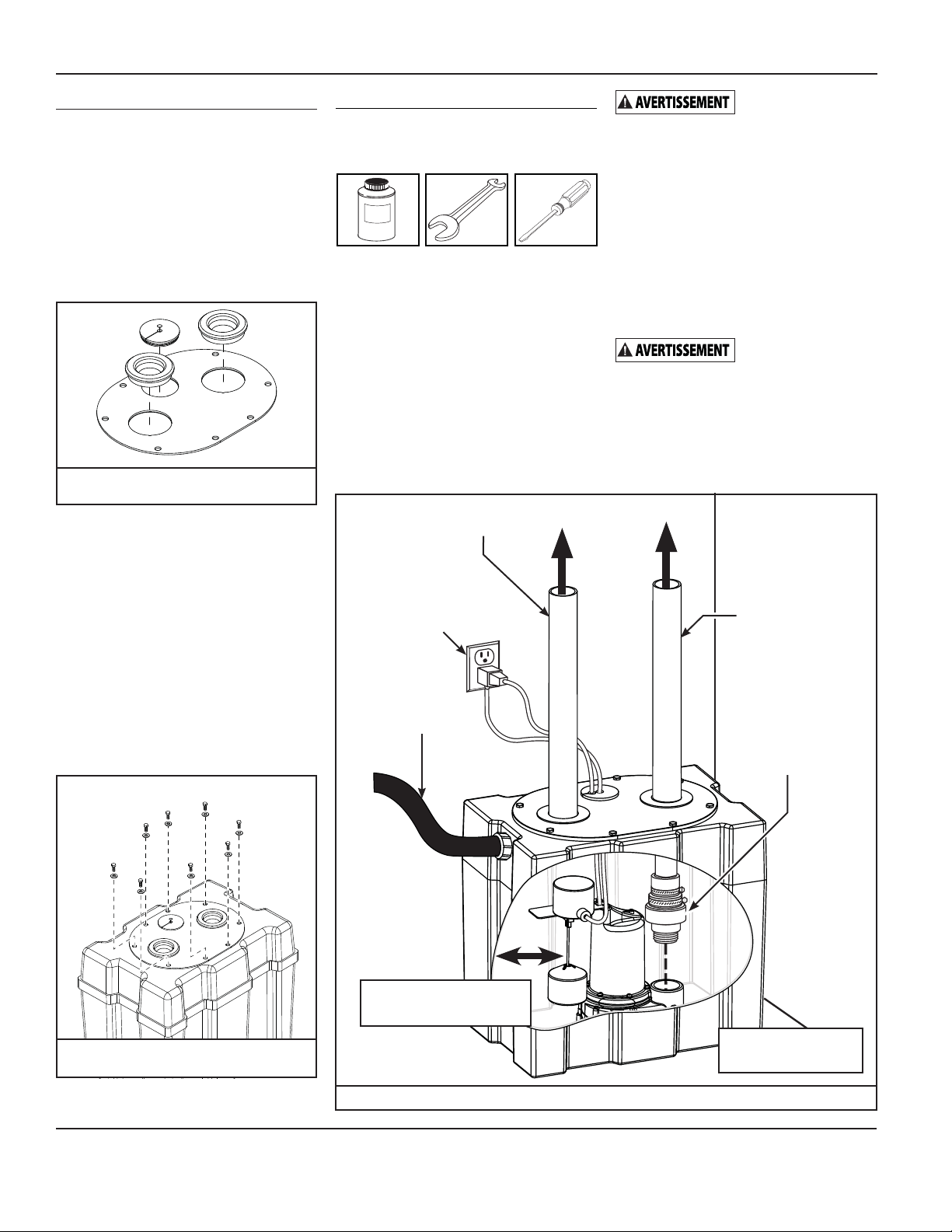

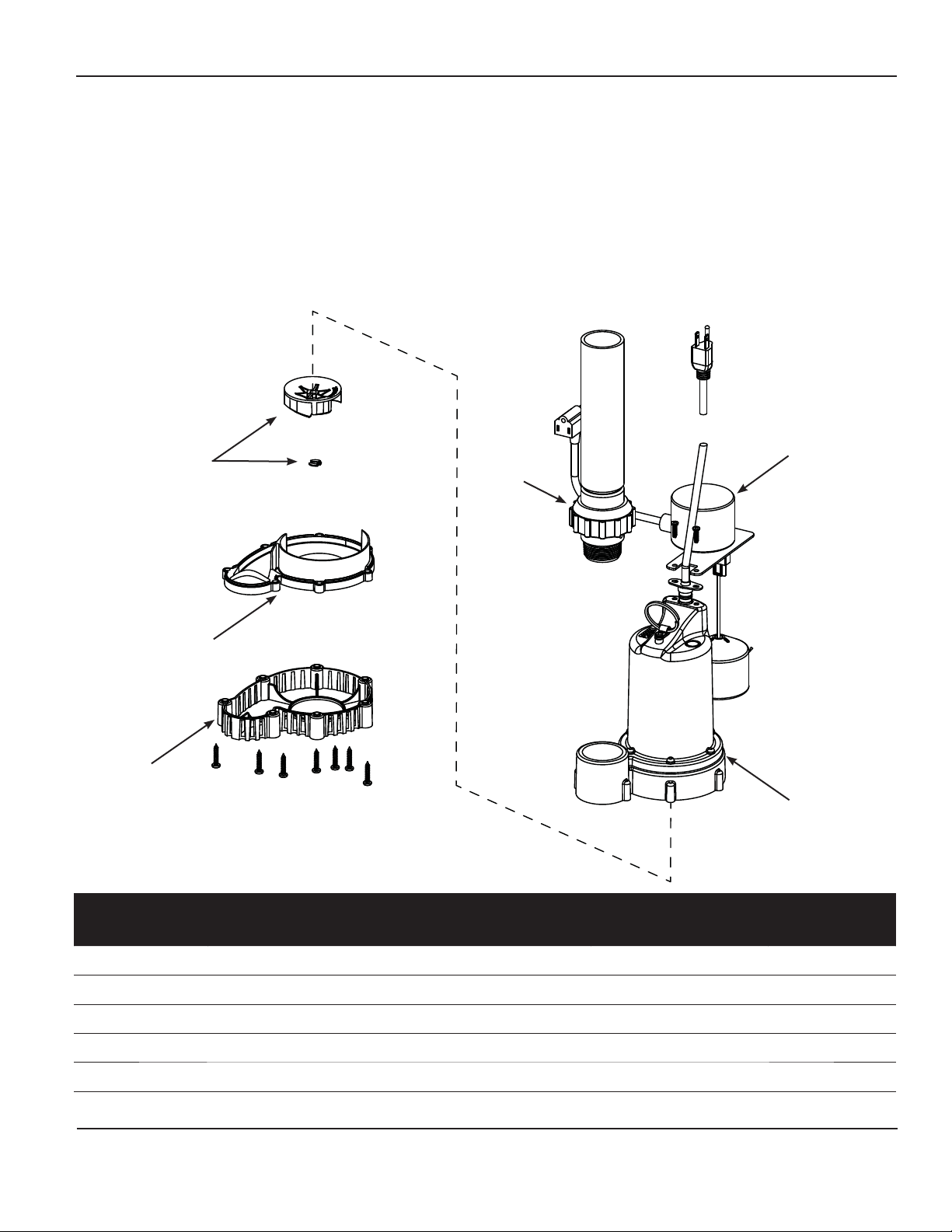

Assembly

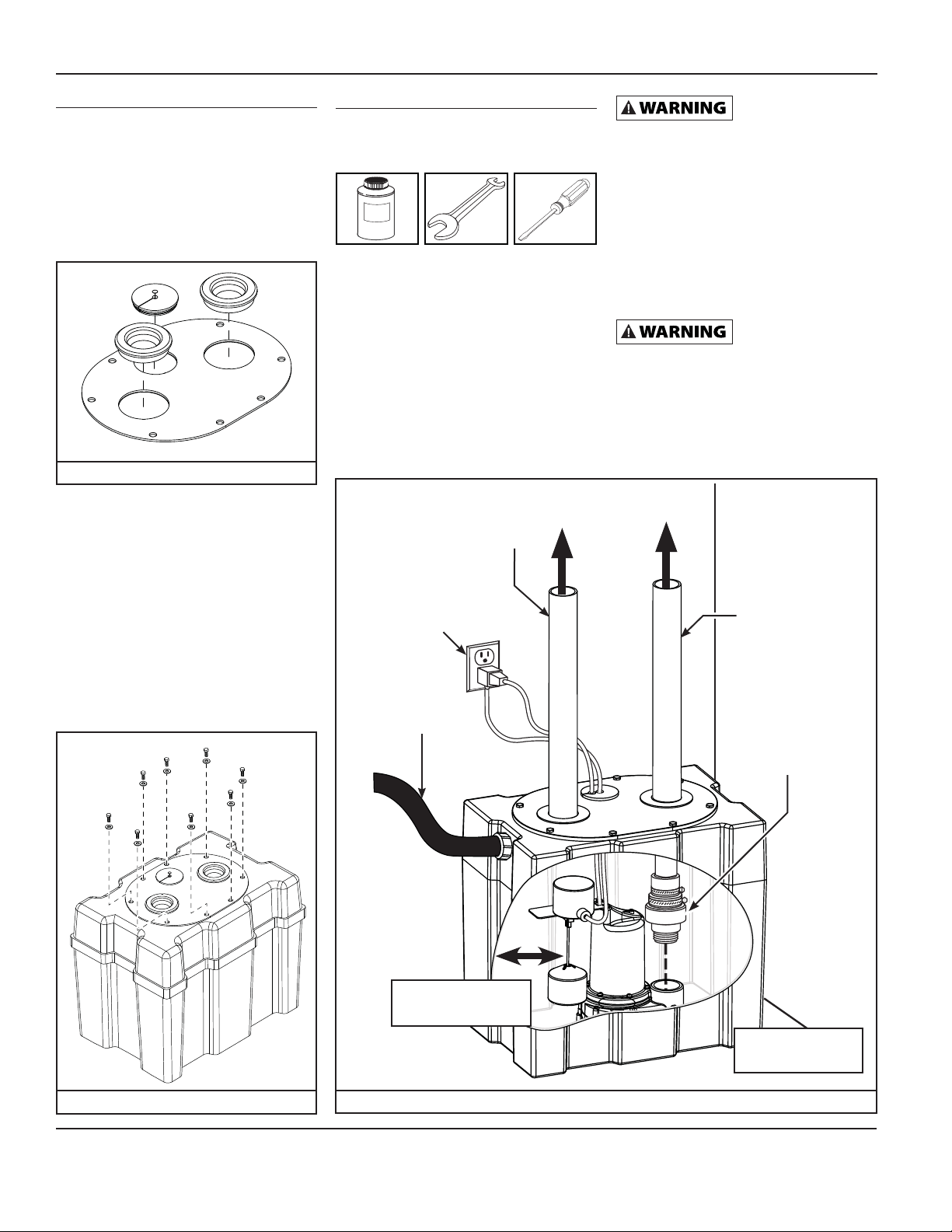

Assembly Instructions:

1. Remove packaging, including the

foam inside the tank.

2. Apply gasket to top of tank, just

outside the opening. (See Figure 1)

Figure 1: Adding Lid Gasket to Tank

REMINDER: Keep your dated proof of purchase for warranty purposes!

© 2011, WAYNE Water Systems/Scott Fetzer.

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.waynepumps.com

332800-001 3/11

Page 2

Operating Instructions and Parts Manual

Assembly (continued)

3. Place pump assembly inside tank,

keeping fl oat away from the walls of

the tank.

4. Run power cord and switch cord

through holes in the power cord seal.

5. Insert seals into the holes in the lid as

shown in Figure 2.

Figure 2: Attach Seals to Tank Lid

6. Lubricate discharge pipe and seal

with soapy water.

7. Slide the lid (while holding the

discharge seal in place) over the

discharge pipe.

8. Line up the holes in the lid with the

threads in the tank.

9. Secure lid to tank using the screws

and washers provided. (See Figure 3)

Hand tighten all screws and then fully

tighten with a 7/16 in. wrench. Do

not over-tighten.

Installation

Tools Required for Installation (not

included): PVC Glue, 7/16 in. wrench and

a screwdriver.

P

C

V

1. Connect discharge pipe (See Figure 4)

on Laundry Tray System to an existing

drain. Make sure all connections are

sealed.

