Page 1

Operating Instruction and Parts Manual Pedestal Series

MANUAL

24 in.

Min.

14 in.

Dia.

Min.

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain

the product described. Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain instructions for future reference.

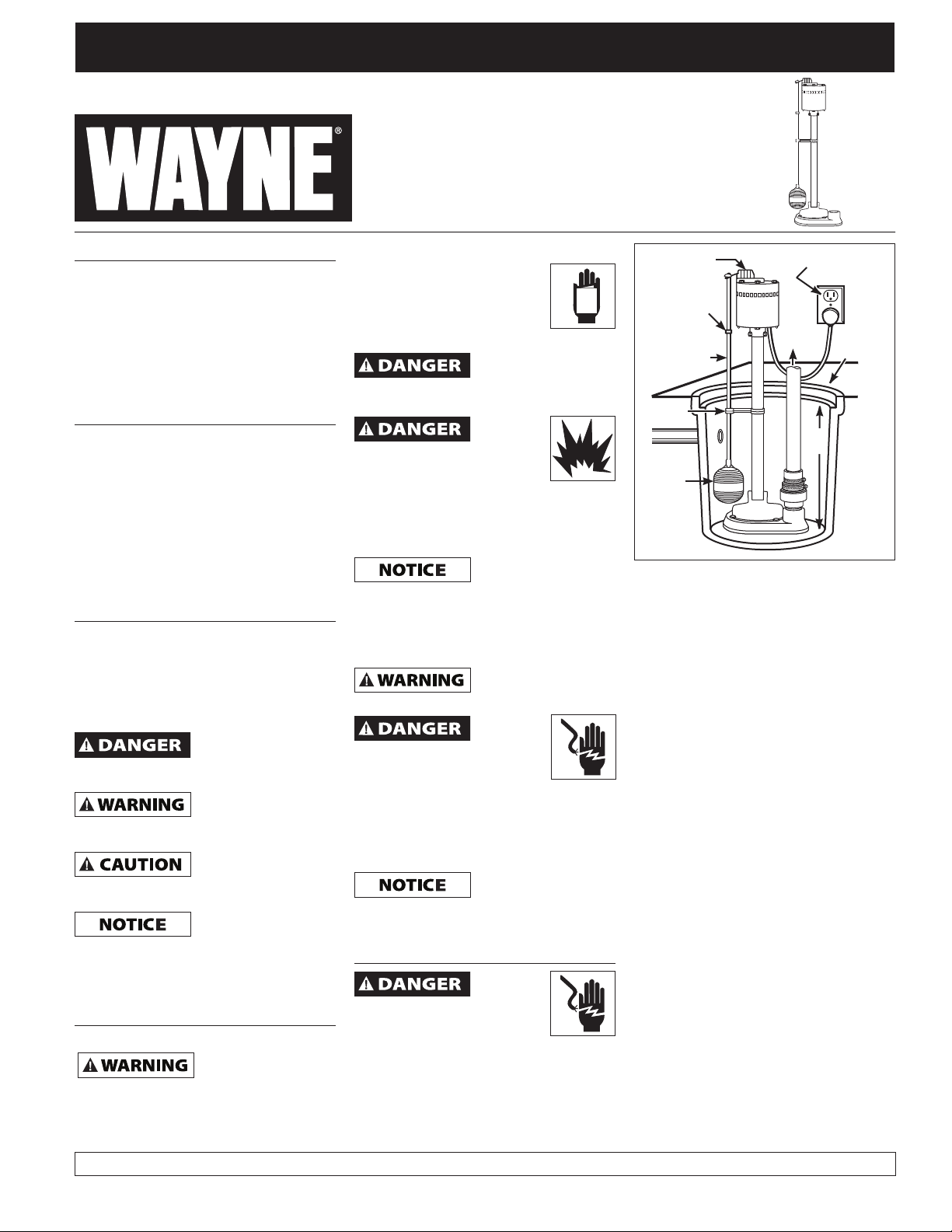

Pedestal Sump

Pump

Description

The pedestal pump is designed for

home sump applications. The unit is

equipped with an 8-ft long, 3-prong

grounding type power cord. Motor is

air cooled; it is not designed to operate

under water. A float switch is provided

for automatic pump operation. This

pump is not suitable for aquatic life.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged during

shipment. If the pump or components are

damaged, return the unit to the place of

purchase for replacement. Failure to do so

could result in serious injury or death. Some

warning labels come affixed to the pump.

Over time, these labels may fade. If this

happens, contact Wayne Water Systems for

a free replacement label.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates

hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates

hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

situation which, if not avoided, may result

in minor or moderate injury.

Notice indicates

information, that if not followed, may

cause damage to equipment.

an imminently

a potentially

potentially hazardous

important

General Safety

Information

CALIFORNIA PROPOSITION 65

This product or its

power cord may

contain chemicals, including lead, known

to the State of California to cause cancer

and birth defects or other reproductive

harm. Wash hands after handling.

GENERAL SAFETY INFORMATION

Read these rules and

instructions carefully. Failure

to follow these instructions

could cause serious bodily

injury and/or property damage.

Do not submerge

motor or allow

motor to be exposed to water. Personal

injury and/or death could result.

Do not

use to

pump flammable or explosive

fluids such as gasoline, fuel

oil, kerosene, etc. Do not

use in a flammable and/or explosive

atmosphere. Pump should only be used

to pump clear water. Personal injury

and/or death could result.

This pump is not

designed to handle

salt water, brine, laundry discharge or

any other application which may contain

caustic chemicals and/or foreign materials.

Pump damage could occur if used in these

applications and will void warranty.

All wiring must be

performed by a

qualified electrician.

If the

basement

has water or moisture on the

floor, do not walk on wet area

until all power is turned off. If

the shut-off box is in the basement, call

an electrician to disconnect the power.

Remove pump and either repair or replace.

Failure to follow this warning could result

in fatal electrical shock.

A battery backup

system should be

used. Please contact your local retailer

to order an emergency backup system.

Assembly

Always

disconnect

the power source before

attempting to install, service,

relocate or maintain the pump.

