Page 1

Operating Instructions

Instructions d’Utilisation

Manual de Instrucciones

Notes

Notas

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

Description

This sewage pump is suitable for

pumping sewage, effluent, wastewater,

groundwater and other nonexplosive,

noncorrosive liquids with up to two

inch solids. The pump includes a wide

angle float switch that turns the pump

on and off as the fluid level rises and

falls.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return the

unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

Operating Instructions Model RPP50

331300-001 8/04

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

General Safety

Information

1. Know the pump application,

limitations, and potential hazards.

Do not use to pump

flammable or explosive

fluids such as gasoline, fuel

oil, kerosene, etc. Do not

use in flammable and/or explosive

atmospheres. Use pump only with

liquids compatible with pump

component materials. Failure to follow

this warning can result in personal

injury and/or property damage.

2. Make certain that the power source

(electric motor) conforms to the

requirements of the equipment.

Disconnect power before

servicing. If the power disconnect is out of sight, lock

in the open position and

tag it to prevent unexpected

application of power. Failure to do so

could result in fatal electrical shock!

© 2004 Wayne Water Systems

Specifications

Power supply requirements......120V, 60 hz

Circuit requirements..................15 amps (min)

Motor duty.................................Intermittent

Motor .........................................120V, 1 Phase

Horsepower ...............................1/2

Motor full load ..........................6.3 amps

Liquid temperature range ........40°F to 120°F

Max. operating position ...........45

o

from vertical

Dimensions.................................14” x 12”

Intake .........................................2”

Discharge....................................2” NPT female

Cut-in level (factory set)............16”

Cut-out level (factory set) .........7.5”

Differential.................................8.5”

Switch .........................................90

o

wide angle

mechanical tether switch

Power cord.................................18 gauge 3 conductor

w/plug

Construction

Motor housing...........................Cast iron

Volute.........................................Cast iron

Impeller ......................................Glass reinforced PBT

Seal plate....................................Cast Iron

Shaft seal....................................Mechanical

GALLONS PER HOUR AT TOTAL HEAD IN FEET

Model 0 5 10 15

RPP50 5700 4560 3240 900

Performance

1/2 HP Cast Iron

Sewage Pump

For parts, product & service information

visit www.waynepumps.com

!

WARNING

!

DANGER

!

WARNING

!

CAUTION

NOTICE

!

DANGER

Page 2

Garantía Limitada

Durante un (1) año a partir de la fecha de compra, Wayne Water Systems ("Wayne") reparará o reemplazará, según lo decida, para

el comprador original, cualquier pieza o piezas de sus Bombas para cloacas o Bombas de agua ("Producto") que después de un

examen sea(n) hallada(s) por Wayne como defectuosa(s) en su material o mano de obra. Sírvase llamar a la compañía Wayne

(800-237-0987, desde EE.UU) para recibir instrucciones al respecto o comuníquese con el distribuidor más cercano a su

domicilio. Para hacer reclamos bajo esta garantía deberá suministrarnos el número del modelo y el número de serie del

producto. El comprador será responsable de pagar todos los gastos de flete para enviar las piezas o el producto para

que sean reparados o reemplazados.

Esta garantía Limitada no cubre los daños que sufra el producto debido a accidentes, abusos, usos inadecuados,

negligencia, instalación incorrecta, mantenimiento inadecuado o haberse utilizado sin seguir las instrucciones escritas

suministradas por la compañía Wayne.

NO EXISTEN OTRAS GARANTIAS EXPRESAS. LAS GARANTIAS IMPLICITAS INCLUYENDO GARANTIAS EN

RELACION AL MERCADEO O USOS ESPECIFICOS ESTAN LIMITADAS A UN AÑO A PARTIR DE LA FECHA DE

COMPRA. ESTA ES LA UNICA GARANTIA DISPONIBLE Y TODAS LAS REPONSABILIDADES CIVILES, DIRECTAS O

INDIRECTAS, O GASTOS POR DAÑOS INDIRECTOS O CONSECUENTES QUEDAN EXCLUIDOS.

Algunos estados no permiten que se establezcan límites en la duración de las garantías implicitas o no permiten que se

excluyan ni se establezcan límites en los daños por incidentes o consecuencias, por lo tanto los límites antes

mencionados podrían ser no válidos. Esta Garantía Limitada le otorga derechos legales especificos, y usted también

puede tener otros derechos que varian de un Estado a otro..

En ningún caso, bien sea por ruptura del contrato de la garantía, responsabilidad civil (incluyendo negligencia) u otra

causa, Wayne o sus distribuidores serán responsables pon daños especiales, consecuentes ni circunstanciales ni penales,

incluyendo, pero no limitados a la pérdida de ganancias, pérdida de uso del producto o equipos asociados, daños a

equipos asociados, costos de capitales, costos para substituir productos, costos para substituir o reemplazar servicios,

costos por pérdida de productividad, o reclamos de clientes del comprador por dichos daños.

DEBE conservar el recibo de compra con esta garantía. En caso de que necesite hacer un reclamo bajo esta garantía,

DEBERA enviarnos una copia del recibo junto con el material o correspondencia. Sírvase comunicarse con la compañía

Wayne (800-237-0987, en EE.UU.) para recibir autorización e instrucciones para enviar el producto.

NO ENVIE ESTA GARANTIA A WAYNE. Use este documento sólo para mantener sus records.

NO DEL MODELO._______________ NO DE SERIE .__________________________ FECHA DE INSTALACION _____________

ANEXE SU RECIBO AQUI

15 Sp

Manual de Instrucciones

child-proof with padlocks, master

switches, and by removing starter

keys.

10. When wiring an electrically driven

pump such as this, follow all

electrical and safety codes, as well

as the most recent National

Electrical Code (NEC) and the Occupational Safety and Health Act

(OSHA).

Risk of electric shock! Never

connect the green (or green

and yellow) wire to a live

terminal!

11. This equipment is only for use on

120 volt (single-phase) and is

equipped with an approved 3-conductor cord and 3-prong,

grounding-type plug as shown in

Figure 1.

Where a 2-prong

wall receptacle is

encountered, it must be replaced with a

properly grounded 3-prong receptacle

installed in accordance with the NEC

and local codes and ordinances.

12. All wiring should be performed by a

qualified electrician.

General Safety

Information (Continued)

3. Release all pressure within the

system before servicing any

component.

4. Drain all liquids from the system

before servicing.

This pump contains

dielectric motor oil

for motor heat transfer. Care should be

taken when disposing of this oil. Do

not use this pump in ponds or fountains

because the motor oil can be harmful to

aquatic life.

5. Secure the discharge line before

starting the pump. An unsecured

discharge line will whip, possibly

causing personal injury and/or

property damage.

6. Check hoses for weak and worn

condition before each use, making

certain that all connections are

secure.

7. Periodically inspect the pump and

system components. Perform

routine maintenance as required

(See Maintenance Section).

8. Provide a means of pressure relief

for pumps whose discharge line can

be shut-off or obstructed.

9. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean,

uncluttered and properly lighted;

replace all unused tools and

equipment.

c. Keep visitors a safe distance from

the work area. Make workshop

2

Operating Instructions

13. It is strongly recommended that this

unit is plugged into a Ground Fault

Circuit Interrupter (GFCI). Consult a

local electrician for installation and

availability.

The pump motor is

equipped with

automatic resetting thermal protector

and may restart unexpectedly.

Protector tripping is an indication of

motor overloading as a result of

operating the pump at low heads (low

discharge restriction), excessively high

or low voltage, inadequate wiring,

incorrect motor conditions, or a

defective motor or pump.

14. This pump is designed to transfer

water in cycles. Using this pump in a

continuous duty application by manipulating the switch to stay on,

will effect the performance and the

life of the product.

15. Protect electrical cord from sharp

objects, hot surfaces, oil, and

chemicals. Avoid kinking the cord.