2. Insert 1-1/2 in. Schedule 40 PVC pipe

into vent opening on top of Laundry

Tray System (See Figure 4). Insert pipe

2 to 3 inches into vent opening.

3. Connect Intake of this Laundry Tray

System (See Figure 4) to your washing

machine or other source. The threads

are 1-1/2 in. NPT.

Ventilation

GFCI

Outlet

Water

Inlet

Support pump and

piping when

assembling and after installation. Failure

to do so could cause piping to break,

pump to fail, etc. which could result in

property damage and/or personal injury.

4. Protect electrical cord from sharp

objects, hot surfaces, oils, and

chemicals. Avoid kinking the cord and

replace damaged cords immediately.

NOTE: Make sure there is adequate room

for the float switch to move freely for

operation.

This pump is NOT

septic tanks or underground vaults to

handle raw sewage or effl uents. NEVER

use this unit in hazardous or explosive

locations.

designed for use in

Discharge

Figure 3: Attach Seals to Tank Lid

www.waynepumps.com

Check Valve

Keep fl oat free of

obstruction

Place the system

on a fl at surface

Figure 4: Installation

2

Page 3

SYLT30

Operation

Always

disconnect

the power source before

attempting to install, service,

relocate or maintain the pump.

NEVER touch the sump pump, pump

motor, water or discharge piping when

pump is connected to electrical power.

NEVER handle a pump or pump motor

with wet hands or when standing on

wet or damp surface or in water. Fatal

electrical shock could occur.