Never touch sump pump, pump motor,

water or discharge piping when pump is

connected to electrical power. Never handle

a pump or pump motor with wet hands or

when standing on wet or damp surface or

in water. Fatal electrical shock could occur.

Switch

Grommet

Float Rod

Guide

Float

Figure 1

GFCI Grounded

FLOAT INSTALLATION SPV800, SPV500

& SSPTU50

1. To attach float for SPV800, SPV500

& SSPTU50. insert float rod through

hole in switch lever.

2. Place rubber grommet on float rod

in temporary position.

3. Slide float guide onto float rod.

4. Using pliers to hold the float rod,

screw the float on.

5. Attach the float guide to pump

halfway up the pumps stand and

properly align with motor switch.

FLOAT INSTALLATION PTU30, PTU33A

& PTU50

1. To attach float for PTU30, PTU33A, and

PTU50 begin by sliding the float guide

onto the open end of the float rod.

2. Next slide a grommet onto the open

end of the float rod about ¼ of the

way down.

3. Guide the open end of the float rod

through the hole in the switch lever.

4. Place the second grommet onto the

open end of the float rod, being sure

to keep the float rod inserted into the

switch lever.

5. Attach the float guide to pump halfway

up the pumps stand and properly align

with motor switch.

NOTE: For all replacement float kits

installation will be the same as for

SPV800, SPV500 & SSPTU50.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.waynepumps.com

360516-001 9/09© 2009 Wayne Water Systems

Outlet

Page 2

Operating Instructions and Parts Manual

Grounding

Blade

Grounded

Outlet

Power

Cord

TEST

RESET

Installation

1. A ground fault circuit interrupter

(GFCI) is required.

2. This pump is for use on 120 Volt

(single phase), 60 hz, 15 amp service

and is equipped with a 3 conductor

cord and a 3 prong grounding plug.

3. Install pump in a sump pit with

minimum size as shown (See Figure

1). Construct sump pit of tile,

concrete, steel or plastic.

4. Locate unit on a solid, level

foundation. Do not place pump

directly on clay, earth, gravel or

sandy surface. These surfaces contain

small stones, gravel, sand, etc. that

may clog or damage the pump and

cause pump failure (See Figure 1).

5. (Optional) Thread check valve (not

included) into pump body carefully

to avoid stripping or cross threading.

Do not use pipe joint sealant.

6. Connect 1-1/4” rigid pipe to rubber

boot on check valve. Reverse boot

for 1-1/2” diameter pipe. Tighten

hose clamps.

Support pump and

piping when

assembling and after installation. Failure

to do so could cause piping to break, pump

to fail, etc. which could result in property

damage and/or personal injury.

Flood risk. If

flexible discharge

hose is used, make sure pump is

secured in sump pit to prevent

movement. Failure to secure pump

could allow pump movement and switch

interference and prevent pump from

starting or stopping.

IMPORTANT: Make sure there is

adequate room for float switch to move

freely during operation.

7. Protect electrical cord from sharp

objects, hot surfaces, oil and

chemicals. Avoid kinking the

cord and replace damaged cords

immediately.

8. A sump pit cover must be installed

to prevent debris from clogging or

damaging the pump.

Risk of

electrical

shock! This pump is supplied

with a grounding conductor

and grounding type attachment plug. Use

a grounded GFCI receptacle to reduce the

risk of fatal electrical shock.

Never cut off the round grounding

prong. Cutting the cord or plug will

void the warranty and make the

pump inoperable.

9. Insert the float switch cord plug

directly into a 120 volt outlet (See

Figure 2).

GFCI

Outlet

Figure 2

ADJUST AND T EST

1. Fill sump with water.

2. Adjust rubber grommet into a

permanent position on float rod

so that the pump switches on with

approximately 14” of water in the sump.

3. While the pump is draining the pit,

verify that the discharge piping is

carrying the water to a point several

feet away from the foundation.

4. If the pump discharge line is

exposed to freezing temperature,

the exposed line must be pitched to

drain. Trapped water will freeze and

damage the pump.

Maintenance

Always

disconnect the electrical

supply before attempting to

install, service, relocate or

perform any maintenance. If the power

source is out of sight, lock and tag

in the open (off) position to prevent

unexpected power application. Failure

to do so could result in fatal electrical

shock. Only qualified electricians should

repair this unit. Improper repair could

result in fatal electrical shock.

1. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required, see

troubleshooting chart.

2. Keep pump inlet clean and free

of all foreign objects and inspect

annually. A clogged inlet will

damage pump.

3. Check pump monthly for proper

operation.

NOTE: A pump that has a tripped

thermal protector may start suddenly!

