Wayne Submersible Operating Instructions And Parts Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

1

Description

The submersible pump is designed for home

sump applications. The unit is equipped with

an 8-ft long, 3-prong grounding type power

cord. Motor is oil filled and sealed for cooler

running and designed to operate under

water. A float switch is provided for

automatic pump operation. This pump is not

suitable for aquatic life.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged during

shipment. If the pump or components are

damaged, return the unit to the place of

purchase for replacement. Failure to do so

could result in serious injury or death.

General Safety Information

Do not use to pump

flammable or explosive

fluids such as gasoline,

fuel oil, kerosene, etc. Do

not use in a flammable and/or explosive

atmosphere. Pump should only be used

to pump clear water. Personal injury

and/or property damage could result.

This pump is not

designed to handle

salt water, brine, laundry discharge or

any other application which may

contain caustic chemicals and/or

foreign materials. Pump damage could

occur if used in these applications and

will void warranty.

All wiring must be

performed by a

qualified electrician. Failure to follow

this warning could result in fatal

electrical shock.

If the basement has water

or moisture on the floor,

do not walk on wet area

until all power is turned

off. If the shutoff box is

in the basement, call an electrician.

Remove pump and either repair or

replace. Failure to follow this warning

could result in fatal electrical shock.

Operating Instructions and Parts Manual Submersible Series

350705-001 7/05

A backup system

should be used.

Wayne offers Model ESP15.

