Page 1

32 Sp

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

Garantía Limitada

Durante tres años a partir de la fecha de compra, Wayne Water Systems ("Wayne") reparará o reemplazará para el

comprador original, según lo que decida, cualquier pieza o piezas de su Juego para estanque, Bombas de resumideros,

Bombas de agua ("Producto") que después de un examen Wayne encuentre que tenían defectos en su material o mano de

obra. Sírvase llamar a la compañía Wayne (800-237-0987, desde EUA) para recibir instrucciones al respecto o comuníquese con

el distribuidor más cercano a su domicilio. Para hacer reclamos bajo esta garantía deberá suministrarnos el número del modelo

y el número de serie del producto. El comprador será responsable de pagar todos los gastos de flete para enviar las piezas o el

Producto para que sean reparados o reemplazados.

Esta Garantía Limitada no cubre los daños que sufra el Producto debido a accidentes, abusos, usos inadecuados, negligencia,

instalación incorrecta, mantenimiento inadecuado o haberse utilizado sin seguir las instrucciones escritas suministradas por la

compañía Wayne.

NO EXISTEN OTRAS GARANTIAS EXPRESAS. LAS GARANTIAS IMPLICITAS INCLUYENDO GARANTIAS EN RELACION AL

MERCADEO O USOS ESPECIFICOS ESTAN LIMITADAS A TRES AÑOS A PARTIR DE LA FECHA DE COMPRA. ESTA ES LA

UNICA GARANTIA DISPONIBLE Y TODAS LAS REPONSABILIDADES CIVILES, DIRECTAS O INDIRECTAS, O GASTOS POR

DAÑOS INDIRECTOS O CONSECUENTES QUEDAN EXCLUIDOS.

Algunos estados no permiten que se establezcan límites en la duración de las garantías implicitas o no permiten que se

excluyan ni se establezcan límites en los daños por incidentes o consecuencias, por lo tanto los límites antes mencionados

podrían ser no válidos. Esta Garantía Limitada le otorga derechos legales especificos, y usted también puede tener otros

derechos que varian de un Estado a otro.

En ningún caso, bien sea por ruptura del contrato de la garantía, responsabilidad civil (incluyendo negligencia) u otra causa,

Wayne o sus distribuidores serán responsables pon daños especiales, consecuentes ni circunstanciales ni penales, incluyendo,

pero no limitados a la pérdida de ganancias, pérdida de uso del producto o equipos asociados, daños a equipos asociados,

costos de capitales, costos para substituir productos, costos para substituir o reemplazar servicios, costos por pérdida de

productividad, o reclamos de clientes del comprador por dichos daños.

DEBE conservar el recibo de compra con esta garantía. En caso de que necesite hacer un reclamo bajo esta garantía, DEBERA

enviarnos una copia del recibo junto con el material o correspondencia. Sírvase comunicarse con la compañía Wayne (800-2370987, en EUA) para recibir autorización e instrucciones para enviar el producto.

NO ENVIE ESTA GARANTIA A WAYNE. Use este documento sólo para mantener sus records.

NO. DEL MODELO _____________________ NO. DE SERIE ________________________ FECHA DE INSTALACION __________________

ANEXE SU RECIBO AQUI

Jet Pump Water Systems

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

© 2008 Wayne Water Systems

Description

Shallow well jet pumps are single stage

domestic water pumps designed for

pumping portable water in applications

where the water is located less than 25

feet vertically from the pump. A

pressure switch is a standard feature.

The shallow well pump can be

mounted to either a precharged,

conventional type or free standing

pressure tank.

Unpacking

After unpacking the jet pump, carefully

inspect for any damage that may have

occurred during transit. Check for

loose, missing or damaged parts.

Safety Guidelines

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

Operating Instructions and Parts Manual Shallow Well Models

General Safety

Information

1. Read the instruction manual included

with the product carefully. Be

thoroughly familiar with the controls

and the proper use of the equipment.

2. Know the pump application,

limitations and potential hazards.

Always install a

pressure relief valve

to match the system pressure rating and

the maximum flow rate.

Do not use to pump

flammable or

explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in explosive

atmospheres. Pump should only be used

with liquids compatible with pump

component materials. Failure to follow

this warning can result in personal injury

and/or property damage.

Disconnect power

and release all

pressure from the system before

attempting to install, service, relocate or

perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

Install a screen

around the inlet

pipe to prevent entrapment of swimmers.

3. Drain all liquids from the system

before servicing.

4. Secure the discharge line before

starting the pump. An unsecured

discharge line will whip and possibly

cause personal injury and/or property

damage.

5. Check hoses for weak or worn

condition before each use. Make

certain all connections are secure.

6. Periodically inspect pump and system

components. Perform routine

maintenance as required (See

Maintenance).

7. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean, uncluttered

and properly lighted - replace all

340106-001 7/08

unused tools and equipment.

c. Keep visitors at a safe distance

from work area.

d. Make the workshop childproof use

padlocks, master switches and

remove starter keys.

8. Do not pump chemicals or corrosive

liquids. Pumping these liquids

shortens the life of the pumps seals

and moving parts and will void the

warranty.

9. When installing pump, cover the

well to prevent foreign matter

from falling into well and

contaminating the water and

damaging internal mechanical

pumping components.

10. Always test the water from the

well for purity before use. Check

with local health department for

test procedure.

11. Complete pump and piping system

MUST be protected against below

freezing temperature. Freezing

temperatures could cause severe

damage and void the warranty.

12. Do not run the pump dry or

damage will occur and will void

warranty.

Risk of electrical

shock. This pump is

designed for indoor installation only.

All wiring should be

performed by a

licensed or certified electrician.

13. For maximum safety, the unit

should be connected to a grounded

circuit equipped with a ground

fault interrupter device.

14. Before installing the pump, have

the electrical outlet checked by a

licensed or certified electrician to

make sure the outlet is properly

grounded.

15. Make sure the line voltage and

frequency of electrical current

supply agrees with the motor

wiring.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.waynewatersystems.com

!

DANGER

!

WARNING

!

CAUTION

NOTICE

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 2

Para Piezas de Repuestos, Llame al 1-800-237-0987

Puede escribirnos a:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

31 Sp

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

1 Motor 32059-001 34142-001 34142-001 1

2 Tornillo 16636-002 16636-002 16636-002 4

3 Placa de sellado 4372-001 4372-001 4372-001 1

4 • Empaquetadura cuadrada de caucho para anillo 17150-001 17150-001 17150-001 1

5 • Ensamblaje de sello del eje 56393 56393 56393 1

6 Impulsor 23285-021 23285-022 23285-022 1

7 Difusor 17148-021 17148-021 17148-021 1

8 Tornillo 67007-001 67007-001 67007-001 2

9 • Anillo en o 15557 15557 15557 1

10 Venturi 17151-002 17151-003 17151-004 1

11 Boquilla 15672 15672 15672 1

12 19,1 mm (3/4”) Tapón de cebado 15921 15921 15921 1

13 Voluta 56869-001 56869-001 56869-001 1

14 6,4 mm (1/4”) NPT Tapón de cebado 16314-002 16314-002 16314-002 1

15 3,2 mm (1/8”) NPT Tapón de cebado 15766-002 15766-002 15766-002 1

17 Base 23029-021 23029-021 23029-021 1

19 Presostato 30010-021 30010-021 30010-021 1

• Juego para reparaciones (Incluyes #4, 5 y 9) 56874-001 56874-001 56874-001 1

No. de Para Los Modelos

Ref. Descripción SWS50-1/2 HP SWS75-3/4 HP SWS100-1 HP Ctd.

17

1

2

3

4

5

6

7

8

11

12

10

13

14

16

9

15

Sírvase proporcionar la suguiente información:

- Número de modelo

- Número de serie (si tiene)

- Descripción y número de repuesto como se muestra

en la lista de repuestos

General Safety

Information (Continued)

16. Do not attempt repairs to the electric

motor. All repairs to the motor must

be completed at a licensed or certified

electrical motor repair shop.

Do not touch an

operating motor.

Modern motors are designed to operate at

high temperatures.

17. Avoid kinking electrical cord and

protect from sharp objects, hot

surfaces, oil and chemicals. Replace

or repair damaged or worn cords

immediately.

Disconnect power

and release all

pressure from the system before

attempting to install, service, relocate or

perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

18. Keep fingers and foreign objects

away from ventilation and other

openings. Do not insert any objects

into the motor.

Risk of electric

shock! Never

connect the green (or green and yellow

wire) to a live terminal!

19. To reduce the risk of electrical

shock, the pump should be plugged

directly into a properly installed and

grounded 3-prong grounding type

receptacle, as shown in Figure 1.

The green (or green and yellow)

conductor in the cord is the

grounding wire. The motor must be

securely and adequately grounded

for protection against shock.

20. Where a 2-prong is encountered,

replace the plug with a properly

grounded 3-prong receptacle in

accordance with the National

Electrical Code, local codes and

ordinances. To ensure a proper

ground, the grounding means must

be tested by a licensed or certified

electrician.

21. Use only 3-wire extension cords that

have a 3-prong, grounding type

plug, and 3-pole receptacles that

accept the equipment plug.

22. Use wire of adequate size to

minimize voltage drop at the motor.

Do not handle

pump or pump

motor with wet hands, when standing

on a wet or damp surface or when

standing in water. Fatal electrical

shock could occur.

Pump motor is

equipped with an

automatic resetting thermal protector and

may restart unexpectedly. Protector

tripping is an indication of motor

overloading because of operating pump

at low heads (low discharge restriction),

excessively high or low voltage,

inadequate wiring, incorrect motor

connections or defective motor or pump.