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not start or

run

Pump start and stops too

often

Pump will not shut off

or thermal protector

turns off

Pump operates but

delivers little or no

water

www.waynepumps.com

1. Blown fuse

2. Low line voltage

3. Defective motor

4. Defective switch

5. Impeller

6. Float obstructed

1. Back flow of water from piping

2. Float out of adjustment

1. Defective switch

2. Obstacle in piping

3. Float obstructed

1. Low line voltage

2. Plugged impeller

1. If blown, replace with proper sized fuse or reset breaker

2. If voltage is under 108 volts, check wiring size

- DO NOT USE AN EXTENSION CORD

3. Replace motor or pump

4. Replace switch

5. If impeller will not turn, remove housing and remove blockage

6. Make sure float moves freely up and down

1. Install or replace check valve (Wayne check valve kit #66005-WYN1)

2. Adjust grommet

1. Replace switch

2. Remove pump and clean pump and piping

3. Make sure float moves freely up and down

1. If voltage is under 108 volts, check wiring size

- DO NOT USE AN EXTENSION CORD

2. Clean out impeller

2

Page 3

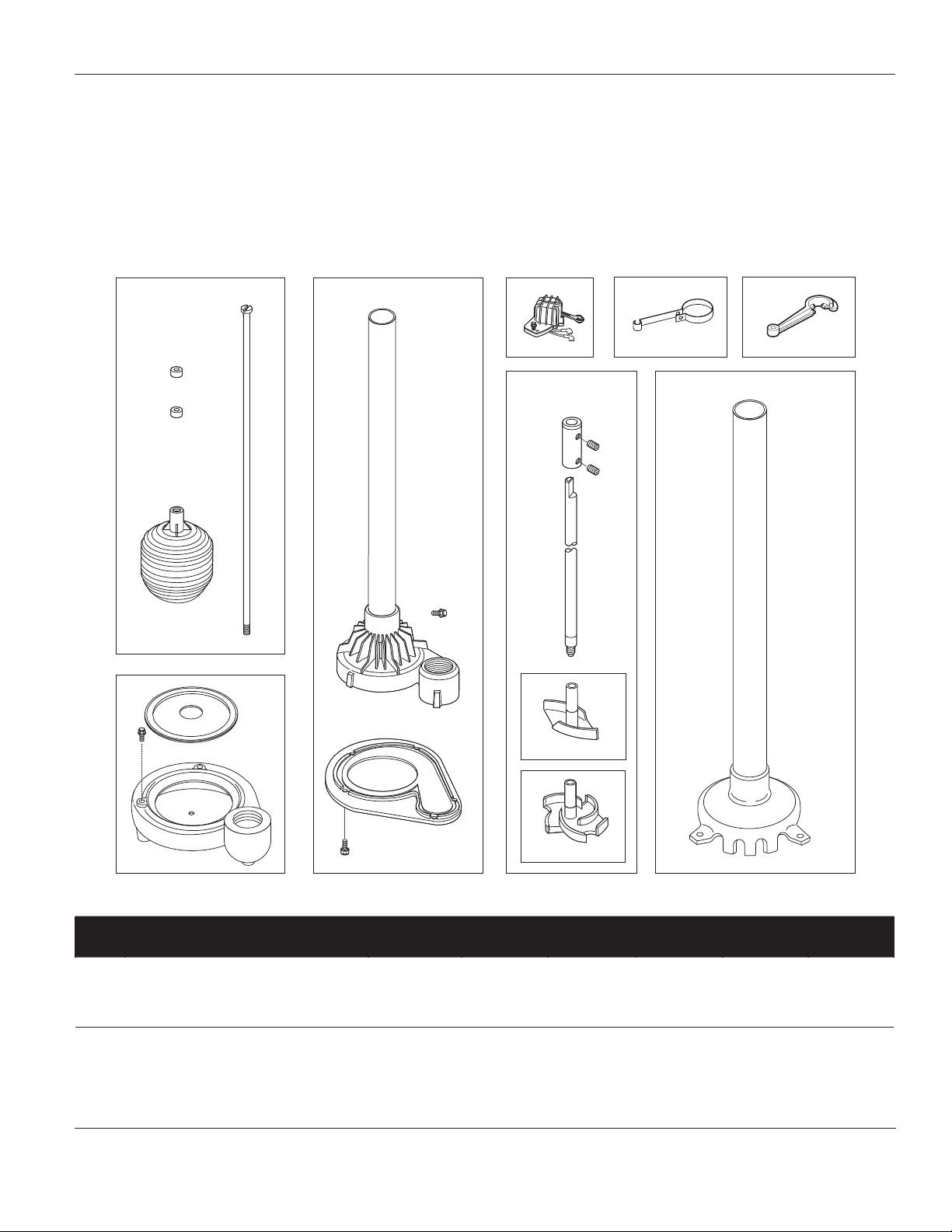

4

1/3 HP

1/2 HP

21

2

3

5

6 6

For Replacement Parts or Technical Assistance,

call 1-800-237-0987

Pedestal Series

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030

Replacement Parts List

Ref.

No. Description PTU30 PTU33A SPV500 SPV800 PTU50 SSPTU50

1 Float Kit 57030-001 57030-001 57030-001 57030-001 57030-001 57030-001

2 Volute Kit 61030-001 61030-001 60057-001 60057-001 61030-001 57509-001

3 Impeller Kit 60131-001 60131-001 60054-001 60055-001 61041-001 60037-001

4 Switch Assembly 56396 56396 56396 56396 56396 56396

5 Pump top housing

(with column and bearing)

6 Float Guide 01509001 01509001 16910 16910 01509001 16910

— — 56638-002 56638-002 — —

www.waynepumps.com

3

Page 4

Operating Instructions and Parts Manual

Pedestal Series

Limited Warranty

For one (PTU30, PTU33A & PTU50), two (SPV500 or SPV800) or three (SSPTU50) year(s) from date of purchase, Wayne Water

Systems (”Wayne“) will repair or replace, at its option, for the original purchaser any part or parts of its Sump Pumps or Water

Pumps (”Product“) found upon examination by Wayne to be defective in materials or workmanship. Please call Wayne (800237-0987) for instructions or see your dealer. Be prepared to provide the model number when exercising this warranty. All

transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Wayne’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED FOR ONE (PTU30, PTU33A & PTU50), TWO (SPV500 OR SPV800)

OR THREE (SSPTU50) YEAR(S) FROM THE DATE OF PURCHASE. THIS IS THE EXCLUSIVE REMEDY AND ANY LIABILITY

FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Wayne or its

suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or

revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call Wayne (800-237-0987) for return

authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

Model No._____________________ Serial No.______________________________ Installation Date __________________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

4

Page 5

Instructions d'Utilisation et Manuel de Piéces Séries sur Jambe

MANUAL

24 in.

Min.

14 in.

Dia.

Min.

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions

peut résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Pompe de Puisard

sur Jambe

Description

La pompe de puisard sur jambe a été

conçue pour l’utilisation domestique.

Le modèle est équipé d’un cordon

d’alimentation de2,4 m à 3-broches

de type mise à la terre. Le moteur est

refroidi par l’air; il n’est pas conçu pour le

fonctionnement sous l’eau. Un interrupteur

flotteur est fourni pour le fonctionnement

automatique. Cette pompe n’est pas

convenable pour les animaux aquatiques.

Déballage

Vérifier cette unité avant l’utilisation.

Parfois, un produit peut être endommagé

pendant le transport. Si la pompe ou

d’autres pièces ont subi de dommages,

retourner l’unité à l’endroit d’achat pour

son remplacement. Sinon, cela pourrait

mener à des blessures graves ou la mort.

Avec le temps, elles pourraient s’effacer.

Si ceci se produit, contacter Wayne Water

Systems pour un remplacement gratuit.