Replace or repair damaged or worn

cords immediately. Use wire of

adequate size to minimize voltage

drop at the motor.

16. Do not handle a pump or pump

motor with wet hands or when

standing on a wet or damp surface,

or in water.

17. Do not hang this product by the

carry handle. Sewage pumps should

be set firmly on their legs and

supported by rigid piping. This

eliminates twisting and damage

during pump operation.

18. Do not use an extension cord.

Grounding

Blade

Figure 1

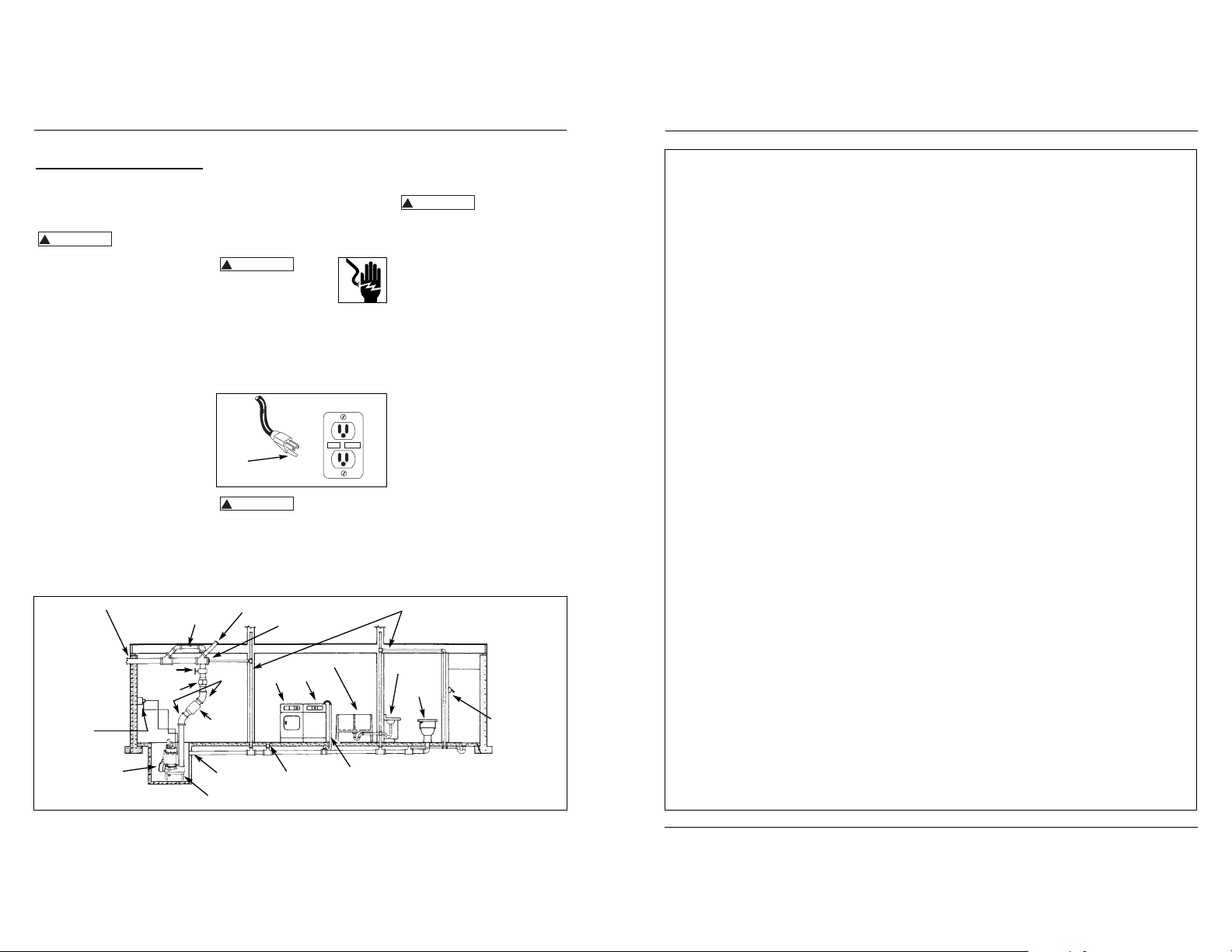

Main waste line to sewer or septic tank

Upper level drainage

Three prong

grounded outlet

equipped with a

ground fault

interruptor

2” Discharge pipe

Float switch

Sewage pump passes 2” dia. solids

Cleanout

Vent pipe

2” Gate

Valve

Union

2” Check

Valve

45

o

Elbow

Laundry tubs

Washer

Dryer

Floor drain

Washer drain

Lavatory

Toilet

Shower

Flange

Figure 2 - Typical Installation

www.waynepumps.com

!

WARNING

!

WARNING

!

WARNING

RESET

TEST

!

WARNING

Page 3

Diagnóstico de Averías

Problema Posible(s) Causa(s) Acción a Tomar

La bomba no se

enciende o funciona

La bomba se

enciende y se apaga

constantemente

La bomba se apaga y

se enciende

independientemente

del interruptor (el

sistema de protección

térmica se activa)

La bomba hace

mucho ruido o vibra

excesivamente

La bomba no deja

de funcionar

La bomba funciona

pero bombea muy

poca agua o no

bombea agua

1. El nivel de agua es muy bajo

2. El fusible está quemado o el

cortacircuito se activó

3. El voltaje es muy bajo

4. El motor está dañado

5. El flotante está dañado

6. El impulsor (la bomba está

obstruída con basura)

7. El interruptor está obstruído

8. Nivel de líquido insuficiente

1. El agua se regresa de las tuberías

2. El interruptor/flotante está dañado

3. No instaló una válvula de chequeo o

la válvula de chequeo tiene una

fuga

4. La distancia de la descarga es

inferior al mínimo recomendado

por el fabricante

1. La temperatura del agua es excesiva

2. El interruptor está dañado u

obstruído y por lo tanto la bomba

funciona al seco

3. El voltaje es muy bajo

1. Los cojinetes están desgastados

2. El impulsor está obstruído con

basura o está rota

3. Las tuberías que conectan la bomba

al edificio son muy rígidas o están

muy flojas

1. El interruptor flotante está dañado

2. El intyerruptor flotante no se puede

mover libremente

3. Las tuberiás de descarga están

obstruídas

4. Entrada excesiva de agua o la

bomba no es la adecuada para la

aplicación en que se está usando

1. El voltaje es muy bajo

2. El impulsor o la tubería de descarga

están obstruídos con basura

3. La bomba tiene alguna pieza

dañada o el impulsor está obstruído

4. La bomba no es la adecuada para la

aplicación en que se está usando

5. La válvula de chequeo está atascada

o instalada incorrectamente

6. La válvula de cierre está cerrada

1. El interruptor no encenderá la bomba a menos que la

bomba esté totalmente sumergida en agua

2. Si el fusible está quemado reemplácelo con uno adecuado o

reconecte el cortacircuito

3. Si el voltaje es inferior al mínimo recomendado, chequée el

alambrado del circuito principal de la propiedad. Si es

adecuado, comuníquese con la compañía de electricidad.

4. Envie el motor al centro de servicio autorizado más cercano

a su domicilio o reemplácelo

5. Reemplace el interruptor flotante

6. Si la propela no gira, destápela y límpiela

7. Coloque el interruptor de modo que se mueva sin

problemas. Reubique la bomba si es necesario

8. Cerciórese de que el nivel de líquido esté por lo menos a 33

cm (13”) del fondo de la pileta

1. Instale una válvula de chequeo

2. Reemplace el interruptor flotante

3. Desconecte la válvula de chequeo y revísela a ver si está

bien instalada y funcionando adecuadamente

4. Haga los cálculos una vez más para cerciorarse de que esté

usando una bomba adecuada

1. La bomba no se debe usar para bombear agua a más de

44°C (120° F).

2. Reemplace o reubique la bomba

La bomba puede comenzar a

funcionar sin previo aviso.