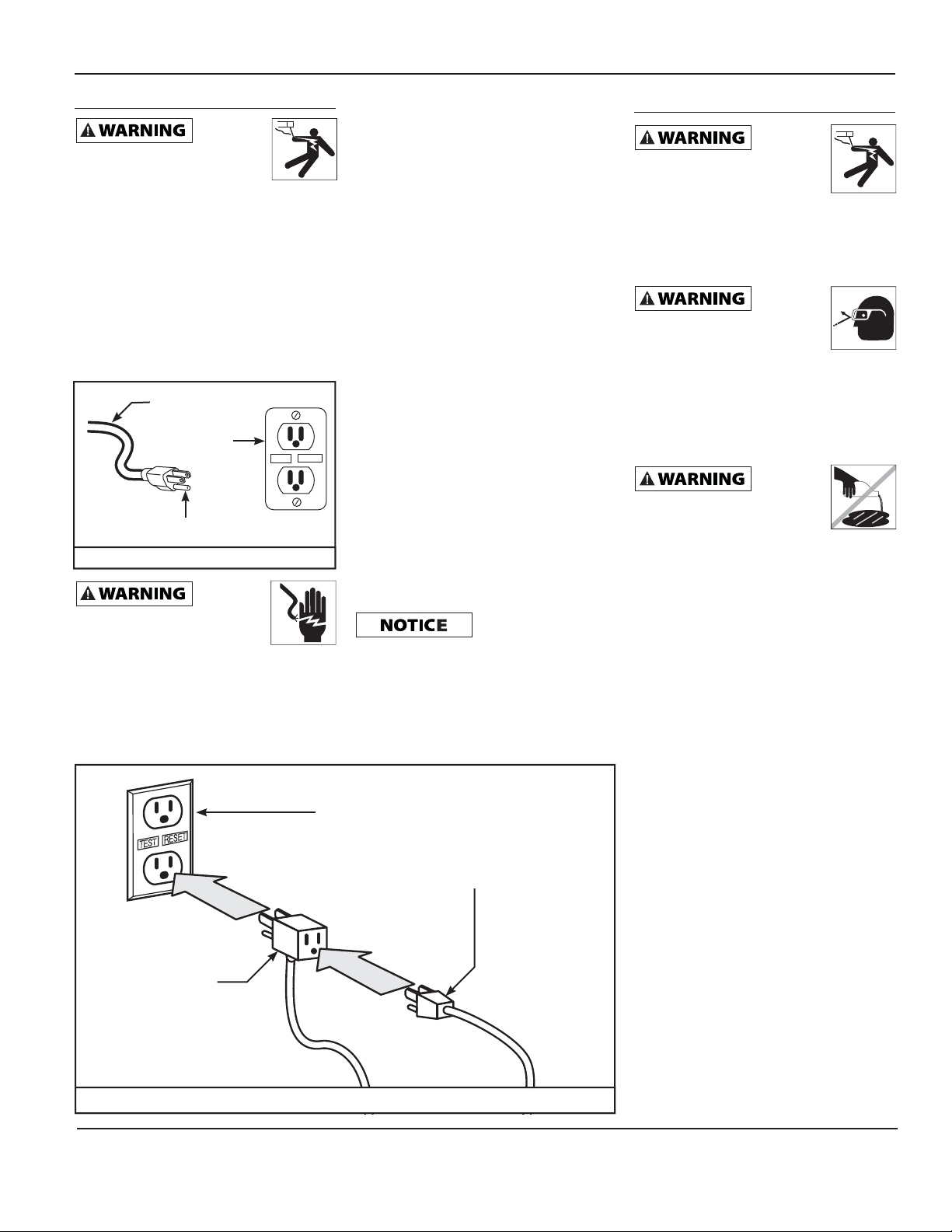

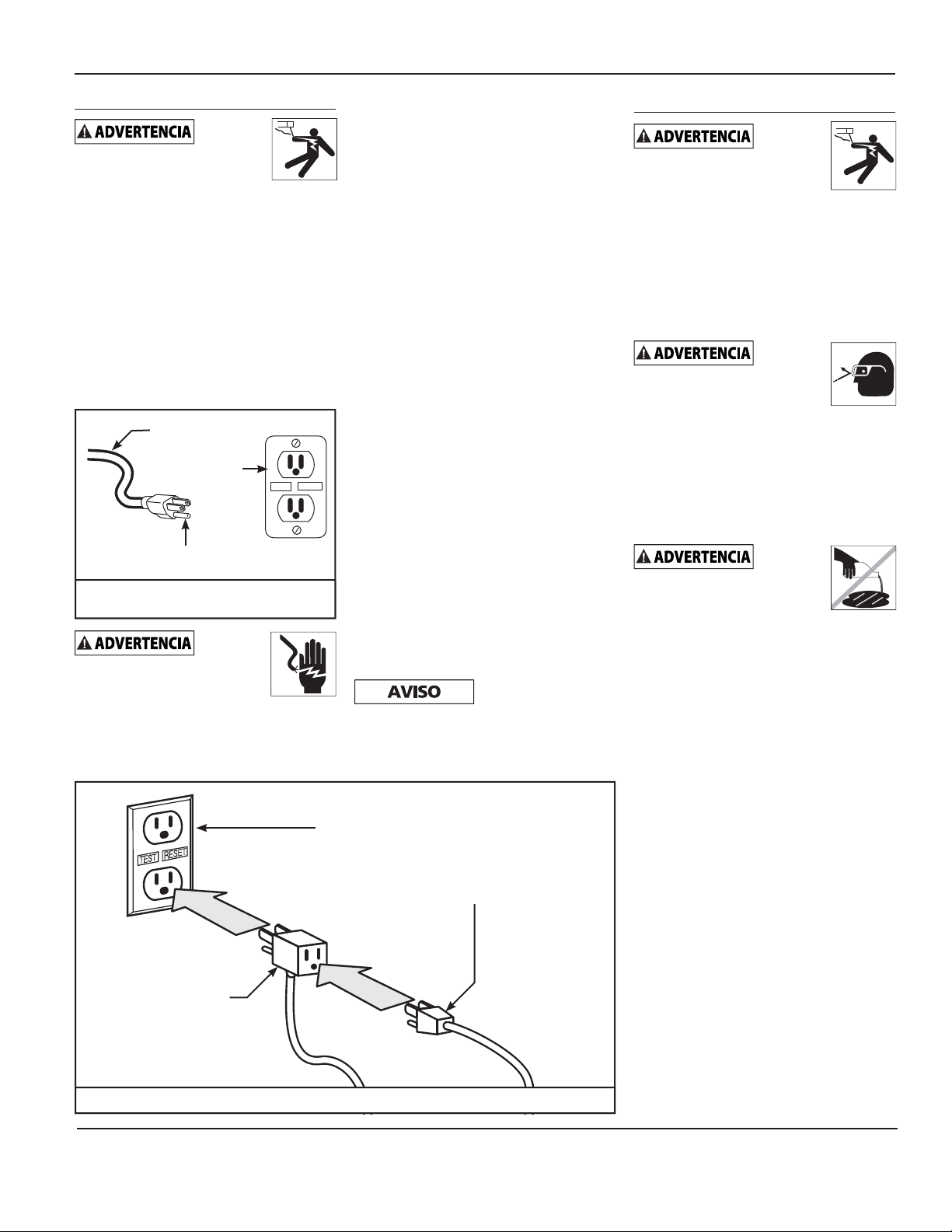

1. It is required that this unit be

2. Protect electrical cord from sharp

3. Do not handle a pump or pump

4. This pump is only for use on 120 Volt

plugged into a Ground Fault Circuit

Interrupter (GFCI) as shown in

Figure 5. Consult a local electrician

for installation and availability.

Power Cord

5. Insert the pump power cord plug

GFCI

RESET

Outlet

TEST

6. Test operation of the system by

Grounding Blade

Figure 5: Grounding outlet and power cord

Risk of

shock! This pump is supplied

with a grounding conductor

and grounding type attachment

plug. Use a grounded receptacle to reduce

the risk of fatal electrical shock. NEVER cut

off the round grounding prong. Cutting

the cord or plug will void the warranty and

make the pump inoperable.

electrical

Do NOT operate the

submerged in water. Dry running causes

pump failure. The motor is equipped

with an automatic reset thermal

protector.

objects, hot sur fac es, oil, and

chemicals. Avoid kinking the cord.

Re place or repair damaged or worn

cords im me di ate ly. Use wire of

adequate size to minimize voltage

drop at the motor.

motor with wet hands or when

standing on a wet or damp surface,

or in water.

(single-phase), 60 Hz, 15 amp service

and is equipped with a 3-conductor

cord and 3-prong, grounding type

plug. Insert the float switch cord plug

directly into a GFCI protected 120 volt

outlet. Do NOT use an extension cord.

directly into the back of the float switch

cord plug (See Figure 6).

adding water to the inlet. The pump

will start automatically when the

water has filled the reservoir to a

depth of approximately 9 inches. The

pump will stop when the water depth

is approximately 4 inches. The pump

will cycle thereafter as required.

pump unless it is

Maintenance

Always

the power source before

attempting to install, service,

relocate or maintain the pump.

NEVER touch sump pump, pump motor,

water or discharge piping when pump is

connected to electrical power. NEVER handle

a pump or pump motor with wet hands or

when standing on wet or damp surface or in

water. Fatal electrical shock could occur.

Risk of

injury! Wear safety glasses

at all times when performing

maintenance on this pump

system. Failure to follow this warning

could result in death or serious injury.

1. Let the pump cool for a minimum of

two hours before servicing because

the pump contains hot oil under

pressure and the motor is hot.

This pump

dielectric motor oil for

lubrication and motor heat

transfer. This oil can be

harmful to the environment. Check

state environmental laws before

disposing of this oil.

2. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required, see

troubleshooting chart.