Pre-Installation

WATER SUPPLIES

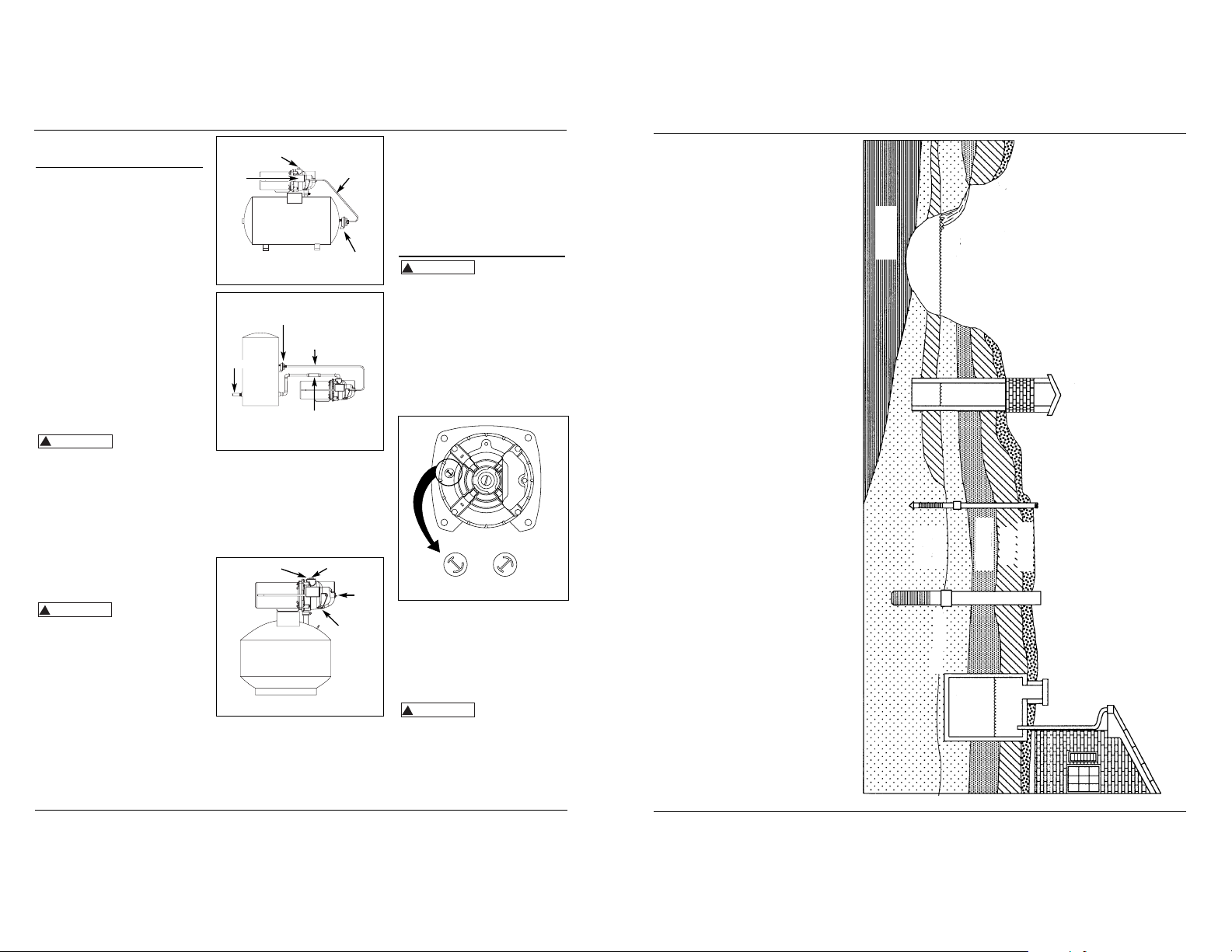

The water supplies illustrated in Figure

12 are possible sources for water.

These water supplies can be divided

into two categories:

SURFACE WATER

Water from a lake, stream, pond and

cistern. This water is usually not fit for

human consumption, but may be

suitable for washing, irrigation or other

household uses.

GROUND WATER

Water found in the water bearing

stratum at various levels beneath the

earth. Of all the fresh water found on

earth only 3 percent is found on the

surface and 97 percent is underground.

TANKS - CONVENTIONAL STORAGE

The function of the tank is to store a

quantity of water under pressure.

When full, the tank contains

approximately 2/3 water and 1/3

2

Operating Instructions and Parts Manual

compressed air. The compressed air

forces the water out of the tank when

a faucet is opened. An air volume

control automatically replaces air lost

or absorbed into the water. The usable

water, or drawdown capacity, of the

tank is approximately 1/6 of the tanks

total volume when operated on a “2040” pressure setting (Figure 2).

TANKS - PRECHARGED STORAGE

A precharged storage tank has a

flexible bladder or diaphragm that acts

as a barrier between the compressed

air and water. This barrier prevents the

air from being absorbed into the water

and allows the water to be acted on by

compressed air at initially higher than

atmospheric pressures (precharged).

More usable water is provided than

with a conventional type tank.

Precharged tanks are specified in terms

of a conventional tank. For example, a

20 gallon precharged tank will have

the same usable water or drawdown

capacity as a 40 gallon conventional

tank, but the tank is smaller in size

(Figure 2).

PRESSURE SWITCH

The pressure switch provides for

automatic operation. The pump starts

when pressure drops to a cut-in setting.

Shallow Well Jet Pump

Air Volume

Control

Type Required

Well X Precharged No

PCA Precharged No

12P & 30P Horizontal Conventional Yes

FX Horizontal Precharged No

CHART 1 - JET PUMP/TANK ASSEMBLIES

Air Volume

Control

Bladder

Conventional

Tank

Precharged

Tank

Figure 2 - Conventional & Precharged

Storage Tanks

Grounded

Pin

Grounded Outlet

Figure 1

www.waynewatersystems.com

!

WARNING

!

WARNING

!

WARNING

RESET

TEST

!

DANGER

!

WARNING

Page 3

30 Sp

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

La bomba no funciona

El motor suena pero no funciona

Desconexión por sobrecarga

La bomba funciona pero no agua

o provee muy poca cantidad

La bomba se prende y apaga continuamente

1. No hay energía eléctrica

2. El fusible se ha quemado o el interruptor se ha

desconectado

3. Interruptor de presión fallado

4. El tubo del interruptor a presión esta obstruído

5. Desconectado por sobrecarga del motor

1. Bajo voltaje en la línea

2. El cableado es demasíado pequeño

3. Los daños o la falta de alineamiento dan lugar

que las piezas rotatorías se peguen

1. Voltaje incorrecto en la línea

2. Los daños o la falta de alineamiento dan lugar

que las piezas rotatorias se peguen

3. Alta temperatura en los alredodores

4. Ciclos rápidos

1. El nivel de agua está por debajo de la toma de la

bomba

2. La válvula de control está demasiado abierta

(pozos profundos)

3. Al cebar no se purgó la descarga

4. Hay fuga en la tubería en el lado del pozo donde

está la bomba

5. Está obsstruida la malla de la bomba o el colador

de aspiración de entrada

6. Boquilla obstruida (pozos profundos)

7. Se ha roto el diafragma del control del volumen

de aire

8. La válvula de aspiración puede estar obstruida o

atascada en la posición de cerrada

9. La bomba no se ha cebado completamente

10. La válvula de control está completamente cerrada

(pozos profundos)

11. Nivel de agua por debajo de lo requerido para

aspirar

12. Tubería de tamaño menor que el requerido

13. Pozo gaseoso

14. Venturi distorsionado

15. Eyector de chorro inadecuado para la aplicación

16. Bomba de tamaño muy pequeño

17. La bomba forma vacios parclales, suena como si

estuviera bombeando cascajo

1. Tanque inundado (Convencional)

2. La tubería del control del volumen de aire está

doblada u obtruida

3. Control de volumen de aire conectado a la salida

incorrecta de la bomba

4. Precarga de tanqueincorrecta (Tanque precargado)

5. Diafragma o bolsa rota (Tanque precargado)

6. Fuga enla tubería de la casa

7. Válvula de pie o válvula de retención atascada en

posición abierta

8. El motor se desconecta por sobrecarga

9. Interruptor de presión incorrectamente ajustado

1. Encienda la corriente eléctrica o llame a la

compañía de suministro eléctrico

2. Cambie el fusible o vuelva a conectar el

interruptor de circuito

3. Cambie el interruptor

4. Limpie o reemplace la tubería de cobre

5. Deje que se enfríe. La sobrecarga se

recalibrará automáticamente

1. Haga un nuevo cableado. Ver la Table 3*

2. Haga un nuevo cableado. Ver la Table 3*

3. Reemplácelas o llévelas a un taller de

servicio para reparaciones

1. Haga un nuevo cableado. Ver la Table 3*

2. Lleve el motor a un taller de reparaciones o

localice donde se pegan las piezas y haga las

reparaciones

3. Coloque la bomba en una zona sombreada

y bien ventilada

4. Vea la sección sobre bombas que funcionan y

se detienon con demasiada frecuencia

1. Baje más el tubo de succión dentro del pozo

2. Repita el procedimiento para cobar

3. Abra el grifo y vuelva a cebar

4. Repare la tubería según sea necesario

5. Límpieia o reemplácela según sea necesario

6. Jale el eyector de chorro y limpie la

obstrucción

7. Repare o cambie el control del volumen de

aire

8. Límpieia o reemplaceia según sea necesario

9. Continúe cebando, haga una pausa cada 5

minutos para que se enfríe el armazón de la

bomba. Vuelva a llenar la bomba según sea

necesario

10. Ajuste la válvula de control según el procedimlento para cebar los pozos profundos

11. Seleccione el ensamblado de la bomba y/o

del eyector de chor ro que correspondan

12. Reemplace según sea necesario

13. Instale un deflector en la entrada a la bomba

para evitar que los gases entren al sistema

14. Inspecciónelo y reemplácelo

15. Adquiera un eyector de chor ro que encaje

en su sistema cuando esté reemplazando

una bomba de otra marca

16. Aumente el caballaje de la bomba

17. Aumente el diámetro de la tubería de succion o disminuya la fricción en la tubería

1. Cambie el tanque o el control del volumen

de aire

2. Límpiela o reemplácela según sea necesario

3. Mueva a la apertura correcta de la bomba

4. Agregue o quite aire cuanto sea necesario

5. Cambie el tanque

6. Localie y repare la fuga

7. Retire y reemplace

8. Vea la sección sobre desconexiones por

sobrecarga

9. Reajuste o cambie el interruptor

* Todas las conexiones eléctricas las debe hacer un electricista certificado o con licencia

Problema Posible(s) Causa(s) Acción a Tomar

Guía de Diagnóstico de Averías

3

Pre-Installation

(Continued)

The pump stops when pressure reaches

a cut-out setting.