Desconéctela del tomacorrientes antes de darle servicio

3. Si el voltaje es inferior al mínimo recomendado, chequée el

alambrado del circuito principal de la propiedad. Si es

adecuado, comuníquese con la compañía de electricidad

1. Cambie la bomba

2. Destape la unidad, limpie el impulsor y/o reemplácelo si está

roto

3. Reemplace una porción de la tubería de descarga con un

conector flexible

1. Reemplace el interruptor flotante

2. Reubique la bomba o limpie la pileta según sea necesario

para que el flotante se mueva sin problemas

3. Desconecte la bomba y limpie la bomba y las tuberías

4. Haga los cálculos una vez más para cerciorarse de que esté

usando una bomba adecuada

1. Si el voltaje es inferior al mínimo recomendado, chequée el

alambrado del circuito principal de la propiedad. Si es

adecuado, comuníquese con la compañía de electricidad.

2. Desconecte el impulsor, límpielo y cerciórese de que esté

bien instalado

3. Reemplace las piezas dañadas o toda la bomba. Si es

necesario limpie las piezas que estén sucias

4. Haga los cálculos una vez más para cerciorarse de que esté

usando una bomba adecuada

5. Desconecte la válvula de chequeo y revísela a ver si está

bien instalada y funcionando adecuadamente

6. Abra la válvula

14 Sp

General Safety

Information (Continued)

Do not walk on wet area

until all power has been

turned off. If the shut-off

box is in basement, call the

electric company to shut-off service to

the house, or call the local fire

department for instructions. Remove

pump and repair or replace. Failure to

follow this warning can result in fatal

electrical shock.

Installation

In any installation

where property

damage and/or personal injury might

result from an inoperative or leaking

pump due to power outages, discharge

line blockage or any other reason, use a

backup system(s).

1. Thread the discharge pipe or pipe

nipple into the discharge

connection.

2. If a check valve is used in a solids

handling system mount the check

valve in a horizontal position or at a

45° angle with the valve pivot on

top. In a vertical position, solids will

tend to lodge on the valve flapper

and can prevent it from opening.

3

Operating Instructions

3. Drill a 1/16" hole in the discharge

pipe approximately 1" to 2” above

the pump discharge when a check

valve is used. The hole prevents air

locking of the pump at the initial

start-up and if it should lose prime.

4. A gate valve should be installed in

the system after the check valve.

This gate valve should be a full port

valve which will pass 2" solids or as

required by state and local codes.

This gate valve permits removal of

the pump and/or check valve for

servicing.

5. A union should be installed

between the check valve and the

pump so the pump can be removed

with least disturbance of the piping.

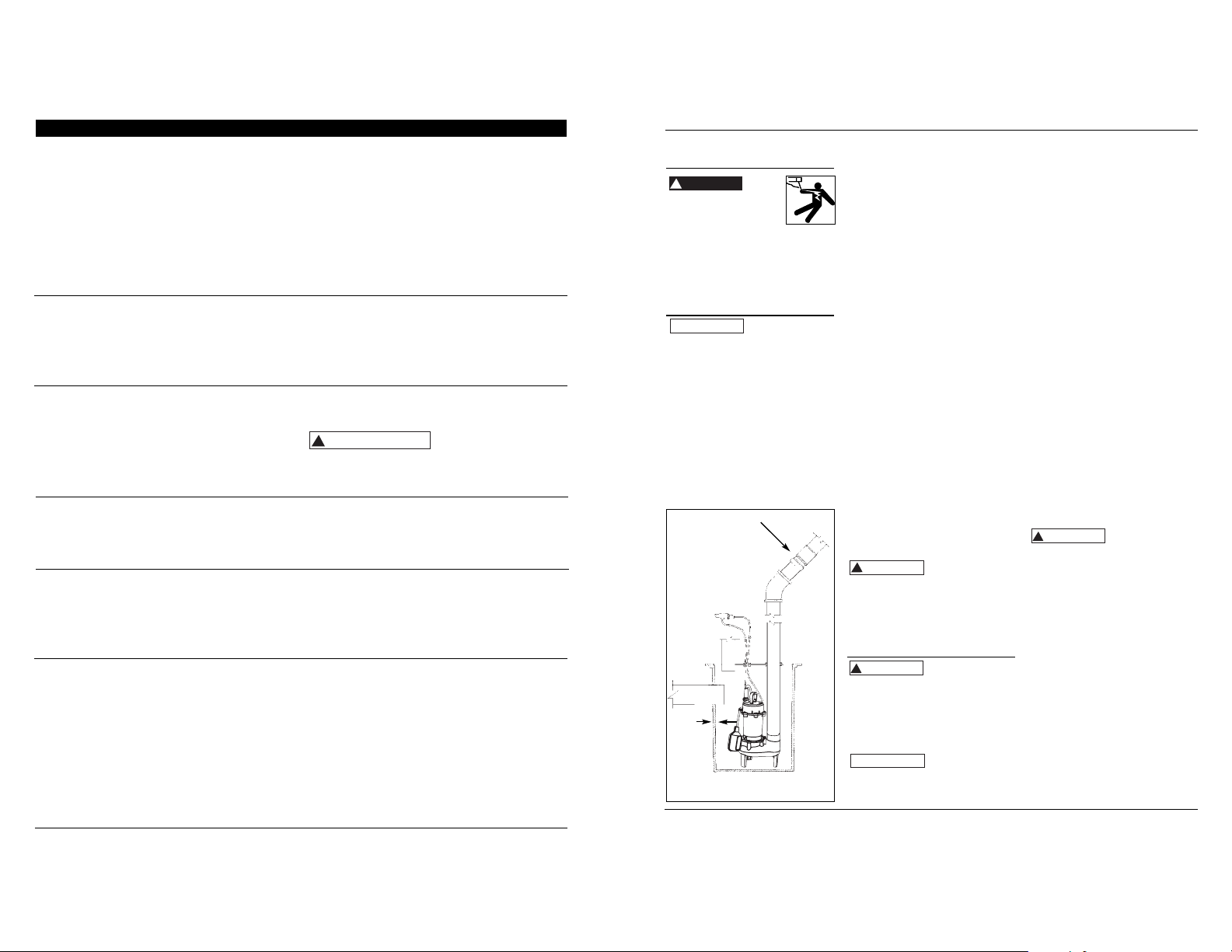

6. The pump has a detachable tether

switch with a piggyback plug (see

figure 3). The length of the tether

(distance of cord from float to

clamp) should not be set shorter

than 3-1/4 inches and should not be

used in a basin smaller than 14

inches in diameter. If using a

differential other than the factory

setting, be sure when the pump

shuts off at least 4” of fluid is left in

the basin so the impeller remains

submerged.

7. When a tether switch is used, rigid

discharge pipe is required. If the

pump is allowed to move, the tether

switch could be restricted by the

basin wall, preventing the pump

from operating.

Before removing

pump from basin

for service, always disconnect electrical

power to pump and control switch. For

any work on pump or switch, ALWAYS

unplug the power cord. Do not just turn

off circuit breaker or unscrew fuse.

Maintenance

Make certain that

the pump is

unplugged before attempting to service

or remove any component. This pump is

assembled in the factory using special

equipment; therefore only authorized

service dealers or qualified electricians

should attempt to repair this unit.

Improper repair can cause an electrical

shock hazard.

The pump contains

oil that may be

under pressure because of heat. Let the

pump cool for a minimum of two hours

before servicing this unit.

Check valve 45

o

Vent

Inlet

Gasket

1/2”

Min.

Clearance

Basin

Figure 3 - Prefabricated Basins

1. Disassembly of the motor prior to

expiration of warranty will void the

warranty. It might also cause

internal leakage and damage to the

unit. If repairs are required, return

the pump to the dealer from whom

it was purchased or call 1-800-237-

0987.

2. After the basin cover is removed

and necessary discharge piping

disconnected, lift pump from basin.