Assembly

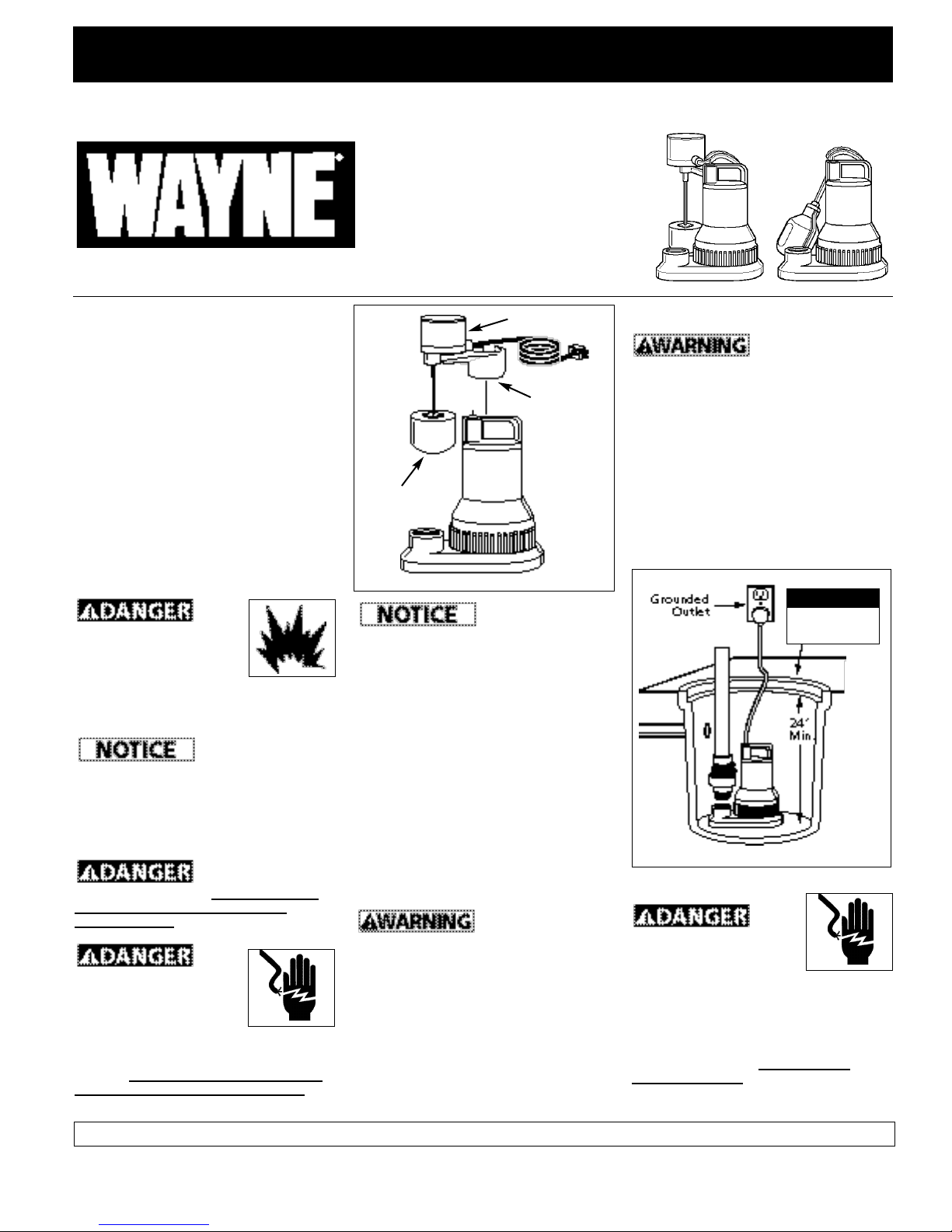

VERTICAL FLOAT SWITCH (FLOAT ONLY)

Place the float bracket onto the handle of

the motor housing and slide the switch

assembly securely into place.