3. Inlet should be kept clean and free

of all foreign objects and inspected

annually. A clogged inlet will damage

the pump.

4. Pump should be checked monthly for

proper operation.

disconnect

personal

contains

OIL

GFCI Outlet

Float Switch

Piggyback Plug

Figure 6: Piggyback Plug and Power Cord

Pump Power

Cord

www.waynepumps.com

3

Page 4

Operating Instructions and Parts Manual

Troubleshooting Chart

Problem Possible Cause(s) Corrective Action(s)

Pump will not start

or run

Pump starts and

stops too often

Pump will not shut

off or thermal

protector turns off

Pump operates but

delivers little or no

water

1. Blown fuse, tripped breaker

2. Low line voltage

3. Float obstructed

4. Defective fl oat switch

5. Impeller bound-up

6. Defective motor

1. Back-fl ow of water from

piping

2. Faulty fl oat switch

1. Defective fl oat switch

2. Obstacle in piping

3. Float obstructed

1. Low line voltage

2. Plugged impeller

3. Obstructed piping

4. Excessive lift height (water

has to go higher than pump

can handle)

1. If blown, replace with proper sized fuse or reset breaker

2. If voltage is under 108 volts, check wiring size. DO NOT USE

AN EXTENSION CORD

3. Make sure fl oat moves freely up and down

4. Replace fl oat switch (Recommended for at least every 2 years)

5. If impeller will not turn, remove housing and remove blockage

6. Replace pump

1. Replace check valve

2. Replace fl oat switch (Recommended for at least every 2 years)

1. Replace fl oat switch (Recommended for at least every 2 years)

2. Remove pump; clean check valve, pump and piping

3. Make sure fl oat move freely up and down

1. If voltage is under 108 volts, check wiring size. DO NOT USE

AN EXTENSION CORD

2. Clean out impeller

3. Remove pump and remove obstruction from piping or

reposition piping to prevent obstruction

4. Reposition pump to a suitable position to decrease lift height

www.waynepumps.com

4

Page 5

For Replacement Parts or Technical Assistance,

Call 1-800-237-0987

Please provide following information: Address any correspondence to:

- Model number WAYNE Water Systems/Scott Fetzer

- Serial number (if any) 101 Production Drive

- Part description and number as shown in parts list Harrison, OH 45030 U.S.A.

1

4

SYLT30

5

2

3

6

Reference Number Description Part Number Quantity

1 Impeller 60138-001 1

2 Volute 28539-001 1

3 Base 28540-001 1

4 Check Valve Kit 60139-001 1

5 Switch Kit 60140-001 1

6 Pump Assembly (pump and switch) 58325-002 1

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual

Limited Warranty

For one (1) year from the date of purchase, WAYNE Water Systems ("WAYNE") will repair or replace, at its option, for the

original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by WAYNE

to be defective in materials or workmanship. Please call WAYNE (1-800-237-0987) for instructions or see your dealer. Be

prepared to provide the model number and serial number when exercising this warranty. All transportation charges on

Products or parts submitted for repair or replacement must be paid by purchaser.

This limited warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with WAYNE'S written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS

THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR

EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations

of incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you

specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall WAYNE or

its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit

or revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost

of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such

damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call WAYNE (1-800-237-0987) for

return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO. _______________________ SERIAL NO. _______________________ INSTALLATION DATE _______________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

6

Page 7

Système / pompe

d’évier de 1/3 CH

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de

procéder à l’entretien du produit décrit. Se protéger ainsi que les autres en observant toutes les instructions de

sécurité, sinon, il y a risque de blessure et/ou dégâts matériels! Conserver ces instructions comme référence.

Instructions d'Utilisation et Pièces de Recahnge SYLT30

Description

Ce système pompe l’eau jusqu’à un drain

de vidange en place et il est conçu pour

une utilisation résidentielle dans les bacs

à laver, les laveuses, les éviers de minibar,

les éviers et cuves, les déshumidifi cateurs

et les climatiseurs. La pompe de puisard

submersible incluse dans ce système est

dotée d’un cordon d’alimentation mis

à la terre, à 3 broches, de 2,4 m (8 pi)

de long. Le moteur est rempli d’huile

et scellé pour un fonctionnement plus

frais et il est conçu pour fonctionner

sous l’eau. Un interrupteur à fl otteur

est fourni pour une opération à pompe

automatique. Cette pompe n’est pas

conçue pour la vie aquatique.

Déballage

Inspecter cet appareil avant de

l’utiliser. À l’occasion, les produits sont

endommagés durant l’expédition.

Si la pompe ou les composants

sont endommagés, appelez notre

département de service au client, au

numéro 1-800-237-0987.

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie

pour la SÉCURITÉ et pour ÉVITER

LES PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Danger indique une

situation

hasardeuse imminente qui résultera en

perte de vie ou blessures graves.

Avertissement

indique une situation

hasardeuse potentielle qui peut résulter en

perte de vie ou blessures graves.

Attention indique

une situation

hasardeuse potentielle qui peut résulter

en blessures.

Avis indique

l’information

importante pour éviter le dommage

de l’équipement.

Généralités sur la

Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

contenir des produits chimiques qui, de

l’avis de l’État de Californie, causent le

cancer et des anomalies congénitales ou

autres problèmes de reproduction. Lavezvous les mains après la manipulation.

GÉNÉRALITÉS SUR LA SÉCURITÉ

1. Se familiariser avec l’application, les limites

et les hasards potentiels de la pompe.

NE PAS

pour le pompage des liquides

infl ammables ou explosifs

tels que l’essence, l’huile à

chauffage, le kérosène, etc. NE PAS utiliser

dans une atmosphère infl ammable et/ou

explosive. Utiliser la pompe seulement

avec les liquides qui sont compatibles avec

les pièces détachées de la pompe. Ne pas

suivre cet avertissement peut résulter en

blessure grave et/ou dégâts matériels.

de courant avant de procéder à

l’entretien et aux réparations.

Si la source d’alimentation

est hors de la vue, la verrouiller dans

la position ouverte et l’étiqueter afi n

d’éviter que l’appareil soit mis sous

tension accidentellemen. Ne pas suivre ces

directives peut résulter en choc électrique!

2. Purger tous liquides de procéder à

l’entretien et aux réparations.

3. Inspecter la pompe et les pièces détachées

du système périod-iquement. Exécuter

l’entretien ordinaire (Se référer à la section

d’entretien).

4. Pendant l’installation de fils d’une pompe

électrique telle que celle-ci, suivre tous les

codes de sécurité ainsi que les codes récents

du National Electrical Code (NEC) et l’ Oc cupa tion al Safety and Health Act (OSHA).

5. Toute installation de fils doit être efectuée

par un électricien qualifié.

6. Il est recommandé que le modèle soit

branché dans un disjoncteur de fuite à la

cordon peuvent

utiliser

Débrancher

la source

terre (DDFT). Con sulter un électricien local

pour la disponibilité et l’installation.

7. Cette pompe est conçue pour transporter

l’eau en cycles. Utiliser cette pompe dans

une application continue en manipulant

l’interrupteur pour qu’il reste enclenché

affectera la performance et l’espérance de

vie du produit.

8. Protéger le cordon d’alimentation des

objets pointus, surfaces chaudes, huile

et produits chimiques. Ne pas tortiller le

cordon. Remplacer ou réparer les cordons

usés ou endommagés immédiatement.

Utiliser des fils de taille suffisante pour

minimiser la chute de tension au moteur.

9. Ne pas manipuler de pompe ou de pompe

de moteur avec les mains trempées ni

lorsque vous êtes debout sur une surface

trempée ou humide, ou dans l’eau.

NE PAS

marcher

dans un endroit trempé jusqu’à

ce que toutes les sources

de courant soient coupées.

Si la boîte d’arrêt est dans le sous-sol,

contacter votre compagnie d’électricité

pour couper le service à la maison ou

contacter le service d’incendie pour des

directives. Enlever la pompe et la réparer

ou la remplacer. Ne pas suivre ces conseils

peut résulter en choc électrique mortel.