3. Pump should be checked on a

regular basis for proper operation.

If anything has changed since unit

was new, the unit should be

removed and replaced. Only

qualified electricians or service people should attempt to repair this

unit. Improper repair and/or

assembly can cause an electrical

shock hazard.

4. Place the pump in a suitable area

where it can be cleaned thoroughly.

Remove all scale and deposits on

pump.

5. Submerge the complete pump in a

disinfectant solution (10% chlorine

bleach solution) for at least one

hour before handling the pump.

6. Clean all dirt and deposits from the

pump float. Make sure float moves

freely after cleaning.

7. Clean all dirt and deposits away

from pump inlet and volute.

This pump contains

dielectric motor oil

for lubrication and motor heat transfer.

This oil can be harmful to the

environment. Check state

environmental laws before disposing of

this oil. This oil can be harmful to

aquatic life so consideration should be

exercised in the application of this

pump.

www.waynepumps.com

!

PRECAUCION

!

DANGER

NOTICE

!

CAUTION

!

WARNING

NOTICE

!

WARNING

Page 4

13 Sp

Manual de Instrucciones

Informaciones

Generales de Seguridad

(Continuación)

17. No cuelgue la bomba por el mango.

Estas bombas deben estar

firmemente instaladas sobre sus

patas y conectadas a una tubería

rígida. Ésto evita que se mueva y se

dañe durante el uso .

18. No use cordones de extensión.

No camine en un área húmeda

antes de desconectar la

energía eléctrica. Si el

cortacircuito está fuera de su alcance

(en el sótano), llame a la compañía de

electricidad o al cuerpo de bombero

para que le asistan. Desconecte la

bomba y repárela o reemplácela. Si no

sigue estas instrucciones podría morir

electrocutado.

Instalación

Si hay

peligro de

que sufra heridas personales o daños a

su propiedad si la bomba se daña o

tiene fugas debido a interrupciones en

el servicio eléctrico, obstrucciones en la

línea de descarga o cualquier otra

razón, instale un sistema auxiliar.

1. Enrosque la tubería de descarga o el

niple en el orificio de descarga de la

unidad.

2. Si usa una válvula de chequeo, en un

sistema con presencia de sólidos,

instálela en posición horizontal o en

un ángulo de 45° con muñón hacia

arriba. En la posición vertical, los

sólidos tienden a permanecer en las

chapaletas de la válvula y pueden

evitar que se abra.

3. Cuando use una válvula de chequeo,

taladre un orificio de 1,6 mm (1/16”)

en la tubería de descarga

aproximadamente a 2,54 -5,08 cm (1”

ó 2”) por encima del orificio de

descarga de la bomba. Este orificio

evita que el aire obstruya la bomba

al encenderla por primera vez o

cuando pierda el cebado.

4. Debe instalar una válvula de entrada

inmediatamente después de la

válvula de chequeo. Esta válvula

debe permitir el paso de sólidos de

5,08 cm (2”) o lo establecido por los

códigos y ordenanzas locales. Esta

válvula le permite desconectar la

bomba o la válvula de chequeo

cuando vaya a darles servicio.

5. Debe conectar un empalme entre la

válvula de chequeo y la bomba de

modo que pueda desconectar la

bomba fácilmente.

6. Esta bomba tiene un interruptor/

flotante desmontable con un

enchufe incorporado (vea la figura

3). La longitud del cordón entre el

flotante y la abrazadera no debe ser

menos de 8,25 cm (3-1/4”) y no se

debe usar en una pileta de menos de

35,6 cm (14”) de diámetro. Si va a

usar un diferencial diferente al fijado

de fábrica, cerciórese de que cuando

la bomba se apague todavía haya por

lo menos 10,2 cm (4”) de agua en la

pileta de modo que el impulsor

permanezca sumergido.

7. Cuando use un interruptor flotante

debe usar una tubería de descarga

rígida. Si la bomba se mueve, el

interruptor flotante podría hacer

contacto con las paredes de la pileta

y la bomba no funcionaría.

Antes de

sacar la

bomba de la pileta para darle servicio,

siempre desconecte el cordón eléctrico

de la bomba y el interruptor. Antes de

darle servicio a la bomba o al

interruptor SIEMPRE desconecte el

cordón eléctrico. No desactive el

cortacircuito o saque un fusible.

Mantenimiento

Siempre

desconecte el cordón eléctrico antes de tratar de

Válvula de

chequeo 45

o

Entrada

Empaque

darle servicio o desconectar un

componente. Esta bomba se ensambla

en la fábrica usando equipo especiales;

por lo tanto sólo los técnicos

(electricistas) especializados o el

personal de los centros de servicio

autorizado deben tratar de reparar esta

unidad. De lo contrario podría

ocasionar peligro de electrocutamiento.

Esta

bomba

contiene aceite que podría estar bajo

presión debido al calor. Espere a que la

bomba se enfríe por lo menos durante 2

horas antes de darle servicio.

1. Si desmantela el motor antes de la

fecha de expiración de la garantía,

esta quedaría cancelada. Igualmente,

podría ocasionar fugas internas y

daños a la unidad. Si necesita

reparación, envie la bomba a la

tienda donde la compró o

comuníquese con el distribuidor más

cercano a su domicilio.

2. Después de destapar la pileta y

desconectar las tuberías necesarias,

saque la bomba de la pileta.

3. Chequée la bomba periódicamente

para ver si está en buen estado. Si el

sistema ha cambiado después de

instalar la unidad, debe desconectar

y reemplazar la bomba. Sólo

electricistas calificados deben tratar

de reparar esta unidad. Reparaciones

y/o ensamblajes incorrectos podrían

ocasionar peligro de electrocución.

4. Coloque la bomba en un sitio

adecuado para limpiarla

completamente. Quítele todos los

residuos e impurezas a la bomba.

5. Sumerje toda la bomba en una

solución desinfectante (10% de lejía)

por lo menos durante una hora antes

de tocar la unidad.

6. Limpie bien el flotante de la bomba.

Cerciórese de que el flotante se

puede mover libremente después de

limpiarlo.

7. Limpie bien el orificio de entrada de

la bomba y la voluta.

Esta

bomba

contiene aceite para motores

dieléctricos para lubricar el motor y

transferir calor. Este aceite podría

contaminar el ambiente. Consulte las

ordenanzas de contaminación ambiental

antes de tirar este aceite. Este aceite

podría ser dañino para los animales

acuáticos, por lo tanto debe tomar ésto

en consideración cuando vaya a usar la

bomba.

Orificio de

Ventilación

Distancia

Mín. de

1,3 cm

(1/2”)

Figura 3 - Piletas Prefabricadas

Pileta

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not start or

run

Pump starts and stops

too often

Pump shuts off and

turns on independently

of switch (trips thermal

overload protection)

Pump operates noisily

or vibrates excessively

Pump will not shut off

Pump operates but

delivers little or no

water

1. Water level too low

2. Blown fuse or tripped circuit

breaker

3. Low line voltage

4. Defective motor

5. Defective float switch

6. Impeller (pump filled with

debris)

7. Tangled switch

8. Insufficient liquid level

1. Backflow of water from piping

2. Faulty float switch

3. Check valve not installed or

leaking

4. Discharge head is less than

manufacturer's minimum

1. Excessive water temperature

2. Defective switch or entangled

switch is causing pump to run

dry

3. Low line voltage

1. Worn bearings

2. Debris in impeller cavity or

broken

3. Piping attachments to building

structure too rigid or too loose

1. Defective float switch

2. Float switch movement restricted

3. Restricted discharge (obstruction

in piping)

4. Excessive inflow or pump not

properly sized for application

1. Low line voltage

2. Debris caught in impeller or

discharge

3. Worn or defective pump parts or

plugged impeller

4. Pump not properly sized for

application

5. Check valve stuck closed or

installed backwards

6. Shut off valve closed

1. Pump switch will not turn on unless water covers top of

pump

2. If blown, replace with proper sized fuse or reset breaker

3. If voltage is under recommended minimum, check wiring

size from the main switch on property. If OK, contact power

company.