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger indique

une situation

hasardeuse imminente qui résultera en

perte de vie ou blessures graves.

Avertissement

indique une

situation hasardeuse potentielle

qui peut résulter en perte de vie ou

blessures graves.

Attention indique

unesituation

hasardeuse potentielle qui peut résulter

en blessures.

Avis indique

l’information

importante pour éviter le dommage de

l’équipement.

Généralités sur la Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son cordon peuvent

contenir des produits chimiques, y

compris du plomb, relevés par l'État

de Californie comme cause de cancer,

d'anomalies congénitales ou d'autres

problèmes reproductifs. Lavez-vous les

mains après toute manipulation.

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie! Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2009 Wayne Water Systems 360516-001 9/09

GÉNÉRALITÉS SUR LA SÉCURITÉ

Lire ces directives et ces

instructions attentivement.

Manque de suivre ces

instructions peut causer de

blessures graves et/ou dégâts matériaux.

Ne pas sub-merger

le moteur ni

permettre que le moteur soit exposé

à l’eau. Ceci peut causer des blessures

personnelles et/ou perte de vie.

Ne pas

pomper

les fluides explosifs tels que

l’essence, l’huile à chauffage,

le kérosène etc. Ne pas utiliser

dans un atmosphère inflammable et/

ou explosif. La pompe devrait être

utilisée pour le pompage de l’eau claire

seulement, sinon, il y a risque de blessures

personnelles et/ou dégâts matériels.

Cette pompe n’est

pas conçue pour les

substances qui contiennent les produits

chimiques caustiques et/ou les matières

étrangères tels que l’eau salée, la saumure,

le décharge de buanderie. L’utilisation de

ces produits peut endommager la pompe

et annulera la garantie.

Toute installation

des fils doit être

effectuée par un électricien qualifié.

Ne pas

marcher

sur un plancher de soussol

trempe ou humide avant de

couper l’électricité. Si la boîte de

branchement est dans le sous-sol, contacter

un électricien pour couper l'énergie. Enlever

la pompe et la réparer ou remplacer.

Manque de suivre cet avertissement peut

résulter en secousse électrique mortelle.

Un système de

batterie de

sauvegarde doit être utilisé. Contactez

s'il vous plaît votre détaillant local pour

ordonner un système de suavegarde

d'urgence.

Montage

Toujours

déconnecter la source de

puissance avant d’essayer de

monter, de déplacer ou de

procéder au service ou à l’entretien de

la pompe. Ne jamais toucher la pompe

de puisard, le moteur de pompe, la

tuyauterie d’eau ou de décharge quand

la pompe est connectée à la puissance

électrique. Ne jamais manipuler une

pompe ni un moteur de pompe avec

les mains trempes ou si debout sur une

surface trempe ou humide. Ceci peut

résulter en secousse électrique mortelle.

5-Fr

Interrupteur

Anneau

Tige de

flotteur

Guide

Flotteur

Figure 1

Prise-Mise

À La Terre

Dia. Min

35,6 cm

Min.

61

cm

INSTALLATION DE FLOTTEUR POUR

SPV800, SPV500 et SSPTU50

1. Pour attacher le flotteur pour les

modèles SPV800, SPV500 et SSPTU50,

insèrer la baguette du flotteur par le

trou dans le levier de l'interrupteur.

2. Placer le passe-fil de caoutchouc sur

la baguette du flotteur, en position

temporaire.

3. Glisser le guide du flotteur sur la

baguette du flotteur.

4. À l'aide des pinces, tenir fixe la baguette

du flotteur et visser le flotteur sur la

baguette.

5. Attacher le guide du flotteur à la pompe,

à mi-chemin vers le haut de la jambe de

la pompe, et l'aligner correctement avec

l'interrupteur du moteur.

INSTALLATION DU FLOTTEUR POUR

PTU30, PTU33A et PTU50

1. Pour attacher le flotteur pour les

modèles PTU30, PTU33A et PTU50,

commencer en glissant le guide du

flotteur sur l'extrémité libre de la

baguette du flotteur.

2. Faire glisser ensuite un passe-fil sur

l'extrémité libre de la baguette du

flotteur d'1/4 vers le bas.

3. Guider l'extrémité libre de la

baguette du flotteur par le trou dans

le levier de l'interrupteur.

4. Placer le deuxième passe-fil sur

l'extrémité libre de la baguette du

flotteur, en s'assurant de garder la

baguette du flotteur insérée dans

le levier de l'interrupteur.

Page 6

Instructions d’utilisation et manual de pièces

TEST

RESET

Montage (suite)

5. Attacher le guide du flotteur à la pompe,

à mi-chemin vers le haut de la jambe de

la pompe, et l'aligner correctement avec

l'interrupteur du moteur.

REMARQUE : Pour toutes les trousses

de flotteur de remplacement,

l'installation sera la même quant aux

modèles SPV800, SPV500 et SSPTU50.

Installation

1. Un interrupteur contre un

dérangement dû à une mise

accidentelle à la terre (DDFT) est requis.

2. Cette pompe est conçue pour le service

de 120 V (monophasé), 60 Hz, 15 A et

est équipé d’un cordon à 3 conducteurs

et d’une fiche à 3 broches.

3. Installer la pompe dans une fosse

de taille minimum telle qu’indiquée.

(Voir Figure 1.) Construire la fosse de

tuiles, béton, acier ou plastique.

4. Situer le modèle sur une fondation

solide et égale. Ne pas placer la

pompe directement sur une surface

d’argile, terre, gravier ou de sable. Ces

surfaces contiennent des particules de

gravier et de sable etc., qui peuvent

obstruer ou endommager la pompe et

causer la panne Voir Figure 1).

5. (En Option) Fileter le clapet (noncompris) dans le corps de la pompe

soigneusement afin d’éviter le foirage

ou l’abattement. Ne pas utiliser le

mastic de fermeture pour joints.

6. Brancher le tuyau rigide de 3,2 cmau

manchon de caoutchouc sur le clapet.

L’inverser pour accepter un tuyau de

3,8 cm. Serrer les colliers de serrage.

Il est nécessaire

de soutenir la pompe

et la tuyauterie pendant le montage et

après l’installation afin d’éviter la rupture

du tuyau ou la panne de la pompe etc., ce

qui peut résulter en dégâts matériels et/ou

blessures personnelles.