Assemblage

Instructions d’assemblage:

1. Retirer l’emballage, incluant la

mousse à l’intérieur du réservoir.

2. Appliquer la bague d’étanchéité sur

le dessus du réservoir, à l’extérieur de

l’ouverture. (Voir la Figure 1)

Figure 1: Ajouter la bague d’étanchéité

du couvercle au réservoir

MÉMENTO: Gardez votre preuve datée d’achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2011, WAYNE Water Systems/Scott Fetzer.

Fr 7

332800-001 3/11

Page 8

Instructions d'Utilisation et Pièces de Recahnge

Assemblage (suite)

3. Placer l’assemblage de pompe à

l’intérieur du réservoir en gardant le

flotteur loin des parois du réservoir.

4. Acheminer le cordon d’alimentation

et le cordon d’interrupteur à travers

les trous dans le joint d’étanchéité du

cordon d’alimentation.

5. Insérer les joints d’étanchéité dans

les trous du couvercle tel qu’indiqué

dans la Figure 2.

Figure 2: Fixer les joints d’étanchéité

au couvercle du réservoir

6. Lubrifier le tuyau de décharge et

le joint d’étanchéité avec de l’eau

savonneuse.

7. Glisser le couvercle (tout en gardant

le joint d’étanchéité de la décharge

en place) sur le tuyau de décharge.

8. Aligner les trous du couvercle avec les

filets du réservoir.

9. Installer le couvercle au réservoir avec

les vis et les rondelles fournies. (Voir

la Figure 3) Resserrer à la main toutes

les vis, puis resserrer entièrement

avec une clé de 7/16 po (1,11 cm). Ne

pas trop resserrer.

Installation

Outils requis pour l’installation (non

inclus): colle PVC, clé de 7/16 po (1,11

cm) et tournevis.

P

C

V

1. Brancher le tuyau de décharge (Voir la

Figure 4) sur le système de plateau de

lessive à un drain déjà en place. S’assurer

que toutes les connexions sont scellées.

2. Insérer le tuyau de PVC schedule 40 de

3,8 cm (1 1/2 po) dans l’ouverture d’évent

sur le système de plateau de lessive (Voir

la Figure 4). Insérer 50,8 à 7,6 mm (2 à 3

po) de tuyau dans l’ouverture d’évent.

3. Brancher l’entrée de ce système de

plateau de lessive (Voir la Figure 4) à

votre laveuse ou à une autre source. Les

filets sont de 3,8 cm (1 1/2 po) NPT

Ventilation

Prise

GFCI

Entrée

d'eau

Supporter la pompe

assemblant et après l’installation. Ne pas

suivre ces directives pourrait mener à des bris

de tuyaux, à la défaillance de la pompe etc.

qui pourrait ensuite mener à des dommages

à la propriété et/ou à des blessures.

et la tuyauterie en

4. Protéger le cordon électrique des objets

tranchants, des surfaces chaudes, de l’huile

et des produits chimiques. Éviter le

tortillement du cordon et remplacer

immédiatement les cordons endommagés.

REMARQUE: S’assurer qu’il y a suffisamment

d’espace pour que l’interrupteur à flotteur se

déplace librement durant l’opération.

Cette pompe N’EST

utilisée dans les fosses septiques ou les

enceintes souterraines pour pomper les

effl uents ou les eaux usées. NE JAMAIS

utiliser cet appareil dans des endroits

dangereux ou explosifs.

PAS conçue pour être

Décharge

Clapet de

non-retour

Figure 3: Visser le couvercle au

réservoir

Garder le fl otteur libre

de toute obstruction

Placer le systèm sur

une surface á plat

Figure 4: Installation

Fr 8

Page 9

SYLT30

Fonctionnement

Toujours

source de courant avant d’essayer

d’installer, de réparer, de déplacer

ou de faire l’entretien de

la pompe. NE JAMAIS toucher la pompe de

puisard, le moteur de pompe, la tuyauterie

d’eau ou de décharge lorsque la pompe est

branchée au courant. NE JAMAIS manipuler

de pompe ou de moteur de pompe avec les

mains humides ou debout dans l’eau ou sur

une surface humide. On pourrait avoir un choc

électrique mortel.

1. Il faut brancher cet appareil dans un

interrupteur à disjoncteur de fuite à

la terre comme indiqué dans la

Figure 5. Consulter un électricien local

pour l’installation et la disponibilité.

Broche de mise à la terre

Figure 5: Prise mise à la terre et

cordon d'alimentation

Risque

électrique! Cette pompe est

fournie avec un conducteur de

terre et une fi che de masse.

Utiliser une prise à la terre pour réduire

le risque de choc électrique mortel. NE

JAMAIS couper la broche de terre ronde.

Couper le cordon ou la fi che annulera la

garantie et rendra la pompe inutilisable.

couper la

Cordon

de choc

Prise

GFCI

TEST

RESET

Prise GFCI

2. Protéger le cordon des objets

tranchants, des surfaces chaudes, de

l’huile et des produits chimiques. Éviter

le tortillement du cordon. Remplacer

ou réparer immédiatement les cordons

endommagés ou usés. Utiliser un fil

de taille adéquate pour réduire toute

chute de tension au moteur.

3. Ne pas manipuler de pompe ou de

moteur de pompe avec les mains

humides ou debout dans l’eau ou sur

une surface humide.

4. Cette pompe ne doit être utilisée

qu’avec 120 volts (monophase), 60 Hz,

15 ampères et est dotée d’un cordon

à 3 conducteurs et 3 broches et à

fiche de masse. Insérer la fiche du

cordon de l’interrupteur à flotteur

directement dans une prise de 120

volts protégée par disjoncteur de fuite

à la terre. NE PAS utiliser de rallonges.

5. Insérer la fiche du cordon de la pompe

directement à l’arrière de la fiche du

cordon de l’interrupteur à flotteur

(Voir la Figure 6).

6. Tester l’opération du système en ajoutant

de l’eau à l’entrée. La pompe démarrera

automatiquement lorsque l’eau remplit

le réservoir à une profondeur d’environ

23 cm (9 po). La pompe s’arrêtera lorsque

la profondeur d’eau sera d’environ

10,2 cm (4 po). La pompe reprendra son

cycle par la suite au besoin.

NE PAS faire

fonctionner la

pompe à moins qu’elle ne soit submergée

dans l’eau. Tourner à sec mène à une

défaillance de pompe. Ce moteur est

doté d’un protecteur thermique à

réinitialisation automatique.

Maintenance

Toujours

source de courant avant d’essayer

d’installer, de réparer, de déplacer

ou de faire l’entretien de la

pompe. NE JAMAIS toucher la pompe de

puisard, le moteur de pompe, la tuyauterie

d’eau ou de décharge lorsque la pompe est

branchée au courant. NE JAMAIS manipuler

de pompe ou de moteur de pompe avec les

mains humides ou debout dans l’eau ou sur

une surface humide. On pourrait avoir un choc

électrique mortel.

Risque de

Porter des lunettes de sécurité en

tout temps pendant l’entretien

de ce système de pompe. Le nonrespect de cet avertissement pourrait mener

à la mort ou à de graves blessures.

1. Laisser la pompe refroidir pendant au

moins deux heures avant tout entretien

ou réparation parce que la pompe

contient de l’huile chaude sous pression

et le moteur est chaud.

Cette

contient de l’huile à moteur

diélectrique pour la lubrifi cation

et le transfert de chaleur au

moteur. Cette huile peut être dangereuse

pour l’environnement. Vérifi er les lois

environnementales de l’État avant de jeter

cette huile.

2. Démonter le moteur avant l’expiration

de la garantie annulera la garantie.

S’il faut des réparations, consulter le

tableau de dépannage.

3. L’entrée doit rester propre et libre de

tous objets étrangers et être inspectée

chaque année. Une entrée bloquée

endommagera la pompe.