Installation

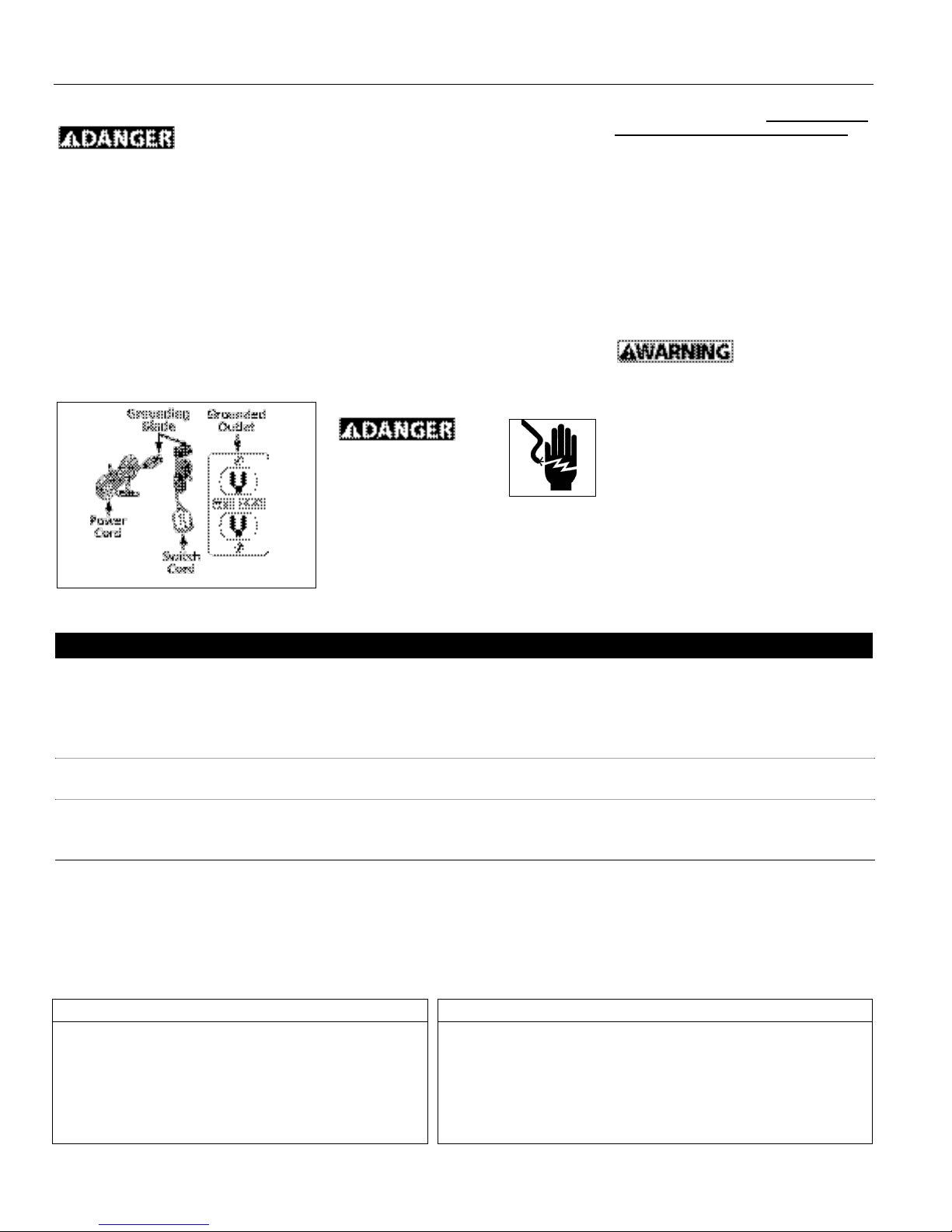

1. Install pump in a sump pit with minimum

size as shown in Figure 2. Construct

sump pit of tile, concrete, steel or plastic.

2. The unit should be located and rest on a

solid, level foundation. Do not place

pump directly on clay, earth, gravel or

sandy surface. These surfaces contain

small stones, gravel, sand, etc. that may

clog or damage the pump and cause

pump failure.

Flood risk. If

flexible discharge

hose is used, make sure pump is

secured in sump pit to prevent

movement. Failure to secure pump

could allow pump movement and

switch interference and prevent pump

from starting or stopping.

3. Thread check valve (Wayne offers Model

66005-WYN) into pump body carefully

to avoid stripping or cross threading. Do

not use pipe joint sealant.

4. Connect 1-1/2” rigid pipe to rubber boot

on check valve. Reverse boot for 1-1/4”

diameter pipe. Tighten hose clamps.

Support pump and

piping when

assembling and after installation.

Failure to do so could cause piping to

break, pump to fail, etc. which could

result in property damage and/or

personal injury.

5. Protect electrical cord from sharp object,

hot surfaces, oil and chemicals. Avoid

kinking the cord and replace damaged

cords immediately.

IMPORTANT: Make sure there is adequate

room for the switch to operate.

6. A sump pit cover must be installed to

prevent debris from clogging or

damaging the pump.

Operation

Always disconnect the

power source before

attempting to install,

service, relocate or maintain the pump.

Never touch sump pump, pump motor,

water or discharge piping when pump is

connected to electrical power. Never

handle a pump or pump motor with wet

hands or when standing on wet or damp

surface or in water. Fatal electrical

shock could occur.

1. A ground fault circuit interrupter (GFCI)

is required.

Figure 2

Float 11”

Tether 14”

Min. Diameter

Switch Housing

Float

Float

Bracket

Figure 1

Submersible

Sump Pump

© 2005 Wayne Water Systems

For parts, product & service information

visit www.waynepumps.com

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

4. Fill sump with water. The pump will start

automatically when the water has filled

the sump to the cut-in level. The pump

will stop when the water reaches the

cut-out level. See specifications for cutin/out levels. The pump will recycle

thereafter as required.

5. Do not operate the pump unless it is

submerged in water. Dry running causes

pump failure.

6. The motor is equipped with an

automatic reset thermal protector.

7. While the pump is draining the pit, verify

that the discharge piping is carrying the

water to a point several feet away from

the foundation.

8. If pump discharge line is exposed to

freezing temperature, the exposed line

must be pitched to drain. Trapped water

will freeze and damage the pump.