Risque d’inondation.

décharge flexible est utilisé, s’assurer

que la pompe soit fixée à la fosse afin

d’éviter le movement inattendu. Manque

de fixer la pompe peut résulter en

movement de la pompe et en interférence

de l’interrupteur et peut empêcher le

démarrage ou l’arrêt de la pompe.

Si un tuyau de

IMPORTANT: S’assurer qui’ y ait assez

d’espace pour le mouvement sans

obstruction de l’interrupteur flotteur

pendant l’opération.

7. Protéger les cordons d’alimentation

contre les objets pointus, les surfaces

chaudes, l’huile et les produits

chimiques. Éviter le tortillement

du cordon et remplacer les cordons

endommagés immédiatement.

8. Il est nécessaire d’installer un

couvercle de réservoir afin

d’empêcher l’obstruction ou le

dommage à la pompe par le débris.

Risque de

électrique! Cette pompe est

fournie d’un conducteur de

terre et d’une fiche de prise de

poste mise à la terre. Utiliser une prise de

courant GFCI mise à la terre pour réduire

le risque de secousse électrique mortelle.

Ne jamais couper ou enlever la broche de

terre ronde. Le coupage du cordon ou de

la fiche annulera la garantie et rendra la

pompe inutile.

secousse

9. Introduire la fiche de l’interrupteur

flotteur directement dans une prise

de 120 volts (Voir Figure 2).

Broche De Terre

Figure 2

Cordon

D'Alimentation

Prise-Mise À

La Terre

AJUSTEMENT ET ESSAI

1. Remplir la fosse d’eau.

2. Ajuster l’anneau en caoutchouc dans

une position permanente sur la tige

de flotteur afin que la pompe se met

en marche avec approximativement

35,56 cm d’eau dans la fosse.

3. Vérifier que le tuyau de décharge

transporte l’eau à un endroit

plusieurs pieds de la fondation

pendant son fonctionnement.

4. Si la ligne de décharge est exposée

à la gelée, elle doit être inclinée.

Les poches d’eau peuvent geler et

endommager la pompe.

Entretien

Toujours

débrancher

la source d’électricité avant

d’essayer d’installer, de déplacer

ou de procéder à l’entretien. Si la

source de puissance est hors vue, verrouiller

et étiquetter dans la position ouverte (off)

pour éviter l’alimentation inattendue.

Manque de suivre ces directives peut

résulter en secousse électrique mortelle.

Seul un électricien qualifié devrait réparer

ce modèle. La réparation incorrecte peut

résulter en secousse électrique mortelle.

1. Le démontage du moteur avant la date

d’expiration de la garantie annulera la

garantie. Si la réparation est requise, se

référer au guide de dépannage.

2. Garder l’arrivée de la pompe propre et

libre de tous matériaux et l’inspecter

annuellement. Une arrivée obstruée

endommagera la pompe.

3. Inspecter la pompe mensuellement

pour assurer le fonctionnement correct.

REMARQUE: Une pompe qui a un

protecteur thermique déclenché peut

démarrer soudainement!!

Guide de Dépannage

Symptôme Cause(s) Possible(s) Mesures Corrective

La pompe ne se démarre

pas et ne fonctionne pas

La pompe se démarre et

s'arrête trop souvant

La pompe ne s'arrête

pas ou le protecteur

thermique s'arrête

La pompe fonctionne mais

refoule peu ou pas d'eau

1. Fusible sauté

2. Tension de ligne basse

3. Moteur défectueux

4. Interrupteur défectueux

5. Turbine

6. Flotteur obstrué

1. Refoulement d'eau du tuyau

2. lotteur mal ajusté

1. Interrupteur défectueux

2. Obstruction dans la tuyauterie

3. Flotteur obstrué

1. Tension de ligne basse

2. Turbine obstruée

1. Si sauté, le remplacer avec un fusible de taille correcte ou rajuster le

disjoncteur.

2. Si la tension est inférieure à 108 volts, vérifier la taille des fils.

- NE PAS UTILISER DE RALLONGE

3. Remplacer le moteur ou la pompe Remplacer l'interrupteur

4. Remplacer l'interrupteur

5. Si la turbine ne tourne pas, enlever le carter et enlever l'obstruction

6. Assurer le movement libre de hout en bas du flotteur

1. Installer ou remplacer le clapet (Nécessaire de clapet Wayne #66005-WYN1)

2. Ajuster l'anneau

1. Remplacer l'interrupteur

2. Enlever la pompe et nettoyer la pompe et la tuyauterie

3. Assurer le movement libre de haut en bas du flotteur

1. Si la tension est inférieure à 108 volts, vérifier la taille des fils.

- NE PAS UTILISER DE RALLONGE

2. Nettoyer la turbine

6-Fr

Page 7

Séries sur Jambe

4

1/3 HP

1/2 HP

21

2

3

5

6 6

Pour les Pièces de Rechange ou l’assistance technique,

appeler 1-800-237-0987

S’il vous plaît fournir l’information suivante:

- Numéro du Modèle

- Numéro de Série (si présent)

- Description et numéro de la pièce

Correspondance:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030

Liste De Pièces De Rechange

N°. de

Ref. Description PTU30 PTU33A SPV500 SPV800 PTU50 SSPTU50

1 Néc. de flotteur 57030-001 57030-001 57030-001 57030-001 57030-001 57030-001

2 Néc. de volute 61030-001 61030-001 60057-001 60057-001 61030-001 57509-001

3 Néc. de turbine 60131-001 60131-001 60054-001 60055-001 61041-001 60037-001

4 Assem. d'interrupteur 56396 56396 56396 56396 56396 56396

5 Carter de pompe supérieur

avec jambe & roulement

6 Guide de Flotteur 01509001 01509001 16910 16910 01509001 16910

— — 56638-002 56638-002 — —

7-Fr

Page 8

Instructions d’utilisation et manual de pièces

Séries sur Jambe

Garantie Limitée

Pour un (PTU30, PTU33A & PTU50), deux (SPV500 ou SPV8000) ou trois (SSPTU50) an(s) à compter de la date d’achat, Wayne

Water Systems (“Wayne”) vas réparer ou remplacer, à son option, pour l’acheteur originel n’importe quelle pièce ou pièces

de ces Pompes De Puisard ou Pompes À Eau (“Produit”) déterminées défectueuses, par Wayne, en matière ou en fabrication.