4. Return for service or replace motor

5. Replace float switch

6. If impeller will not turn, remove housing and remove debris

7. Arrange switch so the switch moves freely. Reposition pump

if necessary

8. Make sure liquid level is at least 13" from the basin floor

1. Install check valve

2. Replace float switch

3. Remove and examine check valve for proper installation

and free operation

4. Recheck all sizing calculations to determine proper pump

size

1. Pump should not be used for water above 120°

2. Replace or reposition pump

Pump may start unexpectedly. Disconnect

power supply before servicing

3. If voltage is under recommended minimum, check wiring

size from the main switch on property. If OK, contact power

company

1. Replace pump

2. Remove housing, clean impeller and/or replace broken

impeller

3. Replace portion of discharge pipe with flexible connector

1. Replace float switch

2. Reposition pump or clean basin as required to provide

adequate clearance for float

3. Remove pump and clean pump & piping

4. Recheck all sizing calculation to determine proper pump

size

1. If voltage is under recommended minimum, check wiring

size from the main switch on property. If OK, contact power

company

2. Remove, clean and check for tightness

3. Replace entire pump. Clean parts if required

4. Recheck all sizing calculations to determine proper pump

size

5. Remove and examine check valve for proper installation

and free operation

6. Open valve

www.waynepumps.com

4

!

CAUTION

!

PELIGRO

AVISO

!

PRECAUCION

!

ADVERTENCIA

AVISO

!

ADVERTENCIA

Page 5

c. Mantenga a los visitantes alejados

del área de trabajo. Cerciórese de

tomar todas las medidas de

seguridad necesarios para evitar

accidentes con niños (use

candados y cortacircuitos y no

deje las llaves al alcance de los

niños).

10. Para instalar el alambrado de

bombas eléctricas, tales como la

descrita en este manual, siga todos

los códigos de seguridad laboral y

electricidad establecidos en su país,

por ejemplo los de la NEC y OSHA

en EE.UU.

¡Peligro de choque eléctrico!

Nunca conecte los cables

verdes o verde con rayas

amarillas, a un terminal con tensión.

11. Este equipo está diseñado sólo para

funcionar en circuitos de 120 voltios

(monofásicos) y está equipado con

un cordón eléctrico de 3 cables y 3

terminales para conexión a tierra tal

como se muestra en la Figura 1.

Si el

tomacorrientes disponible es de dos

orificios, debe reemplazarlo con un

tomacorrientes de 3 orificios. Debe

seguir todos los códigos y ordenanzas

locales para instalar el tomacorrientes.

Informaciones

Generales de Seguridad

(Continuación)

3. Libere toda la presión del sistema

antes de darle servicio a cualquier

componente.

4. Drene todos los líquidos del sistema

antes de darle servicio.

Esta

bomba

contiene aceite de motor dieléctrico

para la transferencia del calor del

motor. Se debe tener cuidado cuando

se deseche este aceite. No use esta

bomba en estanques o fuentes ya que

el aceite de motor puede ser nocivo

para la vida acuática.

5. Asegure la línea de descarga antes

de encender la bomba. De lo

contrario, ésta se enrollará y podría

ocasionarle heridas o daños a su

propiedad.

6. Antes de cada uso, inspeccione las

mangueras, para ver si están

dañadas o desgastados y cerciórese

de que las conexiones estén bien

apretadas.

7. Chequée la bomba y otros

componentes frecuentemente. Déle

el mantenimiento necesario según

las instrucciones en la sección de

mantenimiento.

8. Cerciórese de que haya un sistema

auxiliar de descarga en caso de que

la línea de salida esté fuera de

servicio u obstruída.

9. Seguridad Personal:

a. Siempre use anteojos de

seguridad cuando vaya a trabajar

con la bomba.

b. Mantenga el área de trabajo

limpia, despejada y bien

iluminada; guarde todas la

herramientas que no esté usando.

12 Sp

Manual de Instrucciones

12. Todos los trabajos de electricidad

los debe hacer un electricista

calificado.

13. Es altamente recomendable que

utilice un tomacorrientes que tenga

un sistema de cortacircuito

incorporado. Consúltele a un

electricista local para ver si éstos

están disponibles en su área.

El motor

dee la

bomba tiene un sistema de protección

térmica y puede comenzar a funcionar

sin previo aviso. Si este sistema se

activa es una indicación de que el

motor está sobrecargado debido a que

la distancia de descarga es muy baja,

voltajes excesivamente bajos o altos ,

alambrado inadecuado, condiciones

inadecuadas para el motor o el motor o

la bomba están dañados.

14. Esta bomba está diseñada para

funcionar en ciclos. Si le modifica el

interruptor para que funcione

continuamente, afectará el

rendimiento y la duración de la

unidad.

15. Proteja el cordón eléctrico contra

objetos afilados, superficies

calientes, aceite y químicos. Evite

que el cordón se enrolle. Reemplace

o repare el cordón inmediatamente

cuando se dañe. Use cordones del

calibre adecuado para evitar

pérdidas de voltaje del motor.

16. No toque la bomba o el motor con

las manos mojadas o cuando esté

parado en una superficie húmeda o

en agua.

Terminal para

conexión a

tierra

Figura 1

Bateas

Lavadora

Secadora

Lavamanos

Inodoro

Ducha

Tubería principal hacia el sistema de cloacas

o pozo séptico

Drenaje del segundo piso

Tomacorrientes de 3

orificios conectado a

tierra con dispositivo

contra cortocircuitos

incorporado

Tubería de descarga

de 5,08 cm (2”)

Interruptor/flotante

Bomba para efluentes

Orificio de limpieza

Tubería de ventilación

Válvula de entrada

de 5,08 cm (2”)

Empalme

Válvula

de chequeo

de 5,08 cm (2”)

Codo

de 45

o

Drenaje

Drenaje para la lavadora

Brida

Figura 2 - Instalación Típica

Limited Warranty

For one (1) year from the date of purchase, Wayne Water Systems ("Wayne") will repair or replace, at its option, for the

original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by Wayne

to be defective in materials or workmanship. Please call Wayne (800-237-0987) for instructions or see your dealer. Be

prepared to provide the model number and the serial number when exercising this warranty. All transportation charges

on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Wayne’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS

THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR

EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations

of incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you

specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Wayne or

its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of

profit or revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of

capital, cost of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you

MUST send a copy of the purchase receipt along with the material or correspondence. Please call Wayne (800-237-0987)

for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

5

Operating Instructions

www.waynepumps.com

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

RESET

TEST

!

ADVERTENCIA

Page 6

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

Sírvase leer y guardar estas instrucciones. Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio

al producto descrito en este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no

seguir las instrucciones podría resultar en heridas y/o daños a su propiedad. Guarde este manual como referencia.

Descripción

Esta bomba para aguas negras es

adecuada para bombear aguas

cloacales, efluentes, residuales, agua

subterránea y otros líquidos no

explosivos, no corrosivos con sólidos de

hasta 2 pulgadas (5 cm). La bomba

incluye un interruptor de flotador de

ángulo amplio que enciende y apaga la

bomba a medida que el nivel del fluido

aumenta y disminuye.

Desempaque

Inspeccione esta unidad antes de

usarla. Ocasionalmente, los productos

son dañados durante el envío. Si la

bomba o los componentes están

dañados, devuelva la unidad al lugar

donde la compró para que le sea

reemplazada. Si no lo hace podría

ocasionar lesiones graves o la muerte.

Manual de Instrucciones Modelo RPP50

331300-001 8/04

Medidas de

Seguridad

Este manual contiene información que

es muy importante que sepa y

comprenda. Esta información se la

suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le

indica

que hay una situación inmediata que LE

OCASIONARIA la muerte o heridas de

gravedad.