PACKAGE SYSTEMS

There are four jet pump/tank

assemblies sold as packages (Chart 1).

WELLS

A new well should be pumped clear of

sand before installing the pump. Sand

will damage the pumping parts and

seal. The drawdown level of the well

should not exceed the maximum rated

depth for the pump. The capacity of

the pump will be reduced and a loss of

prime may occur.

Installation

LOCATION

Select a location as close to the water

supply as possible. Be sure to comply

with any state or local codes regarding

the placement of the pump. The

equipment must be protected from the

elements. A basement or heated pump

house is a good location. Make sure

the pump has proper ventilation. The

temperature surrounding the pump is

not to exceed 100° F (40°C) or nuisance

tripping of the motor overload may

occur.

PIPING

Piping may be copper, steel, rigid PVC

plastic or flexible polyethylene plastic.

Flexible pipe is not

recommended on

suction pipe (inlet pipe).

The pipe must be clean and free of rust

or scale. Use a pipe joint compound on

the male threads of the metal pipe.

Teflon

®

tape should be used with

plastic threads. All connections must

be air tight to insure normal operation.

Slope all inlet piping upwards towards

the pump to prevent trapping air.

Unions or hose couplings can be

installed near pump to facilitate

removal for servicing or storage. A

rubber hose installed between the

water system and the house piping will

reduce the noise transmitted to the

house.

PIPE SIZES

Long horizontal pipe runs and an

abundance of fittings and couplers

decrease water pressure due to friction

loss. See Chart 2 to determine the

proper pipe size.

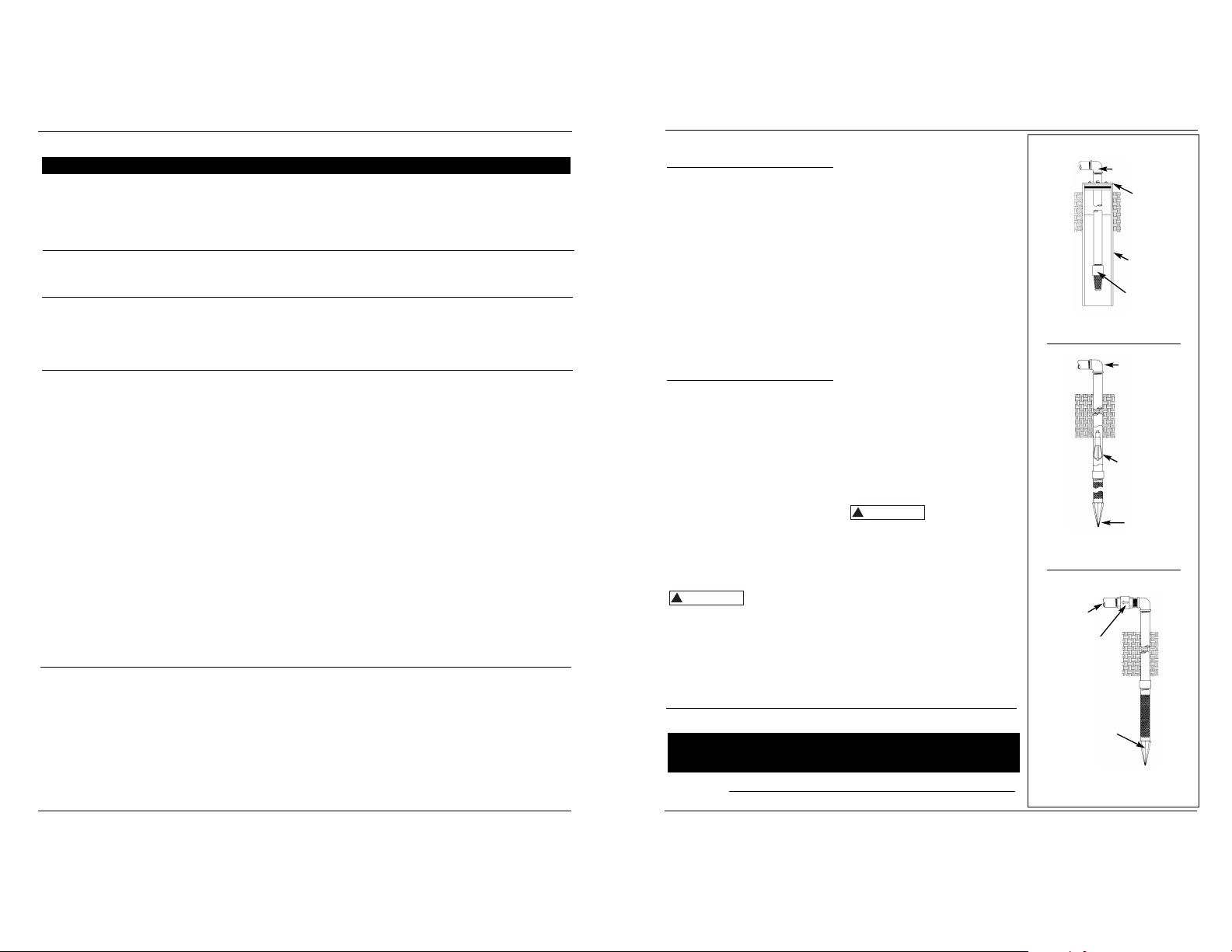

SHALLOW WELL INSTALLATION

A shallow well pump can be used when

the pump is located within 25 feet

vertically of the water level. Shallow

well pumps have only one pipe

between the pump and the water

supply (Figure 3).

DRILLED WELL (FIGURE 12)

1. Install a foot valve on the first section

of pipe (Figure 3, Illustration A).

2. Lower the pipe into the well.

3. Add pipe until the foot valve is 5

feet below the lowest anticipated

water level.

The foot valve

should be at least

18” from the bottom of the well or

sand or sediment could be drawn into

the system.

4. After proper depth is reached,

install a well seal or pitless adapter

to support pipe and prevent surface

water and other contaminants from

entering well.

5. Slope the horizontal pipe upward

toward the pump to eliminate

trapping air. Sloping the pipe will

also aid in priming the pump.

DRIVEN WELL (FIGURE 12)

1. Drive the point several feet below

the water table.

Operating Instructions and Parts Manual

Shallow Well Jet Pump

CHART 2 - PIPE SIZING

Illustration B

Illustration C

Packer

Type

Foot

Valve

Drive

Point

To Pump

Incline

Check

Valve

Drive

Point

To Pump

Figure 3

To Pump

Illustration A

Well

Seal

Well

Casing

Foot

Valve

Horizontal Distance

Pump Pump (Feet)

Model Opening 0-25 26-100 100-300

Shallow Well Inlet 11/4”1

1

/2”2”

Outlet 3/4” 1” 1

1

/4”

www.waynewatersystems.com

!

CAUTION

!

CAUTION

Page 4

(A) MANANTIAL:

Suministros de Agua

Figura 13 - Suministros de Agua

29 Sp

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

noise transmitted to the house

thrugh the piping.

4. Provide a hose bib (faucet) at the

lowest point in the system to drain

the system for service or storage.

SHALLOW WELL PUMP WITH

PRECHARGED STORAGE TANK

(FIGURE 6)

1. Shut off the power to the pump.

2. Open the faucet nearest the tank

and allow all water to drain from

the tank.

3. Measure the tank precharge at the

valve stem using a tire pressure

gauge.

4

4. If necessary, precharge with an air

pump to 28 - 30 psi on 1/2, 3/4 and 1

HP pumps.

5. Slope the horizontal pipes upward

toward the pump to prevent

trapping air. If the horizontal

distance exceeds 25 feet, see Chart

2 for the recommended pipe size.

Electrical

Risk of electrical

shock. This pump is

designed for indoor installation only.

The voltage of power supply must

match the voltage of the pump. All

above ground well pumps except

SWS50BOOST have dual voltage motors

preset at the factory to 230 volts. The

motors can be converted to 115 volts

by turning the voltage selector to the

desired voltage (See Figure 7). Use a

needle nose pliers to pull the selector

out approximately 1/4”, rotate and

then reinsert in correct position.

Select the proper size wire and fuse

(Chart 3). Time delay fuses are

recommended over standard fuses for

motor circuit protection. All pump

motors have built-in automatic

overload protection that will prevent

damage to the motor due to

overheating.

Do not connect to

electric power

supply until unit is permanently

grounded. Connect ground wire to

approved ground then connect terminal

provided.

A metal underground water pipe or

well casing at least 10 feet long makes

the best ground electrode. If plastic

pipe or insulated fittings are used, run

Installation

(Continued)

NOTE: A packer type foot valve can be

installed in the well (Figure 3,

Illustration B). This type of foot valve

allows the well to be filled with water

when priming and makes the inlet pipe

much easier to test for leaks. Follow

the manufacturer’s instructions when

installing the packer type foot valve.