S’il vous plaît appeler Wayne (800-237-0987) pour des instructions ou contacter votre marchand. S’assurer d’avoir, à votre

disposition, le numéro du modèle afin d’effectuer cette garantie. Les frais de transportation des Produits ou pièces soumis

pour la réparation ou le remplacement sont la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident, utilisation abusive,

mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation conformément aux

instructions écrit de Wayne.

IL N’EXISTE AUCUNE AUTRE GARANTIE OU AFFIRMATION. LES GARANTIES EXPRIMÉES, Y COMPRIS CELLES DE

COMMERCIALISABILITÉ ET D’ADAPTION POUR UN (PTU30, PTU33A & PTU50), DEUX (SPV500 OR SPV800) OU TROIS

(SSPTU50) AN(S) À COMPTER DE LA DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE

RESPONSABILITÉ POUR N’IMPORTE QUEL ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST

EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des

dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne, à

l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales qui sont variable d’une Province ou d’un État à

l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement,

ni Wayne ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y compris, mais pas

limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à

l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou abilité de remplaçement, coût

de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre recette d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une copie de la recette d’achat avec

le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît appeler Wayne (800-237-0987)

pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE ______________________ Nº DE SÉRIE _______________________ DATE D’INSTALLATION ______________________

FIXER VOTRE FACTURE ICI

8-Fr

Page 9

Manual de instrucciones de operación y piezas Serie de Pedestal

MANUAL

24 in.

Min.

14 in.

Dia.

Min.

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento

al producto aquí descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. ¡El no cumplir con las

instrucciones puede ocasionar daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Bomba de Pedestal para

Sumideros

Descripción

La bomba de pedestal está diseñada para

aplicaciones de sumidero domésticas. La

unidad está equipada con un cordón

eléctrico de 2,44 m (8 pies) de largo y

enchufe de 3 clavijas de conexión a tierra.

El motor es enfriado por aire; no está

diseñado para funcionar bajo el agua.

Se suministra un interruptor de flotación

para el funcionamiento automático de la

bomba. Esta bomba no es apropiada para

vida acuática.

Desempacar

Revise esta unidad antes de usarla. A veces,

el producto puede sufrir daños durante el

transporte. Si la bomba u otras piezas se han

dañado, devuelva la unidad al lugar donde

ha sido comprada para que la sustituyan. De

no hacer eso, se pueden producir serios daños

o la muerte. Con el tiempo, estas etiquetas

pueden decolorarse. Si esto sucede, póngase

en contacto con Wayne Water Systems para

obtener una etiqueta de reemplazo gratuita.

Medidas de Seguridad

Este manual contiene información que es

muy importante que sepa y comprenda.

Esta información se la suministramos como

medida de SEGURIDAD y para EVITAR

PROBLEMAS CON EL EQUIPO. Debe

reconocer los siguientes símbolos.

Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica que

hay una situación

que PODRIA ocasionarle la muerte o

heridas de gravedad.

Ésto le indica que

hay una situación

que PODRIA ocasionarle heridas no

muy graves.

Ésto le indica una

información

importante, que de no seguirla, le

podría ocasionar daños al equipo.

Informaciones Generales

de Seguridad

PROPOSICIÓN 65 DE CALIFORNIA

Este producto o su

cable de corriente

pueden contener químicos, incluido

plomo, que es conocido por el Estado

de California como causante de cáncer

y defectos de nacimiento u otros

daños reproductivos. Lávese las manos

después de manipularlo.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía! Adjúntela a este manual o archívela en lugar seguro.

© 2009 Wayne Water Systems

INFORMACIONES GENERALES DE

SEGURIDAD

Lea estas instrucciones con

cuidado. Si no sigue estas

instrucciones podría sufrir

heridas de gravedad y/o

daños a su propiedad.

No sumerja el

motor en el agua

ni permita que esté expuesto a ella.

Puede ocasionar lesiones y/o muerte.

No use

esta

unidad para bombear líquidos

inflamables o explosivos

tales como gasolina, petróleo

diesel, querosene, etc. No la utilice

en una atmósfera combustible o

explosiva. La bomba debe usarse sólo

para bombear agua limpia. Puede

ocasionarle lesiones y/o muerte.

Esta bomba no ha

sido diseñada para

manipular agua salada, salmuera,

descargas de lavandería o cualquier

otra aplicación que pueda contener

sustancias químicas cáusticas y/o

materias extrañas. Podría producirse

un daño en la bomba si se usa en estas

aplicaciones, invalidando la garantía.

Todas las conexiones

deben ser efectuadas

por un electricista calificado.

Si hay

agua o

humedad en el piso del sótano,

no pise el área mojada hasta que

toda la energía eléctrica haya

sido desconectada. Si la caja de desconexión

principal está en el sótano, llame a un

electricista para desconectar l'electricidad.

Retire la bomba y repárela o reemplácela. El

incumpli-miento de esta advertencia puede

ocasionar un choque eléctrico fatal.

Debe utilizarse un

sistema de respaldo

de la pila. Por favor, contacte su detallista

local para pedir un sistema de respaldo

para emergencias.

Ensamblaje

Desconecte

siempre la fuente de energía

antes de intentar instalar,

dar servicio, reubicar o dar

mantenimiento a la bomba. Nunca toque la

bomba de sumidero, el motor de la bomba,

el agua o la tubería de descarga cuando la

bomba esté conectada a la energía eléctrica.

Nunca manipule una bomba o motor de

bomba con las manos mojadas o cuando

esté parado en una superficie húmeda o

mojada o en el agua. Puede ocurrir un

choque eléctrico fatal.

9-Sp

Interruptor

Buje

Varilla del

flotador

Guide

Floatteur

Figura 1

Tomacorriente

Conectado a tierra

35,6 cm

dia. min

Min.