Ésto le

indica

que hay una situación que PODRIA

ocasionarle la muerte o heridas de

gravedad.

Ésto le

indica

que hay una situación que PODRIA

ocasionarle heridas no muy graves.

Ésto le

indica

una información importante, que de no

seguirla, le podría ocasionar daños al

equipo.

Informaciones

Generales de

Seguridad

1. Familiarícese con las aplicaciones

adecuadas para el equipo, sus

limitaciones y los peligros al usarlo.

No use esta bomba para

bombear fluídos inflamables

o explosivos tales como

gasolina, combustibles, kerosene, etc.

No la use en atmósferas inflamables o

explosivas. La bomba sólo se debe usar

para bombear agua pura. De lo

contrario pudiera ocasionarle heridas

de gravedad y/o la muerte.

2. Cerciórese de que el motor eléctrico

sea adecuado para el equipo.

Desconecte el cordón

eléctrico antes de darle

servicio. Si el tomacorrientes

está fuera de su alcance, apague la

unidad con el interruptor y asegúrelo

de modo que la unidad no pueda

encenderse accidentalmente. ¡De no

hacerlo podría morir electrocutado!

© 2004 Wayne Water Systems

Especificaciones

Requerimientos del circuito ..................120V, 60 hz

Requerimientos eléctricos .....................15 amperios (mín)

Ciclo del motor.......................................Intermitente

Motor......................................................120V, 1 fase

Caballos de fuerza ................................1/2

Motor (Cap. máx.)..................................6.3 amperios

Temp. de funcionamiento.....................4°C a 44°C (40°F a 120°F)

Posición máx. de funcionamiento ........45

o

de la posición vertical

Dimensiones...........................................35,6 cm X 30,5 cm (14” x 12”)

Orificio de Entrada ................................5,05 cm (2”)

Orificio de Salida....................................5,05 cm (2”) NPT (hembra),

................................................................7,6 cm (3”) NPT (macho)

Nivel para encender

(fijado de fábrica) ..................................40,6 cm (16”)

Nivel para apagar (fijado de fábrica) ...19,1 cm (7.5”)

Diferencial ..............................................21,6 cm (8.5”)

Interruptor .............................................interruptor mecánico de

ángulo de 90

o

Cordón eléctrico.....................................calibre 18 con 3 cables y

enchufe

Materiales de fabricación

Cubierta del motor....Hierro colado

Caja espiral.................Hierro colado

Impulsor .....................Plástico PBT reforzado con

vidrio

Sello de la placa .........Hierro colado

Sello del eje................Mecánico

RPP50 5700 4560 3240 900

Rendimiento

Bomba de Aguas

Negras de Hierro

Fundido de 1/2 HP

LITERS POR HORA A LA DISTANCIA TOTAL DE

DESCARGA EN PIES

Modelo 0 5 10 15

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à

l’entretien du produit décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il

y a risque de blessure et/ou dégâts matériels! Conserver ces instructions comme référence.

6

Description

Cette pompe d'égout convient pour

pomper les égouts, les effluents, les

eaux usées, les eaux de fond, et autres

liquides non-explosifs, non-corrosifs

jusqu'à deux pouces ou cinq

centimètres de solides. La pompe inclut

un interrupteur à flotteur à angle large

qui met la pompe en marche et l'arrête

tandis que le niveau de fluide monte et

descend.

Déballage

Inspecter cet appareil avant de l'utiliser.

À l'occasion, les produits sont

endommagés durant l'expédition. Si la

pompe ou les composants sont

endommagés, rapporter l'appareil à

l'endroit d'achat pour son remplacement. Ne pas suivre ces instructions

pourraient mener à de graves blessures

ou à la mort.

Instructions d’Utilisation Modèle RPP50

331300-001 8/04

Directives de

Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Danger

indique

une situation hasardeuse imminente

qui résultera en perte de vie ou

blessures graves.

Avertis-

sement

indique une situation hasardeuse

potentielle qui peut résulter en perte

de vie ou blessures graves.

Attention

indique

une situation hasardeuse potentielle qui

peut résulter en blessures.

Avis

indique

l’information importante pour éviter le

dommage de l’équipement.

Généralités sur la

Sécurité

1. Se familiariser avec l’application, les

limites et les hasards potentiels de

la pompe.

Ne pas utiliser pour le

pompage des liquides

inflammables ou explosifs tels

que l’essence, l’huile à chauffage, le

kérosène, etc. Ne pas utiliser dans une

atmosphère inflammable et/ou

explosive. Utiliser la pompe seulement

avec les liquides qui sont compatibles

avec les pièces détachées de la pompe.

Ne pas suivre cet avertissement peut

résulter en blessure grave et/ou dégâts

matériels.

2. S’assurer que la source de courant

(moteur électrique) se conforme

aux exigences de l’équipement..

© 2004 Wayne Water Systems

Spécifications

Alimentation requiert ......................120V, 60 hz

Exigences de circuit...........................15 A (min)

Service du moteur.............................Intermittent

Moteur...............................................120V, Monophasé

Horse Power .....................................1/2

Moteur à pleine charge....................6.3 A

Gamme de température

du liquide ..........................................4°C à 44°C (40°F à 120°F)

Position de fonctionnement max. ...45

o

du vertical

Dimensions ........................................35,6 cm X 30,5 cm

(14 po x 12 po)

Entrée ................................................5,05 cm (2 po)

Décharge ...........................................5,05 cm (2 po) NPT femelle,

7,6 cm (3 po) NPT mâle

Niveau de démarrage

(réglé à l’usine)..................................40,6 cm (16 po)

Niveau d’arrêt (réglé à l’usine) ........19, cm (7.5 po)

Différentiel........................................21,6 cm (8.5 po)

Interrupteur.......................................90

o

mécanique à longe,

angle large

Cordon d’alimentation.....................calibre 18, 3 fils avec fiche

Fabrication

Carter du moteur.................Fonte

Volute...................................Fonte

Turbine.................................PBT renforcé de verre

Plaque d’étanchéité ............En fonte

Joint d’arbre ........................Mécanique

GALLONS PAR HEURE À PLEINE HAUTEUR EN

PIEDS

Modèle 0 5 10 15

RPP50 5700 4560 3240 900

Rendement

Pompe d'égout

de fonte 1/2 HP

!

!

DANGER

!

AVERTISSEMENT

!

ATTENTION

AVIS

AVERTISSEMENT

!

PELIGRO

!

ADVERTENCIA

!

PRECAUCION

AVISO

!

ADVERTENCIA

!

PELIGRO

Page 7

Garantie Limitée

Pendant un (1) an à partir de la date d'achat, Wayne Water Systems (« Wayne ») réparera ou remplacera, à sa

discrétion, à l'acheteur original toute pièce ou pièces de ses Pompes de puisard ou ses Pompes à l'eau (le « Produit »)

qui s'avère défectueux au niveau des matériaux ou de la main d'œuvre suite à un examen de la part de Wayne. S’il

vous plaît appeler Wayne (800-237-0987) pour des instructions ou contacter votre marchand. S’assurer d’avoir, à votre

disposition, le numéro du modèle afin d’effectuer cette garantie. Les frais de transportation des Produits ou pièces

soumis pour la réparation ou le remplacement sont la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident, utilisation

abusive, mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation

conformément aux instructions écrit de Wayne.

IL N’EXISTE AUCUNE AUTRE GARANTIE OU AFFIRMATION. LES GARANTIES EXPRIMÉES, Y COMPRIS CELLES DE

COMMERCIALISABILITÉ ET D’ADAPTION À UNE FONCTION PARTICULIÈRE, SONT LIMITÉES À UN AN À

COMPTER DE LA DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ

POUR N’IMPORTE QUEL ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation

des dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie

limitée donne, à l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales qui sont variable d’une

Province ou d’un État à l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou

autrement, ni Wayne ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y

compris, mais pas limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement

associé, dommage à l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou

abilité de remplaçement, coût de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur

pour ces dommages.