4. La pompe doit être vérifiée chaque mois

pour assurer son bon fonctionnement.

couper la

blessure!

pompe

OIL

Prise

superposée

d'inerrupteur

à fl otteur

Figure 6: Prise superposée et cordon d'alimentation

Cordon d'alimentation

de la pompe

Fr 9

Page 10

Instructions d'Utilisation et Pièces de Recahnge

Dépannage

Problème Cause(s) Possible(s) Mesure(s) corrective(s)

La pompe ne démarre

pas ou ne fonctionne

pas

La pompe démarre et

s’arrête trop souvent

Pompe ne s’arrête

pas ou le protecteur

thermique s’éteint

La pompe

fonctionne, mais

donne peu ou

aucune eau

1. Fusible grillé ou disjoncteur

déclenché

2. Basse tension de ligne

3. Flotteur obstrué

4. Interrupteur à fl otteur

défectueux

5. Impulseur enroulé

6. Moteur défectueux

1. Retour d’eau de tuyauterie

2. Interrupteur à fl otteur

défectueux

1. Interrupteur à fl otteur

défectueux

2. Obstacle dans la tuyauterie

3. Flotteur obstrué

1. Basse tension de ligne

2. Impulseur bloqué

3. Tuyauterie obstruée

4. Hauteur de relèvement

excessive (l’eau doit aller plus

haut que ce que la pompe

peut traiter)

1. Si grillé, remplacer en utilisant la bonne taille de fusible ou

réinitialiser le disjoncteur

2. Si la tension est inférieure à 108 volts, vérifi er la taille du

câblage - NE PAS UTILISER DE RALLONGES

3. S’assurer que le fl otteur se déplace librement vers le haut et

vers le bas

4. Remplacer l’interrupteur à fl otteur (Recommandé pendant au

moins tous les 2 ans)

5. Si l’impulseur ne tourne pas, retirer le boîtier et retirer

le blocage

6. Remplacer la pompe

1. Remplacer le clapet

2. Remplacer l’interrupteur à fl otteur (Recommandé pendant au

moins tous les 2 ans)

1. Remplacer l’interrupteur à fl otteur (Recommandé pendant au

moins tous les 2 ans)

2. Retirer la pompe; la nettoyer ainsi que le clapet et la

tuyauterie

3. S’assurer que le fl otteur se déplace librement vers le haut et

vers le bas

1. Si la tension est inférieure à 108 volts, vérifi er la taille du

câblage NE PAS UTILISER DE RALLONGES

2. Nettoyer l’impulseur

3. Retirer la pompe et l’obstruction de la tuyauterie ou replacer la

tuyauterie pour éviter toute obstruction

4. Replacer la pompe à une position convenable pour réduire la

hauteur de relèvement

Fr 10

Page 11

Pour Pièces de Rechange ou Assistance Technique,

Appeler 1-800-237-0987

S'il vous plaît fournir l'information suivante: Adresser toute correspondance à:

- Numéro de Modèle WAYNE Water Systems/Scott Fetzer

- Numéro de série (si présent) 101 Production Drive

- Description et numéro de la pièce Harrison, OH 45030 U.S.A.

1

4

SYLT30

5

2

3

6

Numéro de

référence Description Numéro de pièce Quantité

1 Impulseur 60138-001 1

2 Volute 28539-001 1

3 Base 28540-001 1

4 Trousse de clapet de non-retour 60139-001 1

5 Trousse d'interrupteur 60140-001 1

6 Montage de la pompe (pompe et interrupteur) 58325-002 1

Fr 11

Page 12

Instructions d'Utilisation et Pièces de Recahnge

Garantie Limitée

Pour un (1) an à compter de la date d’achat, WAYNE Water Systems (« WAYNE ») réparera ou remplacera, à son choix,

pour l’acheteur original, toute pièce(s) de sa Pompe de puisard ou Pompe à eau (le « Produit ») qui, après une inspection

par WAYNE, s’est révélée défectueuse en matière ou en fabrication. S’il vous plaît appeler WAYNE (1-800-237-0987) pour

des instructions ou contacter votre marchand. S’assurer d’avoir, à votre disposition, le numéro du modèle afin d’effectuer

cette garantie. Les frais de transportation des Produits ou pièces soumis pour la réparation ou le remplacement sont la

responsabilité de l’acheteur.

Cette garantie limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident, utilisation abusive,

mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation conformément aux

instructions écrit de WAYNE'S.

IL N’Y A AUCUNE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS CELLES DE

COMMERCIALISATION OU CONVENABLE À UN USAGE PARTICULIER, SONT LIMITÉES À UN (1) AN, À COMPTER DE LA

DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ POUR N’IMPORTE QUEL ET

TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des

dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne, à

l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales qui sont variable d’une Province ou d’un État à

l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement,

ni WAYNE ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y compris, mais pas

limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à

l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou abilité de remplaçement, coût

de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre facture d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une COPIE de la recette d’achat avec

le matériel ou correspondance afin d’effectuer une réclamation de la garantie.

pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE________________________ Nº DE SÉRIE______________________ DATE D’INSTALLATION________________________

FIXER VOTRE FACTURE ICI

S’il vous plaît appeler

WAYNE

(1-800-237-0987)

Fr 12

Page 13

Sistema de bomba

para pileta de 1/3 HP

Sírvase leer y guardar estas instrucciones. Lea con cuidado antes de tratar de armar, instalar, manejar

o darle servicio al producto descrito en este manual. Protéjase Ud. y a los demás observando todas las

reglas de seguridad. ¡El no seguir las instrucciones podría resultar en heridas y/o daños a su propiedad!

Guarde este manual como referencia.

Manual de Instrucciones y Repuestos SYLT30

Descripción

Este sistema bombea agua hasta un drenaje

de agua existente y está diseñado para uso

residencial en piletas de lavado, máquinas

de lavar, piletas de bares para el hogar,

piletas y bañeras, deshumidificadores y aire

acondicionados. La bomba para sumidero

sumergible que se incluye en este sistema

está equipada con un cable de corriente

de 2,4 m (8 pies) de largo con enchufe

de tres clavijas con conexión a tierra. El

motor está lleno de aceite y sellado para

un funcionamiento a menor temperatura y

está diseñado para funcionar bajo agua. El

interruptor de flotador se proporciona para el

funcionamiento automático de la bomba. La

bomba no es adecuada para la vida acuática.

Desempaque

Inspeccione esta unidad antes de usarla.

Ocasionalmente, los productos son

dañados durante el envío. Si la bomba o

los componentes están dañados, llame a

nuestro departamento de servicio al cliente,

en el 1-800-237-0987.

Medidas de Seguridad

Este manual contiene información

que es muy importante que sepa

y comprenda. Esta información se

la suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le indica una

información

importante, que de no seguirla, le

podría ocasionar daños al equipo.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

Informaciones

7. Esta bomba está diseñada para funcionar

Generales de Seguridad

PROPOSITION 65 DE CALIFORNIE

Este producto, o

su cordón eléctrico,

puede contener productos químicos conocidos

por el estado de California como causantes de

cáncer y defectos de nacimiento u otros daños

reproductivos. Lave sus manos después de usar.

INFORMACIONES GENERALES DE

SEGURIDAD

1. Familiarícese con las aplicaciones

adecuadas para el equipo, sus

limitaciones y los peligros al usarlo.

NO use

esta

bomba para bombear fl uídos

infl amables o explosivos tales

como gasolina, combustibles,

kerosene, etc. NO la use en atmósferas

infl amables o explosivas. La bomba sólo

se debe usar para bombear agua pura. De

lo contrario pudiera ocasionarle heridas

de gravedad y/o la muerte.

Desconecte

el cordón

eléctrico antes de darle

servicio. Si el tomacorrientes

está fuera de su alcance,

apague la unidad con el interruptor y

asegúrelo de modo que la unidad no

pueda encenderse accidentalmente. ¡De

no hacerlo podría morir electrocutado!

2. Drene todos los líquidos del sistema antes

de darle servicio.