61

cm

SPV800, SPV500 y SSPTU50 INSTALACIÓN DEL FLOTADOR

1. Para sujetar el flotador para SPV800,

SPV500 et SSPTU50, inserte la varilla

del flotador por el agujero en la

palanca del interruptor.

2. Coloque el ojal de caucho en el vástago

del flotador en posición temporal.

3. Deslice la guía del flotador por la

varilla del flotador

4. Sujete el vástago del flotador con

unos alicates y enrosque el flotador.

5. Sujete la guía del flotador a la

bomba a media altura del soporte

y alíneela correctamente con el

interruptor del motor.

PTU30, PTU33A y PTU50 INSTALACIÓN DEL FLOTADOR

1. Para sujetar el flotador para PTU30,

PTU33A, y PTU50, comience deslizando

la guía del flotador por el extremo

libre de la varilla del flotador.

2. Después, deslice un ojal en el

extremo libre de la varilla del

flotador, cerca de 1/4 hacia abajo.

3. Pase el extremo libre del vástago del

flotador por el orificio de la palanca

del interruptor.

4. Coloque el segundo ojal en el

extremo libre de la varilla del

flotador, asegurándose de mantener

la varilla del flotador insertada en la

palanca del interruptor.

5. Sujete la guía del flotador a la

bomba a media altura del soporte

y alíneela correctamente con el

interruptor del motor.

NOTA: Para todos los juegos de flotador

de reemplazo, la instalación será la

misma de SPV800, SPV500 y SSPTU50.

360516-001 9/09

Page 10

Manual de Instrucciones de Operación y Lista de Partes

TEST

RESET

Instalación

1. Se requiere un interruptor de circuito

de pérdida a tierra. (GFCI)

2. Esta bomba es para usarse con un

suministro de 120 V (monofásica), 60

Hz y 15 A. Viene con un cordón de 3

conductores y un enchufe de 3 clavijas

de conexión a tierra.

3. Instale la bomba en un pozo de

sumidero con el tamaño mínimo que

se indica. (Ver Figura 1). Construya

el pozo del sumidero con locetas,

concreto, acero o plástico.

4. Ubique la unidad sobre una base

sólida nivelada. No coloque la bomba

directamente sobre arcilla, tierra,

grava o una superficie arenosa. Estas

superficies contienen piedrecillas,

grava, arena, etc., que pueden obstruir

o dañar la bomba y ocasionar fallas en

la misma. (Ver Figura 1).

5. (Opcional) Atornille la válvula de

retención (no incluida) en el cuerpo

de la bomba, teniendo cuidado de

no dañar la rosca. No use sellador de

uniones para tubo.

6. Conecte un tubo rígido de 3,2 cm a la

lengüeta de caucho en la válvula de

retención. Invierta la lengüeta para un

tubo de 3,8 cm de diámetro. Ajuste las

abrazaderas de manguera.

Apoye la bomba y la

tubería cuando esté

armando y después de la instalación.

Si no cumple esta indicación, puede

ocasionar roturas en la tubería, fallas en

la bomba, etc., las cuales podrían originar

daños materiales y/o personales.

Riesgo de inundación.

Si se utiliza manguera

flexible para la descarga, asegúrese de

que la bomba esté sujeta en el pozo del

sumidero de manera que no se mueva.

El no sujetar la bomba puede permitir el

movimiento de la misma y la interferencia

del interruptor, e impedir que la bomba

funcione o se detenga.

IMPORTANTE: Asegúrese de que

haya espacio adecuado para que el

interruptor de flotación se mueva

libremente durante el funcionamiento.

7. Proteja el cordón eléctrico de objetos

afilados, superficies calientes, aceite

y sustancias químicas. Evite retorcer

el cordón y cambie los cordones

dañados de inmediato.

8. Debe instalarse una cubierta para el

pozo del sumidero a fin de impedir

que los desperdicios obstruyan o

dañen la bomba.

¡Hay riesgo

eléctrico! Esta bomba se

suministra con un conductor de

pérdida a tierra y un enchufe

del tipo de conexión a tierra. Use un

tomacorriente GFCI con conexión a tierra,

para reducir el riesgo de un choque

eléctrico mortal.

Nunca corte la clavija redonda de

conexión a tierra. Si se recorta el cordón

o el enchufe, se invalidará la garantía y la

bomba no podrá funcionar.

de choque

9. Inserte el enchufe del cordón del

interruptor de flotación directamente en

un tomacorriente de 120 V. (Ver Figura 2).

Broche De Terre

Figure 2

Cordon

D'Alimentation

Prise-Mise À

La Terre

AJUSTE Y PRUEBA

1. Llene el sumidero con agua.

2. Ajuste el buje de caucho en una

posición permanente en la varilla del

flotador, de modo que la bomba se

encienda con aproximadamente 35,6

cm de agua en el sumidero.

3. Mientras la bomba está desaguando

el pozo, verifique que la tubería

de descarga lleve el agua hasta un

punto de varios centímet-ros (pies)

de distancia de la base.

4. Si la línea de descarga de la bomba

está expuesta a temperaturas de

congelación, ésta debe tener un declive

para su desagüe. El agua retenida se

congelará y dañará la bomba.

Mantenimiento

Desconecte

siempre el

suministro eléctrico antes de

intentar instalar, dar servicio,

reubicar o efectuar cualquier

mantenimiento. Si la fuente de energía

no está a la vista, bloquéela en posición

abierta (apagado) y ponga una tarjeta

de advertencia para impedir la aplicación

de energía inesperada. El no hacerlo así

podría ocasionar un choque eléctrico

fatal. Esta unidad debe ser reparada

sólo por electricistas calificados. La

reparación defectuosa puede ocasionar

un choque eléctrico fatal.

1. Si se desarma el motor antes de que

expire la garantía, ésta quedará

anulada. Si se necesitan reparaciones,

consulte la Tabla de Detección de Fallas.

2. Mantenga la entrada de la bomba limpia

y libre de cualquier objeto extraño e

inspecciónela anualmente. Una entrada

obstruida dañará la bomba.

3. Compruebe mensualmente el

funcionamiento adecuado de la

bomba.

NOTA: ¡una bomba que tiene un

protector térmico disparado puede

iniciarse repentinamente!