Maintenance

Always disconnect the

electrical supply before

attempting to install,

service, relocate or

perform any maintenance. If the power

source is out of sight, lock and tag in

the open (off) position to prevent

unexpected power application. Failure

to do so could result in fatal electrical

Operation (Continued)

Risk of electrical

shock! This pump

is supplied with a grounding conductor

and grounding type attachment plug.

Use a grounded receptacle to reduce

the risk of fatal electrical shock.

Never cut off the round grounding prong.

Cutting the cord or plug will void the

warranty and make the pump inoperable.

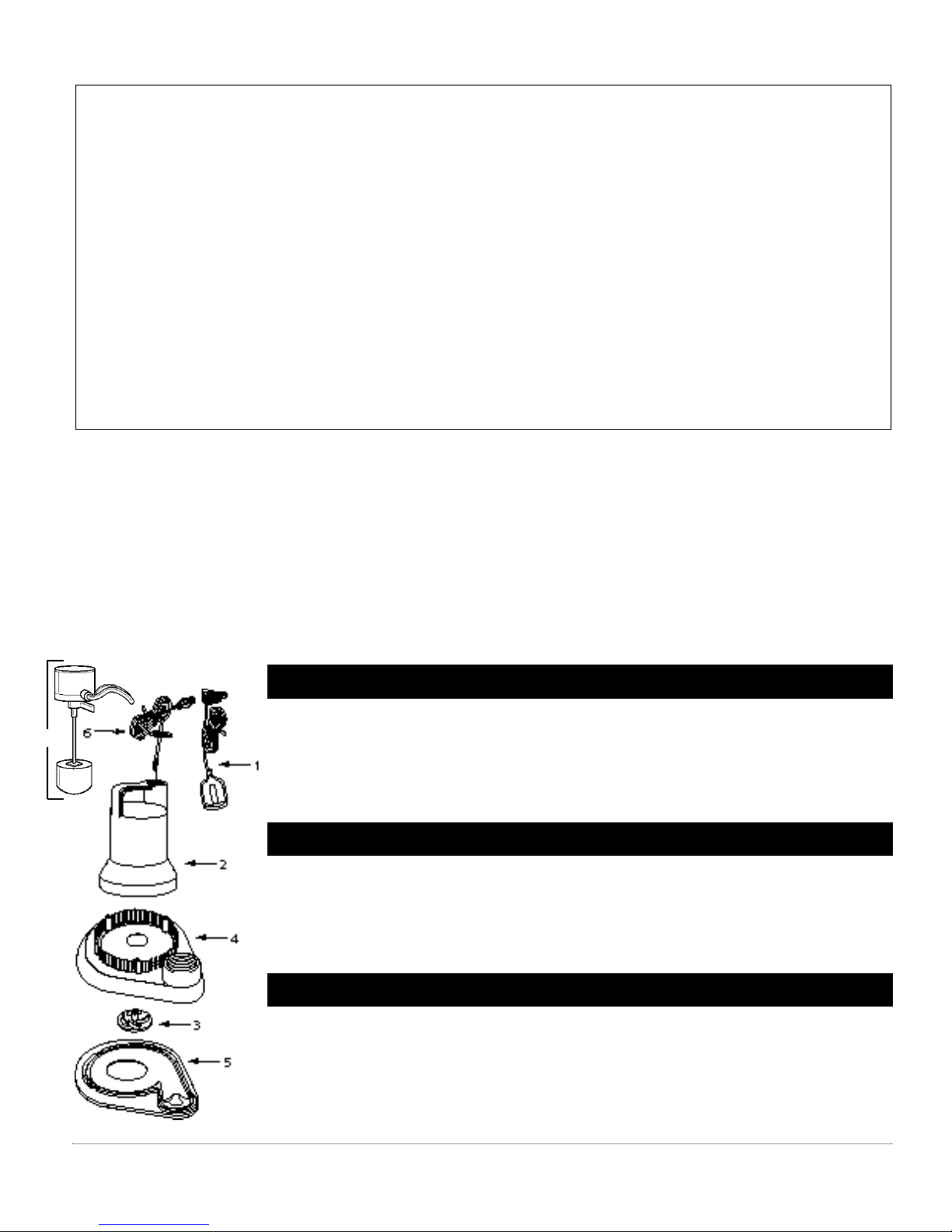

2. This pump is only for use on 120 Volt

(single-phase), 60 hz, 15 amp service and

is equipped with a 3-conductor cord and

3-prong, grounding type plug. Insert the

float switch cord plug directly into a 120

volt outlet.