As an alternative, an in-line check valve

can be used with a driven well (Figure

3, Illustration C). The pipe between the

check valve and the water level will

always be under a vacuum.

Leaking joints or couplings will allow

air to leak into the pipe and cause

abnormal pump operation. Make sure

to use pipe joint compound on all male

pipe threads.

DUG WELL, CISTERN, LAKE AND SPRING

INSTALLATION (FIGURE 12)

1. Install a foot valve on inlet pipe and

lower into water.

The foot valve

should be at least

18” from the bottom of the well or

sand or sediment could be drawn into

the system.

NOTE: When a lake is used as a water

supply, make sure the inlet pipe is deep

enough to be submerged at all times.

Slope the horizontal piping upward

toward the pump to prevent trapping

air. The pipe must be removed during

winter months or protected against

freezing.

Protect the pipe from damage from

swimmers and boats.

Install a screen

around the inlet

pipe to prevent the entrapment of

swimmers.

SHALLOW WELL PUMP WITH

CONVENTIONAL STORAGE TANK

(FIGURES 4 & 5)

1. Install air volume control on tank.

2. Connect the copper tube from the

air volume control to the

uppermost 1/8” NPT opening on the

side of pump. Be sure the

connections are tight. Leaking can

cause the pump not to prime.

3. Install a valve and an isolator hose

between the tank and the house

plumbing to aid in pump removal

for servicing and for reducing the

Operating Instructions and Parts Manual

Shallow Well Jet Pump

Figure 4 - Horizontal Tank

Air

Volume

Control

Tubing

Pressure

Switch

Prime

Plug

Air

Volume

Control

Figure 5 - Vertical Tank

Air

Volume

Control

Outlet

Air Volume

Control

Tubing

Hose

Coupling

Figure 6 - Precharged Storage Tank

28-30 psi

3/4 HP & 1 HP

Motor

www.waynewatersystems.com

Outlet

Priming

Plug

Nozzle

Clean

Out

Drain

Fitting

Figure 7 - Voltage Selector

Un manantial que emerge

de la tierra. Ocurre cuando

el agua en materiales

permeables está atrapada

entre materiales

impermeables tales como

roca o arcilla.

!

CAUTION

!

WARNING

!

WARNING

230 V

115 V

115 V

230 V

!

WARNING

(B) LAGO, ARROYO o ESTANQUE:

Agua superficial, que a menos

que sea tratada, por lo general

no es apta para consumo

humano. Puede ser utilizada

para fines tales como lavado

o irrigación.

(C) POZO EXCAVADO:

Se excava un hoyo de

varios pies de diámetro

hasta una profundidad

basante superficial.

Luego se reviste con

ladrillo, piedra o

concreto para evitar

que se derrumbe.

(D) POZO ACCIONADO:

Se acciona una tubería

con una pantalla con

punta en la tierra, por

debajo de la capa

freática. La profundidad

por lo general es menor

a 15,25 m (50 pies).

Los diámetros comunes

fluctúan entre 2,5 cm (1")

y 5,1 cm (2")

(E) POZO PERFORADO:

Un hoyo perforado en

la tierra con maquinaria y

revestido con tuberías.

Las profundidades

fluctúan entre algunos

pies hasta más de 305 m

(1000 pies). Los diámetros

comunes son 5,1 cm (2"),

7,6 cm (3"), 10,2 cm (4") y

15,2 cm (6") para pozos

de agua de uso doméstico.

(F) CISTERNA:

Un tanque subterráneo

construido para recolectar

agua de lluvias de los

techos. El agua no es

apta para consumo

humano.

ESQUISTO

ACUIFERA

ARENA

CAPA FREATICA

ARROYO,

ESTANQUE

(A) MANANTIAL

(B) LAGO,

(C) POZO EXCAVADO

(D) POZO

ACCIONADO

PERMEABLE

SUPERFICIAL

MATERIAL

ARCILLA

TIERRA

(E) POZO

PERFORADO

(F) CISTERNA

Page 5

5. Sasegure el difusor en la placa de

sellado con los dos pernos.

Cerciórese de que los pernos estén

orientados horizontalmente como

se describe en el paso 2.

6. Coloque con cuidado la

empquetadura de la cubierta en

espiral (voluta) sobre el difusor en la

placa de sellado. En todas las

aplicaciones de conversión, el anillo

de sellado también debe estar

colocado sobre el difusor. En todas

las aplicaciones en pozos poco

profundos se debe tener cuidado de

que los anillos en o (juntas tóricas)

estén limpios y colocados

adecuadamente sobre el Venturi. La

limpieza y la colocación correcta

hacen que exista un uen sellado

dentro del difusor cuando se

ensambla.

7. Acople la cubierta en espiral

(voluta) de la bomba al motor con

los cuatro pernos. Asegúrese de que

la empaquetadura de la cubierta en

espiral (voluta) esté bien colocada y

ajuste bien los pernos.

NOTA: El eje debe poder girar

libremente y la cubierta del extremo

del motor debe estar asegurada antes

de hacer funcionar la bomba.

Mantenimiento

(Continuación)

6. Con un destornillador o una llave

graduable, impida que l eje gire y

retire el impulsor con la mano

(roscado estándar de mano

derecha). Cerciórese de guardar la

placa de sellado de hierro forjado

cuando saque el impulsor del eje.

7. Saque la placa de sellado.

8. Planquee la pieza rotatoria de

sellado del eje para que salga del

impulsor (Figura 10).

9. Empuje o palanquee el

asentamiento de cerámica para

separarlo de la placa de sellado

(Figura 10).

10. Elimine las partículas sueltas del

núcleo del impulsor y la placa de

sellado.

INSTALACIÓN DE UN NUEVO SELLO

DEL EJE

Antes de

manipular las piezas del sello del eje

límpiese las manos con un paño. El

polvo y la grasa pueden dañar el sello.

1. Humedezca con aceite de cocina, la

parte interior de la cavidad del sello

en la placa de sellado y los

empaques de caucho acopados que

rodean el nuevo asentamiento de

cerámica. Tenga cuidado de no

raspar la superficie de cerámica del

asentamiento del sello y empuje el

asentamiento incluido en el caucho

en la cavidad del sello en la placa de

sellado. Use una rondana de cartón

para proteger la superficie pulida

cuando empuje contra el

asentamiento de cerámica con

cualquier objeto. Cerciórese de

sacar la rondana de cartón.

28 Sp

2. Deslice con cuidado la placa de

sellado sobre el eje de modo que no

se mueva el sello de su posición en

la placa de sellado. Durante el

ensamblado, la placa de sellado

debe estar orientada de modo que

los dos orificios estén en una línea

horizontal a través del eje del

motor y que las cuatro (4) clavijas

de localización de la parte posterior

estén alineadas con las lengüetas

del armazón del motor (Figura 11).

Esta ubicación se debe hacer para

asegurar un drenaje y cebado

adecuados.

3. Sitúe la pieza rotatoria del sello del

eje en el impulsor y presiónela para

que quede en su sitio. Tenga

cuidado de no presionar contra la

superficie pulida del sello.

4. Coloque el impulsor en el eje y

ajústelo bien (Figura 12).

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

Figura 10 - Remoción del Sello del Eje

y el Asentamiento de

Cerámica

Place de

Sellado

Asentamiento

de Cerámica

Pieza Rotatoria

de Sellado del

Eje

Anillo de

Caucho de

Asentamiento

Impulsor

Figura 11 - Reemplazo de la Placa Sellado

Orificios para

los Tornillos

Eje del

Motor

Placa de Sellado

Asentamiento

del Sello

Figura 12 - Eje del Motor

Motor

Impulsor

Asentamiento

del Sello

Para que el Sellado Sea

Adecuado, es Necesario

que la Cara del Sello este

Limpia

5

Operating Instructions and Parts Manual

Shallow Well Jet Pump

Distance In Feet

From Meter To Motor

Dual 0 51 101 201

Element To To To To

Fuse 50 100 200 300

HP Volt 250V Wire Size

115 15 14 14 12 10

230 10 14 14 14 14

115 15 14 14 10 8

230 10 14 14 14 14

115 20 12 12 10 8

230 10 14 14 14 14

CHART 3 - RECOMMENDED FUSE & WIRING DATA - 60 HZ MOTORS

1/2

3/4

1

www.waynewatersystems.com

Electrical (Continued)

a wire directly to the metal well casing

or use a ground electrode furnished by

the power company.

There is only one proper ground

terminal on the unit. The terminal(s) is

located under the pressure switch

cover, is painted green and is identified

as GRD. The ground connection must

be made at this terminal (Figure 8).

The ground conductor must not be

smaller than the circuit conductors

supplying the motor.

Disconnect power

and release all

pres

sure from the system before

attempting to install, service, relocate or

perform any maintenance.

Operation

PRIMING THE SHALLOW WELL PUMP

To prevent damage

to the pump, do not

start motor until pump has been filled

with water.

1. Remove prime plug (Figure 4 or 5).

2. Fill pump and piping completely full

of water.

3. Replace the prime plug.

4. Open a faucet to vent the system.

5. Start the motor. Water will pump in

a few minutes. If pump fails to

prime in 5 minutes, stop motor and

refill pump with water. Priming

time is proportional to the amount

of air in inlet pipe.

6. Let the system operate for several

minutes to flush all pipes.

7. Close faucet and allow pump to

build pressure in tank. When the

pressure reaches the cut-out setting,

the motor will stop.

The system is now in operation and will

automatically cycle on demand.

Maintenance

Disconnect power

and release all

pressure from the system before

attempting to install, service, relocate or

perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

Protect the pump

from freezing

during winter conditions.