Vous DEVEZ garder votre facture d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une COPIE de la recette

d’achat avec le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît appeler

Wayne (800-237-0987) pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE__________________________ Nº DE SÉRIE________________________________

DATE D’INSTALLATION_____________________________________________

FIXER VOTRE FACTURE ICI

Instructions d’Utilisation

10 Fr

8. Fournir un système de dégagement

de pression pour les pompes avec

lignes de décharge qui peuvent

devenir obstruées ou coupées.

9. Sécurité Personnelle:

a. Toujours porter des lunettes de

sécurité si vous travaillez avec les

pompes.

b. Garder l’endroit de travail propre,

non-encombré et bien illuminé.

Ranger tous les outils et

l’équipement après l’usage.

c. Garder les visiteurs à une distance

sans danger de l’endroit de

travail. Protéger l’atelier pour les

enfants avec des cadenas,

interrupteurs principaux et en

enlevant les clefs de démarrage.

10. Pendant l’installation de fils d’une

pompe électrique telle que celle-ci,

suivre tous les codes de sécurité ainsi

que les codes récents du National

Electrical Code (NEC) et l’ Occupational Safety and Health Act (OSHA).

Risque de secousse

électrique! Ne jamais

brancher le fil vert (ou vert et jaune) à

une borne électrisée!

11. Cet équipement est conçu pour un

circuit de 120 v (monophasé) et est

équipé d’un cordon approuvé à trois

conducteurs et une fiche de terre à

trois broches tel qu’indiqué dans la

Figure 1.

Remplacer

les prises

à deux broches avec des prises à trois

broches mises à la terre correctement

selon les codes et ordonnances locaux

et de NEC.

12. Toute installation de fils doit être

efectuée par un électricien qualifié.

Généralités sur la

Sécurité (Suite)

Débrancher la source de

courant avant de procéder à

l’entretien et aux réparations.

Si la source d’alimentation est hors de

la vue, la verrouiller dans la position

ouverte et l’étiqueter afin d’éviter que

l’appareil soit mis sous tension

accidentellemen. Ne pas suivre ces

directives peut résulter en choc

électrique!

3. Dissiper toute la pression dans le

système avant de procéder à

l’entretien et aux réparations de

n’importe quelle pièce détachée.

4. Purger tous liquides de procéder à

l’entretien et aux réparations.

Cette

pompe

contient de l'huile à moteur

diélectrique pour le transfert de chaleur

du moteur. Attention en éliminant cette

huile. Ne pas utiliser cette pompe dans

les étangs ou les fontaines car l'huile à

moteur pourrait être dangereux pour la

vie aquatique.

5. Fixer la ligne de décharge avant de

démarrer la pompe. Une ligne de

décharge non-fixée peut fouetter et

causer des blessures personnelles

et/ou des dégâts matériels.

6. Inspecter les tuyaux pour tout signe

de faiblesse et d’usure avant chaque

utilisation et vérifier le serrage de

tous les branchements.

7. Inspecter la pompe et les pièces

détachées du système périodiquement. Exécuter l’entretien

ordinaire (Se référer à la section

d’Entretien).

7Fr

Instructions d’Utilisation

13. Il est recommandé que le modèle

soit branché dans un disjoncteur de

fuite à la terre (DDFT). Consulter un

électricien local pour la disponibilité

et l’installation.

Le

moteur

de la pompe est équipé d’un protecteur

thermique à réenclenchement

automatique et peut se mettre en

marche subitement. Le déclenchement

du protecteur est une indication de

surcharge du moteur résultant du

fonctionnement de la pompe à basse

pression (restriction de décharge

basse), tension extrêmement élevée ou

basse, installation de fils insuffisante,

conditions de moteur incorrectes, ou un

moteur ou une pompe défectueux.

14. Cette pompe est conçue pour

transporter l’eau en cycles. Utiliser

cette pompe dans une application

continue en manipulant

l’interrupteur pour qu’il reste

enclenché affectera la performance

et l’espérance de vie du produit.

15. Protéger le cordon d’alimentation

des objets pointus, surfaces

chaudes, huile et produits

chimiques. Ne pas tortiller le

cordon. Remplacer ou réparer les

cordons usés ou endommagés

immédiatement. Utiliser des fils de

taille suffisante pour minimiser la

chute de tension au moteur.

Broche de

terre

Figure 1

Canalisation

principale aux

égouts ou fosse

septique

Vidange de niveau supérieur

Prise tripolaire mise à

la terre équipée d’un

disjoncteur de fuite à

la terre

Tuyau de

décharge 2 po

Interrupteur Flotteur

Pompe pour eaux usées passe des solides de 2 po

Trappe de nettoyage

Tuyau d’évent

Vanne

2 po

Raccord

Clapet

2 po

Coude

45

o

Bacs à lessive

Laveuse

Sécheuse

Drain de plancher

Vidange de laveuse

Lavabo

Toilette

Douche

Bride

Figure 2 - Installation typique

!

DANGER

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

RESET

TEST

!

AVERTISSEMENT

Page 8

8Fr

Instructions d’Utilisation

Généralités sur la

Sécurité (Suite)

16. Ne pas manipuler de pompe ou de

pompe de moteur avec les mains

trempées ni lorsque vous êtes

debout sur une surface trempée ou

humide, ou dans l’eau.

17. Ne pas pendre ce produit par la

poignée. Les pompes pour eaux

usées devraient être placées

fermement sur leurs pieds et

supportées avec de la tuyauterie

rigide. Ceci empêche le tortillement

et les dommages pendant le

fonctionnement de la pompe.

18. Ne pas utiliser un cordon

prolongateur.

Ne pas marcher dans un

endroit trempé jusqu’à ce que

toutes les sources de courant

soient coupées. Si la boîte d’arrêt est

dans le sous-sol, contacter votre

compagnie d’électricité pour couper le

service à la maison ou contacter le

service d’incendie pour des directives.

Enlever la pompe et la réparer ou la

remplacer. Ne pas suivre ces conseils

peut résulter en choc électrique mortel.

Installation

Utiliser

un/des

système(s) de sauvegarde là où il y a

risque de dégâts matériels et/ou

blessures personnelles à cause d’une

pompe qui ne fonctionne pas ou qui a

des fuites à cause des manques de

puissance, canalisations de décharge

obstruées ou autres raisons.

1. Fileter le tuyau de décharge ou le

mamelon de tuyau dans le raccord de

décharge.

2. Si un clapet est utilisé, monter le

clapet dans une position horizontale

ou à un angle de 45° avec le pivot de

la soupape en haut. Dans une position

verticale, les solides on tendance à se

déposer sur le volet de la soupape et

peuvent l’empêcher de s’ouvrir.

3. Percer un trou de 1/16 po dans le

tuyau de décharge environ 1 à 2 po

par-dessus la décharge de la pompe

lorsque vous utilisez un clapet. Le

trou empêche le blocage par l’air de

la pompe au départ initial et si elle

perd l’amorçage.

4. Une vanne devrait être installée dans

le système après le clapet. La vanne

devrait être de type à orifice plein

qui passera des solides de 2 po ou

selon les exigences des codes locaux

et de la Province. Cette vanne permet

l’enlevage de la pompe et/ou du

clapet pour l’entretien.

5. Installer un raccord-union entre le

clapet et la pompe pour que la

pompe puisse être enlevée sans trop

déranger la tuyauterie.

6. Cette pompe a un interrupteur à

longe détachable avec une fiche

superposée (Voir figure 3). La

longueur de cordon (distance du

cordon du flotteur à la pince) ne

devrait pas être ajustée moins que

8,26 cm (3-1/4 po) et ne devrait pas

être utilisé dans un bassin plus petit

que 35,6 cm (14 po) de diamètre. Si

vous utilisez un différentiel autre que

celui réglé à l’usine, s’assurer que

lorsque la pompe s’arrête, il y ait au

moins 4 po de fluide dans le bassin

pour que la turbine reste submergée.