3. Insert the pump power cord plug directly

into the back of the float switch cord

plug (See Fig. 3).

2

Operating Instructions and Parts Manual

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not start or

run

Pump starts and stops

too often

Pump will not shut off

or thermal protector

turns off

Pump operates but

delivers little or no

water

1. Blown fuse

2. Low line voltage

3. Defective motor

4. Defective float switch

5. Impeller bound-up

6. Float obstructed

1. Backflow of water from piping

2. Faulty float switch

1. Defective float switch

2. Obstacle in piping

3. Float obstructed

1. Low line voltage

2. Plugged impeller

1. If blown, replace with proper sized fuse or reset breaker

2. If voltage is under 108 volts, check wiring size

3. Replace pump

4. Replace float switch

5. If impeller will not turn, remove housing and remove blockage

6. Make sure float move freely up and down

1. Install or replace check valve (Wayne check valve kit #66005-WYN)

2. Replace float switch

1. Replace float switch

2. Remove pump and clean pump and piping

3. Make sure float move freely up and down

1. If voltage is under 108 volts, check wiring size

2. Clean out impeller

shock. Only qualified electricians

should repair this unit. Improper repair

could result in fatal electrical shock.

1. Let the pump cool for a minimum of two

hours before servicing because the

pump contains hot oil under pressure

and the motor is hot.

2. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required, see

troubleshooting chart.

4. Inlet should be kept clean and free of all

foreign objects and inspect annually. A

clogged inlet will damage pump.

5. Pump should be checked monthly for

proper operation.

This pump contains

dielectric oil for

cooling. This oil can be harmful to the

environment. Check the state

environmental laws before disposing

this oil.

Specifications

Power supply requirements.............120V, 60 hz

Motor................................................Single phase, oil filled

Liquid temperature range...............40°F to 120°F

Circuit requirements ........................15 amps (min)

Dimensions .......................................11” high x 9” base

Cut-in level (factory set) ..................Tether...14” Float .....7”

Cut-out level (factory set)................Tether...7” Float .....2 1/2”

Construction

Motor housing .................................Glass reinforced thermoplastic

Volute ...............................................Thermoplastic

Impeller.............................................Glass reinforced thermoplastic

Shaft..................................................416 Stainless steel

Seals ..................................................Buna N

Discharge ..........................................11/2” NPT

Figure 3

www.waynepumps.com

3

Operating Instructions and Parts Manual

1 Tether Float Switch Kit (WST) 60022-001 60022-001 60022-001 60022-001 60022-001 —

2 Motor Assy Kit 60046-001 60047-001 60048-001 60049-001 60049-002 60049-002

3 Impeller Kit 66010-001 66011-001 66012-001 66013-001 66013-002 66013-001

4 Volute 28416-001 28416-001 28416-001 28416-001 28416-001 28416-001

5 Base 28418-001 28418-001 28418-001 28418-001 28418-001 28418-001

6 Power Cord Kit 62003-001 62003-001 62003-001 62003-001 62003-001 62003-001

7 Vertical Float Switch Kit (WSF) 60051-001 60051-001 60051-001 60051-001 — 60051-001

Ref. Part Numbers for Models WSF50

No. Description W25T/F WST/F30 W33T/F WST/F40 W50T WSF510

For Replacement Parts, call 1-800-237-0987

Pour Les Pièces de Rechange, appeler 1-800-237-0987

Para ordenar repuestos, comuníquese con el distribuidor más

cercano a su domicilio.