DRAINING THE PUMP

Drain openings are provided on all

models. To drain the pump:

1. Remove drain plug and prime plug

to vent the system.

2. Drain all piping to a point below

the freeze line.

DRAINING THE TANK

Conventional tanks can be drained by

opening an outlet at the lowest point

in the system. Remove plug or the air

volume control to vent the tank.

Precharged tanks force virtually all the

water from the tank when system

pressure is released. No draining is

necessary.

RESTARTING PUMP

If the pump has been serviced, drained

or has not been used for some time, be

sure there is water in the pump

housing (volute) and the piping to the

well. There must be water in the pump

housing (volute) at all times when the

pump is running to avoid internal

damage of seal members (Priming the

Shallow Well).

WATERLOGGED TANKS:

CONVENTIONAL

When a tank system has an inadequate

ratio of air and water, the pump will

start and stop often and eradically.

1. Disconnect the power to the pump.

2. Open the lowest faucet in the

system to release all pressurized

water in the system.

3. Prime the pump (Priming the

Shallow Well).

4. Reconnect the power to the pump.

NOTE: As the pump refills the tank with

water, the air volume control supplies

the tank with the correct air to water

ratio for the system to operate. If the air

volume control is good, the pump will

shut off at the desired cut-off and will be

adjusted correctly.

WATERLOGGED TANKS:

PRECHARGED

If a precharged tank becomes

waterlogged, the bladder is normally

leaking or broken.

1. Test the tank by depressing the air

valve. The air valve will expel water if

the bladder is broken.

2. Replace the tank.

NOTE: Once a bladder is leaking or

broken, the bladder cannot be repaired.

The tank must be replaced.

L2

3

L1

1

Figure 8 - Electrical Connections

Motor

Motor

Line

Line

Ground

!

PRECAUCION

L1

L2

3

1

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

Page 6

NOTA: Si la cámara elástica tiene fugas o

se ha roto, no se puede reparar. Hay que

reemplazar el tanque.

LUBRICACIÓN

Los cojinetes que se usan en las bombas

vienen lubricados de fábrica para una

duración permanente y no necesitan

lubricación adicional.

PRECARGADO

En todos los tanques se pierde algo de

aire a través de la cámara elástica. Para

evitar que el tanque falle, examine la

precarga una vez al año.

1. Abra el grifo más cercano al tanque y

deje que drene toda el agua del

tanue.

2. Mida la precarga del tanque en el

pitón de la válvula con un medidor de

presión para llantas.

3. Si es necesario, ajuste con una bomba

de aire la precarga a una presion

entre 1,93 y 2,07 bar en bombas de

1/2, 3/4 y 1 CP.

PARA SACAR EL SELLO USADO

DEL EJE

Gire el

interruptor de desconexión a la posición

“off.”

1. Abra el grifo más cercano al tanque y

deje que drene toda el agua del

tanque.

2. Saque los cuatro pernos que

mantienen la cubierta en espiral de la

bomba (voluta) unida al motor

(Figura 9).

3. Separe la cubierta en espiral de la

bomba (voluta) del motor para

exponer el difusor y la placa de

sellado.

4. Retire los dos pernos y el difusor de

la placa de sellado para exponer el

impulsor.

5. Saque la tapa pequeña del extremo

del motor opuesto al impulsor

Funcionamiento

CEBADO DE LA BOMBA PARA

POZOS POCO PROFUNDOS

Para

evitar

dañar la bomba, no arranque el motor

hasta que la haya llenado con agua.

1. Retire el tapón para cebar (Figura 4

o 5).

2. Llene la bomba y la tubería

completamente con agua.

3. Vuelva a colocar el tapón para

cebar.

4. Abra el grifo para purgar el

sistema.

5. Arranque el motor. El agua

empezará a bombearse en pocos

minutos. Si la bomba no se ceba en

5 minutos, detenga el motor y

vuelva a llenar la bomba con agua.

El tiempo necesario para cebar es

proporcional a la cantidad de agua

en la tubería de ingreso.

6. Deje que el sistema funcione por

varios minutos para que se limpien

todos los tubos.

7. Cierre el grifo y deje que la bomba

desarrolle presión en el tanque.

Cuando la presión alcance el límite

establecido, el motor se detendrá.

El sistema está ahora en

funcionamiento y hará ciclos

automáticos según la demanda.

Mantenimiento

Desco-

necte la

corriente eléctrica y libere toda la presión

del sistema antes de intentar instalar,

darle servicio, mantenimiento o cambiarlo

de lugar. Trabe el desconector de

corriente en la posición de abierto y

rotúlelo para evitar una aplicación

inesperada de corriente.

Proteja

la

bomba para que no se congele durante

los meses de inierno.

DRENAJE DEL BOMBA

Todos los modelos vienen con

aberturas para drenar. Para drenar la

bomba:

1. Saque el tapón de drenaje y el

tapón para cebar a fin de que se

vacíe el sistema.

2. Drene todas las tuberías hasta un

nivel por debajo de la línea de

congelación.

27 Sp

DRENAJE DEL TONQUE

Los tanques convencionales se pueden

drenar al abrir una salida en el punto

más bajo del sistema. Retire el tapón o

el control de volumen del aire para

vaciar el tanque.

Los tanques precargados fuerzan

prácticamente toda el agua del tanque

cuando se libera la presión del sistema.

No es necesario drenar.

PARA VOLVER A HACER

FUNCIONAR LA BOMBA

Si a la bomba se le ha dad servicio, se la

ha drenado o no se la ha usado por

algun tiempo, cerciorese de que haya

agua en la cubierta en espiral (voluta) y

en la tuberia del pozo. En todo

momento debe haber agua en la

cubierta en espiral de la bomba (voluta)

cuando este funcionando para evitar

danos internos en las piezas de sellado

(Vea las secciones sobre cebado de

pozos poco profundos o de pozos

profundos).

MOVIMIENTO DE AGUA SE HACE

LENTO: CONVENCIONAL

Cuando el sistema de un tanque tiene

una relación inadecuada entre aire y

agua, la bomba arrancará y se detendrá

con frecuencia en forma errática.

1. Desconecte la corriente eléctrica

que va a la bomba.

2. Abra el grifo más bajo del sistema

para liberar toda el agua

presurizada del sistema.

3. Cebe la bomba (Ccebado para pozos

poco profundos o pozos profundos).

4. Vuelva a conectar la corriente

eléctrica a la bomba.

NOTA: Conforme la bomba vuelve a

llenar el tanque con agua, el control de

volumen de aire suministra al tanque la

relación adecuada de aire y agua para

que el sistema funcione. Si el control del

volumen de aire está bien, la bomba se

parará en el nivel límite que se haya

establecido y se ajustará

adecuadamente.

MOVIMIENTO DE AGUA SE HACE

LENTO: : PRECARDGADO

Si en un tanque precargdo, el

movimiento de agua se hace lento,

habitualmente se debe a que la cámara

elástica tiene fugas o se ha roto.

1. Pruebe el tanque presionando la

válvula de aire. La válvula de aire

expelerá agua si la cámara elástica se

ha roto.

2. Reemplace el tanque.

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

Tornillos de

Casquetes

Figura 9 - Bomba Convertible

para Pozos

Placa de

Sellado

Difusor

Cubierta en

Espiral (Voluta)

Impulsor

Motor

Maintenance

(Continued)

LUBRICATION

The bearings used in the pumps are

lifetime lubricated at the factory and

require no additional lubrication.

PRECHARGED TANK

Some air is lost through the bladder in

any tank. To prevent tank failure, check

the tank precharge on a yearly basis.

1. Open a faucet nearest the tank and

allow all water to drain from the

tank.

2. Measure the tank precharge at the

valve stem using a tire gauge.

3. If necessary, adjust the precharge

with an air pump 28 - 30 psi on 1/2,

3/4 and 1 HP pumps.

REMOVING OLD SHAFT SEAL

Turn disconnect

switch to “off”

position.

1. Open a faucet nearest the tank and

allow all water to drain from the

tank.

2. Remove the four cap screws holding

the pump housing (volute) to the

motor (Figure 9).

3. Separate the pump housing

(volute) from the motor to expose

the diffuser and the seal plate.

4. Remove the two cap screws and

diffuser from the seal plate to

expose the impeller.

5. Remove the small end cap on the

end of the motor opposite the

impeller.

6. With a large screwdriver or

adjustable wrench, keep the shaft

from rotating and remove the

impeller by hand (standard right

hand thread). Be sure to hold onto

the seal plate when removing the

impeller from the shaft.

7. Remove the seal plate.

8. Pry the rotating shaft seal member

from the impeller (Figure 10).

9. Push or pry the ceramic seat free

from the seal plate (Figure 10).

10. Remove loose particles from

impeller hub and seal plate.

Shallow Well Jet Pump

Operating Instructions and Parts Manual

INSTALLING NEW SHAFT SEAL

Before handling

shaft seal parts

wipe hands clean. Dirt or grease can

damage the seal.

1. Wet the inside of the seal cavity on

seal plate and the rubber cup

enclosing the new ceramic seat with

cooking oil. Be careful not to

scratch the ceramic surface of the

seal seat and push seat enclosed in

rubber into seal cavity on seal plate.

Use a cardboard washer to protect

polished surface when pushing

against ceramic seat with any

object. Be sure to remove

cardboard washer.

2. Carefully slip seal plate over shaft.

Do not disturb seal position in seal

plate. The seal plate must be

orientated during assembly so the

two screw holes are on a horizontal

line across the motor shaft and the (4)

locating pins on the back of the seal

plate line up with the tabs on the

motor housing (Figure 11). This

placement should be done to ensure

proper draining and priming.

3. Place rotating shaft seal member in

position on impeller and press into

place. Take care not to press against

polished seal surface.