Guía de Diagnóstico de Averías

Problema Posible(s) Causa(s) Acción a Tomar

La bomba no se enciende

ni funciona

La bomba se enciende

y se apaga constatemente

La bomba no se apaga o

el protector térmico se

apaga

La bomba funciona pero

bombea poca agua o no

bombea agua

1. Un fusible quemado

2. El voltaje es muy bajo

3. El motor está dañado

4. El interruptor está dañado

5. La propela

6. El flotante está obstruído

1. El agua se regresa en la tubería

2. El flotante está desajustado

1. El interruptor está dañado

2. Las tuberías están obstruídas

3. El flotante está obstuído

1. El voltaje es muy bajo

2. La propela está atascada

1. Si está quemado, reemplácelo con un fusible adecuado o active el

cortacircuito.

2. Si el voltaje es menos de 108 voltios, chequée el alambrado

– NO USE UN CABLE DE EXTENSIÓN

3. Reemplace el motor o la bomba

4. Reemplace el interruptor

5. Si la propela no gira, detápela y quítele lo que la está obstruyendo

6. Cerciórese de que el flotante puede subir y bajar libremente

1. Instale o reemplace la válvula de chequeo (Juego de válvula de

chequeo Wayne #66005-WYN1)

2. Ajuste la arandela de cabo

1. Reemplace el interruptor

2. Saque la bomba y limpie la bomba y las tuberías

3. Cerciórese de que el flotante puede subir y bajar libremente

1. Si el voltaje es menos de 108 voltios, chequée el alambrado

– NO USE UN CABLE DE EXTENSIÓN

2. Límpiela

10-Sp

Page 11

Serie de Pedestal

4

1/3 HP

1/2 HP

21

2

3

5

6 6

Para ordenar repuestos, comuníquese con el distribuidor

más cercano a su domicilio.

Sírvase darnos la siguiente información:

- Número del modelo

- Número de serie (de haberlo)

- Descripción y número del repuesto según la lista

Puede escribirnos a:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030

Lista de repuestos

No de

Ref. Descripción PTU30 PTU33A SPV500 SPV800 PTU50 SSPTU50

1 Piezas del flotante 57030-001 57030-001 57030-001 57030-001 57030-001 57030-001

2 Piezas de la voluta 61030-001 61030-001 60057-001 60057-001 61030-001 57509-001

3 Piezas de la propela 60131-001 60131-001 60054-001 60055-001 61041-001 60037-001

4 Ensamblaje del interruptor 56396 56396 56396 56396 56396 56396

5 Cubierata superior de la bomba

con columna y cojinetes

6 Guía del flotador 01509001 01509001 16910 16910 01509001 16910

— — 56638-002 56638-002 — —

11-Sp

Page 12

Manual de Instrucciones de Operación y Lista de Partes

Serie de Pedestal

Garantía Limitada

Wayne Water Systems (”Wayne“) le ofrece una garantía de un año (PTU30,PTU33A & PTU50), dos años (SPV500 o SPV800) o tres años

(SSPTU50) a partir de la fecha de compra, para reparar o reemplazar, según lo decida la compañía, cualquier pieza de esta bomba para

sumideros (“Producto”)que el comprador original envie a reparación y los empleados o representantes autorizados de Wayne determinen

que están defectuosos debido a problemas de materiales o manufactura. Para recibir información sobre los pasos a seguir, comuníquese

directamente con la compañía Wayne (800-237-0987, sólo desde EE.UU.), o con el distribuidor autorizado más cercano a su domicilio. En

el momento de reclamar sus derechos bajo esta garantía deberá suministrarnos el número del modelo. Todos los gastos de flete serán la

responsabilidad del comprador.

Esta garantía limitada no cubre los daños debido a accidentes, abusos, uso inadecuado, negligencia, instalación inadecuada, mantenimiento

inadecuado, o funcionamiento sin seguir las instrucciones suministradas por escrito por la compañía Wayne.

NO HAY NINGUNA OTRA GARANTIA EXPRESA O IMPLISITA. IN CLUYENDO AQUELLAS SOBRE VENTA O USOS ESPECIFICOS, Y LAS

GARANTIAS ESTAN LIMITADAS A UNO (PTU30, PTU33A & PTU50), DOS (SPV500 OR SPV800) O TRES (SSPTU50) AÑO(S) A PARTIR

DE LA FECHA DE COMPRA. ESTA ES LA UNICA GARANTIA Y CUALQUIER PERDIDA O RESPONSABILIDAD CIVIL, SEA DIRECTA O

INDIRECTA COMO CONSECUENCIA DE DAÑOS SON EXCLUIDAS.

Algunos estados no permiten límites en la duración de las garantías, o no permiten que se limiten o excluyan casos por daños por accidentes

o consecuentes, en dichos casos los límites arriba enumerados tal vez no apliquen para Ud. Esta garantía limitada le otorga a Ud. ciertos

derechos que pueden variar de un estado a otro.

Bajo ninguna circunstyancia, aunque sea debido al incumplimiento del contrato de garantía, culpabilidad (in cluyendo negligencia) u otras

causas,la compañía Wayne o ninguno de sus surtidores serán responsables legalmente por ningún fallo legal en su contra, incluyendo, pero no

limitado apérdida de ganancias, pérdidas del uso del producto o piezas asociadas con el equipo, pérdidas de capital, gastos para reemplazar

los productos dañados, pérdidas por cierre de fábrica, servicios o pérdida de electricidad, o demandas persentadas por los clientes del

comprador por dichos daños.

Ud. DEBE conservar el recibo como prueba de compra junto con esta garantía. En caso de que necesite presentar un reclamo de sus derechos

bajo esta garantía, Ud DEBERA enviar una copia del recibo de la tienda junto con el producto o correspondencia. Comuníquese con la

compañía Wayne (800-237-0987, sólo desde EE.UU) para recibir autorización e instrucciones de como enviar la mercancía.

NO ENVIE ESTOS DATOS A WAYNE. Conserve esto sólo como datos.

MODEL NO. ________________________ NO. DE SERIE ________________________________ FECHA DE INSTALACION ________________________

GRAPE SU RECIBO DE COMPRA AQUI

12-Sp

Loading...

Loading...