3. Chequée la bomba y otros componentes

frecuentemente. Déle el mantenimiento

necesario según las instrucciones en la

sección de mantenimiento.

4. Para instalar el alambrado de bombas

eléctricas, tales como la descrita en este

manual, siga todos los códigos de seguridad

laboral y electricidad establecidos en su país,

por ejemplo los de la NEC y OSHA en EE.UU.

5. Todos los trabajos de electricidad los debe

hacer un electricista calificado.

6. Es altamente recomendable que utilice

un tomacorrientes que tenga un sistema

de cortacircuito incorporado. Con súltele a

un electricista local para ver si éstos están

disponibles en su área.

8. Proteja el cordón eléctrico contra

9. No toque la bomba o el motor con las

húmeda antes de desconectar

la energía eléctrica. Si el

cortacircuito está fuera de su

alcance (en el sótano), llame a la compañía

de electricidad o al cuerpo de bombero

para que le asistan. Desconecte la bomba

y repárela o reemplácela. Si no sigue estas

instrucciones podría morir electrocutado.

Ensamblaje

Instrucciones de ensamblaje:

1. Quite el envoltorio, junto con la espuma

que se encuentra dentro del tanque.

2. Aplique la junta a la parte superior del

tanque, justo por debajo de la abertura

(Ver Figura 1)

3. Coloque el ensamble de la bomba

dentro del tanque, manteniendo el

flotador alejado de las paredes del

tanque.

Figura 1: Colocación de la junta de la

tapa en el tanque

en ciclos. Si le modifica el interruptor para

que funcione continuamente, afectará el

rendimiento y la duración de la unidad.

objetos afilados, superficies calientes,

aceite y químicos. Evite que el cordón se

enrolle. Reem place o repare el cordón

inmediatamente cuando se dañe. Use

cordones del calibre adecuado para evitar

pérdidas de voltaje del motor.

manos mojadas o cuando esté parado en

una superficie húmeda o en agua.

NO camine

en un área

© 2011, WAYNE Water Systems/Scott Fetzer.

Sp 13

332800-001 3/11

Page 14

Manual de Instrucciones y Repuestos

Ensamblaje (continuación)

4. Pase el cable de corriente y el cable del

interruptor a través de los orificios del

sellado del cable de corriente.

5. Introduzca los sellos en los orificios de la

tapa como se muestra en la Figura 2.

6. Lubrique la tubería de descarga y el sello

con agua con agua y jabón.

7. Deslice la tapa (mientras sostiene el sello

de descarga en su lugar) sobre el tubería

de descarga.

Figura 2: Conecte los sellos a la tapa

del tanque

8. Alinee los orificios de la tapa con las

roscas del tanque.

9. Asegure la tapa usando los tornillos y

arandelas proporcionados. (Ver Figura 3)

Ajuste a mano todos los tornillos y luego

ajuste con una llave de 11,1 mm (7/16

pulg). No apriete en exceso.

Instalación

Herramientas necesarias para la

instalación (no se incluyen): Pegamento

PVC, llave de 11,1 mm (7/16 pulg.) y

destornillador.

P

C

V

1. Conecte la tubería de descarga (Ver Figura

4) del sistema de pileta de lavado a un

drenaje existente. Asegúrese de que todas

las conexiones estén selladas.

2. Introduzca la tubería de PVC Schedule

40 de 3,81 cm (1 1/2 pulg.) en la abertura

de ventilación en la parte superior del

sistema de pileta de lavado (Ver Figura 4).

Introduzca la tubería por la abertura de

ventilación de 5,08 a 7,62 cm (2 a 3 pulg.).

3. Conecte la entrada de este sistema de

pileta de lavado (Ver Figura 4) a su lavadora

u otra fuente. Las roscas son de 3,81 cm

(1 1/2 pulg.) NPT.

Ventilación

Tomacorriente

GFCI

Sujete la bomba y la

ensamblando y después de la instalación.

El no hacerlo podría provocar que la

tubería se rompa, que la bomba falle, etc.,

lo que podría dar como resultado daño a la

propiedad y/o lesiones personales.

tubería cuando la esté

4. Proteja el cable eléctrico de objetos

punzantes, superficies calientes, aceite y

productos químicos. Evite doblar el cable y

reemplace los cables dañados de inmediato.

NOTA: Asegúrese de que haya espacio

suficiente para que el interruptor de

flotador se mueva libremente durante

el funcionamiento.

usada en tanques sépticos ni sótanos

subterráneos para manejar aguas

residuales ni efl uentes. NUNCA utilice

esta unidad en ubicaciones peligrosas

o explosivas.

Esta bomba NO está

diseñada para ser

Descarga

Figura 3: Enrosque la tapa al tanque

Entrada

de agua

Válvula de retención

Mantenga el fl otador

libre de obstrucciones

Coloque el sistema en

una superfi cie plana

Figura 4: Instalación

Sp 14

Page 15

SYLT30

Funcionamiento

Siempre

la fuente de energía antes de

intentar instalar, efectuar un

servicio, reubicar o realizar el

mantenimiento de la bomba. NUNCA toque

la bomba de sumidero, el motor de la bomba,

la tubería del agua o de descarga cuando

la bomba esté conectada a la corriente

eléctrica. NUNCA manipule la bomba ni el

motor de la bomba con las manos húmedas

o cuando se encuentre sobre una superfi cie

húmeda o mojada ni dentro del agua. Corre

riesgo de choque eléctrico mortal.

1. Se requiere que esta unidad se enchufe

en un interruptor de circuito de

descarga a tierra (GFCI) como se muestra

en la Figura 5. Consulte a un electricista

local para su instalación y disponibilidad.

Tomacorriente

Paleta de conexión tierra

Figura 5: Tomacorriente conectado a

tierra y cable de corriente

eléctrico! Esta bomba viene con

un conductor de conexión a tierra

y un enchufe de conexión a tierra.

Use un receptáculo con conexión a tierra para

reducir el riesgo de choque eléctrico mortal.

NUNCA corte la clavija redonda de conexión a

tierra. Si corta el cable o el enchufe se anulará la

garantía y hará que la bomba no funcione.

desconecte

Cable de

corriente

GFCI

¡Riesgo de

choque

TEST

RESET

Tomacorriente GFCI

2. Proteja el cable eléctrico de objetos

punzantes, superficies calientes, aceite

y productos químicos. Evite doblar

el cable. Cambie o repare los cables

dañados o desgastados de forma

inmediata. Use cables del tamaño

adecuado para minimizar la caída de

voltaje en el motor.

3. No manipule una bomba ni el motor de

una bomba con las manos mojadas ni si

está parado en superficies húmedas, ni

en el agua.

4. Esta bomba está diseñada para usarse

sólo con 120 voltios (monofásico), 60 Hz,

15 amp. y está equipada con un cable

de 3 conductores y un enchufe del tipo

de conexión a tierra de tres clavijas.

Introduzca el enchufe del cable de

corriente del interruptor de flotación

directamente en un tomacorriente con

protección GFCI de 120 voltios. NO use

un cable de extensión.

5. Introduzca el enchufe del cable de

corriente de la bomba directamente en la

parte posterior del enchufe del cable del

interruptor de flotación (Ver Figure 6).

6. Compruebe el funcionamiento del

sistema agregando agua a la entrada.

La bomba se iniciará automáticamente

cuando el agua haya llenado el depósito

hasta una profundidad de 22,86 cm

(9 pulg.). La bomba se detendrá cuando

la profundidad del agua sea de 10,16 cm

(4 pulg.) aproximadamente. La bomba

comenzará el ciclo a partir de ese

momento, cada vez que sea necesario.

NO ponga la bomba

en funcionamiento

a menos que esté sumergida en agua.

El funcionamiento en seco puede ocasionar

daños a la bomba. El motor está equipado

con un protector térmico de reposición

automática.