Please provide following information:

- Model number

- Serial number (if any)

- Part descriptions and number as shown

in parts list

Address parts correspondence to:

Correspondance:

Puede escribirnos a:

Wayne Water Systems

100 Production Drive

Harrison, OH 45030 U.S.A.

Sírvase darnos la siguiente información:

- Número del modelo

- Número de serie (de haberlo)

- Descripción y número del repuesto según la lista

S’il vous plaît fournir l’information suivante:

- Numéro du Modèle

- Numéro de Série (si présent)

- Description et numéro de la pièce

Replacement Parts List

Liste de Pièces de Rechange

Lista de repuestos

• Only use factory parts to repair this

pump.

• Utiliser seulement les pièces de l’usine

pour la réparation de cette pompe.

• Use sólo repuestos legítimos para

reparar esta bomba.

Limited Warranty

For 90 days from the date of purchase, Wayne Water Systems Division ("Wayne") will repair or re place, at its option, for the original

purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by Wayne to be defective in

materials or work man ship. Please call Wayne (800-237-0987) for instructions or see your dealer. Be pre pared to provide the model

number and the serial number when exercising this warranty. All transportation charges on Products or parts submitted for repair or

replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper

installation, improper maintenance, or failure to operate in accordance with Wayne’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANT ABIL I TY AND FITNESS FOR

A PARTICULAR PUR POSE, ARE LIMITED TO 90 DAYS FROM THE DATE OF PURCHASE. THIS IS THE EXCLUSIVE REM E DY AND ANY

LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAM AG ES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of incidental or

consequential damages, so the above lim i ta tions might not apply to you. This limited war ran ty gives you specific legal rights, and you

may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise, shall Wayne or its suppliers be

liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or revenues, loss of use of the

products or any associated equipment, damage to associated equip ment, cost of capital, cost of substitute products, facilities, services or

replacement power, downtime costs, or claims of buyer’s cus tom ers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a copy of

the purchase receipt along with the material or correspondence. Please call Wayne (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

1 Jeu d’Interrupteur Flotteur (WST)66014-001 60022-001 66014-001 60022-001 66014-001 —

2 Jeu d’assem. de moteur 60046-001 60047-001 60048-001 60049-001 60049-002 60049-002

3 Jeu de turbine 66010-001 66011-001 66012-001 66013-001 66013-002 66013-001

4 Volute 28416-001 28416-001 28416-001 28416-001 28416-001 28416-001

5 Base 28418-001 28418-001 28418-001 28418-001 28418-001 28418-001

6 Jeu de cordon d’alimentation 62003-001 62003-001 62003-001 62003-001 62003-001 62003-001

7 Jeu d’Interrupteur À Flotteur (WSF) 60051-001 60051-001 60051-001 60051-001 — 60051-001

Nº de Numéros de Pièces pour Modèles WSF50

Réf. Description W25T/F WST/F30 W33T/F WST/F40 W50T WSF510

1 Flotante/interruptor (WST) 66014-001 60022-001 66014-001 60022-001 66014-001 —

2 Motor 60046-001 60047-001 60048-001 60049-001 60049-002 60049-002

3 Impulsor (propela) 66010-001 66011-001 66012-001 66013-001 66013-002 66013-001

4 Voluta 28416-001 28416-001 28416-001 28416-001 28416-001 28416-001

5 Base 28418-001 28418-001 28418-001 28418-001 28418-001 28418-001

6 Cordón eléctrico 62003-001 62003-001 62003-001 62003-001 62003-001 62003-001

7 Juego de interruptor/ 60051-001 60051-001 60051-001 60051-001 — 60051-001

flotante vertical (WSF)

No. de Número de Piezas para los Modelos WSF50

Ref. Descripción W25T/F WST/F30 W33T/F WST/F40 W50T WSF510

7

www.waynepumps.com

Loading...

Loading...