7. Lorsque vous utilisez un interrupteurancré, il faut une tuyauterie de

décharge rigide. Si la pompe peut se

déplacer, l’interrupteur ancrépeut

être limité par le mur du bassin,

empêchant la pompe de fonctionner.

Avant

d’enlever

la pompe du bassin pour l’entretien,

toujours couper le courant à la pompe

et à l’interrupteur de commande. Pour

procéder à l’entretien de la pompe ou

l’interrupteur, TOUJOURS débrancher le

cordon d’alimentation. Ne pas

seulement couper le disjoncteur ou

desserrer le fusible.

Entretien

S’assurer

que la

pompe soit débranchée avant d’essayer

de procéder à l’entretien ou d’enlever

les pièces détachées. La pompe est

montée à l’usine avec de l’équipement

spécial, donc seulement un centre de

service authorisé ou un électricien

qualifié devrait essayer de réparer ce

modèle. La réparation incorrecte peut

causer un danger de choc électrique.

La pompe

contient

de l’huile qui peut être sous pression à

cause de la chaleur. Laisser refroidir la

pompe pendant au moins deux heures

de procéder à l’entretien de ce modèle.

1. Démonter le moteur avant

l’expiration de la garantie annulera

la garantie. Il est aussi possible de

causer des fuites internes et

d’endommager le modèle. S’il faut

réparer, retourner la pompe au

marchand de qui vous l’avez acheté

ou composer le 1-800-237-0987.

2. Enlever le couvercle du bassin et

débrancher la tuyauterie de décharge

avant de soulever la pompe du bassin.

3. Inspecter la pompe à intervalles

réguliers pour s’assurer de son bon

fonctionnement. S’il y a eu des

changements depuis l’achat du

modèle, l’enlever et Le remplacer.

Seulement un électricien ou des

personnes de service qualifiées

devraient essayer de réparer ce

modèle. La réparation et/ou le

montage incorrect peuvent résulter

en danger de choc électrique.

4. Placer la pompe dans un endroit

convenable, là où elle peut être bien

nettoyée. Enlever tous les déchets et

dépôts sur la pompe.

5. Immerger la pompe entière dans une

solution désinfectante (10% solution

de blanchissage) pour au moins une

heure avant de manipuler la pompe.

6. Nettoyer toute la saleté du flotteur de

la pompe. S’assurer que le flotteur se

déplace librement suite au nettoyage.

7. Netttoyer toute saleté et dépôts de

l’arrivée de la pompe et la volute.

Cette

pompe

contient de l’huile de moteur

dielectrique pour le graissage et le

transfert de chaleur du moteur. Cette

huile peut nuire à l’environnement.

Consulter les règlements locaux avant

de se débarrasser de l’huile. Considérer

que cette huile peut nuire à la vie

aquatique lorsque vous choisissez

d’utiliser cette pompe. débarasser de

l’huile. Considérer que cet huile peut

nuire à la vie aquatique lorsque vous

choississez d’utiliser cette pompe.

Guide de Dépannage

Symptôme Cause(s) Possible(s) Mesure Corrective

La pompe ne se

démarre pas et ne

fonctionne pas

La pompe se démarre

et s’arrête trop souvant

La pompe s’arrête et se

démarre

indépendamment de

l’interrupteur

(déclenche le

protecteur de

surcharge thermique)

La pompe fonctionne

bruyamment et vibre

excessivement

La pompe ne s’arrête

pas

La pompe fonctionne

mais délivre peu ou pas

d’eau

1. Niveau d’eau trop bas

2. Fusible sauté ou disjoncteur

déclenché

3. Tension de ligne basse

4. Moteur défectueux

5. Interrupteur flotteur défectueux

6. Impulseur (pompe remplie de

débris)

7. Interrupteur enmèlé

8. Niveau de liquide insuffisant

1. Refoulement d’eau de la

tuyauterie

2. Interrupteur flotteur défectueux

3. Clapet non-installé ou qui a des

fuites

4. Hauteur de décharge inférieur

au minimum du fabricant

1. Température d’eau excessive

2. Interrupteur défectueux

ointerrupteur enmêlé cause que

la pompe fonctionne à sec

3. Tension de ligne basse

1. Roulements usés

2. Débris dans la cavité de

l’impulseur ou en panne

3. Raccords de tuyauterie à l’édifice

trop rigides ou trop desserrés

1. Interrupteur flotteur défectueux

2. Mouvement de l’interrupteur

flotteur limité

3. Décharge limité (tuyauterie

obstruée)

4. Arrivée excessive ou pompe de

taille incorrecte pour

l’application

1. Tension de ligne basse

2. Débris pris dans l’impulseur ou le

décharge

3. Pièces de la pompe usées ou

défectueuses, ou impulseur

obstrué

4. Pompe de mauvaise taille pour

l’application

5. Clapet pris dans la position

fermée ou installée à l’envers

6. Soupape d’arrêt fermée

1. L’interrupteur de la pompe ne se met pas en marche sans

que l’eau recouvre le haut de la pompe

2. Si sauté, remplacer avec un fusible de taille correcte ou

réenclencher le disjoncteur

3. Si la tension est sous le minimum recommandé, vérifier la

taille des fils de l’interrupteur général de la propriété. Si

correcte, contacter la compagnie de service publique.

4. Retourner pour l’entretien ou remplacer le moteur

5. Remplacer l’interrupteur flotteur

6. Si la turbine ne tourne pas, enlever le carter et enlever le

débris

7. Positionner l’interrupteur pour qu’elle se déplace librement.

Déménager la pompe si nécessaire

8. S’assurer que le niveau de liquide soit au moins 33,02 cm

(13po) du fond du bassin

1. Installer un clapet

2. Remplacer l’interrupteur flotteur

3. Enlever et examiner le clapet pour l’installation correcte et

le fonctionnement libre

4. Vérifier de nouveau les calculs de taille pour déterminer la

taille de pompe correcte

1. La pompe ne devrait pas être utilisée pour l’eau au delà de

44° C (120° F)

2. Remplacer ou repositionner la pompe

La pompe peut se démarrer

subitement. Débrancher la source de

puissance avant de procéder à l’entretien

3. Si la tension est sous le minimum recommandé, vérifier la

taille des fils de l’interrupteur général de la propriété. Si

correcte, contacter la compagnie de service publique

1. Remplacer la pompe

2. Enlever le carter, nettoyer la turbine et/ou remplacer la

turbine en panne

3. Remplacer la section de tuyau de décharge avec un raccord

flexible

1. Remplacer l’interrupteur flotteur

2. Positionner de nouveau la pompe ou nettoyer le bassin au

besoin pour fournir l’espace nécessaire pour le flotteur

3. Enlever la pompe et nettoyer la pompe et la tuyauterie

4. Vérifier de nouveau les calculs de taille pour déterminer la

taille de pompe correcte

1. Si la tension est sous le minimum recommandé, vérifier la

taille des fils de l’interrupteur général de la propriété. Si

correcte, contacter la compagnie de service publique.

2. Enlever, nettoyer et vérifier le serrage

3. Remplacer la pompe entière. Nettoyer les pièces au besoin

4. Vérifier de nouveau les calculs de taille pour déterminer la

taille de pompe correcte

5. Enlever et examiner le clapet pour l’installation correcte et

le fonctionnement libre

6. Ouvrir la soupape

Clapet 45

o

Évent

Arrivée

Joint

d’étanchéité

Espace

min.

1/2 po

Bassin

Figure 3 - Bassins préfabriqués

9Fr

!

DANGER

AVIS

!

ATTENTION

!

AVERTISSEMENT

AVIS

!

AVERTISSEMENT

!

ATTENTION

Loading...

Loading...