4. Position impeller on shaft and tighten

securely (Figure 12).

5. Secure diffuser to seal plate using the

two cap screws. Be sure the screws

are orientated on a horizontal line as

described in Step 2.

6. Carefully position pump housing

(volute) gasket over the diffuser onto

the seal plate. In all shallow well

applications care must be taken that

the o-ring is clean and properly

positioned on the venturi. Cleaning

and positioning makes a good seal

inside the diffuser when assembled.

7. Assemble the pump housing (volute)

to the motor using the four cap

screws. Be sure the pump housing

(volute) gasket is positioned correctly

and tighten the screws securely.

NOTE: Shaft must rotate freely and

motor end cap should be secured

before operation.

Seal

Plate

Seal

Seat

Figure 12 - Motor Shaft

Figure 11 - Seal Plate Replacement

Screw Holes

Motor

Shaft

Motor

Impeller

Seal

Plate

Seal Facing Must

Be Clean For

Proper Seal

Figure 10 - Removing Shaft Seal &

Ceramic Seat

Seal

Plate

Ceramic

Seat

Rotating

Shaft Seal

Member

Rubber

Seat Ring

Impeller

Cap

Screws

Figure 9 - Shaft Seal

Seal

Plate

Diffuser

Pump

Housing

(Volute)

Impeller

Motor

www.waynewatersystems.com

6

!

CAUTION

!

CAUTION

!

ADVERTENCIA

!

ADVERTENCIA

!

PRECAUCION

!

PRECAUCION

Page 7

26 Sp

Instalación

(Continuación)

3. Instale una válvula y una manguera

de aislamiento entre el tanque y la

tubería de la casa para facilitar

poder separar la bomba cuando se

le dé servicio, y disminuir el ruido

transmitido a la casa a través de la

tubería.

4. Coloque una manguera de desagüe

con llave en el punto más bajo del

sistema para poder drenar cuando

se vaya a dar servicio o guardar el

equipo.

BOMBA PARA POZOS POCO

PROFUNDOS CONTANQUE DE

ALMACENAMIENTO PRECARGADO

(FIGURE 6)

1. Desconecte la corriente eléctrica

que va a la bomba.

2. Abra el grifo más cercano y deje que

drene toda el agua del tanque.

3. Mida la precarga del tanque en el

pitón de la válvula con un medidor

de presión para llantas.

4. Si es necesario, precargue con una

bomba de aire a una presión entre

1,93-2,07 bar en las bombas de 1/2,

3/4 y 1 CP.

5. Incline los tubes horizontales hacia

arriba en dirección de la bomba para

evitar que quede aire atrapado. Si la

distancia horizontal excede los 7,62 m

(25 pies), use tubos de los tamaños

que se recomiendan en la Tabla 2.

Eléctricas

Existe

riesgo de

un choque eléctrico.

Esta bomba está

diseñada únicamente para ser instalada en

interiores.

El voltaje de la fuente de suministro

eléctrico debe ser similar al de la bomba.

Todas las bombas para pozo de

instalación sobre superficie, excepto la

SWS50BOOST, tienen motores de doble

voltaje preconfigurados en la fábrica a

230 voltios. Para conectarlas a circuitos de

115 voltios simplemente gire la perilla al

voltaje deseado (Vea la Figura 6). Use

una pinza (alicate) de punta afilada para

halar la perilla aproximadamente un 6,4

mm (1/4”), gírela y colóquela en su

posición correcta.

Seleccione los alambres y el fusible del

tamaño adecuado (Tabla 3). Para la

protección del circuito del motor, se

recomiendan los fusibles que

interrumpen por un tiempo en vez de

los fusibles convencionales. Todos los

motores de bomba tienen incorporada

una protección automática contra

sobrecargas que evitará que se dañe el

motor debido a sobrecalentamiento.

No haga la

conexión

a

la fuente de suministro eléctrico hasta

que la unidad esté conectada a tierra en

forma permanente. Conecte el alambre a

tierra a una conexión a tierra aprobada y

luego conecte el terminal que se

suministra.

Una tubería subterránea para agua y una

armazón de pozo de por lo menos 3 m

(10 pies) largo sons los mejores electrodos

de tierra. Si se usa tubería de plástico o

adaptadores con aislamiento, pase un

alambre directamente a la armazón

metálica del pozo o use un electrodo de

tierra proporcionado por la compañíia de

servicio eléctrico.

La unidad sólo tiene un terminal

adecuado para conexión a tierra que

está localizado debajo de la cubierta

del interruptor a presión, está pintado

de verde y se identifica como GRD. La

conexión a tierra se debe hacer desde

este terminal (Figura 8). El conductor a

tierra no debe ser más pequeño que los

conductores de circuito que vienen con

el motor.

Desconecte

el

suministro eléctrico y libere toda la

presión del sistema antes de intentar

instalar, dar servicio, reubicar o llevar a

cabo cualquier mantenimiento.

Distancia en Metros

de Medidor a Motor

Fusible 0 15,6 30,8 61,3

de Dos To To To To

Elementos 15,2 30,5 61 91,4

CP Voltios 250V Tamano del alambre

115 15 14 14 12 10

230 10 14 14 14 14

115 15 14 14 10 8

230 10 14 14 14 14

115 20 12 12 10 8

230 10 14 14 14 14

TABLA 3 - DATOS DE LOS FUSIBLES Y ALAMBRES RECOMMENDADOS-MOTORES DE 60 HZ

1/2

3/4

1

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

Figura 6 - Tanque de Almacenamiento

Precargado

1,93-2,07 bar

3/4 CP & 1 CP

L2

3

L1

1

Figura 8 - Conexiónes Eléctricas

Motor

Motor

Motor

Conexión

Conexion a Tierra

Conexión

Salida

Tapón del

Sistema de

Cebado

Tronçon

de Buse

Adaptador

de drenaje

Figura 7 - Perilla para Seleccionar el

Voltaje

7

Shallow Well Jet Pump

Operating Instructions and Parts Manual

(A) SPRING:

Water Supplies

Figure 13 - Water Supplies

www.waynewatersystems.com

A spring that emerges

from the ground.

Occurs when water in

permeable materials is

trapped between

impermeable

material as rock or clay.

!

ADVERTENCIA

230 V

115 V

230 V

115 V

!

ADVERTENCIA

L2

3

!

ADVERTENCIA

L1

1

for purposes such as washing

or irrigation.

depth. It is then lined

with brick, stone or

concrete to prevent

cave-in.

the water table.

The depth is usually

less than 50 feet.

Available

diameters are

1" through 2".

range from a few feet

to over 1000 feet.

Common well diameters

are 2", 3", 4" and 6" for

domestic water wells.

The water is not fit

for human consumption.

SHALE

(B) LAKE, STREAM or POND:

Surface water, unless treated,

is usually not safe for human

consumption. It may be used

(C) DUG WELL:

A hole is excavated

several feet in diameter

to a fairly shallow

(D) DRIVEN WELL:

Pipe with a pointed

screen is driven into

the ground below

(E) DRILLED WELL:

A hole bored into the

earth with machinery and

lined with pipe. Depths

(F) CISTERN:

An underground tank

built to collect rain

water from rooftops.

(A) SPRING

(B) LAKE,

STREAM, POND

(C) DUG WELL

(D) DRIVEN WELL

WATER

MATERIAL

CLAY

TOP SOIL

BEARING

SAND

PERMEABLE

(E) DRILLED WELL

WATER TABLE

(F) CISTERN

Page 8

La válvula

de aspiración debe estar por lo menos a 45 cm

(18 pulg.) del fondo del pozo de no ser

así, podría aspirar arena o sedimento

dentro del sistema.

4. Después que se haya alcanzado la

profundidad adecuada, instale un

sellado del pozo o un adaptador

para sostener la tubería y evitar que

el agua de la superficie y otros

contaminantes entren al pozo.

5. Incline el tubo horizontal hacia

arriba en direccion a la bomba para

evitar que quede aire atrapado. La

inclinacion del tubo tambien ayuda

a cebar la bomba.

POZO ACCIONADO (FIGURA 12)

1. Lleve la punta a varios pies por

debajo del nivel del agua

subterránea.

NOTA: Se puede instalar en el pozo

una válvula de aspiración de tipo

tampón (Figura 3, Ilustracion B). Este de

tipo de válvula de aspiración permite

que el pozo se llene con agua cuando

se está cebando y permite verificar con

mayor facilidad si hay escapes en la

tubería de ingreso. Cuando instale la

válvula de aspiración de tipo tampón

siga las instrucciones del fabricante.

Como alternativa, se puede usar una

válvula unidireccional en la tubería de

un pozo excavado (Figura 3, Ilustración

C). La tubería entre la válvula

unidireccional y el nivel de agua estará

siempre bajo un vacío.

Las uniones o conexiones con fugas

dejan que entre aire en la tubería y dan

lugar a que la bomba no funcione bien.

Asegúrese de usar un compuesto para

uniones de tubería en todos los

roscados machos de los tubos.

INSTALACIÓN DEL POZO EXCAVADO,

CISTERNA, LAGO Y MANANTIAL

(FIGURA 12)

1. Instale una válvula de aspiración en

la tubería de entrada y bájela

dentro del agua.

La válvula

de

aspiración debe estar a por lo menos 45

cm (18”) del fondo del pozo de no ser

así se podría aspirar arena o sedimento

dentro del sistema.

NOTA: Cuando se usa un lago como

fuente de suministro de agua,

asegúrese que la tubería de entrada

25 Sp

tenga la suficiente profundidad para

que esté siempre sumergida. Proteja

la tubería para que no la dañenni los

bañistas ni los botes.

Incline la tubería horizontal hacia

arriba en dirección de la bomba para

evitar que quede aire atrapado. Se

debe sacar la tubería durante los

meses de invierno o protegerla para

que no se congele.