Maintenimiento

Siempre

la fuente de energía antes de

intentar instalar, efectuar un

servicio, reubicar o realizar

el mantenimiento de la bomba. NUNCA

toque la bomba de sumidero, el motor

de la bomba, la tubería del agua o de

descarga cuando la bomba esté conectada

a la corriente eléctrica. NUNCA manipule

la bomba ni el motor de la bomba con las

manos húmedas o cuando se encuentre

sobre una superfi cie húmeda o mojada ni

dentro del agua. Corre riesgo de choque

eléctrico mortal.

¡Riesgo

Use gafas de protección en

todo momento cuando realice

el mantenimiento de este

sistema de bomba. El no cumplir con esta

advertencia podría dar como resultado la

muerte o lesiones graves.

1. Deje enfriar la bomba durante

un mínimo de dos horas antes de

realizar el servicio debido a que la

bomba contiene aceite caliente bajo

presión y el motor está caliente.

La bomba

aceite de motor dieléctrico para

lubricación y transferencia del

calor del motor. Este aceite

puede ser nocivo para el medioambiente.

Verifi que las leyes ambientales de su

estado antes de desechar este aceite.

2. Desensamblar el motor antes

del vencimiento de la garantía

anulará la misma. Si debe hacer

reparaciones, consulte la tabla de

resolución de problemas.

3. La entrada se debe mantener limpia

y libre de cualquier objeto extraño

e inspeccionarse anualmente. Una

entrada obstruida dañará la bomba.

4. La bomba debe controlarse

mensualmente para verifi car su

correcto funcionamiento.

desconecte

de lesión!

tiene

OIL

Enchufe de fl otador

incorporado en serie

Figura 6: Enchufe en serie y cable de energía

Cable de energía

de la bomba

Sp 15

Page 16

Manual de Instrucciones y Repuestos

Diagnóstico y resolución de problemas

Problema Causa(s) posible(s) Acciones a tomar

La bomba no

enciende o no

funciona

La bomba se inicia

y se detiene con

demasiada frecuencia

La bomba no se

apaga o el protector

térmico se apaga

La bomba funciona

pero sale muy poca

agua o nada

1. Fusible quemado, disyuntor

disparado

2. Bajo voltaje

3. Flotador obstruido

4. Interruptor de fl otador

defectuoso

5. Impulsor atascado

6. Motor defectuoso

1. Refl ujo de agua desde la

tubería

2. Interruptor de fl otador

defectuoso

1. Interruptor de fl otador

defectuoso

2. Obstrucción en la tubería

3. Flotador obstruido

1. Bajo voltaje

2. Impulsor obstruido

3. Tubería obstruida

4. Altura de succión excesiva

(el agua tiene que subir a

una altura mayor de lo que

la bomba puede elevarla)

1. Si está quemado, cámbielo por un fusible del tamaño correcto

o reajuste el disyuntor

2. Si el voltaje es menor a 108 voltios, verifi que el tamaño del

cableado – NO USE UN CABLE DE EXTENSIÓN

3. Asegúrese de que el fl otador se mueva libremente hacia arriba

y hacia abajo

4. Cambie el interruptor de fl otador (Se recomienda por lo

menos cada 2 años)

5. Si el impulsor no funciona, retire la caja y quite la obstrucción

6. Reemplace la bomba

1. Cambie la válvula de retención

2. Cambie el interruptor de fl otador (Se recomienda por lo

menos cada 2 años)

1. Cambie el interruptor de fl otador (Se recomienda por lo

menos cada 2 años)

2. Quite la bomba; limpie la válvula de retención, la bomba y

la tubería

3. Asegúrese de que el fl otador se mueva libremente hacia arriba

y hacia abajo

1. Si el voltaje es menor a 108 voltios, verifi que el tamaño del

cableado – NO USE UN CABLE DE EXTENSIÓN

2. Limpie el impulsor

3. Quite la bomba y quite la obstrucción de la tubería o vuelva a

colocar la tubería para evitar la obstrucción

4. Vuelva a colocar la bomba en una posición adecuada para

disminuir la altura de succión

Sp 16

Page 17

Para Ordenar Repuestos o Asistencia Técnica,

llame 1-800-237-0987

Sirvase darnos la siguiente información: Dirija toda la correspondencia a:

- Número del modelo WAYNE Water Systems/Scott Fetzer

- Código impreso 101 Production Drive

- Descripción y número del repuesto Harrison, OH 45030 U.S.A.

según la lista de repuestos

1

4

SYLT30

5

2

3

Número de Ref. Descripción Numero de pieza Ctd.

1 Impulsor 60138-001 1

2 Voluta 28539-001 1

3 Base 28540-001 1

4 Conjunto de válvula de retención 60139-001 1

5 Juego de interruptor 60140-001 1

6

6 Ensamble de la bomba (bomba y interruptor) 58325-002 1

Sp 17

Page 18

Manual de Instrucciones y Repuestos

Notas

Sp 18

Page 19

Notas

SYLT30

Sp 19

Page 20

Manual de Instrucciones y Repuestos

Garantía Limitada

Durante uno (1) año, WAYNE Water Systems (“WAYNE”) reparará o reemplazará, según lo decida, para el comprador

original, cualquier pieza o piezas de sus Bombas para cloacas o Bombas de agua (“Producto”) que después de un examen

sea(n) hallada(s) por WAYNE como defectuosa(s) en su material o mano de obra. Sírvase llamar a la compañía WAYNE (1-800237-0987, desde EE.UU) para recibir instrucciones al respecto o comuníquese con el distribuidor más cercano a su domicilio.

Para hacer reclamos bajo esta garantía deberá suministrarnos el número del modelo y el número de serie del producto. El

comprador será responsable de pagar todos los gastos de flete para enviar las piezas o el producto para que sean reparados o

reemplazados.

Esta garantía limitada no cubre los daños que sufra el producto debido a accidentes, abusos, usos inadecuados, negligencia,

instalación incorrecta, mantenimiento inadecuado, o haberse utilizado sin seguir las instrucciones escritas suministradas por la

compañía WAYNE'S.

NO EXISTE OTRA GARANTÍA EXPRESA. LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO AQUELLAS DE COMERCIALIZACIÓN

Y APTITUD PARA UN PROPÓSITO EN PARTICULAR, ESTÁN LIMITADAS A UNO AÑO, A PARTIR DE LA FECHA DE

COMPRA. ESTA ES LA UNICA GARANTIA DISPONIBLE Y TODAS LAS REPONSABILIDADES CIVILES, DIRECTAS O

INDIRECTAS, O GASTOS POR DAÑOS INDIRECTOS O CONSECUENTES QUEDAN EXCLUIDOS.

Algunos estados no permiten que se establezcan límites en la duración de las garantías implicitas, o no permiten que se

excluyan ni se establezcan límites en los daños por incidentes o consecuencias, por lo tanto los límites antes mencionados

podrían ser no válidos. Esta garantía limitada le otorga derechos legales especificos, y usted también puede tener otros

derechos que varian de un Estado a otro.

En ningún caso, bien sea por ruptura del contrato de la garantía, responsabilidad civil (incluyendo negligencia) u otra causa,

WAYNE o sus distribuidores serán responsables pon daños especiales, consecuentes, ni circunstanciales ni penales, incluyendo,

pero no limitados a la pérdida de ganancias, pérdida de uso del producto o equipos asociados, daños a equipos asociados,

costos de capitales, costos para substituir productos, costos para substituir o reemplazar servicios, costos por pérdida de

productividad, o reclamos de clientes del comprador por dichos daños.

DEBE conservar el recibo de compra con esta garantía. En caso de que necesite hacer un reclamo bajo esta garantía, DEBERA

enviarnos una COPIA del recibo junto con el material o correspondencia. Sírvase comunicarse con la compañía WAYNE (1-800-

237-0987, en EE.UU.) para recibir autorización e instrucciones para enviar el producto.

NO ENVIE ESTA GARANTIA A WAYNE. Use este documento sólo para mantener sus records.

NO DEL MODELO _______________ NO DE SERIE __________________________ FECHA DE INSTALACION _____________

ANEXE SU RECIBO AQUI

Sp 20

Loading...

Loading...