Proteja la tubería para que no la

dañenni los bañistas ni los botes.

Instale

una

malla alrededor de la tubería de entrada

para evitar que qu eden atrapados los

bañistas.

BOMBA PARA POZOS POCO

PROFUNDOS CON TANQUE DE

ALMACENAMIENTO

CONVENCIONAL (FIGURAS 4 Y 5)

1. Instale el control del volumen de

aire en el tanque.

2. Conecte el tube de cobre del

control del volumen de aire en la

abertura NPT de 3,2 mm (1/8”)

superior al lado de la bomba.

Cerciórese de que las conexiones

estén bien ajustadas. Las fugas

puede evitar que la bomba se

cebe.

Instalación

(Continuación)

No se

recomienda tubería flexible para el

tubo de succión (tubo de entrada).

Los tubos deben estar limpios y no

estar oxidados ni con descamaciones.

Utilice un compuesto para conexiones

de tubería en el roscado macho de los

tubos de metal. Para los roscados de

plástico se debe usar una cinta de

Teflon

®

. Todas las conexiones deben

estar herméticas para asegurar un

funcionamiento normal.

Incline todas las tuberías de entrada

hacia arriba en dirección a la bomba

para evitar que quede aire atrapado.

Se pueden instalar uniones o

conectores de manguera cerca de la

bomba para que sea fácil sacarlas

cuando se necesite dar servicio o

almacenarlas. Una manguera de

caucho instalada entre el sistema de

agua y la tubería de la casa reducirá el

ruido que se transmite a la casa.

TAMANOS DE LOS TUBOS

Los tendidos largos de la tubería

horizontal y el uso de numerosos

adaptadores y conectores disminuyen

la presión de agua debido a la pérdida

por fricción. Vea la tabla 2 para

determinar el tamaño adecuado de

tubo.

INSTALACIÓN EN POZOS POCO

PROFUNDOS

Se puede usar una bomba para pozos

poco profundos cuando esta ubicada

dentro de los 25 pies en sentido vertical

del nivel de agua. Las bombas para

pozos poco profundos tienen un solo

tubo entre la bomba y la fuente de

suministro de agua.

POZO PERFORADO (FIGURA 12)

1. Instale una válvula de aspiración en

la primera sección del tubo (Figura

3, Ilustración A).

2. Baje el tubo dentro del pozo.

3. Aumente la tubería hasta que la

válvula de aspiración este a 1,5 m (5

pies) por debajo del nivel de agua

más bajo que se anticipa.

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

Figura 4 - Tanque Horizontal

Tampón

Tuberia

del

Control

del

Volumen

de Aire

Control

del

Volumen

de Aire

Presostato

Figura 5 - Tanque Vertical

Salida

Tubería del Control

del Volumen de Aire

Conector de

la Manguera

Control del Volumen de Aire

Operating Instructions and Parts Manual

Shallow Well Jet Pump

8

Symptom Possible Cause(s) Corrective Action

Troubleshooting Chart

Pump will not run

Motor hums but will not run

Overload trips

Pump runs but delivers little or

no water

Pump starts and stops too

often

1. Power off

2. Blown fuse or tripped breaker

3. Faulty pressure switch

4. Pressure switch tubing obstructed

5. Motor overload tripped

1. Low line voltage

2. Wiring too small

3. Damage or misalignment causing rotating

parts to bind

1. Incorrect line voltage

2. Damage or misalignment causing rotating

parts to bind

3. High surrounding temperature

4. Rapid cycling

1. Water level below pump intake

2. Control valve open too far (deep well)

3. Discharge not vented while priming

4. Leaking in piping on well side of pump

5. Well screen or inlet strainer clogged

6. Clogged nozzle (deep well)

7. Air volume control diaphragm ruptured

8. Foot valve may be clogged or stuck closed

9. Pump not fully primed

10. Control valve completely closed (deep well)

11. Water level below maximum lift

specification

12. Undersized piping

13. Gaseous well

14. Distorted venturi

15. Incorrect jet for application

16. Undersized pump

17. Pump cavitates, sounds like pumping gravel

1. Water logged tank (conventional tank)

2. Air volume control tubing kinked or clogged

3. Air volume control tubing connected to

wrong opening on pump

4. Incorrect tank precharged (precharged tank)

5. Ruptured diaphragm/bladder (precharged

tank)

6. Leak in house piping

7. Foot valve or check valve stuck open

8. Motor overload tripping

9. Improperly adjusted pressure switch

1. Turn power on or call power company

2. Replace fuse or reset circuit breaker

3. Replace switch

4. Clean or replace copper tubing

5. Let cool. Overload will automatically

reset

1. Rewire. See Chart 3*

2. Rewire. See Chart 3*

3. Replace or take to service shop for

repair

1. Rewire. See Chart 3*

2. Take to motor repair shop or locate

and repair mechanical binding

3. Provide a shaded, well-ventilated area

for pump

4. Pump starts and stops too often section

1. Lower suction pipe further into well

2. Repeat priming procedure

3. Open faucet, repeat priming procedure

4. Repair piping as needed

5. Clean or replace as necessary

6. Pull jet and clear obstruction

7. Repair or replace air volume control

8. Clean or replace as needed

9. Continue priming, pausing every 5

minutes to cool pump body. Refill

pump as needed

10. Adjust control valve per deep well

priming procedure

11. Select applicable pump and/or jet

assembly

12. Replace as needed

13. Install baffle on pump intake to prevent gas from entering system

14. Inspect and replace

15. Purchase a jet matched to your system

when replacing another brand pump

16. Increase horsepower of pump

17. Increase suction plumbing diameter or

decrease pipe friction

1. Replace tank or air volume control

2. Clean or replace as needed

3. Move to correct pump opening

4. Add or release air as needed

5. Replace tank

6. Locate and repair leak

7. Remove and replace

8. See overload trips section

9. Readjust or replace switch

* All rewiring and motor repair must be done by licensed or certified professionals

www.waynewatersystems.com

!

PRECAUCION

!

PRECAUCION

!

PRECAUCION

!

ADVERTENCIA

Page 9

Pre-Instalación

(Continuación)

vaciado es aproximadamente 1/6 del

volumen total del tanque cuando se

hace funcionar a una presion de “1,38 2,76 bar” (Figure 2).

TANQUES - ALMACENAMIENTO

PRECARGADO

Un tanque de almacenamiento

precargado tiene una cámara elástica o

un diafragma flexible que funciona

como una barrera entre el aire

comprimido y el agua. Esta barrera

evita que el aire sea absorbido por el

agua y permite que el agua reciba el

efecto del aire comprimido a una

presión inicialmente más alta que la

presión atmosféria (precargado). Este

tipo de tanque proporciona más agua

que los tanques convencionales. Por

ejemplo, un tanque precargado de 75,7

L (20 galones) rendirá la misma

cantidad de agua utilizable o

capacidad de vaciado que un tanque

convencional de 151,4 L (40 galones),

con la ventaja de que el tanques es más

pequeño. (Figura 2).

PRESOSTATO

El interruptor que funciona con la

presión permite la operación

automática. La bomba comienza a

24 Sp

funcionar cuando la presión baja al

nivel límite establecido para funcionar

y dejará de hacerlo cuando la presión

llegue al nivel límite establecido para

apagarse.

PAQUETES DE SISTEMAS

Hay cuatro ensamblados de bomba y

tanque que se venden como paquettes

(Tabla 1).

POZOS

Un pozo nuevo debe bombearse para

que quede sin arena antes de instalar la

bomba. La arena dañará las piezas y los

sellos de la bomba. El nivel más bajo

del pozo no debe exceder la

profundidad máxima permitida para la

bomba. Esto haría que se reduzca la

capacidad de la bomba y se podría

perder el cebado.

Instalación

UBICACIÓN

Escoja una ubicación lo más cercana

posible a la fuente de suministro de

agua.

Asegúrese de cumplir con los códigos

estatales o locales sobre ubicación de

bombas. El equipo debe protegerse de

la intemperie. Una buena ubicación es

un sótano o una casita de bombeo

calentada. Cerciórese de que la bomba

tenga una ventilación adecuada. La

temperatura alrededor de la bomba no

debe exceder de 40° C (100° ) ya que

podrían ourrir desconexiones molestas

del motor por estar sobrecargado.

TUBERÍA

La tubería puede ser de cobre, acero,

PVC plástico rigido o polietileno

plástico flexible.

Distancia Horizontal

Modelo de Abertura de (Metres)

Bomba la Bomba 0-7,62 7,93-30,5 7,93-91,4

TABLA 2 - TAMAÑO DE LOS TUBOS

Ilastración B

Ilastración C

Valvula de Pie

Tipo Portadora

Punta de Acción

A la Bomba

Válvula de

Retención en

Línea

Punta de

Acción

A la Bombo

Figura 3

A la Bomba

Ilastración A

Obturador

del Pozo

Tubería de

Revestimiento

del Pozo

Válvula de Pie

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

Control de Volumen

de Aire

Cámara

Elástica

Tanques

Convencional

Tanques

Precargado

Figura 2 - Tanque de Almacenamiento

Convencional y Precargado

Inlet 3,18 cm 3,81 cm 5,08 cm

Outlet 19,1 mm 2,54 cm 3,18 cm

Pozo

Profundo

9

Shallow Well Jet Pump

Operating Instructions and Parts Manual

For Replacement Parts, call 1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

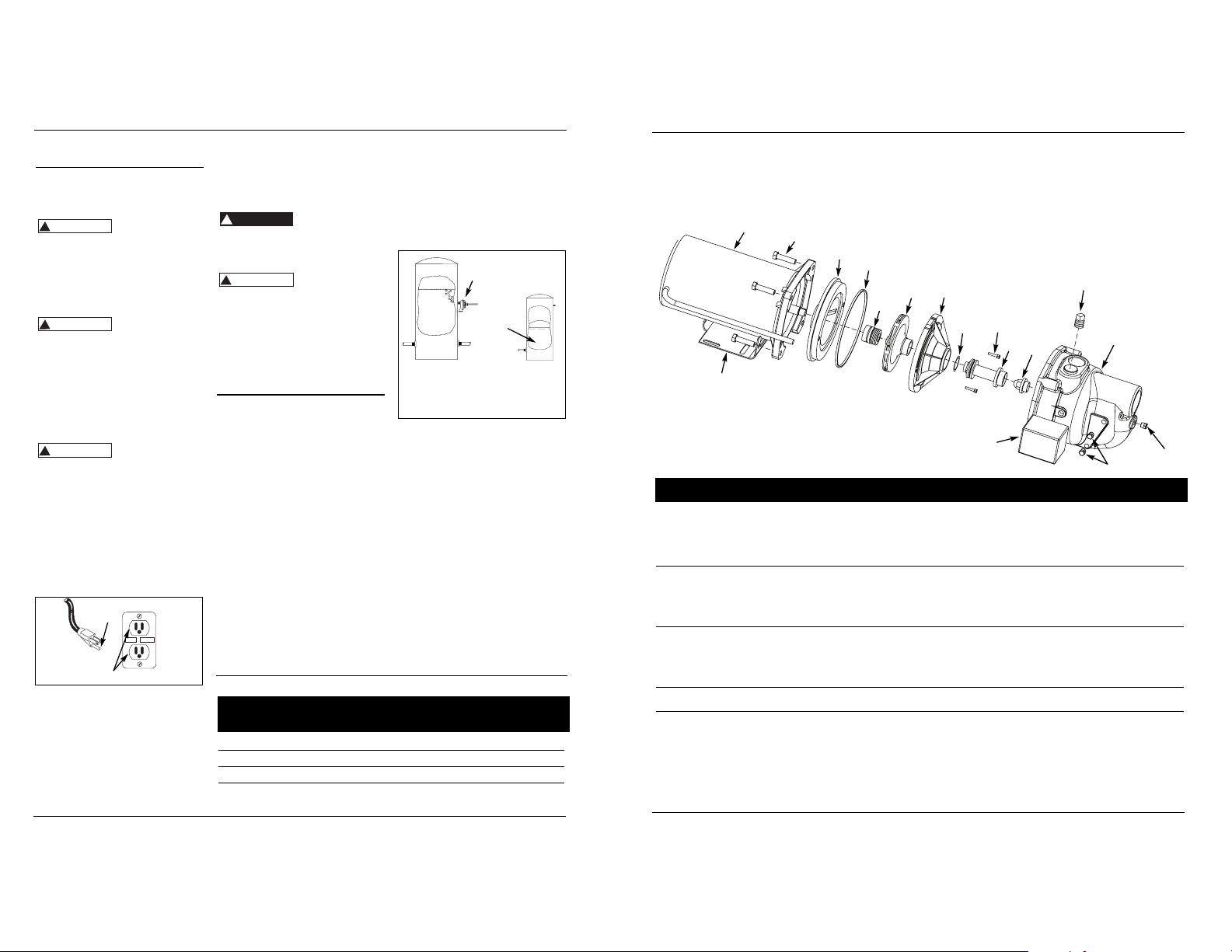

1 Motor 32059-001 34142-001 34142-001 1

2 Screw 16636-002 16636-002 16636-002 4

3 Seal plate 4372-001 4372-001 4372-001 1

4 • Square ring rubber gasket 17150-001 17150-001 17150-001 1

5 • Shaft seal assembly 56393 56393 56393 1

6 Impeller 23285-021 23285-022 23285-022 1

7 Diffuser 17148-021 17148-021 17148-021 1

8 Screw 67007-001 67007-001 67007-001 2

9 • O-ring 15557 15557 15557 1

10 Venturi 17151-002 17151-003 17151-004 1

11 Nozzle 15672 15672 15672 1

12 Pipe plug 3/4” 15921 15921 15921 1

13 Volute 56869-001 56869-001 56869-001 1

14 Pipe plug 1/4” NPT 16314-002 16314-002 16314-002 1

15 Pipe plug 1/8” NPT 15766-002 15766-002 15766-002 1

16 Base 23029-021 23029-021 23029-021 1

17 Pressure switch 30010-021 30010-021 30010-021 1

• Repair kit (Includes #4, 5 and 9) 56874-001 56874-001 56874-001 1

Ref. Part Numbers for Models

No. Description SWS50-1/2 HP SWS75-3/4 HP SWS100-1 HP Qty.

17

1

2

3

4

5

6

7

8

11

12

10

13

14

16

9

15

www.waynewatersystems.com

Page 10

19. Para reducir el riesgo de choque

eléctrico, la bomba se debe

enchufar directamente en un

tomacorriente para tres patillas

debidamente instalado y conectado

a tierra, como se muestra en la

Figura 1. El conductor verde (o

verde y amarillo) del cordón es el

alambre a tierra. Para la protección

contra el choque eléctrico, el motor

debe estar conectado a tierra en

forma segura y adecuada.

20. Cuando se encuentre un

tomacorriente para dos patillas se

debe reemplazar con uno para tres

patillas de acuerdo con el Código

Nacional de Electricidad de EUA y

los códigos y ordenanzas locales.

Para estar seguro de que la

conexión a tierra sea adecuada, la

debe probar un electricista

certificado o con licenia.

21. Use solamente cordones de

extensión de tres alambres que

tengan un enchurfe de tres puntas y

tomacorriente un que acepte el

enchufe del equipo.

22. Use alambres del tamaño adecuado

para reducir al mínimo la caída de

voltaje en el motor.

No mani-

pule la

bomba ni su motor con las manos

mojadas, ni cuando esté parado en

superficies húmedas, mojadas o en el

agua. Puede ocurrir un choque eléctrico

fatal.

23 Sp

Manual de instrucciones de operación y piezas

Informaciones

Generales de Seguridad

(Continuación)

Existe

riesgo de

un choque eléctrico. Está bomba está

diseñada únicamente para ser instalada en

interiores.

Todas las

conexiones eléctricas las debe hacer un

electricista certificado o con licenia.

13. Para máxima seguridad, la unidad

se debe conectar a un circuito con

conexión a tierra que tenga un

dispositivo de interrupción para

cuando falle la conexión a tierra.

14. Antes de instalar la bomba, haga

que un electricista certificado o con

licencia verifique el tomacorriente

para comprobar que tenga una

conexión a tierra adecuada.

15. Asegúrese de que las conexiones

eléctricas del motor sean adecuadas

para el voltaje y la frecuencia de la

linea de suministro eléctrico.

16. No intente reparar el motor

eléctrico. Todas las reparaciones del

motor deben hacerse en un taller

certificado o con licenia para

reparar motores eléctricos.

No toque

un motor

en funcionamiento. Los motores

modernos están diseñados para trabajar a

altas temperaturas.

17. Evite doblar el cordón de

electricidad y protéjalo de objetos

cortantes, superficies calientes,

aceite y químicos. Reemplace o

repare los cordones dañados o

gastados de inmediato.

Descon-

ecte la

corriente eléctrica y libere toda la presión

del sistema antes de intentar instalar,

darle servicio, mantenimiento o cambiarlo

de lugar. Trabe el desconector de corriente

en la posicion de abierto, y rotúlelo para

evitar una aplicación inesperada de

corriente.

18. Mantenga los dedos y los objetos

extraños alejados de la ventilación y

otras aberturas. No inserte ningún

objeto en el motor.

Existe

riesgo de

un choque eléctrico! Nunca conecte el

alambre verde (o el verde y amarillo) a un

terminal con corriente.

El motor

de la

bomba está equipado con un protector

automático termal de recalibración por lo

que puede volver a funcionar en forma

inesperada. Cuando el protector hace la

desconexión, esto es una indicación de

que el motor está sobrecargado porque la

bomba esta funcionando a niveles bajos

(restricción de descarga baja), el voltaje es

excesivamente bajo o alto, el cableado es

inadecuado, las conexiones del motor no

son las correctas o el motor o la bomba

tiene defectos.

Pre-Instalación

FUENTES DE SUMINISTRO DE AGUA

Las posibles fuentes de suministro de

agua se ilustran en la Figurra 16. Se

pueden clasificar en dos categorías:

AGUAS DE SUPERFICIE

Agua de un lago, arroyo, laguna o

cisterna. Esta agua habitualmente no

es adecuada para consumo humano,

pero podría usarse para lavar, irrigar u

otros usos domésticos.

AGUAS SUBTERRÁNEAS

El agua que se encuentra en los

diversos estratos por debajo de la

superficie. De toda el agua dulce que

se encuentra en la tierra, solamente el

3% está en la superficie y el 97% es

subterrénea.

TANQUES - ALMACENAMIENTO

CONVENCIONAL

El objeto de un tanque es almacenar

una cantidad de agua bajo presion.

Cuando esta lleno, el tanque contiene

aproximadamente 2/3 de agua y 1/3 de

aire comprimido. El aire comprimido

fuerza el agua a salir del tanque

cuando se abre un grifo. Un control del

volumen de aire reemplaza

automaticamente el aire perdido o

absorbido por el agua. La cantidad de

agua utilizable o la capacidad de

!

Modelos para pozos profundos

Se Necesita

Control del

Tipo Volume de Aire

Pozo X Precargado No

PCA Precargado No

12P & 30P Horizontal Convencional Sí

FX Horizontal Precargado No

TABLA 1 - ENSAMBLADOS DE

Terminal de

Conexión a

Tierra